Influence of Ca2+ on Early Degradation of Cast-In-Situ Mortar Induced by Sulfate-Magnesium Multiple Combined Attack

Abstract

:1. Introduction

2. Experimental Materials and Methods

2.1. Materials

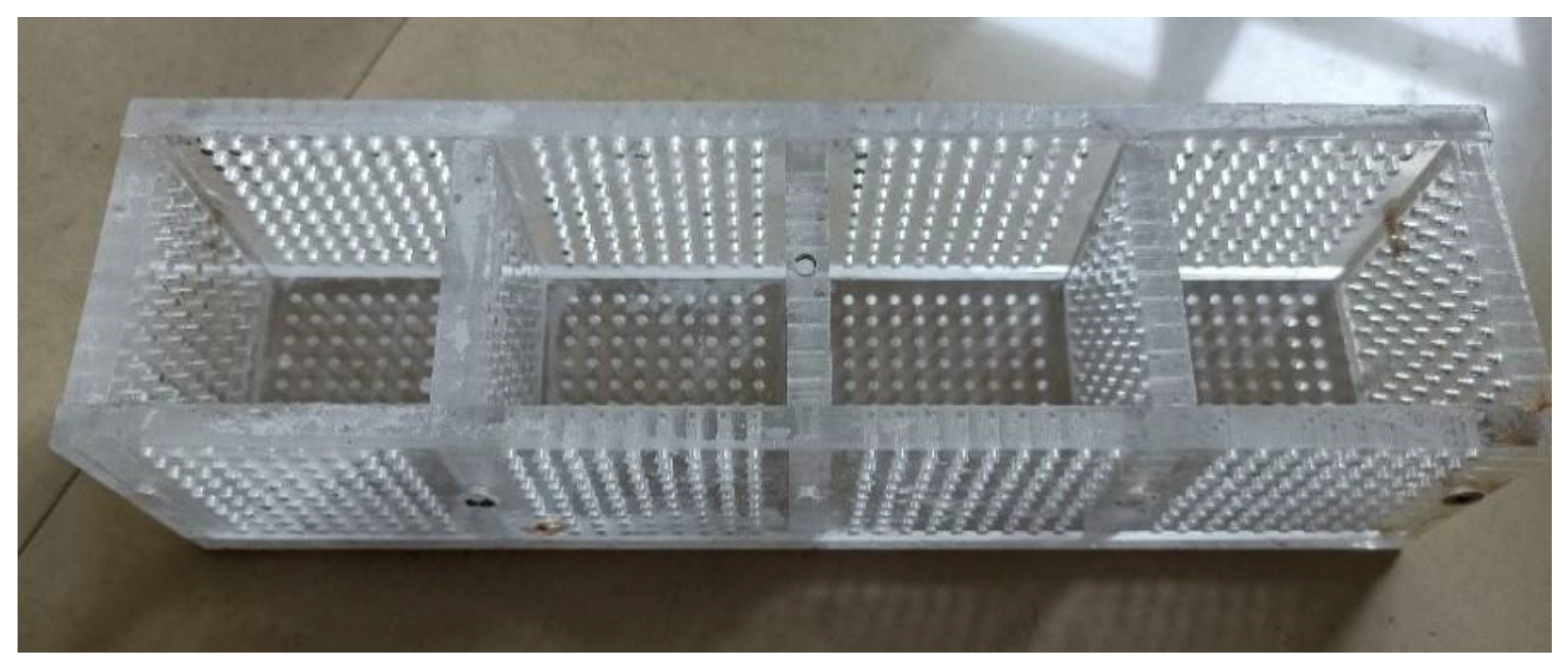

2.2. Specimens and Immersion Solution Preparation

