Development of Test Methods to Evaluate the Printability of Concrete Materials for Additive Manufacturing

Abstract

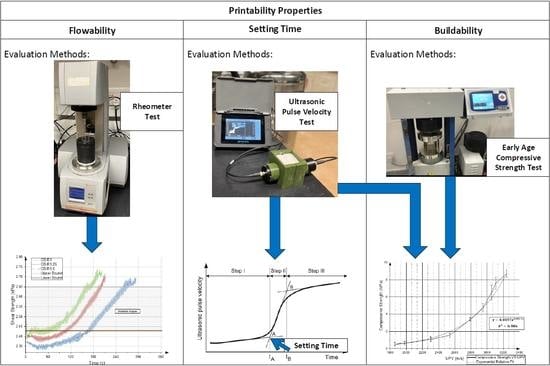

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Flowability Test Methods

2.3. Setting Time Test Methods

2.4. Buildability Test Methods

3. Results and Discussion

3.1. Flowability

3.2. Setting Time

3.3. Buildability

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tofail, S.A.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive manufacturing: Scientific and technological challenges, market uptake and opportunities. Mater. Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- Paolini, A.; Kollmannsberger, S.; Rank, E. Additive manufacturing in construction: A review on processes, applications, and digital planning methods. Addit. Manuf. 2019, 30, 100894. [Google Scholar] [CrossRef]

- Shakor, P.; Sanjayan, J.; Nazari, A.; Nejadi, S. Modified 3D printed powder to cement-based material and mechanical properties of cement scaffold used in 3D printing. Constr. Build. Mater. 2017, 138, 398–409. [Google Scholar] [CrossRef]

- Biernacki, J.J.; Bullard, J.W.; Sant, G.; Brown, K.; Glasser, F.P.; Jones, S.; Ley, T.; Livingston, R.; Nicoleau, L.; Olek, J. Cements in the 21st century: Challenges, perspectives, and opportunities. J. Am. Ceram. Soc. 2017, 100, 2746–2773. [Google Scholar] [CrossRef]

- Panda, B.; Mohamed, N.A.N.; Tan, M.J. Effect of 3D printing on mechanical properties of fly ash-based inorganic geopolymer. In International Congress on Polymers in Concrete; Springer: Berlin/Heidelberg, Germany, 2018; pp. 509–515. [Google Scholar]

- Antoni, A.; Widjaya, D.C.; Wibowo, A.R.K.; Chandra, J.; Pudjisuryadi, P.; Hardjito, D. Using Calcium Oxide and Accelerator to Control the Initial Setting Time of Mortar in 3D Concrete Printing. In Proceedings of the 5th International Conference on Sustainable Civil Engineering Structures and Construction Materials; Springer: Berlin/Heidelberg, Germany, 2022; pp. 871–880. [Google Scholar]

- Tay, Y.W.D.; Qian, Y.; Tan, M.J. Printability region for 3D concrete printing using slump and slump flow test. Compos. Part B Eng. 2019, 174, 106968. [Google Scholar] [CrossRef]

- Figueiredo, S.C.; Rodríguez, C.R.; Ahmed, Z.Y.; Bos, D.; Xu, Y.; Salet, T.M.; Çopuroğlu, O.; Schlangen, E.; Bos, F.P. An approach to develop printable strain hardening cementitious composites. Mater. Des. 2019, 169, 107651. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.; Liu, G.; Yang, Y.; Wu, M.; Pang, B. Fresh properties of a novel 3D printing concrete ink. Constr. Build. Mater. 2018, 174, 263–271. [Google Scholar] [CrossRef]

- Zhang, C.; Deng, Z.; Chen, C.; Zhang, Y.; Mechtcherine, V.; Sun, Z. Predicting the static yield stress of 3D printable concrete based on flowability of paste and thickness of excess paste layer. Cem. Concr. Compos. 2022, 129, 104494. [Google Scholar] [CrossRef]

- Souza, M.T.; Ferreira, I.M.; de Moraes, E.G.; Senff, L.; de Oliveira AP, N. 3D printed concrete for large-scale buildings: An overview of rheology, printing parameters, chemical admixtures, reinforcements, and economic and environmental prospects. J. Build. Eng. 2020, 32, 101833. [Google Scholar] [CrossRef]

- Zhang, C.; Hou, Z.; Chen, C.; Zhang, Y.; Mechtcherine, V.; Sun, Z. Design of 3D printable concrete based on the relationship between flowability of cement paste and optimum aggregate content. Cem. Concr. Compos. 2019, 104, 103406. [Google Scholar] [CrossRef]

- Shahzad, Q.; Wang, X.; Wang, W.; Wan, Y.; Li, G.; Ren, C.; Mao, Y. Coordinated adjustment and optimization of setting time, flowability, and mechanical strength for construction 3D printing material derived from solid waste. Constr. Build. Mater. 2020, 259, 119854. [Google Scholar] [CrossRef]

