Study and Characterization of Special Gypsum-Based Pastes for Their Use as a Replacement Material in Architectural Restoration and Construction

Abstract

1. Introduction

2. Materials and Methods

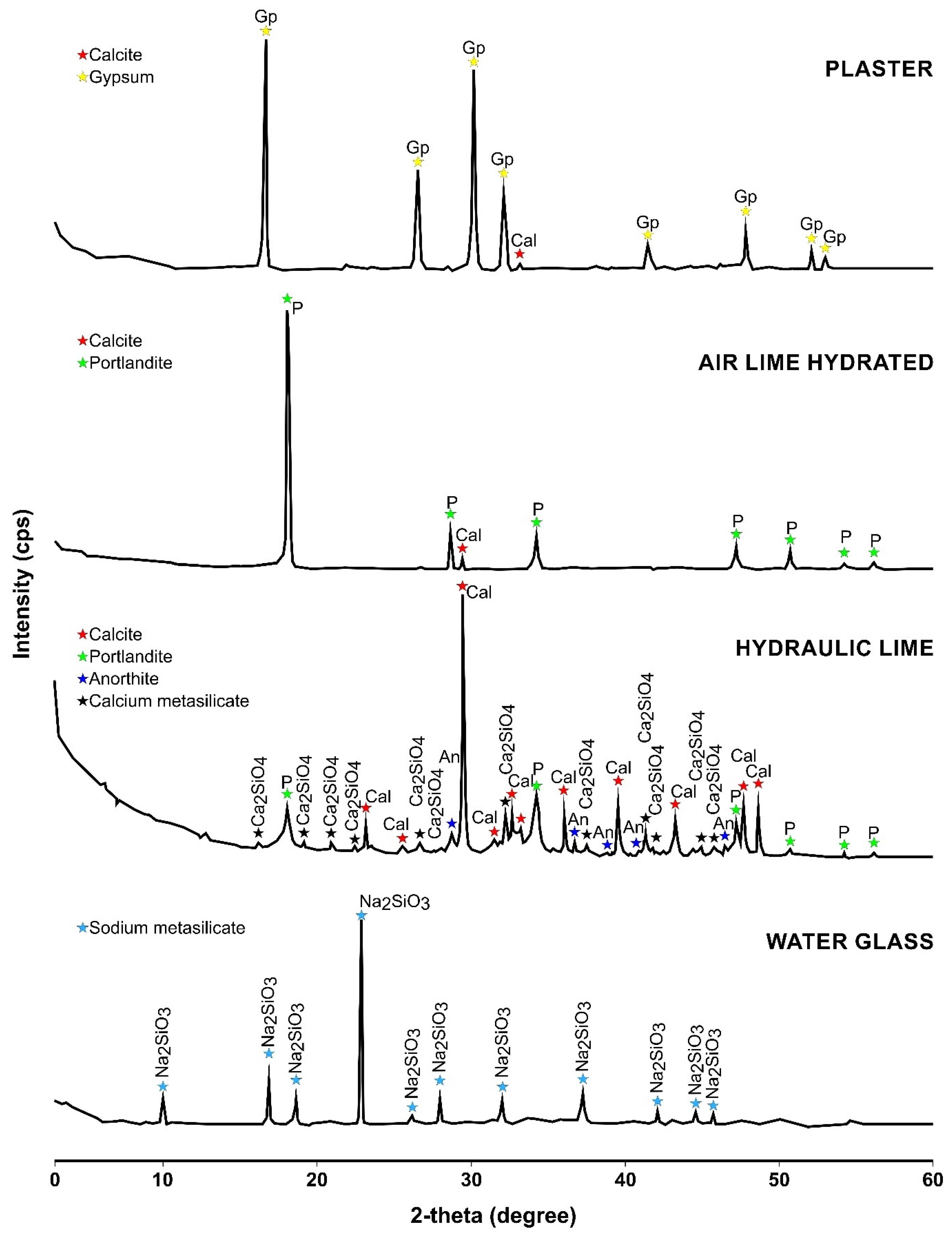

2.1. Binder Characterization

2.2. Sample Design and Preparation

2.3. Methods

2.3.1. Scanning Electron Microscopy (SEM)

2.3.2. Water Vapor Permeability

2.3.3. Mechanical Tests

2.3.4. Color Tests

3. Results

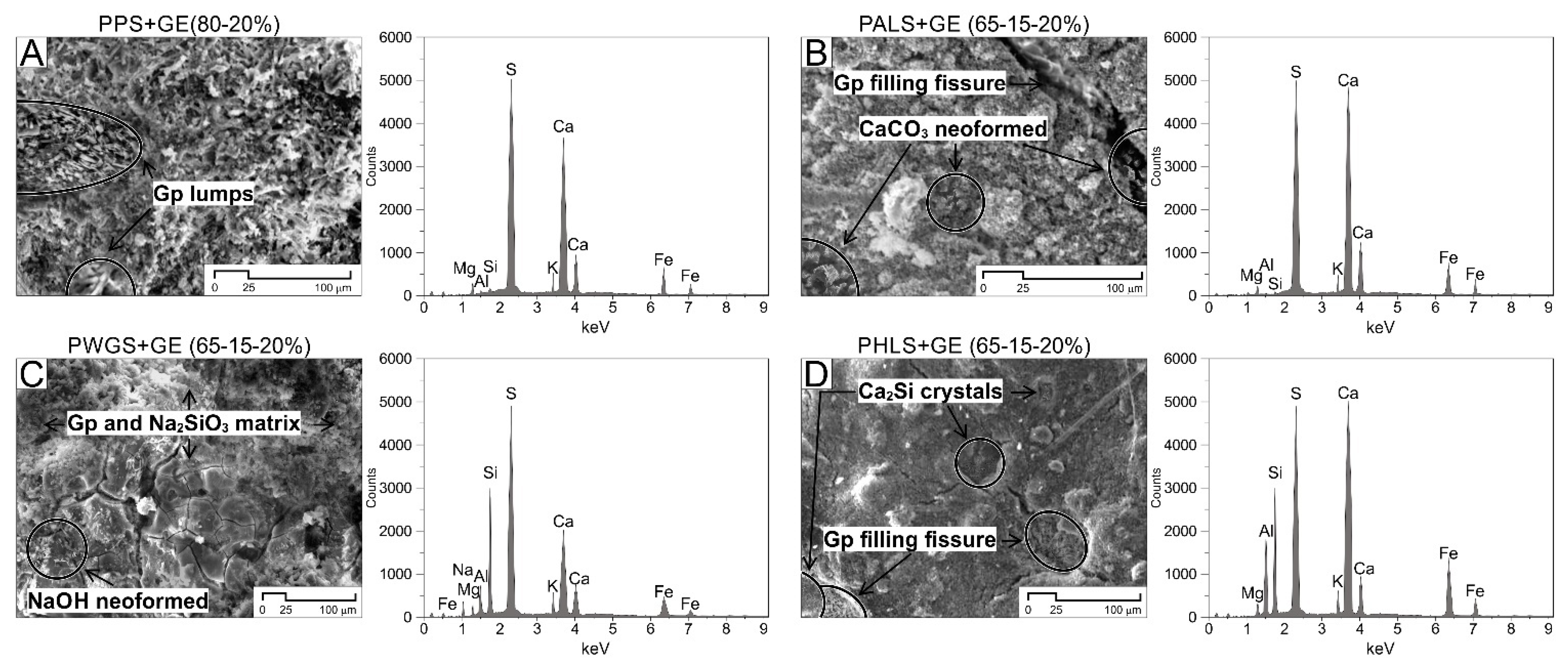

3.1. Scanning Electron Microscopy (SEM)

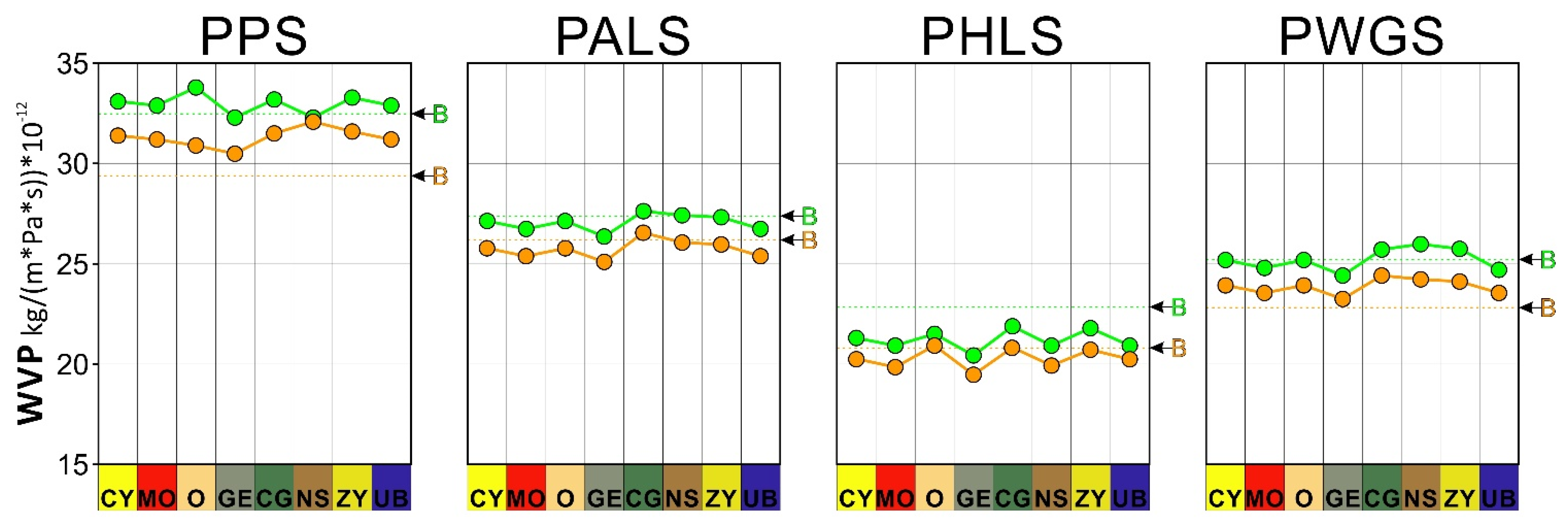

3.2. Water Vapor Permeability Test

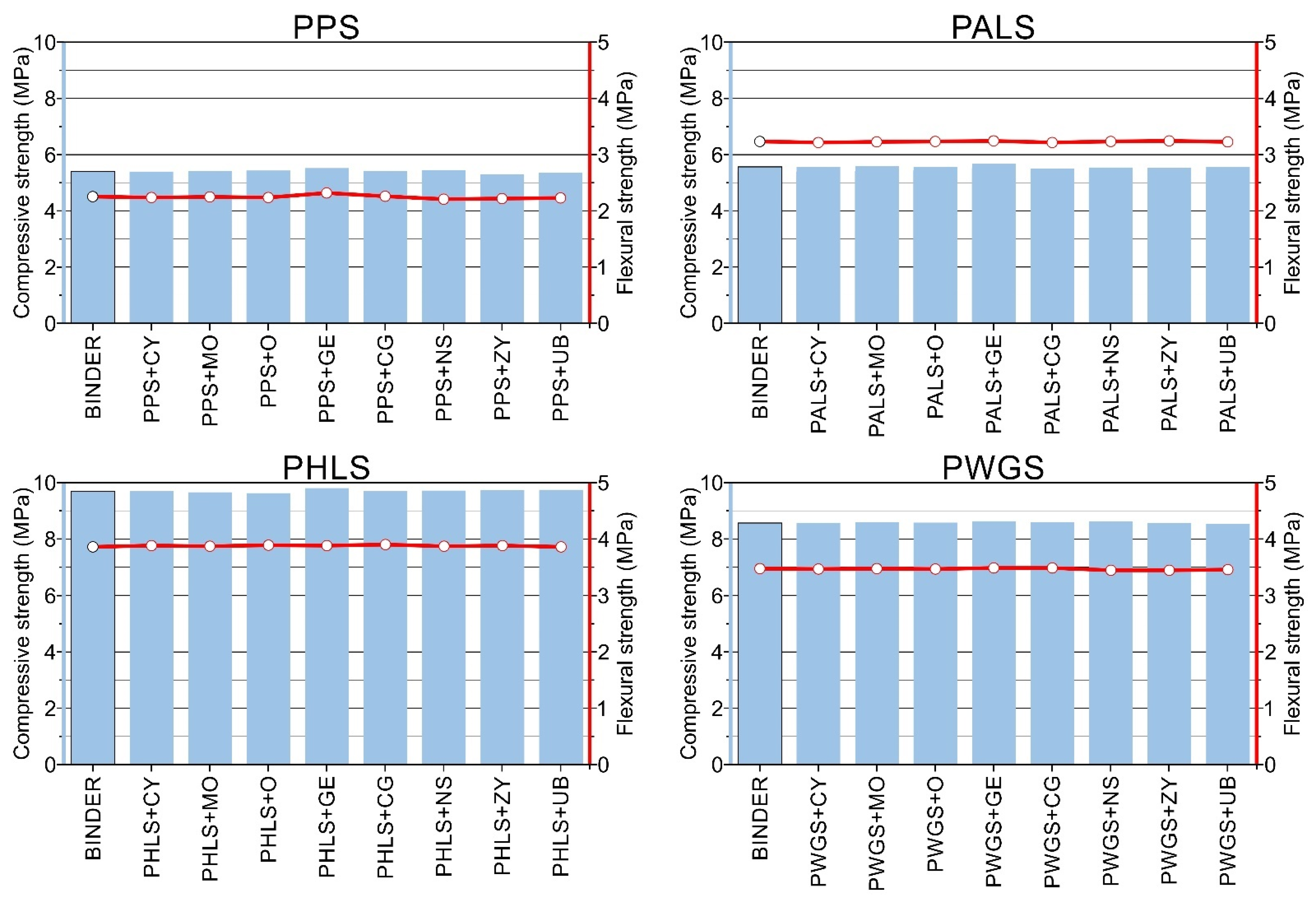

3.3. Mechanical Tests

3.3.1. Compressive Strength

PPS + Pigment Samples

PALS + Pigment Samples

PWGS + Pigment Samples

PHLS + Pigment Samples

3.3.2. Flexural Strength

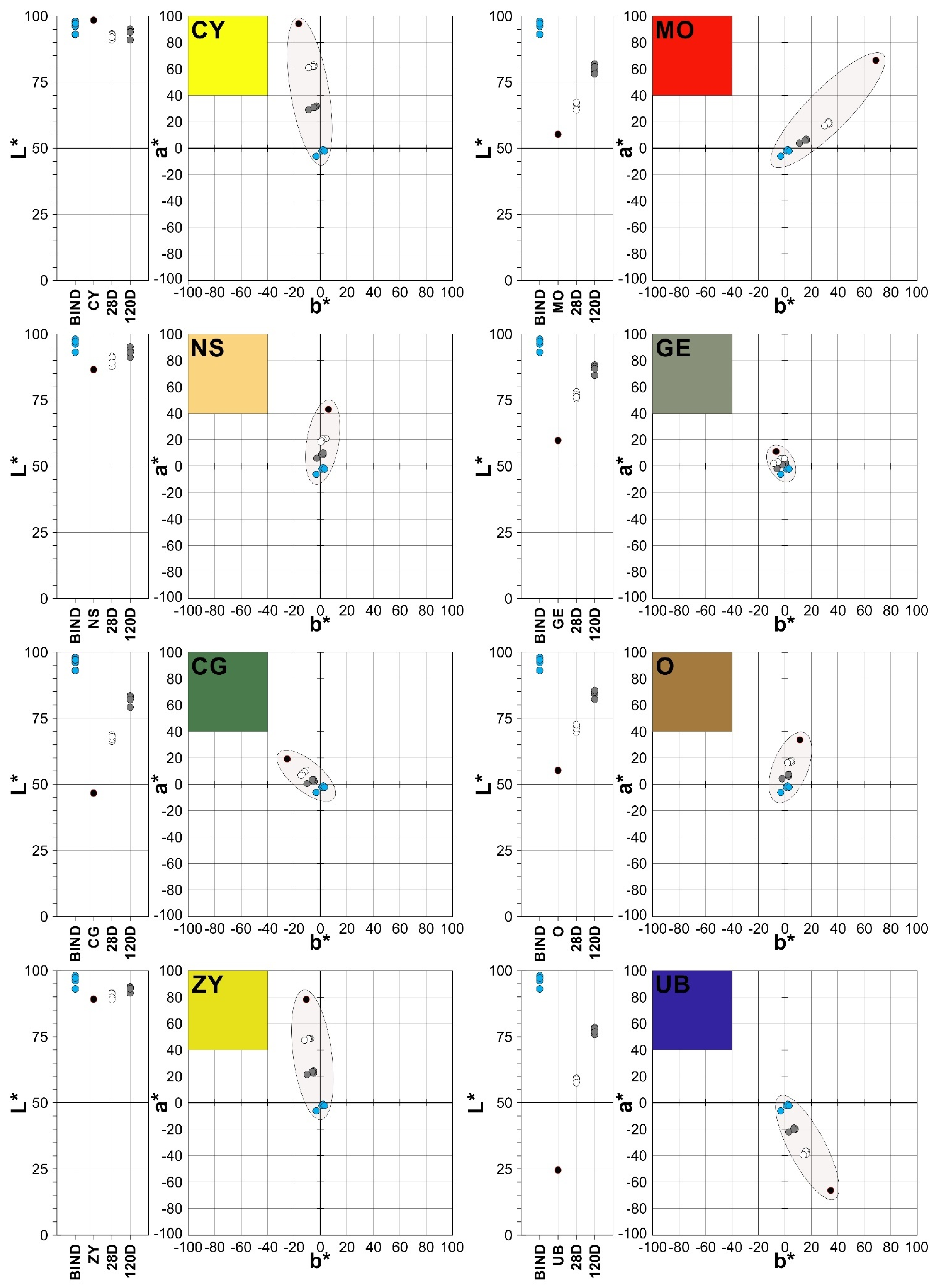

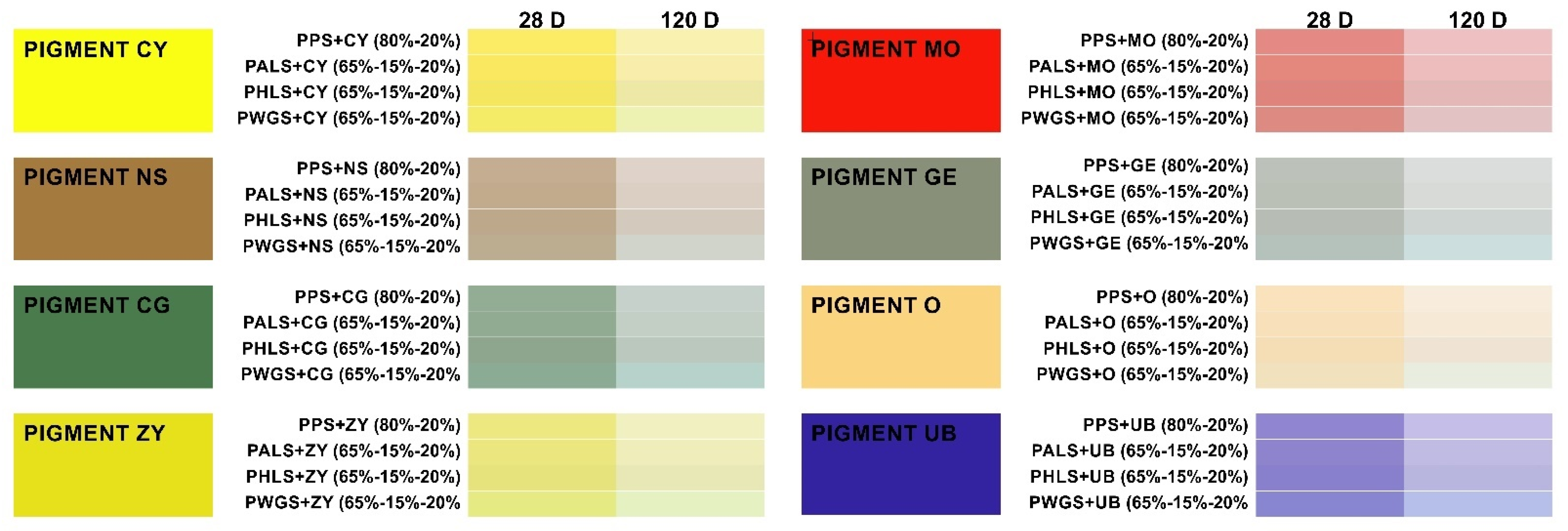

3.4. Color Tests

4. Conclusions

- The characterization of the products primarily confirmed the suitability of the pastes containing pigments for use in the most common applications for mixes of this kind.

- The results obtained in relation to mechanical strength confirmed the increases when air lime and hydraulic lime are used. Likewise, the inclusion of water glass induced improvements in all cases with regard to the samples containing plaster, whilst not outperforming the pastes containing hydraulic lime.

