1. Introduction

The emission of CO2 is a major environmental concern. It is important to take specific steps in order to minimize the amount of CO2 emissions into the environment. India ranks third in the world in terms of CO2 emissions. Concrete is a major contributor to increased CO2 levels in the atmosphere. Concrete consists of three major ingredients such as cement, which contributes to the improvement of concrete’s strength; aggregates, which provides the bulkiness to the concrete; and water, which reacts with cement, which leads to the hydration process and provides strength to concrete. Except for cement, all of the other components are readily available across the world. The only method to produce cement is to manufacture it. CO2 is released during cement production, which pollutes the environment. Over-exploitation of materials is on the rise as a result of their widespread use.

The most efficient method for reducing the negative effects that concrete has on the environment is to reduce the amount of cement that is used in its production. This goal can be accomplished through the use of alternative building materials [

1,

2,

3]. Concrete is frequently utilized in industries, which increases its demand and will result in its depletion. It would be economically viable to employ waste material in infrastructure development if it met the required specifications [

4,

5]. Various hazardous wastes are generated as a result of industrialization, which can be managed by incorporating them into basic concrete components. Some mineral additions in concrete, for example, fly ash, silica fumes, and blast furnace slag, might increase the demand for water in the concrete mix, which can be addressed with the use of a superplasticizer [

6].

The bond strength of the concrete matrix can be improved by using calcium carbonate whiskers and basalt fiber in the concrete matrix [

7]. Furthermore, silica fume can be used in place of cement in concentrations ranging from 0 to 10%, which improves the interface bond. Apart from silica-fume and basalt fiber, some researchers use coconut fiber as a partial replacement for cement [

8]. As an alternative [

9,

10,

11,

12], WMP can be used instead of cement or fine aggregates. WMP is a promising resource that may be used to partially replace cement and sand. CaO, SiO

2, Al2O3, and Fe

2O

3 are significant constituents, whereas MgO, SO

3, K

2O, and Na

2O are minor constituents. India is the world’s third largest producer of marble trash. From the beginning of the mining process until the end, waste is produced. If the waste created by the marble business is not correctly utilized, it may have an adverse effect on both the environment and the economy. Marble is frequently used for ornamental purposes, increasing its market demand. Marble manufacturing results in a variety of chemical formations that are classified as hazardous waste. Waste disposal is not cost-effective, and the environment is also a concern. The use of properly integrated industrial waste can help to minimize the amount of cement required in the concrete mix [

13]. Marble sludge may be recycled and used as a major component of concrete mix, which can then be used as a construction material or in road pavements, among other things [

14]. In comparison to the nominal mix, Soliman [

15] found that as the amount of WMP in the nominal concrete in place of cement increases, it deteriorates concrete strength. The effect of partially replacing cement with WMP and finding suggests that tensile strength with WMP begins to deteriorate as the amount of waste marble powder increases [

16]. Replacement of 10% WMP with cement improves the tensile behavior of concrete [

17]. Many researchers use waste marble powder as a replacement for cement by weight [

18,

19]. When an experiment was carried out by Kelestemur [

20] on a concrete mix containing various amounts of glass fiber, it can be seen that by adding WMP, it achieves the highest compressive strength. The capillarity properties of SCC were altered by adding WMP in place of cement, and it was found that the addition of WMP had no effect on workability, but tensile strength decreased [

21]. Ashish [

22] investigated the possibility of using WMP as a partial replacement for fine aggregate and cement amalgam. Uysal and Yilmaz [

23] performed experiments incorporating lime, basalt and WMP as Portland cement substitutes. Hebhoub [

24] found that when gravel or both were substituted with sand, the 28-day tensile strength was higher. The use of marble powder as a filler was found to be adequate by Corinaldesi [

25]. As per literature, use of 10% WMP in lieu of sand during the 28 days of curing offers maximum compressive strength at roughly the same workability as cement replacement. Due to its fineness, marble powder offers good cohesiveness to mortar. SCC was used as an alternative to WMP [

26]. At the 28-day curing time, Demirel [

27] discovered that when the fine particles in the matrix were replaced with waste marble powder, the porosity decreased but the compressive strength increased. The use of WMP as a filler affected the concrete’s mechanical and physical properties [

28]. Talah [

29] looked at the results of tests carried out with and without WMP and found that MP can be used to make high-performance concrete.

Soft computing approaches are now being used by researchers to solve the issues [

30,

31,

32,

33,

34,

35,

36,

37,

38]. The hardened property of concrete is primarily determined by the amount of cement, aggregates, water, admixtures, and wastes used in the mix. These factors can be used as an input parameter to aid in the prediction of the final result. The linear and non-linear regression approaches are mostly used in traditional methods for anticipating outcomes. However, in recent years, AI approaches such as ANN, LR, GMDH, RF, SVM and RT have been used to estimate the mechanical characteristics of concrete [

39,

40]. The majority of the study is focused on predicting the mechanical characteristics of concrete mixes. Several regressions, NNT, and ANFIS models are constructed by Sobhani [

32] using concrete components as input parameters in the estimation of the hardened property of concrete. The outcome demonstrates that the NNT and ANFIs algorithms are more accurate compared to proposed standard regression algorithms for predicting the 28-day compressive strength. Madandoust [

41] used GMDH, NNT, and ANFIs modelling for predicting the CS of concrete using cementitious materials. A genetic algorithm was used in the study to build the GMDH kind of neural network. In order to forecast output strength, parameters such as length to diameter ratio, core diameter, and so on were used as input. The study was directed by Ayat [

42] to evaluate the affectability of the constructed model to some basic factors influencing concrete compressive strength. It was discovered that the suggested ANNs model’s performance was outstanding with a highly effective tool for the simulation of the compressive strength with LF. Deepa [

43] estimates the CS of concrete utilizing classification methods such as M5P Tree models, Multilayer Perceptron’s, and Linear Regression. The results show that tree-based algorithms predict better results for concrete strength.

The purpose of this study was to determine whether or not machine learning could be used to make accurate predictions regarding the compressive and flexural strengths of concrete mixtures by adding waste marble powder in place of cement and sand together. To achieve the objective of the study, experimental data obtained by using waste marble powder as a partial replacement with cement and sand in the following proportions: 0–100, 25–75, 50–50, 75–25, and 100–0, respectively, was analyzed with soft computing techniques such as Support Vector Machines (SVM), Gaussian Processes (GP), and Linear Regressions (LR). The findings were than compared by using statistical parameters such as Coefficient of correlation (CC), Mean absolute error (MAE), Root mean square error (RMSE), relative absolute error (RAE), and Root relative squared error (RRSE). Further to identify the most relevant parameters (C, FA, CA, w, MP, and CD) in terms of predicting the compressive and flexural strength of concrete mixes and to ascertain the best modelling technique for predicting the compressive and flexural strength of concrete, sensitivity analysis has been carried out.

4. Evaluation Parameters

Evaluating parameters must be applied to the applicable algorithms in order to verify their performance. Coefficient of correlation (CC), Mean absolute error (MAE), Root mean square error (RMSE), relative absolute error (RAE), and Root relative squared error (RRSE) were utilized as evaluating parameters in this study.

