NiCrBSi Coatings Fabricated on 45 Steel Using Large Spot Laser Cladding

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

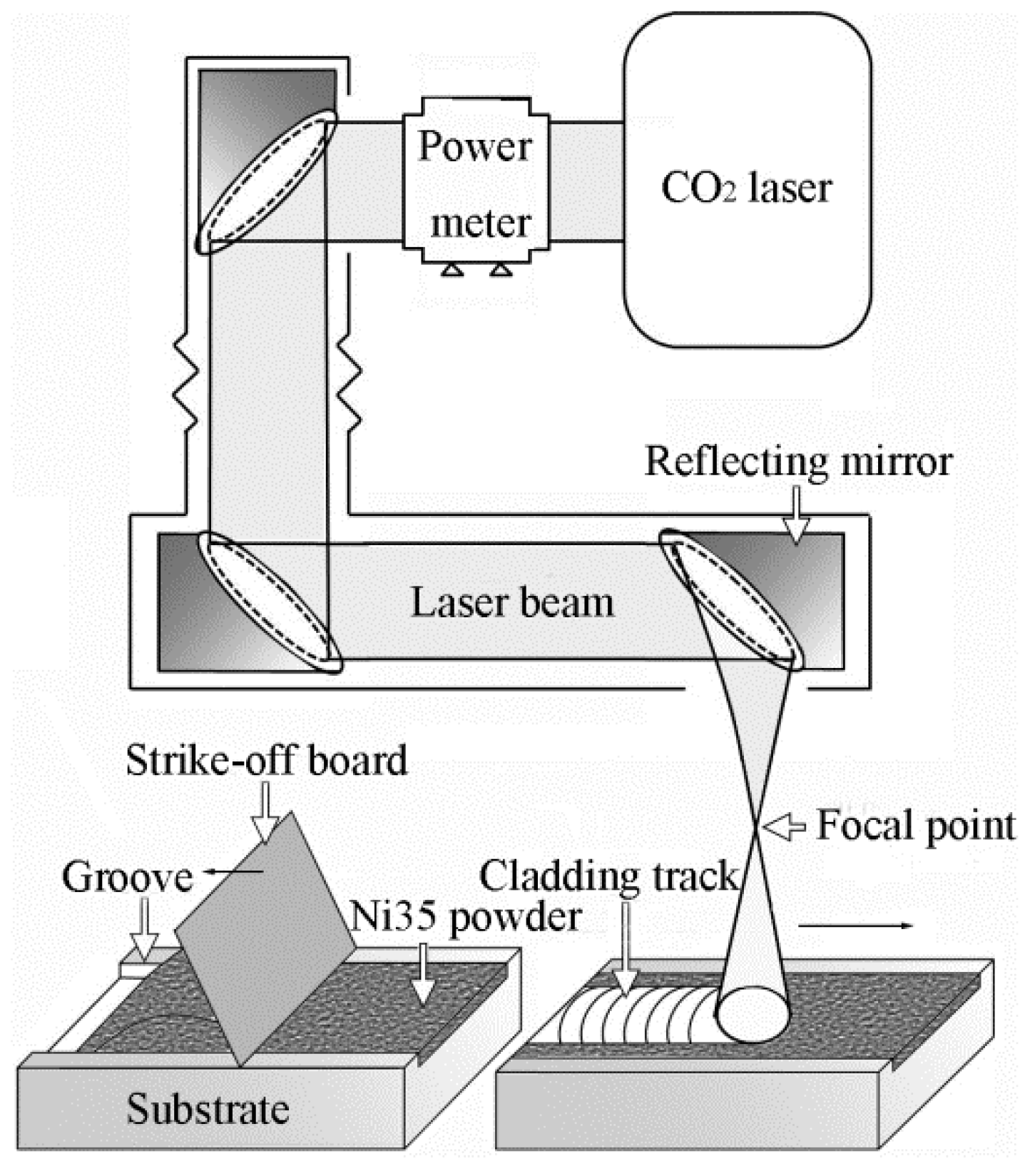