- From previous studies and the mechanical results obtained, it can be concluded that the presence of magnesium silica aluminates could have been partly responsible for the increases in compressive strength of the mixes containing Green Earth pigment.

- The crystallization of gypsum minerals, observed in all of the mixes, helped to consolidate the shrinkage cracks which appeared in them, improving their mechanical strength values, just as in the cases of neoformed calcium carbonate and belite originating in PALS and PHLS or sodium metasilicate in the PWGS samples.

- The water vapor permeability values were high in all cases due to the dominant presence of plaster; nevertheless, the mixes of binders and pigments had reduced values: by around 15% for the pastes after 28 days, and by 25% for the mixes after 120 days.

- The colorimetric analysis offerred total color differences in the pastes containing added pigments, compared to the pure pigments, which were clearly detectable by the human eye in all cases, after 28 and 120 days. Pigment O and its mixes were at the limits of visual perception, the ΔE values being close to three. The main modifications were determined by the variations in chromaticity (ΔC), resulting in subsaturation and duplicating that perception in the majority of cases after 120 days. Meanwhile, the variation in luminosity induced by the whitish appearance of the binders was a decisive factor in the perception of the total color of the pastes.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mileto, C.; Vegas, F.; La SpinaIs, V. Is Gypsum External Rendering Possible? The Use of Gypsum Mortar for Rendering Historic Façades of Valencia’s City Centre. Adv. Mater. Res. 2011, 250–253, 1301–1304. [Google Scholar] [CrossRef]

