Novel Composites of Poly(vinyl chloride) with Carbon Fibre/Carbon Nanotube Hybrid Filler

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Production of the Hybrid Filler

2.3. Production of PVC Composites with the Hybrid Filler

2.4. Characterisation of the Hybrid Filler and PVC Composites

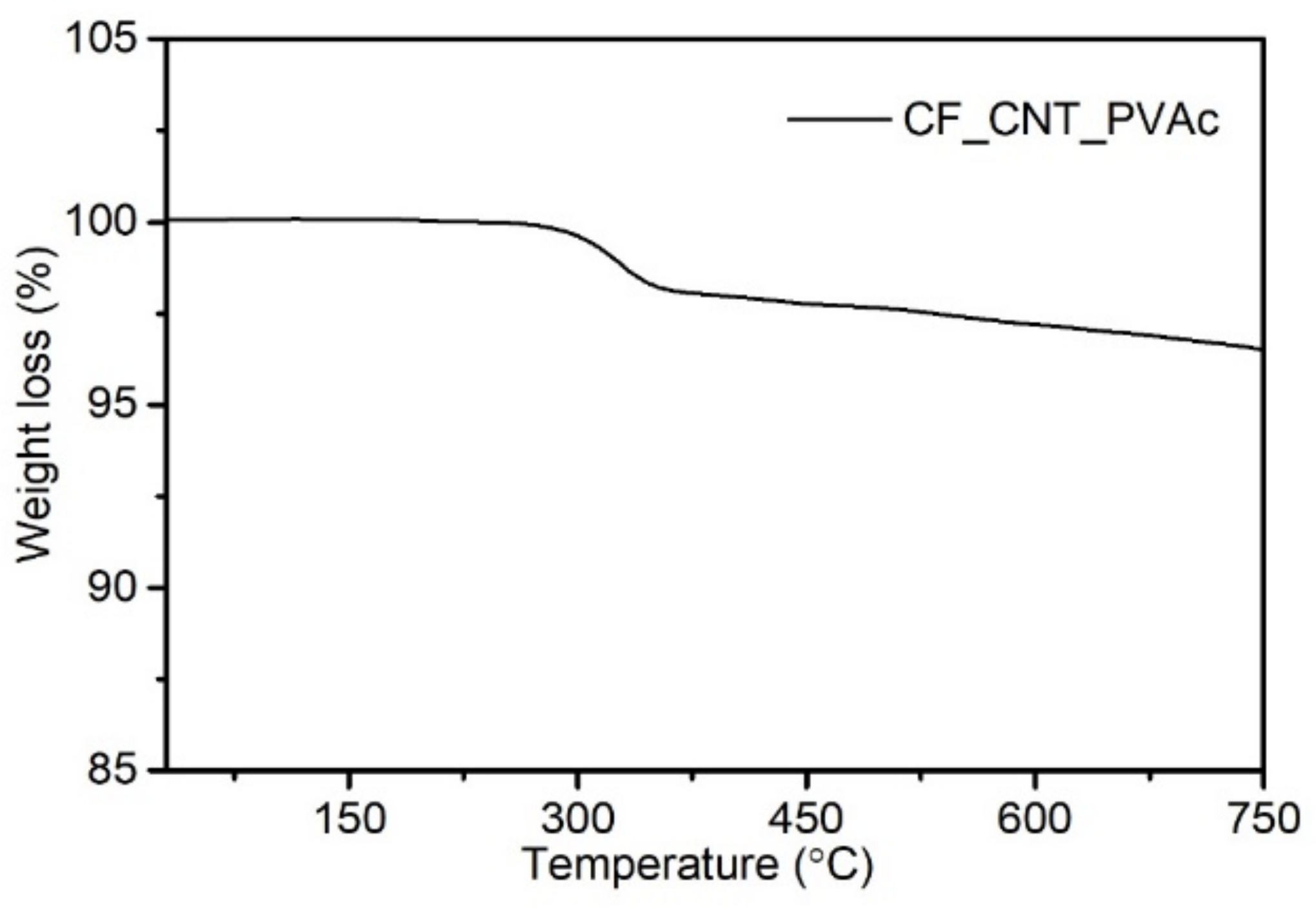

2.4.1. Thermogravimetric Analysis

2.4.2. Determination of Mechanical Properties

2.4.3. Determination of Thermal Stability

2.4.4. Dynamical Mechanical Analysis (DMA)