Coefficient of correlation (CC): The coefficient of correlation (R) was utilised as the primary criterion to assess the effectiveness of the created models. The following equation was used to acquire the value of CC:

Root mean square error (RMSE): Mean Squared Error is the most often used method for determining a model’s success. It is the square root of Mean-Squared-Error with the same dimensions as the estimated values. The root mean square error (RMSE) is computed as follows:

Mean absolute error (MAE): The mean absolute error is used to assess the accuracy of numerical estimation. The mean absolute error (MAE) is calculated as follows:

Relative absolute error (RAE): The relative absolute error (RAE) is a metric used to assess the performance of a predictive model. It is calculated by using following equation:

Root relative squared error (RRSE): It is defined as the square root of a predictive model’s sum of squared errors normalized by the sum of squared errors of a simple model. To put it another way, it is the square root of the Relative Squared Error (RSE) and calculated by using formula:

Z = Observed readings;

= Average of observed readings; W = Predicted readings; y = Number of readings.

Coefficient of correlation (CC) values vary from −1 to +1; the greater the CC number, the better the anticipated outcomes. Lower the values better will be the outcomes, i.e., if computed error is low, it predicts better output results [

62].

6. Comparison

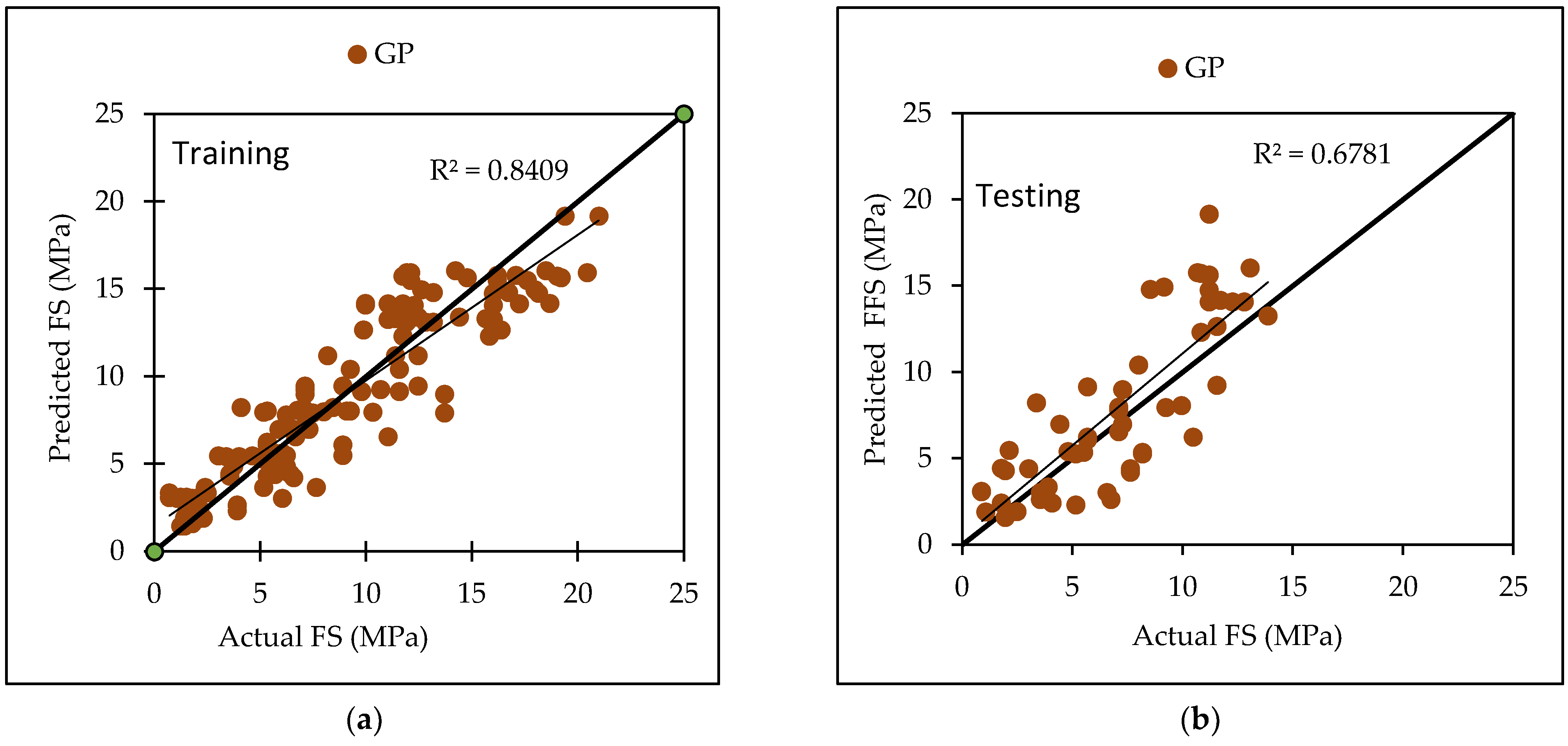

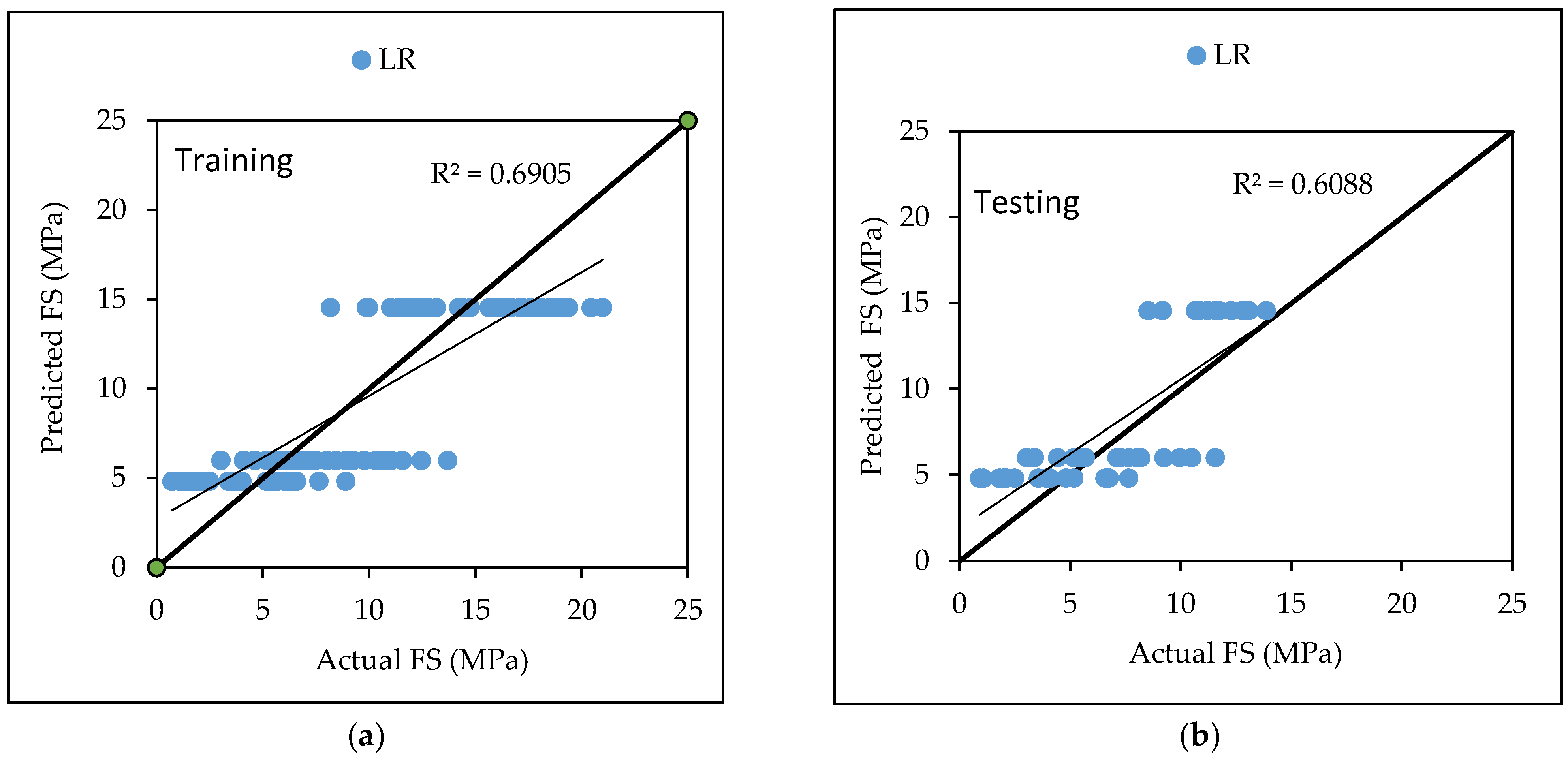

Various machine learning approaches were used in this research. When these models are compared, it appears that the GP model outperforms the others for both training and testing datasets for FS.

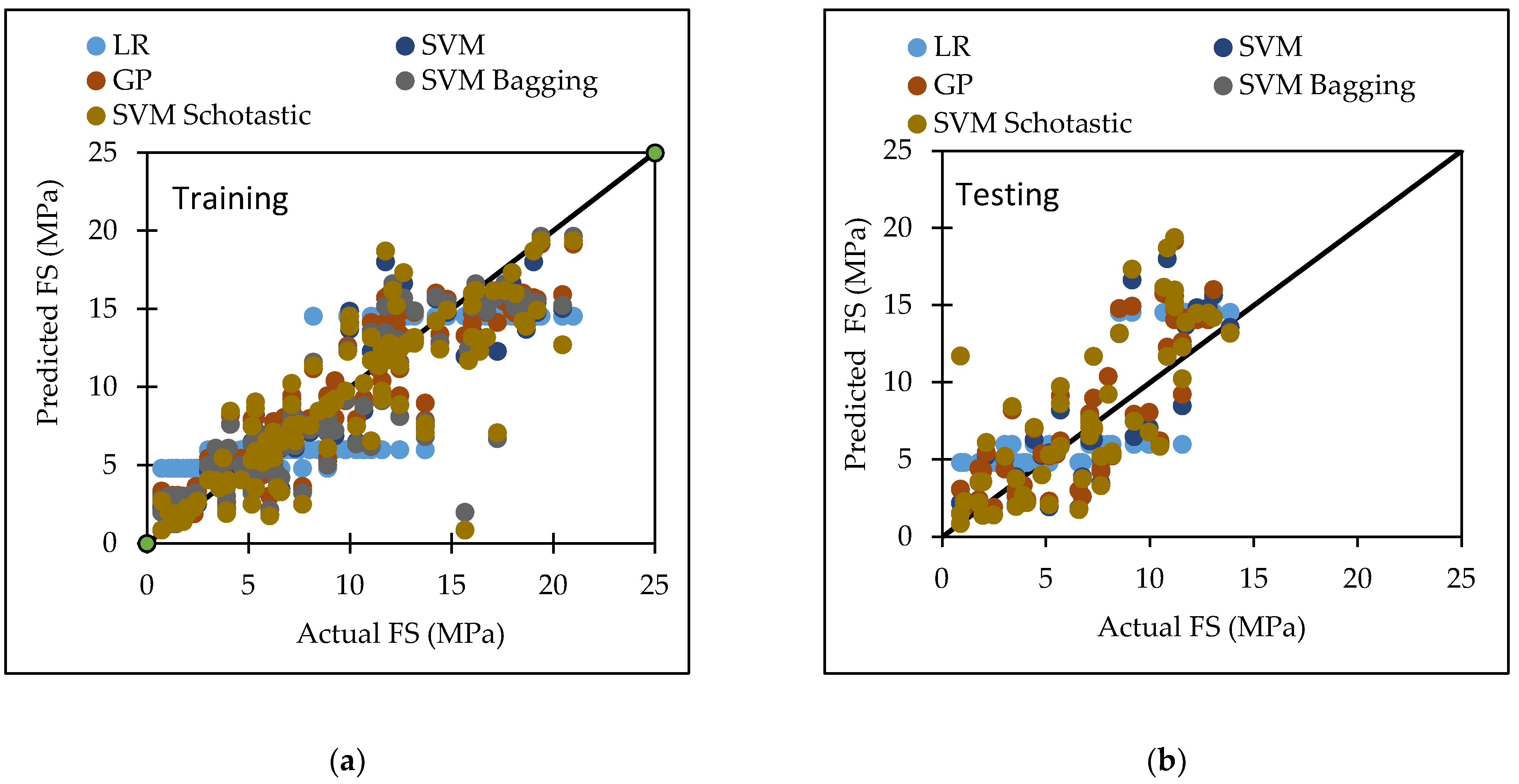

Figure 7 represents the scatter plot for the observed and predicted FS values using SVM, GP, and LR.

Table 6 indicate that the GP model has the greatest CC value for both training and testing datasets for FS, i.e., 0.9170 and 0.8235, respectively, as well as the lowest error values, i.e., MAE (2.2808) and RAE (66%), for the testing dataset. It can be seen from

