Distortion Prediction in Inconel-718 Part Fabricated through LPBF by Using Homogenized Support Properties from Experiments and Numerical Simulation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

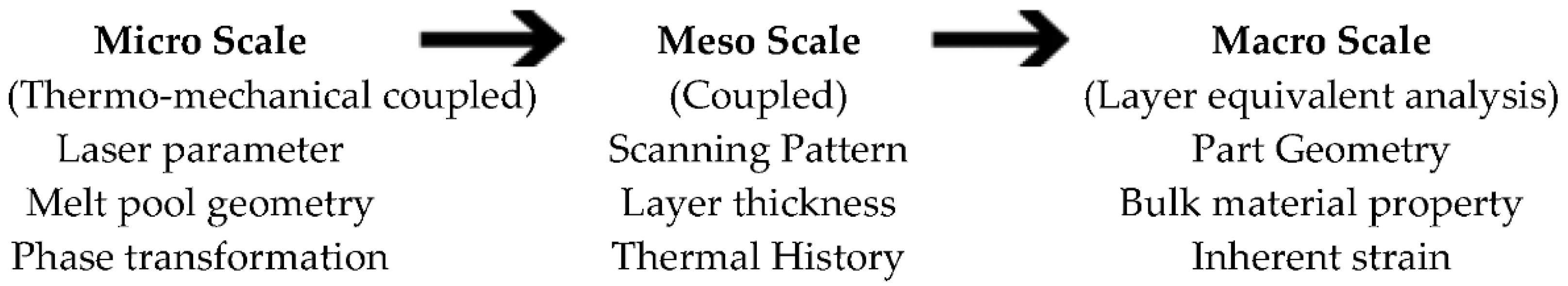

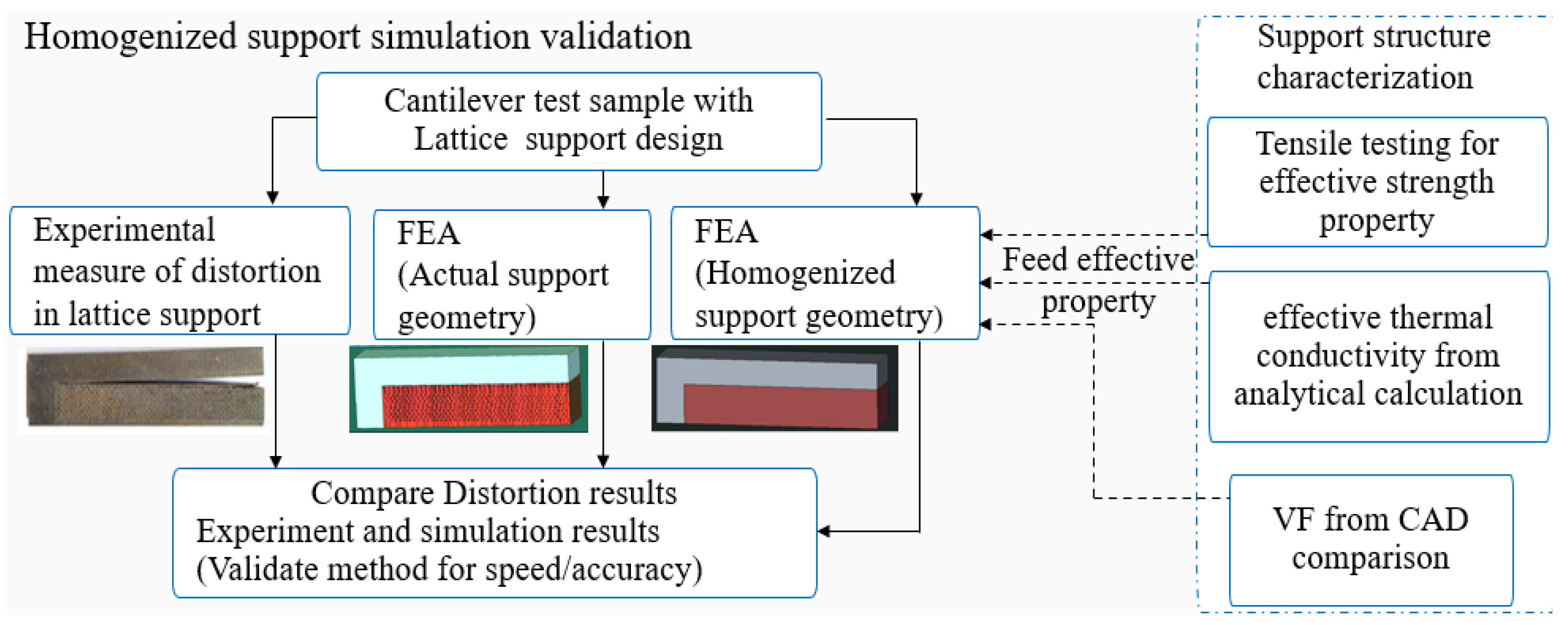

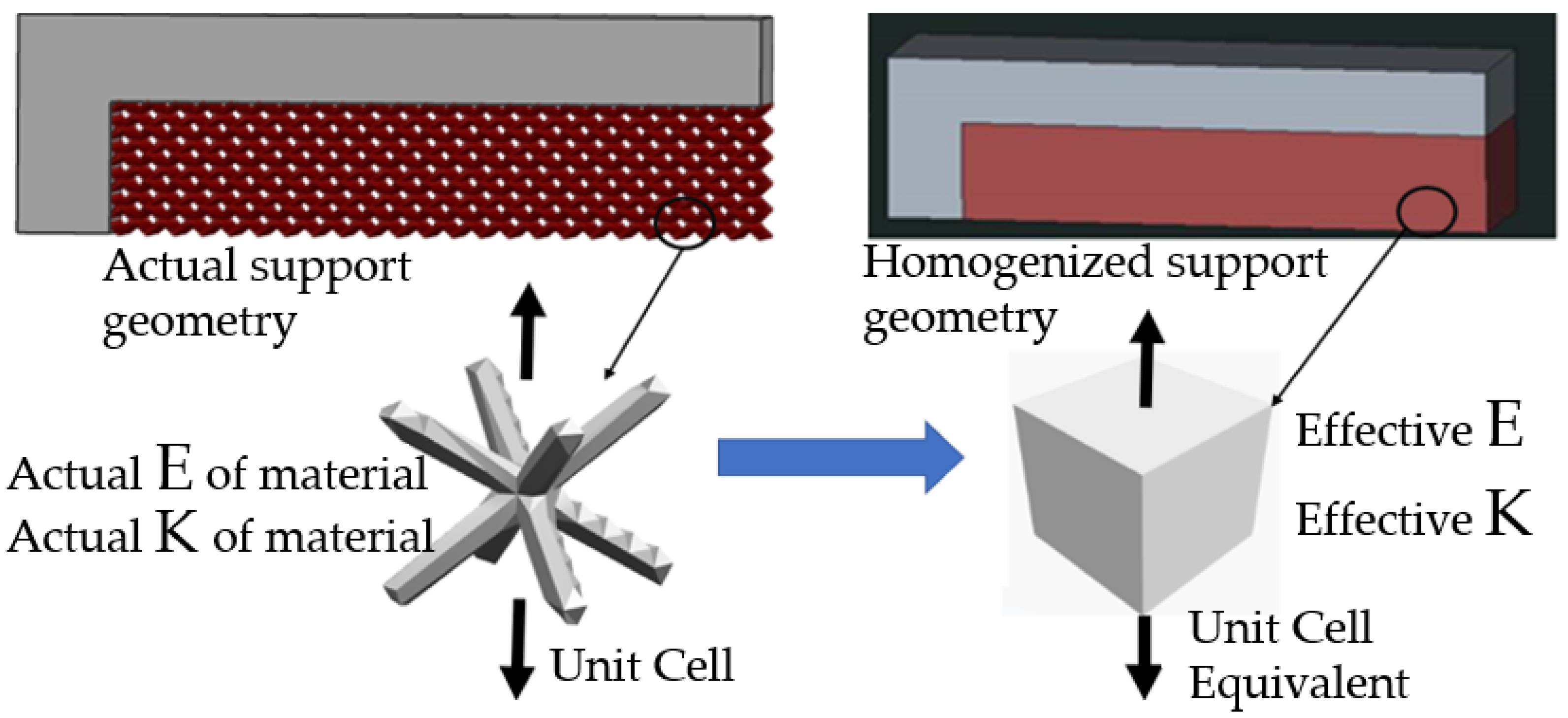