2.4.5. Determination of Glass Transition Temperature by the DSC Method

2.4.6. Scanning Electron Microscopy (SEM)

2.4.7. Filler and Composite Testing by the Raman Spectroscopy Method

2.4.8. Electrical Properties

3. Test Results and Discussion

3.1. Results of the Hybrid Filler Analysis

3.2. Results of PVC/Hybrid Filler Testing

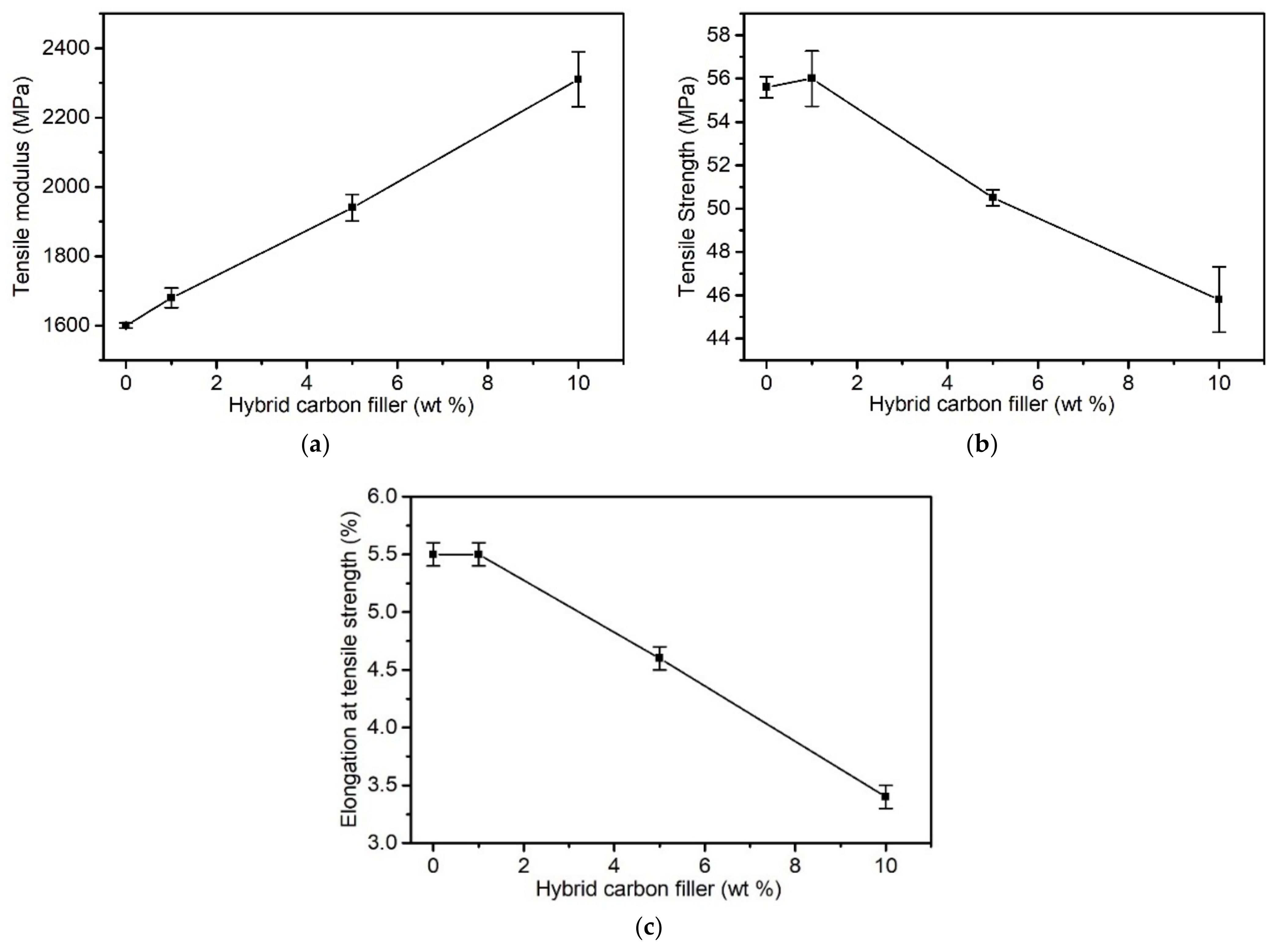

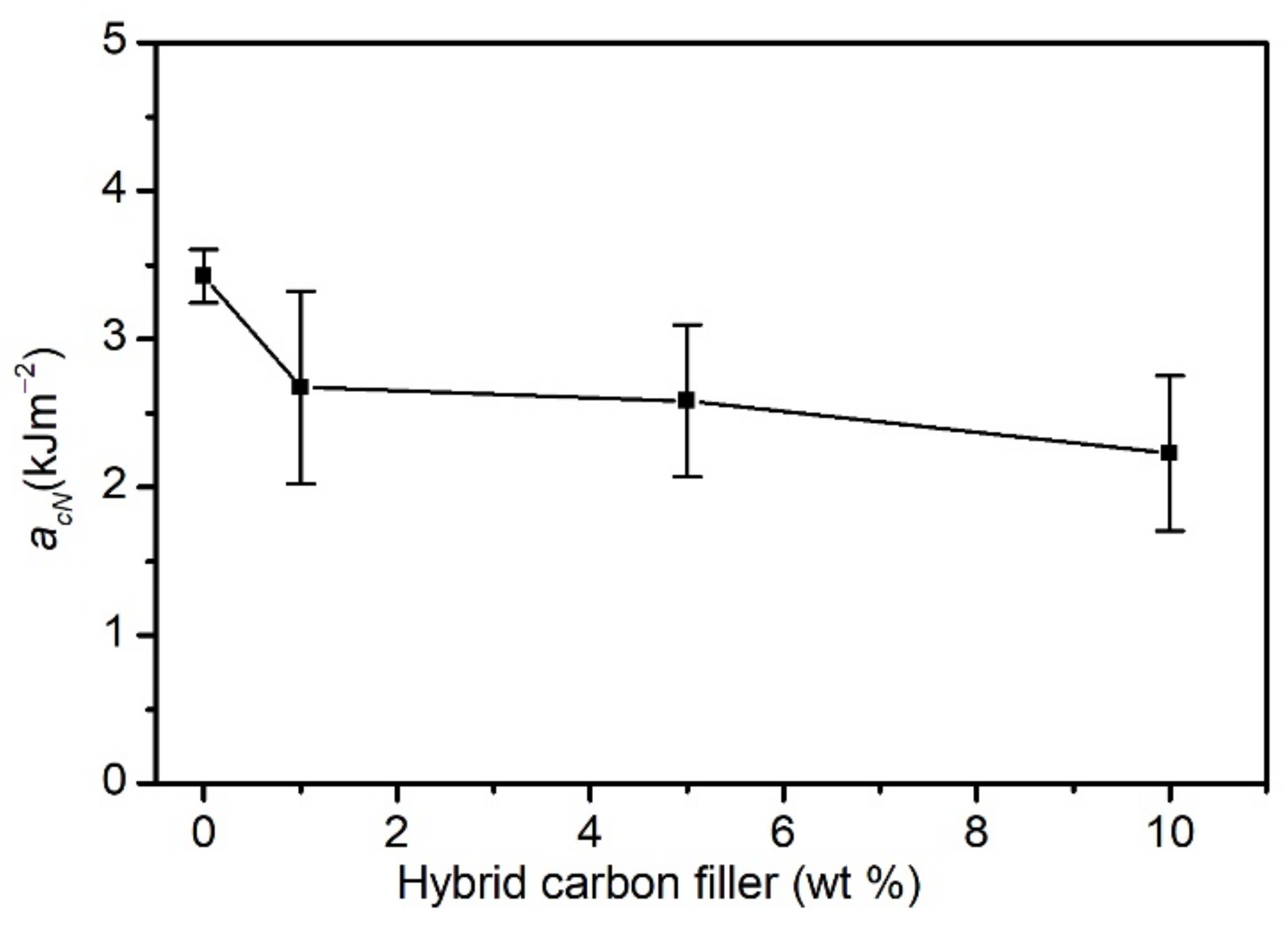

3.2.1. Mechanical Properties

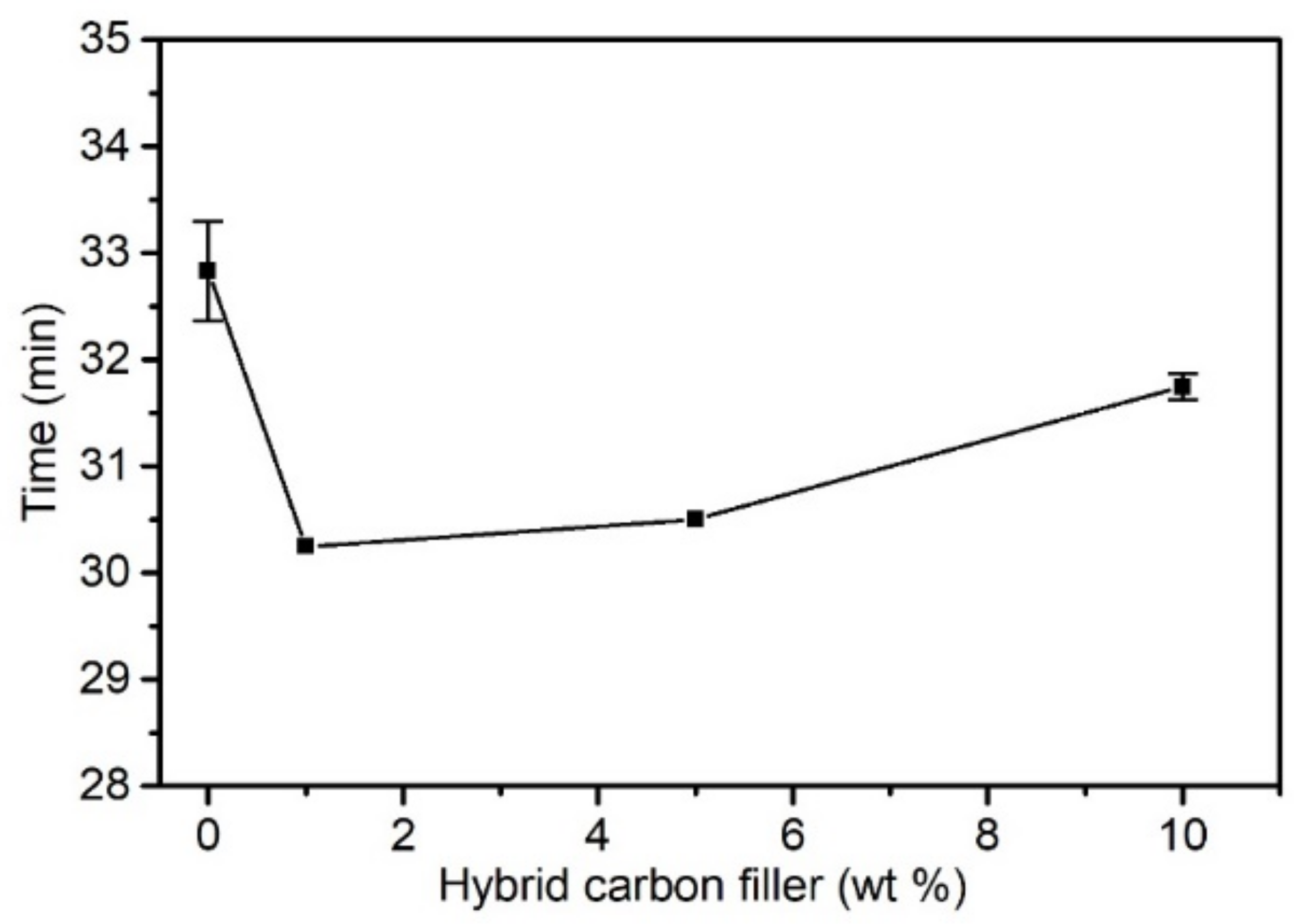

