Color Conversion Light-Emitting Diodes Based on Carbon Dots: A Review

Abstract

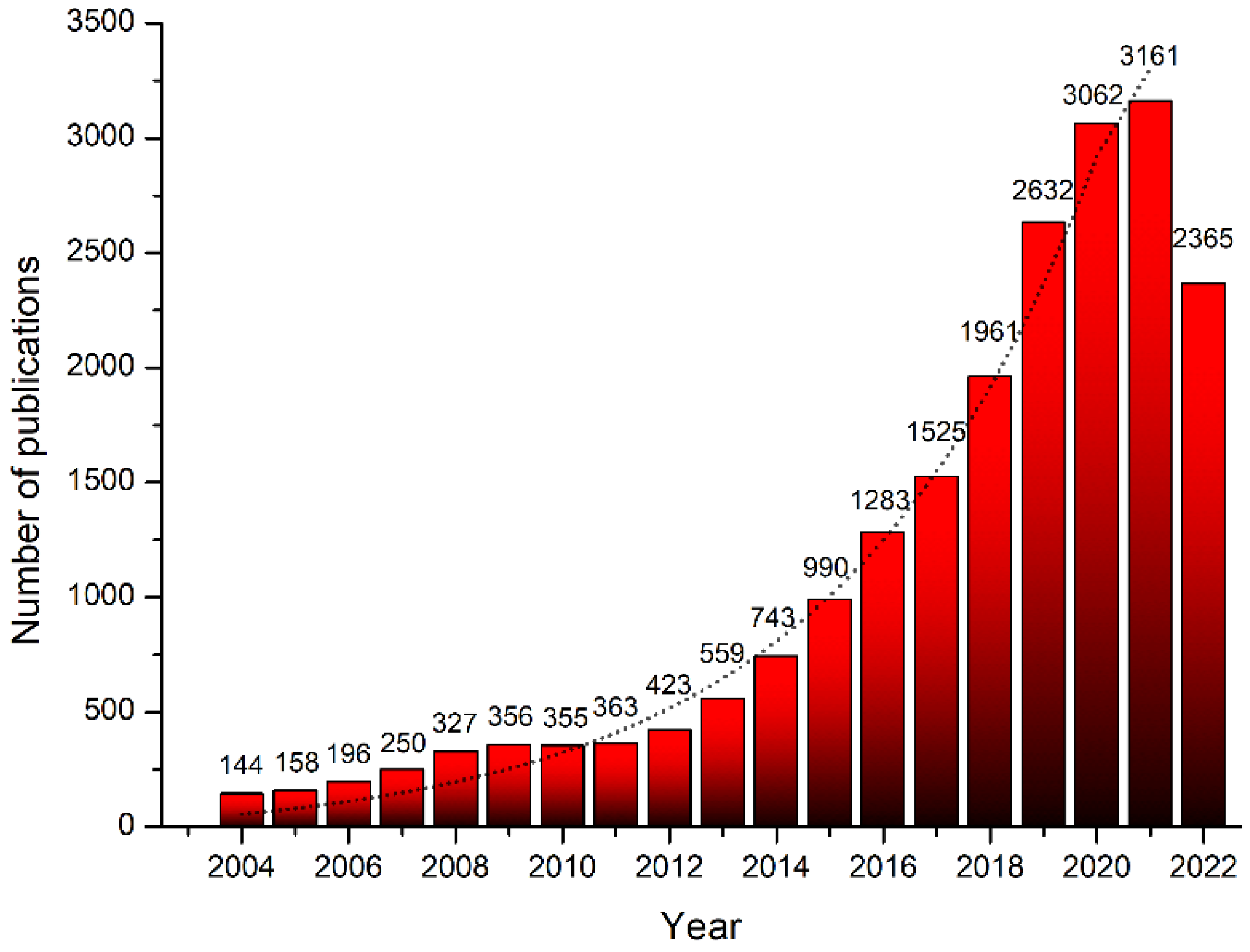

