Flexural Performance and Microstructural Studies of Trough-Shaped Geopolymer Ferrocement Panels

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Fly Ash

2.1.2. Steel Slag

2.1.3. Alkaline Solution

2.1.4. Chicken Mesh

2.2. Methods

2.2.1. Compressive Strength of Geopolymer Mortar

2.2.2. Microstructure Studies of Geopolymer Mortar

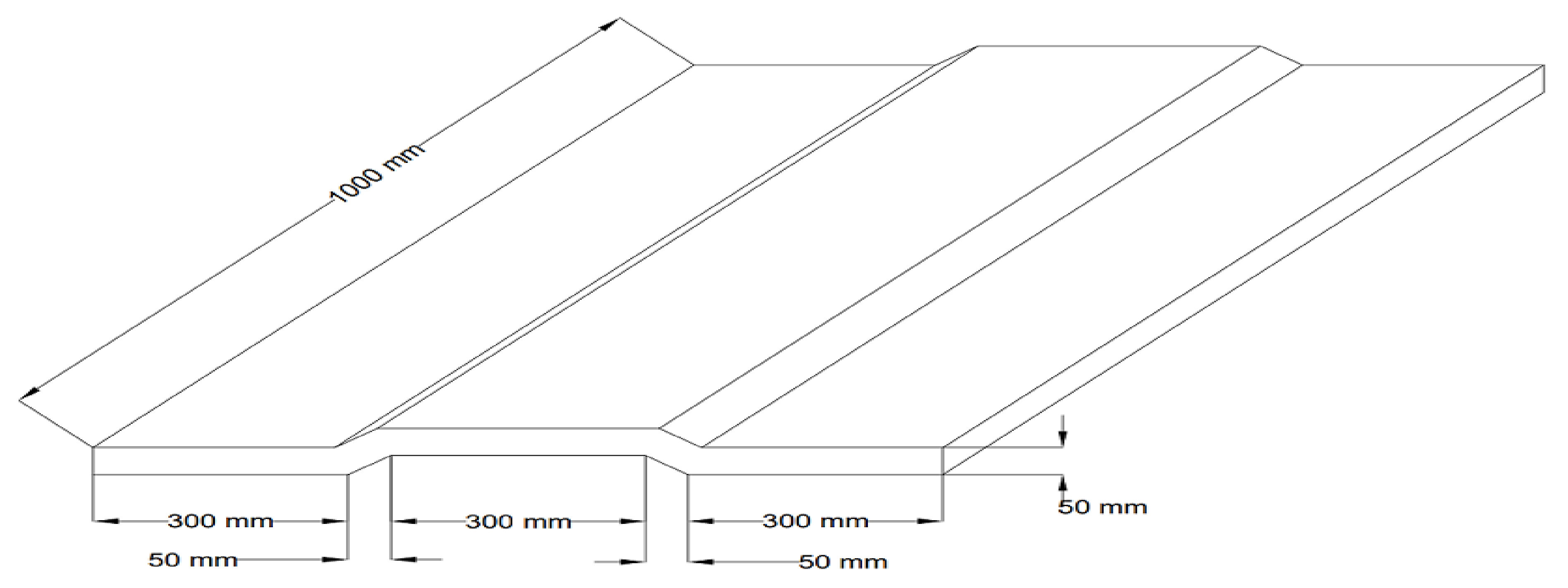

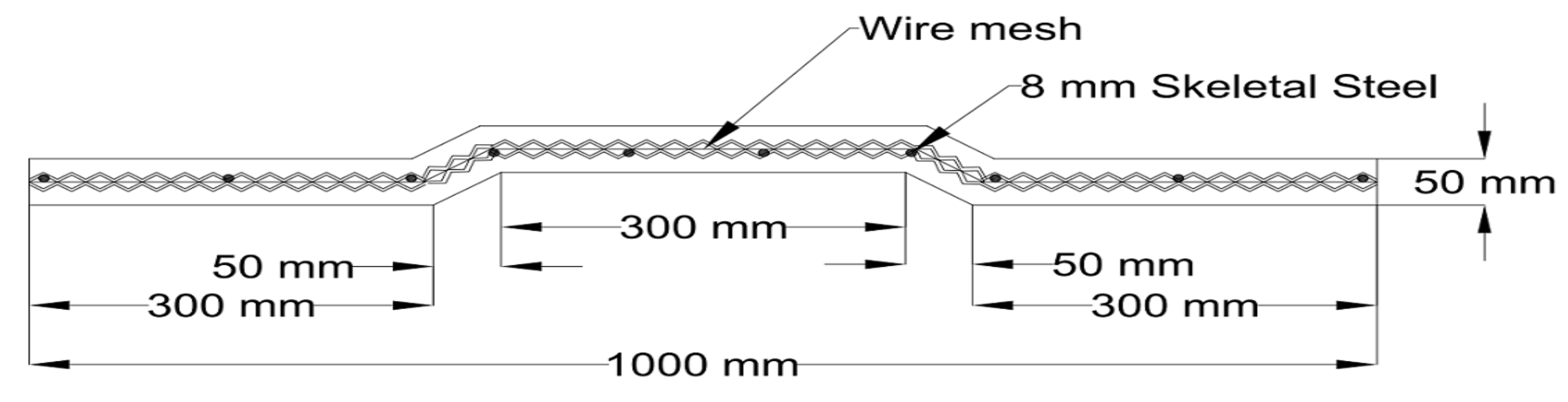

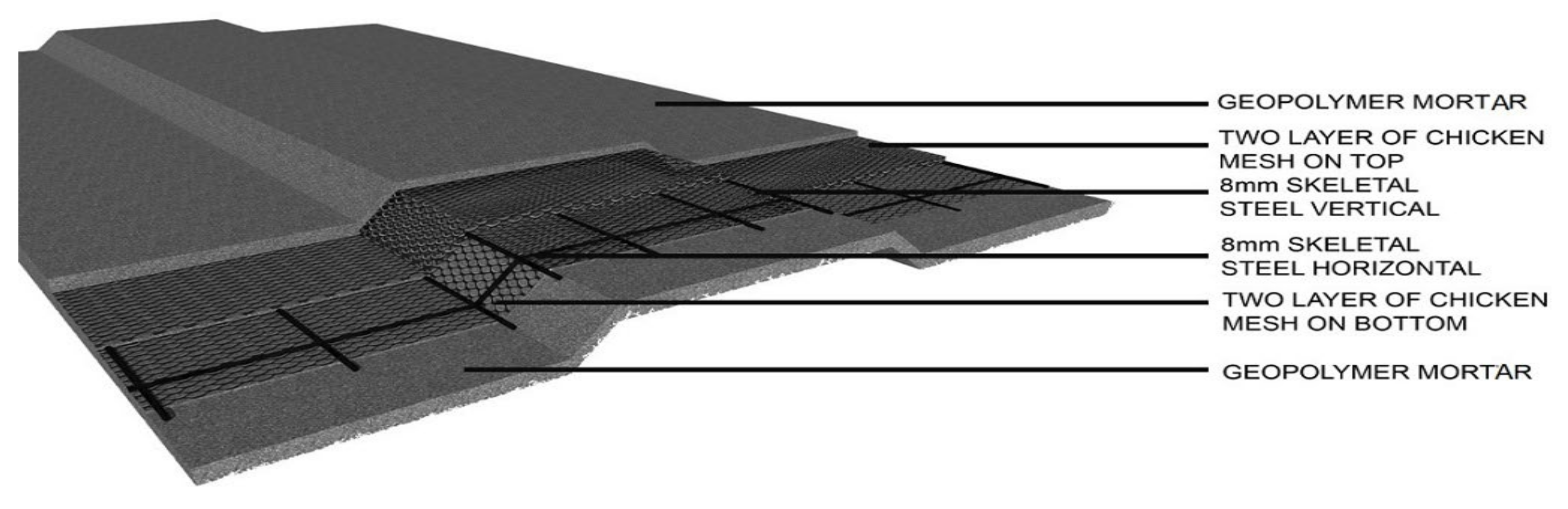

2.2.3. Details of the Geopolymer Ferrocement Panels

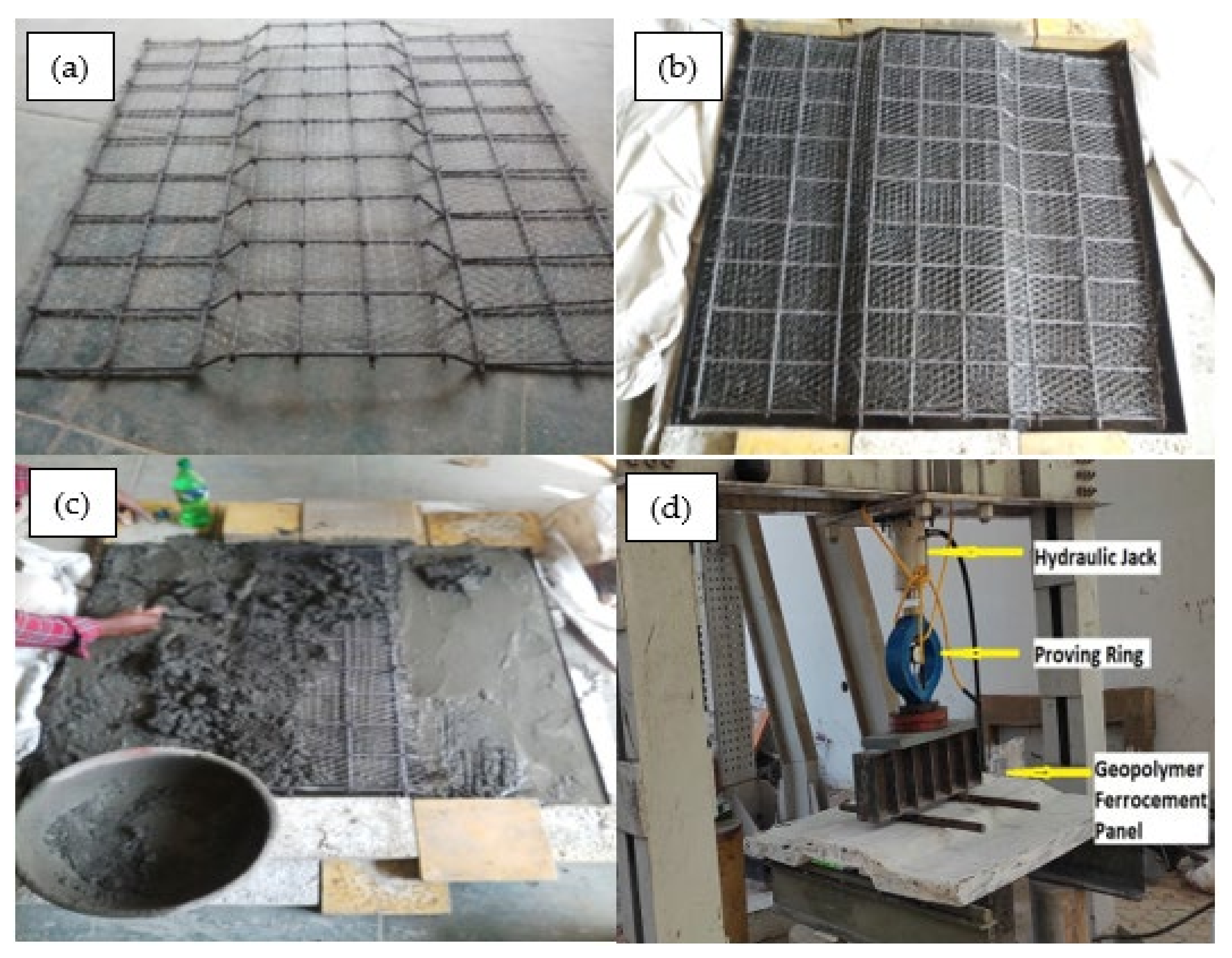

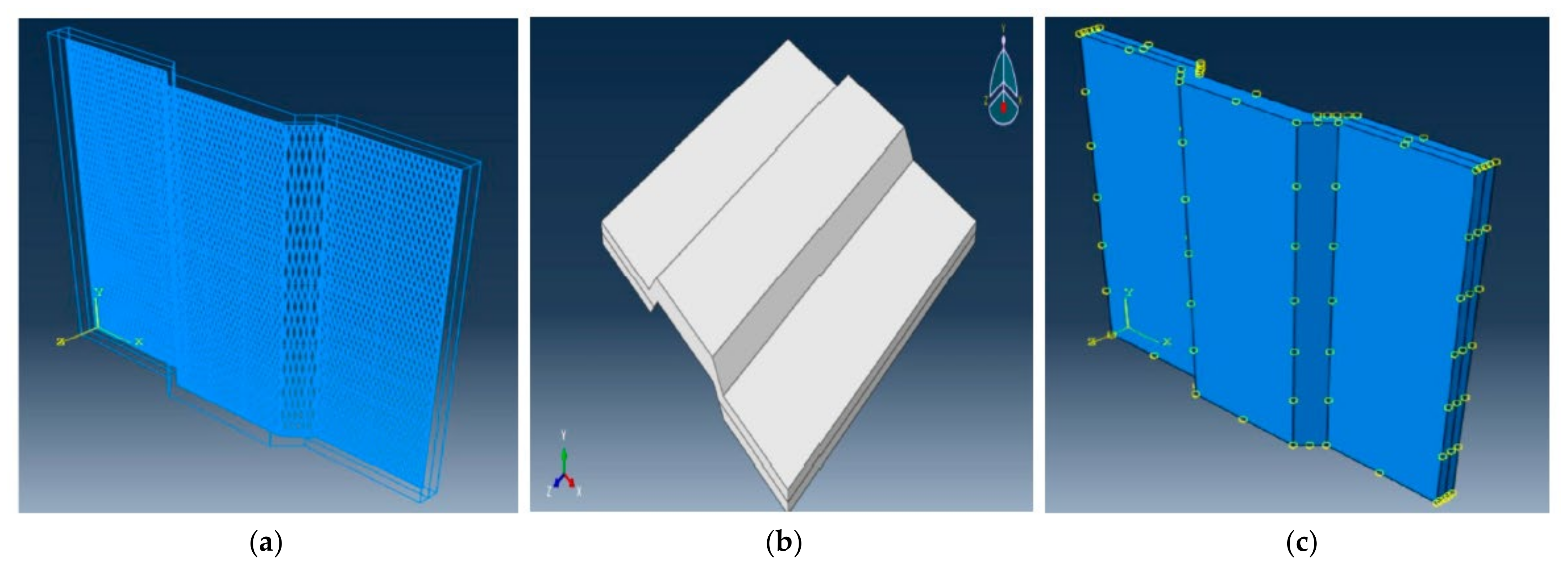

2.2.4. Preparation of Trough-Shaped Geopolymer Ferrocement Panels

2.2.5. Preparation of Multipurpose Geopolymer Ferrocement Panels

2.2.6. Flexural Behavior of Geopolymer Ferrocement Panel

2.2.7. Analytical Work of Geopolymer Ferrocement Panel

3. Results and Discussion

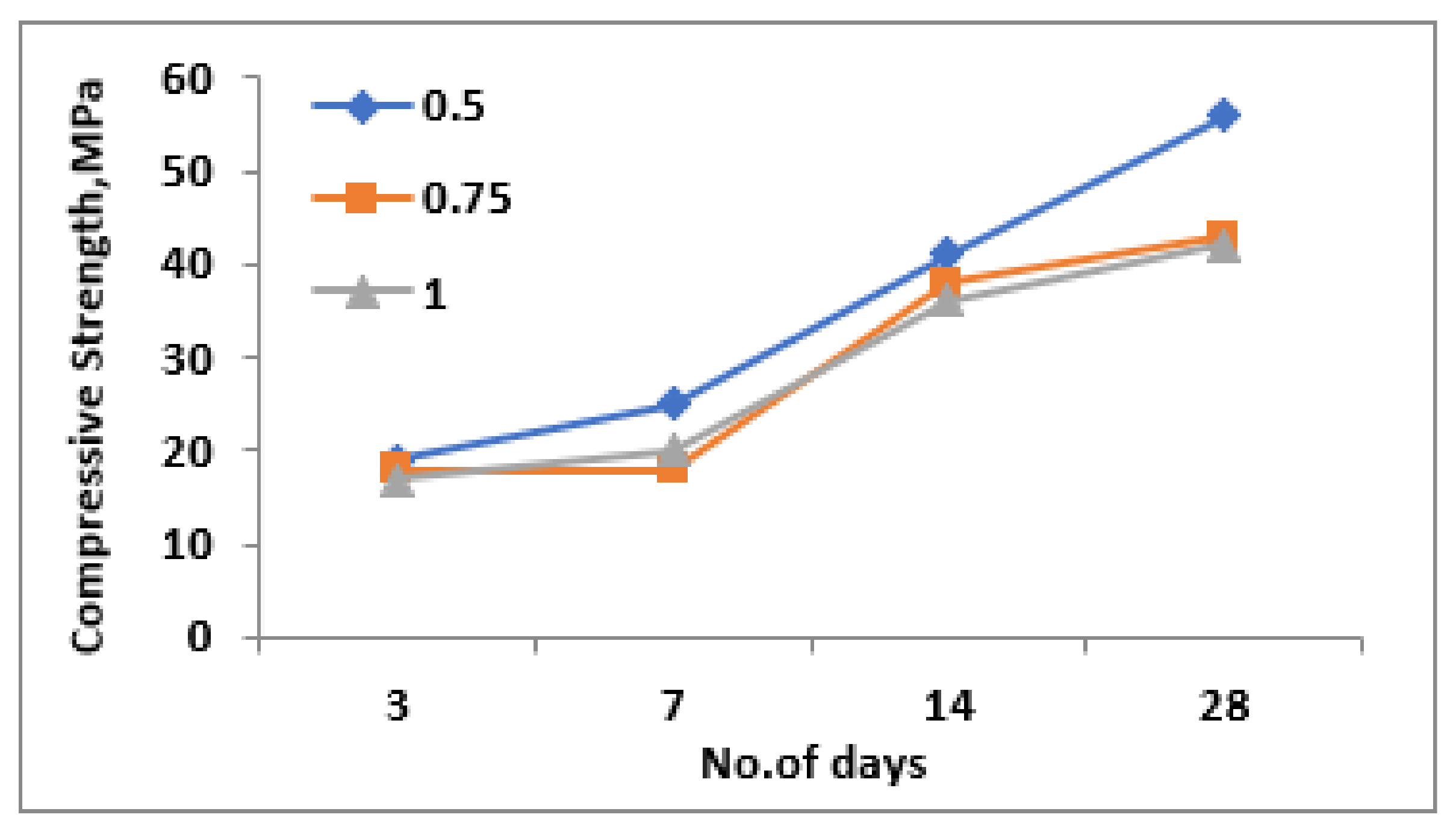

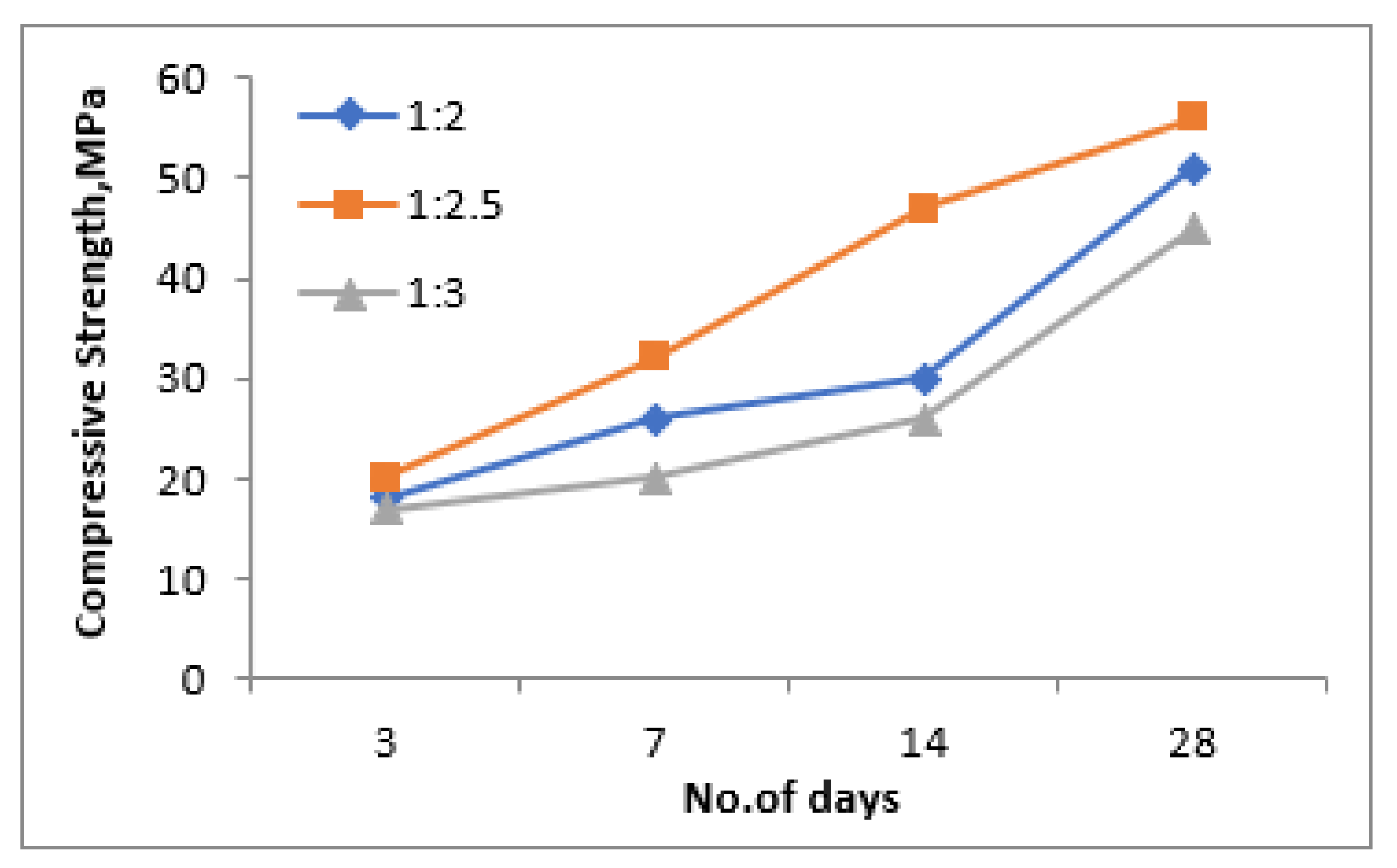

