The Mechanism of Wear Reduction in the Ni-CaF2 Composite Material: Raman and Confocal Microscopy Insights

Abstract

1. Introduction

2. Experimental Methods

2.1. Powder Metallurgy

2.2. Wear Tests

2.3. SEM and EDS Analysis

2.4. Confocal Microscopy

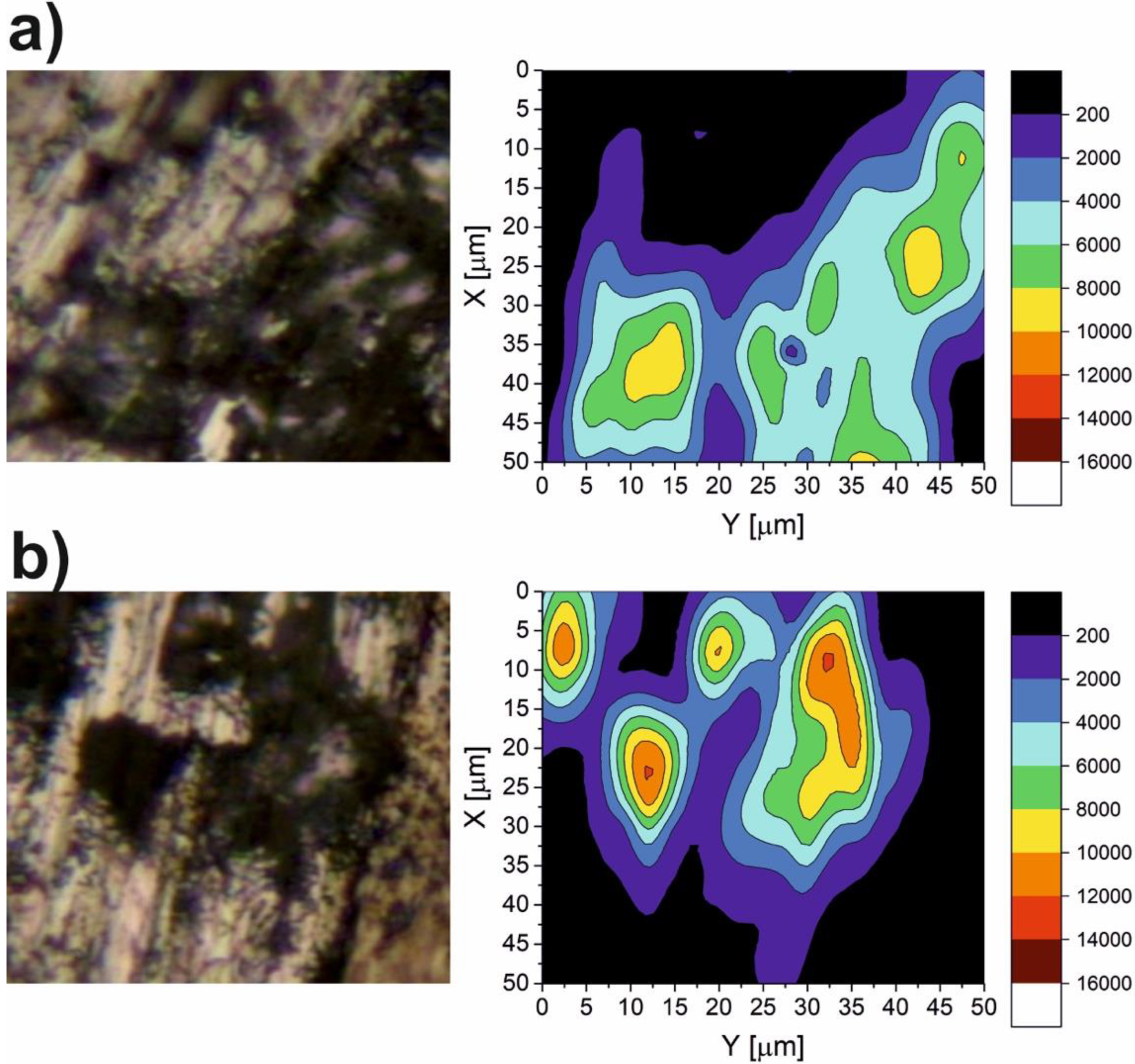

2.5. Raman Spectroscopy

3. Results and Discussion

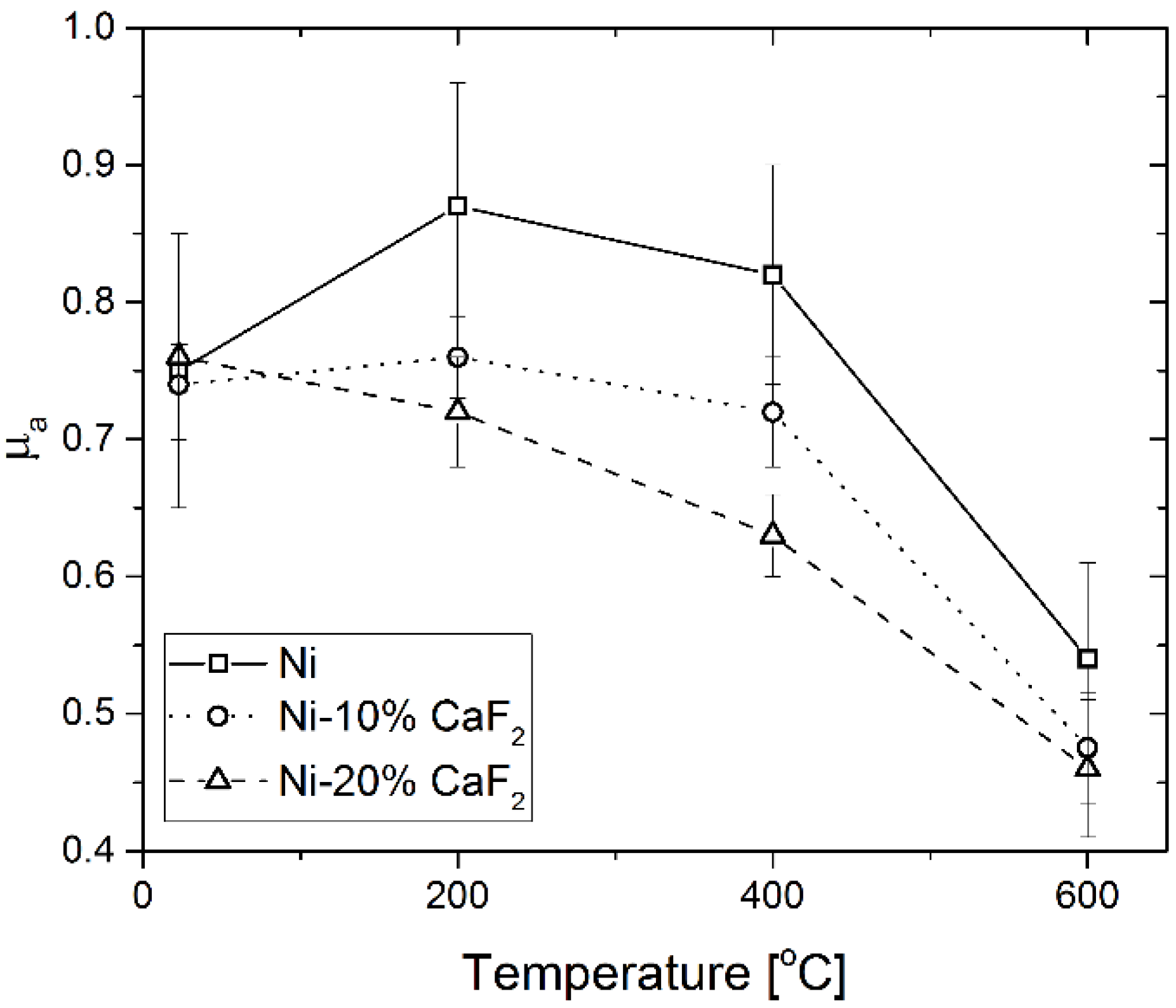

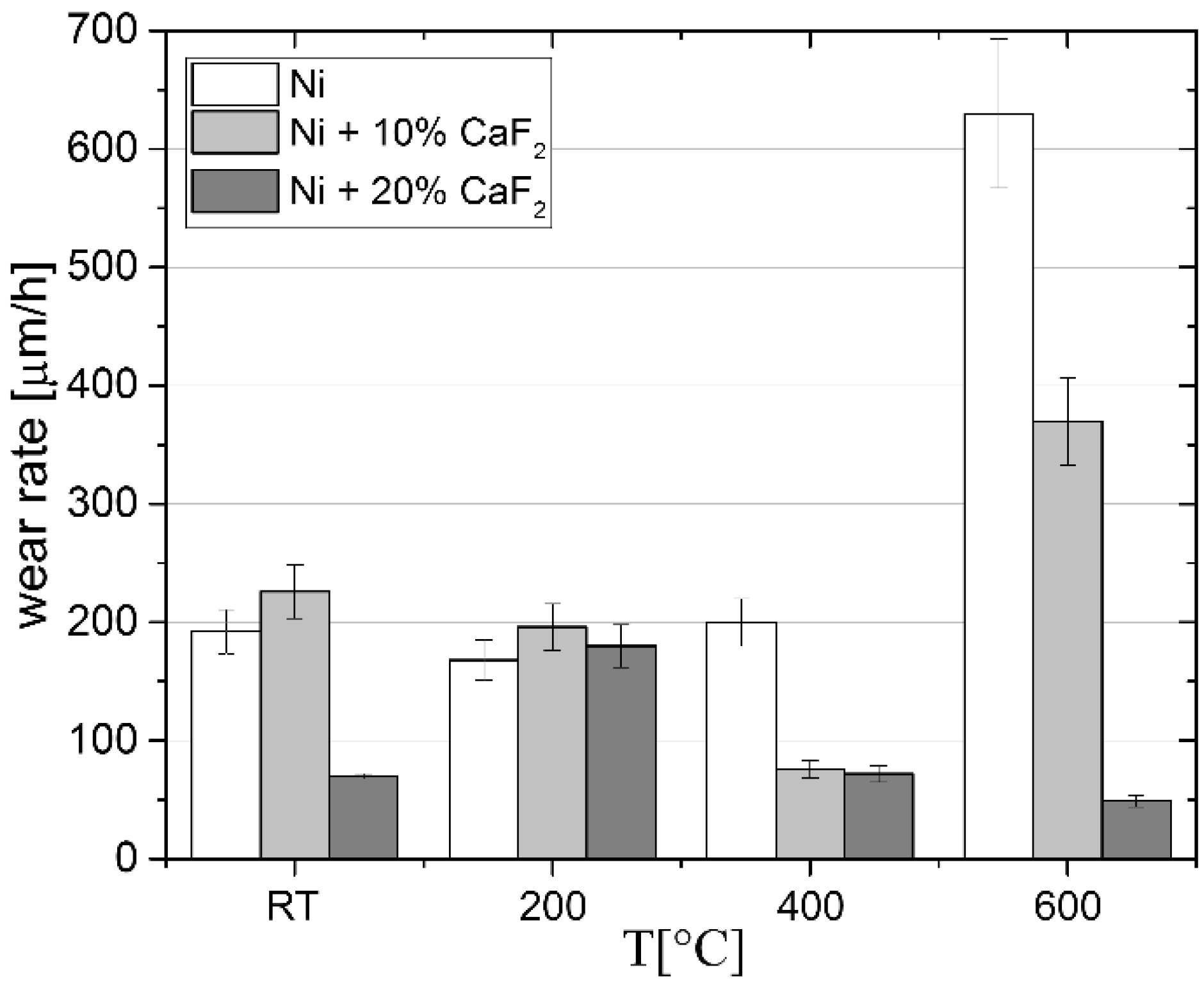