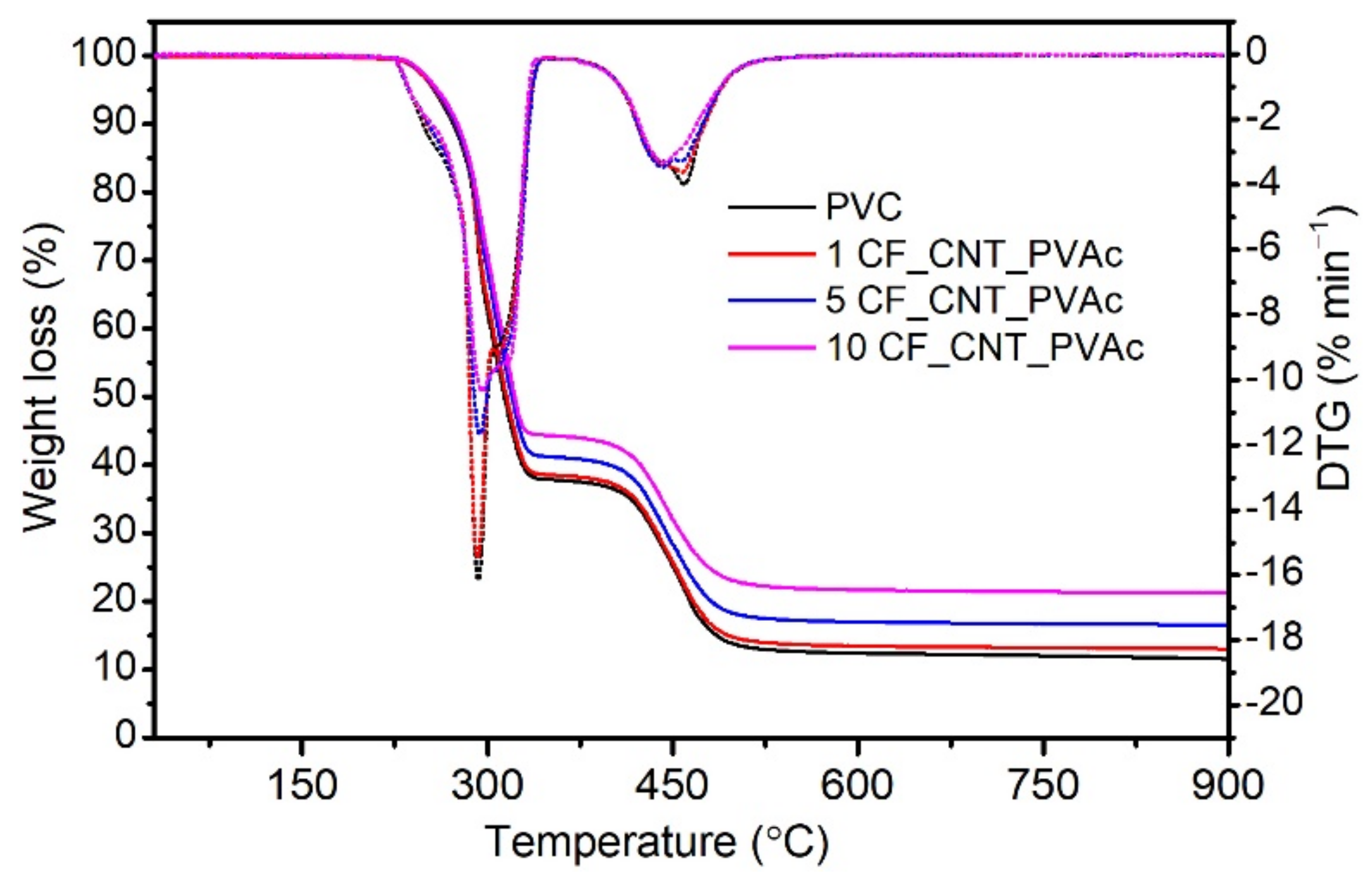

3.2.2. Results of Thermal Stability Testing

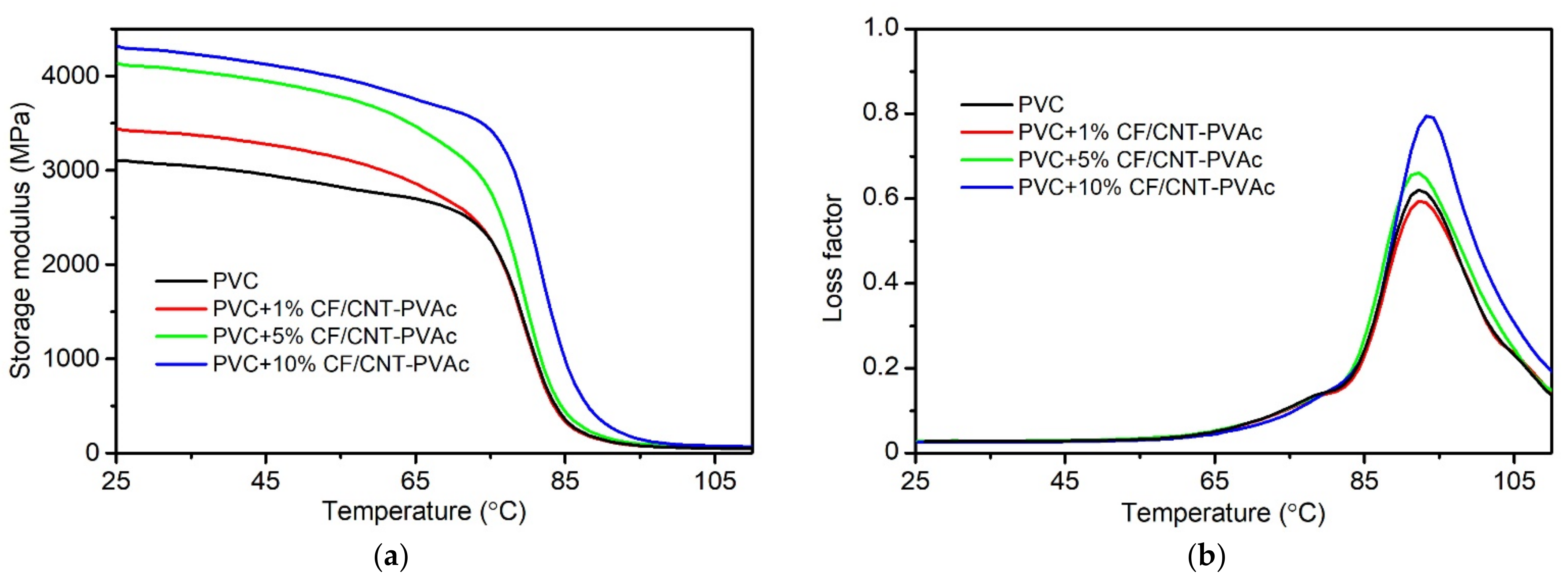

3.2.3. Results of DMA Analysis

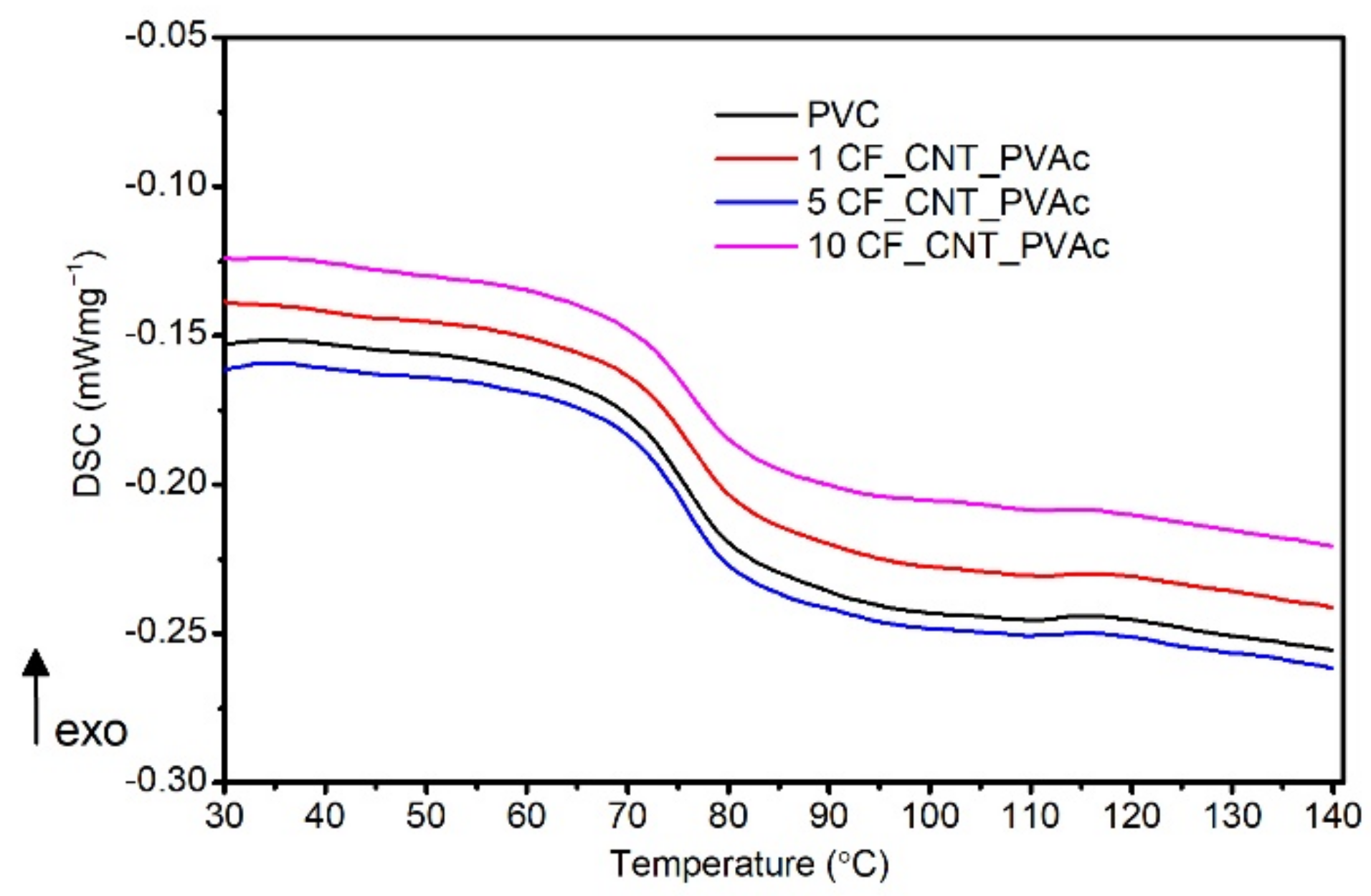

3.2.4. Results of Tg Testing by DSC Method

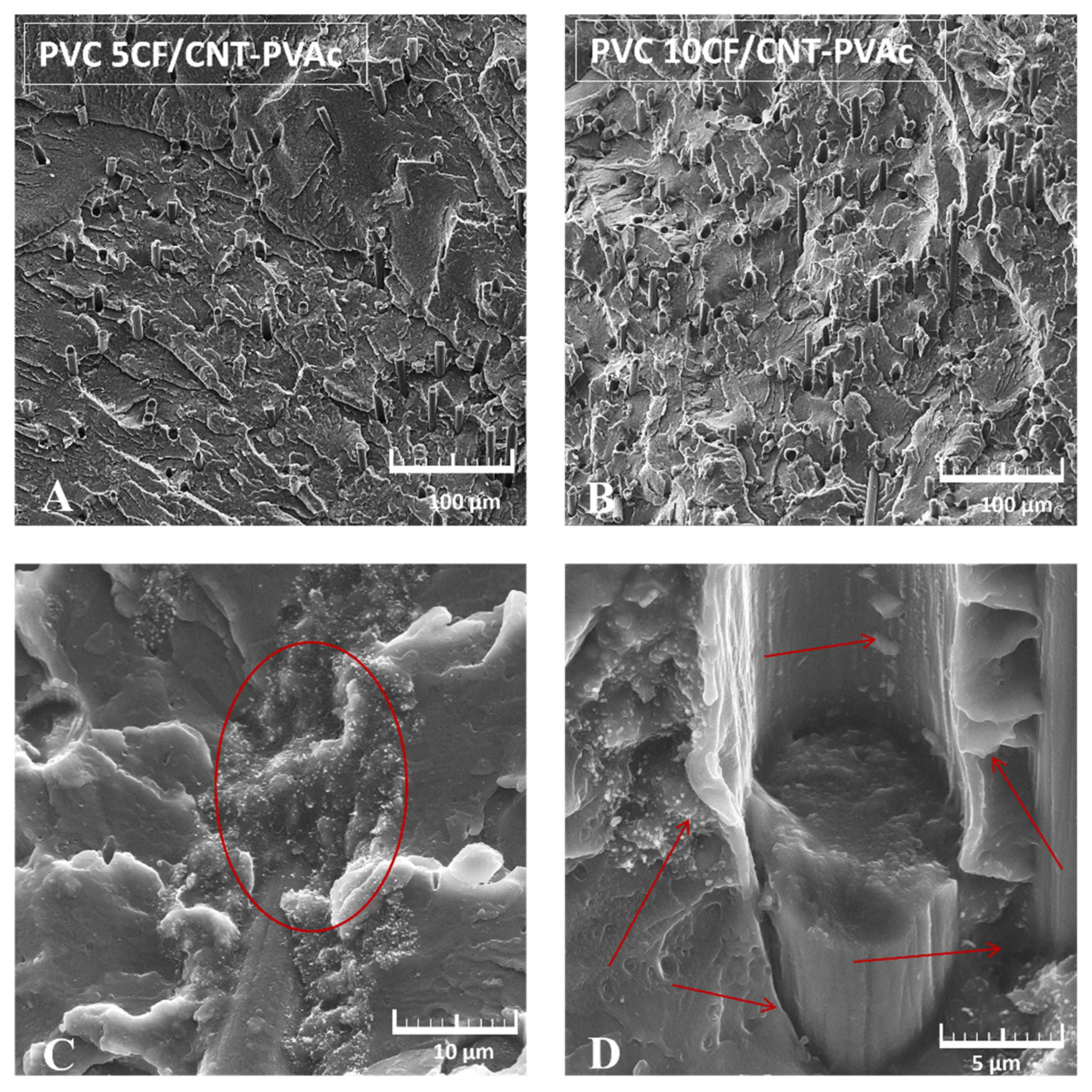

3.2.5. Analysis of PVC/Hybrid Filler Structure by SEM Observations

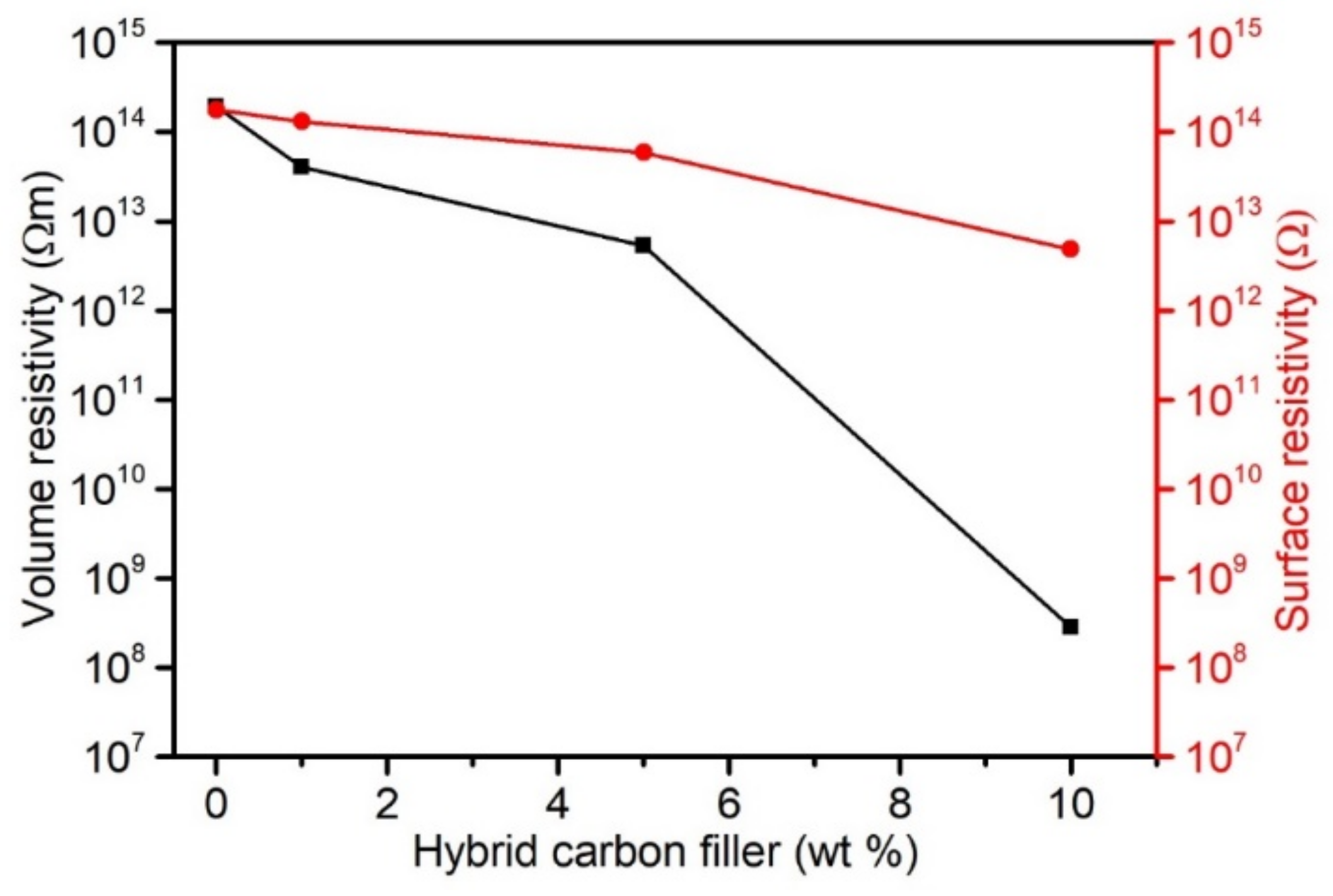

3.2.6. Analysis of Electrical Properties

3.2.7. Results of Raman Spectroscopy

4. Conclusions

- The proposed method of hybrid filler production enabled the deposition of CNTs on the CF surface; however, its distribution was not homogeneous. The CNT aggregates present in the hybrid filler were characterised by a loose structure, and their distribution was fairly homogeneous.

- By using PVAc as an adhesive, it was possible to achieve partial distribution of carbon nanotubes on the CF’s surface. In addition, its presence can contribute to an increase in the filler–matrix adhesive influence.