2.2. Methodology

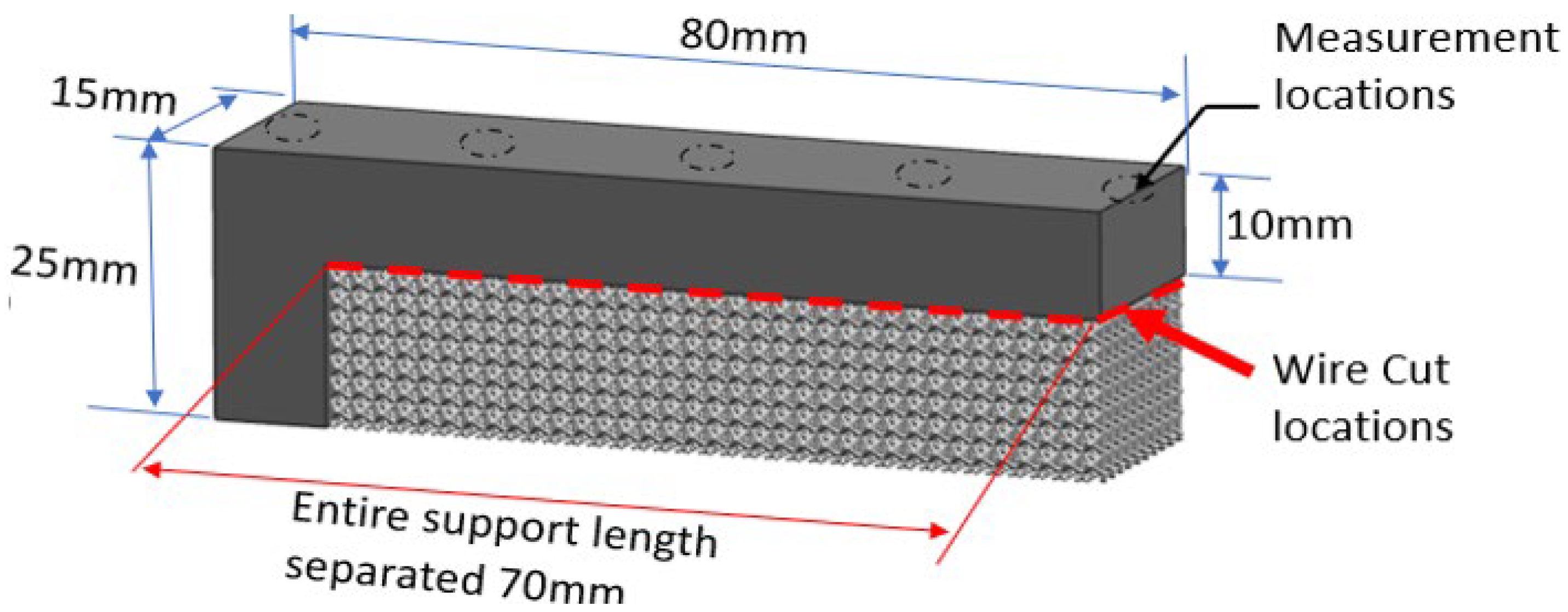

2.3. Distortion Measurement and Benchmarking FE Simulation for Distortion Prediction

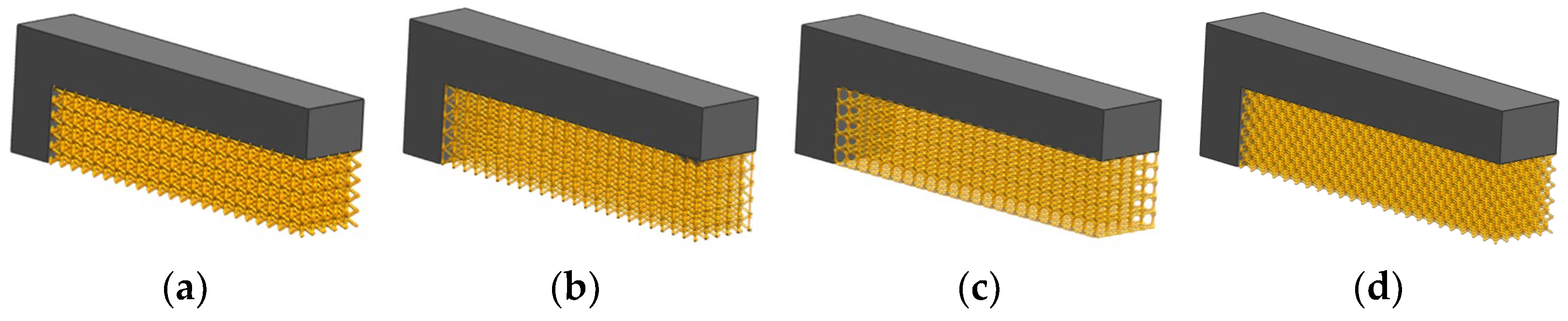

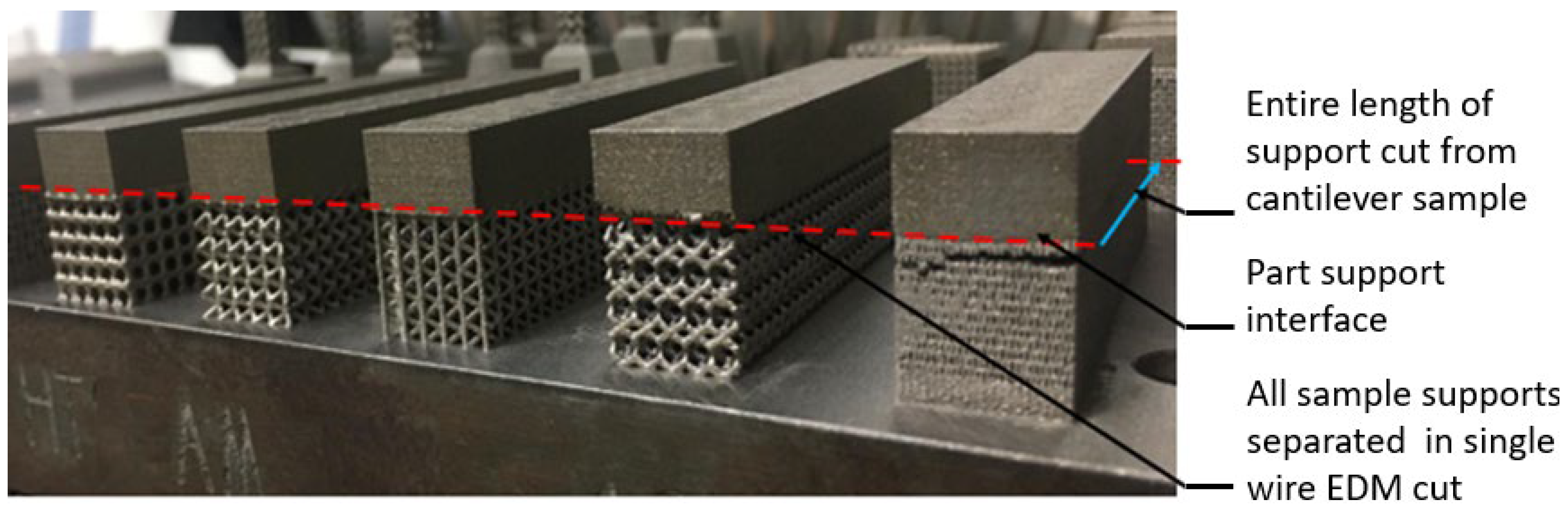

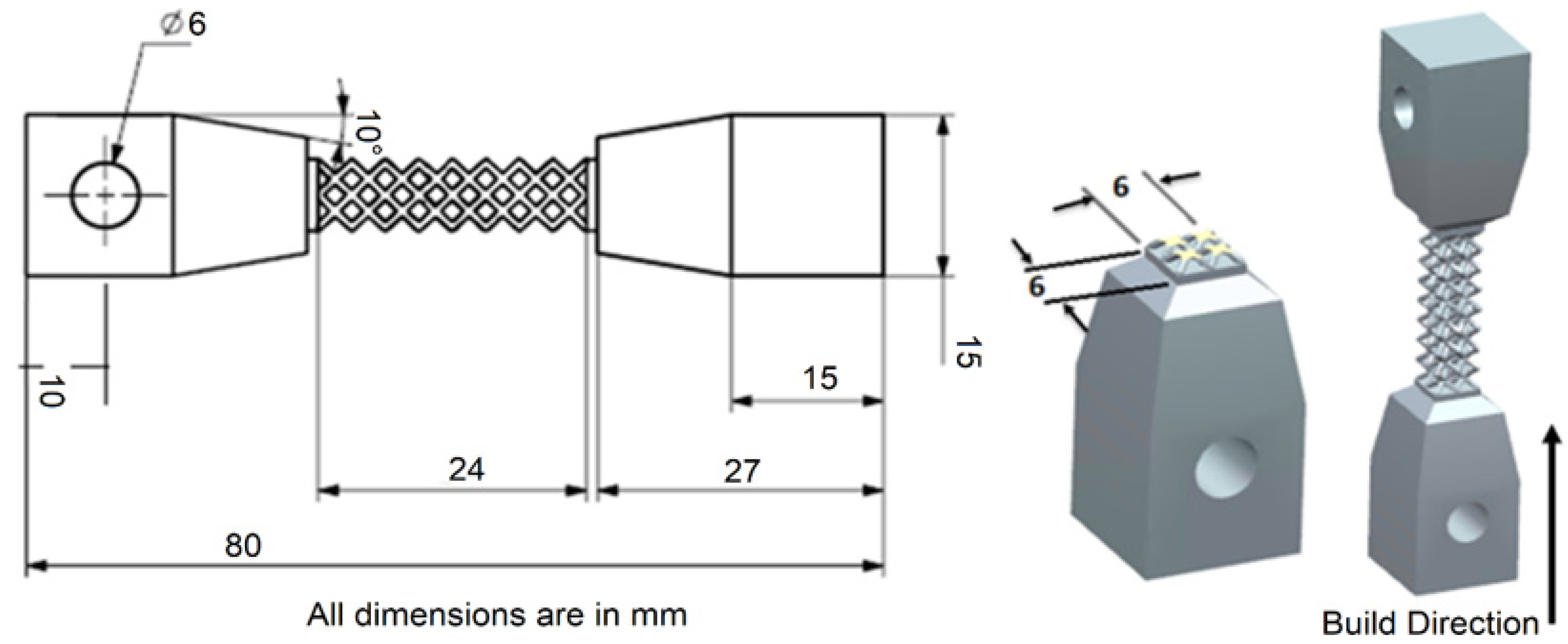

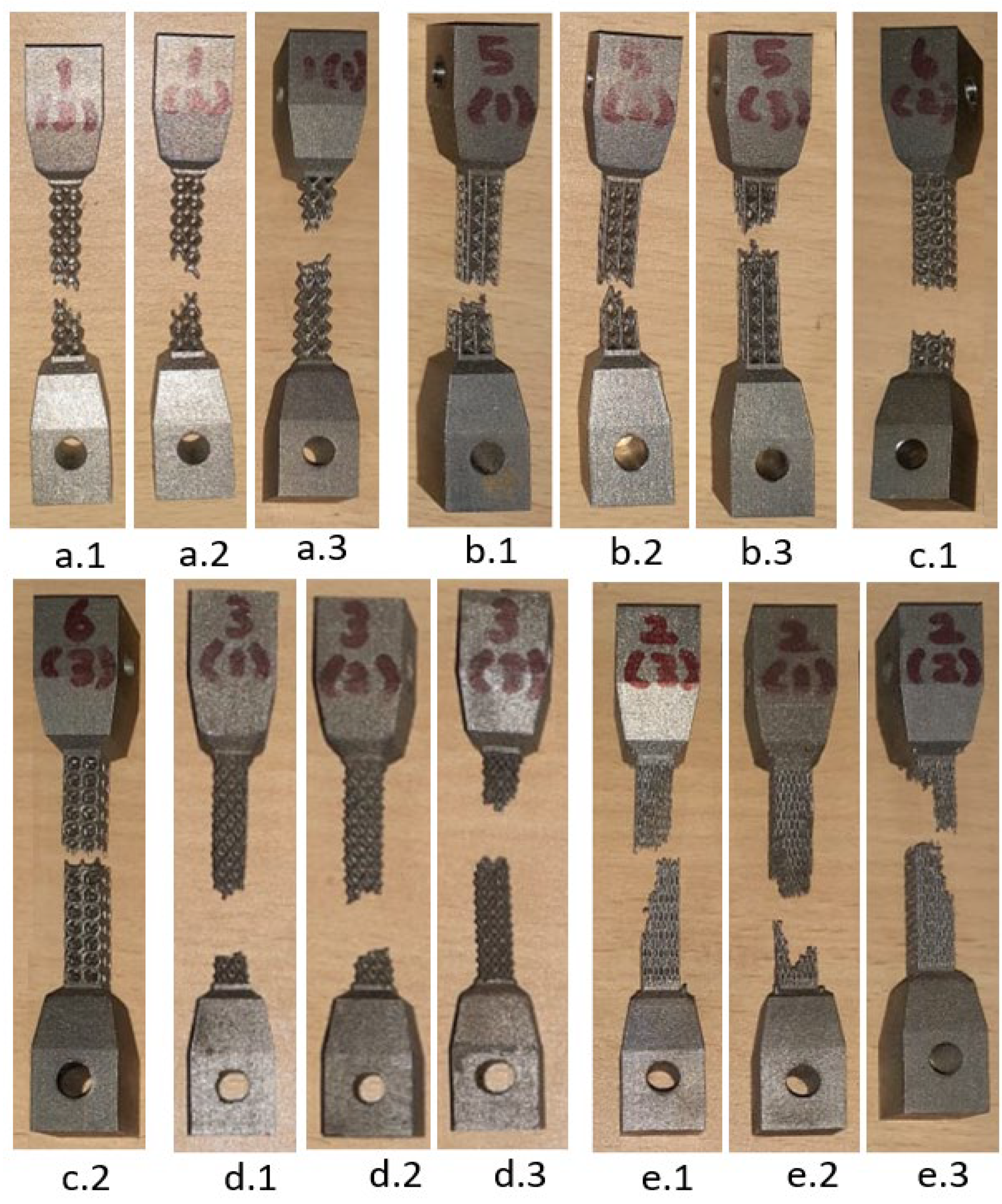