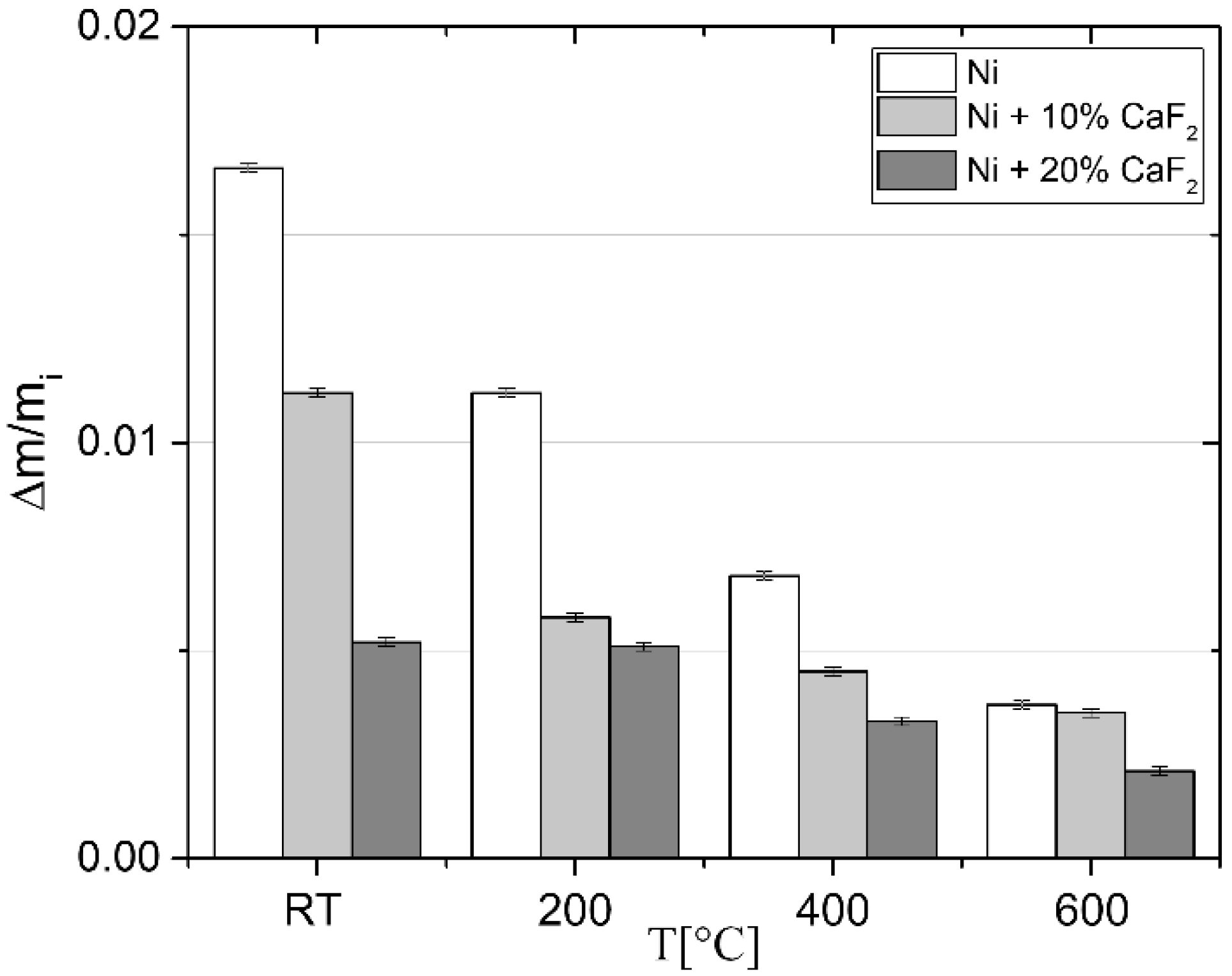

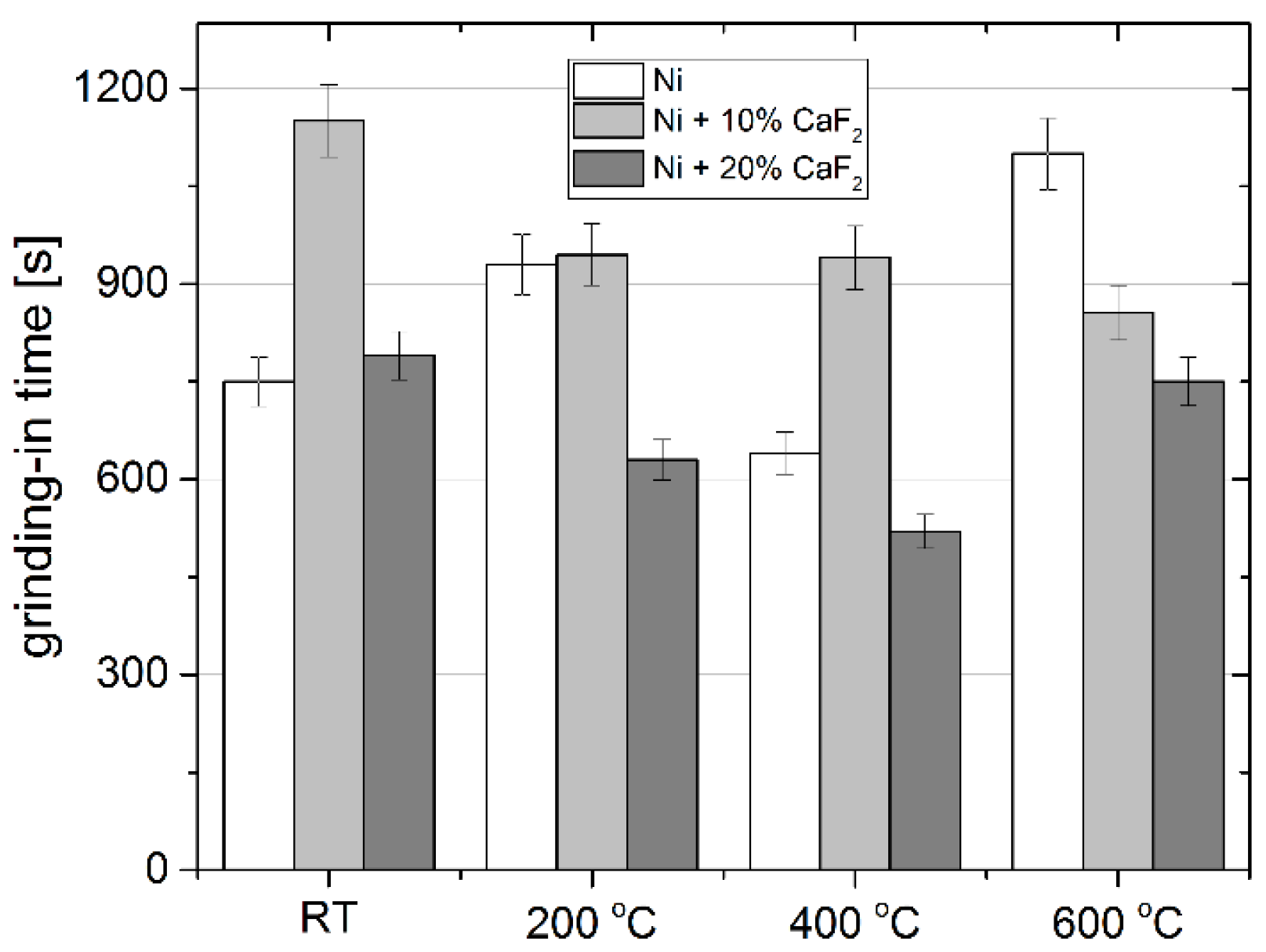

3.1. Wear Tests

- -

- ∆m—mass loss (mg),

- -

- mi—initial mass of counter-sample (mg),

- -

- mf—final mass of counter-sample (mg).