- PVC composites with a carbon hybrid filler are characterised by a substantially higher rigidity and comparable impact strength when compared to PVC. No improved tensile strength was identified, which was due to the filler’s anisotropic distribution, uneven adhesion, and wettability, but also due to the presence of carbon aggregates which acted as a discontinuity of the composite structure.The thermal stability analysis allowed for the conclusion that the developed filler did not shorten the thermal stability, but it slightly increased its temperature (T5).

- A slight increase in the Tg of the composites’ matrix observed at the maximum share of hybrid filler in the matrix was related to the increased share of nanofiller and its interaction with the matrix’s macromolecules.

- The hybrid filler substantially changed the materials’ electrical properties, thereby lowering the volume resistivity. The proposed method of hybrid filler production did not cause structural defects in the filler’s components, but it increased the quality of nanoparticle dispersion, thereby enabling the creation of a conductive, interpenetrating network on micro and nanometric scales.

- Further research will be focused on developing a method of modifying the carbon hybrid filler to improve its mechanical properties and to maintain its electrical properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mirowski, J.; Oliwa, R.; Oleksy, M.; Rój, E.; Tomaszewska, J.; Mizera, K.; Ryszkowska, J. Composites of poly(Vinyl chloride) with residual hops after supercritical extraction in CO2. Polymers 2021, 13, 2736. [Google Scholar] [CrossRef] [PubMed]

- Edraki, M.; Sheydaei, M.; Alinia-Ahandani, E.; Nezhadghaffar-Borhani, E. Polyvinyl chloride: Chemical modification and investigation of structural and thermal properties. J. Sulfur Chem. 2021, 42, 397–409. [Google Scholar] [CrossRef]

- Sterzyński, T.; Tomaszewska, J.; Andrzejewski, J.; Skórczewska, K. Evaluation of glass transition temperature of PVC/POSS nanocomposites. Compos. Sci. Technol. 2015, 117, 398–403. [Google Scholar] [CrossRef]

- Wypych, G. PVC Degradation and Stabilization, 3rd ed.; ChemTec Publishing: Toronto, ON, Canada, 2015; ISBN 9781927885000. [Google Scholar]

- Polyvinyl Chloride Industry Installed Capacity and Capital Expenditure (CapEx) Forecast by Region and Countries Including Details of All Active Plants, Planned and Announced Projects, 2022–2026. Available online: https://www.globaldata.com/store/report/polyvinyl-chloride-market-analysis/ (accessed on 10 August 2022).

- Lewandowski, K.; Skórczewska, K. A Brief Review of Poly(Vinyl Chloride) (PVC) Recycling. Polymers 2022, 14, 3035. [Google Scholar] [CrossRef]

- IPEX. Chemical Resistance Guide. Thermoplastic: Polyvinyl Chloride, 1st ed.; IPEX: Oakville, ON, Canada, 2020. [Google Scholar]

- Patrick, S.G. Practical Guide to Polyvinyl Chloride; Rapra Technology Limited: Shawbury, UK, 2005; ISBN 1-85957-511-01. [Google Scholar]

- Miliute-Plepiene, J.; Fråne, A.; Almasi, A.M. Overview of polyvinyl chloride (PVC) waste management practices in the Nordic countries. Clean. Eng. Technol. 2021, 4, 100246. [Google Scholar] [CrossRef]

- Bolat, H.; Erkus, P. Use of polyvinyl chloride (PVC) powder and granules as aggregate replacement in concrete mixtures. Sci. Eng. Compos. Mater. 2016, 23, 209–216. [Google Scholar] [CrossRef]

- Hajibabaei, M.; Nazif, S.; Tavanaei Sereshgi, F. Life cycle assessment of pipes and piping process in drinking water distribution networks to reduce environmental impact. Sustain. Cities Soc. 2018, 43, 538–549. [Google Scholar] [CrossRef]

- Alam, S.; Allouche, E.N. Experimental Investigation of Pipe Soil Friction Coefficients for Direct Buried PVC Pipes. In Pipelines 2010; American Society of Civil Engineers: Reston, VA, USA, 2010; Volume 386, pp. 1160–1169. [Google Scholar]

- Basfar, A. Flame retardancy of radiation cross-linked poly(vinyl chloride) (PVC) used as an insulating material for wire and cable. Polym. Degrad. Stab. 2002, 77, 221–226. [Google Scholar] [CrossRef]

- Beneš, M.; Plaček, V.; Matuschek, G.; Kettrup, A.; Györyová, K.; Balek, V. Characterization of PVC cable insulation materials and products obtained after removal of additives. J. Appl. Polym. Sci. 2006, 99, 788–795. [Google Scholar] [CrossRef]

- Beneš, M.; Plaček, V.; Matuschek, G.; Kettrup, A.A.; Györyová, K.; Emmerich, W.D.; Balek, V. Lifetime simulation and thermal characterization of PVC cable insulation materials. J. Therm. Anal. Calorim. 2005, 82, 761–768. [Google Scholar] [CrossRef]

- Moustafa, H.; Morsy, M.; Ateia, M.A.; Abdel-Haleem, F.M. Ultrafast response humidity sensors based on polyvinyl chloride/graphene oxide nanocomposites for intelligent food packaging. Sens. Actuators A Phys. 2021, 331, 112918. [Google Scholar] [CrossRef]

- Tomaszewska, J.; Sterzyński, T.; Walczak, D. Thermal stability of nanosilica-modified poly(Vinyl chloride). Polymers 2021, 13, 2057. [Google Scholar] [CrossRef]

- Karmalm, P.; Hjertberg, T.; Jansson, A.; Dahl, R. Thermal stability of poly(vinyl chloride) with epoxidised soybean oil as primary plasticizer. Polym. Degrad. Stab. 2009, 94, 2275–2281. [Google Scholar] [CrossRef]

- Mirowski, J.; Oliwa, R.; Oleksy, M.; Tomaszewska, J.; Ryszkowska, J.; Budzik, G. Poly(Vinyl chloride) composites with raspberry pomace filler. Polymers 2021, 13, 1079. [Google Scholar] [CrossRef]

- Iulianelli, G.C.V.; MacIel, P.D.M.C.; Tavares, M.I.B. Preparation and characterization of PVC/natural filler composites. In Macromolecular Symposia; WILEY-VCH Verlag: Wehenheim, Germany, 2011; Volume 299–300, pp. 227–233. [Google Scholar]

- Khalil, H.A.; Tehrani, M.; Davoudpour, Y.; Bhat, A.; Jawaid, M.; Hassan, A. Natural fiber reinforced poly(vinyl chloride) composites: A review. J. Reinf. Plast. Compos. 2013, 32, 330–356. [Google Scholar] [CrossRef]

- Visakh, P.M.; Darie-Nita, R.N. Polyvinylchloride (PVC)-Based Blends: State of Art, New Challenges and Opportunities. In Polyvinylchloride-Based Blends; Springer International Publishing: Cham, Switzerland, 2022; pp. 1–17. [Google Scholar]

- Wilczewski, S.; Skórczewska, K.; Tomaszewska, J.; Lewandowski, K. Structure and properties of poly(vinyl chloride)/graphene nanocomposites. Polym. Test. 2020, 81, 106282. [Google Scholar] [CrossRef]

- Wilczewski, S.; Skórczewska, K.; Tomaszewska, J.; Lewandowski, K.; Szulc, J.; Runka, T. Manufacturing homogenous PVC/graphene nanocomposites using a novel dispersion agent. Polym. Test. 2020, 91, 106868. [Google Scholar] [CrossRef]

- Tomaszewska, J.; Sterzyński, T.; Skórczewska, K. Effect of Polyhedral Oligomeric Silsesquioxanes Nanoparticles on Thermal and Mechanical Properties of Poly(vinyl chloride) Composite Materials. J. Vinyl Addit. Technol. 2019, 25, E48–E54. [Google Scholar] [CrossRef]

- Hajibeygi, M.; Maleki, M.; Shabanian, M.; Ducos, F.; Vahabi, H. New polyvinyl chloride (PVC) nanocomposite consisting of aromatic polyamide and chitosan modified ZnO nanoparticles with enhanced thermal stability, low heat release rate and improved mechanical properties. Appl. Surf. Sci. 2018, 439, 1163–1179. [Google Scholar] [CrossRef]

- Taha, T.A. Optical properties of PVC/Al2O3 nanocomposite films. Polym. Bull. 2019, 76, 903–918. [Google Scholar] [CrossRef]

- Djidjelli, H.; Boukerrou, A.; Founas, R.; Rabouhi, A.; Kaci, M.; Farenc, J.; Martinez-Vega, J.J.; Benachour, D. Preparation and characterization of poly(vinyl chloride)/virgin and treated sisal fiber composites. J. Appl. Polym. Sci. 2007, 103, 3630–3636. [Google Scholar] [CrossRef]

- Rimdusit, S.; Damrongsakkul, S.; Wongmanit, P.; Saramas, D.; Tiptipakorn, S. Characterization of coconut fiber-filled polyvinyl chloride/acrylonitrile styrene acrylate blends. J. Reinf. Plast. Compos. 2011, 30, 1691–1702. [Google Scholar] [CrossRef]