:1. Introduction

2. Materials for Frequency Down-Conversion LEDs

2.1. Phosphors

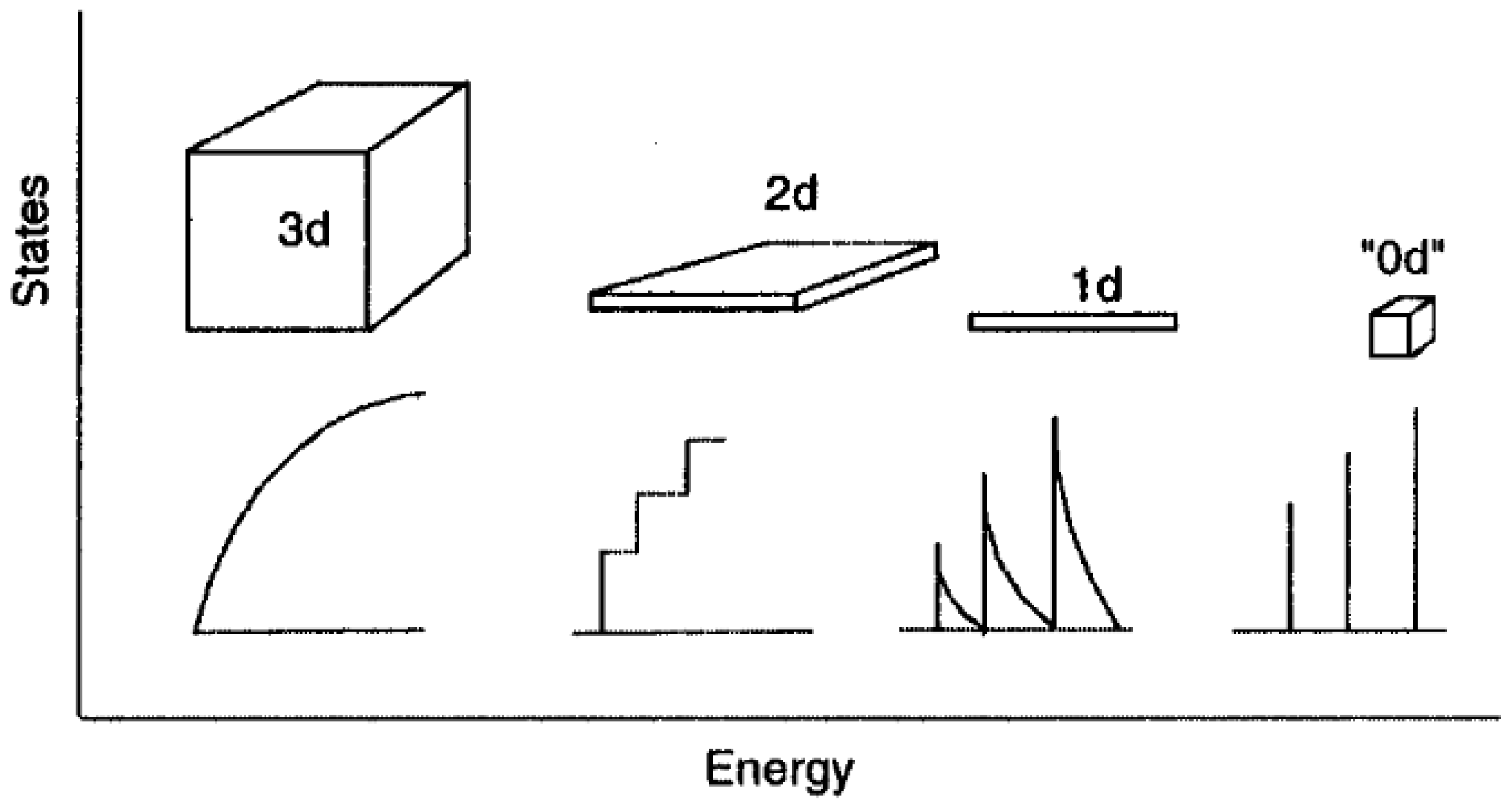