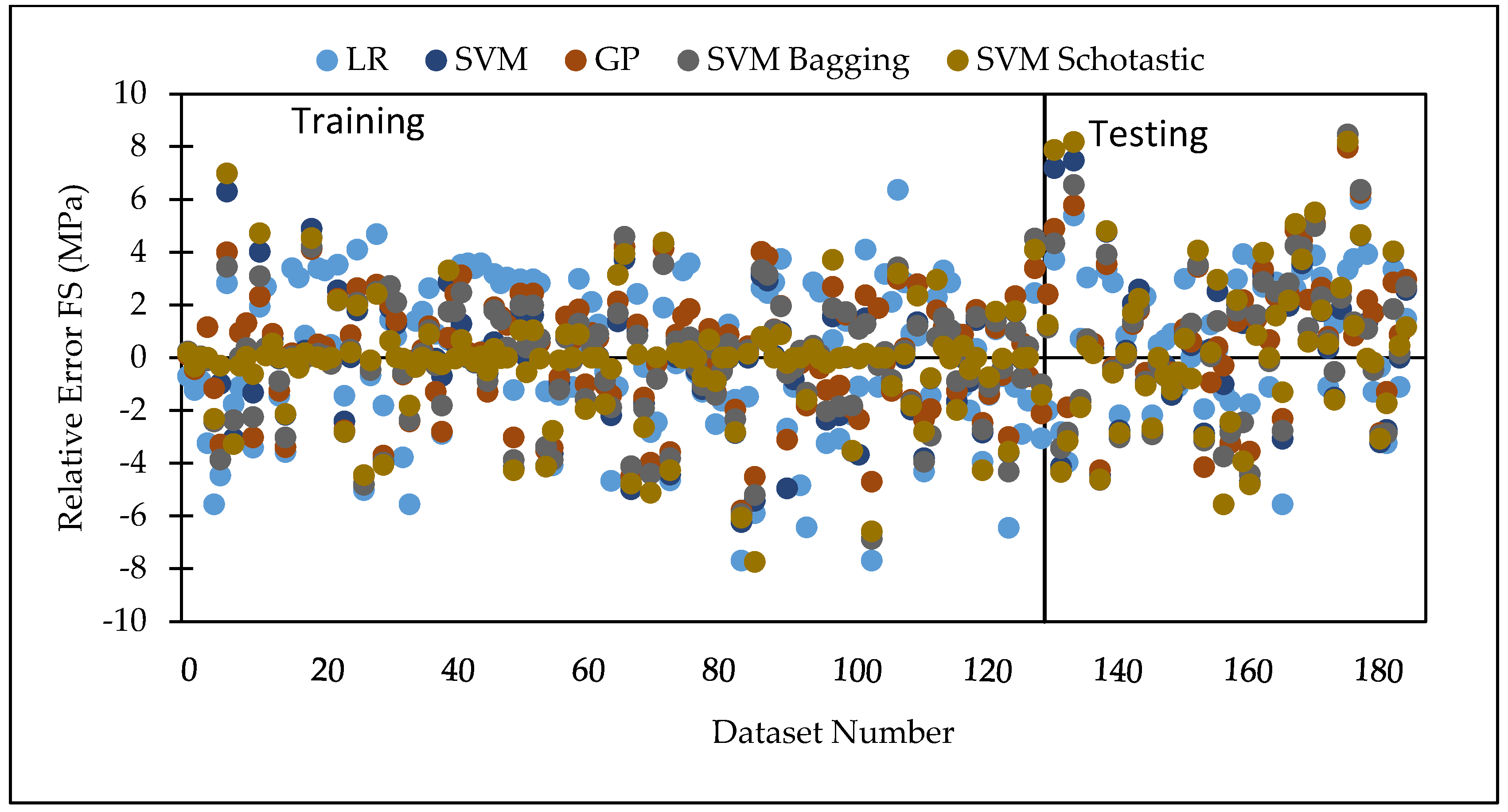

Figure 8 that the error band width is lesser in GP based model as compared to other applied models for the prediction of FS of concrete mix [

63].