2.4. Lattice Support Characterization

3. Results

4. Discussion

4.1. Distortion for Various VF Using Actual Lattice Geometry in AM Simulation

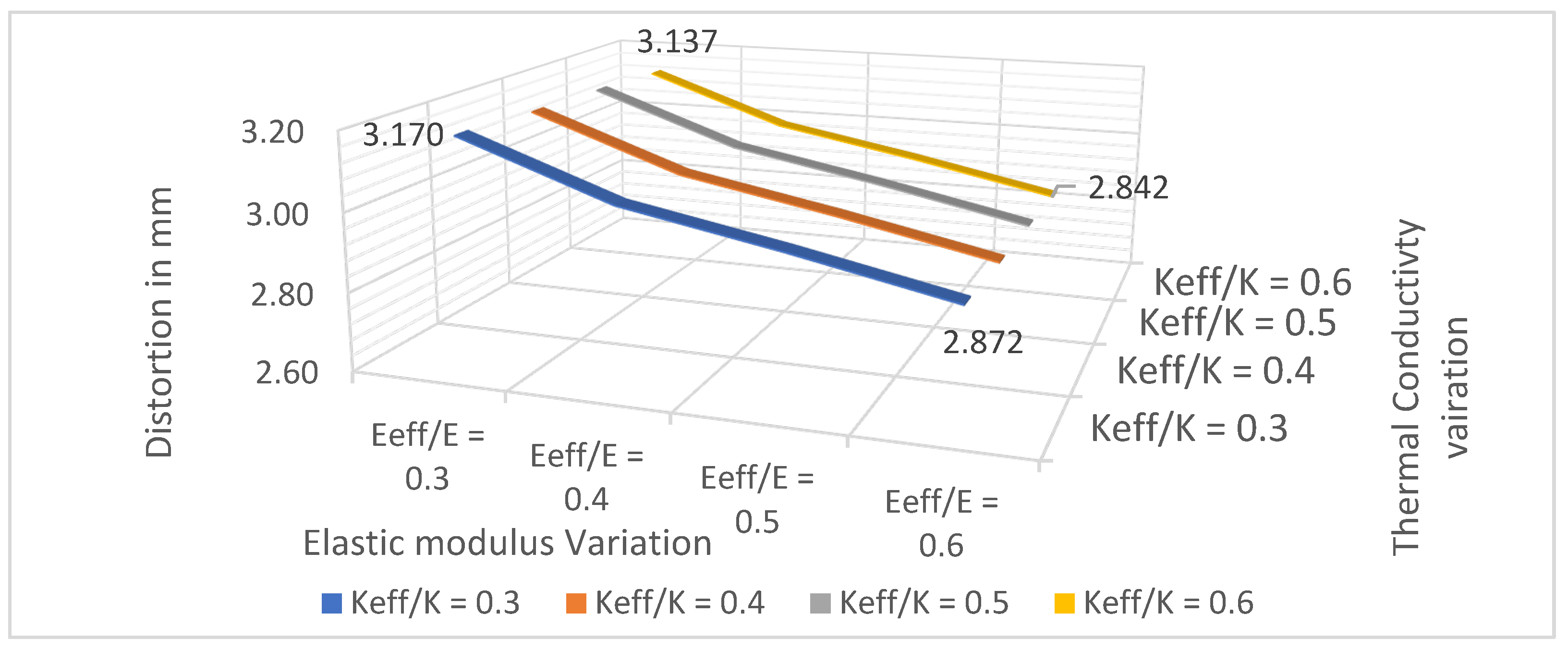

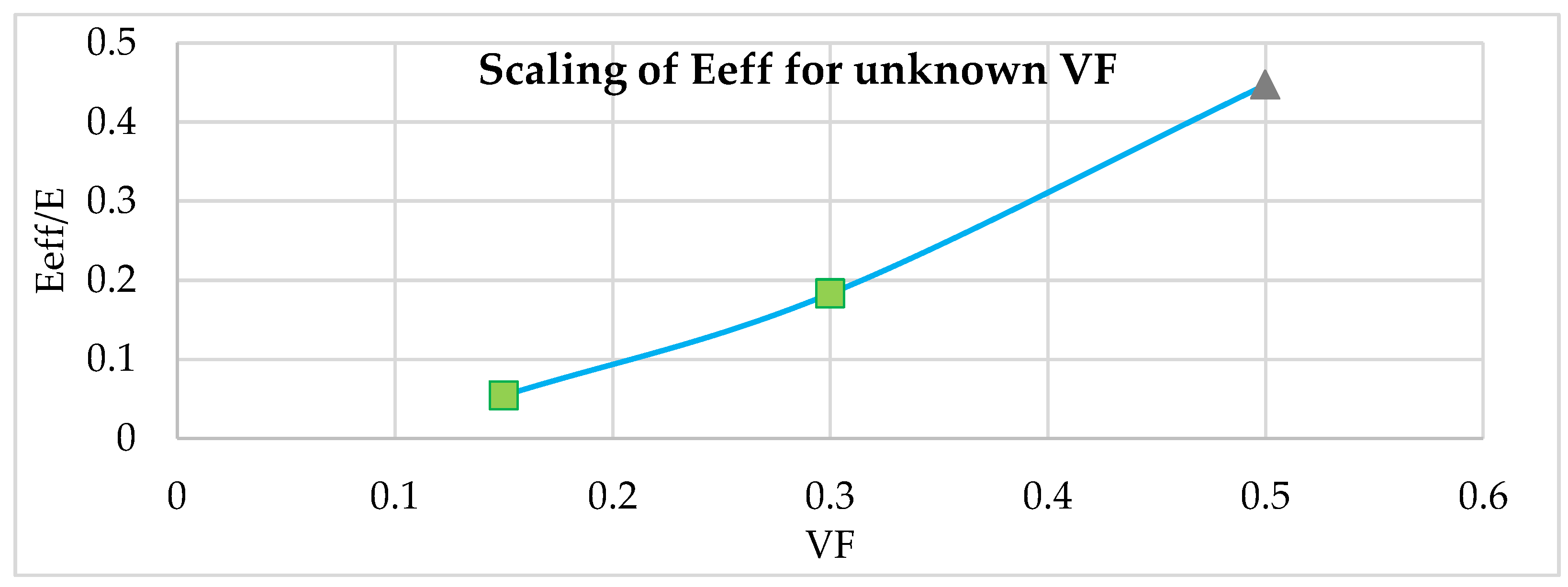

4.2. Scaling of Effective Property

5. Conclusions