2.3. Test Methods

2.3.1. Physical and Mechanical Properties

2.3.2. Sulfate Concentration

2.3.3. SEM-EDS, XRD and TG/DTG Analysis

3. Results

3.1. Changes in Weight, Size and Appearance

3.1.1. Weight Change

3.1.2. Size and Appearance Changes

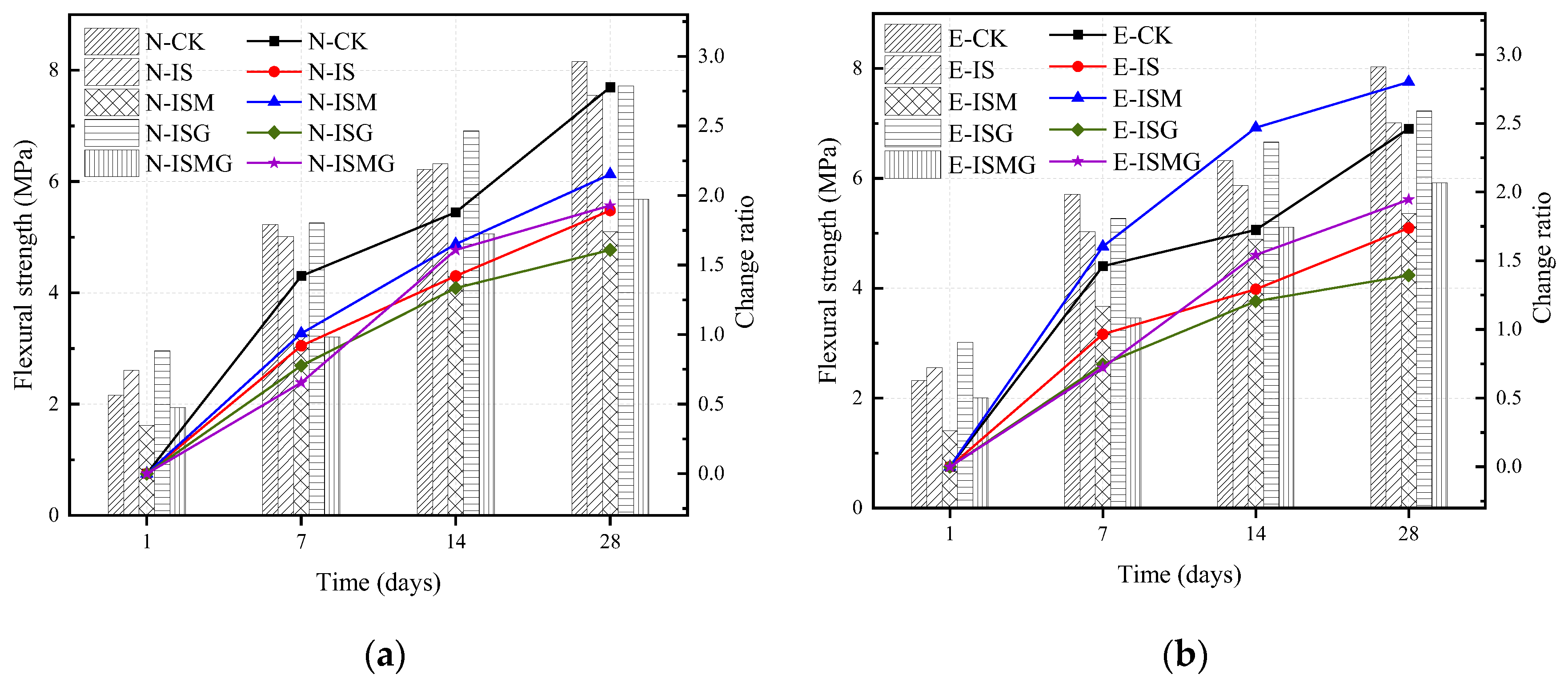

3.2. Mechanical Properties

3.2.1. Flexural Strength

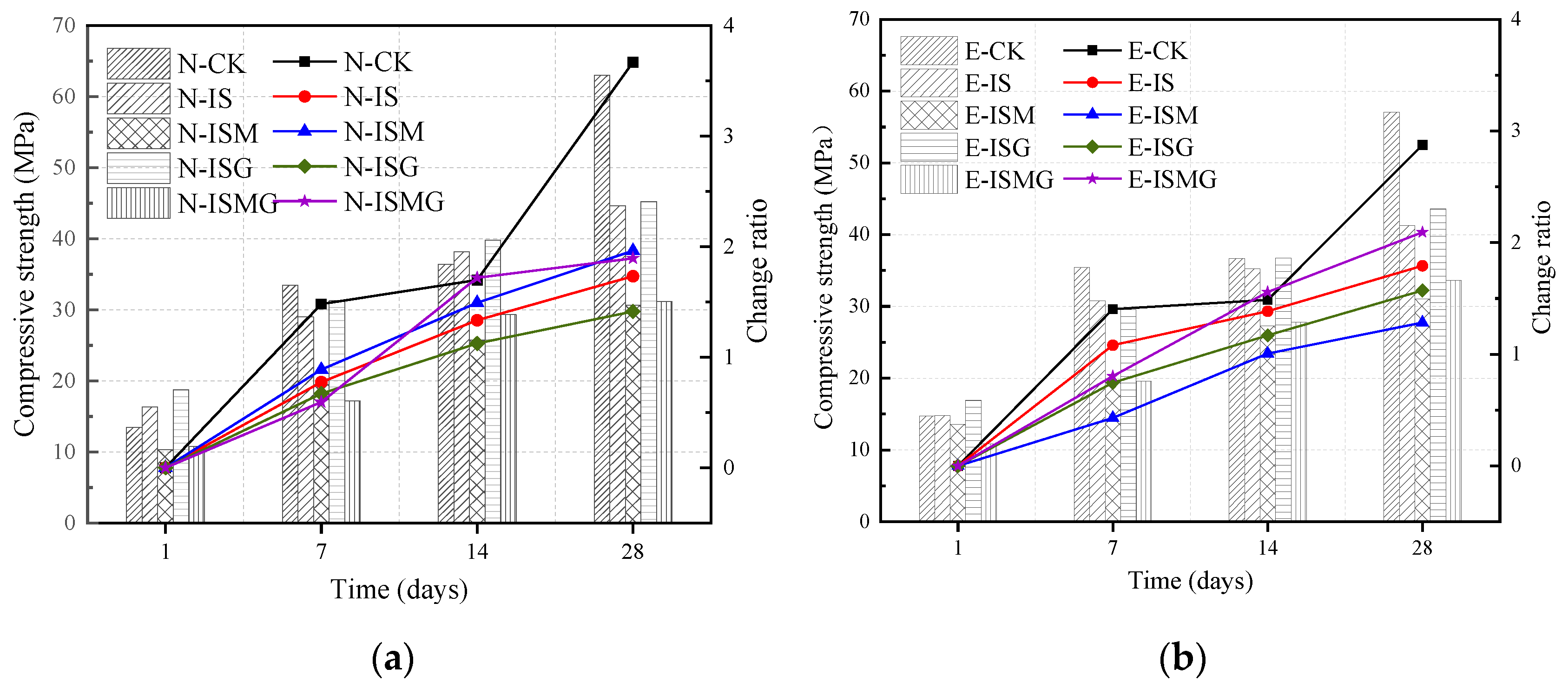

3.2.2. Compressive Strength

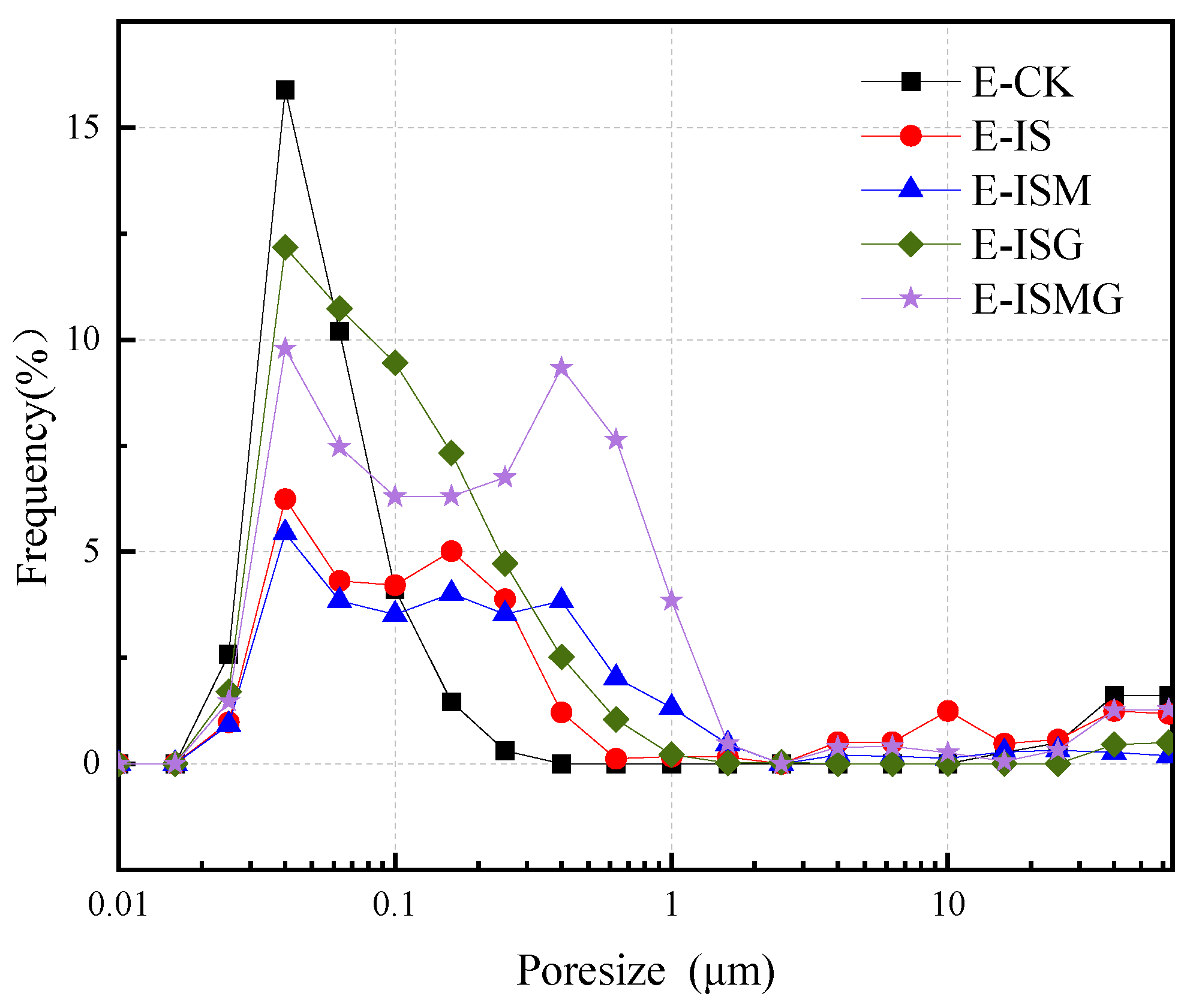

3.3. Porosity

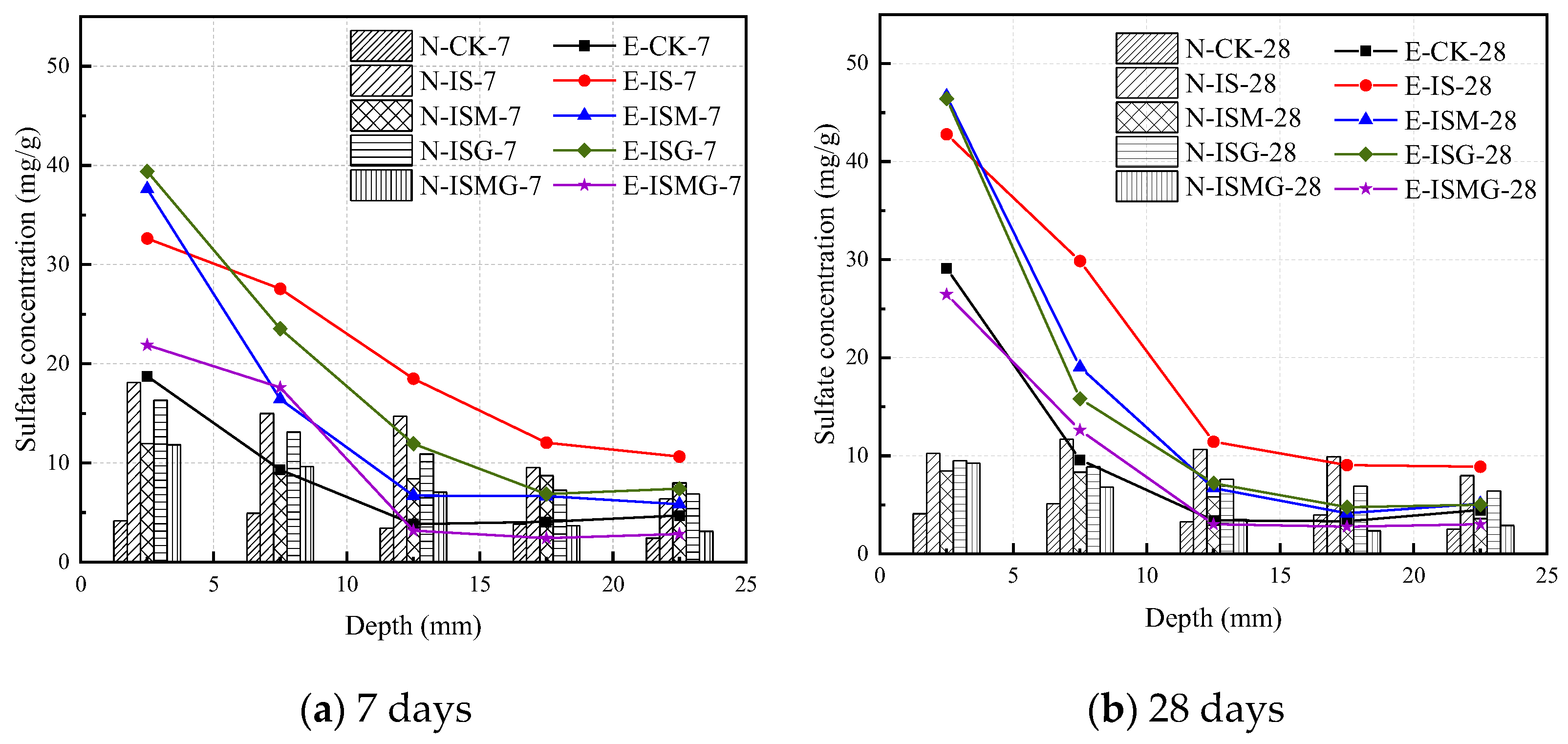

3.4. Sulfate Concentration

