Construction and Validation of Simulation Models of Samples Made from 316L Steel by Applying Additive Technique

Abstract

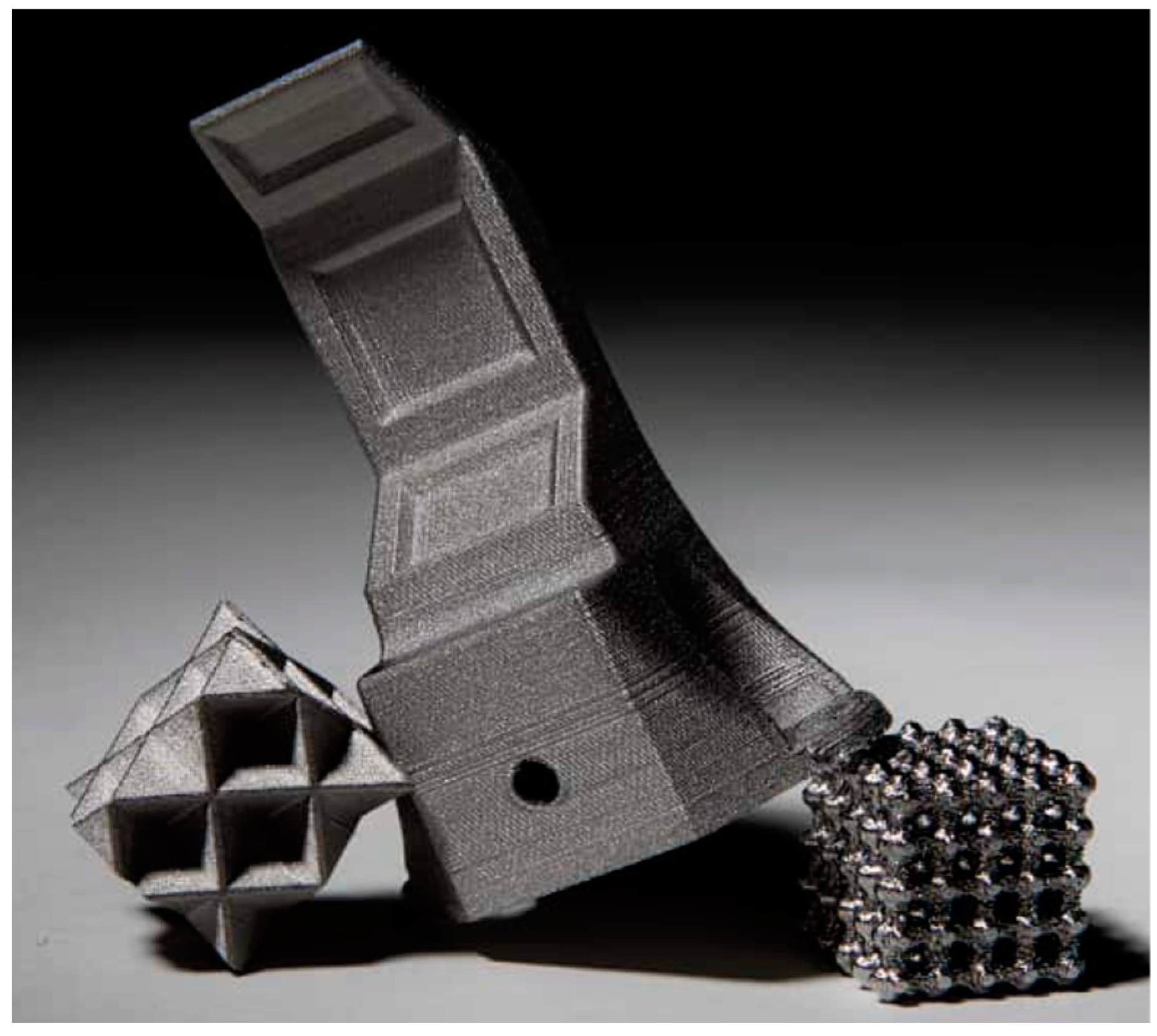

1. Introduction

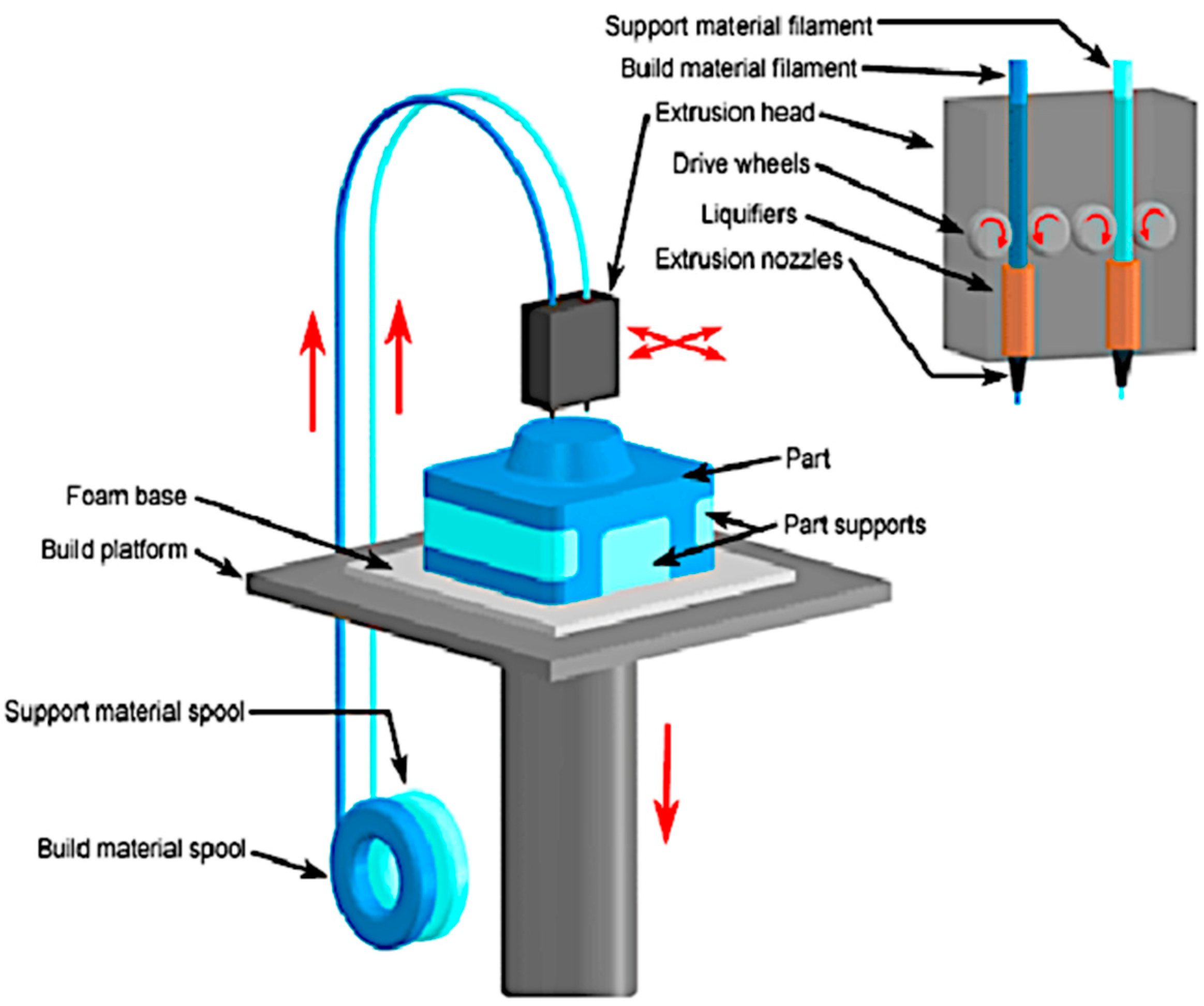

2. Materials and Methods

2.1. Experimental Methods

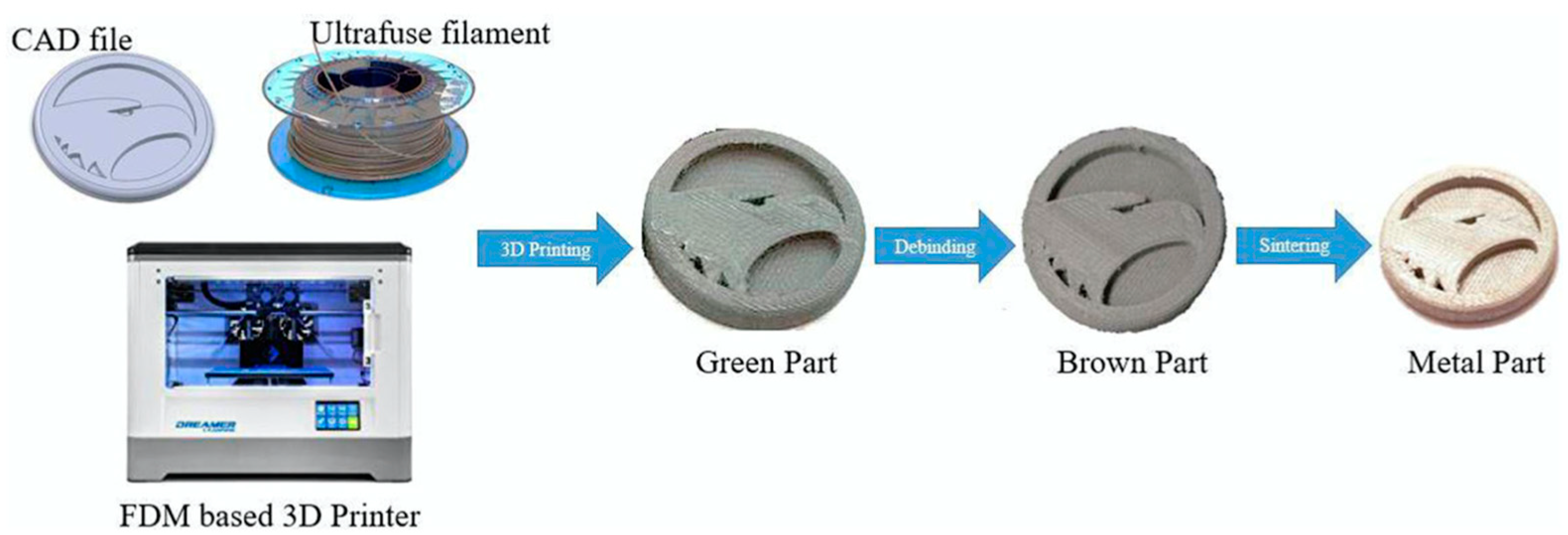

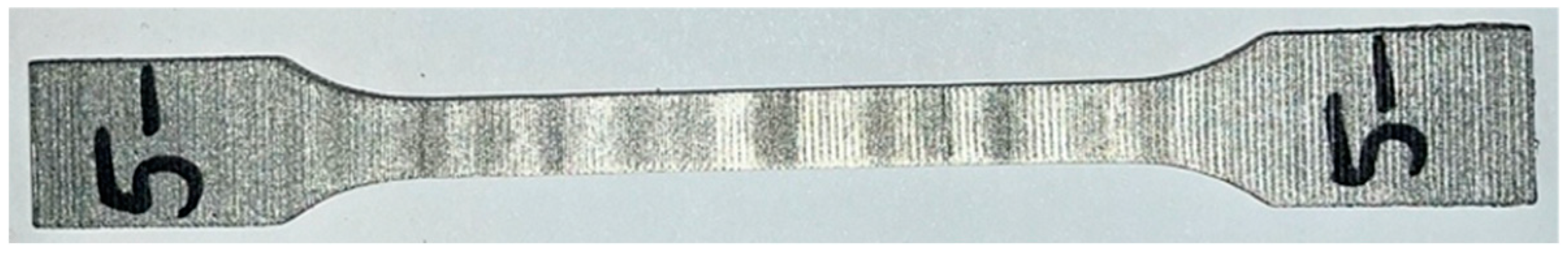

2.1.1. Materials and Specimens

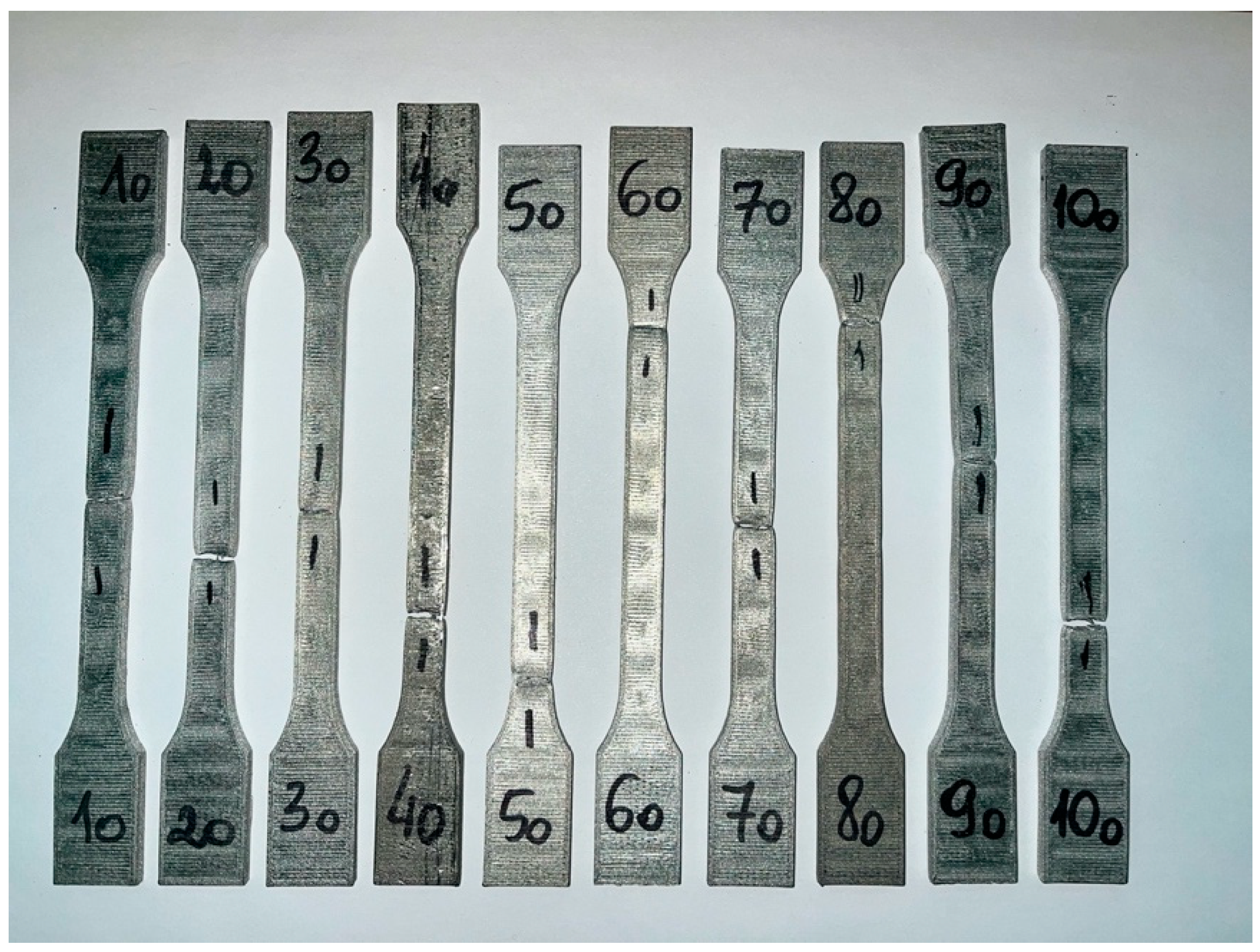

2.1.2. Printed Samples

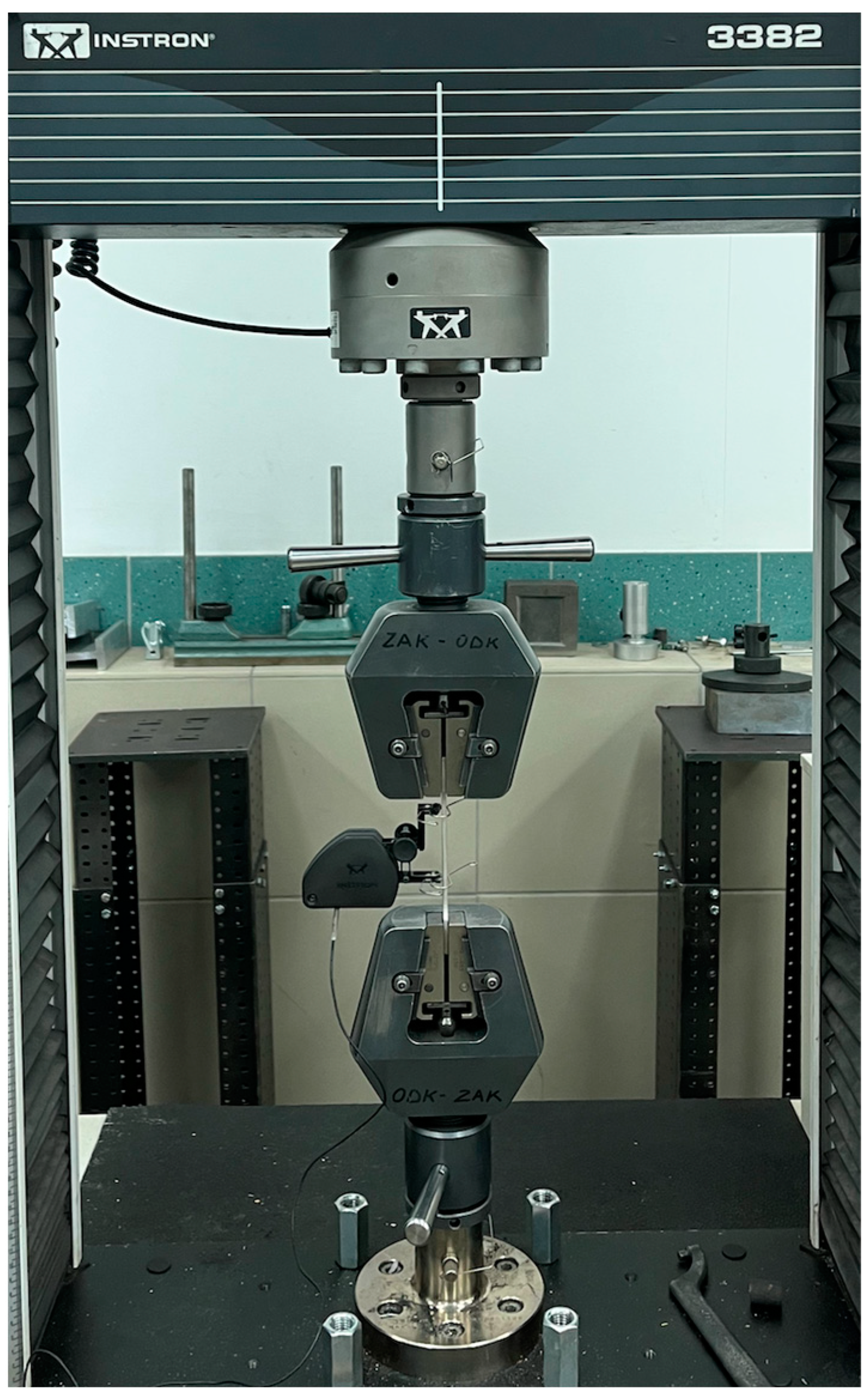

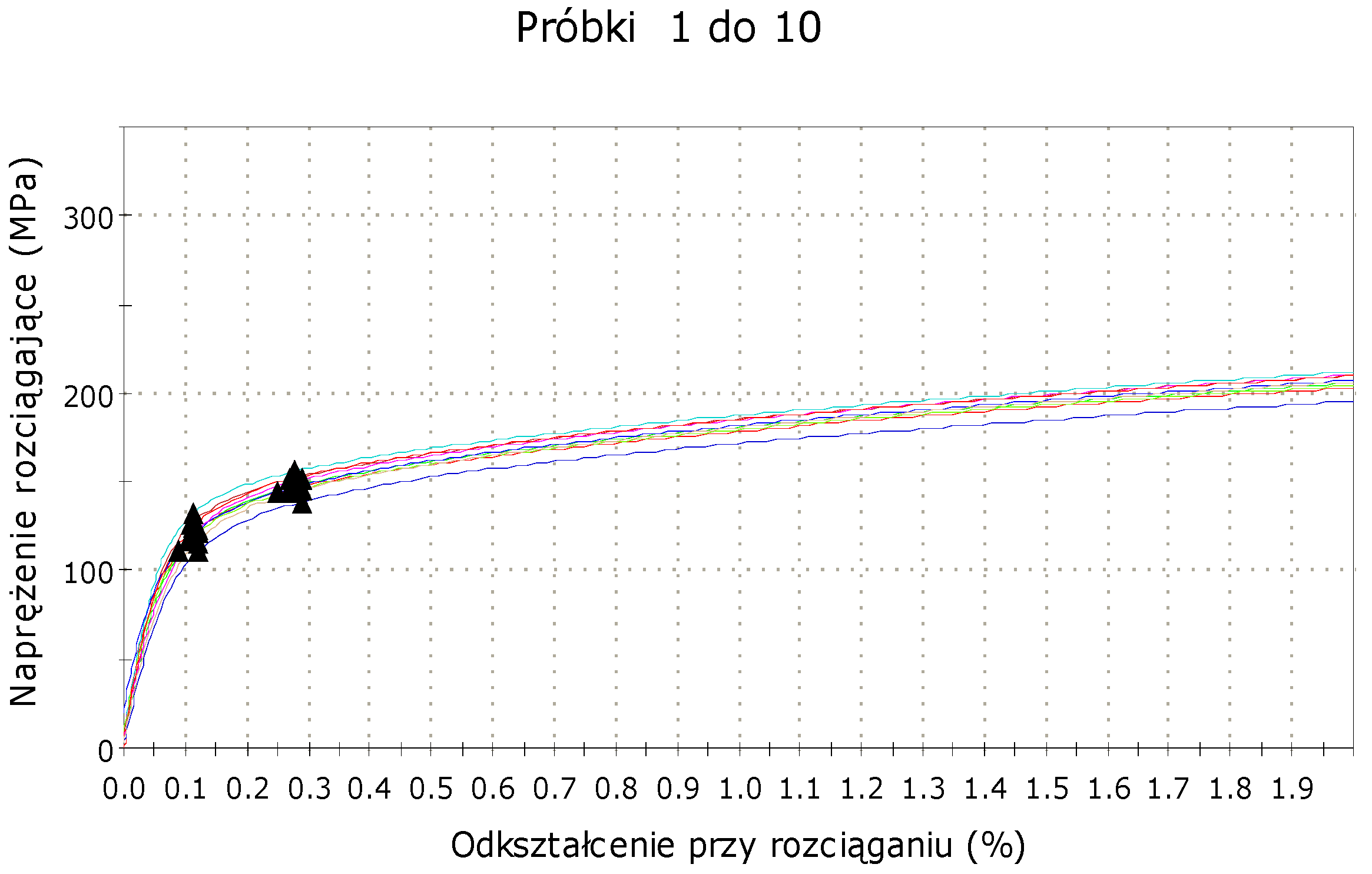

2.1.3. Static Tensile Tests

2.1.4. Probe’s Scans and Poisson’s Ratio

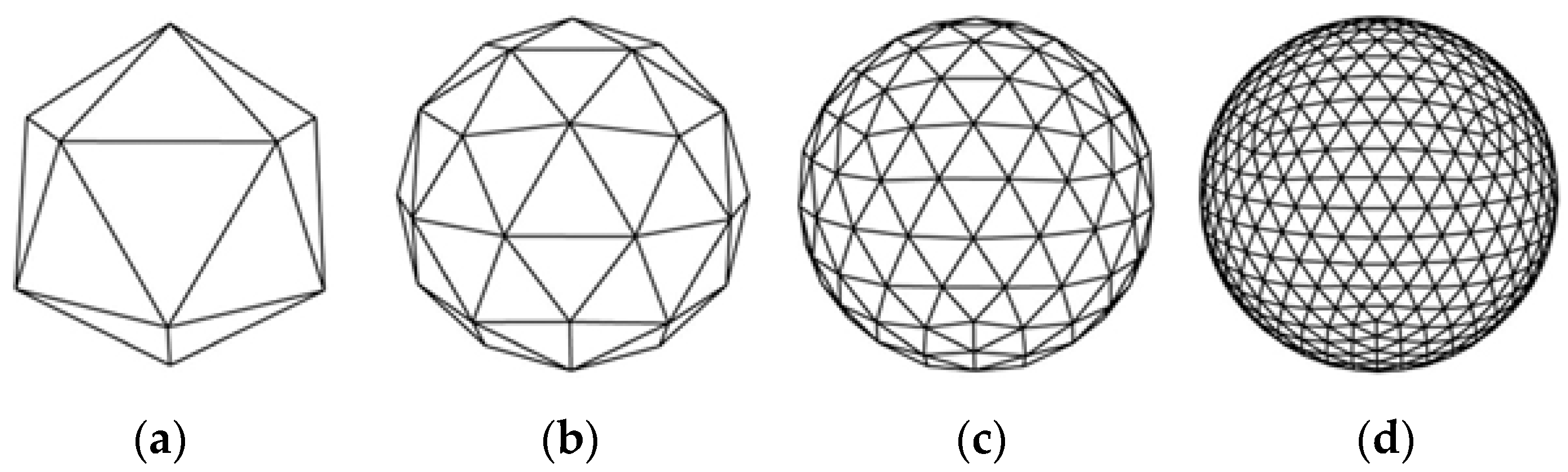

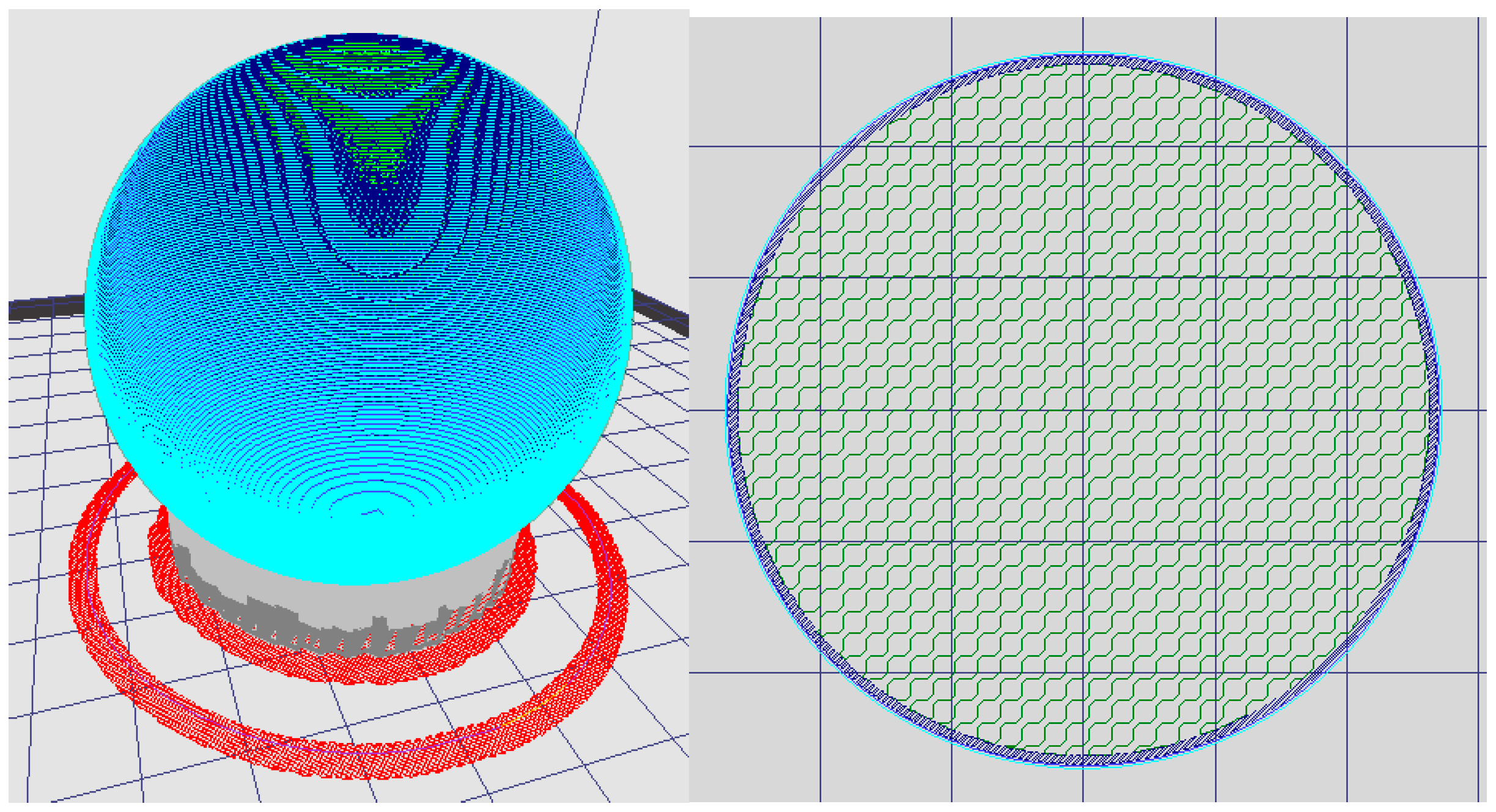

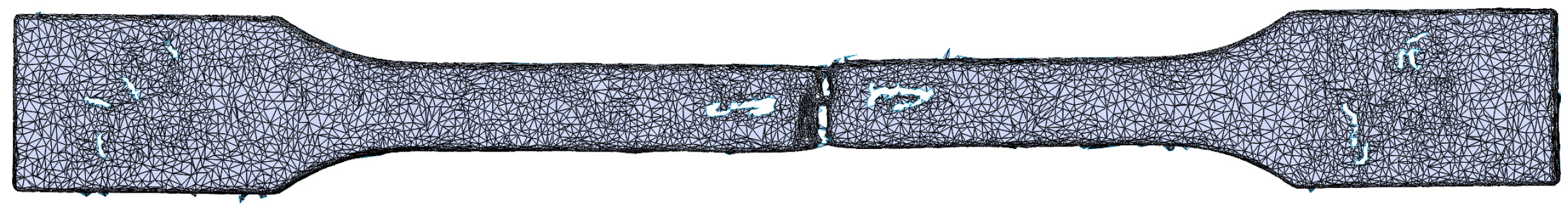

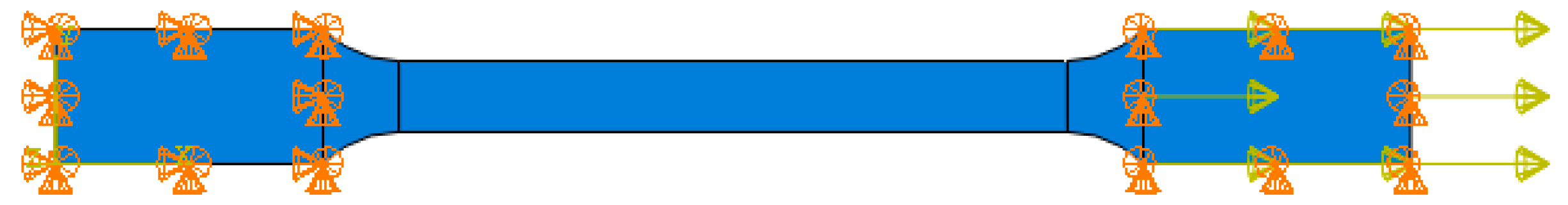

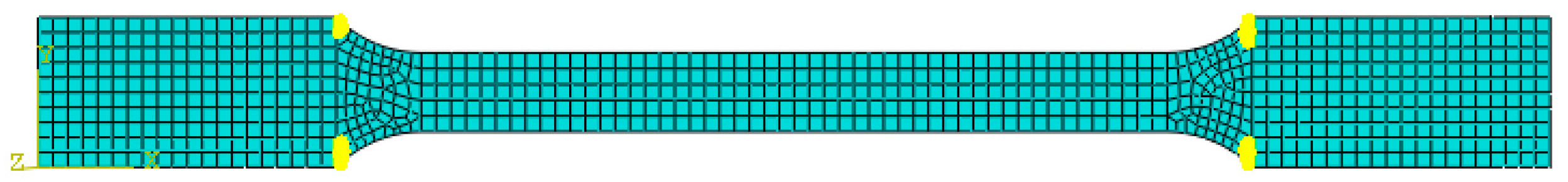

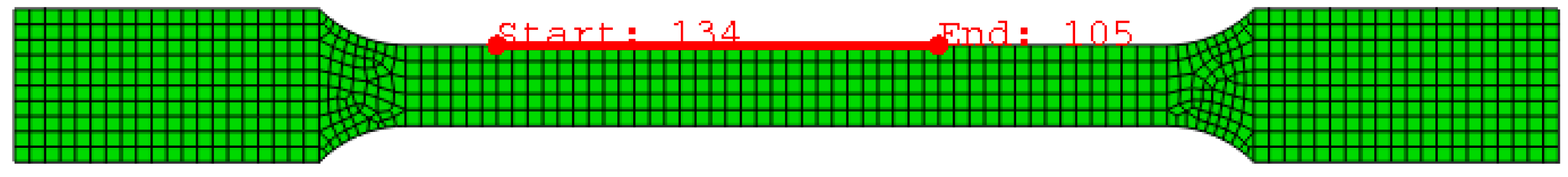