- Rampazzi, L.; Corti, C.; Bugini, R.; Sansonetti, A.; Biraghi, M.; Castelletti, L.; Nobile, I.; Orsenigo, C. Thermal analysis and archaeological chronology: The ancient mortars of the site of Baradello (Como, Italy). Thermochim. Acta 2013, 572, 71–84. [Google Scholar] [CrossRef]

- Lucolano, F.; Boccarusso, L.; Langella, A. Hemp as eco-friendly substitute of glass fibres for gypsum reinforcement: Impact and flexural behavior. Compos. Part B Eng. 2019, 175, 107073. [Google Scholar] [CrossRef]

- Martias, C.; Joliff, Y.; Favotto, C. Effects of the addition of glass fibers, mica and vermiculite on the mechanical properties of a gypsum-based composite at room temperature and during a fire test. Compos. Part B Eng. 2014, 62, 37–53. [Google Scholar] [CrossRef]

- Henrik, L.N. Now: 100% wallboard recycling with gypsum recycling international. Glob. Gypsum Mag. 2017, 98, 122–129. [Google Scholar]

- Rashad, A.M. Phosphogypsum as a construction material. J. Clean. Prod. 2017, 166, 732–743. [Google Scholar] [CrossRef]

- Gencel, O.; Diaz, J.J.D.C.; Sutcu, M.; Koksal, F.; Rabanal, F.P.A.; Martínez-Barrera, G. A novel lightweight gypsum composite with diatomite and polypropylene fibers. Constr. Build. Mater. 2016, 113, 732–740. [Google Scholar] [CrossRef]