2.2. Powder Preplacing and Laser Cladding

2.3. Characterization of the Coatings

3. Results and Discussion

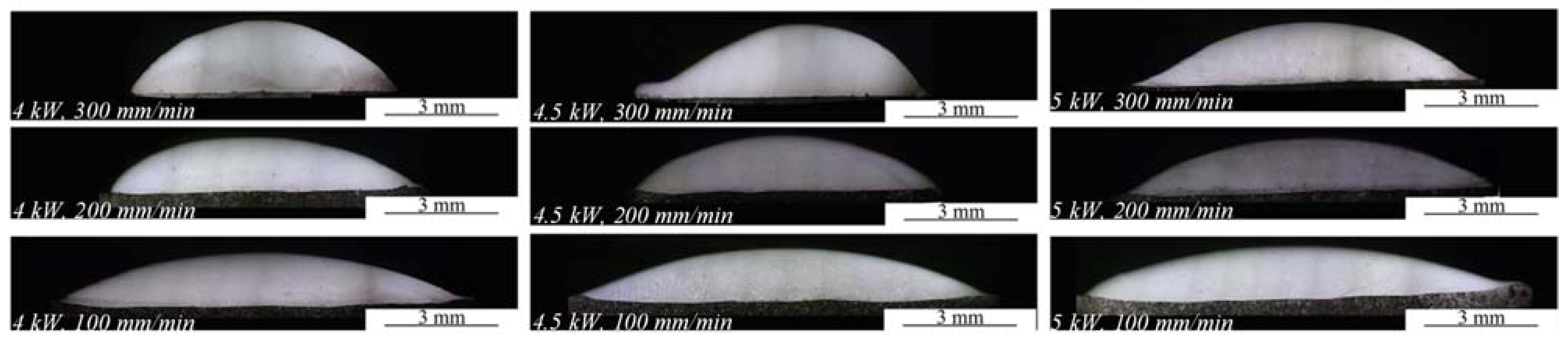

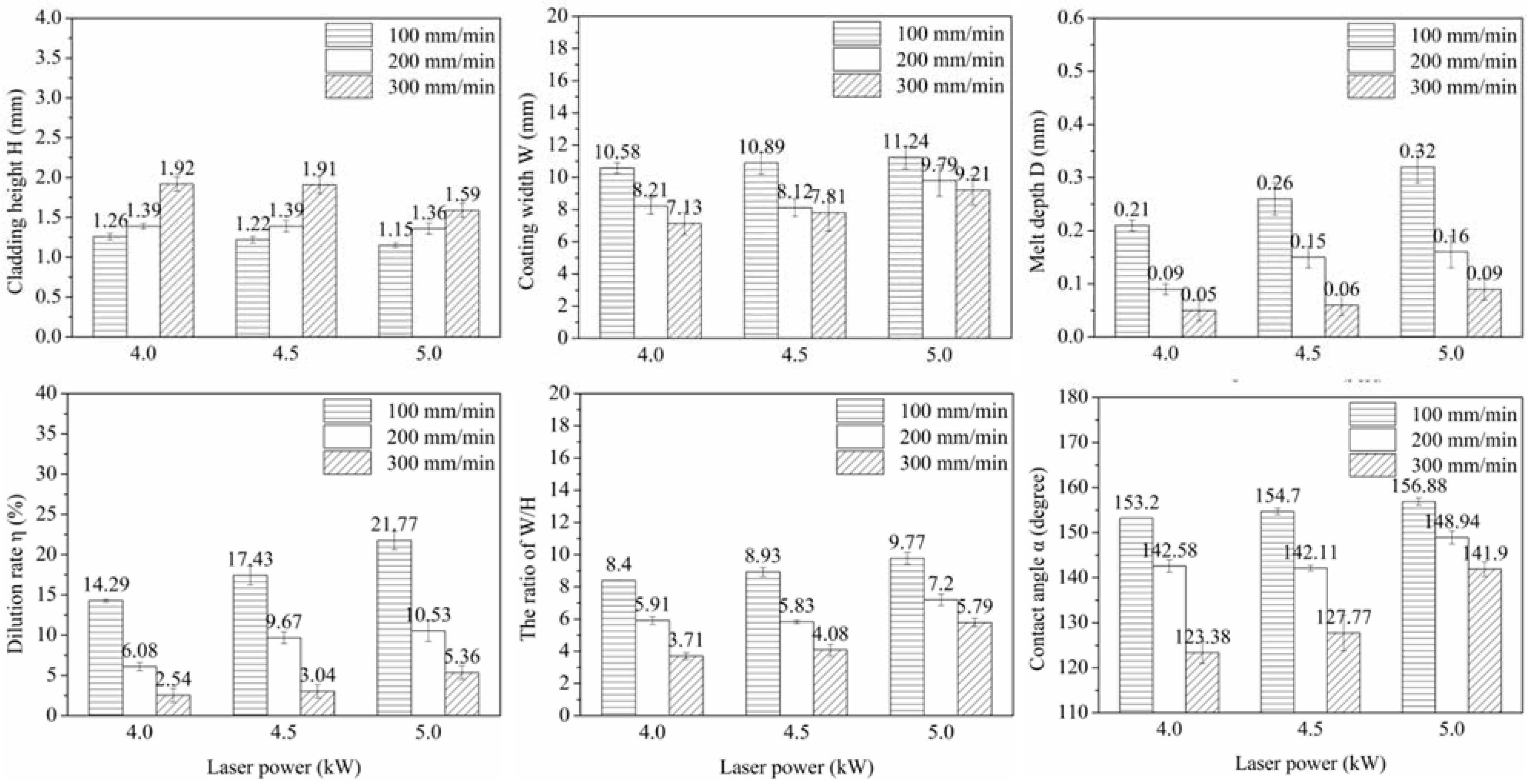