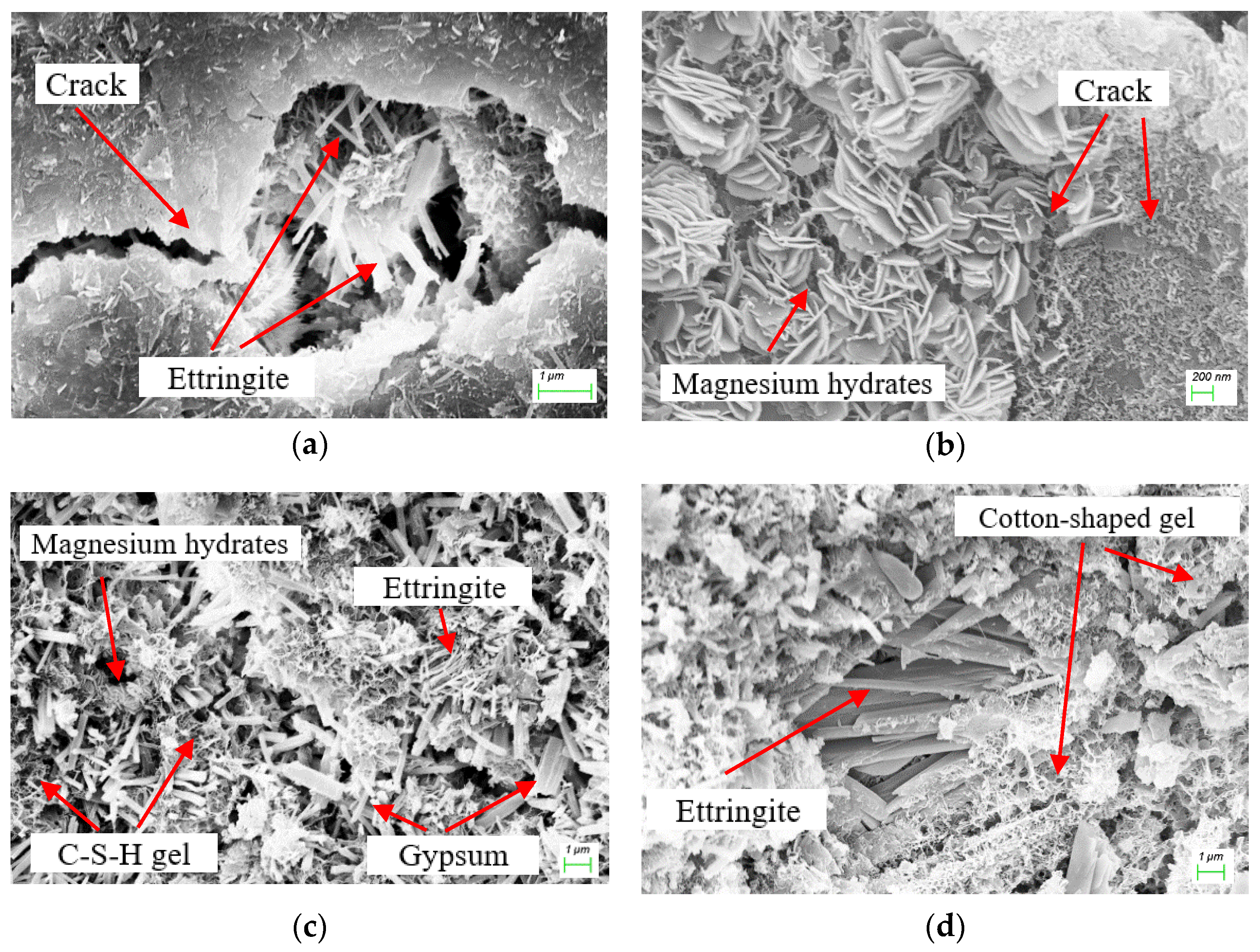

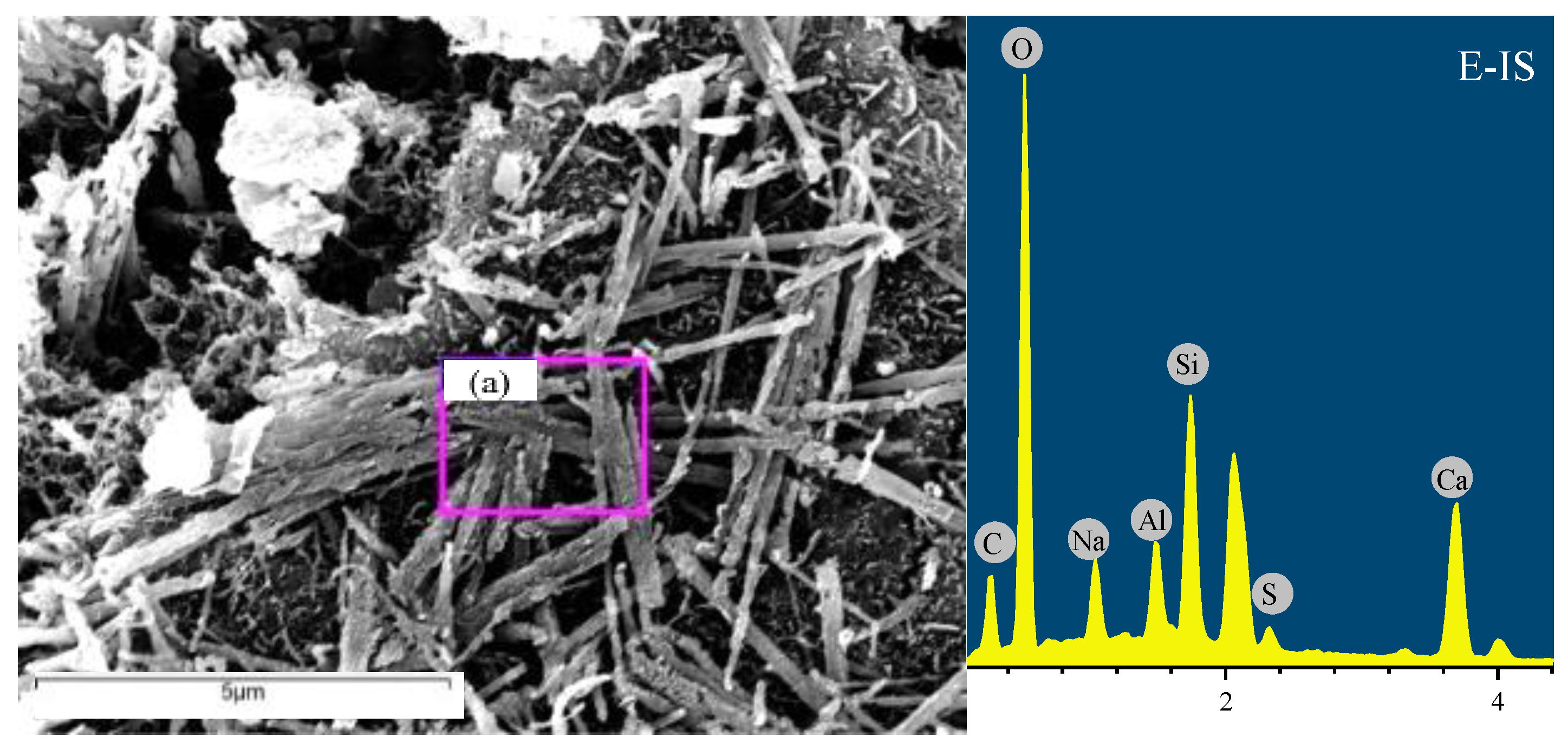

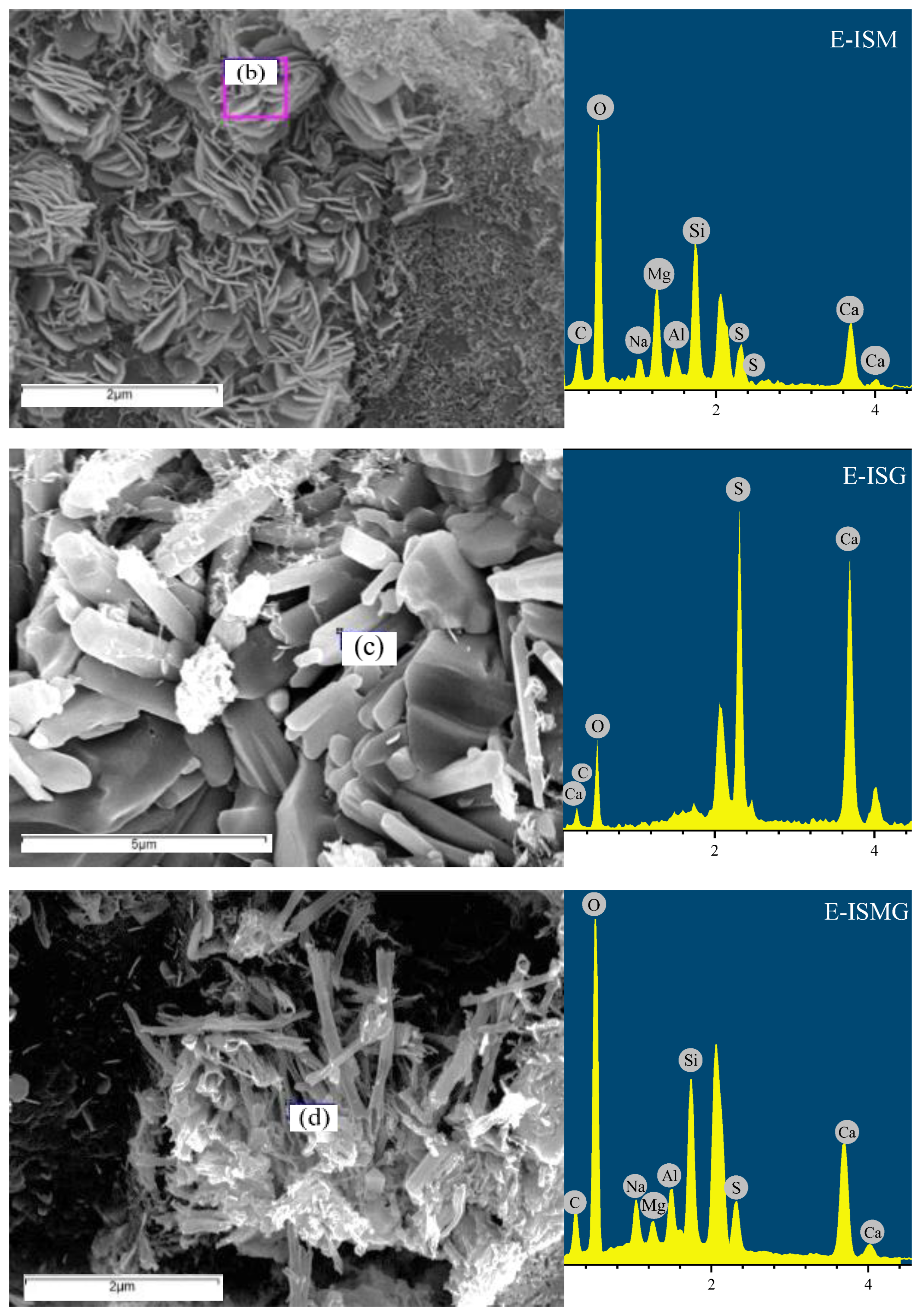

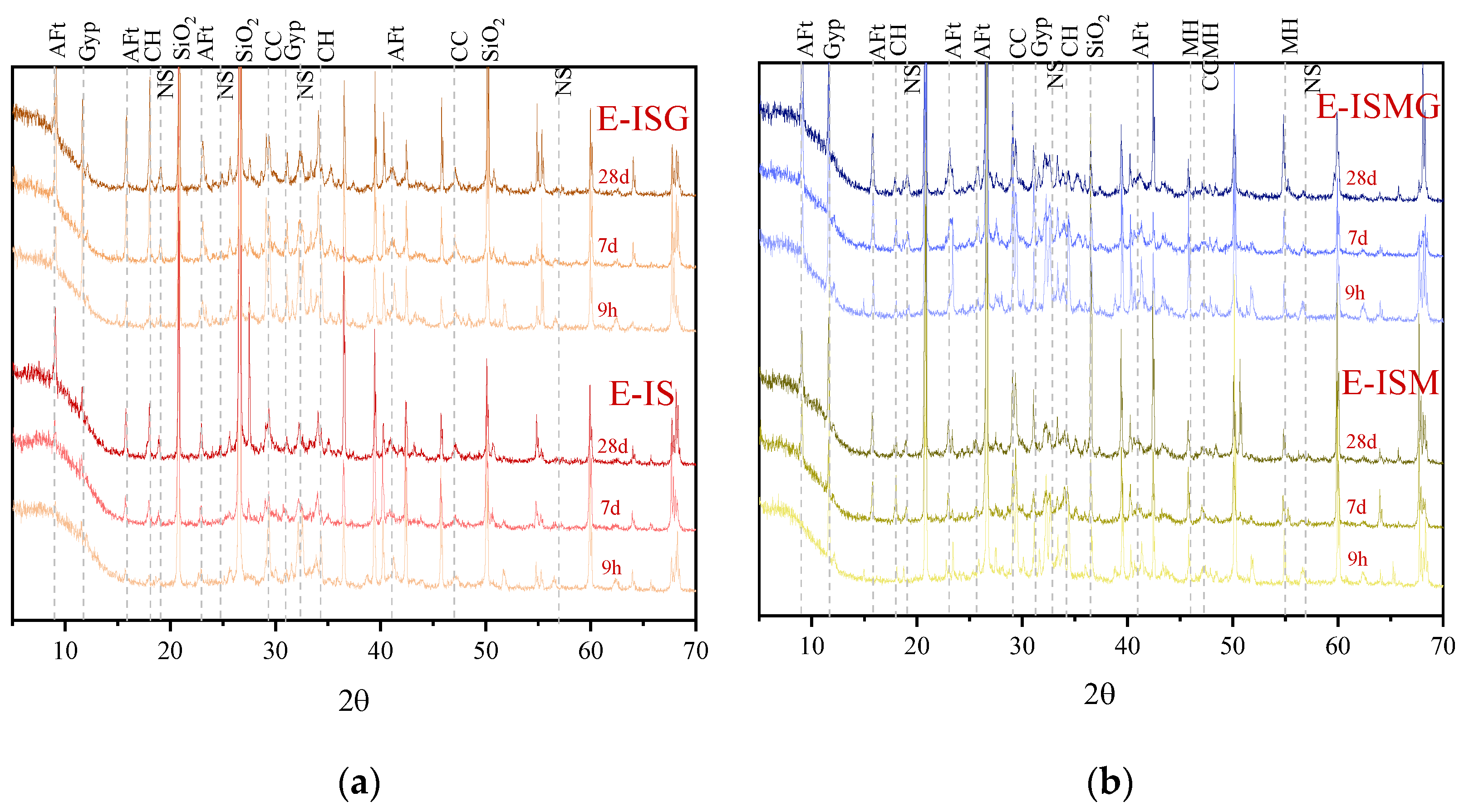

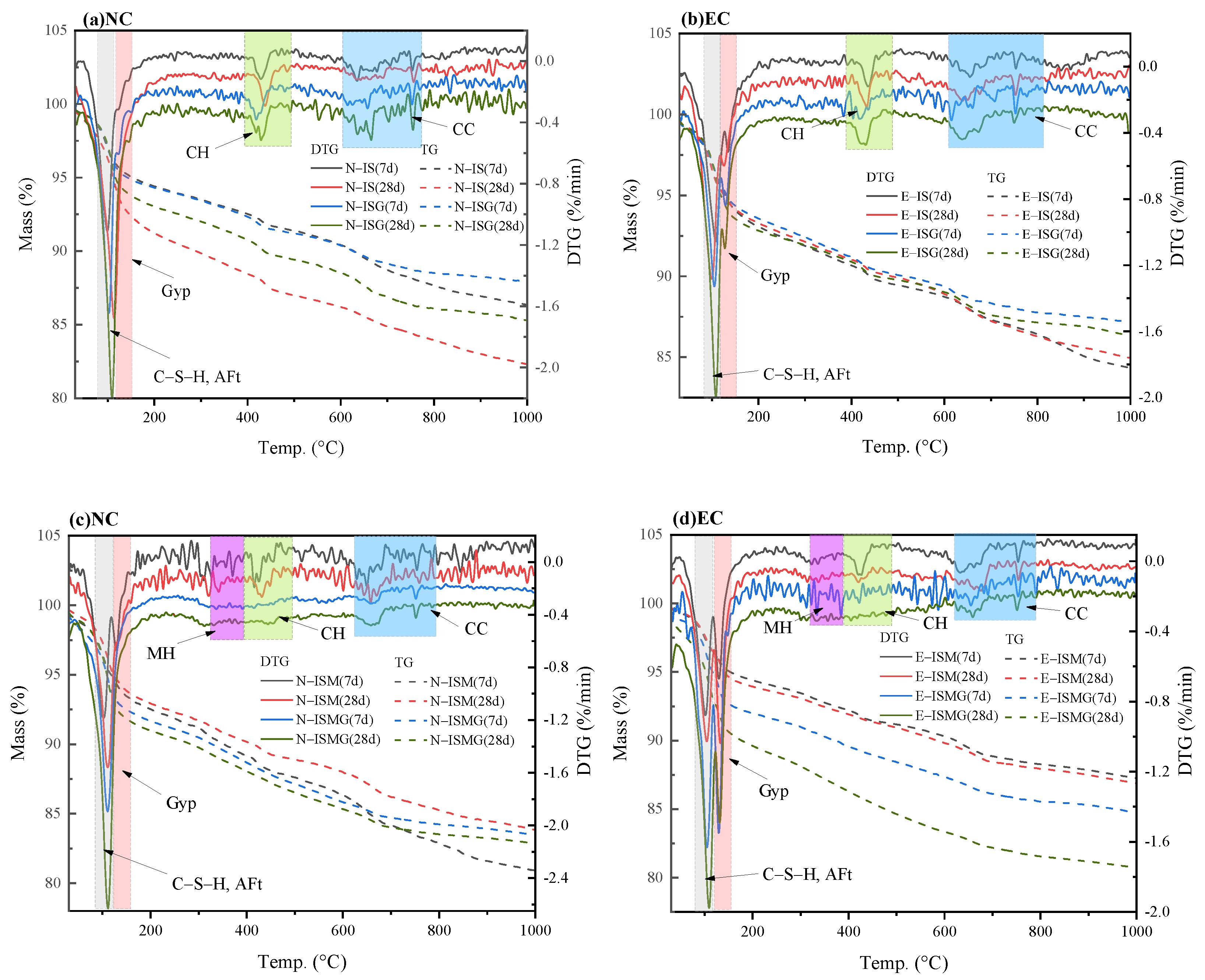

3.5. Microstructure and Mineral Analysis

4. Discussion

4.1. ESA-ISA-IMA

4.2. Effect of Ca2+ on ESA-ISA-IMA

5. Conclusions

- (1)

- ISA and ISA-IMA negatively influence both pore structures and the early strength development of cast-in-situ mortars. Early expansion and microcracks induced by multiple internal–external combined attacks would accelerate the process of degradation induced by ESA.

- (2)

- Flake-like magnesium hydrates hinder the expansion of microcracks and the penetration of external sulfate ions. However, it would not be enough to neutralize the negative effects induced by IMA.