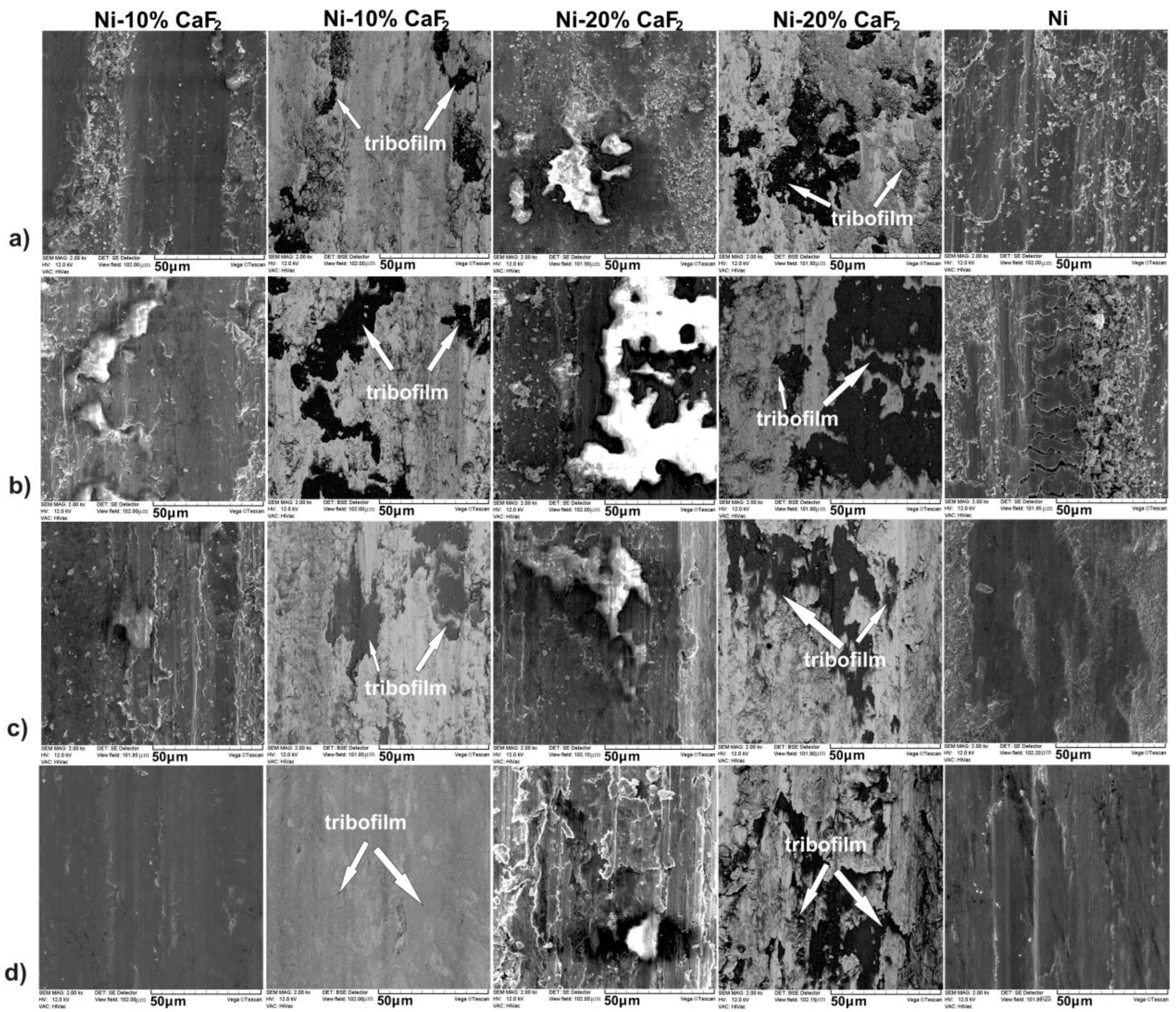

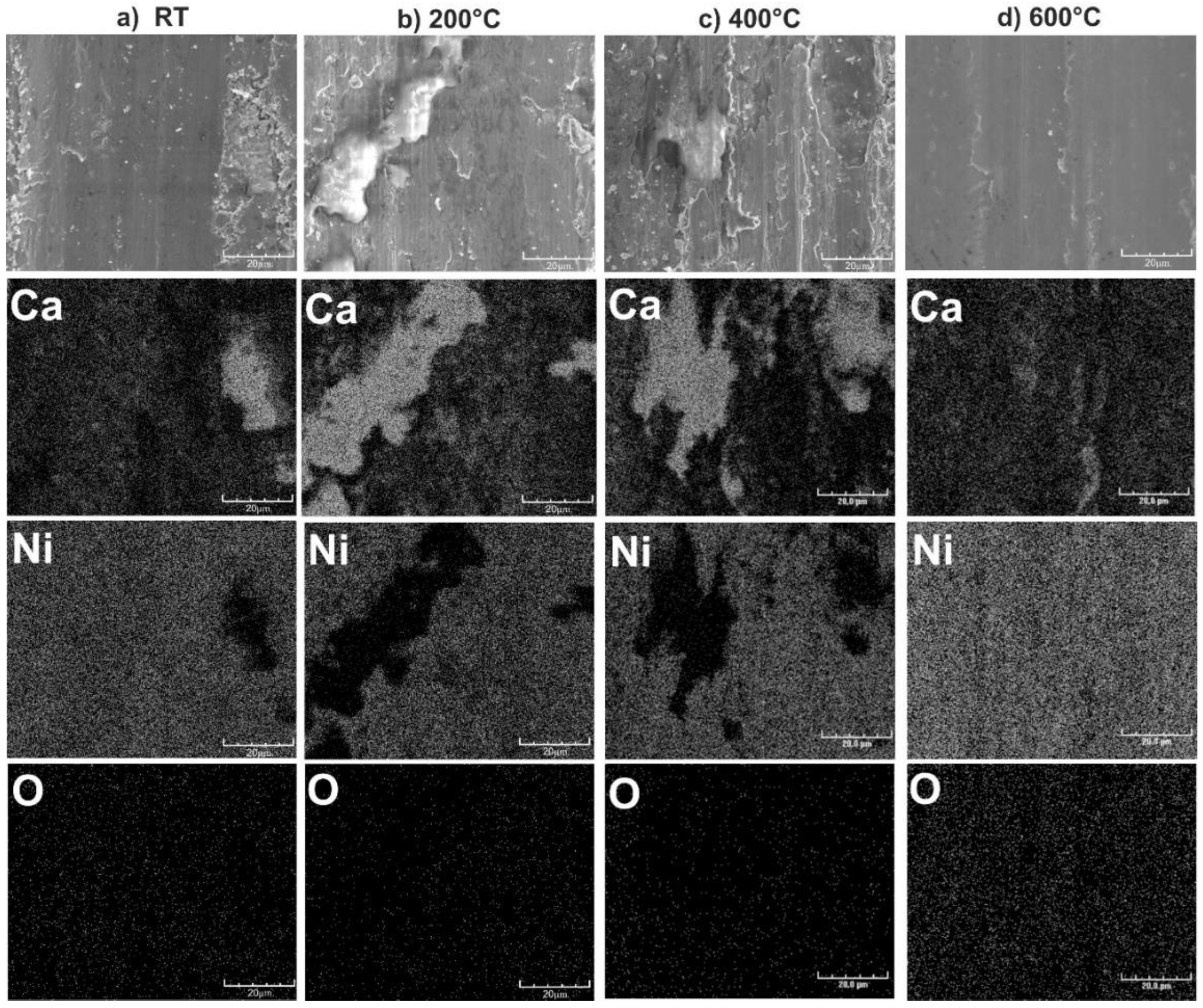

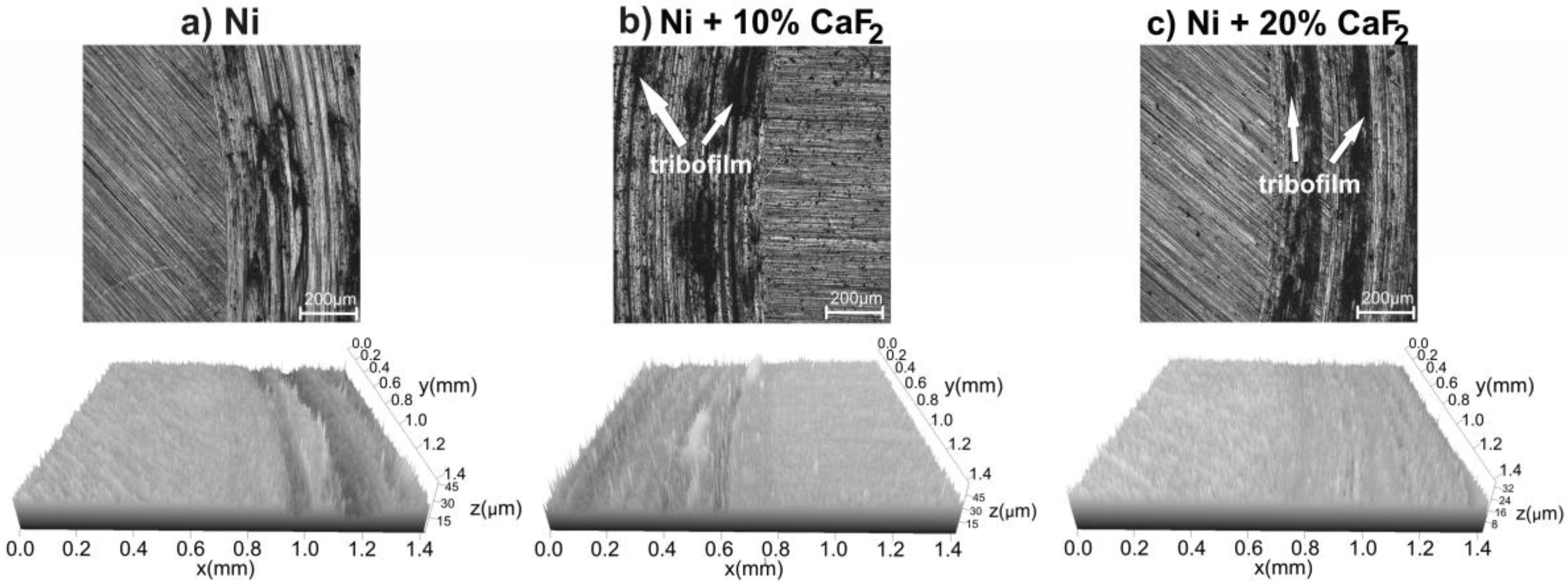

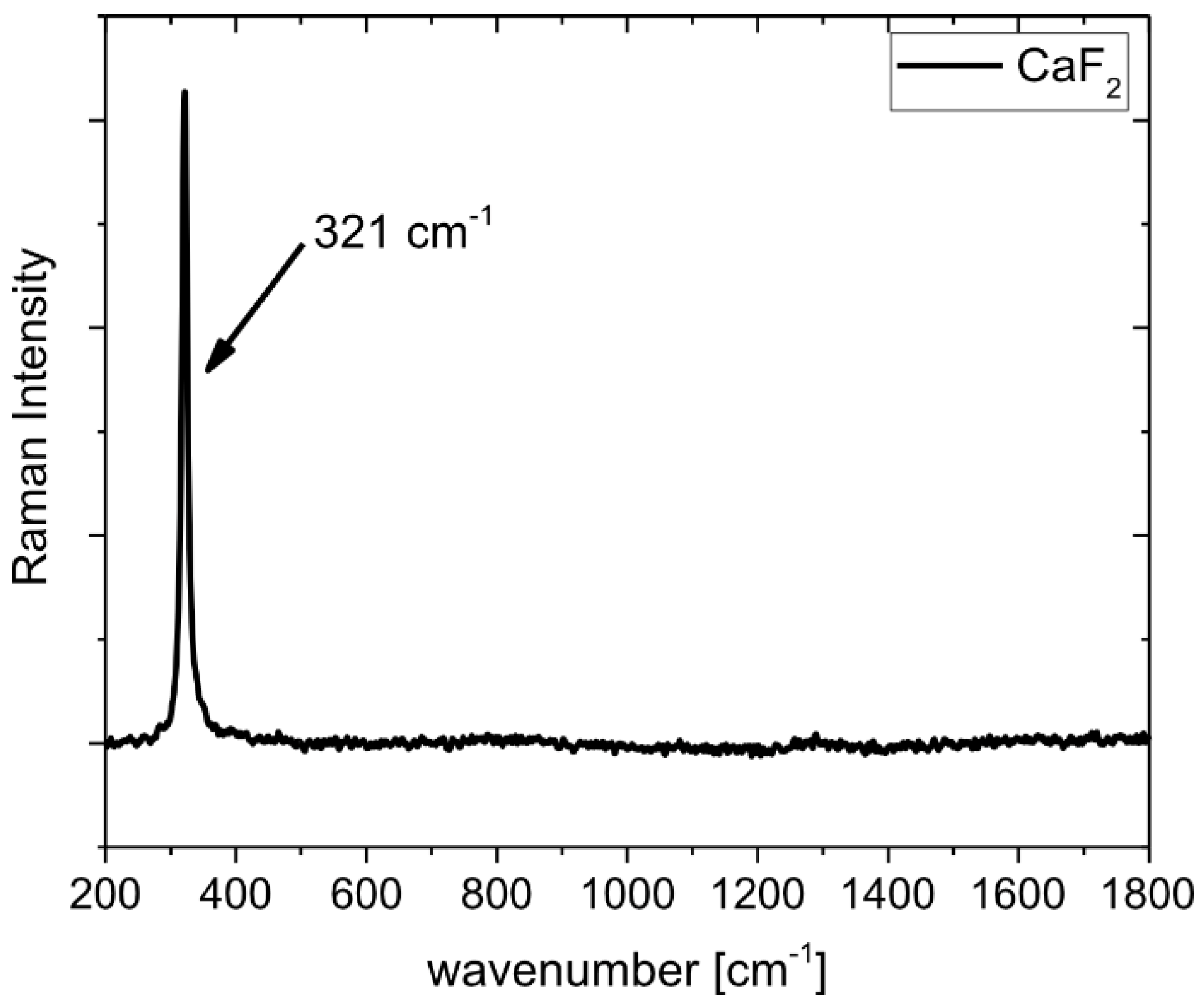

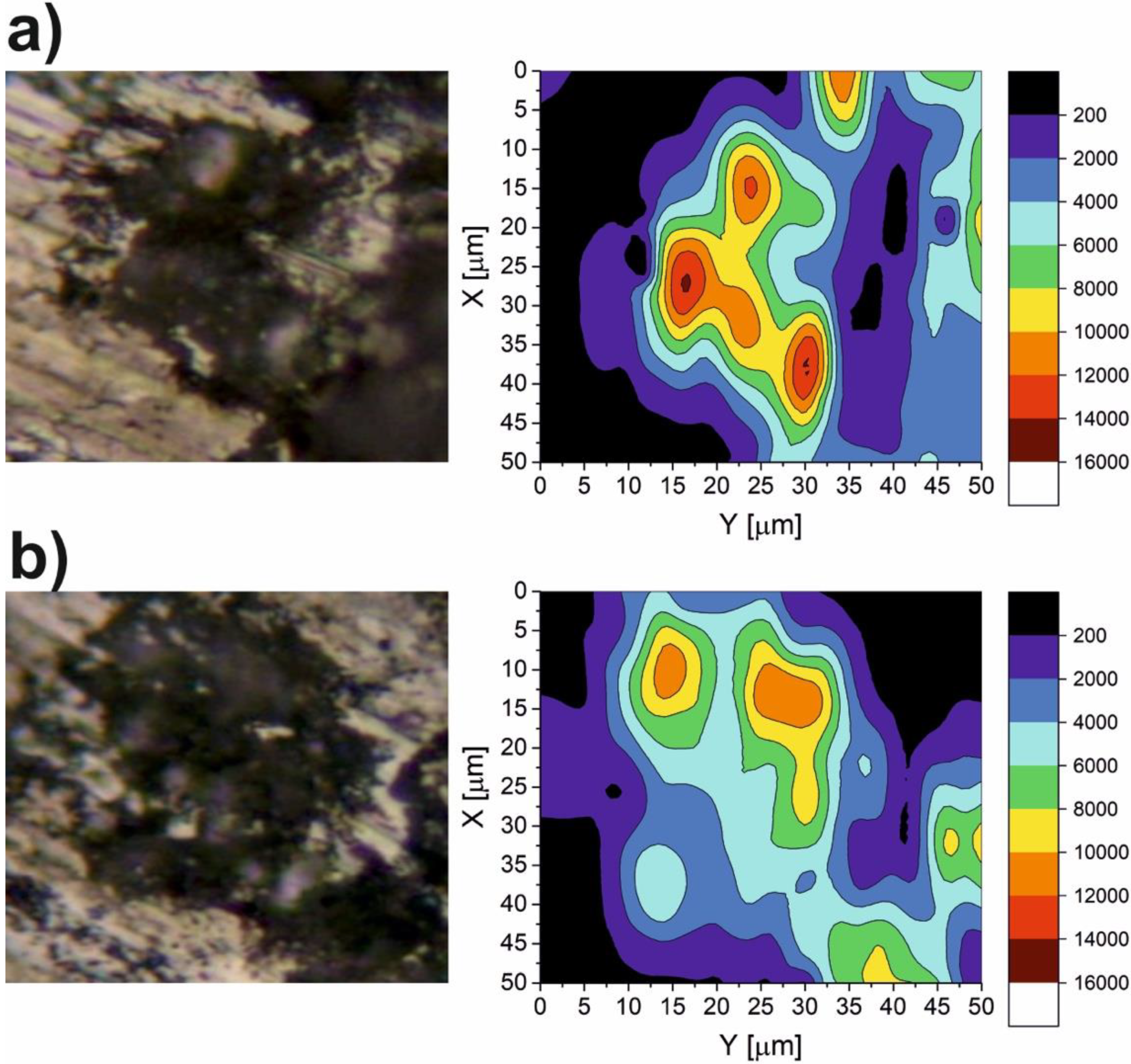

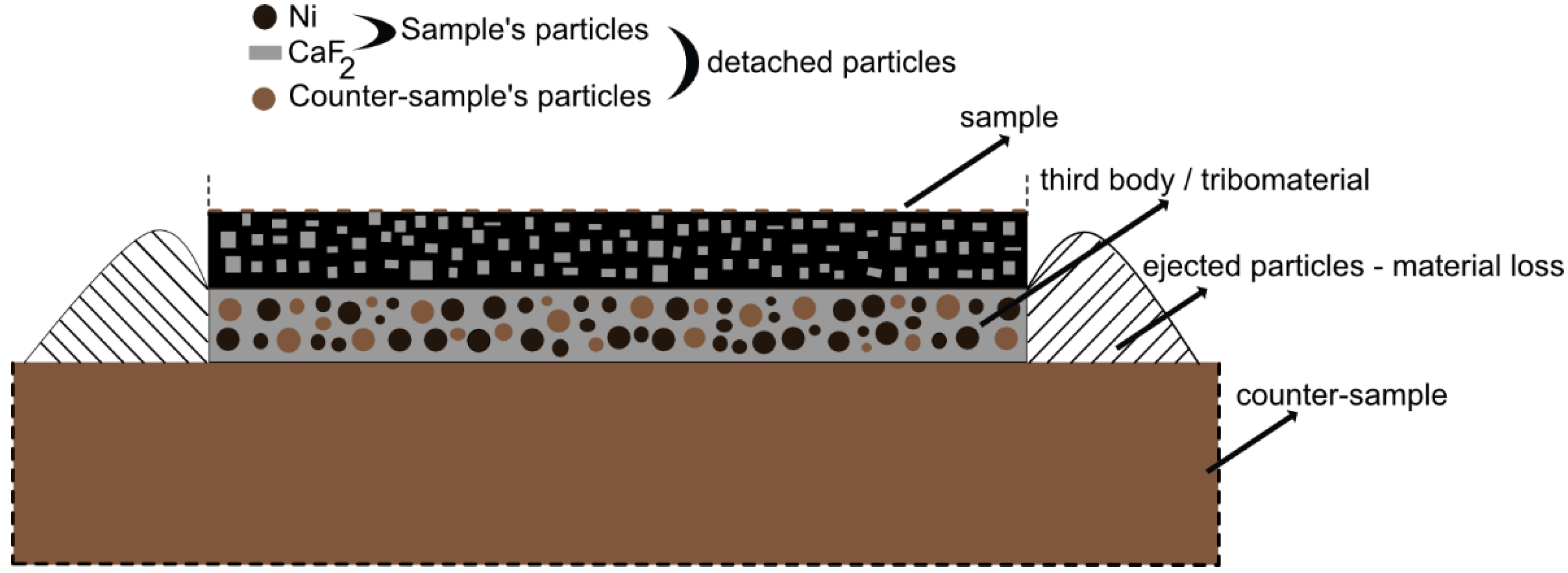

3.2. Worn Surface Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, X.; Yuan, J.; Lou, S.; Li, D.; Cheng, W. Effect of Fe on the High-Temperature Tribological Behavior of NiAl/WC-Fexself-Lubricating Composites Produced by Thermal Explosion. Mater. Res. Express 2020, 7, 076516. [Google Scholar] [CrossRef]

- Lo, W.-L.; Hsu, S.-Y.; Lin, Y.-C.; Tsai, S.-Y.; Lai, Y.-T.; Duh, J.