- Arikan, M.; Sobolev, K. The optimization of a gypsum-based composite material. Cem. Concr. Res. 2002, 32, 1725–1728. [Google Scholar] [CrossRef]

- Pang, M.; Sun, Z.; Huang, H. Compressive Strength and Durability of FGD Gypsum-Based Mortars Blended with Ground Granulated Blast Furnace Slag. Materials 2020, 13, 3383. [Google Scholar] [CrossRef]

- Flores Medina, N.; Barbero-Barrera, M.M. Mechanical and physical enhancement of gypsum composites through a synergic work of polypropylene fiber and recycled isostatic graphite filler. Constr. Build. Mater. 2017, 131, 165–177. [Google Scholar] [CrossRef]

- Wang, W.; Chouw, N. The behaviour of coconut fibre reinforced concrete (CFRC) under impact loading. Constr. Build. Mater. 2017, 134, 452–461. [Google Scholar] [CrossRef]

- Firmo, J.P.; Correia, J.R.; Bisby, L.A. Fire behaviour of FRP-strengthened reinforced concrete structural elements: A state-of-the-art review. Compos. Part B Eng. 2015, 80, 198–216. [Google Scholar] [CrossRef]

- Asprone, D.; Cadoni, E.; lucolano, F.; Prota, A. Analysis of the strain-rate behavior of a basalt fiber reinforced natural hydraulic mortar. Cem. Concr. Compos. 2014, 53, 52–58. [Google Scholar] [CrossRef]

- Hamzaoui, R.; Guessasma, S.; Mecheri, B.; Eshtiaghi, A.M.; Bennabi, A. Microstructure and mechanical performance of modified mortar using hemp fibres and carbon nanotubes. Mater. Des. 2014, 56, 60–68. [Google Scholar] [CrossRef]

- Iucolano, F.; Liguori, B.; Colella, C. Fibre-reinforced lime-based mortars: A possible resource for ancient masonry restoration. Constr. Build. Mater. 2013, 38, 785–789. [Google Scholar] [CrossRef]

- Thanon Dawood, E.; Meshal Mezal, A. The Properties of Fiber Reinforced Gypsum Plaster. J. Sci. Res. Rep. 2014, 3, 1339–1347. [Google Scholar]

- Álvarez, M.; Ferrández, D.; Morón, C.; Atanes-Sánchez, E. Characterization of a New Lightened Gypsum-Based Material Reinforced with Fibers. Materials 2021, 14, 1203. [Google Scholar] [CrossRef]

- Majumdar, A.J. Glass fibre reinforced cement and gypsum products. Proc. Math. Phys. Eng. Sci. 2006, 319, 69–78. [Google Scholar] [CrossRef]

- Eve, S.; Gomina, M.; Gmouh, A.; Samdi, A.; Moussa, R.; Orange, G. Microstructural and mechanical behaviour of polyamide fibre-reinforced plaster composites. J. Eur. Ceram. Soc. 2002, 22, 2269–2275. [Google Scholar] [CrossRef]

- Elsen, J. Microscopy of historic mortars—A review. Cem. Concr. Res. 2006, 36, 1416–1424. [Google Scholar] [CrossRef]

- Freire, M.T. Restoration of Ancient Portuguese Interior Plaster Coatings: Characterization and Development of Compatible Gypsum-Based Products. Ph.D. Thesis, University of Lisbon, Lisbon, Portugal, 2016. [Google Scholar]

- Vasconcelos, F. Considerations about decorative plasterwork. Bol. Do Mus. Nac. Arte Antiga. V 1966, 1, 34–43. (In Portuguese) [Google Scholar]

- Conde, M. Interview to Vítor Serrão; Pedra & Cal: Faro, Portugal, 2001; pp. 14–16. [Google Scholar]

- Vieira, E. Stuccos in the context of decorative arts in Portugal. In I Encontro Sobre Estuques Port.; Museu do estuque: Oporto, Portugal, 2008; pp. 19–26. [Google Scholar]

- Brunello, V.; Canevali, C.; Corti, C.; De Kock, T.; Rampazzi, L.; Recchia, S.; Sansonetti, A.; Tedeschi, C.; Cnudde, V. Understanding the Microstructure of Mortars for Cultural Heritage Using X-ray CT and MIP. Materials 2021, 14, 5939. [Google Scholar] [CrossRef] [PubMed]

- Brunello, V. Mortars: A Complex Material in Cultural Heritage a Multi-Analytical Procedure to Characterize Historical Mortars. Ph.D. Thesis, Università dell’Insubria, Varese, Italy, 2020. [Google Scholar]

- Brunello, V.; Corti, C.; Sansonetti, A.; Tedeschi, C.; Rampazzi, L. Non-invasive FTIR study of mortar model samples: Comparison among innovative and traditional techniques. Eur. Phys. J. Plus 2019, 134, 270. [Google Scholar] [CrossRef]

- Fischer, H.B.; Vtorov, B. Characterization of historical gypsum mortars. ZKG Int. 2002, 55, 92–99. [Google Scholar]

- Sanz, D. Analysis of Gypsum Used in External Renders Using Geological Techniques. Ph.D. Thesis, Polytechnic University of Madrid, Madrid, Spain, 2009. [Google Scholar]

- Franzoni, E.; Sandrolini, F.; Baldazzi, L. Characterization of gypsum-selenite plasters from historic buildings in the Emilia- Romagna region (Italy). In RILEM TC 203-RHM Final Work, Proceedings of the 2nd Historic Mortars Conference (HMC2010), Prague, Czech Republic, 22–24 September 2011; Válek, J., Groot, C., Hughes, J.J., Eds.; RILEM Publications s.a.r.l.: Bagneux, France, 2010; pp. 157–164. [Google Scholar]

- Igea, J.; Lapuente, P.; Blanco-Varela, M.T.; Martínez-Ramírez, S. Ancient gypsum mortars from Sta. María Magdalena church (Zaragoza, Spain): Advances in technological manufacture. In RILEM TC 203-RHM Final Work, Proceedings of the 2nd Historic Mortars Conference (HMC2010), Prague, Czech Republic, 22–24 September 2011; Válek, J., Groot, C., Hughes, J.J., Eds.; RILEM Publications s.a.r.l.: Bagneux, France, 2010; pp. 197–205. [Google Scholar]

- Igea, J.; Lapuente, P.; Martínez-Ramírez, S.; Blanco-Varela, M.T. Characterization of mudejar mortars from San Gil Abbot church (Zaragoza, Spain): Investigation of the manufacturing technology of ancient gypsum mortars. Mater. Constr. 2012, 62, 515–529. [Google Scholar] [CrossRef]

- Igea, J.; Romera, J.; Martínez-Ramírez, S.; Lapuente, P.; Blanco-Varela, M.T. Assessment of the physico-mechanical behaviour of gypsum-lime repair mortars as a function of curing time. Environ. Earth Sci. 2013, 70, 1605–1618. [Google Scholar] [CrossRef][Green Version]

- Bel-Anzué, P.; Almagro, A.; Sáez Pérez, M.P.; Rodriguez-Navarro, C. Influence of the calcination process in traditional gypsum with structural behavior. Ge-Conservacion 2017, 11, 79–85. [Google Scholar] [CrossRef][Green Version]

- Ranesi, A.; Faria, P.; Veiga, M.D.R. Traditional and Modern Plasters for Built Heritage: Suitability and Contribution for Passive Relative Humidity Regulation. Heritage 2021, 4, 2337–2355. [Google Scholar] [CrossRef]

- Theodoridou, M.; Lofa, M.; Ioannou, I. Historic Gypsum Mortars from Cyprus: Characterization and Reinvention for Conservation Purposes. In Proceedings of the 3rd Historic Mortars Conference HMC2013, Glasgow, Scotland, 11–13 September 2013; pp. 1–8. [Google Scholar]

- Middendorf, B.; Knöfel, D. Characterization of historic mortars from buildings in Germany and The Netherlands. In Conservation of Historic Brick Structures; Baer, N., Fitz, S., Livingstone, R.A., Eds.; Routledge: Oxfordshire, UK, 1998; pp. 178–196. [Google Scholar]