3.1. Compressive Response of Geopolymer Mortar

3.2. Microstructural Analysis

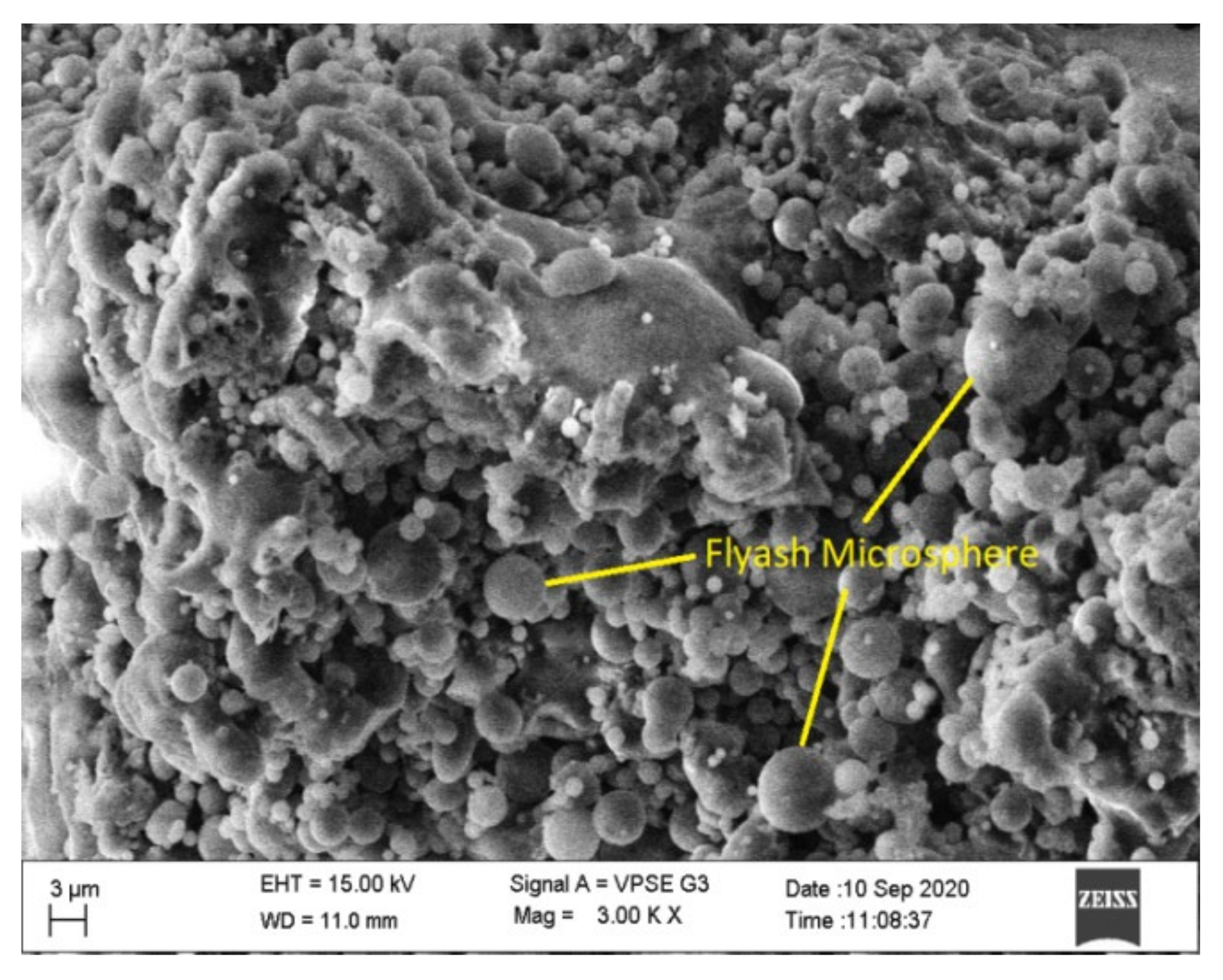

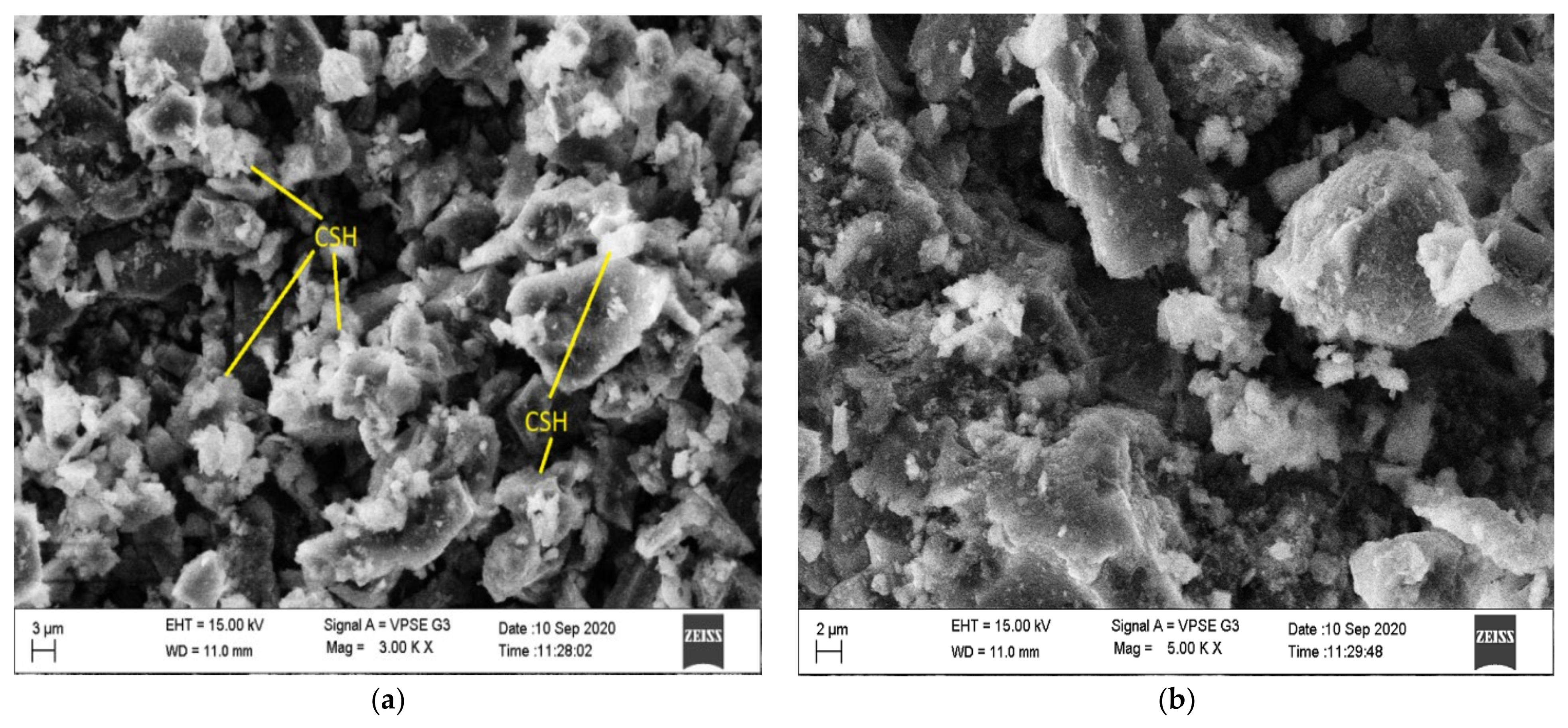

3.2.1. Scanning Electron Microscope Analysis

3.2.2. EDAX (Energy Dispersive X-ray Spectroscopy)

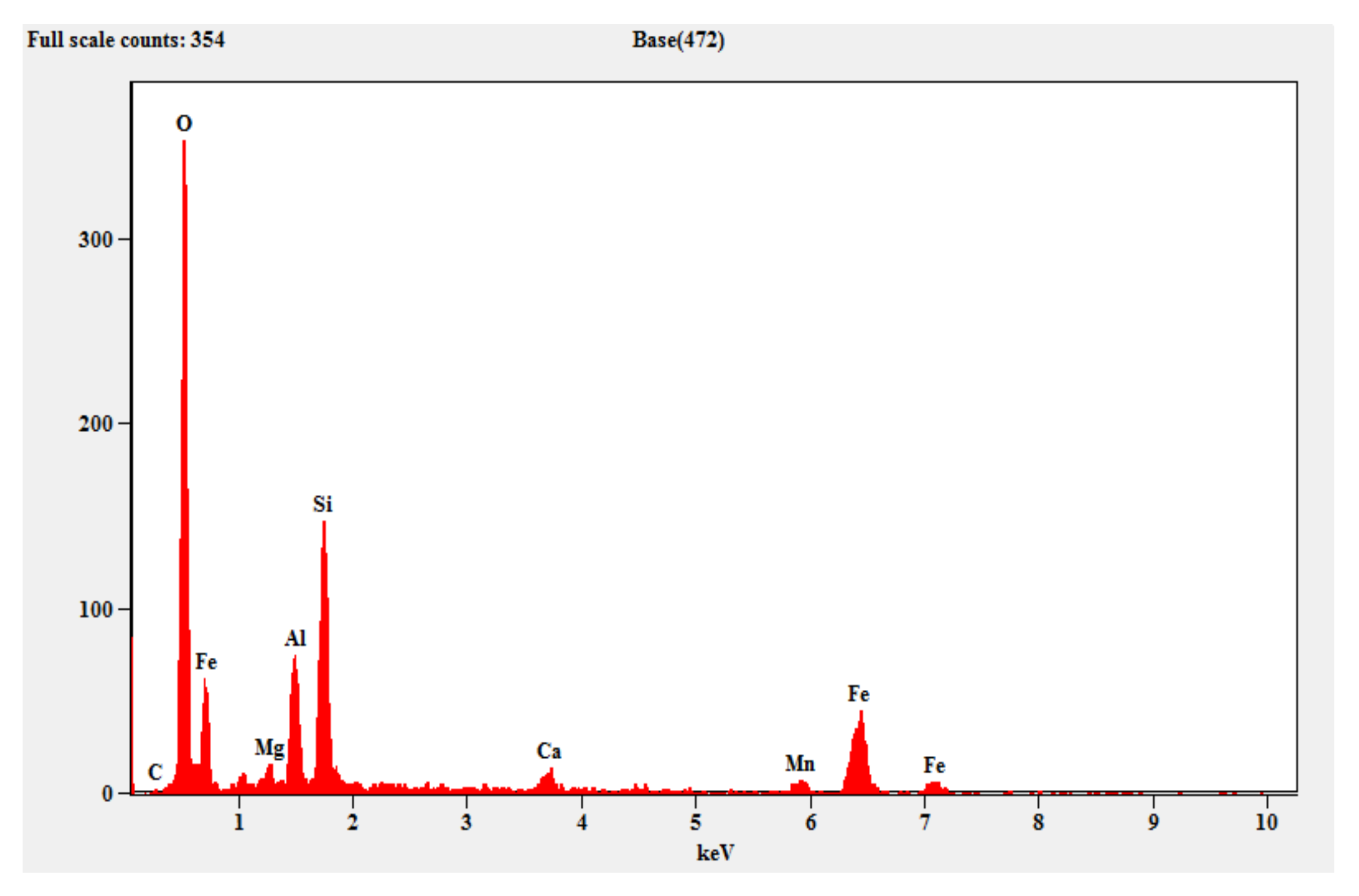

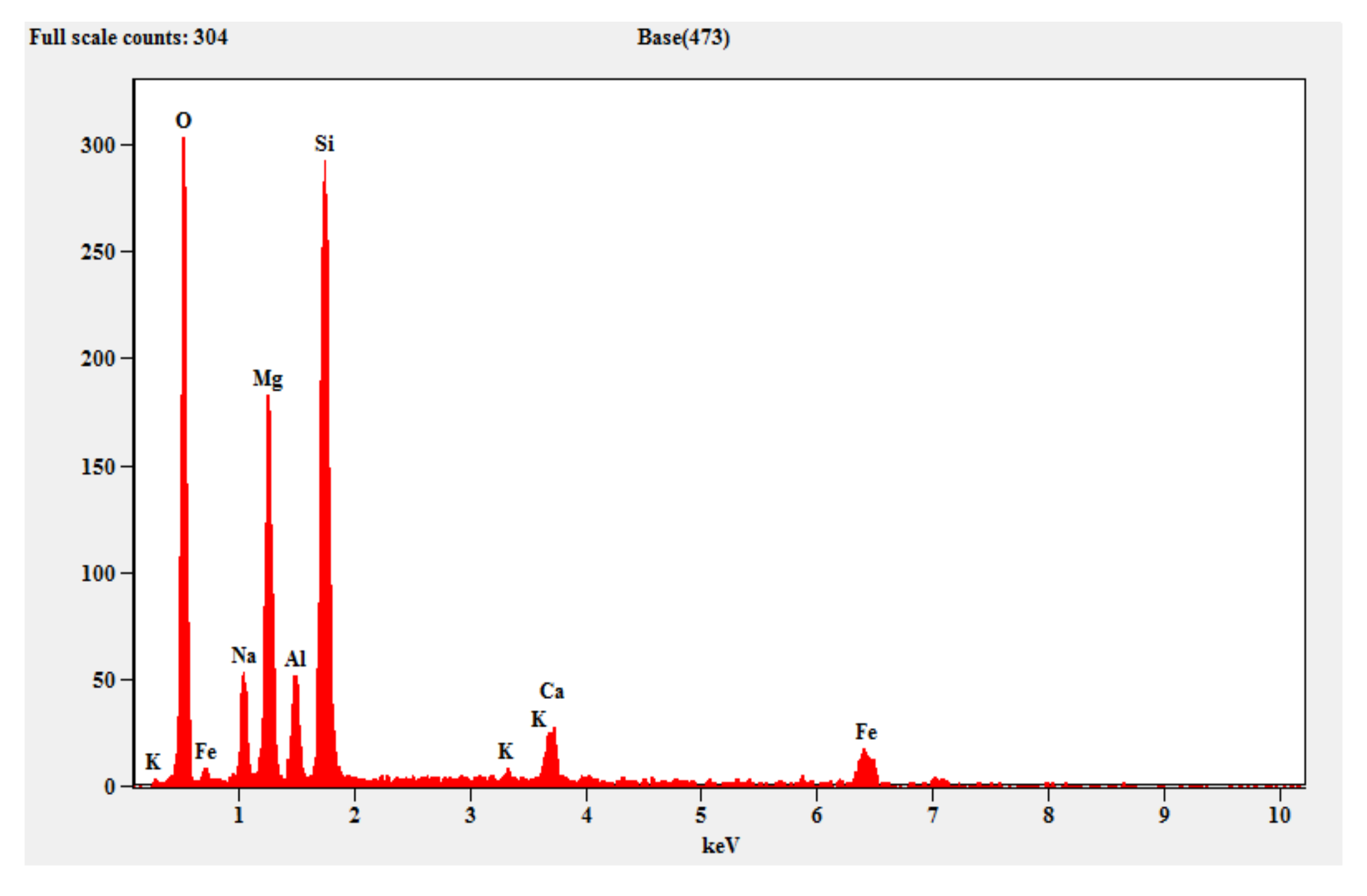

3.2.3. XRD (X-ray Diffraction)

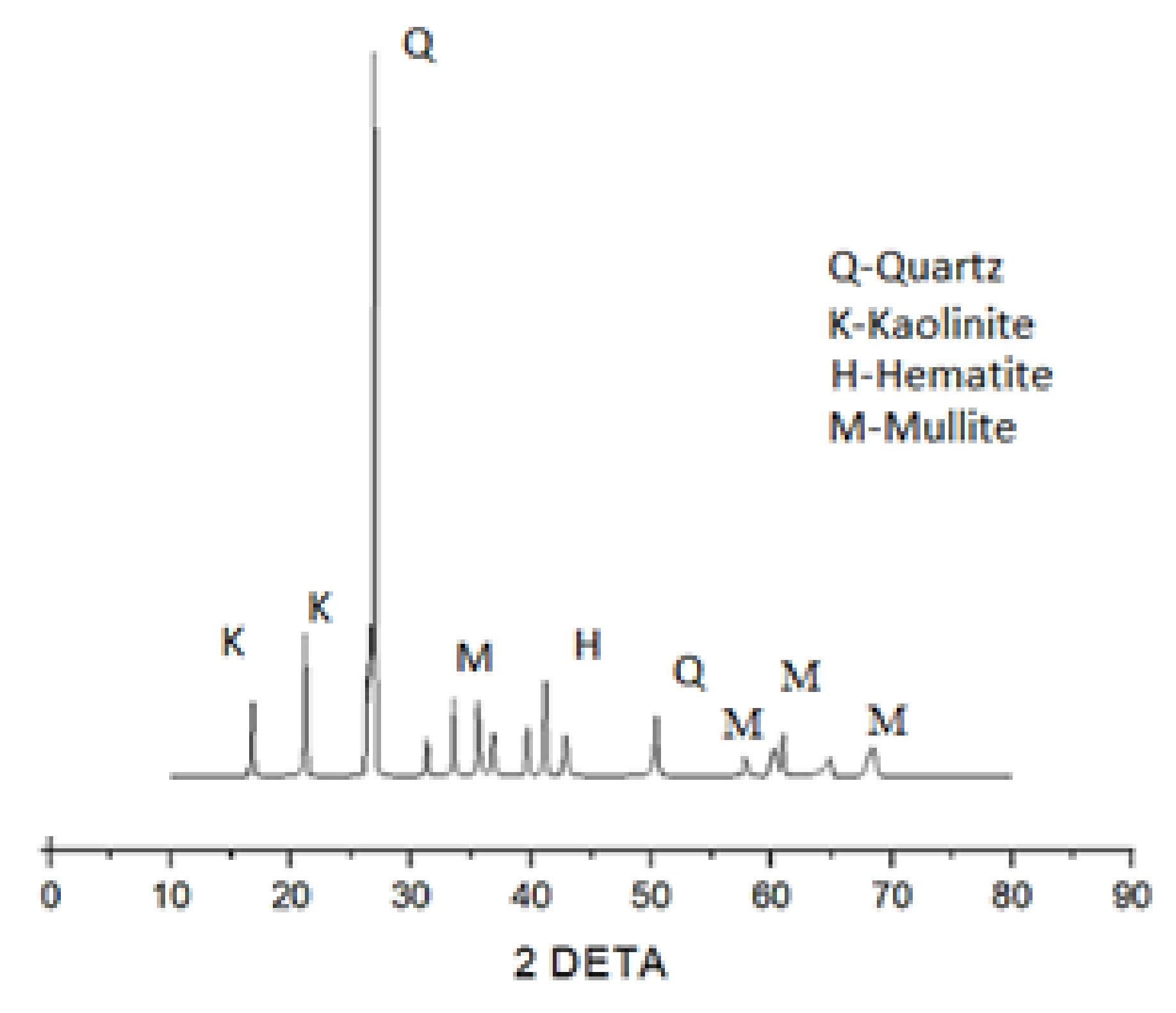

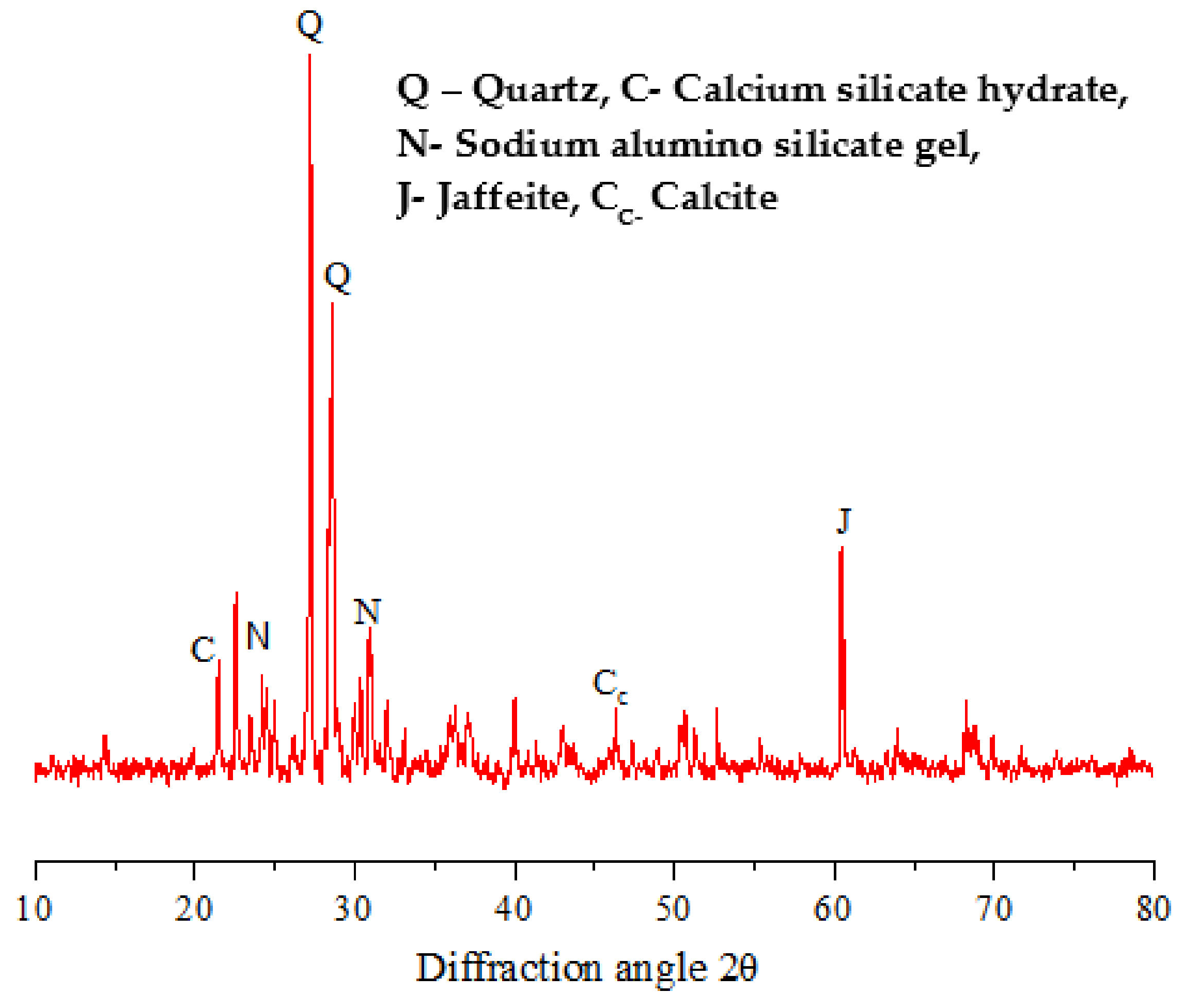

3.3. Flexural Behaviour of Geopolymer Ferrocement Panels

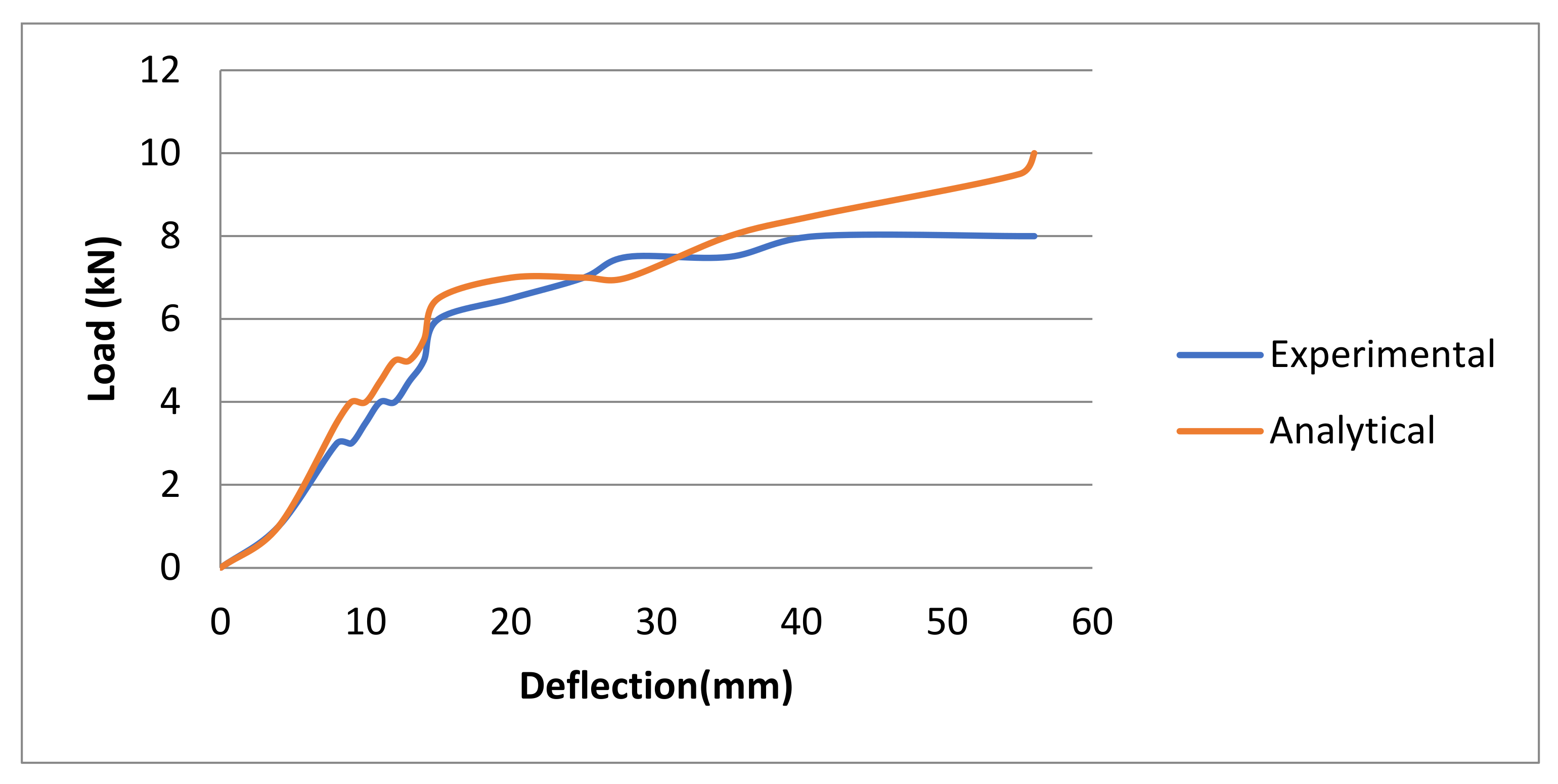

3.3.1. Load-Deflection Behaviour

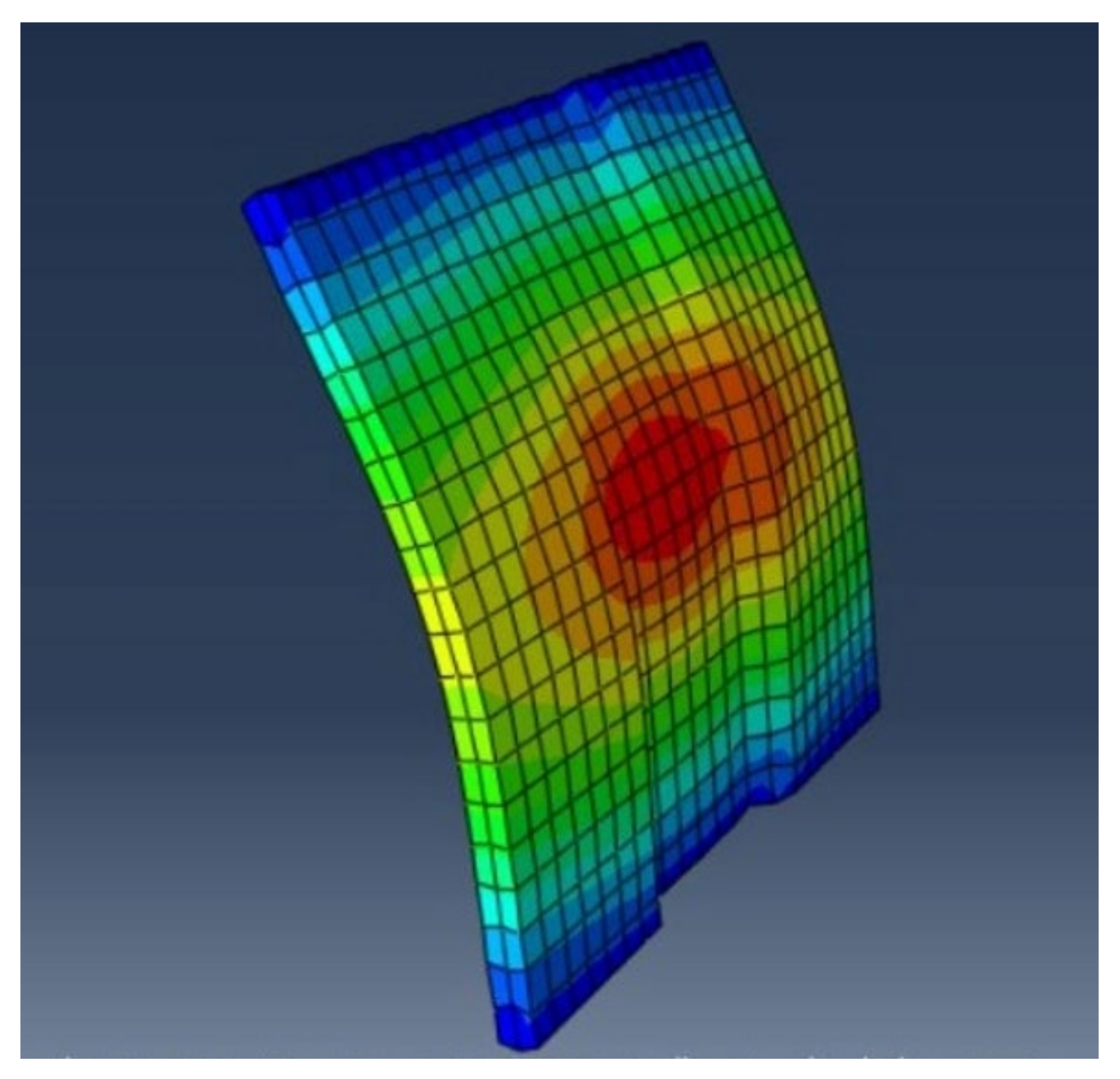

3.3.2. Crack Pattern

3.4. Analytical Study of Geopolymer Ferrocement Panels

4. Conclusions

- The compressive strength results of the geopolymer mortar mix increases with the increase in the NaOH concentration, reduces with the increase in the ratio of NaOH to Na2SiO3, and the optimum replacement level of fly ash with steel slag was observed to be 2.5.