2.2. Numerical Implementation

3. Results

3.1. Experimental Methods

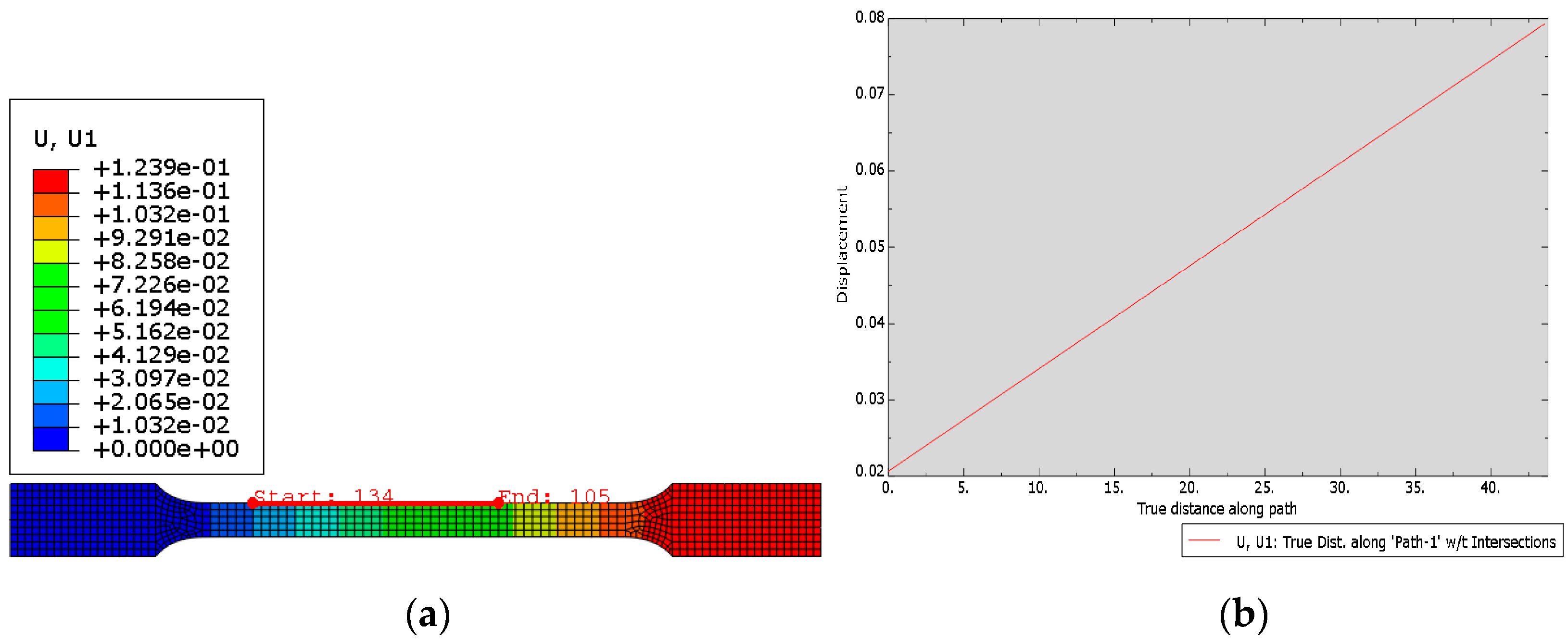

3.2. Numerical Implementation

3.3. Comparison of Displacement Results from the Experimental and Numerical Methods

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Mirzababaei, S.; Pasebani, S. A Review on Binder Jet Additive Manufacturing of 316L Stainless Steel. J. Manuf. Mater. Process. 2019, 3, 82. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Wong, K.V.; Hernandez, A. A Review of Additive Manufacturing. ISRN Mech. Eng. 2012, 2012, 208760. [Google Scholar] [CrossRef]

- CADblog. Available online: https://www.cadblog.pl/CADblog_CAD_do_druku_3D_STL_AMF_3MF.htm (accessed on 10 July 2022).

- Iancu, C.; Iancu, D.; Stamcioiu, A. From CAD model to 3D print via “STL” file format. Fiability Durab./Fiabil. Si Durabilitate 2010, 1, 73–80. [Google Scholar]