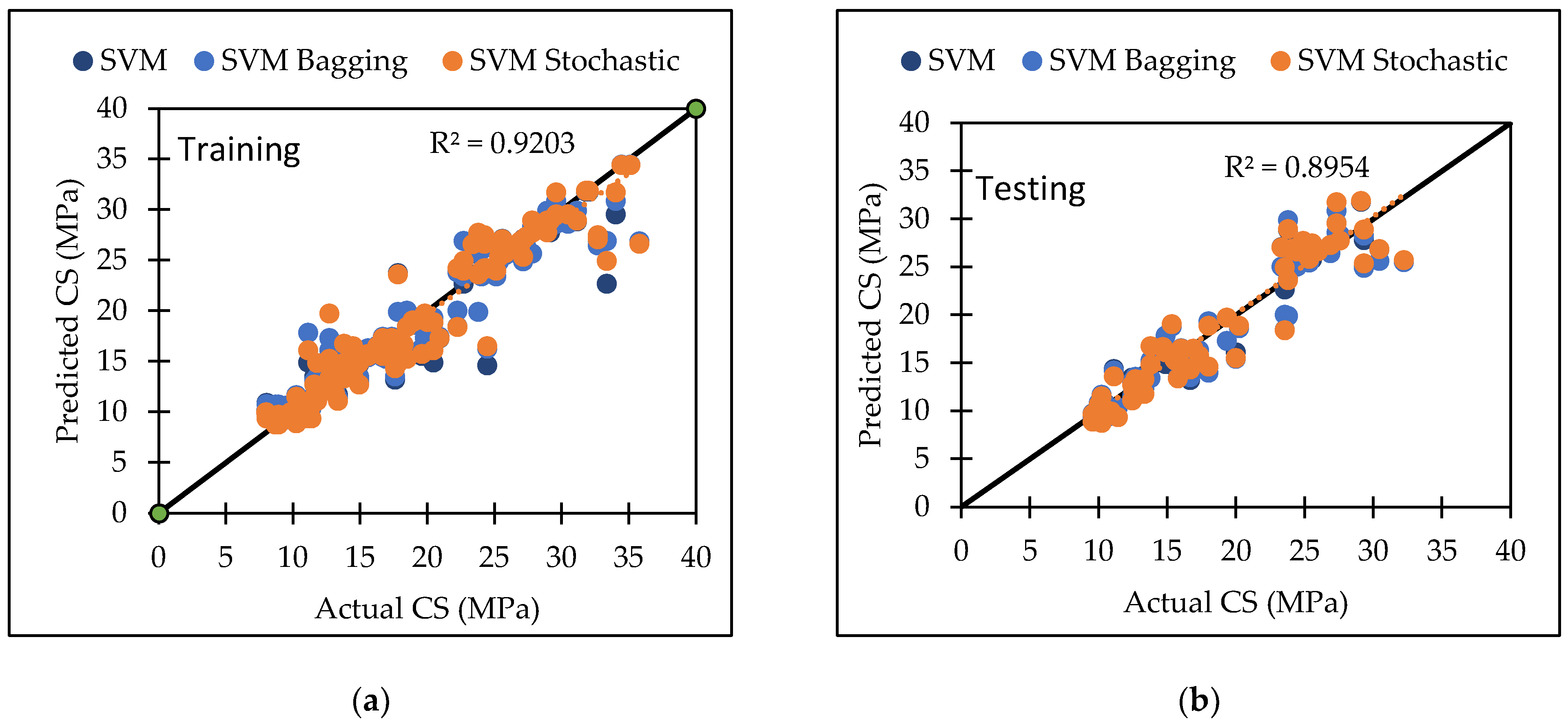

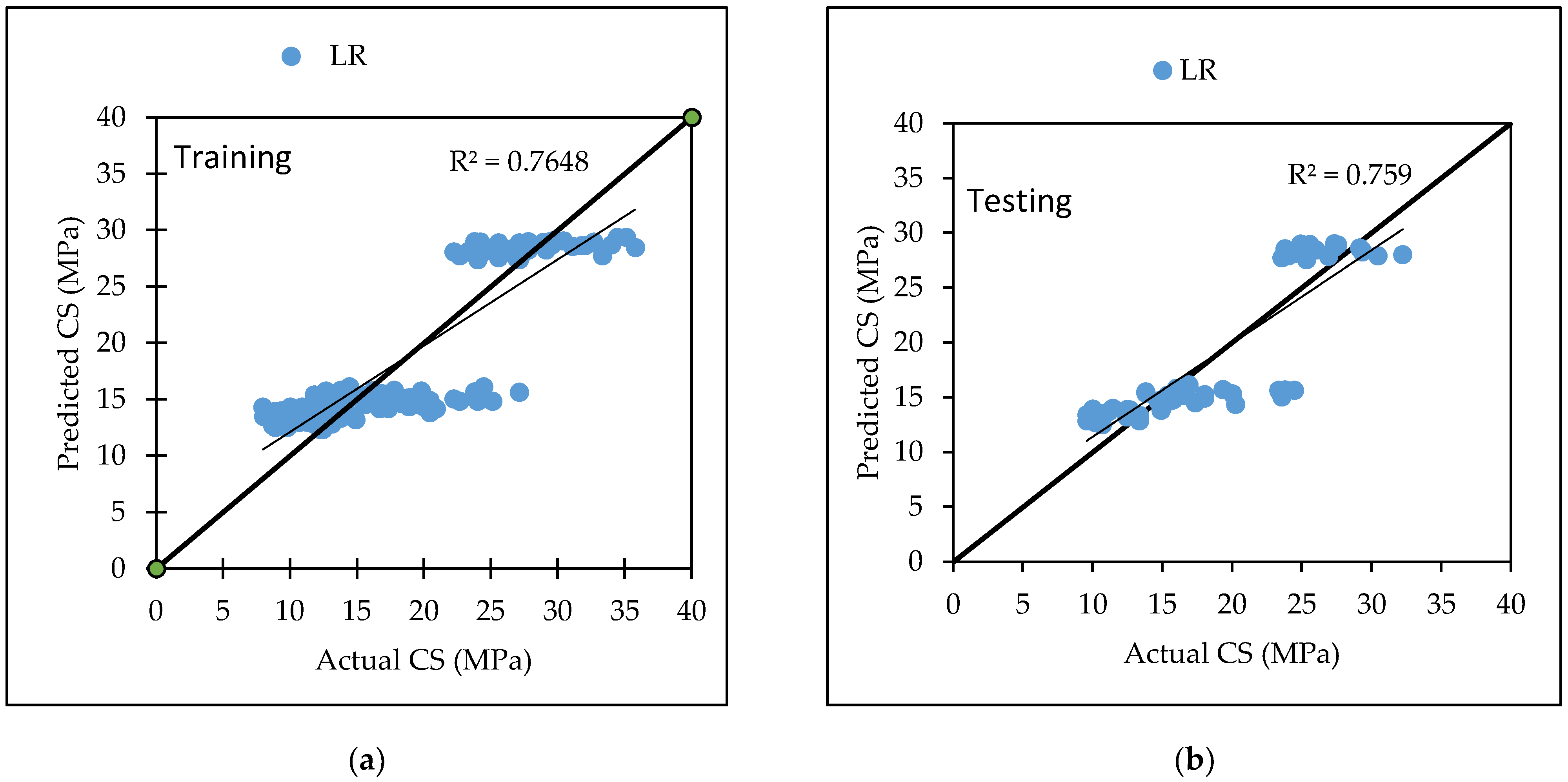

Figure 1,

Figure 3 and

Figure 5 for the SVM, GP, and LR testing models show that the GP model has a high correlation with the maximum R