-G. Improvement of High Entropy Alloy Nitride Coatings (AlCrNbSiTiMo)N on Mechanical and High Temperature Tribological Properties by Tuning Substrate Bias. Surf. Coat. Technol. 2020, 401, 126247. [Google Scholar] [CrossRef]

- Vuchkov, T.; Yaqub, T.B.; Evaristo, M.; Cavaleiro, A. Synthesis, Microstructural and Mechanical Properties of Self-Lubricating Mo-Se-C Coatings Deposited by Closed-Field Unbalanced Magnetron Sputtering. Surf. Coat. Technol. 2020, 394, 125889. [Google Scholar] [CrossRef]

- Xiao, J.; Wu, Y.; Zhang, W.; Chen, J.; Zhang, C. Friction of Metal-Matrix Self-Lubricating Composites: Rrelationships among Lubricant Content, Lubricating Film Coverage, and Friction Coefficient. Friction 2020, 8, 517–530. [Google Scholar] [CrossRef]

- Kim, S.H.; Wohn Lee, S. Wear and Friction Behavior of Self-Lubricating Alumina-Zirconia-Fluoride Composites Fabricated by the PECS Technique. Ceram. Int. 2014, 40, 779–790. [Google Scholar] [CrossRef]

- Li, R.; Yamashita, S.; Yoshida, K.; Kita, H. Effect of Counterbody on Friction and Wear Properties of Copper-MgP-Graphite Composites Prepared by Powder Metallurgy. Processes 2022, 10, 804. [Google Scholar] [CrossRef]

- Mohamad, W.F.; Khan, A.A.; Barroy, P.; Durand-Drouhin, O.; Puille, C.; Lahmar, A.; Ahmad, F. Microstructure and Surface Characterization of Ni-Cr Based Composites Containing Variable Solid Lubricants. Tribol.-Mater. Surf. Interfaces 2020, 14, 219–228. [Google Scholar] [CrossRef]