- Lewandowski, K.; Zajchowski, S.; Mirowski, J.; Kościuszko, A. Studies of processing properties of PVC/wood composites. Chemik 2011, 64, 333–336. [Google Scholar]

- Yotkaew, P.; Kositchaiyong, A.; Wimolmala, E.; Rosarpitak, V.; Sombatsompop, N. Use of synthetic fibers as co-reinforcing agents in wood/PVC hybrid composites: Effect on tribological properties. J. Reinf. Plast. Compos. 2014, 33, 964–976. [Google Scholar] [CrossRef]

- Chen, Q.; Linghu, T.; Gao, Y.; Wang, Z.; Liu, Y.; Du, R.; Zhao, G. Mechanical properties in glass fiber PVC-foam sandwich structures from different chopped fiber interfacial reinforcement through vacuum-assisted resin transfer molding (VARTM) processing. Compos. Sci. Technol. 2017, 144, 202–207. [Google Scholar] [CrossRef]

- Ráthy, I.; Kuki, Á.; Borda, J.; Deák, G.; Zsuga, M.; Marossy, K.; Kéki, S. Preparation and characterization of poly(vinyl chloride)-continuous carbon fiber composites. J. Appl. Polym. Sci. 2012, 124, 190–194. [Google Scholar] [CrossRef]

- Zhang, J.; Cheng, B. Synthesis of Ag@SrFe12O19@carbon fiber microwave absorption composite and its application in PVC resin. J. Mater. Sci. Mater. Electron. 2017, 28, 18944–18950. [Google Scholar] [CrossRef]

- Tanaka, K.; Yamaguchi, M.; Hayashi, K.; Adachi, K. Mechanical properties of poly(vinyl chloride) filled with pitch-based carbon short fibers. Adv. Compos. Mater. 1992, 2, 85–101. [Google Scholar] [CrossRef]

- Ramnath, B.V.; Kesavan, A.; Chinnadurai, E. Mechanical and thermal properties of PVC and polyurethane foam hybrid composites. Mater. Test. 2020, 62, 544–552. [Google Scholar] [CrossRef]

- Pekdemir, M.E. Synthesis, Characterization and Thermal Behavior of Carbon Fiber Reinforced Poly(vinyl chloride) and Poly(ε-Caprolactone). Fibers Polym. 2021, 22, 2861–2868. [Google Scholar] [CrossRef]

- Kiani, M.; Parvaneh, V.; Abbasi, M.; Dadrasi, A. Fabrication and investigation of the mechanical properties of PVC/carbon fiber/graphene nanocomposite pipes for oil and gas applications. J. Thermoplast. Compos. Mater. 2020, 35, 1263–1278. [Google Scholar] [CrossRef]

- Guoquan, W.; Peng, Z. Electrical conductivity of poly(vinyl chloride) plastisol-short carbon fiber composite. Polym. Eng. Sci. 1997, 37, 96–100. [Google Scholar] [CrossRef]

- Mousavi, S.R.; Estaji, S.; Paydayesh, A.; Arjmand, M.; Jafari, S.H.; Nouranian, S.; Khonakdar, H.A. A review of recent progress in improving the fracture toughness of epoxy-based composites using carbonaceous nanofillers. Polym. Compos. 2022, 43, 1871–1886. [Google Scholar] [CrossRef]

- Sayam, A.; Rahman, A.N.M.M.; Rahman, M.S.; Smriti, S.A.; Ahmed, F.; Rabbi, M.F.; Hossain, M.; Faruque, M.O. A review on carbon fiber-reinforced hierarchical composites: Mechanical performance, manufacturing process, structural applications and allied challenges. Carbon Lett. 2022, 32, 1173–1205. [Google Scholar] [CrossRef]

- Ismail, A.H.M.; AL-Oqla, F.M.; Risby, M.S.; Sapuan, S.M. On the enhancement of the fatigue fracture performance of polymer matrix composites by reinforcement with carbon nanotubes: A systematic review. Carbon Lett. 2022, 32, 727–740. [Google Scholar] [CrossRef]

- Lemartinel, A.; Castro, M.; Fouché, O.; De-Luca, J.-C.; Feller, J.-F. A Review of Nanocarbon-Based Solutions for the Structural Health Monitoring of Composite Parts Used in Renewable Energies. J. Compos. Sci. 2022, 6, 32. [Google Scholar] [CrossRef]

- Joshi, G.M.; Deshmukh, K. Optimized Quality Factor of Graphene Oxide-Reinforced PVC Nanocomposite. J. Electron. Mater. 2014, 43, 1161–1165. [Google Scholar] [CrossRef]

- Seeponkai, N.; Wootthikanokkhan, J.; Thanachayanont, C. Synthesis and characterization of fullerene functionalized poly(vinyl chloride) (PVC) and dehydrochlorinated PVC using atom transfer radical addition and AIBN based fullerenation. J. Appl. Polym. Sci. 2013, 130, 2410–2421. [Google Scholar] [CrossRef]

- Skórczewska, K.; Chmielewska, D.; Piszczek, K.; Tomaszewska, J. Obtaining PVC/CNT nanocomposites with the use of dispersing agents. Chemik 2011, 65, 337–342. [Google Scholar]

- Haruna, H.; Pekdemir, M.E.; Tukur, A.; Coşkun, M. Characterization, thermal and electrical properties of aminated PVC/oxidized MWCNT composites doped with nanographite. J. Therm. Anal. Calorim. 2020, 139, 3887–3895. [Google Scholar] [CrossRef]

- Harris, P.J.F. Carbon Nanotube Science: Carbon Nanotube Science Synthesis, Properties and Applications; Cambridge University Press: Cambridge, UK, 2009; ISBN 9780521535854. [Google Scholar]

- Endo, M.; Iijima, S.; Dresselhaus, M. Carbon Nanotubes, 1st ed.; Elsevier Science Ltd.: Amsterdam, The Netherlands, 1996; ISBN 0080426824. [Google Scholar]

- Sharma, H.; Kumar, A.; Rana, S.; Guadagno, L. An Overview on Carbon Fiber-Reinforced Epoxy Composites: Effect of Graphene Oxide Incorporation on Composites Performance. Polymers 2022, 14, 1548. [Google Scholar] [CrossRef]

- Zheng, H.; Zhang, W.; Li, B.; Zhu, J.; Wang, C.; Song, G.; Wu, G.; Yang, X.; Huang, Y.; Ma, L. Recent advances of interphases in carbon fiber-reinforced polymer composites: A review. Compos. Part B Eng. 2022, 233, 109639. [Google Scholar] [CrossRef]

- Khan, A.; Saxena, K.K. A review on enhancement of mechanical properties of fiber reinforcement polymer composite under different loading rates. Mater. Today Proc. 2022, 56, 2316–2322. [Google Scholar] [CrossRef]

- Montes-Morán, M.A.; Young, R.J. Raman spectroscopy study of HM carbon fibres: Effect of plasma treatment on the interfacial properties of single fibre/epoxy composites. Carbon. 2002, 40, 845–855. [Google Scholar] [CrossRef]

- Zakaria, M.R.; Md Akil, H.; Abdul Kudus, M.H.; Ullah, F.; Javed, F.; Nosbi, N. Hybrid carbon fiber-carbon nanotubes reinforced polymer composites: A review. Compos. Part B Eng. 2019, 176, 107313. [Google Scholar] [CrossRef]

- Zhang, R.L.; Huang, Y.D.; Liu, L.; Tang, Y.R.; Su, D.; Xu, L.W. Effect of the molecular weight of sizing agent on the surface of carbon fibres and interface of its composites. Appl. Surf. Sci. 2011, 257, 1840–1844. [Google Scholar] [CrossRef]

- Lamorinière, S.; Jones, M.P.; Ho, K.; Kalinka, G.; Shaffer, M.S.P.; Bismarck, A. Carbon nanotube enhanced carbon Fibre-Poly(ether ether ketone) interfaces in model hierarchical composites. Compos. Sci. Technol. 2022, 221, 109327. [Google Scholar] [CrossRef]

- Yousefi, N.; Fisher, S.J.; Burgstaller, C.; Shaffer, M.S.P.; Bismarck, A. Hierarchical carbon fibre composites incorporating high loadings of carbon nanotubes. Compos. Sci. Technol. 2022, 222, 109369. [Google Scholar] [CrossRef]

- Hu, Y.; Wei, Y.; Han, G.; Zhang, J.; Sun, G.; Hu, X.; Cheng, F. Comparison of impact resistance of carbon fibre composites with multiple ultra-thin CNT, aramid pulp, PBO and graphene interlayers. Compos. Part A Appl. Sci. Manuf. 2022, 155, 106815. [Google Scholar] [CrossRef]

- Jin, S.-Y.; Young, R.J.; Eichhorn, S.J. Hybrid carbon fibre–carbon nanotube composite interfaces. Compos. Sci. Technol. 2014, 95, 114–120. [Google Scholar] [CrossRef]