- The optimum mix proportioning was found to be: fly ash to steel slag ratio of 1:2.5, NaOH/Na2SiO3 ratio of 0.5 and NaOH concentration of 12M, which results in a 28th day compressive strength of about 56 MPa, which is higher than the corresponding mixes.

- The test results of SEM, EDAX and XRD show dense homogenous and silicious ingredients in the form of quartz, C-S-H gels and mullite, which enhance the formation of the geopolymerization reaction with improved compressive strength results.

- About 98% of the 28 days compressive strength values were attained at 14 days of curing, which signifies that the target strength has been achieved before 28 days of curing.

- Ferrocement panels are crack-resistant due to the delay in the occurrence of their initial crack. Initial cracks occur at a load of 10 kN with a corresponding deflection of 4 mm.

- It was observed that the trough-shaped ferrocement panels provide improved ultimate strength and crack width of the geopolymer ferrocement panels, and are considerably narrow.

- The ultimate load carrying capacity of the geopolymer ferrocement panel substantially improved.

- The experimental results of the trough-shaped geopolymer ferrocement panel exhibits 56% higher load carrying capacity in its ultimate stage than in the analytical work. The crack Pattern obtained in the software correlates effectively with the experimental results.

- The use of industrial byproducts in the production of geopolymer mortar significantly improves the sustainable nature of geopolymer mixes compared to the conventional cement mortar. The prepared trough-shaped geopolymer ferrocement panel results in improved performance in the analytical results, which shows the effective utilization of geopolymer materials in the production of the ferrocement panel, which results in sustainable construction practices.