- Tatarczyk, J.; Krzysiak, Z.; Samociuk, W.; Kalinkiewicz, Z.; Krzywonos, L. A review of the newest 3D printing technology for metal objects. Mechanik 2017, 90, 612–614. [Google Scholar] [CrossRef][Green Version]

- Rapid Crafting. Available online: https://rapidcrafting.com/en/materials/ (accessed on 21 August 2022).

- Vora, J.; Parikh, N.; Chaudhari, R.; Patel, V.; Paramar, H.; Pimenov, D.; Giasin, K. Optimization of Bead Morphology for GMAW-Based Wire-Arc Additive Manufacturing of 2.25 Cr-1.0 Mo Steel Using Metal-Cored Wires. Appl. Sci. 2022, 12, 5060. [Google Scholar] [CrossRef]

- Smith, C.J.; Gilbert, M.; Todd, I.; Derguti, F. Application of layout optimalization to the design of additively manufactured metallic components. Struct. Multidiscip. Optim. 2016, 54, 1297–1313. [Google Scholar] [CrossRef]

- Liu, B.; Wang, Y.; Lin, Z.; Zhang, T. Creating metal parts by Fused Deposition Modeling and Sintering. Mater. Lett. 2020, 263, 127252. [Google Scholar] [CrossRef]

- Suwanpreecha, C.; Manonukul, A. A Review on Material Extrusion Additive Manufacturing of Metal and How It Compares with Metal Injection Moulding. Metals 2022, 12, 429. [Google Scholar] [CrossRef]

- Li, N.; Huang, S.; Zhang, G.; Qin, R.; Liu, W.; Xiong, H.; Shi, G.; Blackburn, J. Progress in additive manufacturing on new materials: A review. J. Od Mater. Sci. Technol. 2019, 65, 242–269. [Google Scholar] [CrossRef]

- Chennakesava, P.; Shrivaj Narayan, Y. Fused Deposition Modeling. In Proceedings of the International Conference on Advances in Design & Manufacturing, Tamil Nadu, India, 5–7 December 2014. [Google Scholar]

- Zein, I.; Hutmacher, W.; Chen Tan, K.; SweeHin, T. Fused Deposition Modeling of Novel Scaffold Architectures for Tissue Engineering Aplications. Biomaterials 2002, 23, 1169–1185. [Google Scholar] [CrossRef]