- Tesch, V.; Middendorf, B. Optimised microstructure of calcium sulphate based mortars for the restoration of historic masonry. In Repair Mortars for Historic Masonry; Groot, C., Ed.; RILEM: Delft, The Netherlands, 2005; pp. 345–353. [Google Scholar]

- Shen, J.; Liang, J.; Lin, X.; Lin, H.; Yu, J.; Yang, Z. Recent Progress in Polymer-Based Building Materials. Int. J. Polym. Sci. 2020, 2020, 8838160. [Google Scholar] [CrossRef]

- Zhukov, A.D.; Bessonov, I.V.; Bobrova, E.Y.; Gorbunova, E.A.; Demissie, B.A. Materials based on modified gypsum for facade systems. Nanotechnol. Constr. 2021, 13, 144–149. [Google Scholar] [CrossRef]

- Prałat, K.; Ciemnicka, J.; Koper, A.; Buczkowska, K.E.; Łoś, P. Comparison of the Thermal Properties of Geopolymer and Modified Gypsum. Polymers 2021, 13, 1220. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.; Zhang, R.; Zhang, Y.; He, F. The fractal characteristics of pore size distribution in cement-based materials and its effect on gas permeability. Sci. Rep. 2019, 9, 17191. [Google Scholar] [CrossRef] [PubMed]

- Zuena, M.; Tomasin, P.; Alberghina, M.F.; Longo, A.; Marrale, M.; Gallo, S.; Zendri, E. Comparison between mercury intrusion porosimetry and nuclear magnetic resonance relaxometry to study the pore size distribution of limestones treated with a new consolidation product. Measurement 2019, 143, 234–245. [Google Scholar] [CrossRef]

- Justicia Muñoz, H.; Sáez-Pérez, M.P.; Durán-Suárez, J.A.; Villegas Broncano, M.Á. Estudio de materiales de construcción vernáculos empleados en el patrimonio cultural: Guía para la restauración arquitectónica del Colegio Máximo de Cartuja. Granada-España (siglo XIX). Inf. Constr. 2021, 73, e381. [Google Scholar] [CrossRef]

- Durán-Suárez, J.A.; Sáez-Pérez, M.P.; Peralbo-Cano, R.; Fernández-Martínez, V.M. Classical construction techniques in 17th century Jesuit architecture. Tools for the restoration of historic heritage. J. Cult. Herit. 2018, 35, 139479511. [Google Scholar] [CrossRef]

- Ramos Molina, J.; Durán Suárez, J.A.; Sebastián Pardo, E.; Sáez Pérez, M.P. Estudio del estado de conservación de las yeserías del Oratorio de la Madraza de Granada. Identificación, evaluación y análisis. Inf. Constr. 2017, 69, e175. [Google Scholar] [CrossRef]

- Sáez-Pérez, M.P.; Durán-Suárez, J.A.; Verdú-Vázquez, A.; Gil-López, T. Characterization and chromatic evaluation of gypsum-based pastes for construction and heritage restoration. Constr. Build. Mater. 2021, 307, 124981. [Google Scholar] [CrossRef]

- Rodríguez-Gordillo, J.; Sáez-Pérez, M.P.; Durán-Suárez, J.A.; García-Beltrán, A. Chromatic behavior of inorganic pigments in restoration mortars (nonhydraulic lime, hydraulic lime, gypsum, and portland cement). A comparative study. Color Res. Appl. 2007, 32, 65–70. [Google Scholar] [CrossRef]

- Sansonetti, A.; Andreotti, A.; Bertasaa, M.; Bonaduce, I.; Corti, C.; Facchin, L.; La Nasa, J.; Spiriti, A.; Rampazzia, L. Territory and related artworks: Stuccoworks from the Lombard lakes. J. Cult. Heritage. 2020, 46, 382–398. [Google Scholar] [CrossRef]

- Vignola, M.; Bosia, D.; Pennacchio, R.; Zerbinatti, M. Mortars and plasters produced with earth-based sustainable mixes: A methodology proposal for recovery of vernacular architecture in Roero, Piedmont (Italy). The International Archives of the Photogrammetry, Remote Sensing and Spatial Information Sciences. In Proceeding of the HERITAGE2020 (3DPast|RISK-Terra) International Conference, Valencia, Spain, 9–12 September 2020; Volume XLIV-M-1-2020. [Google Scholar]

- Melgosa, M.; Collado-Montero, F.J.; Fernández, E.; Medina, V.J. Estudio colorimétrico de los azulejos del Patio de las Doncellas del Real Alcázar de Sevilla (España). Boletín Soc. Española Cerámica Y Vidr. 2015, 54, 109–118. [Google Scholar] [CrossRef]

- Rodríguez-Gordillo, J.; Durán-Suárez, J.A.; Sáez-Pérez, M.P. Efecto de Agentes Ambientales en el Cromatismo de Pigmentos con Aglutinantes Pictóricos para su Aplicación en Conservación y Restauración Patrimonial. PH Investig. 2014, 3, 35–53. Available online: http://www.iaph.es/phinvestigacion/index.php/phinvestigacion/article/view/52 (accessed on 1 February 2022).

- Rodríguez-Gordillo, J.; Sáez-Pérez, M.P.; Durán-Suárez, J.A. Evaluación Experimental del Comportamiento Cromático de Pigmentos Inorgánicos en Diversos Aglutinantes Pictóricos. PH Investig. 2013, 1, 41–53. Available online: http://www.iaph.es/phinvestigacion/index.php/phinvestigacion (accessed on 1 February 2022).

- Pridmore, R.W. 14th century example of the four unique hues. Color Res. Appl. 2006, 31, 364–365. [Google Scholar] [CrossRef]

- Reillon, V.; Berthier, S. Modelization of the optical and colorimetric properties of lustred ceramics. Appl. Phys. A 2006, 83, 257–265. [Google Scholar] [CrossRef]

- Durán-Suárez, J.A.; García-Beltrán, A.; Sáez-Pérez, M.P.; Rodríguez-Gordillo, J. Evaluation of the chromatic effectiveness of color pigments in restoration materials (lime and Portland cement). Color Res. Appl. 2000, 25, 286–291. [Google Scholar] [CrossRef]

- Kirchner, E.; van den Kieboom, G.-J.; Njo, L.; Supèr, R.; Gottenbos, R. Observation of visual texture of metallic and pearlescent materials. Color Res. Appl. 2007, 32, 256–266. [Google Scholar] [CrossRef]

- Sáez-Pérez, M.P.; Rodríguez-Gordillo, J.; Durán-Suárez, J.A. Synthetic white pigments (white titanium and white zinc) in different binding media. Influence of environmental agents. Constr. Build. Mater. 2016, 114, 151–161. [Google Scholar] [CrossRef]

- UNE-EN 459-1:2016; Cales Para la Construcción. Parte 1: Definiciones, Especificaciones y Criterios de Conformidad. UNE: Portland, ME, USA, 2016.

- Whitney, D.L.; Evans, B.W. Abbreviations for names of rock-forming minerals. Am. Mineral. 2010, 95, 185–187. [Google Scholar] [CrossRef]

- AAtcc. Colour Index International. Bradford: American Association of Textile Chemist and Colorist and Society of Dyers and Colourists. 2002. Available online: http://www.colour-index.com/ (accessed on 10 February 2022).

- Available online: https://sdc.org.uk/ (accessed on 7 January 2022).

- Available online: https://www.aatcc.org/ (accessed on 7 January 2022).

- Martín Ramos, J.D. Using XPowder—A sofware package for powder X-ray diffraction analysis. Legal Deposit GR-1001/04; XPowder: Granada, Spain, 2004; ISBN 84-609-1497-6. [Google Scholar]

- McLaren, K. The Development of the CIE 1976 (L*a*b*) Uniform Colour-Space and Colour-Difference Formula. Coloration Technol. 2008, 92, 338–341. [Google Scholar] [CrossRef]

- Judd, D.B.; Wyszecki, G. Color in Business, Science, and Industry, 3rd ed.; Wiley-Interscience: New York, NY, USA, 1975; ISBN-13: 978-0471452126. [Google Scholar]

- UNE-EN 15803:2010; Conservation of Cultural Property—Test Methods—Determination of Water Vapour Permeability (dp). UNE: Portland, ME, USA, 2010.