- Robeyst, N.; Gruyaert, E.; Grosse, C.U.; De Belie, N. Monitoring the setting of concrete containing blast-furnace slag by measuring the ultrasonic p-wave velocity. Cem. Concr. Res. 2008, 38, 1169–1176. [Google Scholar] [CrossRef]

- Ivanova, I.; Ivaniuk, E.; Bisetti, S.; Nerella, V.N.; Mechtcherine, V. Comparison between methods for indirect assessment of buildability in fresh 3D printed mortar and concrete. Cem. Concr. Res. 2022, 156, 106764. [Google Scholar] [CrossRef]

- Casagrande, L.; Esposito, L.; Menna, C.; Asprone, D.; Auricchio, F. Effect of testing procedures on buildability properties of 3D-printable concrete. Constr. Build. Mater. 2020, 245, 118286. [Google Scholar] [CrossRef]

- Wolfs, R.J.M.; Bos, F.P.; Salet, T.A.M. Triaxial compression testing on early age concrete for numerical analysis of 3D concrete printing. Cem. Concr. Compos. 2019, 104, 103344. [Google Scholar] [CrossRef]

- Suiker, A.S.J. Mechanical performance of wall structures in 3D printing processes: Theory, design tools and experiments. Int. J. Mech. Sci. 2018, 137, 145–170. [Google Scholar] [CrossRef]

- Kruger, J.; Zeranka, S.; van Zijl, G. 3D concrete printing: A lower bound analytical model for buildability performance quantification. Autom. Constr. 2019, 106, 102904. [Google Scholar] [CrossRef]

- Rehman, A.U.; Kim, J.-H. 3D Concrete Printing: A Systematic Review of Rheology, Mix Designs, Mechanical, Microstructural, and Durability Characteristics. Materials 2021, 14, 3800. [Google Scholar] [CrossRef]

- CyBe Construction B.V. Professional 3Dconcrete printing CyBe MORTAR Datasheet; CyBe Construction B.V.: Molenstraat, The Netherlands, 23 June 2018. [Google Scholar]

- Cell, A. Accessories for MCR: Ball Measuring System & Building Material Cell: [Online] Anton Paar. 2022. Available online: https://www.anton-paar.com/corp-en/products/details/ball-measuring-system/ (accessed on 5 May 2022).

- Lee, H.; Lee, K.; Kim, Y.; Yim, H.; Bae, D. Ultrasonic in-situ monitoring of setting process of high-performance concrete. Cem. Concr. Res. 2004, 34, 631–640. [Google Scholar] [CrossRef]

- Smith, A.; Chotard, T.; Gimet-Breart, N.; Fargeot, D. Correlation between hydration mechanism and ultrasonic measurements in an aluminous cement: Effect of setting time and temperature on the early hydration. J. Eur. Ceram. Soc. 2002, 22, 1947–1958. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, W.; She, W.; Ma, L.; Zhu, W. Ultrasound monitoring of setting and hardening process of ultra-high performance cementitious materials. Ndt E Int. 2012, 47, 177–184. [Google Scholar] [CrossRef]

- Trtnik, G.; Gams, M. Recent advances of ultrasonic testing of cement based materials at early ages. Ultrasonics 2014, 54, 66–75. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, Y.; Liu, L.; Zhang, G.; Liu, Z. Investigation of the influence of curing temperature and silica fume content on setting and hardening process of the blended cement paste by an improved ultrasonic apparatus. Constr. Build. Mater. 2012, 33, 32–40. [Google Scholar] [CrossRef]

- Chotard, T.; Gimet-Breart, N.; Smith, A.; Fargeot, D.; Bonnet, J.; Gault, C. Application of ultrasonic testing to describe the hydration of calcium aluminate cement at the early age. Cem. Concr. Res. 2001, 31, 405–412. [Google Scholar] [CrossRef]

- Trtnik, G.; Turk, G.; Kavčič, F.; Bosiljkov, V.B. Possibilities of using the ultrasonic wave transmission method to estimate initial setting time of cement paste. Cem. Concr. Res. 2008, 38, 1336–1342. [Google Scholar] [CrossRef]

- Wang, X.; Taylor, P.; Wang, K.; Lim, M. Monitoring of setting time of self-consolidating concrete using ultrasonic wave propagation method and other tools. Mag. Concr. Res. 2016, 68, 151–162. [Google Scholar] [CrossRef]

- Tekle, B.; Hertwig, L.; Holschemacher, K. Setting Time and Strength Monitoring of Alkali-Activated Cement Mixtures by Ultrasonic Testing. Materials 2021, 14, 1889. [Google Scholar] [CrossRef]

- Garnier, V.; Corneloup, G.; Sprauel, J.-M.; Perfumo, J. Setting time study of roller compacted concrete by spectral analysis of transmitted ultrasonic signals. Ndt E Int. 1995, 28, 15–22. [Google Scholar] [CrossRef]

- ASTM C191-21; Standard Test Methods for Time of Setting of Hydraulic Cement by Vicat Needle. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2021.