- (3)

- Premixed excessive Ca2+ would retard the degradation triggered by CSA or ESA-ISA-IMA and improves the durability of cast-in-situ structures against sulfate-rich environments. Sufficient Ca2+ would improve the porosity and strength of mortar during the early hydration process.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ouyang, C.; Nanni, A.; Chang, W.F. Internal and external sources of sulfate ions in Portland cement mortar: Two types of chemical attack. Cem. Concr. Res. 1988, 18, 699–709. [Google Scholar] [CrossRef]

- Irassar, E.F. Sulfate attack on cementitious materials containing limestone filler—A review. Cem. Concr. Res. 2009, 39, 241–254. [Google Scholar] [CrossRef]

- Colman, C.; Bulteel, D.; Thiery, V.; Rémond, S.; Michel, F.; Courard, L. Internal sulfate attack in mortars containing contaminated fine recycled concrete aggregates. Constr. Build. Mater. 2021, 272, 121851. [Google Scholar] [CrossRef]

- Islam, M.A.; Golrokh, A.J.; Lu, Y. Chemomechanical modeling of sulfate attack–induced damage process in cement-stabilized pavements. J. Eng. Mech. 2019, 145, 04018117. [Google Scholar] [CrossRef]

- Chen, W.; Huang, B.; Yuan, Y.; Deng, M. Deterioration process of concrete exposed to internal sulfate attack. Materials 2020, 13, 1336. [Google Scholar] [CrossRef] [Green Version]

- Skalny, J.; Marchand, J.; Odler, I. Sulfate Attack on Concrete; CRC Press: Boca Raton, FL, USA, 2001. [Google Scholar]

- Dobrovolski, M.E.G.; Munhoz, G.S.; Pereira, E.; Medeiros, R.A., Jr. Effect of crystalline admixture and polypropylene microfiber on the internal sulfate attack in Portland cement composites due to pyrite oxidation. Constr. Build. Mater. 2021, 308, 125018. [Google Scholar] [CrossRef]

- Diamond, S. Delayed ettringite formation—Processes and problems. Cem. Concr. Compos. 1996, 18, 205–215. [Google Scholar] [CrossRef]

- Blanco, A.; Pardo-Bosch, F.; Cavalaro, S.; Aguado, A. Lessons learned about the diagnosis of pathologies in concrete dams: 30 years of research and practice. Constr. Build. Mater. 2019, 197, 356–368. [Google Scholar] [CrossRef] [Green Version]

- Jebli, M.; Jamin, F.; Pelissou, C.; Lhopital, E.; El Youssoufi, M. Characterization of the expansion due to the delayed ettringite formation at the cement paste-aggregate interface. Constr. Build. Mater. 2021, 289, 122979. [Google Scholar] [CrossRef]

- Zhang, F.; Hu, Z.; Dai, L.; Wen, X.; Wang, R.; Zhang, D.; Song, X. Study on corrosion mechanism of different concentrations of Na2SO4 Solution on early-age cast-in-situ concrete. Materials 2021, 14, 2018. [Google Scholar] [CrossRef]

- Fu, Y.; Ding, J.; Beaudoin, J. Expansion of Portland cement mortar due to internal sulfate attack. Cem. Concr. Res. 1997, 27, 1299–1306. [Google Scholar] [CrossRef]

- Zhao, G.; Guo, M.; Wang, Z.; Hu, Y.; Li, S.; Wei, F. Effect of Ca2+ on the sulfate multiple combined induced degradation of early aged mortar. Constr. Build. Mater. 2022, 325, 126769. [Google Scholar] [CrossRef]

- Kunther, W.; Lothenbach, B.; Scrivener, K.L. Deterioration of mortar bars immersed in magnesium containing sulfate solutions. Mater. Struct. 2013, 46, 2003–2011. [Google Scholar] [CrossRef]

- Pinto, S.R.; Da Luz Angulski, C.; Munhoz, G.S.; Medeiros, A.R., Jr. Durability of phosphogypsum-based supersulfated cement mortar against external attack by sodium and magnesium sulfate. Cem. Concr. Res. 2020, 136, 106172. [Google Scholar] [CrossRef]

- Zhao, G.; Guo, M.; Cui, J.; Li, J.; Xu, L. Partially-exposed cast-in-situ concrete degradation induced by internal-external sulfate and magnesium multiple coupled attack. Constr. Build. Mater. 2021, 294, 123560. [Google Scholar] [CrossRef]

- Santhanam, M.; Cohen, M.; Olek, J. Differentiating seawater and groundwater sulfate attack in Portland cement mortars. Cem. Concr. Res. 2006, 36, 2132–2137. [Google Scholar] [CrossRef]

- Higgins, D.D. Increased sulfate resistance of ggbs concrete in the presence of carbonate. Cem. Concr. Compos. 2003, 25, 913–919. [Google Scholar] [CrossRef]

- Williams, M.; Ortega, J.; Sánchez, I.; Cabeza, M.; Climent, M. Non-destructive study of the microstructural effects of sodium and magnesium sulphate attack on mortars containing silica fume using impedance spectroscopy. Appl. Sci. 2017, 7, 648. [Google Scholar] [CrossRef]

- Neville, A. The confused world of sulfate attack on concrete. Cem. Concr. Res. 2004, 34, 1275–1296. [Google Scholar] [CrossRef]

- Huang, Q.; Zhu, X.; Xiong, G.; Zhang, M.; Deng, J.; Zhao, M.; Zhao, L. Will the magnesium sulfate attack of cement mortars always be inhibited by incorporating nanosilica? Constr. Build. Mater. 2021, 305, 124695. [Google Scholar] [CrossRef]

- Al-Amoudi, O.S.B. Performance of 15 reinforced concrete mixtures in magnesium-sodium sulphate environments. Constr. Build. Mater. 1995, 9, 149–158. [Google Scholar] [CrossRef]

- Yu, X.; Chen, D.; Feng, J.; Zhang, Y. Behavior of mortar exposed to different exposure conditions of sulfate attack. Ocean Eng. 2018, 157, 1–12. [Google Scholar] [CrossRef]

- González, J.G.; Robles, D.R.; Valdés, A.J.; del Pozo, J.M.M.; Romero, M.I.G. Porosity and pore size distribution in recycled concrete. Mag. Concr. Res. 2015, 67, 1214–1221. [Google Scholar] [CrossRef]

- Kumar, R.; Bhattacharjee, B. Porosity, pore size distribution and in situ strength of concrete. Cem. Concr. Res. 2003, 33, 155–164. [Google Scholar] [CrossRef]

- Xie, F.; Li, J.; Zhao, G.; Zhou, P.; Zheng, H. Experimental study on performance of cast-in-situ recycled aggregate concrete under different sulfate attack exposures. Constr. Build. Mater. 2020, 253, 119144. [Google Scholar] [CrossRef]

- Santhanam, M.; Cohen, M.D.; Olek, J. Sulfate attack research—Whither now? Cem. Concr. Res. 2001, 31, 845–851. [Google Scholar] [CrossRef]