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tempest, B.; Sanusi, O.; Gergely, J.; Ogunro, V.O. Compressive strength and embodied energy optimization of fly ash based Geopolymer concrete. In Proceedings of the 2009 World of Coal Ash (WOCA) Conference, Lexington, KY, USA, 4–7 May 2009. [Google Scholar]

- Petrillo, A.; Cioffi, R.; Ferone, C.; Colangelo, F.; Borrelli, C. Eco-sustainable Geopolymer concrete blocks production process. Agric. Agric. Sci. Proc. 2016, 8, 408–418. [Google Scholar] [CrossRef]

- Ahmed, M.F.; Nuruddin, M.F.; Shafiq, N. Compressive strength and workability characteristics of low-calcium fly ash-based self-compacting Geopolymer concrete. Int. J. Civ. Environ. Eng. 2011, 5, 64–70. [Google Scholar] [CrossRef]

- Adam, A.A.; Horianto, X.X.X. The effect of temperature and duration of curing on the strength of fly ashbased Geopolymer mortar. In Proceedings of the 2nd International Conference on Sustainable Civil Engineering Structures and Construction Materials 2014 (SCESCM 2014), Yogyakarta, Indonesia, 23–25 September 2014; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Parthiban, K.; Saravanarajamohan, K.; Shobana, S.; Anchal Bhaskar, A. Effect of replacement of Slag on the mechanical properties of flyash based Geopolymer Concrete. Int. J. Eng. Technol. IJET 2013, 5, 2555–2559. [Google Scholar]

- Trindade, A.C.C.; Silva, F.D.A.; Alcamand, H.A.; Borges, P.H.R. On the Mechanical behaviour of metakaolin based Geopolymers under elevated temperatures. Mater. Res. 2017, 20, 265–272. [Google Scholar] [CrossRef] [Green Version]

- Parthiban, K.; Saravana Raja Mohan, K. Effect of sodium hydroxide concentration and alkaline ratio on the compressive strength of slag based geopolymer concrete. Int. J. ChemTech Res. 2014, 6, 2446–2450. [Google Scholar]

- Yang, W.; Zhu, P.; Liu, H.; Wang, X.; Ge, W.; Hua, M. Resistance to Sulfuric Acid Corrosion of Geopolymer Concrete Based on Different Binding Materials and Alkali Concentrations. Materials 2021, 14, 7109. [Google Scholar] [CrossRef]

- Debanath, O.C.; Rahman, M.S.; Islam, M.S.; Islam, M.M. A study on strength and durability of slag (GGBS) based Geopolymer mortar in chloride environment. In Proceedings of the International Conference on Recent Innovation in Civil Engineering for Sustainable Development (IICSD-2015), DUET, Gazipur, Bangladesh, 11–13 December 2015. [Google Scholar]

- Sun, B.; Ye, G.; de Schutter, G. A review: Reaction mechanism and strength of slag and fly ash-based alkali-activated materials. Constr. Build. Mater. 2022, 326, 126843. [Google Scholar] [CrossRef]

- Nagral, M.R.; Ostwal, T.; Chitawadagi, M.V. Effect of curing temperature and curing hours on the properties of geo-polymer concrete. Int. J. Comput. Eng. Res. 2014, 4, 1–11. [Google Scholar]

- Davidovits, J. High-Alkali Cements for 21st centuryConcretes in Concrete Technology. Spec. Publ. 1994, 144, 383–397. [Google Scholar]