2 value for the flexural strength of concrete, whereas

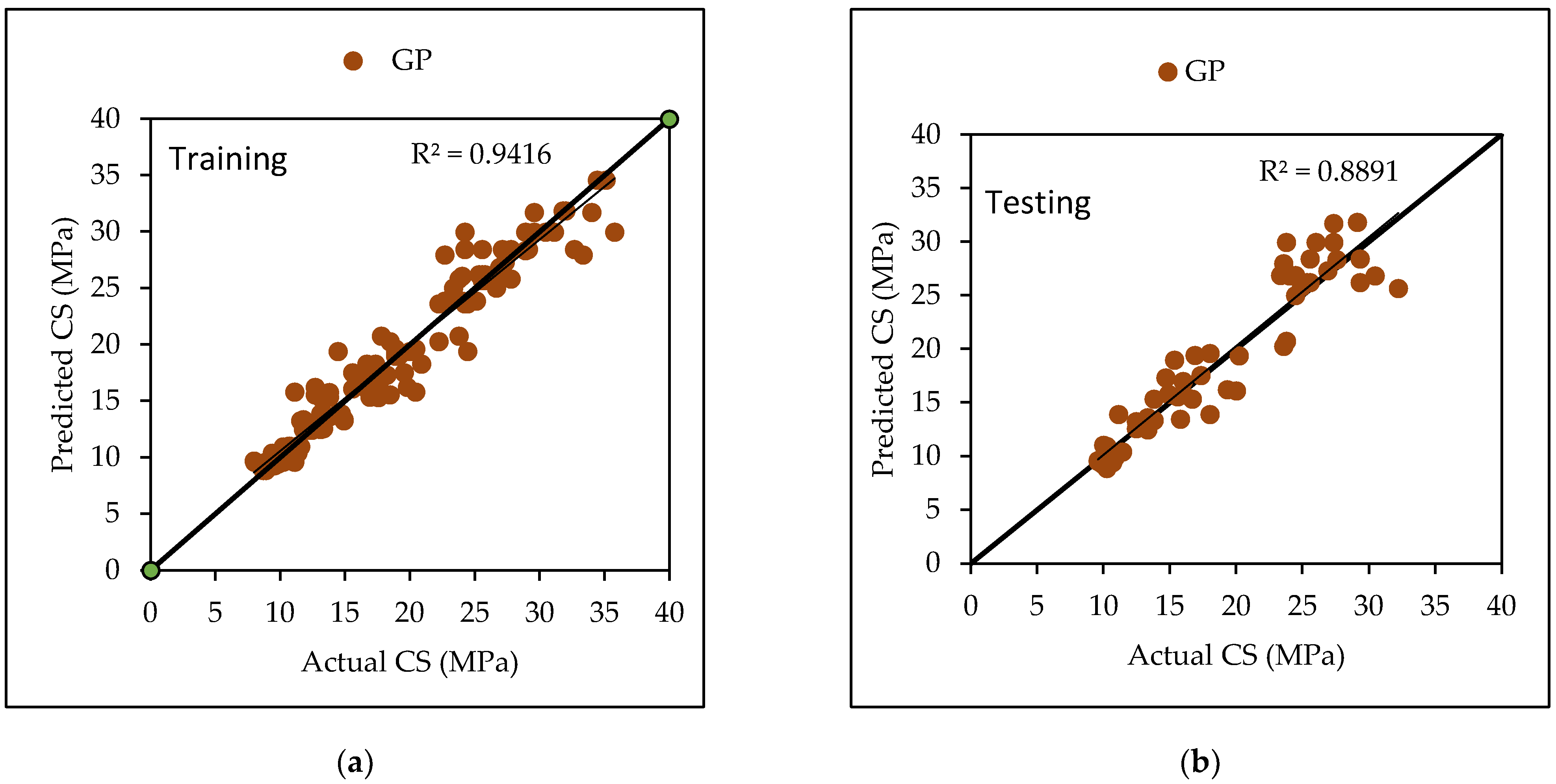

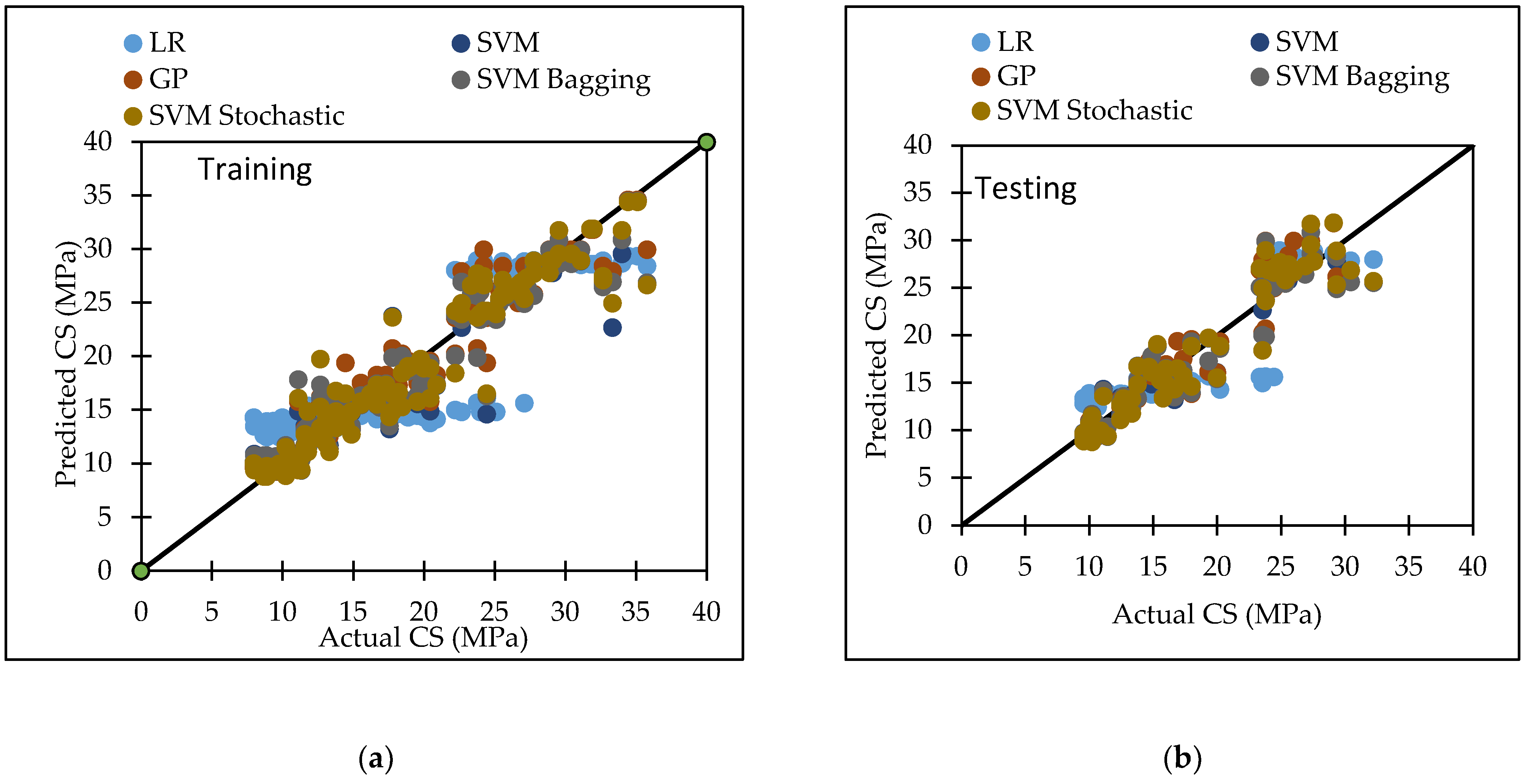

Figure 2,

Figure 4 and

Figure 6 for the SVM, GP, and LR testing models show that the SVM-Stochastic model has a high correlation for the compressive strength of concrete.

Figure 9 represents the scatter plot for the observed and predicted compressive strength values using SVM, GP, and LR.