- Ikumi, T.; Cavalaro, S.H.; Segura, I.; Aguado, A. Alternative methodology to consider damage and expansions in external sulfate attack modeling. Cem. Concr. Res. 2014, 63, 105–116. [Google Scholar] [CrossRef] [Green Version]

- Geng, J.; Easterbrook, D.; Li, L.; Mo, L. The stability of bound chlorides in cement paste with sulfate attack. Cem. Concr. Res. 2015, 68, 211–222. [Google Scholar] [CrossRef]

- Siad, H.; Lachemi, M.; Bernard, S.K.; Sahmaran, M.; Hossain, A. Assessment of the long-term performance of SCC incorporating different mineral admixtures in a magnesium sulphate environment. Constr. Build. Mater. 2015, 80, 141–154. [Google Scholar] [CrossRef]

- Wu, M.; Zhang, Y.; Ji, Y.; She, W.; Yang, L.; Liu, G. A comparable study on the deterioration of limestone powder blended cement under sodium sulfate and magnesium sulfate attack at a low temperature. Constr. Build. Mater. 2020, 243, 118279. [Google Scholar] [CrossRef]

- Alarcon-Ruiz, L.; Platret, G.; Massieu, E.; Ehrlacher, A. The use of thermal analysis in assessing the effect of temperature on a cement paste. Cem. Concr. Res. 2005, 35, 609–613. [Google Scholar] [CrossRef]

- Morandeau, A.; Thiery, M.; Dangla, P. Investigation of the carbonation mechanism of CH and CSH in terms of kinetics, microstructure changes and moisture properties. Cem. Concr. Res. 2014, 56, 153–170. [Google Scholar] [CrossRef] [Green Version]

- Fang, Y.; Chang, J. Microstructure changes of waste hydrated cement paste induced by accelerated carbonation. Constr. Build. Mater. 2015, 76, 360–365. [Google Scholar] [CrossRef]

- Chen, Y.; Gao, J.; Tang, L.; Li, X. Resistance of concrete against combined attack of chloride and sulfate under drying–wetting cycles. Constr. Build. Mater. 2016, 106, 650–658. [Google Scholar] [CrossRef]

- Shi, Z.; Geiker, M.R.; De Weerdt, K.; Østnor, T.A.; Lothenbach, B.; Winnefeld, F.; Skibsted, J. Role of calcium on chloride binding in hydrated Portland cement–metakaolin–limestone blends. Cem. Concr. Res. 2017, 95, 205–216. [Google Scholar] [CrossRef]

- Guan, Y.; Hu, Z.; Zhang, Z.; Chang, J.; Bi, W.; Cheeseman, C.R.; Zhang, T. Effect of hydromagnesite addition on the properties and water resistance of magnesium oxysulfate (MOS) cement. Cem. Concr. Res. 2021, 143, 106387. [Google Scholar] [CrossRef]

- Hu, L.; Yoshitake, I.; Sayama, M.; Sayama, S. Effect of surface bugholes on chloride penetration of concrete coated with penetrants. Mag. Concr. Res. 2021, 74, 217–224. [Google Scholar] [CrossRef]

- Mazer, W.; Lima, M.G.; Medeiros, R.A., Jr.; Wickzick, L.F. Chloride ingress into concrete under different conditions of temperature and marine zones. Mag. Concr. Res. 2021, 73, 1180–1188. [Google Scholar] [CrossRef]

- Elahi, M.M.A.; Shearer, C.R.; AReza, N.R.; Saha, A.K.; Khan, M.N.N.; Hossain, M.M.; Sarker, P.K. Improving the sulfate attack resistance of concrete by using supplementary cementitious materials (SCMs): A review. Constr. Build. Mater. 2021, 281, 122628. [Google Scholar] [CrossRef]

- Tumidajski, P.J.; Chan, G. Durability of high performance concrete in magnesium brine. Cem. Concr. Res. 1996, 26, 557–565. [Google Scholar] [CrossRef]

| Composition | CaO | SiO2 | Al2O3 | Fe2O3 | SO3 | MgO | Cl | Na2O | TiO2 | K2O |

| Content (%) | 60.71 | 20.45 | 4.14 | 2.85 | 2.73 | 1.63 | 0.027 | 0.702 | 0.339 | 0.44 |

| W/C | Water (kg/m3) | Cement (kg/m3) | Standard Sand (kg/m3) |

|---|---|---|---|

| 0.5 | 1 | 2 | 3 |

| Sample | Size (cm) | Purpose |

|---|---|---|

| A | 4 × 4 × 16 | Flexural strength, sulfate concentration, weight and size changes, appearance |

| B | 5 × 5 × 5 | Compressive strength, porosity, SEM-EDS, XRD and TG/DTG analysis |

| Solutions | Internal Attack | |||

|---|---|---|---|---|

| No External Sulfate | External Sulfate Solution | SO42− | Mg2+ | Ca2+ |

| N-CK | E-CK | 0 | 0 | 0 |

| N-IS | E-IS | 3% | 0 | 0 |

| N-ISM | E-ISM | 3% | 3% | 0 |

| N-ISG | E-ISG | 3% | 0 | 3% |

| N-ISMG | E-ISMG | 3% | 3% | 3% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, G.; Guo, M.; Li, S.; Weng, X.; Ding, S.; Han, F.; Wang, H. Influence of Ca2+ on Early Degradation of Cast-In-Situ Mortar Induced by Sulfate-Magnesium Multiple Combined Attack. Materials 2022, 15, 5752. https://doi.org/10.3390/ma15165752

Zhao G, Guo M, Li S, Weng X, Ding S, Han F, Wang H. Influence of Ca2+ on Early Degradation of Cast-In-Situ Mortar Induced by Sulfate-Magnesium Multiple Combined Attack. Materials. 2022; 15(16):5752. https://doi.org/10.3390/ma15165752

Chicago/Turabian StyleZhao, Gaowen, Mengzhen Guo, Shaomin Li, Xiaolin Weng, Shijun Ding, Fangzhou Han, and Haoran Wang. 2022. "Influence of Ca2+ on Early Degradation of Cast-In-Situ Mortar Induced by Sulfate-Magnesium Multiple Combined Attack" Materials 15, no. 16: 5752. https://doi.org/10.3390/ma15165752

APA StyleZhao, G., Guo, M., Li, S., Weng, X., Ding, S., Han, F., & Wang, H. (2022). Influence of Ca2+ on Early Degradation of Cast-In-Situ Mortar Induced by Sulfate-Magnesium Multiple Combined Attack. Materials, 15(16), 5752. https://doi.org/10.3390/ma15165752