- Bashar, I.I.; Alengaram, U.J.; Jumaat, M.Z.; Islam, A. The effect of variation of Molarity of Alkali Activator and Fine aggregate content on the compressive strength of the fly ash: Palm oil fuel ash based Geopolymer mortar. Adv. Mater. Sci. Eng. 2014, 1, 245473. [Google Scholar] [CrossRef] [Green Version]

- Sreevidya, V.; Anuradha, R.; Dinakar, D.; Venkatasubramani, R. Acid resistance of fly ash based Geopolymer mortar under ambient curing and heat curing. Int. J. Eng. Sci. Technol. 2012, 4, 681–684. [Google Scholar]

- Verma, M.; Dev, N.; Rahman, I.; Nigam, M.; Ahmed, M.; Mallick, J. Geopolymer Concrete: A Material for Sustainable Development in Indian Construction Industries. Crystals 2022, 12, 514. [Google Scholar] [CrossRef]

- Ramli, M.I.I.; Salleh, M.A.A.M.; Abdullah, M.M.A.B.; Aziz, I.H.; Ying, T.C.; Shahedan, N.F.; Kockelmann, W.; Fedrigo, A.; Sandu, A.V.; Vizureanu, P.; et al. The Influence of Sintering Temperature on the Pore Structure of an Alkali-Activated Kaolin-Based Geopolymer Ceramic. Materials 2022, 15, 2667. [Google Scholar] [CrossRef]

- Kathirvel, P.; Kaliyaperumal, S.R.M. Influence of recycled concrete aggregates on the engineering and durability properties of alkali activated slag concrete. Constr. Build. Mater. 2017, 133, 65–72. [Google Scholar] [CrossRef]

- Kathirvel, P.; Kaliyaperumal, S.R.M. Influence of recycled concrete aggregates on the flexural properties of reinforced alkali activated slag concrete. Constr. Build. Mater. 2016, 102, 51–58. [Google Scholar] [CrossRef]

- Dawood, E.T.; Ahmed, A.A.; Hassan, A.M. Production of geopolymer mortar reinforced with sustainable fibers. J. Mech. Behav. Mater. 2020, 29, 114–123. [Google Scholar] [CrossRef]

- Wazien, A.W.; Abdullah, M.M.A.B.; Razak, R.A.; Rozainy, M.M.R.; Tahir, M.F.M. Strength and density of Geopolymer mortar cured at ambient temperature for use as repair material. Mater. Sci. Eng. 2016, 133, 012042. [Google Scholar] [CrossRef]

- Abdila, S.R.; Abdullah, M.M.A.B.; Ahmad, R.; Burduhos Nergis, D.D.; Rahim, S.Z.A.; Omar, M.F.; Sandu, A.V.; Vizureanu, P.; Syafwandi. Potential of Soil Stabilization Using Ground Granulated Blast Furnace Slag (GGBFS) and Fly Ash via Geopolymerization Method: A Review. Materials 2022, 15, 375. [Google Scholar] [CrossRef]

- Kumar, S.S.A.; Madhavan, A.; Dharmar, S. Experimental study on impact resistance of Geopolymer ferrocement flat panel. SSRG Int. J. Civ. Eng. 2017, 1, 278–282. [Google Scholar]

- Padmavathy, R.; Dharmar, S. Study on Flexural behaviour of Flat Ferrocement Panels. Int. J. Sci. Res. 2015, 4, 1495–1498. [Google Scholar]

- Palomo, A.; Maltseva, O.; Garcia-Lodeiro, I.; Fernández-Jiménez, A. Portland Versus Alkaline Cement: Continuity or Clean Break: “A Key Decision for Global Sustainability”. Front. Chem. 2021, 9, 705475. [Google Scholar] [CrossRef] [PubMed]

- Ouellet-Plamondon, C.; Habert, G. Life cycle analysis (LCA) of alkali-activated cements and concretes. In Handbook of Alkali-Activated Cements, Mortars and Concretes; WoodHead Publishing-Elsevier: Cambridge, UK, 2014; pp. 663–686. [Google Scholar] [CrossRef]

- Van Deventer, J.S.J.; Provis, J.; Duxson, P. Technical and commercial progress in the adoption of geopolymer cement. Miner. Eng. 2012, 29, 89–104. [Google Scholar] [CrossRef]

- IS:516-1959; Indian Standard Methods of Tests for Strength of Concrete. Bureau of Indian Standards: New Delhi, India, 1959.

- ACI 549.1R-93; Guide for the Design, Construction, and Repair of Ferrocement. ACI Committee 549: Farmington Hills, MI, USA, 1993.

- IS:456-2000; Indian Standard Plain and Reinforced Concrete—Code of Practice. Bureau of Indian Standards: New Delhi, India, 2000.

- Kathirvel, P.; Kaliyaperumal, S.R.M. Probabilistic modeling of geopolymer concrete using response surface methodology. Comput. Concr. 2016, 19, 737–744. [Google Scholar] [CrossRef]

- Thakur, R.N.; Ghosh, S. Effect of mix composition on compressive strength and microstructure of alyash based Geopolymer composites. ARPN J. Eng. Appl. Sci. 2009, 4, 68–74. [Google Scholar]

- Vyas, S.; Sameer, M.; Pal, S.; Singh, N. Strength and durability performance of fly ash based Geopolymer concrete using nano silica. Int. J. Eng. Sci. Technol. 2020, 4, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Haha, M.B.; le Saout, G.; Winnefeld, F.; Lothenbach, B. Influence of Activator type on hydration kinetics, Hydrate Assemblage and Microstructural Development of Alkali Activated blast-Furnace Slag. Cem. Concr. Res. 2011, 41, 301–310. [Google Scholar] [CrossRef]

- Gao, K.; Lin, K.L.; Wang, D.; Shiu, H.S.; Hwang, C.L.; Cheng, T.W. Effect of Nano-SiO2 on Setting time and compressive strength of Alkali-activated metakaolin-based Geopolymer. Open Civ. Eng. J. 2013, 7, 84–92. [Google Scholar] [CrossRef] [Green Version]

- Abideng, H.A.W.A.; Tonnayopas, D.; Prachasaree, W. Performance Evaluation of Metakaolin Based Geopolymer Containing Parawood Ash and Oil palm ash Blends. Mater. Sci. 2014, 20, 339–344. [Google Scholar] [CrossRef] [Green Version]

- Guo, X.; Pan, X. Effects of Steel Slag on Mechanical Properties and Mechanism of Fly Ash–Based GeoPolymer. J. Mater. Civ. Eng. 2020, 32, 04019348. [Google Scholar] [CrossRef]

- Yip, C.K.; van Deventer, J.S.J. Microanalysis of Calcium Silicate Hydrate Gel Formed within a Geopolymeric Binder. J. Mater. Sci. 2003, 38, 3851–3860. [Google Scholar] [CrossRef]

- Burduhos Nergis, D.D.; Abdullah, M.M.A.B.; Sandu, A.V.; Vizureanu, P. XRD and TG-DTA Study of New Alkali Activated Materials based on Fly-ash with sand and glass powder. Materials 2020, 13, 343. [Google Scholar] [CrossRef] [Green Version]

- Khater, H.M.; el Gawaad, H.A.A. Characterization of alkali activated Geopolymer mortar doped with MWCNT. Constr. Build. Mater. 2016, 102, 329–337. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramalingam, M.; Mohan, P.; Kathirvel, P.; Murali, G. Flexural Performance and Microstructural Studies of Trough-Shaped Geopolymer Ferrocement Panels. Materials 2022, 15, 5477. https://doi.org/10.3390/ma15165477

Ramalingam M, Mohan P, Kathirvel P, Murali G. Flexural Performance and Microstructural Studies of Trough-Shaped Geopolymer Ferrocement Panels. Materials. 2022; 15(16):5477. https://doi.org/10.3390/ma15165477

Chicago/Turabian StyleRamalingam, Malathy, Poornima Mohan, Parthiban Kathirvel, and Gunasekaran Murali. 2022. "Flexural Performance and Microstructural Studies of Trough-Shaped Geopolymer Ferrocement Panels" Materials 15, no. 16: 5477. https://doi.org/10.3390/ma15165477

APA StyleRamalingam, M., Mohan, P., Kathirvel, P., & Murali, G. (2022). Flexural Performance and Microstructural Studies of Trough-Shaped Geopolymer Ferrocement Panels. Materials, 15(16), 5477. https://doi.org/10.3390/ma15165477