- UNE-EN 1015-11:2000/A1:2007; Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. UNE: Portland, ME, USA, 2007.

- Fernández-Abascal, H.; Guijarro, M.; RoJo, J.L.; Sanz, J.A. Cálculo de Probabilidades y Estadística; Editorial Ariel: Barcelona, Spain, 1994; 282p, ISBN 84-344-2094-5. [Google Scholar]

- Pacheco-Torgal, F.; Faria, J.; Jalali, S. Some considerations about the use of lime-cement mortars for building conservation purposes in Portugal: A reprehensible option or a lesser evil? Constr. Build. Mater. 2012, 30, 488–494. [Google Scholar] [CrossRef]

- Salih, M.A.; Hussein, A.A. Enhancing the compressive strength property of gypsum used in walls plastering by adding lime. J. Univ. Babylon Eng. Sci. 2018, 26, 3. [Google Scholar]

- Prasanna, K.A.; Sanjaya, K.P. Effect of lime and ferrochrome ash (FA) as partial replacement of cement on strength, ultrasonic pulse velocity and permeability of concrete. Constr. Build. Mater. 2015, 94, 448–457. [Google Scholar] [CrossRef]

- Brunello, V.; Bersani, D.; Rampazzi, L.; Sansonetti, A.; Tedeschi, C. Gypsum based mixes for conservation purposes: Evaluation of microstructural and mechanical features. Mater. Constr. 2020, 70, 337. [Google Scholar] [CrossRef]

- Atzeni, C.; Massidda, L.; Sanne, U. Magnesian lime. Experimental contribution to interpreting historical data. Sci. Technol. Conserv. Cult. Herit. 1996, 5, 29–36. [Google Scholar]

- Dheilly, R.M.; Bouguerra, A.; Beaudoin, B.; Tudo, J.; Queneudec, M. Hydromagnesite development in magnesian lime mortars. Mater. Sci. Eng. A 1999, 268, 127–131. [Google Scholar] [CrossRef]

- AATCC (2005) Test Method 173 CMC (TM-173-2005); Calculation of Small Differences for Acceptability. American Association of Textile Chemist and Colorist: Research Triangle, NC, USA, 2006; pp. 311–315.

- Jara, L.M.S.; Yepes, J.A.F.; Pérez, J.J.P. Analysis of the Resistance to Bending of Gypsum with Added Graphene. Coatings 2021, 11, 650. [Google Scholar] [CrossRef]

- Cˇáchová, M.; Konˇáková, D.; Vejmelková, E.; Bartonˇková, E.; Keppert, M.; Cˇerný, R. Properties of lime-cement plasters incorporating ceramic powder. Int. J. Comp. Meth. Exp. Meas 2017, 5, 144–153. [Google Scholar] [CrossRef]

- Krejsová, J.; Doleželová, M. Resistance of mortars with gypsum, lime and composite binders against molds. Acta Polytech. CTU Proc. 2019, 21, 16–20. [Google Scholar] [CrossRef]

| Name | Commercial Pigment/Binders [62,63] | Colour Index Name | Manufacturer’s Composition | Acronym |

|---|---|---|---|---|

| CY | Chromium yellow pigment | 77600 | Lead chromate | PY34 |

| MO | Molybdenum orange pigment | 77629 | Lead chromate, sulfate and molybdate | PR104 |

| O | Ochre pigment | 77492 | Iron hydroxide | PY43 |

| GE | Green earth pigment | 77009 | Iron (II) silicoaluminate, Mg and K | PG23 |

| CG | Chromium green pigment | 77288 | Chromium oxide | PG15 |

| NS | Natural sienna pigment | 77491-2 | Calcined natural iron oxide | PBr7 |

| ZY | Zinc yellow pigment | 77956 | Zinc chromate | PY36 |

| UB | Ultramarine blue pigment | 77007 | Sodium polysulfide-aluminosilicate | PB29 |

| Name | Commercial Pigment/Binders [62,63] | Colour Index Name | Manufacturer’s Composition | Acronym |

|---|---|---|---|---|

| P | Plaster of paris | 77231 | Hemihydrite | PW25 |

| LW | Lime White | 77220 | Calcium hydroxide-Portlandite | PW18 |

| NHL | Natural hydraulic lime | 77230 | Silica calcium aluminates and calcium hydroxide | PW28 |

| WG | Water glass | 77007 | Sodium metasilicate | PB29 |

| SAMPLE (wt %) | SiO2 | Al2O3 | Fe2O3 | MnO | MgO | CaO | Na2O | K2O | TiO2 | P2O5 | SO3 | Cl | LOI |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Plaster | 0.508 | 0.402 | 0.212 | 0.108 | 0.602 | 32.205 | 0.047 | 0.196 | 0.021 | 45.450 | 20.106 | ||

| Aerial lime | 0.202 | 0.076 | 0.516 | 76.292 | 0.128 | 0.068 | 0.630 | 0.196 | 0.412 | 21.430 | |||

| Hidraulic lime | 12.908 | 4.052 | 1.902 | 0.028 | 0.944 | 58.653 | 0.098 | 0.925 | 0.247 | 0.052 | 0.093 | 19.918 | |

| Sodium silicate | 48.09 | 0.18 | 0.03 | 0.03 | 19.57 | 0.08 | 0.01 | 0.01 | 0.05 | 31.78 |

| Name | Plaster | Aerial Lime | Hidraulic Lime | Sodium Silicate Solution (25–75%) | Pigment | Water Added |

|---|---|---|---|---|---|---|

| % | % | % | % | % | parts | |

| PPS | 80 | 0 | 0 | 20 | 0.5 | |

| PALS | 65 | 15 | 0 | 20 | 0.5 | |

| PHLS | 65 | 0 | 15 | 20 | 0.5 | |

| PWGS | 65 | 15 | 20 |

| WVP (kg/(m·Pa·s))·10−12 | ||||||||

|---|---|---|---|---|---|---|---|---|

| 28 Days | 120 Days | |||||||

| PIGMENT | PPS | PALS | PWGS | PHLS | PPS | PALS | PWGS | PHLS |

| Binder | 33.4 ± 1.50 | 27.2 ± 1.70 | 25.30 ± 0.40 | 22.8 ± 0.45 | 28.95 ± 1.35 | 25.89 ± 0.95 | 22.91 ± 0.83 | 20.96 ± 1.33 |