- Popescu, D.; Zapciu, A.; Amza, C.; Basiu, F.; Marinescu, R. FDM process parameters influence over the technical properties of polymer specimens: A review. Polym. Test. 2018, 69, 157–166. [Google Scholar] [CrossRef]

- Wankhede, V.; Jagetiya, D.; Joshi, A.; Chaudhari, R. Experimental investigation of FDM process parameters using Taguchi analysis. Mater. Today Proc. 2020, 27, 2117–2120. [Google Scholar] [CrossRef]

- Chacon, J.M.; Nunez, P.J.; Caminero, M.A.; Garcia-Plaza, E.; Vallejo, J.; Blanco, M. 3D printing of patient-specific 316L–stainless–steel medical implants using fused filament fabrication technology: Two veterinary case studies. Bio-Des. Manuf. 2022, 5, 1–8. [Google Scholar] [CrossRef]

- Ansari, P.; Rehman, A.; Pitir, F.; Veziroglu, S.; Mishra, Y.; Aktas, O.; Salamci, M. Selective Laser Melting of 316L Austenitic Stainless Steel: Detailed Process Understanding Using Multiphysics Simulation and Experimentation. Metals 2021, 11, 1076. [Google Scholar] [CrossRef]

- Li, Y.; Ge, Y.; Lei, J.; Bai, W. Mechanical Properties and Constitutive Model of Selective Laser Melting 316L Stainless Steel at Different Scanning Speeds. Adv. Mater. Sci. Eng. 2022, 2022, 2905843. [Google Scholar] [CrossRef]

- Yang, X.; Liu, Y.; Ye, J.; Wang, R.; Zhou, T.; Mao, B. Enhanced mechanical properties and formability of 316L stainless steel materials 3D-printed using selective laser melting. Int. J. Miner. Metall. Mater. 2019, 26, 1396–1404. [Google Scholar] [CrossRef]

- Gong, H.; Crater, C.; Ordonez, A.; Ward, C.; Waller, M.; Ginn, C. Material Properties and Shrinkage of 3D Printing Parts using Ultrafuse Stainless Steel 316LX Filament. MATEC Web Conf. 2018, 249, 01001. [Google Scholar] [CrossRef]

- Kuros, T.; Abe, Y.; Santos, M.; Kanaya, Y.; Ishigami, A.; Tanaka, S.; Ito, H. Influence of the Layer Directions on the Properties of 316L Stainless Steel Parts Fabricated through Fused Deposition of Metals. Materials 2020, 13, 2493. [Google Scholar] [CrossRef] [PubMed]

- Geno, H.; Snelling, D.; Kardel, K.; Carrano, A. Comparison of Stainless Steel 316L Parts Made by FDMand SLM-Based Additive Manufacturing Processes. J. Minerals. Met. Mater. Soc. 2019, 71, 880–885. [Google Scholar]

- Pellegrini, A.; Palmieri, M.; Guerra, M. Evaluation of anisotropic mechanical behaviour of 316L parts realized by metal fused filament fabrication using digital image correlation. Int. J. Adv. Manuf. Technol. 2022, 120, 7951–7965. [Google Scholar] [CrossRef]

- Get3D. Available online: https://get3d.pl/sklep/filamenty/basf-forward-am/basf-ultrafuse-316l/ (accessed on 15 July 2022).