2.2. Quantum Dots (QDs)

2.3. Carbon Dots (CDs)

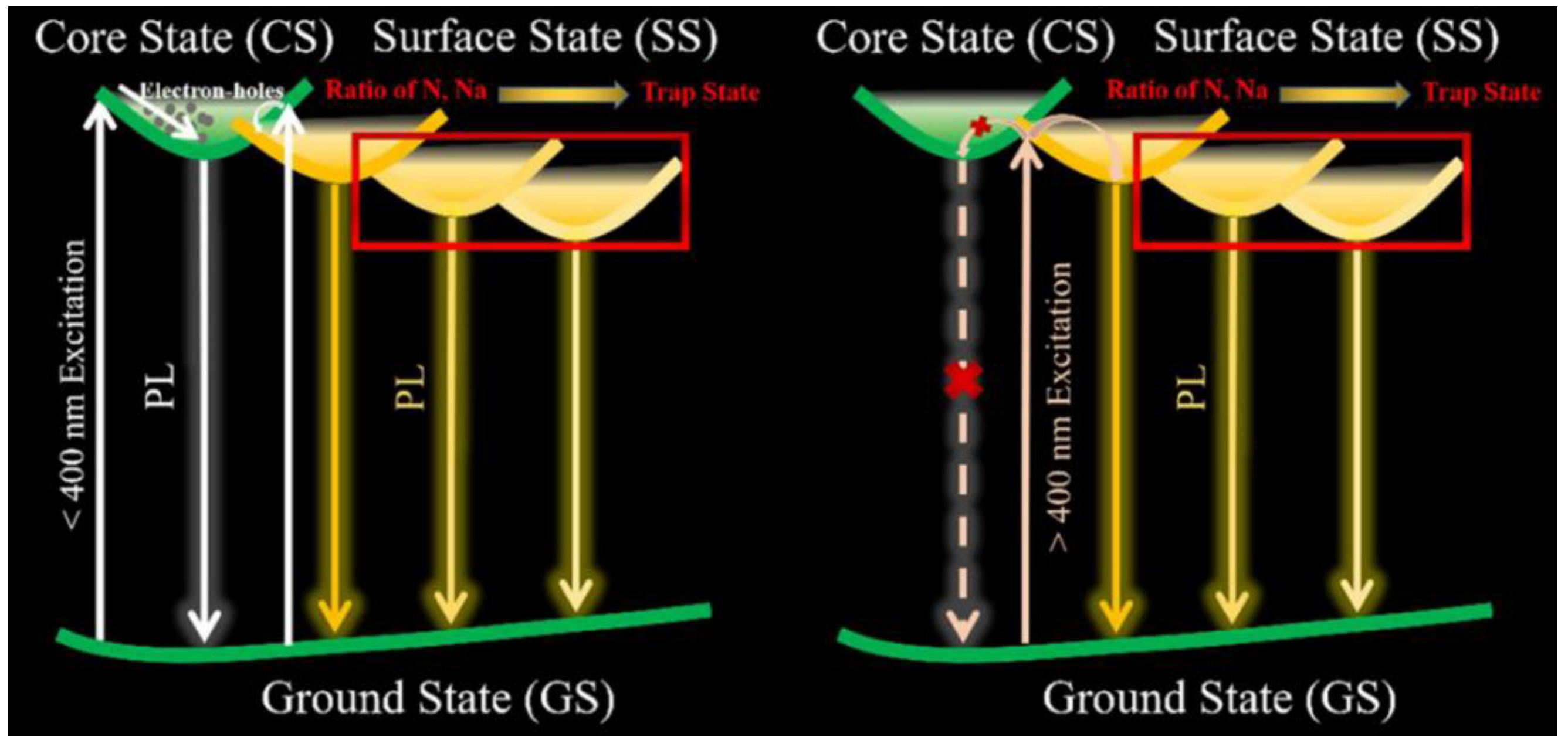