| CY | 33.1 ± 0.80 | 26.9 ± 1.10 | 24.90 ± 1.25 | 20.9 ± 1.17 | 31.4 ± 0.90 | 25.5 ± 0.95 | 23.6 ± 0.83 | 19.8 ± 1.33 |

| MO | 32.9 ± 1.10 | 26.5 ± 1.30 | 24.50 ± 1.10 | 20.5 ± 1.07 | 31.2 ± 1.30 | 25.1 ± 1.18 | 23.2 ± 1.13 | 19.4 ± 1.25 |

| O | 33.8 ± 1.70 | 26.9 ± 1.50 | 24.90 ± 1.33 | 21.1 ± 1.25 | 30.9 ± 0.80 | 25.5 ± 0.95 | 23.6 ± 1.06 | 20.5 ± 1.10 |

| GE | 32.3 ± 1.3 | 26.1 ± 1.20 | 24.10 ± 1.11 | 20.0 ± 1.50 | 30.5 ± 1.80 | 24.8 ± 0.91 | 22.9 ± 1.12 | 19.0 ± 1.30 |

| CG | 33.2 ± 0.70 | 27.4 ± 1.33 | 25.43 ± 1.20 | 21.5 ± 0.94 | 31.5 ± 1.20 | 26.3 ± 1.46 | 24.1 ± 1.38 | 20.4 ± 0.98 |

| NS | 32.3 ± 1.50 | 27.2 ± 0.95 | 25.72 ± 1.80 | 20.5 ± 1.37 | 32.1 ± 1.50 | 25.8 ± 1.13 | 23.9 ± 0.95 | 19.48 ± 1.80 |

| ZY | 33.3 ± 1.12 | 27.1 ± 1.17 | 25.47 ± 1.40 | 21.4 ± 1.22 | 31.6 ± 1.10 | 25.7 ± 1.20 | 23.8 ± 1.05 | 20.3 ± 1.10 |

| UB | 32.9 ± 1.13 | 26.5 ± 1.08 | 24.39 ± 1.18 | 20.5 ± 1.30 | 31.2 ± 1.10 | 25.1 ± 1.32 | 23.2 ± 0.88 | 19.8 ± 1.18 |

| Samples | Compressive Strength (MPa) | Flexural Strength (MPa) | ||

|---|---|---|---|---|

| σ | σ | |||

| PP | 5.40 | 0.02 | 2.25 | 0.03 |

| PAL | 5.62 | 0.04 | 2.93 | 0.06 |

| PHL | 9.79 | 0.03 | 3.90 | 0.05 |

| PWG | 8.65 | 0.01 | 3.51 | 0.04 |

| Samples | Compressive Strength (MPa) | Flexural Strength (MPa) | ||

|---|---|---|---|---|

| PPS | σ | σ | ||

| PPS + CY | 5.40 | 0.03 | 2.24 | 0.02 |

| PPS + MO | 5.42 | 0.05 | 2.25 | 0.04 |

| PPS + O | 5.43 | 0.04 | 2.24 | 0.03 |

| PPS + GE | 5.52 | 0.02 | 2.32 | 0.03 |

| PPS + CG | 5.42 | 0.03 | 2.26 | 0.02 |

| PPS + NS | 5.45 | 0.04 | 2.21 | 0.05 |

| PPS + ZY | 5.30 | 0.05 | 2.22 | 0.04 |

| PPS + UB | 5.36 | 0.03 | 2.23 | 0.03 |

| PALS | σ | σ | ||

| PALS + CY | 5.61 | 0.02 | 2.91 | 0.04 |

| PALS + MO | 5.64 | 0.05 | 2.92 | 0.05 |

| PALS + O | 5.63 | 0.04 | 2.93 | 0.06 |

| PALS + GE | 5.74 | 0.05 | 2.94 | 0.03 |

| PALS + CG | 5.56 | 0.03 | 2.91 | 0.06 |

| PALS + NS | 5.60 | 0.02 | 2.93 | 0.05 |

| PALS + ZY | 5.58 | 0.05 | 2.94 | 0.04 |

| PALS + UB | 5.62 | 0.03 | 2.92 | 0.02 |

| PWGS | σ | σ | ||

| PWGS + CY | 8.66 | 0.03 | 3.50 | 0.02 |

| PWGS + MO | 8.68 | 0.01 | 3.51 | 0.01 |

| PWGS + O | 8.67 | 0.02 | 3.50 | 0.06 |

| PWGS + GE | 8.72 | 0.01 | 3.52 | 0.04 |

| PWGS + CG | 8.68 | 0.04 | 3.52 | 0.05 |

| PWGS + NS | 8.71 | 0.05 | 3.48 | 0.03 |

| PWGS + ZY | 8.65 | 0.06 | 3.48 | 0.06 |

| PWGS + UB | 8.62 | 0.01 | 3.49 | 0.02 |

| PHLS | σ | σ | ||

| PHLS + CY | 9.80 | 0.02 | 3.92 | 0.05 |

| PHLS + MO | 9.76 | 0.04 | 3.91 | 0.06 |

| PHLS + O | 9.73 | 0.01 | 3.93 | 0.04 |

| PHLS + GE | 9.91 | 0.02 | 3.92 | 0.03 |

| PHLS + CG | 9.80 | 0.05 | 3.94 | 0.03 |

| PHLS + NS | 9.82 | 0.03 | 3.91 | 0.05 |

| PHLS + ZY | 9.84 | 0.03 | 3.92 | 0.02 |

| PHLS + UB | 9.85 | 0.03 | 3.90 | 0.07 |

| 28D | 120D | 28D | 120D | 28D | 120D | 28D | 120D | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| a* | b* | L* | a* | b* | L* | ΔE | ΔE | ΔC | ΔC | ΔL | ΔL | |

| PIGMENT CY | −17.03 | 92.10 | 98.40 | −17.03 | 92.10 | 98.40 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| PPS + CY (80–20%) | −5.00 | 62.00 | 93.20 | −3.99 | 31.09 | 95.02 | −23.80 | −23.84 | −31.46 | −62.32 | −5.20 | −3.38 |

| PALS + CY (65–15–20%) | −5.00 | 63.12 | 92.80 | −3.00 | 32.00 | 94.00 | −23.51 | −23.58 | −30.34 | −61.52 | −5.60 | −4.40 |

| PHLS + CY (65–15–20%) | −6.00 | 62.00 | 91.03 | −5.00 | 31.00 | 91.00 | −25.55 | −25.60 | −31.37 | −62.26 | −7.37 | −7.40 |

| PWGS + CY (65–15–20%) | −9.00 | 61.00 | 92.00 | −9.00 | 29.07 | 93.91 | −25.10 | −25.10 | −32.00 | −63.23 | −6.40 | −4.49 |

| X | −6.25 | 62.03 | 92.26 | −5.25 | 30.79 | 93.48 | −24.49 | −24.53 | −31.29 | −62.33 | −6.14 | −4.92 |

| σ | 1.89 | 0.87 | 0.96 | 2.63 | 1.23 | 1.73 | 0.99 | 0.97 | 0.69 | 0.70 | 0.96 | 1.73 |

| PIGMENT MO | 74.20 | 65.13 | 55.40 | 74.20 | 65.13 | 55.40 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| PPS + MO (80–20%) | 33.40 | 18.41 | 67.09 | 16.14 | 6.09 | 81.88 | −36.04 | −41.79 | −60.59 | −81.48 | 11.69 | 26.48 |

| PALS + MO (65–15–20%) | 33.00 | 20.01 | 67.00 | 16.15 | 7.00 | 81.00 | −35.89 | −41.45 | −60.14 | −81.13 | 11.60 | 25.60 |

| PHLS + MO (65–15–20%) | 32.99 | 19.05 | 65.00 | 15.08 | 6.03 | 78.14 | −37.87 | −43.82 | −60.63 | −82.49 | 9.60 | 22.74 |

| PWGS + MO (65–15–20%) | 30.00 | 17.02 | 66.00 | 11.00 | 4.00 | 81.00 | −38.74 | −44.17 | −64.24 | −87.03 | 10.60 | 25.60 |

| X | 32.35 | 18.62 | 66.27 | 14.59 | 5.78 | 80.51 | −37.14 | −42.81 | −61.40 | −83.03 | 10.87 | 25.11 |

| σ | 1.58 | 1.25 | 0.98 | 2.45 | 1.27 | 1.63 | 1.40 | 1.39 | 1.91 | 2.72 | 0.98 | 1.63 |

| PIGMENT NS | 11.40 | 37.20 | 55.47 | 11.40 | 37.20 | 55.47 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| PPS + NS (80–20%) | 5.00 | 16.99 | 71.80 | 2.79 | 5.88 | 85.00 | 6.20 | 6.08 | −21.20 | −32.40 | 16.33 | 29.53 |

| PALS + NS (65–15–20%) | 4.99 | 18.00 | 71.00 | 3.00 | 6.99 | 84.50 | 5.66 | 5.55 | −20.23 | −31.30 | 15.53 | 29.03 |

| PHLS + NS (65–15–20%) | 4.00 | 17.07 | 69.99 | 2.40 | 7.01 | 82.10 | 4.40 | 4.33 | −21.38 | −31.50 | 14.52 | 26.63 |

| PWGS + NS (65–15–20% | 1.99 | 16.04 | 71.09 | −2.00 | 4.03 | 84.10 | 5.15 | 5.15 | −22.74 | −34.41 | 15.62 | 28.63 |

| X | 4.00 | 17.03 | 70.97 | 1.55 | 5.98 | 83.93 | 5.35 | 5.28 | −21.39 | −32.40 | 15.50 | 28.46 |

| σ | 1.42 | 0.80 | 0.74 | 2.38 | 1.40 | 1.27 | 0.77 | 0.74 | 1.04 | 1.42 | 0.74 | 1.27 |