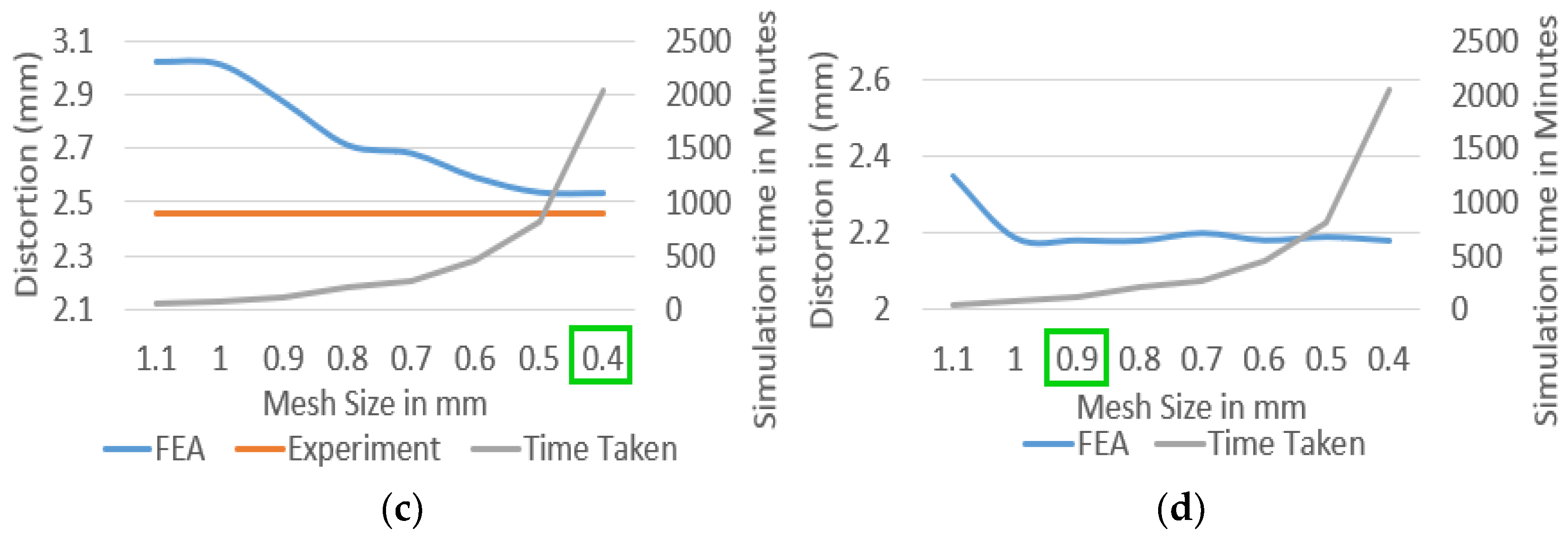

- Results show that substituting complex lattice geometry with a homogenized solid has increased simulation speed by 6–7 times.

- The error between homogenized model simulation and experiment results is consistent, whereas actual geometry simulation accuracy depends on the shape selected; this is the advantage of experimental characterization and can capture geometry-dependent printing variations.

- FE and experiment result comparisons of scaled VF show good agreement with approximately less than 10% variation. This provides evidence for the scalability of the proposed methodology.