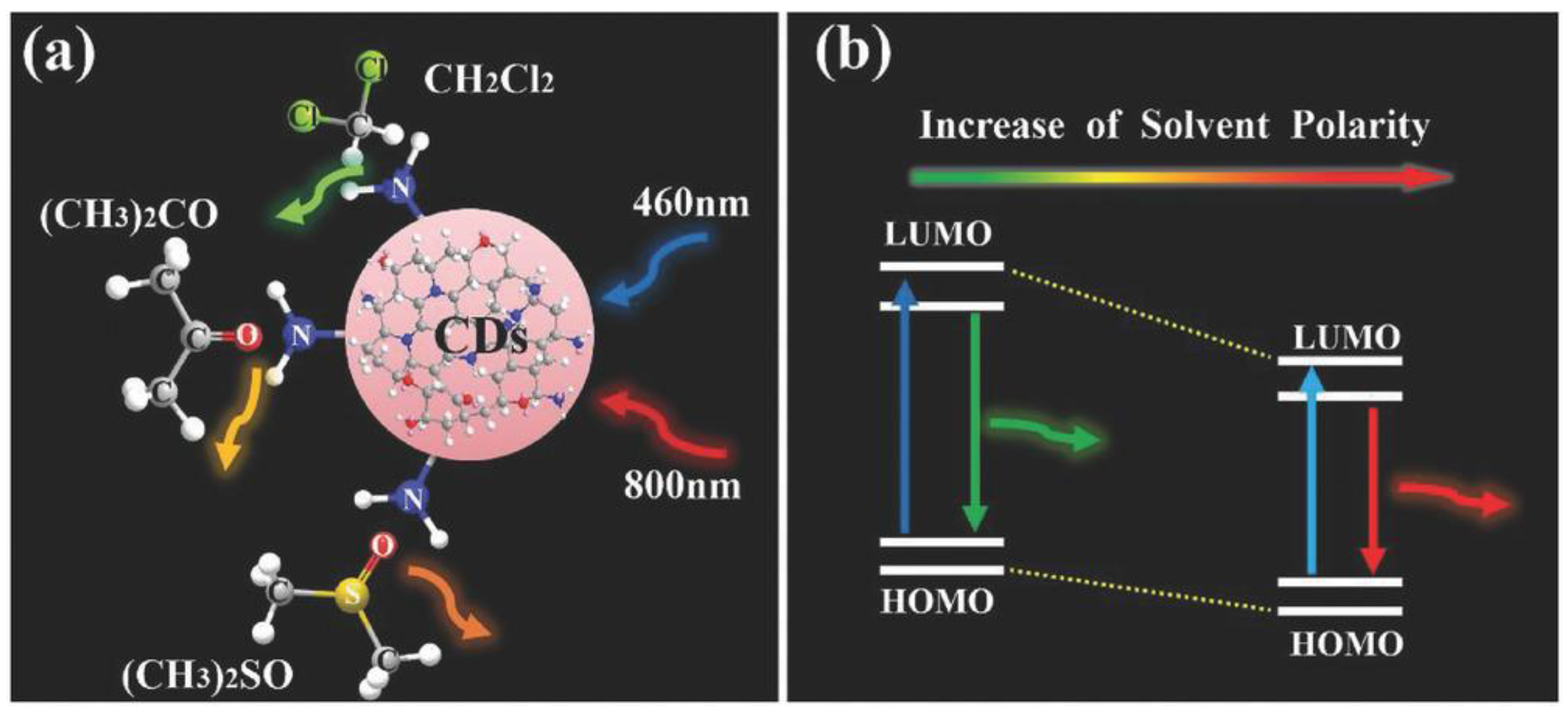

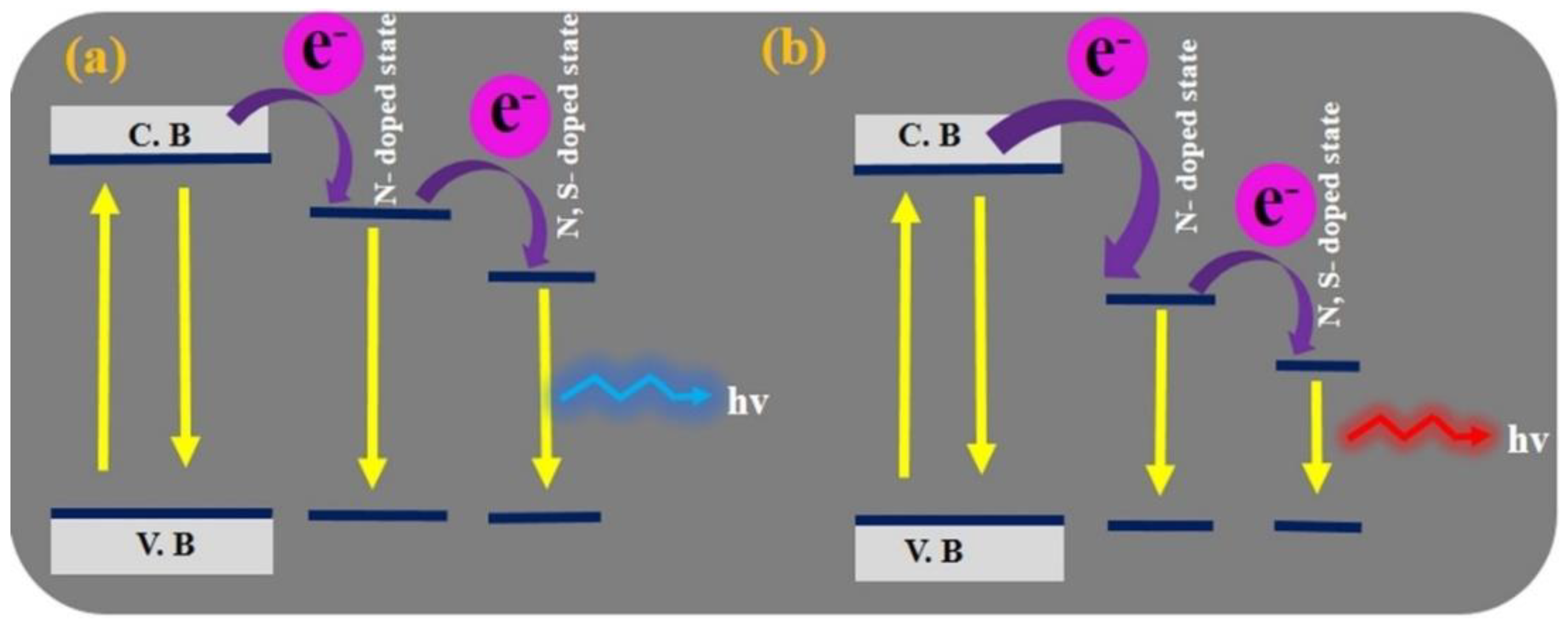

3. CD Photoluminescence Quenching

4. CD Preparation