3.1. Coating Geometry

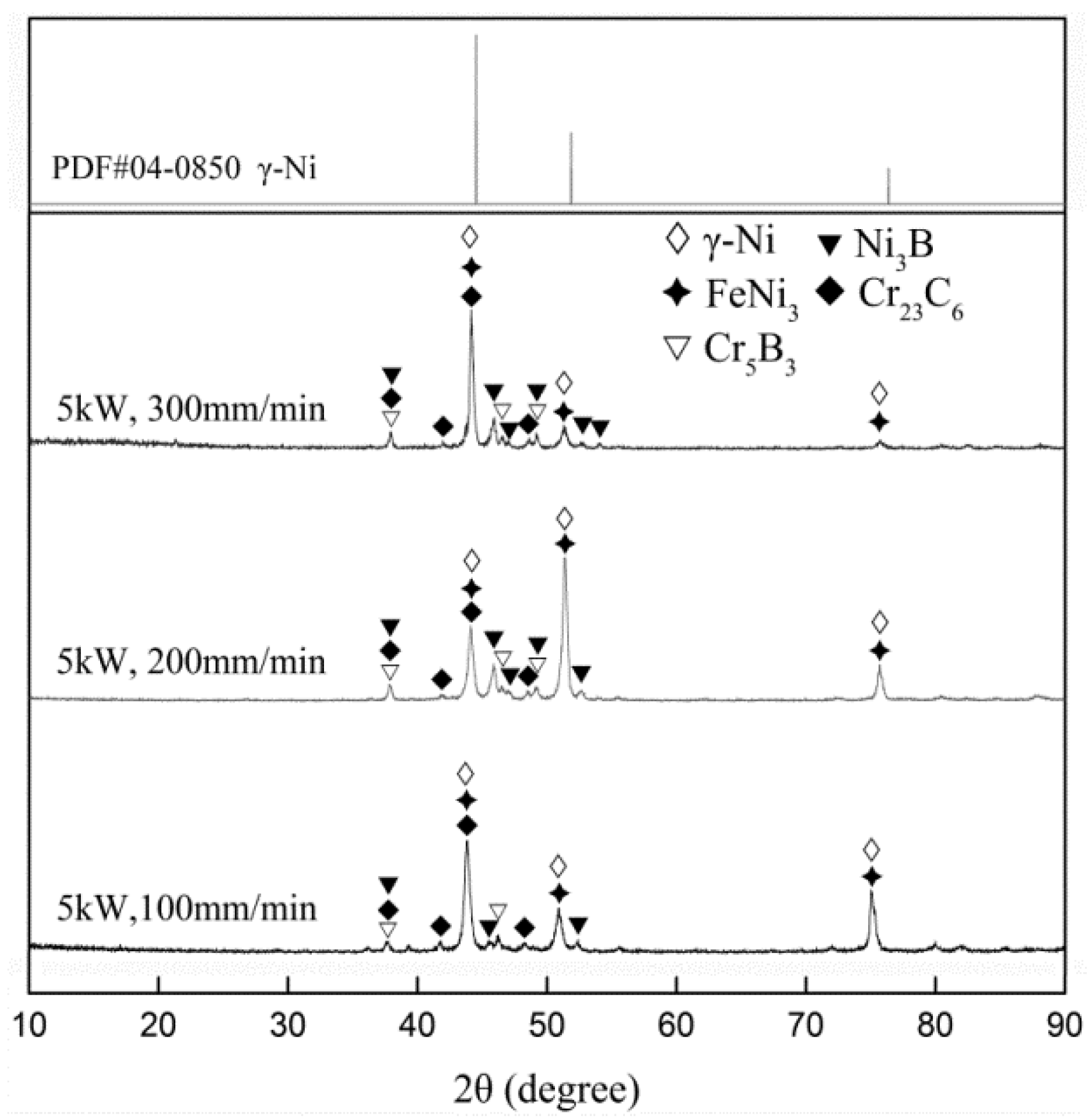

3.2. Coating Phase Constitution

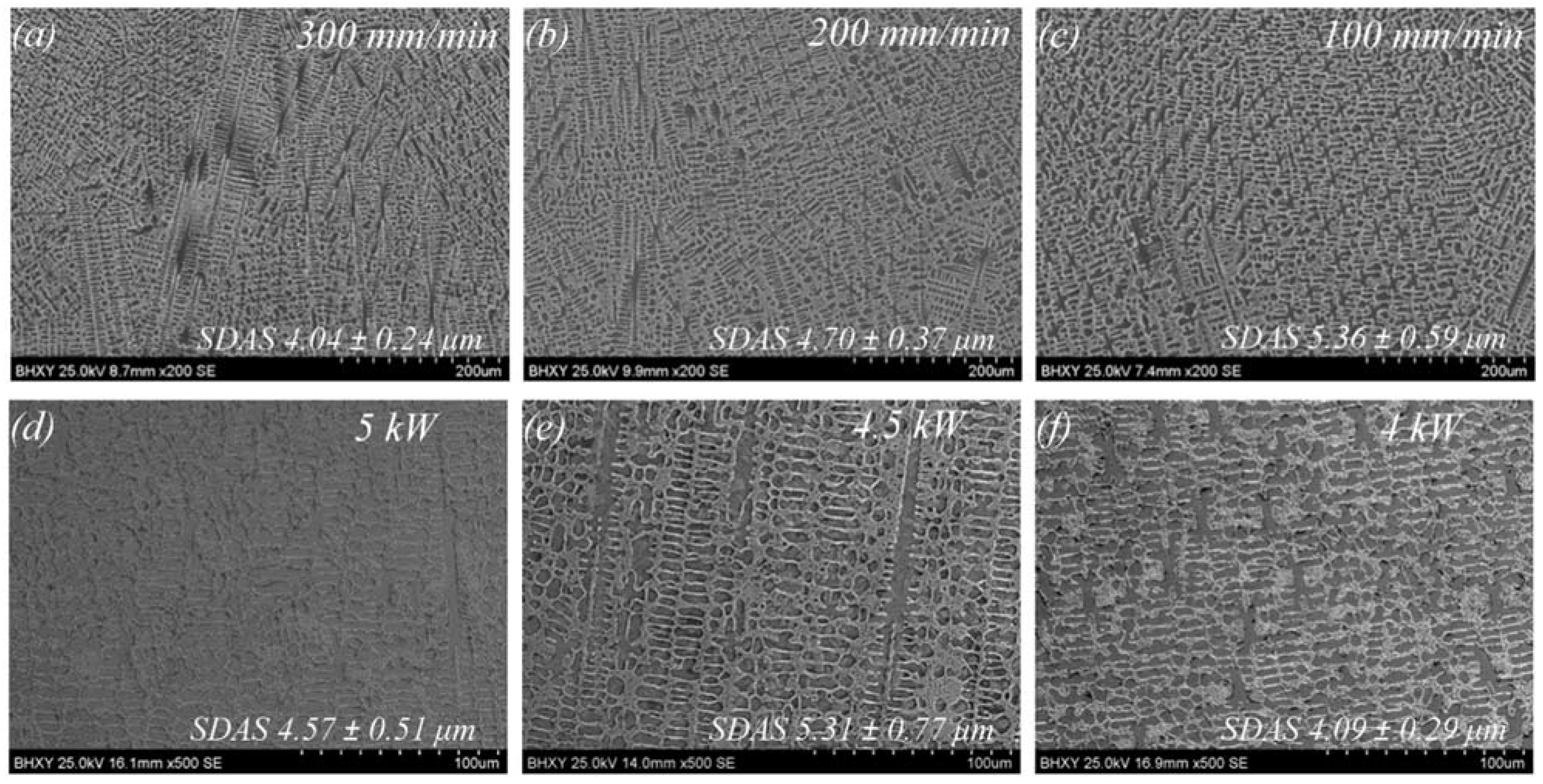

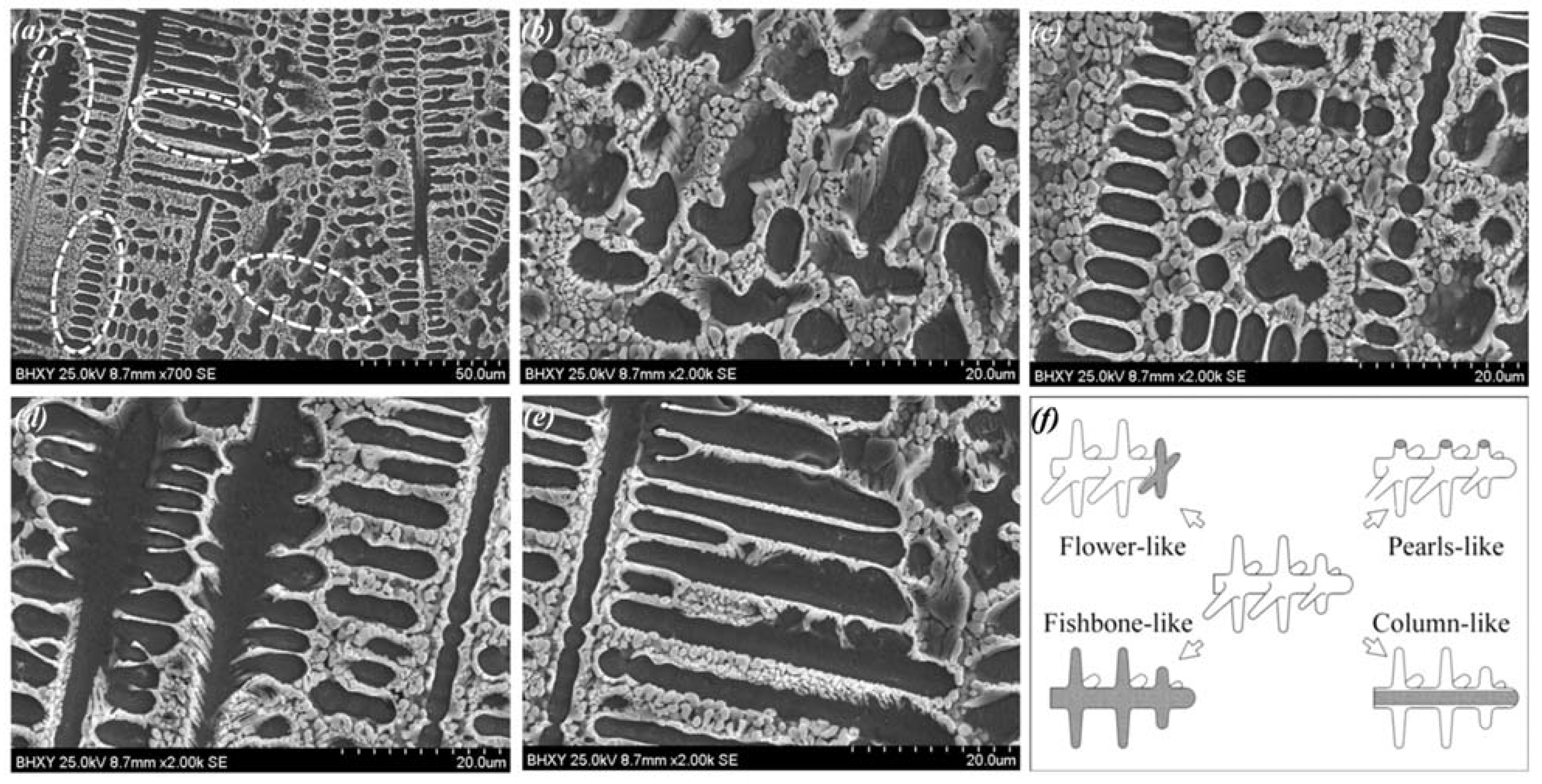