- Qian, H.; Bismarck, A.; Greenhalgh, E.S.; Shaffer, M.S.P. Carbon nanotube grafted carbon fibres: A study of wetting and fibre fragmentation. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1107–1114. [Google Scholar] [CrossRef]

- Pawlik, M.; Le, H.; Lu, Y. Effects of the graphene nanoplatelets reinforced interphase on mechanical properties of carbon fibre reinforced polymer–A multiscale modelling study. Compos. Part B Eng. 2019, 177, 107097. [Google Scholar] [CrossRef]

- Sánchez-Romate, X.F.; Del Bosque, A.; Artigas-Arnaudas, J.; Muñoz, B.K.; Sánchez, M.; Ureña, A. A proof of concept of a structural supercapacitor made of graphene coated woven carbon fibers: EIS study and mechanical performance. Electrochim. Acta 2021, 370, 137746. [Google Scholar] [CrossRef]

- Islam, M.S.; Deng, Y.; Tong, L.; Faisal, S.N.; Roy, A.K.; Minett, A.I.; Gomes, V.G. Grafting carbon nanotubes directly onto carbon fibers for superior mechanical stability: Towards next generation aerospace composites and energy storage applications. Carbon N. Y. 2016, 96, 701–710. [Google Scholar] [CrossRef]

- He, X.; Zhang, F.; Wang, R.; Liu, W. Preparation of a carbon nanotube/carbon fiber multi-scale reinforcement by grafting multi-walled carbon nanotubes onto the fibers. Carbon 2007, 45, 2559–2563. [Google Scholar] [CrossRef]

- Jin, Y.; Sun, T.; Do, H.; Hwa, J. Electrical conductivity of chemically modified multiwalled carbon nanotube/epoxy composites. Carbon 2005, 43, 23–30. [Google Scholar] [CrossRef]

- Liu, W.; Zhang, S.; Hao, L.; Yang, F.; Jiao, W.; Li, X.; Wang, R. Fabrication of carbon nanotubes/carbon fiber hybrid fiber in industrial scale by sizing process. Appl. Surf. Sci. 2013, 284, 914–920. [Google Scholar] [CrossRef]

- Wu, Z.; Cui, H.; Chen, L.; Jiang, D.; Weng, L.; Ma, Y.; Li, X.; Zhang, X.; Liu, H.; Wang, N.; et al. Interfacially reinforced unsaturated polyester carbon fiber composites with a vinyl ester-carbon nanotubes sizing agent. Compos. Sci. Technol. 2018, 164, 195–203. [Google Scholar] [CrossRef]

- Tang, H.; Zhou, H.; Cheng, X. Friction process analysis of carbon fiber-carbon nanotube multiscale hybrid reinforced epoxy with excellent tribological performance. Tribol. Int. 2022, 171, 107559. [Google Scholar] [CrossRef]

- Kim, J.; Cha, J.; Chung, B.; Ryu, S.; Hong, S.H. Fabrication and mechanical properties of carbon fiber/epoxy nanocomposites containing high loadings of noncovalently functionalized graphene nanoplatelets. Compos. Sci. Technol. 2020, 192, 108101. [Google Scholar] [CrossRef]

- Tefera, G.; Bright, G.; Adali, S. Flexural and shear properties of CFRP laminates reinforced with functionalized multiwalled CNTs. Nanocomposites 2021, 7, 141–153. [Google Scholar] [CrossRef]

- Qin, J.; Wang, C.; Yao, Z.; Ma, Z.; Gao, Q.; Wang, Y.; Wang, Q.; Wei, H. Growing carbon nanotubes on continuous carbon fibers to produce composites with improved interfacial properties: A step towards commercial production and application. Compos. Sci. Technol. 2021, 211, 108870. [Google Scholar] [CrossRef]

- Pozegic, T.R.; Anguita, J.V.; Hamerton, I.; Jayawardena, K.D.G.I.; Chen, J.-S.; Stolojan, V.; Ballocchi, P.; Walsh, R.; Silva, S.R.P. Multi-Functional Carbon Fibre Composites using Carbon Nanotubes as an Alternative to Polymer Sizing. Sci. Rep. 2016, 6, 37334. [Google Scholar] [CrossRef]

- Siddiqui, N.A.; Sham, M.-L.; Tang, B.Z.; Munir, A.; Kim, J.-K. Tensile strength of glass fibres with carbon nanotube–epoxy nanocomposite coating. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1606–1614. [Google Scholar] [CrossRef]

- Nguyen-Tran, H.-D.; Hoang, V.-T.; Do, V.-T.; Chun, D.-M.; Yum, Y.-J. Effect of Multiwalled Carbon Nanotubes on the Mechanical Properties of Carbon Fiber-Reinforced Polyamide-6/Polypropylene Composites for Lightweight Automotive Parts. Materials 2018, 11, 429. [Google Scholar] [CrossRef]

- Petrény, R.; Mészáros, L. Moisture dependent tensile and creep behaviour of multi-wall carbon nanotube and carbon fibre reinforced, injection moulded polyamide 6 matrix multi-scale composites. J. Mater. Res. Technol. 2022, 16, 689–699. [Google Scholar] [CrossRef]

- Petrény, R.; Almásy, L.; Mészáros, L. Investigation of the interphase structure in polyamide 6–matrix, multi-scale composites. Compos. Sci. Technol. 2022, 225, 109489. [Google Scholar] [CrossRef]

- Naji, A.; Krause, B.; Pötschke, P.; Ameli, A. Hybrid conductive filler/polycarbonate composites with enhanced electrical and thermal conductivities for bipolar plate applications. Polym. Compos. 2019, 40, 3189–3198. [Google Scholar] [CrossRef]

- Yang, R.; Chen, F.; Iqbal, M.I.; Wang, L.; Zhang, C.; Bao, H. The Effect of Carbon Fibre Reinforced on Polyamide1012. J. Fiber Bioeng. Inform. 2018, 11, 41–47. [Google Scholar] [CrossRef]

- Li, Q.; Church, J.S.; Naebe, M.; Fox, B.L. Interfacial characterization and reinforcing mechanism of novel carbon nanotube–Carbon fibre hybrid composites. Carbon 2016, 109, 74–86. [Google Scholar] [CrossRef]

- Boroujeni, A.Y.; Tehrani, M.; Nelson, A.J.; Al-Haik, M. Hybrid carbon nanotube-carbon fiber composites with improved in-plane mechanical properties. Compos. Part B Eng. 2014, 66, 475–483. [Google Scholar] [CrossRef]

- Abdelghany, A.M.; Meikhail, M.S.; Asker, N. Synthesis and structural-biological correlation of PVC\PVAc polymer blends. J. Mater. Res. Technol. 2019, 8, 3908–3916. [Google Scholar] [CrossRef]

- Ziv, E.; Attia, D.; Vasilyev, G.; Mendelson, O.; Zussman, E.; Yerushalmi-Rozen, R. The role of polymer-solvent interactions in polyvinyl-alcohol dispersions of multi-wall carbon nanotubes: From coagulant to dispersant. Soft Matter 2019, 15, 47–54. [Google Scholar] [CrossRef] [PubMed]

- ISO 527-1:2012; Plastics-Determination of Tensile Properties-Part 1: General Principles. International Organization for Standardization: Brussels, Belgium, 2012.

- ISO 527-2:2012; Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics. International Organization for Standardization: Brussels, Belgium, 2012.

- ISO 179-1:2010; Plastics—Determination of Charpy impact properties—Part 1: Non-Instrumented Impact Test. International Organization for Standardization: Brussels, Belgium, 2010.