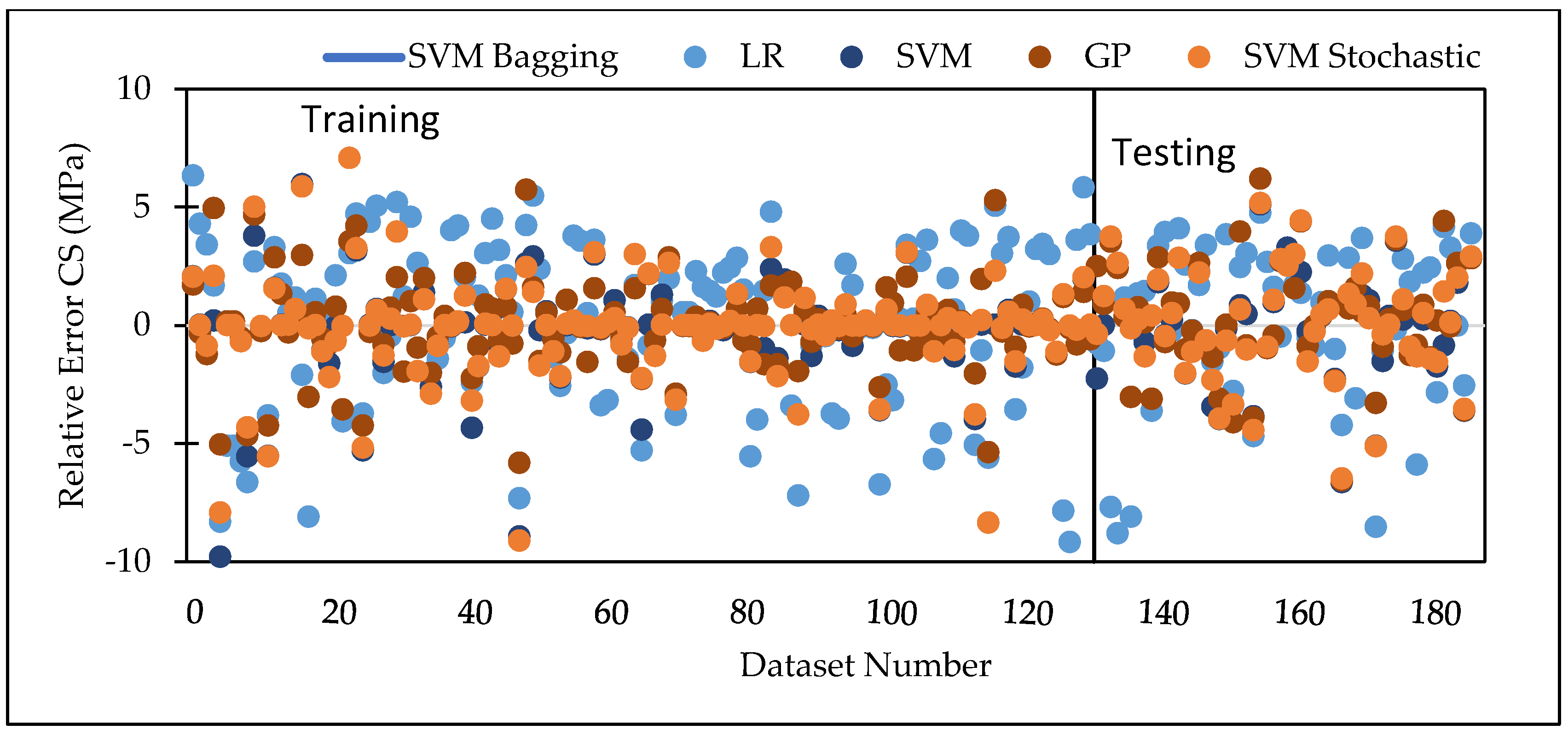

Table 7 indicate that the SVM model has the greatest CC value for testing datasets for the compressive strength, i.e., 0.9450, as well as the lowest error values, i.e., MAE (1.7305), RMSE (2.2908), RAE (28.46%) and RRSE (33.93%) for the testing dataset. It can be seen from

Figure 10 that the error band width is lesser in SVM based model as compared to other applied model for the prediction of CS of concrete mix.

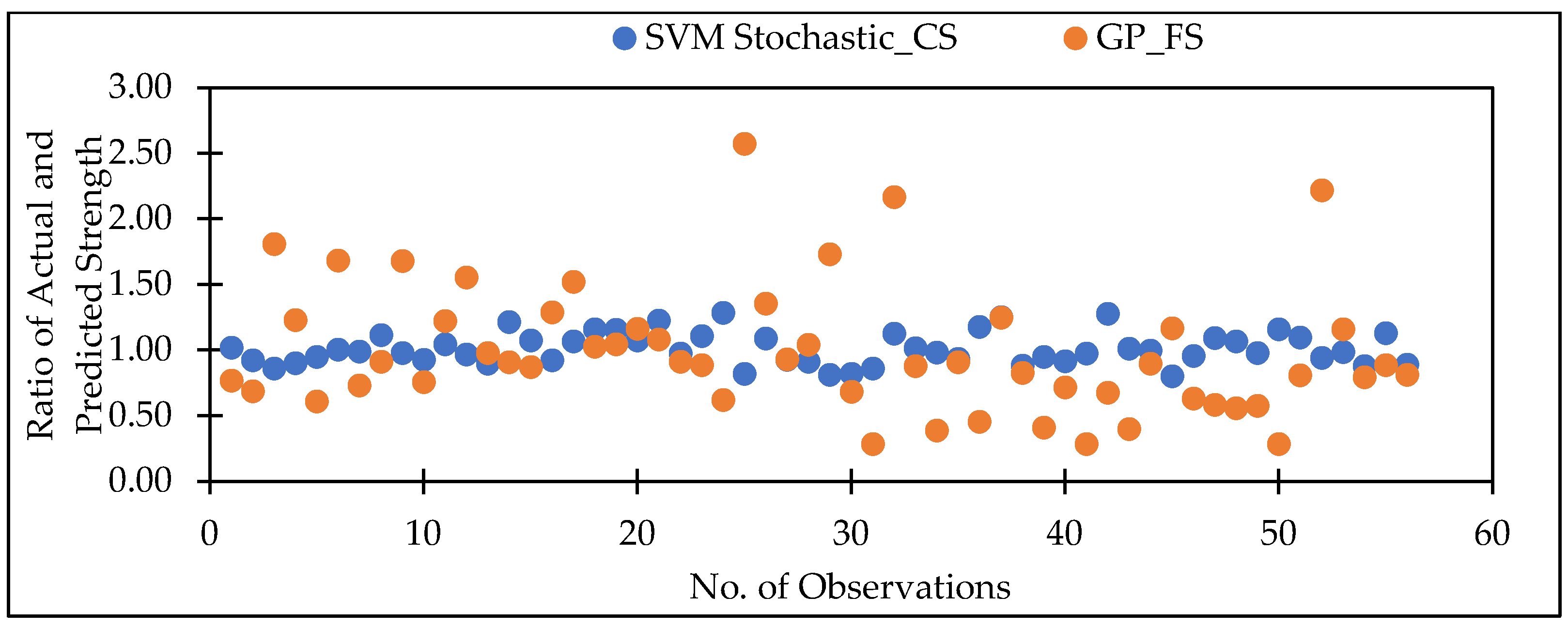

Figure 11 represents the scatter plot between no. of observation and ratio of actual and predicted strength. It shows that SVM-Schotastic based model is reliable for compressive strength prediction followed by SVM [

64] as compared to GP model for flexural strength because the values are more scatter in the ratio of actual and predicted flexural strength.