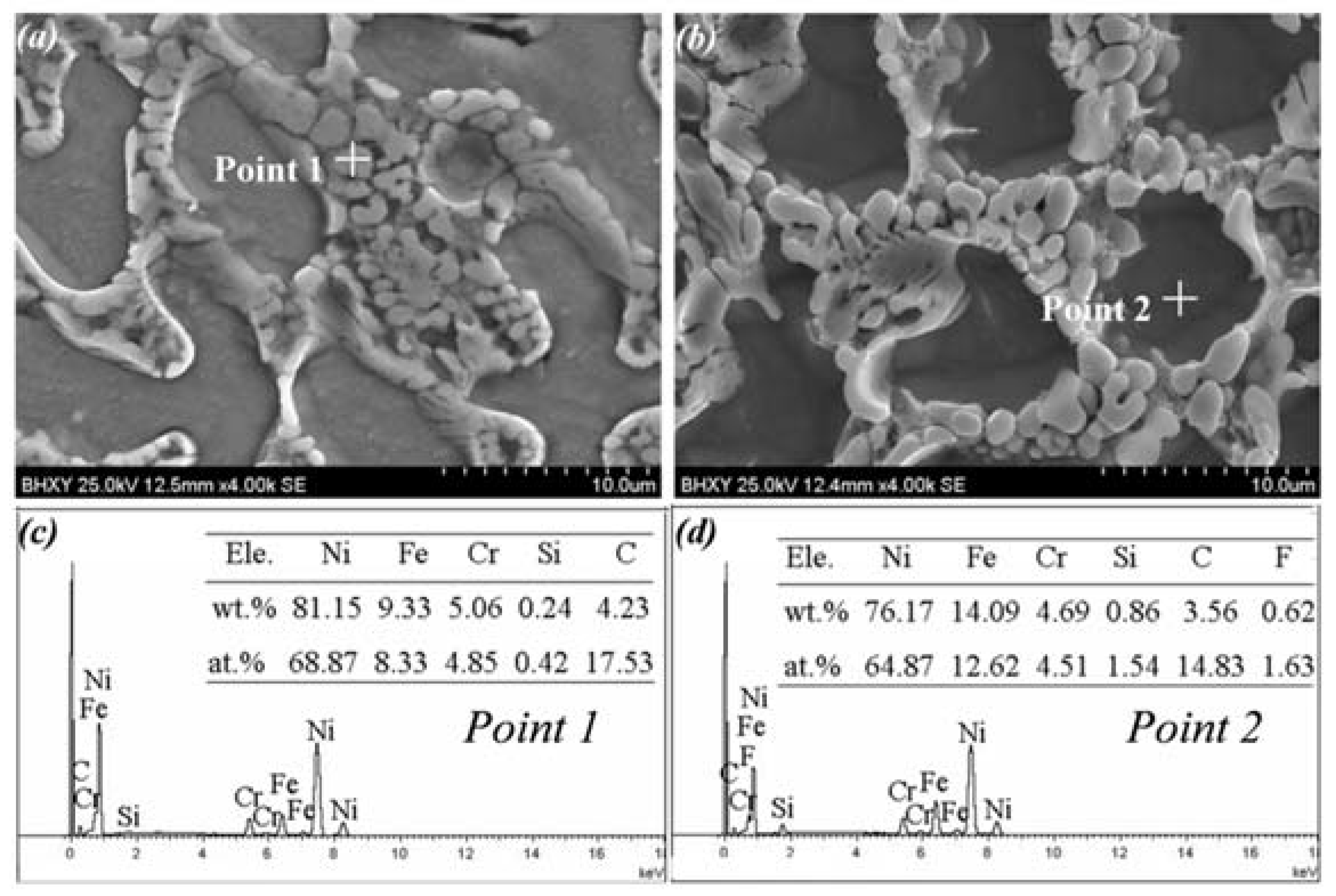

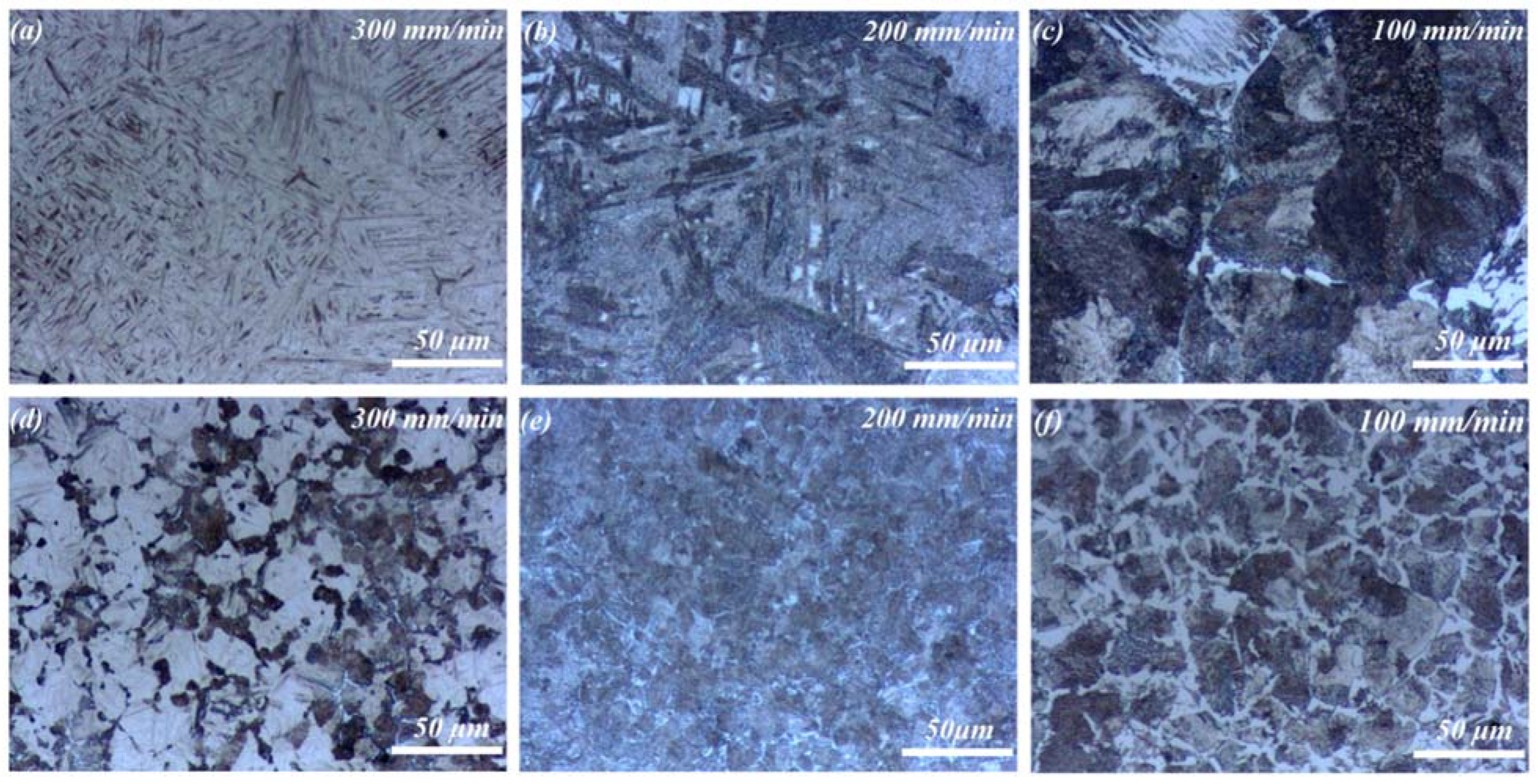

3.3. Coating Microstructure

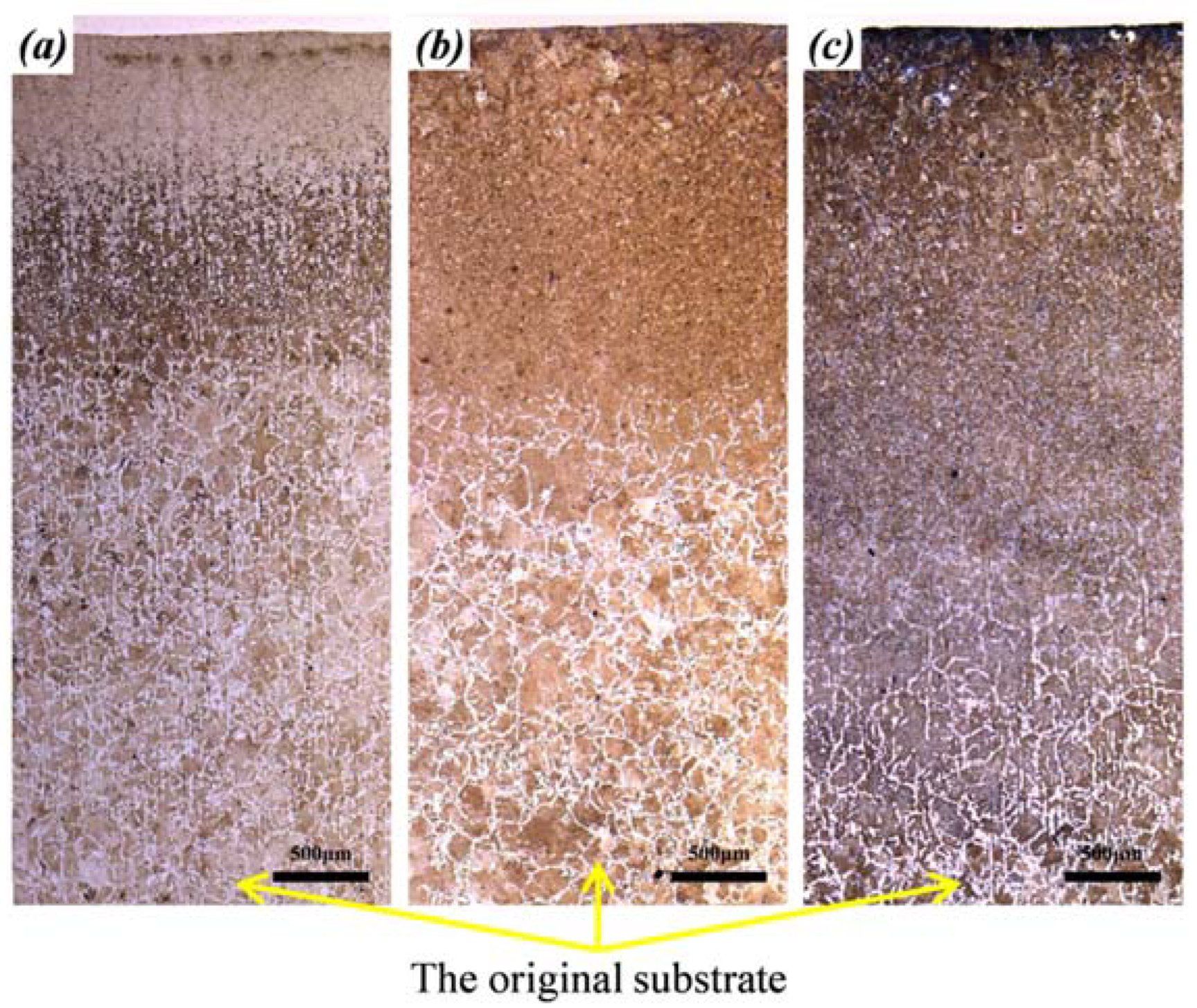

3.4. The Microstructure Evolution of HAZ