- Jayathilakage, R.; Rajeev, P.; Sanjayan, J.G. Yield stress criteria to assess the buildability of 3D concrete printing. Constr. Build. Mater. 2020, 240, 117989. [Google Scholar] [CrossRef]

- Roussel, N. Rheological requirements for printable concretes. Cem. Concr. Res. 2018, 112, 76–85. [Google Scholar] [CrossRef]

- Wolfs, R.J.M.; Bos, F.P.; Salet, T.A.M. Early age mechanical behaviour of 3D printed concrete: Numerical modelling and experimental testing. Cem. Concr. Res. 2018, 106, 103–116. [Google Scholar] [CrossRef]

- Trtnik, G.; Kavčič, F.; Turk, G. Prediction of concrete strength using ultrasonic pulse velocity and artificial neural networks. Ultrasonics 2009, 49, 53–60. [Google Scholar] [CrossRef]

- Bogas, J.A.; Gomes, M.G.; Gomes, A. Compressive strength evaluation of structural lightweight concrete by non-destructive ultrasonic pulse velocity method. Ultrasonics 2013, 53, 962–972. [Google Scholar] [CrossRef]

- Hedjazi, S.; Castillo, D. Relationships among compressive strength and UPV of concrete reinforced with different types of fibers. Heliyon 2020, 6, e03646. [Google Scholar] [CrossRef]

- ASTM C109/C109M; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50 mm] Cube Specimens). American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2021.

| Mix # | Mix Name | CyBe MORTAR (g) | Water (g) | Retarder (g) |

|---|---|---|---|---|

| 1 | CB-R1 | 800 | 128 | 1.00 |

| 2 | CB-R1.25 | 800 | 128 | 1.25 |

| 3 | CB-R1.50 | 800 | 128 | 1.5 |

| 4 | CB-R1.75 | 800 | 128 | 1.75 |

| Mixes | UPV Time (Min) | Vicat Needle Time (Min) | % Difference |

|---|---|---|---|

| CB-R1 | 8.2 ± 0.8 | 8.5 ± 0.6 | 3.5 |

| CB-R1.25 | 8.8 ± 0.6 | 8.6 ± 0.9 | 2.3 |

| CB-R1.75 | 11.3 ± 1.1 | 10.7 ± 1.0 | 4.7 |

| CB-R2 | 15.7 ± 0.6 | 16.2 ± 0.7 | 3.0 |

| Time (Min) | Compressive Strength (MPa) | UPV (m/s) |

|---|---|---|

| 10 | 0.56 | 1858.8 |

| 11 | 0.66 | 1979.5 |

| 13.5 | 1.08 | 2301.8 |

| 15 | 1.57 | 2539.0 |

| 20 | 3.40 | 2791.2 |

| 25 | 4.74 | 2945.9 |

| 30 | 6.50 | 3052.7 |

| 35 | 7.61 | 3105.8 |

| 45 | 8.69 | 3237.4 |

| Time (Min) | UPV Values (m/s) | Predicted Compressive Strength Values (MPa) | Actual Compressive Strength Values (MPa) | Percentage Difference (%) |

|---|---|---|---|---|

| 10 | 1786.3 | 0.41 | 0.44 | 5.7 |

| 11 | 1876.4 | 0.50 | 0.49 | 1.6 |

| 13.5 | 2127.2 | 0.85 | 0.92 | 8.0 |

| 15 | 2356.9 | 1.37 | 1.42 | 3.8 |

| 20 | 2723.7 | 2.96 | 2.73 | 8.2 |

| 25 | 2916.7 | 4.44 | 4.43 | 0.1 |

| 30 | 3030.3 | 5.63 | 4.98 | 12.9 |

| 35 | 3139 | 7.07 | 7.48 | 5.5 |

| 45 | 3223.4 | 8.44 | 8.77 | 3.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mortada, Y.; Mohammad, M.; Mansoor, B.; Grasley, Z.; Masad, E. Development of Test Methods to Evaluate the Printability of Concrete Materials for Additive Manufacturing. Materials 2022, 15, 6486. https://doi.org/10.3390/ma15186486

Mortada Y, Mohammad M, Mansoor B, Grasley Z, Masad E. Development of Test Methods to Evaluate the Printability of Concrete Materials for Additive Manufacturing. Materials. 2022; 15(18):6486. https://doi.org/10.3390/ma15186486

Chicago/Turabian StyleMortada, Youssef, Malek Mohammad, Bilal Mansoor, Zachary Grasley, and Eyad Masad. 2022. "Development of Test Methods to Evaluate the Printability of Concrete Materials for Additive Manufacturing" Materials 15, no. 18: 6486. https://doi.org/10.3390/ma15186486

APA StyleMortada, Y., Mohammad, M., Mansoor, B., Grasley, Z., & Masad, E. (2022). Development of Test Methods to Evaluate the Printability of Concrete Materials for Additive Manufacturing. Materials, 15(18), 6486. https://doi.org/10.3390/ma15186486