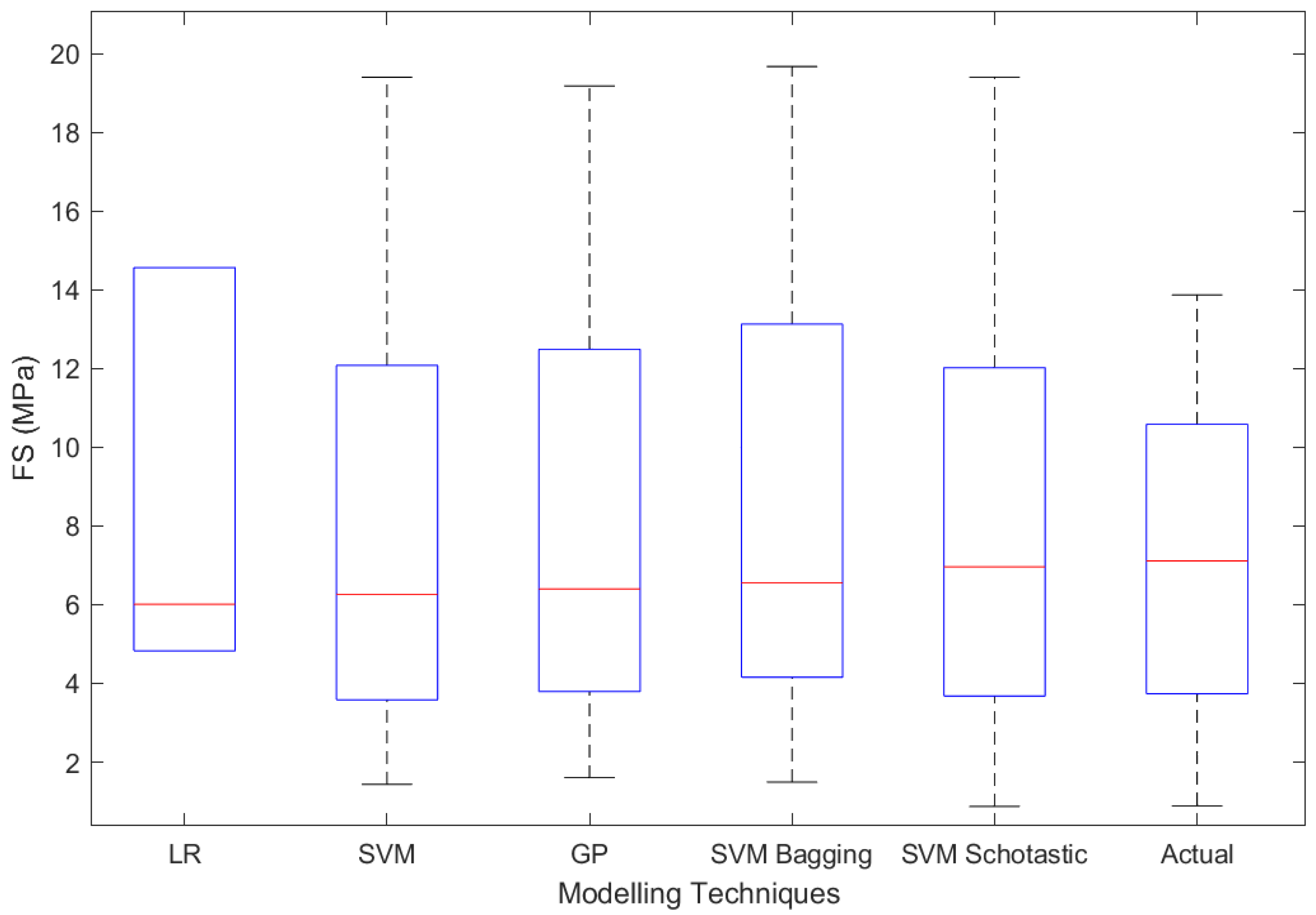

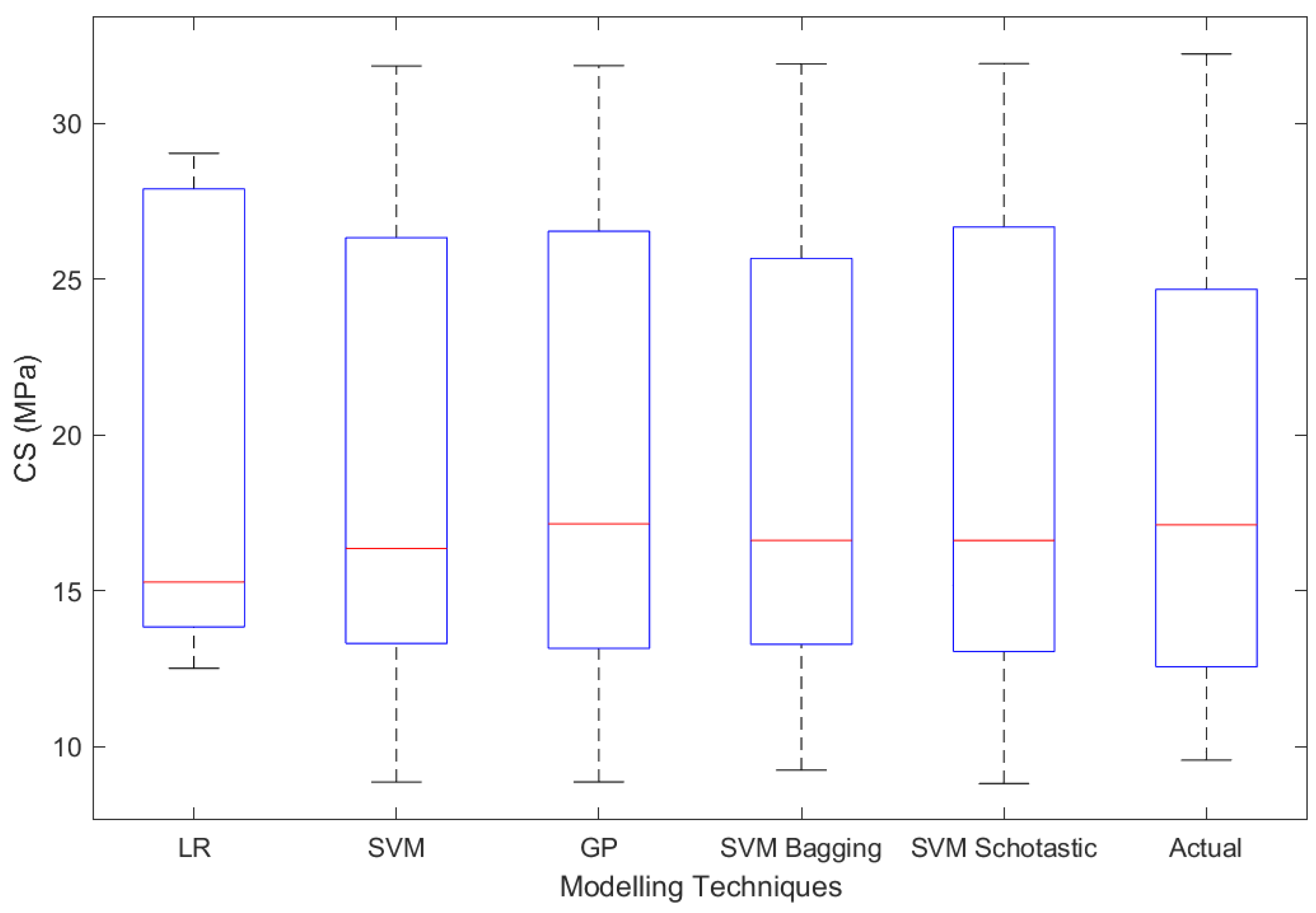

In addition to the actual value, quartile values of 25%, 50%, and 75% were assessed for the evaluation of FS and CS of concrete containing marble powder, as shown in

Table 8. The inter quartile range (IQR) of SVM-Schotastic and SVM Bagging is closer to the IQR of real data, as seen in

Figure 12 and

Figure 13 for FS and CS, respectively.

8. Conclusions

This study compared the CS and FS using WMP by three machine learning techniques: SVM, LR, and GP based models. CC, MAE, RMSE, RAE, and RRSE were applied to evaluate the performance of these models. The following is a summary of the study’s findings:

The GP and SVM model’s results were shown to be the best for predicting concrete flexural and compressive strength of concrete mix, respectively. For the testing dataset, GP predicts better outcomes followed by SVM with CC values of 0.8235 and 0.8153, lower MAE values of 2.2808 and 2.3456, and lower RMSE values of 2.8527 and 3.0367, respectively, for flexural strength of concrete. SVM-Schotastic predicts better results with CC values of 0.9462, lower MAE values of 1.8104 and lower RMSE values of 2.3430 for compressive strength of concrete. The scatter plot reveals that the GP and SVM-Schotastic has the smallest error band width and is a strong match for predicting flexural and compressive strength as output, respectively.

In comparison to input factors for this data set, the number of curing days followed by the CA, C, w and MP is essential in predicting the flexural and compressive strength of a concrete mix for this data set. These findings are restricted to a 0–20% cement sand substitute with marble powder. Additionally, CD is a more sensitive parameter, and some further investigation is warranted. In addition,

Table 9 and

Table 10 demonstrate that CA, C, FA, MP and w have minimal effects on CC. This indicates that additional study is required to examine the input variables.