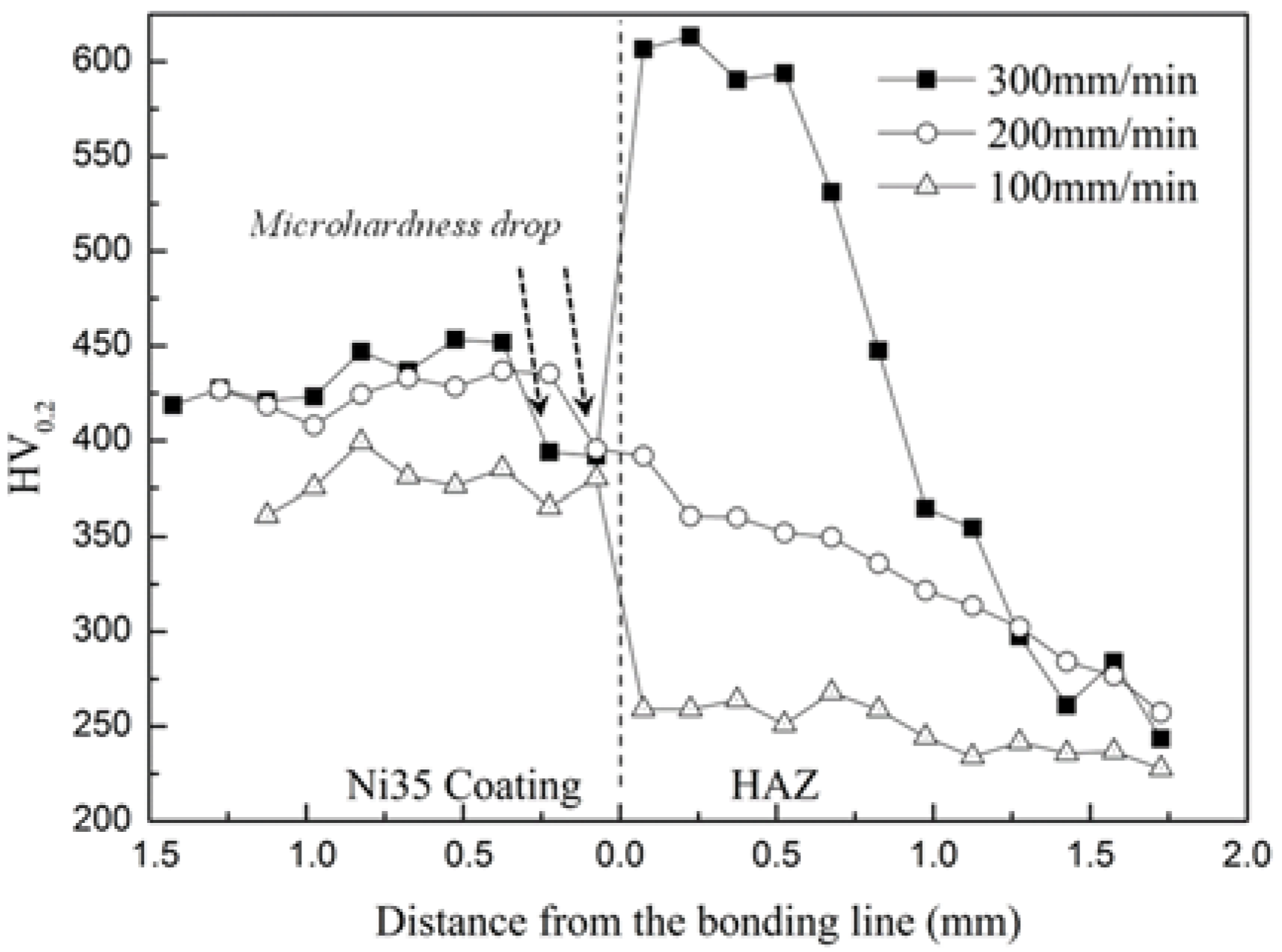

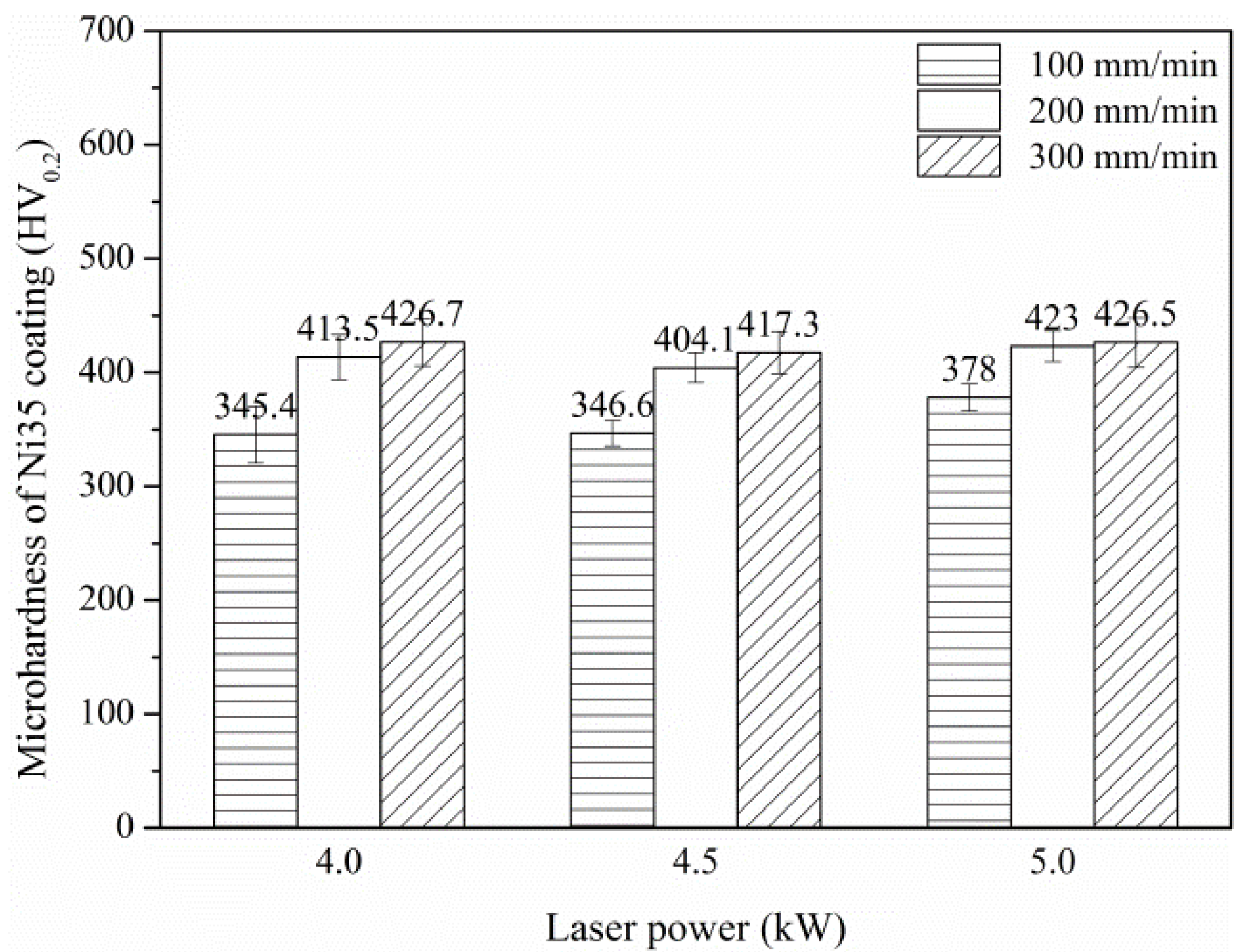

3.5. Microhardness

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Huang, G.; Qu, L.; Lu, Y.; Wang, Y.; Li, H.; Qin, Z.; Lu, X. Corrosion Resistance Improvement of 45 Steel by Fe-based Amorphous Coating. Vacuum 2018, 153, 39–42. [Google Scholar] [CrossRef]