- Effective thermal conductivity used in this study by a generic equation fails to capture the effect of various lattice topologies, providing scope for future improvement to find actual thermal conductivity from the experimental method.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Serrano-Munoz, I.; Mishurova, T.; Thiede, T.; Sprengel, M.; Nadammal, N.; Nolze, G.; Saliwan-Neumann, R.; Evans, A.; Bruno, G. The residual stress in as-built Laser Powder Bed Fusion IN718 alloy as a consequence of the microstructure induced by the scan strategy. Sci. Rep. 2020, 10, 14645. [Google Scholar] [CrossRef] [PubMed]

- Ghasri-Khouzani, M.; Peng, H.; Rogge, R.; Attardo, R.; Ostiguy, P.; Neidig, J.; Billo, R.; Hoelzle, D.; Shankar, M.R. Experimental measurement of residual stress and distortion in additively manufactured stainless steel components with various dimensions. Mater. Sci. Eng. 2017, 707, 689–700. [Google Scholar]

- Mishurova, T.; Cabeza, S.; Thiede, T.; Nadammal, N.; Kromm, A.; Klaus, M.; Genzel, C.; Haberland, C.; Bruno, G. The Influence of the Support Structure on Residual Stress and Distortion in SLM Inconel 718 Parts. Met. Mat. Trans. A Phys. Metall. 2018, 49, 3038–3046. [Google Scholar] [CrossRef]

- Cooper, K.; Steele, P.; Cheng, B.; Chou, K. Contact-Free Support Structures for Part Overhangs in Powder-Bed Metal Additive Manufacturing. Inventions 2018, 3, 2. [Google Scholar] [CrossRef]

- Cheng, B.; Chou, K. A numerical investigation of support structure designs for overhangs in powder bed electron beam additive manufacturing. J. Manuf. Process. 2020, 49, 187–195. [Google Scholar] [CrossRef]

- Fu, C.H.; Guo, Y.B. Three-dimensional temperature gradient mechanism in selective laser melting of Ti-6Al-4V. J. Manuf. Sci. Eng. 2014, 136, 061004. [Google Scholar] [CrossRef]

- Prabhakar, P.; Sames, W.; Dehoff, R.; Babu, S. Computational modeling of residual stress formation during the electron beam melting process for Inconel 718P. Addit. Manuf. 2015, 7, 83–91. [Google Scholar]

- Keller, N.; Ploshikhin, V. New method for fast predictions of residual stress and distortion of am parts. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 4–6 August 2014; p. 14. [Google Scholar]

- Hussein, L.H.A.; Yan, C.; Everson, R. Finite element simulation of the temperature and stress fields in single layers built without-support in selective laser melting. Mater. Des. 2013, 52, 638–647. [Google Scholar] [CrossRef]

- Lianga, X.; Donga, W.; Hinnebuscha, S.; Chena, Q.; Trana, H.T.; Lemonb, J.; Chenga, L.; Zhoua, Z.; Haydukec, D.; Toa, A.C. Inherent strain homogenization for fast residual deformation simulation of thin-walled lattice support structures built by laser powder bed fusion additive manufacturing. Addit. Manuf. 2020, 32, 101091. [Google Scholar] [CrossRef]

- Peng, H.; Ghasri-Khouzani, M.; Gong, S.; Attardo, R.; Ostiguy, P.; Rogge, R.B.; Gatrell, B.A.; Budzinski, J.; Tomonto, C.; Neidig, J. Fast Prediction of Thermal Distortion in Metal Powder Bed Fusion Additive Manufacturing: Part 2, a Quasi-Static Thermo-Mechanical Model. Addit. Manuf. 2018, 22, 869–882. [Google Scholar] [CrossRef]

- Chen, Q.; Lianga, X.; Haydukeb, D.; Liua, J.; Chenga, L.; Oskina, J. An inherent strain based multi-scale modeling framework for simulating part-scale residual deformation for direct metal laser sintering. Addit. Manuf. 2019, 28, 406–418. [Google Scholar]

- Cheng, L.; Liang, X.; Bai, J.; Chen, Q.; Lemon, J.; To, A. On utilizing topology optimization to design support structure to prevent residual stress induced build failure in laser powder bed metal additive manufacturing. Addit. Manuf. 2019, 27, 209–304. [Google Scholar] [CrossRef]

- Simufact Engineering GmbH. Hexagon’s Manufacturing Intelligence Division. 2021. Available online: https://www.simufact.com/technology.html#calculation%20methods (accessed on 12 August 2021).

- Li, C.; Liu, J.F.; Fang, X.Y.; Guo, Y.B. Efficient predictive model of part distortion and residual stress in selective laser melting. Addit. Manuf. 2017, 17, 157–168. [Google Scholar] [CrossRef]

- Zeng, K.; Pal, D.; Tenga, C.; Stucker, B.E. Evaluations of effective thermal conductivity of support structures inselective laser. melting. Addit. Manuf. 2015, 6, 67–73. [Google Scholar]

- EOS GmbH Electro Optical Systems, Germany. Available online: https://www.eos.info/03_system-related-assets/material-related-contents/metal-materials-and-examples/metal-material-datasheet/nickelalloy-inconel/material_datasheet_eos_nickelalloy_in718_en.pdf (accessed on 15 August 2021).

- Nguyen, Q.B.; Nai, M.L.S.; Zhu, Z.; Sun, C.-N.; Wei, J.; Zhou, W. Characteristics of Inconel Powders for Powder-Bed Additive Manufacturing. Engineering 2017, 3, 695–700. [Google Scholar] [CrossRef]

- Klingbeil, N.W.; Beuth, J.L.; Chin, R.K.; Amon, C.H. Residual stress-induced warping in direct metal solid freeform fabrication. Int. J. Mech. Sci. 2002, 44, 57–77. [Google Scholar] [CrossRef]

- Daňa, M.; Zetková, I.; Mach, J. Mechanical Properties of Inconel Alloy 718 Produced by 3D printing using DMLS. Manuf. Technol. 2018, 18, 559–562. [Google Scholar] [CrossRef]

- Luo, Z.; Zhao, Y. Efficient thermal finite element modeling of selective laser melting of Inconel 718. Comput. Mech. 2020, 65, 763–787. [Google Scholar] [CrossRef]

- Hussein, A.; Hao, L.; Yan, C.; Everson, R.; Young, P. Advanced lattice support structures for metal additive manufacturing. J. Mater. Process. Technol. 2013, 213, 1019–1026. [Google Scholar] [CrossRef]

- Lindecke, P.N.J.; Blunk, H.; Wenzl, J.; Moller, M.; Em-melmann, C. Optimization of support structures for the laser additive manufacturing of TiAl6V4 parts. Procedia CIRP 2018, 74, 53–58. [Google Scholar] [CrossRef]

- Kohnen, P.; Haase, C.; Bultmann, J.; Ziegler, S.; Schleifenbaum, J.H.; Bleck, W. Mechanical properties and deformation behavior of additively manufactured lattice structures of stainless steel. Mater. Des. 2018, 145, 205–217. [Google Scholar] [CrossRef]

- Maskery, I.; Aremu, A.O.; Simonelli, M.; Tuck, C.; Wildman, R.D.; Ashcroft, I.A.; Hague, R.J.M. Mechanical Properties of Ti-6Al-4V Selectively Laser Melted Parts with Body-Centred-Cubic Lattices of Varying cell size. Exp. Mech. 2015, 55, 1261–1272. [Google Scholar] [CrossRef]

- ASTM E8/E8M-16; Standard Test Methods for Tension Testing of Metallic Materials. Available online: https://www.astm.org/e0008_e0008m-16.html (accessed on 30 August 2021).