- Ferry, J.D. Viscoelastic Properties of Polymers, 3rd ed.; John Wiley and Sons: New York, NY, USA, 1980; ISBN 9780471048947. [Google Scholar]

- Sterzyński, T.; Tomaszewska, J.; Piszczek, K.; Skórczewska, K. The influence of carbon nanotubes on the PVC glass transition temperature. Compos. Sci. Technol. 2010, 70, 966–969. [Google Scholar] [CrossRef]

- Moya, R.; Rodríguez-Zúñiga, A.; Vega-Baudrit, J. Effects of Adding Multiwall Carbon Nanotubes on Performance of Polyvinyl Acetate and Urea-Formaldehyde Adhesives in Tropical Timber Species. J. Nanomater. 2015, 2015, 290. [Google Scholar] [CrossRef]

- Schlange, A.; dos Santos, A.R.; Kunz, U.; Turek, T. Continuous preparation of carbon-nanotube-supported platinum catalysts in a flow reactor directly heated by electric current. Beilstein J. Org. Chem. 2011, 7, 1412–1420. [Google Scholar] [CrossRef]

- Kitiyanan, B.; Alvarez, W.E.; Harwell, J.H.; Resasco, D.E. Controlled production of single-wall carbon nanotubes by catalytic decomposition of CO on bimetallic Co–Mo catalysts. Chem. Phys. Lett. 2000, 317, 497–503. [Google Scholar] [CrossRef]

- Alig, I.; Pötschke, P.; Lellinger, D.; Skipa, T.; Pegel, S.; Kasaliwal, G.R.; Villmow, T. Establishment, morphology and properties of carbon nanotube networks in polymer melts. Polymer 2012, 53, 4–28. [Google Scholar] [CrossRef]

- Lewandowski, K.; Skórczewska, K.; Piszczek, K.; Urbaniak, W. Recycled glass fibres from wind turbines as a filler for poly(Vinyl chloride). Adv. Polym. Technol. 2019, 2019, 8960503. [Google Scholar] [CrossRef]

- Yu, J.; Sun, L.; Ma, C.; Qiao, Y.; Yao, H. Thermal degradation of PVC: A review. Waste Manag. 2016, 48, 300–314. [Google Scholar] [CrossRef]

- Vasanthkumar, M.S.; Bhatia, R.; Arya, V.P.; Sameera, I.; Prasad, V.; Jayanna, H.S. Characterization, charge transport and magnetic properties of multi-walled carbon nanotube–polyvinyl chloride nanocomposites. Phys. E Low-Dimens. Syst. Nanostructures 2014, 56, 10–16. [Google Scholar] [CrossRef]

- Ganjali, M.R.; Pirzadeh-Naeeni, S.; Faridbod, F.; Attar, H.; Hosseini, M.; Norouzi, P. Nano-composite carbon paste electrode and PVC membrane sensor for potentiometric determination of erythromycin. Int. J. Electrochem. Sci. 2011, 6, 1968–1980. [Google Scholar]

- Salavagione, H.J.; Ellis, G.; Martínez, G. Poly(vinyl chloride)/Multiwalled Carbon Nanotube Nanocomposites: Effect of the Tacticity Distribution on the Polymer/Nanofiller Interface. J. Phys. Chem. C 2012, 116, 18256–18262. [Google Scholar] [CrossRef]

- Petrény, R.; Mészáros, L. The effect of microstructure on the dynamic mechanical properties of carbon fiber and carbon nanotube reinforced multi-scale composites with a polyamide 6 matrix. IOP Conf. Ser. Mater. Sci. Eng. 2020, 903, 012021. [Google Scholar] [CrossRef]

- Hornbostel, B.; Pötschke, P.; Kotz, J.; Roth, S. Mechanical properties of triple composites of polycarbonate, single-walled carbon nanotubes and carbon fibres. Phys. E Low-Dimens. Syst. Nanostructures 2008, 40, 2434–2439. [Google Scholar] [CrossRef]

- Tomaszewska, J.; Sterzyński, T.; Woźniak-Braszak, A.; Banaszak, M. Review of Recent Developments of Glass Transition in PVC Nanocomposites. Polymers 2021, 13, 4336. [Google Scholar] [CrossRef]

- Kamae, T.; Drzal, L.T. Carbon fiber/epoxy composite property enhancement through incorporation of carbon nanotubes at the fiber-matrix interphase–Part II: Mechanical and electrical properties of carbon nanotube coated carbon fiber composites. Compos. Part A Appl. Sci. Manuf. 2022, 160, 107023. [Google Scholar] [CrossRef]

- Mamunya, Y.P.; Levchenko, V.V.; Rybak, A.; Boiteux, G.; Lebedev, E.V.; Ulanski, J.; Seytre, G. Electrical and thermomechanical properties of segregated nanocomposites based on PVC and multiwalled carbon nanotubes. J. Non. Cryst. Solids 2010, 356, 635–641. [Google Scholar] [CrossRef]

- Abdullah, E.T.; Naje, A.N. AC electrical and dielectric properties of PVC-MWCNT nanocomposites. Indian J. Sci. Technol. 2011, 4, 731–735. [Google Scholar] [CrossRef]

- Broza, G.; Piszczek, K.; Schulte, K.; Sterzynski, T. Nanocomposites of poly(vinyl chloride) with carbon nanotubes (CNT). Compos. Sci. Technol. 2007, 67, 890–894. [Google Scholar] [CrossRef]

- Krause, B.; Rzeczkowski, P.; Pötschke, P. Thermal Conductivity and Electrical Resistivity of Melt-Mixed Polypropylene Composites Containing Mixtures of Carbon-Based Fillers. Polymers 2019, 11, 1073. [Google Scholar] [CrossRef]

- Haghgoo, M.; Ansari, R.; Hassanzadeh-Aghdam, M.K. Prediction of electrical conductivity of carbon fiber-carbon nanotube-reinforced polymer hybrid composites. Compos. Part B Eng. 2019, 167, 728–735. [Google Scholar] [CrossRef]

- Singh, A.K.; Yasri, N.; Karan, K.; Roberts, E.P.L. Electrocatalytic Activity of Functionalized Carbon Paper Electrodes and Their Correlation to the Fermi Level Derived from Raman Spectra. ACS Appl. Energy Mater. 2019, 2, 2324–2336. [Google Scholar] [CrossRef]

- Dresselhaus, M.S.; Jorio, A.; Saito, R. Characterizing Graphene, Graphite, and Carbon Nanotubes by Raman Spectroscopy. Annu. Rev. Condens. Matter Phys. 2010, 1, 89–108. [Google Scholar] [CrossRef]

- Melanitis, N.; Tetlow, P.L.; Galiotis, C. Characterization of PAN-based carbon fibres with laser Raman spectroscopy. J. Mater. Sci. 1996, 31, 851–860. [Google Scholar] [CrossRef]

- Lee, S.-H.; Lee, S.-M.; Roh, J.-S. Microstructure of Milled Polyacrylonitrile-Based Carbon Fiber Analyzed by Micro-Raman Spectroscopy and TEM. Materials 2021, 14, 4711. [Google Scholar] [CrossRef]

- Naim, A.F.A.; Alfannakh, H.; Arafat, S.; Ibrahim, S.S. Characterization of PVC/MWCNTs Nanocomposite: Solvent Blend. Sci. Eng. Compos. Mater. 2020, 27, 55–64. [Google Scholar] [CrossRef]

| Filler Content (wt%) | T5 (°C) | T10 (°C) | T50 (°C) | TDTG (°C) | RM at 900 °C (%) |

|---|---|---|---|---|---|

| 0 | 254.5 | 270.4 | 313.8 | 291.5 | 11.3 |

| 1 | 258.1 | 274.3 | 315.2 | 291.1 | 13.2 |

| 5 | 259.2 | 274.5 | 319.8 | 292.5 | 16.6 |

| 10 | 260.1 | 275.8 | 321.8 | 292.3 | 21.3 |

| Filler Content (wt%) | E′ 25 °C (MPa) | E′ 40 °C (MPa) | E′ 60 °C (MPa) | E′ 80 °C (MPa) | E′ 90 °C (MPa) | Tg E′ (°C) | Tg tanδ (°C) |

|---|---|---|---|---|---|---|---|

| 0 | 3115.0 | 3008.5 | 2769.4 | 1268.8 | 144.4 | 74.9 | 92.3 |

| 1 | 3427.1 | 3335.0 | 3017.6 | 1232.3 | 138.1 | 73.6 | 92.6 |

| 5 | 4117.6 | 4008.0 | 3658.1 | 1512.8 | 179.0 | 73.7 | 92.0 |

| 10 | 4296.4 | 4186.6 | 3878.2 | 2517.0 | 334.1 | 76.6 | 93.6 |

| Filler Content (wt%) | Tg Mid (°C) | Tg Infl (°C) |

|---|---|---|

| 0 | 75.7 | 75.4 |

| 1 | 75.9 | 75.3 |

| 5 | 75.8 | 74.5 |

| 10 | 76.2 | 77.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skórczewska, K.; Lewandowski, K.; Wilczewski, S. Novel Composites of Poly(vinyl chloride) with Carbon Fibre/Carbon Nanotube Hybrid Filler. Materials 2022, 15, 5625. https://doi.org/10.3390/ma15165625

Skórczewska K, Lewandowski K, Wilczewski S. Novel Composites of Poly(vinyl chloride) with Carbon Fibre/Carbon Nanotube Hybrid Filler. Materials. 2022; 15(16):5625. https://doi.org/10.3390/ma15165625

Chicago/Turabian StyleSkórczewska, Katarzyna, Krzysztof Lewandowski, and Sławomir Wilczewski. 2022. "Novel Composites of Poly(vinyl chloride) with Carbon Fibre/Carbon Nanotube Hybrid Filler" Materials 15, no. 16: 5625. https://doi.org/10.3390/ma15165625

APA StyleSkórczewska, K., Lewandowski, K., & Wilczewski, S. (2022). Novel Composites of Poly(vinyl chloride) with Carbon Fibre/Carbon Nanotube Hybrid Filler. Materials, 15(16), 5625. https://doi.org/10.3390/ma15165625