- Ranaware, P.G.; Rathod, M.J. Combined Effect of Shot Peening, Subcritical Austenitic Nitriding, and Cryo-Treatment On Surface Modification of AISI 4140 Steel. Mater. Manuf. Processes 2017, 32, 349–354. [Google Scholar] [CrossRef][Green Version]

- Elosegui, I.; Alonso, U.; de Lacalle, L.N.L. PVD Coatings for Thread Tapping of Austempered Ductile Iron. Int. J. Adv. Manuf. Technol. 2017, 91, 2663–2672. [Google Scholar] [CrossRef]

- Syundyukov, I.; Skotnikova, M.; Padgurskas, J.; Tsvetkova, G.; Tarasenko, E. Wearproof Structural and Phase Status of the Surface of Preparation of Steel 45 After Plasma Spraying of Powder PN85Y15. Mater. Today Proc. 2020, 30, 650–655. [Google Scholar] [CrossRef]

- Sui, Y.; Yang, F.; Qin, G.; Ao, Z.; Liu, Y.; Wang, Y. Microstructure and Wear Resistance of Laser-Cladded Ni-based Composite Coatings On Downhole Tools. J. Mater. Processing Technol. 2018, 252, 217–224. [Google Scholar] [CrossRef]

- Zeng, X.; Wang, Q.; Chen, C.; Lian, G.; Huang, X. Effects of WC Addition On the Morphology, Microstructure and Mechanical Properties of Fe50/TiC/WC Laser Claddings On AISI 1045 Steel. Surf. Coat. Technol. 2021, 427, 127781. [Google Scholar] [CrossRef]

- Lu, D.; Liu, S.; Zhang, X.; Zhang, W. Effect of Y2O3 On Microstructural Characteristics and Wear Resistance of Cobalt-Based Composite Coatings Produced On TA15 Titanium Alloy Surface by Laser Cladding. Surf. Interface Anal. 2015, 47, 239–244. [Google Scholar] [CrossRef]

- Qu, K.L.; Wang, X.H.; Wang, Z.K. Characterization of VC–VB Particles Reinforced Fe-Based Composite Coatings Produced by Laser Cladding. Surf. Rev. Lett. 2016, 23, 32. [Google Scholar] [CrossRef]

- Meng, L.; Zhao, W.; Hou, K.; Kou, D.; Yuan, Z.; Zhang, X.; Xu, J.; Hu, Q.; Wang, D.; Zeng, X. A Comparison of Microstructure and Mechanical Properties of Laser Cladding and Laser-Induction Hybrid Cladding Coatings On Full-Scale Rail. Mater. Sci. Eng. A 2019, 748, 1–15. [Google Scholar] [CrossRef]

- Zhai, L.L.; Ban, C.Y.; Zhang, J.W. Microstructure, Microhardness and Corrosion Resistance of NiCrBSi Coatings Under Electromagnetic Field Auxiliary Laser Cladding. Surf. Coat. Technol. 2019, 358, 531–538. [Google Scholar] [CrossRef]

- Hu, G.; Yang, Y.; Sun, R.; Qi, K.; Lu, X.; Li, J. Microstructure and Properties of Laser Cladding NiCrBSi Coating Assisted by Electromagnetic-Ultrasonic Compound Field. Surf. Coat. Technol. 2020, 404, 126469. [Google Scholar] [CrossRef]

- Awasthi, R.; Limaye, P.K.; Kumar, S.; Kushwaha, R.P.; Viswanadham, C.S.; Srivastava, D.; Soni, N.L.; Patel, R.J.; Dey, G.K. Wear Characteristics of Ni-Based Hardfacing Alloy Deposited on Stainless Steel Substrate by Laser Cladding. Metall. Mater. Trans. A-Phys. Metall. Mater. Sci. 2015, 46, 1237–1252. [Google Scholar] [CrossRef]

- Han, T.; Xiao, M.; Zhang, Y.; Shen, Y. Effect of Cr Content On Microstructure and Properties of Ni-Ti-xCr Coatings by Laser Cladding. Optik 2019, 179, 1042–1048. [Google Scholar] [CrossRef]

- Yan, X.; Chang, C.; Deng, Z.; Lu, B.; Chu, Q.; Chen, X.; Ma, W.; Liao, H.; Liu, M. Microstructure, Interface Characteristics and Tribological Properties of Laser Cladded NiCrBSi-WC Coatings On PH 13-8 Mo Steel. Tribol. Int. 2021, 157, 106873. [Google Scholar] [CrossRef]

- Zhai, L.L.; Ban, C.Y.; Zhang, J.W. Investigation On Laser Cladding Ni-base Coating Assisted by Electromagnetic Field. Opt. Laser Technol. 2019, 114, 81–88. [Google Scholar] [CrossRef]

- Wan, M.Q.; Shi, J.; Lei, L.; Cui, Z.Y.; Wang, H.L.; Wang, X. A Comparative Study of the Microstructure, Mechanical Properties and Corrosion Resistance of Ni- or Fe- Based Composite Coatings by Laser Cladding. J. Mater. Eng. Perform. 2018, 27, 2844–2854. [Google Scholar] [CrossRef]

- Devojno, O.G.; Feldshtein, E.; Kardapolava, M.A.; Lutsko, N.I. On the Formation Features, Microstructure and Microhardness of Single Laser Tracks Formed by Laser Cladding of a NiCrBSi Self-Fluxing Alloy. Opt. Lasers Eng. 2018, 106, 32–38. [Google Scholar] [CrossRef]

- Costa, L.; Felde, I.; Réti, T.; Kálazi, Z.; Colaço, R.; Vilar, R.; Ver, B. A Simplified Semi-Empirical Method to Select the Processing Parameters for Laser Clad Coatings. Mater. Sci. Forum 2003, 414, 385–394. [Google Scholar] [CrossRef]

- Zhang, T.G.; Sun, R.L.; Lei, Y.W.; Niu, W.; Tang, Y. Influence of MoS2 on the Microstructure and Properties of Laser Clad NiCrBSi Coatings. Lasers Eng. 2017, 37, 261–272. [Google Scholar]

- Zhang, H.X.; Yu, H.J.; Chen, C.Z. Microstructure and Wear Resistance of Composite Coating by Laser Cladding Al/TiN on the Ti-6Al-4V Substrate. Surf. Rev. Lett. 2015, 22, 1550044. [Google Scholar] [CrossRef]

- Telasang, G.; Majumdar, J.D.; Wasekar, N.; Padmanabham, G.; Manna, I. Microstructure and Mechanical Properties of Laser Clad and Post-Cladding Tempered AISI H13 Tool Steel. Metall. Mater. Trans. A-Phys. Metall. Mater. Sci. 2015, 46, 2309–2321. [Google Scholar] [CrossRef]