- Ashby, M. The properties of foams and lattices. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2005, 364, 15–30. [Google Scholar] [CrossRef] [PubMed]

- Sharma, P.; Pandey, P.M. Morphological and mechanical characterization of topologically ordered open cell porous iron foam fabricated using 3D printing and pressureless microwave sintering. Mater. Des. 2018, 160, 442–454. [Google Scholar] [CrossRef]

- Deshpande, V.S.; Ashby, M.F.; Fleck, N.A. Foam topology: Bending versus stretching dominated architectures. Acta Mater. 2001, 49, 1035–1040. [Google Scholar] [CrossRef]

- Maconachie, T.; Leary, M.; Lozanovski, B.; Zhang, X.; Qian, M.; Faruque, O.; Brandt, M. SLM lattice structures: Properties, performance, applications and challenges. Mater. Des. 2019, 183, 108137. [Google Scholar] [CrossRef]

| Nickel (Ni) | Chromium (Cr) | Iron (Fe) | Cobalt (Co) | Aluminum (Al) | Molybdenum (Mo) | Niobium (Nb) | Titanium (Ti) | Silicon (Si) |

|---|---|---|---|---|---|---|---|---|

| 53.20% | 18.91% | 17.96% | 0.15% | 0.37% | 3.04% | 5.14% | 0.92% | 0.08% |

| Process Parameter | Units | Value |

|---|---|---|

| Laser Power | W | 285 |

| Scanning speed | mm/s | 960 |

| Hatch Spacing | mm | 0.11 |

| Size of Laser Beam | mm | 0.3 |

| Lag between layer | seconds | 10 |

| Layer thickness | μm | 40 |

| Scan strategy | – | 10 mm Strips 67° rotation on each layer |

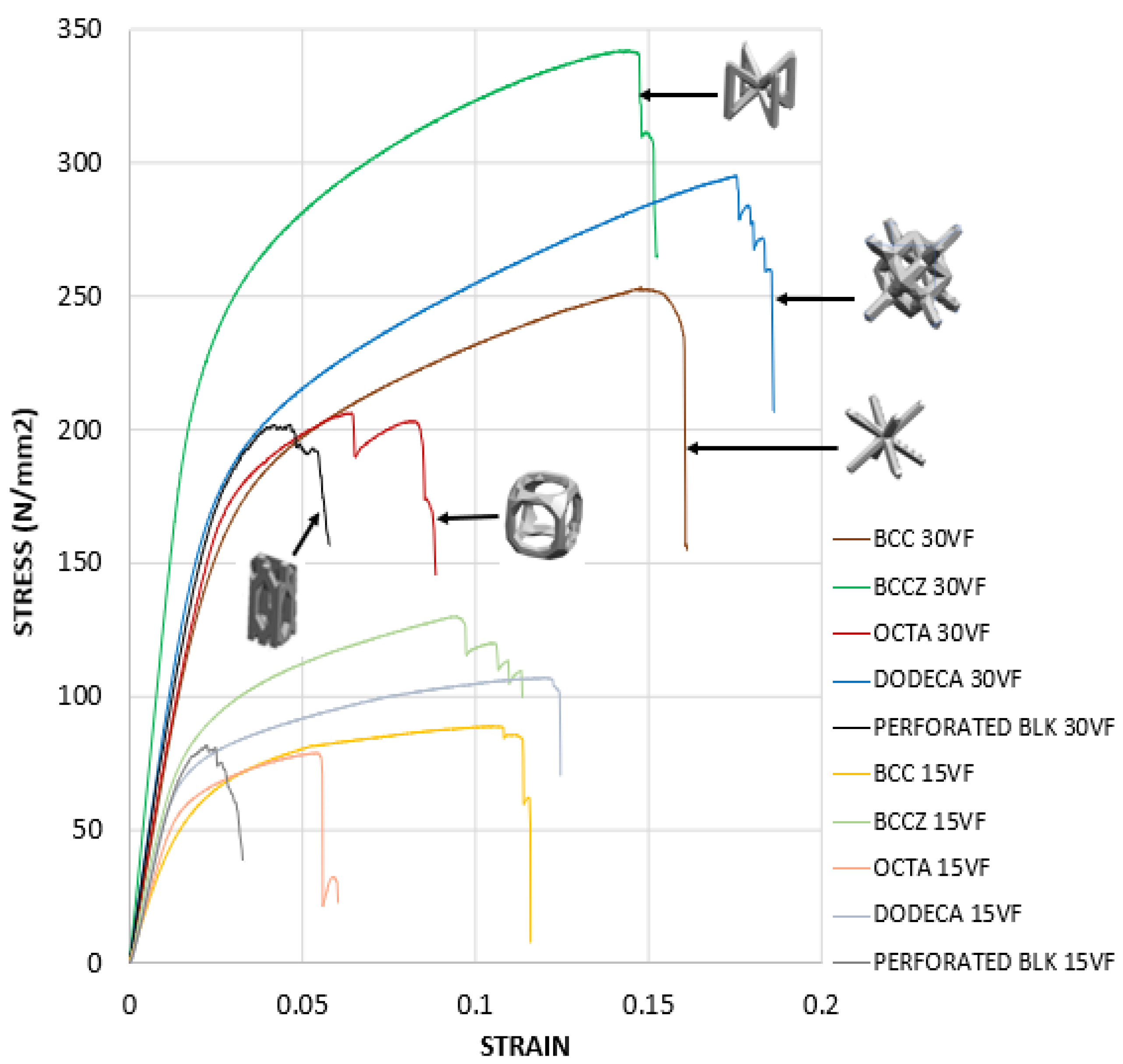

| Support Structure | Sample VF | 0.2% Yield Stress (N/mm2) | Ultimate Tensile Stress (N/mm2) | Effective Modulus Eeff (N/mm2) | Ratio Eeff/E |

|---|---|---|---|---|---|

| BCC | 0.30 | 172.2 | 251.6 | 24,480 | 0.153 |

| 0.15 | 68.2 | 91.2 | 7246 | 0.045 | |

| BCCZ | 0.30 | 201.2 | 341.5 | 38,880 | 0.243 |

| 0.15 | 86.4 | 130.7 | 14,240 | 0.089 | |

| Octahedroid | 0.30 | 172.5 | 205.3 | 26,240 | 0.164 |

| 0.15 | 72.3 | 79.8 | 6960 | 0.043 | |

| Dodecahedron | 0.30 | 173.5 | 293.8 | 28,960 | 0.181 |

| 0.15 | 74.6 | 123.2 | 9140 | 0.057 | |

| Perforated Bock | 0.30 | 179.5 | 198.5 | 29,280 | 0.183 |

| 0.15 | 78.5 | 80.4 | 8780 | 0.054 |

| Struts (s) | Nodes (N) | Maxwell Number M | Remarks | |

|---|---|---|---|---|

| BCC | 8 | 9 | −13 | Bending-dominated |

| BCCZ | 12 | 9 | −9 | Bending-dominated |

| Octahedroid | 12 | 8 | −6 | Bending-dominated |

| Dodecahedron | 32 | 21 | −25 | Bending-dominated |

| Perforated Block (VF) | Gibson–Ashby Coefficients | Eeff | Knockdown Factor Eeff/E | |