- Piasecki, A.; Kotkowiak, M.; Makuch, N.; Kulka, M. Wear Behavior of Self-Lubricating Boride Layers Produced on Inconel 600-Alloy by Laser Alloying. Wear 2019, 426–427, 919–933. [Google Scholar] [CrossRef]

- Piasecki, A.; Kotkowiak, M.; Kulka, M. Self-Lubricating Surface Layers Produced Using Laser Alloying of Bearing Steel. Wear 2017, 376–377, 993–1008. [Google Scholar] [CrossRef]

- Zhu, L.; Luo, L.; Wu, Y.; Cheng, J. Microstructure and Tribological Properties of Laser Clad Ni-Ag/Tic Composite Coating. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2014, 29, 242–245. [Google Scholar] [CrossRef]

- Niu, W.; Sun, R.; Lei, Y. Microstructure and Wear Properties of Laser Clad NiCrBSi-MoS2 Coating. Frict. Wear Res. 2014, 2, 2–6. [Google Scholar]

- Yan, H.; Zhang, J.; Zhang, P.; Yu, Z.; Li, C.; Xu, P.; Lu, Y. Laser Cladding of Co-Based Alloy/TiC/CaF2 Self-Lubricating Composite Coatings on Copper for Continuous Casting Mold. Surf. Coat. Technol. 2013, 232, 362–369. [Google Scholar] [CrossRef]

- Luo, J.; Liu, X.B.; Xiang, Z.F.; Shi, S.H.; Chen, Y.; Shi, G.L.; Wu, S.H.; Wu, Y.N. Synthesis of High-Temperature Self-Lubricating Wear Resistant Composite Coating on Ti6Al4V Alloy by Laser Deposition. J. Mater. Eng. Perform. 2015, 24, 1881–1889. [Google Scholar] [CrossRef]

- Yan, H.; Zhang, P.; Yu, Z.; Lu, Q.; Yang, S.; Li, C. Microstructure and Tribological Properties of Laser-Clad Ni-Cr/TiB2 Composite Coatings on Copper with the Addition of CaF2. Surf. Coat. Technol. 2012, 206, 4046–4053. [Google Scholar] [CrossRef]

- Liu, S.; Pang, M. Effect of TiB2 Content on Properties of Nickel-Coated Graphite Self-Lubricating Coating Prepared by Laser Cladding. Coatings 2021, 11, 1501. [Google Scholar] [CrossRef]

- Liu, K.; Yan, H.; Zhang, P.; Zhao, J.; Yu, Z.; Lu, Q. Wear Behaviors of TiN/WS2 + HBN/NiCrBSi Self-Lubricating Composite Coatings on TC4 Alloy by Laser Cladding. Coatings 2020, 10, 747. [Google Scholar] [CrossRef]

- OuYang, C.S.; Liu, X.B.; Luo, Y.S.; Liang, J.; Wang, M.; Chen, D.Q. Preparation and High Temperature Tribological Properties of Laser In-Situ Synthesized Self-Lubricating Composite Coating on 304 Stainless Steel. J. Mater. Res. Technol. 2020, 9, 7034–7046. [Google Scholar] [CrossRef]

- Deng, J.; Liu, L.; Yang, X.; Liu, J.; Sun, J.; Zhao, J. Self-Lubrication of Al2O3/TiC/CaF2 Ceramic Composites in Sliding Wear Tests and in Machining Processes. Mater. Des. 2007, 28, 757–764. [Google Scholar] [CrossRef]

- Yang, J.F.; Jiang, Y.; Hardell, J.; Prakash, B.; Fang, Q.F. Influence of Service Temperature on Tribological Characteristics of Self-Lubricant Coatings: A Review. Front. Mater. Sci. 2013, 7, 28–39. [Google Scholar] [CrossRef]

- Wu, G.; Xu, C.; Xiao, G.; Yi, M.; Chen, Z. Structure Design of Al2O3/TiC/CaF2 Multicomponent Gradient Self-Lubricating Ceramic Composite and Its Tribological Behaviors. Ceram. Int. 2018, 44, 5550–5563. [Google Scholar] [CrossRef]

- Ouyang, J.H.; Sasaki, S. Effects of Different Additives on Microstructure and High-Temperature Tribological Properties of Plasma-Sprayed Cr2O3 Ceramic Coatings. Wear 2001, 249, 56–66. [Google Scholar] [CrossRef]

- Konopka, K.; Roik, T.A.; Gavrish, A.P.; Vitsuk, Y.Y.; Mazan, T. Effect of CaF2 Surface Layers on the Friction Behavior of Copper-Based Composite. Powder Metall. Met. Ceram. 2012, 51, 363–367. [Google Scholar] [CrossRef]

- Zhen, J.; Han, Y.; Cheng, J.; Chen, W.; Yang, J.; Jia, Z.; Zhang, R. Enhancing the Wide Temperature Dry Sliding Tribological Performance of Nickle-Alloy by Adding MoS2/CaF2. Tribol. Int. 2022, 165, 107254. [Google Scholar] [CrossRef]

- Zhang, G.; Xiao, G.; Chen, Z.; Guo, N.; Xu, C.; Yi, M.; Zhang, J.; Zhou, T. A New Preparation Method of CaF2@SiO2 Nano Solid Lubricant and Analysis of Its Coating Mechanism. J. Alloys Compd. 2021, 883, 160795. [Google Scholar] [CrossRef]

- Ouyang, J.H.; Li, Y.F.; Wang, Y.M.; Zhou, Y.; Murakami, T.; Sasaki, S. Microstructure and Tribological Properties of ZrO2(Y2O3) Matrix Composites Doped with Different Solid Lubricants from Room Temperature to 800 °C. Wear 2009, 267, 1353–1360. [Google Scholar] [CrossRef]

- Cho, J.; Xiong, Y.; Kim, J.; Lee, C.; Hwang, S.Y. Tribological Behavior of NiCr-Base Blended and Nanostructured Composite APS Coatings by Rig Test. Wear 2008, 265, 1565–1571. [Google Scholar] [CrossRef]

- Cui, G.; Lu, L.; Wu, J.; Liu, Y.; Gao, G. Microstructure and Tribological Properties of Fe-Cr Matrix Self-Lubricating Composites against Si3N4 at High Temperature. J. Alloys Compd. 2014, 611, 235–242. [Google Scholar] [CrossRef]

- Kumar, R.; Hussainova, I.; Rahmani, R.; Antonov, M. Solid Lubrication at High-Temperatures—A Review. Materials 2022, 15, 1695. [Google Scholar] [CrossRef]

- Zuomin, L.; Childs, T.H.C. The Study of Wear Characteristics of Sintered High Speed Steels Containing CaF2, MnS and TiC Additives at Elevated Temperature. Wear 2004, 257, 435–440. [Google Scholar] [CrossRef]

- Zhang, X.F.; Zhang, L.; Huang, Z.Y. Characterization of Ni-Based Alloy Submicron WS2/CaF2 Composite Coatings Deposited by High Velocity Oxy-Fuel (HVOF) Spray Process. Adv. Mater. Res. 2014, 881–883, 1407–1411. [Google Scholar] [CrossRef]