- Zhuang, Q.; Zhang, P.; Li, M.; Yan, H.; Yu, Z.; Lu, Q. Microstructure, Wear Resistance and Oxidation Behavior of Ni-Ti-Si Coatings Fabricated on Ti6Al4V by Laser Cladding. Materials 2017, 10, 1248. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.X.; Yu, H.J.; Chen, C.Z.; Dai, J.J. Microstructure and Dry Sliding Wear Resistance of Laser Cladding Ti-Al-Si Composite Coating. Surf. Rev. Lett. 2017, 241 (Suppl. 1), 1850009. [Google Scholar] [CrossRef]

- Yang, J.; Bai, B.; Ke, H.; Cui, Z.; Liu, Z.; Zhou, Z.; Xu, H.; Xiao, J.; Liu, Q.; Li, H. Effect of Metallurgical Behavior On Microstructure and Properties of FeCrMoMn Coatings Prepared by High-Speed Laser Cladding. Opt. Laser Technol. 2021, 144, 107431. [Google Scholar] [CrossRef]

- Ibrahim, M.Z.; Sarhan, A.A.D.; Kuo, T.Y.; Hamdi, M.; Yusof, F.; Chien, C.S.; Chang, C.P.; Lee, T.M. Advancement of the Artificial Amorphous-Crystalline Structure of Laser Cladded FeCrMoCB On Nickel-Free Stainless-Steel for Bone-Implants. Mater. Chem. Phys. 2019, 227, 358–367. [Google Scholar] [CrossRef]

- Wang, X.-L.; Deng, D.-W.; Zhang, H.-C. Effects of Mass Energy and Line Mass on Clad Characteristics in the Laser Cladding Process. Lasers Eng. 2016, 34, 1–14. [Google Scholar]

- Ya, W.; Pathiraj, B.; Matthews, D.T.A.; Bright, M.; Melzer, S. Cladding of Tribaloy T400 On Steel Substrates Using a High Power Nd:YAG Laser. Surf. Coat. Technol. 2018, 350, 323–333. [Google Scholar] [CrossRef]

- Abioye, T.E.; Farayibi, P.K.; Clare, A.T. A Comparative Study of Inconel 625 Laser Cladding by Wire and Powder Feedstock. Mater. Manuf. Processes 2017, 32, 1653–1659. [Google Scholar] [CrossRef]

- Wu, Q.L.; Li, W.G.; Zhong, N.; Fan, C.H.; Liu, B.Y.; Ying, Y.S. Preparation of a Double Layer Composite Coating on a Steel Substrate by Laser Cladding. Lasers Eng. 2016, 35, 389–401. [Google Scholar]

- Bergant, Z.; Batič, B.Š.; Felde, I.; Šturm, R.; Sedlaček, M. Tribological Properties of Solid Solution Strengthened Laser Cladded NiCrBSi/WC-12Co Metal Matrix Composite Coatings. Materials 2022, 15, 342. [Google Scholar] [CrossRef]

- Zhan, X.; Qi, C.; Gao, Z.; Tian, D.; Wang, Z. The Influence of Heat Input On Microstructure and Porosity During Laser Cladding of Invar Alloy. Opt. Laser Technol. 2019, 113, 453–461. [Google Scholar] [CrossRef]

- Rubino, F.; Astarita, A.; Carlone, P.; Genna, S.; Leone, C.; Minutolo, F.M.C.; Squillace, A. Selective Laser Post-Treatment On Titanium Cold Spray Coatings. Mater. Manuf. Processes 2016, 31, 1500–1506. [Google Scholar] [CrossRef]

- Qunshuang, M.; Yajiang, L.; Juan, W. Surface Modification of Q550 HSLA Steel with Co-Fe-Cr Composite Coatings Manufactured by Fibre Laser Cladding. Surf. Eng. 2016, 32, 934–942. [Google Scholar] [CrossRef]

- Savrai, R.A.; Makarov, A.V.; Soboleva, N.N.; Malygina, I.Y.; Osintseva, A.L. The Behavior of Gas Powder Laser Clad NiCrBSi Coatings Under Contact Loading. J. Mater. Eng. Perform. 2016, 25, 1068–1075. [Google Scholar] [CrossRef]

- Yao, J.; Yang, L.; Li, B.; Li, Z. Characteristics and Performance of Hard Ni60 Alloy Coating Produced with Supersonic Laser Deposition Technique. Mater. Des. 2015, 83, 26–35. [Google Scholar] [CrossRef]

- Xuan, H.F.; Wang, Q.Y.; Bai, S.L.; Liu, Z.D.; Sun, H.G.; Yan, P.C. A Study On Microstructure and Flame Erosion Mechanism of a Graded Ni–Cr–B–Si Coating Prepared by Laser Cladding. Surf. Coat. Technol. 2014, 244, 203–209. [Google Scholar] [CrossRef]

- Cabeza, M.; Castro, G.; Merino, P.; Pena, G.; Roman, M. A Study of Laser Melt Injection of TiN Particles to Repair Maraging Tool Steels. Surf. Interface Anal. 2014, 46, 861–864. [Google Scholar] [CrossRef]

- Bergant, Z.; Felde, I.; Grum, J. Modelling of remelted and heat affected zone during laser alloying of C45 steel with nickel-based powder. Int. J. Microstruct. Mater. Prop. 2015, 10, 129. [Google Scholar] [CrossRef]

| Element | C | B | Si | Cr | Fe | Ni |

|---|---|---|---|---|---|---|

| wt.% | ≤0.25 | 1.5~3 | 2.5~4 | 9~12 | ≤14 | Bal. |

| Element | C | Cr | Mn | Ni | Si | P | S | Fe |

|---|---|---|---|---|---|---|---|---|

| wt.% | 0.42~0.50 | ≤0.25 | 0.50~0.80 | ≤0.25 | 0.17~0.37 | ≤0.035 | ≤0.035 | Bal. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, L.; Yu, H.; Wang, Y.; Zhao, Z.; Song, W.; Chen, C. NiCrBSi Coatings Fabricated on 45 Steel Using Large Spot Laser Cladding. Materials 2022, 15, 6246. https://doi.org/10.3390/ma15186246

Zhao L, Yu H, Wang Y, Zhao Z, Song W, Chen C. NiCrBSi Coatings Fabricated on 45 Steel Using Large Spot Laser Cladding. Materials. 2022; 15(18):6246. https://doi.org/10.3390/ma15186246

Chicago/Turabian StyleZhao, Longjie, Huijun Yu, Yanxiang Wang, Zhihuan Zhao, Weihai Song, and Chuanzhong Chen. 2022. "NiCrBSi Coatings Fabricated on 45 Steel Using Large Spot Laser Cladding" Materials 15, no. 18: 6246. https://doi.org/10.3390/ma15186246

APA StyleZhao, L., Yu, H., Wang, Y., Zhao, Z., Song, W., & Chen, C. (2022). NiCrBSi Coatings Fabricated on 45 Steel Using Large Spot Laser Cladding. Materials, 15(18), 6246. https://doi.org/10.3390/ma15186246