- Carminati, M.; Quarto, M.; D’Urso, G.; Giardini, C.; Maccarini, G. Mechanical Characterization of AISI 316L Samples Printed Using Material Extrusion. Appl. Sci. 2022, 12, 1433. [Google Scholar] [CrossRef]

- Syrlybayev, D.; Zharylkassyn, B.; Seiskulova, A.; Akhmetov, M.; Perveen, A.; Talamona, D. Optimisation of Strength Properties of FDM Printed Parts—A Critical Review. Polymers 2021, 13, 1587. [Google Scholar] [CrossRef]

- Ngo, T.; Kashami, A.; Imbalzano, G.; Nguyen, K.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

| Number of Layers | ||||

|---|---|---|---|---|

| Number of Layers | ||||

|---|---|---|---|---|

| Width (mm) | Thickness (mm) | Yield Strength (0.2%) (Mpa) | Tensile Strength (Mpa) | Young’s Modulus (Mpa) | |

|---|---|---|---|---|---|

| 1 | 8.4 | 3.30 | 145.7 | 287.5 | 95 384 |

| 2 | 8.4 | 3.30 | 151.3 | 309.1 | 104 172 |

| 3 | 8.4 | 3.30 | 148.0 | 343.3 | 94 870 |

| 4 | 8.4 | 3.30 | 155.7 | 364.5 | 118 331 |

| 5 | 8.4 | 3.30 | 144.4 | 235.2 | 87 035 |

| 6 | 8.4 | 3.30 | 151.1 | 319.4 | 89 617 |

| 7 | 8.4 | 3.30 | 144.7 | 230.0 | 94 131 |

| 8 | 8.4 | 3.30 | 138.8 | 249.9 | 74 835 |

| 9 | 8.4 | 3.30 | 152.2 | 322.4 | 95 953 |

| 10 | 8.4 | 3.30 | 145.4 | 3.0 | 81 643 |

| Average | 8.4 | 3.30 | 147.7 | 295.7 | 93 597 |

| Sample Number | |||||

|---|---|---|---|---|---|

| Average |

| Sample Number | |||||

|---|---|---|---|---|---|

| Average |

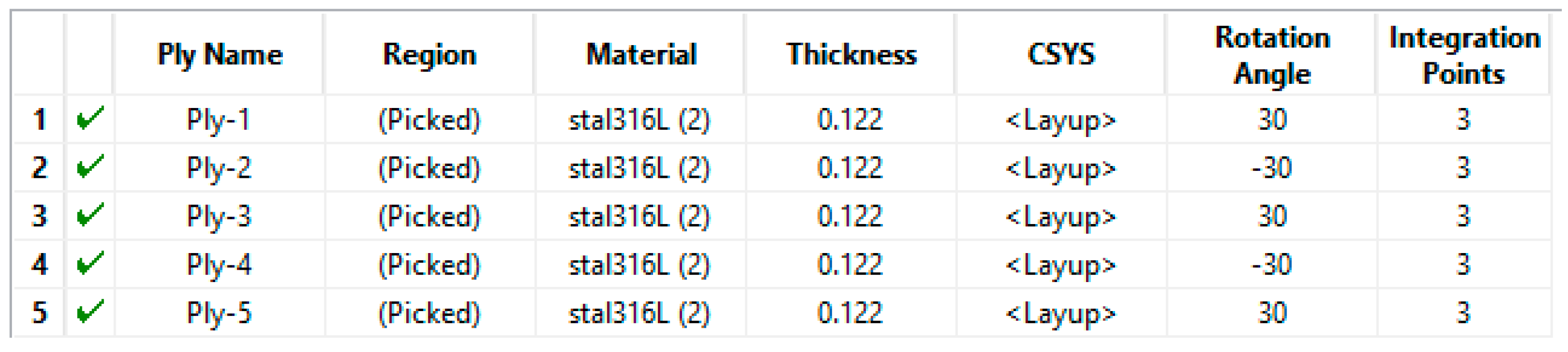

| Lamination Angle | ||||

|---|---|---|---|---|

| (with envelope) |

| Experimental method | |

| FEM analysis | |

| 14.4% |

| Experimental method | |

| FEM analysis | |

| 3.6% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dąbrowska, K.; Nowak, R.; Rumianek, P.; Seńko, J. Construction and Validation of Simulation Models of Samples Made from 316L Steel by Applying Additive Technique. Materials 2022, 15, 6244. https://doi.org/10.3390/ma15186244

Dąbrowska K, Nowak R, Rumianek P, Seńko J. Construction and Validation of Simulation Models of Samples Made from 316L Steel by Applying Additive Technique. Materials. 2022; 15(18):6244. https://doi.org/10.3390/ma15186244

Chicago/Turabian StyleDąbrowska, Kamila, Radosław Nowak, Przemysław Rumianek, and Jarosław Seńko. 2022. "Construction and Validation of Simulation Models of Samples Made from 316L Steel by Applying Additive Technique" Materials 15, no. 18: 6244. https://doi.org/10.3390/ma15186244

APA StyleDąbrowska, K., Nowak, R., Rumianek, P., & Seńko, J. (2022). Construction and Validation of Simulation Models of Samples Made from 316L Steel by Applying Additive Technique. Materials, 15(18), 6244. https://doi.org/10.3390/ma15186244