- Kobayashi, T.; Maruyama, T.; Yasuda, T. Sliding Properties of Composite Sprayed Coating between Bronze Powder and Solid Lubricant. Mater. Trans. 2003, 44, 1024–1028. [Google Scholar] [CrossRef][Green Version]

- Song, P.; Yang, X.; Wang, S.; Yang, L. Tribological Properties of Self-Lubricating Laminated Ceramic Materials. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2014, 29, 906–911. [Google Scholar] [CrossRef]

- Podgornik, B.; Vižintin, J.; Borovšak, U.; Megušar, F. Tribological Properties of DLC Coatings in Helium. Tribol. Lett. 2012, 47, 223–230. [Google Scholar] [CrossRef]

- Dhiman, N.; Ghosh, S.; Mishra, Y.K.; Tripathi, K.M. Prospects of Nano-Carbons as Emerging Catalysts for Enzyme-Mimetic Applications. Mater. Adv. 2022, 3, 3101–3122. [Google Scholar] [CrossRef]

- Li, X.; Dai, W.; Wang, Q.; Liang, Y.; Wu, Z. Diamond-like/Graphite-like Carbon Composite Films Deposited by High-Power Impulse Magnetron Sputtering. Diam. Relat. Mater. 2020, 106, 107818. [Google Scholar] [CrossRef]

- Xin, Y.; Li, T.; Gong, D.; Xu, F.; Wang, M. Preparation and Tribological Properties of Graphene Oxide/Nano-MoS2 Hybrid as Multidimensional Assembly Used in the Polyimide Nanocomposites. RSC Adv. 2017, 7, 6323–6335. [Google Scholar] [CrossRef]

- Jia, Z.; Hao, C.; Yan, Y.; Yang, Y. Effects of Nanoscale Expanded Graphite on the Wear and Frictional Behaviors of Polyimide-Based Composites. Wear 2015, 338–339, 282–287. [Google Scholar] [CrossRef]

- Xu, X.; Wang, C.; Chen, M.; Zhu, S.; Chen, Z.; Chen, J.; Wang, F. An Easy-Processing Organic-Inorganic Self-Lubricating Composite Coating with High Corrosion Resistance. Prog. Org. Coat. 2019, 137, 105377. [Google Scholar] [CrossRef]

- Peng, S.; Zhang, L.; Xie, G.; Guo, Y.; Si, L.; Luo, J. Friction and Wear Behavior of PTFE Coatings Modified with Poly (Methyl Methacrylate). Compos. Part B Eng. 2019, 172, 316–322. [Google Scholar] [CrossRef]

- Xu, Y.; Gong, Y.; Li, P.; Yang, Y.; Qi, Y. The Effect of Laser Power on the Microstructure and Wear Performance of IN718 Superalloy Fabricated by Laser Additive Manufacturing. Int. J. Adv. Manuf. Technol. 2020, 108, 2245–2254. [Google Scholar] [CrossRef]

- Schwingenschlögl, P.; Merklein, M. Characterization of Tribological Conditions within Direct Hot Stamping. J. Mater. Process. Technol. 2020, 278, 116535. [Google Scholar] [CrossRef]

- Davis, D.; Marappan, G.; Sivalingam, Y.; Panigrahi, B.B.; Singh, S. Tribological Behavior of NiMoAl-Based Self-Lubricating Composites. ACS Omega 2020, 5, 14669–14678. [Google Scholar] [CrossRef] [PubMed]

- Kotkowiak, M.; Piasecki, A.; Kulka, M. The Influence of Solid Lubricant on Tribological Properties of Sintered Ni–20% CaF2 Composite Material. Ceram. Int. 2019, 45, 17103–17113. [Google Scholar] [CrossRef]

- Liying, Y.; Zuomin, L. Microstructure and Mechanical Properties of Ti-48Al-2Nb-2Cr Matrix High Temperature Self-Lubricating Composites by Addition of 38% CaF2-62% BaF2 Eutectic Solid Lubricants. J. Compos. Mater. 2007, 41, 3079–3089. [Google Scholar] [CrossRef]

- Liu, W.G.; Liu, X.B.; Zhang, Z.G.; Guo, J. Development and Characterization of Composite Ni-Cr-C-CaF2 Laser Cladding on γ-TiAl Intermetallic Alloy. J. Alloys Compd. 2009, 470, 25–28. [Google Scholar] [CrossRef]

- Zhang, X.-f; Zhang, X.-l.; Wang, A.-h.; Huang, Z.-w. Microstructure and Properties of HVOF Sprayed Ni-Based Submicron WS2/CaF2 Self-Lubricating Composite Coating. Trans. Nonferr. Met. Soc. China Engl. Ed. 2009, 19, 85–92. [Google Scholar] [CrossRef]

- Fillot, N.; Iordanoff, I.; Berthier, Y. Wear Modeling and the Third Body Concept. Wear 2007, 262, 949–957. [Google Scholar] [CrossRef]

- Arnaud, P.; Fouvry, S. Modeling the Fretting Fatigue Endurance from Partial to Gross Slip: The Effect of Debris Layer. Tribol. Int. 2020, 143, 106069. [Google Scholar] [CrossRef]

- Arnaud, P.; Fouvry, S. A Dynamical FEA Fretting Wear Modeling Taking into Account the Evolution of Debris Layer. Wear 2018, 412–413, 92–108. [Google Scholar] [CrossRef]

- Arteaga-Hernandez, L.A.; Cuao-Moreu, C.A.; Gonzalez-Rivera, C.E.; Alvarez-Vera, M.; Ortega-Saenz, J.A.; Hernandez-Rodriguez, M.A.L. Study of Boriding Surface Treatment in the Tribological Behavior of an AISI 316L Stainless Steel. Wear 2021, 477, 203825. [Google Scholar] [CrossRef]

| Material | Ni | Cr | Mo | Nb + Ta | Fe | C | Mn | Si | S | Al | Ti | P | Co |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inconel ®625 | balance | 22 | 8.6 | 3.6 | 4.1 | 0.03 | 0.06 | 0.02 | 0.001 | 0.2 | 0.2 | 0.005 | 0.13 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kotkowiak, M.; Piasecki, A.; Kotkowiak, M.; Buchwald, T. The Mechanism of Wear Reduction in the Ni-CaF2 Composite Material: Raman and Confocal Microscopy Insights. Materials 2022, 15, 5501. https://doi.org/10.3390/ma15165501

Kotkowiak M, Piasecki A, Kotkowiak M, Buchwald T. The Mechanism of Wear Reduction in the Ni-CaF2 Composite Material: Raman and Confocal Microscopy Insights. Materials. 2022; 15(16):5501. https://doi.org/10.3390/ma15165501

Chicago/Turabian StyleKotkowiak, Mateusz, Adam Piasecki, Michał Kotkowiak, and Tomasz Buchwald. 2022. "The Mechanism of Wear Reduction in the Ni-CaF2 Composite Material: Raman and Confocal Microscopy Insights" Materials 15, no. 16: 5501. https://doi.org/10.3390/ma15165501

APA StyleKotkowiak, M., Piasecki, A., Kotkowiak, M., & Buchwald, T. (2022). The Mechanism of Wear Reduction in the Ni-CaF2 Composite Material: Raman and Confocal Microscopy Insights. Materials, 15(16), 5501. https://doi.org/10.3390/ma15165501