5. Fluorescent CDs in Solid-State Form

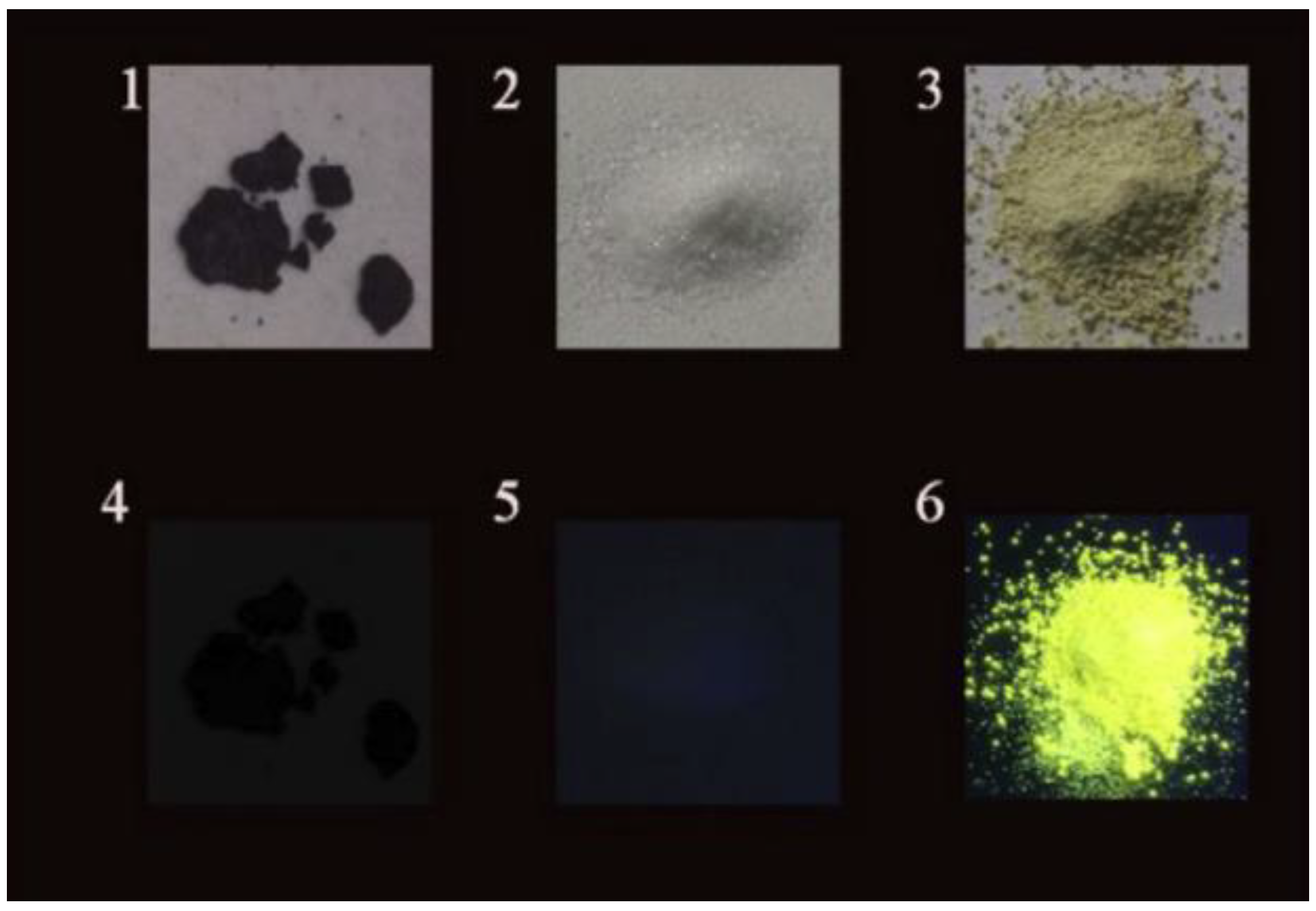

5.1. Solid-State Fluorescence in Matrices