|---|---|---|---|---|

| C1 | m | |||

| 0.15 | 1.51 | 1.75 | 8730 | 0.054 |

| 0.30 | 1.51 | 1.75 | 29287 | 0.183 |

| 0.45 | 1.51 | 1.75 | 59549 | 0.372 |

| 0.60 | 1.51 | 1.75 | 98542 | 0.616 |

| 0.50 | 1.51 | 1.75 | 71612 | 0.447 |

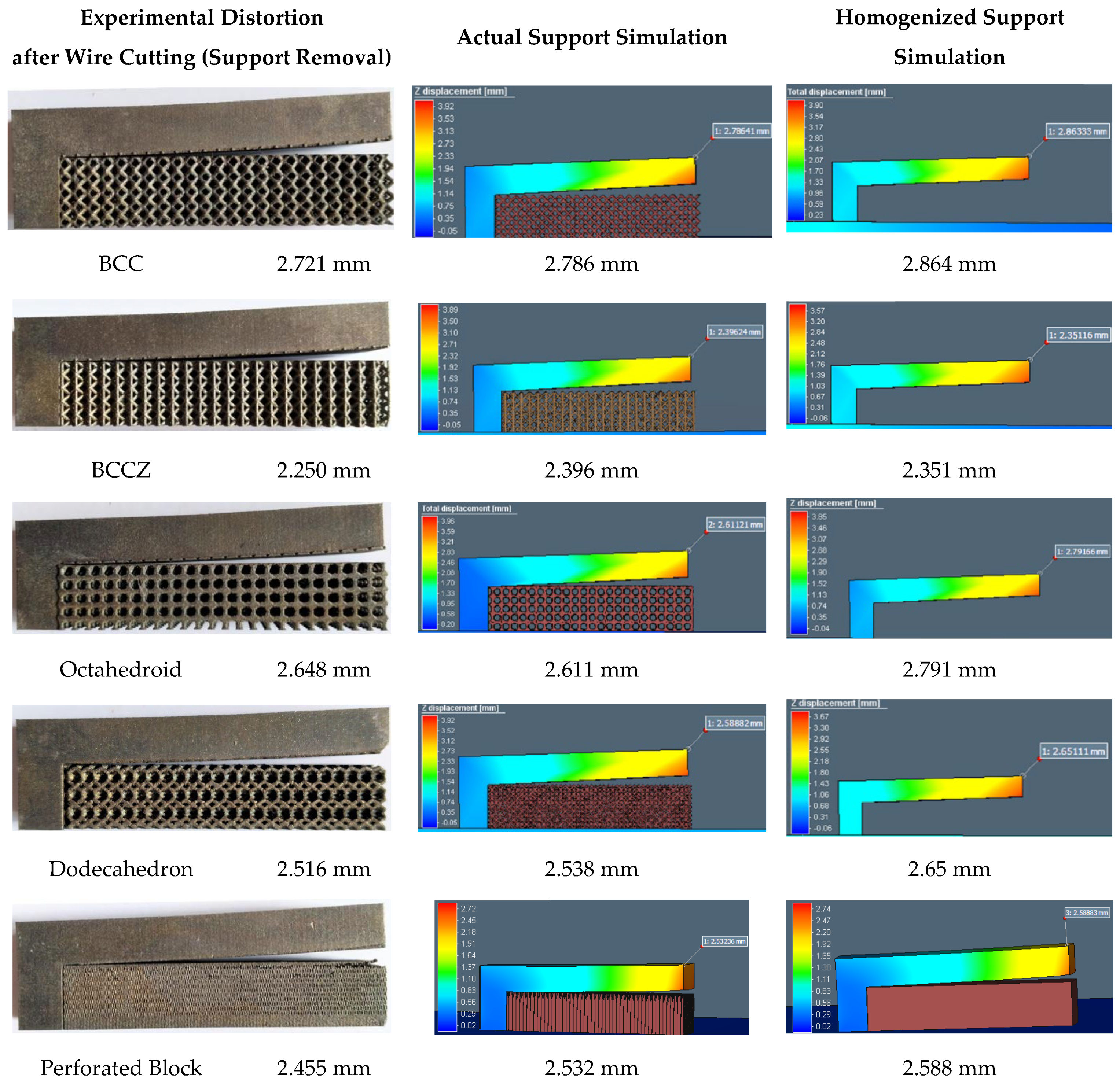

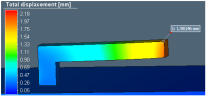

| Experimental Distortion | Actual Support Simulation | Homogenized Support FEA | |

|---|---|---|---|

|  |  | |

| VF 0.15 perforated | 2.993 mm | 3.070 mm | 3.181 mm |

|  |  | |

| VF 0.30 perforated | 2.455 mm | 2.532 mm | 2.588 mm |

|  |  | |

| VF 0.50 perforated | 1.794 mm | 1.819 mm | 1.981 mm (With scaled Eeff) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ananda, V.; Saravana Kumar, G.; Jayaganthan, R.; Srinivasan, B. Distortion Prediction in Inconel-718 Part Fabricated through LPBF by Using Homogenized Support Properties from Experiments and Numerical Simulation. Materials 2022, 15, 5909. https://doi.org/10.3390/ma15175909

Ananda V, Saravana Kumar G, Jayaganthan R, Srinivasan B. Distortion Prediction in Inconel-718 Part Fabricated through LPBF by Using Homogenized Support Properties from Experiments and Numerical Simulation. Materials. 2022; 15(17):5909. https://doi.org/10.3390/ma15175909

Chicago/Turabian StyleAnanda, Varun, Gurunathan Saravana Kumar, Rengaswamy Jayaganthan, and Balamurugan Srinivasan. 2022. "Distortion Prediction in Inconel-718 Part Fabricated through LPBF by Using Homogenized Support Properties from Experiments and Numerical Simulation" Materials 15, no. 17: 5909. https://doi.org/10.3390/ma15175909

APA StyleAnanda, V., Saravana Kumar, G., Jayaganthan, R., & Srinivasan, B. (2022). Distortion Prediction in Inconel-718 Part Fabricated through LPBF by Using Homogenized Support Properties from Experiments and Numerical Simulation. Materials, 15(17), 5909. https://doi.org/10.3390/ma15175909