| PIGMENT GE | −6.00 | 10.00 | 59.15 | −6.00 | 10.00 | 59.15 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| PPS + GE (80–20%) | −3.00 | 3.00 | 78.00 | −1.01 | 0.30 | 87.88 | 17.83 | 17.78 | −7.42 | −10.61 | 18.85 | 28.73 |

| PALS + GE (65–15–20%) | −3.00 | 4.00 | 77.00 | −1.00 | 1.00 | 87.62 | 16.87 | 16.82 | −6.66 | −10.25 | 17.85 | 28.47 |

| PHLS + GE (65–15–20%) | −2.99 | 3.02 | 76.13 | −2.00 | 0.99 | 84.40 | 15.96 | 15.93 | −7.41 | −9.43 | 16.98 | 25.25 |

| PWGS + GE (65–15–20% | −6.09 | 1.99 | 76.99 | −6.07 | −2.00 | 86.85 | 16.97 | 16.97 | −5.26 | −5.27 | 17.84 | 27.70 |

| X | −3.77 | 3.00 | 77.03 | −2.52 | 0.07 | 86.69 | 16.91 | 16.87 | −6.69 | −8.89 | 17.88 | 27.54 |

| σ | 1.55 | 0.82 | 0.76 | 2.41 | 1.42 | 1.59 | 0.76 | 0.76 | 1.02 | 2.46 | 0.76 | 1.59 |

| PIGMENT CG | −25.30 | 19.02 | 47.04 | −25.30 | 19.02 | 47.04 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| PPS + CG (80–20%) | −12.00 | 9.00 | 68.00 | −5.00 | 2.00 | 83.00 | 12.94 | 12.08 | −16.65 | −26.27 | 20.96 | 35.96 |

| PALS + CG (65–15–20%) | −11.99 | 8.99 | 67.04 | −4.99 | 3.01 | 82.89 | 12.00 | 11.13 | −16.67 | −25.82 | 20.00 | 35.85 |

| PHLS + CG (65–15–20%) | −12.00 | 9.00 | 66.30 | −6.02 | 2.95 | 79.09 | 11.28 | 10.48 | −16.65 | −24.95 | 19.26 | 32.05 |

| PWGS + CG (65–15–20% | -14.00 | 6.89 | 67.00 | −10.01 | 0.09 | 82.07 | 12.10 | 11.40 | −16.05 | −21.64 | 19.96 | 35.03 |

| X | −12.50 | 8.47 | 67.09 | −6.51 | 2.01 | 81.76 | 12.08 | 11.27 | −16.50 | −24.67 | 20.05 | 34.72 |

| σ | 1.00 | 1.05 | 0.70 | 2.39 | 1.36 | 1.83 | 0.68 | 0.66 | 0.30 | 2.09 | 0.70 | 1.83 |

| PIGMENT O | 7.40 | 45.30 | 87.20 | 7.40 | 45.30 | 87.20 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| PPS + O (80–20%) | 4.01 | 20.99 | 91.20 | 1.97 | 8.98 | 95.10 | −4.87 | −4.94 | −24.53 | −36.71 | 4.00 | 7.90 |

| PALS + O (65–15–20%) | 4.02 | 21.00 | 91.49 | 2.00 | 10.00 | 93.80 | −4.59 | −4.65 | −24.52 | −35.70 | 4.29 | 6.60 |

| PHLS + O (65–15–20%) | 4.00 | 20.98 | 89.04 | 2.00 | 9.00 | 91.25 | −6.98 | −7.04 | −24.54 | −36.68 | 1.84 | 4.05 |

| PWGS + O (65–15–20%) | 0.99 | 19.00 | 91.00 | −2.94 | 5.99 | 93.01 | −5.58 | −5.53 | −26.87 | −39.23 | 3.80 | 5.81 |

| X | 3.26 | 20.49 | 90.68 | 0.76 | 8.49 | 93.29 | −5.50 | −5.54 | −25.12 | −37.08 | 3.48 | 6.09 |

| σ | 1.51 | 1.00 | 1.11 | 2.47 | 1.73 | 1.61 | 1.07 | 1.07 | 1.17 | 1.51 | 1.11 | 1.61 |

| PIGMENT ZY | −10.99 | 78.08 | 88.10 | −10.99 | 78.08 | 88.10 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| PPS + ZY (80–20%) | −8.00 | 48.00 | 91.00 | −5.00 | 22.00 | 94.00 | −15.04 | −15.23 | −30.19 | −56.29 | 2.90 | 5.90 |

| PALS + ZY (65–15–20%) | −8.00 | 47.99 | 90.10 | −5.00 | 24.02 | 93.20 | −15.84 | −16.03 | −30.20 | −54.31 | 2.00 | 5.10 |

| PHLS + ZY (65–15–20%) | −9.00 | 48.03 | 89.00 | −6.00 | 23.20 | 91.40 | −16.70 | −16.92 | −29.98 | −54.89 | 0.90 | 3.30 |

| PWGS + ZY (65–15–20% | −11.79 | 47.10 | 91.16 | −9.99 | 21.04 | 93.00 | −14.95 | −15.14 | −30.30 | −55.56 | 3.06 | 4.90 |

| X | −9.20 | 47.78 | 90.32 | −6.50 | 22.57 | 92.90 | −15.63 | −15.83 | −30.17 | −55.26 | 2.22 | 4.80 |

| σ | 1.79 | 0.45 | 0.99 | 2.38 | 1.31 | 1.09 | 0.82 | 0.83 | 0.13 | 0.85 | 0.99 | 1.09 |

| PIGMENT UB | 36.60 | −65.67 | 24.98 | 36.60 | −65.67 | 24.98 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| PPS + UB (80–20%) | 16.00 | −37.99 | 59.00 | 8.00 | −20.00 | 78.00 | −7.25 | −8.59 | −33.96 | −53.64 | 34.02 | 53.02 |

| PALS + UB (65–15–20%) | 15.99 | −37.00 | 58.04 | 7.00 | −19.04 | 77.08 | −8.56 | −10.04 | −34.87 | −54.89 | 33.06 | 52.10 |

| PHLS + UB (65–15–20%) | 16.01 | −38.98 | 57.51 | 6.82 | −20.04 | 75.90 | −7.93 | −9.41 | −33.04 | −54.01 | 32.53 | 50.92 |

| PWGS + UB (65–15–20% | 14.02 | −39.40 | 58.70 | 3.00 | −22.10 | 78.03 | −7.15 | −8.46 | −33.36 | −52.88 | 33.72 | 53.05 |

| X | 15.51 | −38.34 | 58.31 | 6.21 | −20.30 | 77.25 | −7.72 | −9.13 | −33.81 | −53.86 | 33.33 | 52.27 |

| σ | 0.99 | 1.07 | 0.67 | 2.20 | 1.29 | 1.00 | 0.66 | 0.74 | 0.81 | 0.84 | 0.67 | 1.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sáez-Pérez, M.P.; Durán-Suárez, J.A.; Verdú-Vázquez, A.; Gil-López, T. Study and Characterization of Special Gypsum-Based Pastes for Their Use as a Replacement Material in Architectural Restoration and Construction. Materials 2022, 15, 5877. https://doi.org/10.3390/ma15175877

Sáez-Pérez MP, Durán-Suárez JA, Verdú-Vázquez A, Gil-López T. Study and Characterization of Special Gypsum-Based Pastes for Their Use as a Replacement Material in Architectural Restoration and Construction. Materials. 2022; 15(17):5877. https://doi.org/10.3390/ma15175877

Chicago/Turabian StyleSáez-Pérez, María Paz, Jorge A. Durán-Suárez, Amparo Verdú-Vázquez, and Tomás Gil-López. 2022. "Study and Characterization of Special Gypsum-Based Pastes for Their Use as a Replacement Material in Architectural Restoration and Construction" Materials 15, no. 17: 5877. https://doi.org/10.3390/ma15175877

APA StyleSáez-Pérez, M. P., Durán-Suárez, J. A., Verdú-Vázquez, A., & Gil-López, T. (2022). Study and Characterization of Special Gypsum-Based Pastes for Their Use as a Replacement Material in Architectural Restoration and Construction. Materials, 15(17), 5877. https://doi.org/10.3390/ma15175877