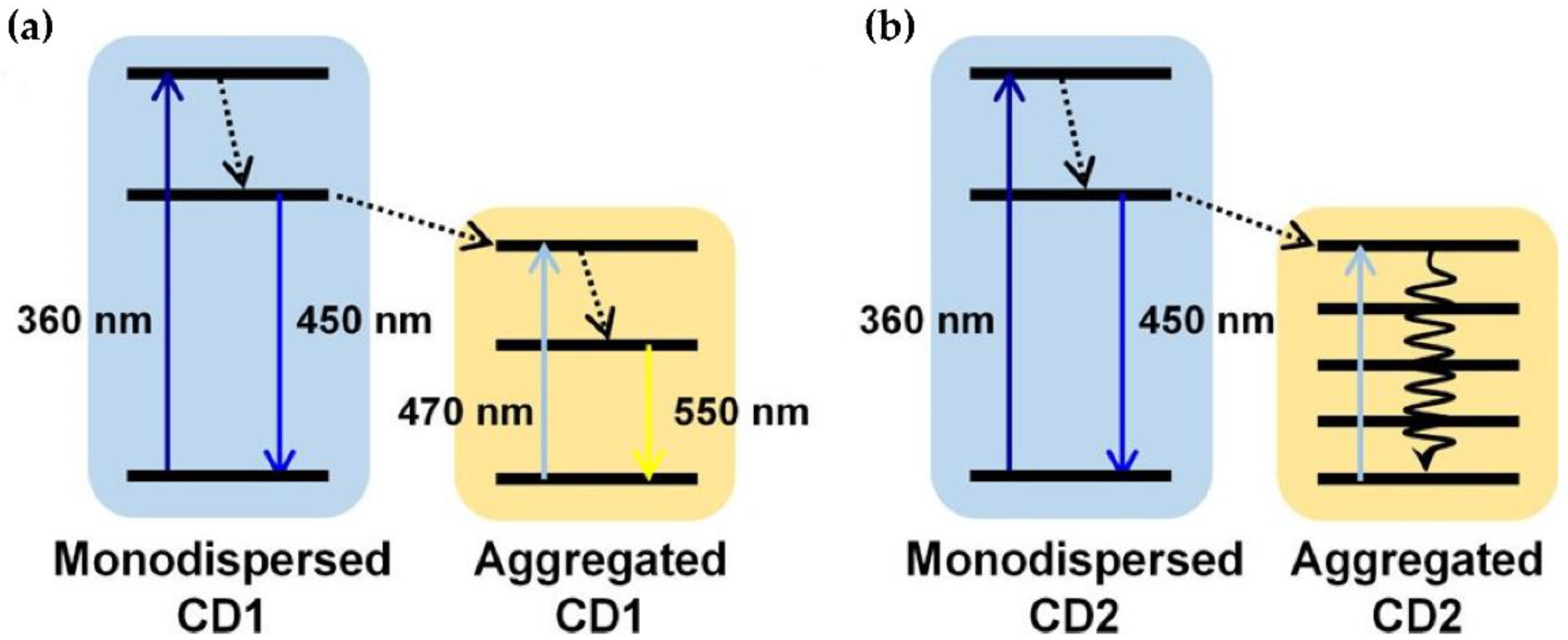

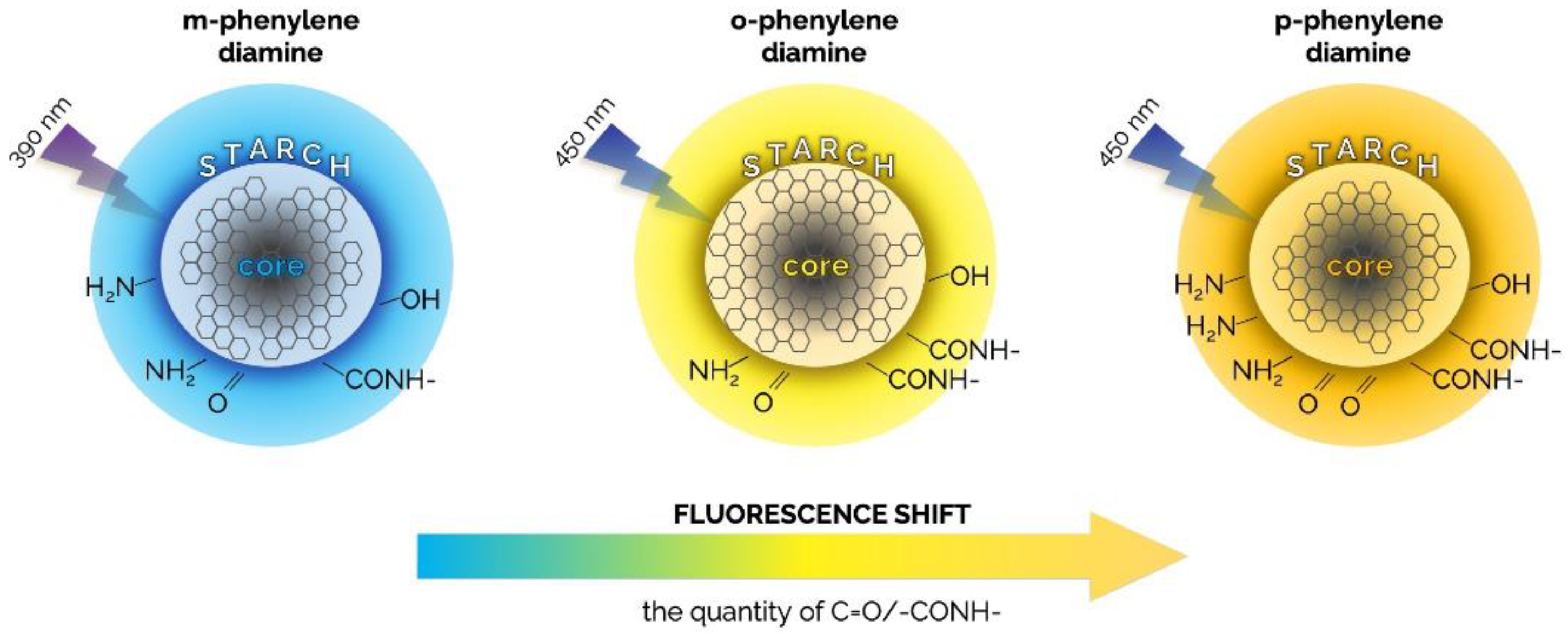

5.2. Self-Quenching-Resistant CDs

6. Color Conversion CD-Based LEDs

6.1. AIQ and Possible Solutions

6.2. Chromaticity and Luminescence Properties

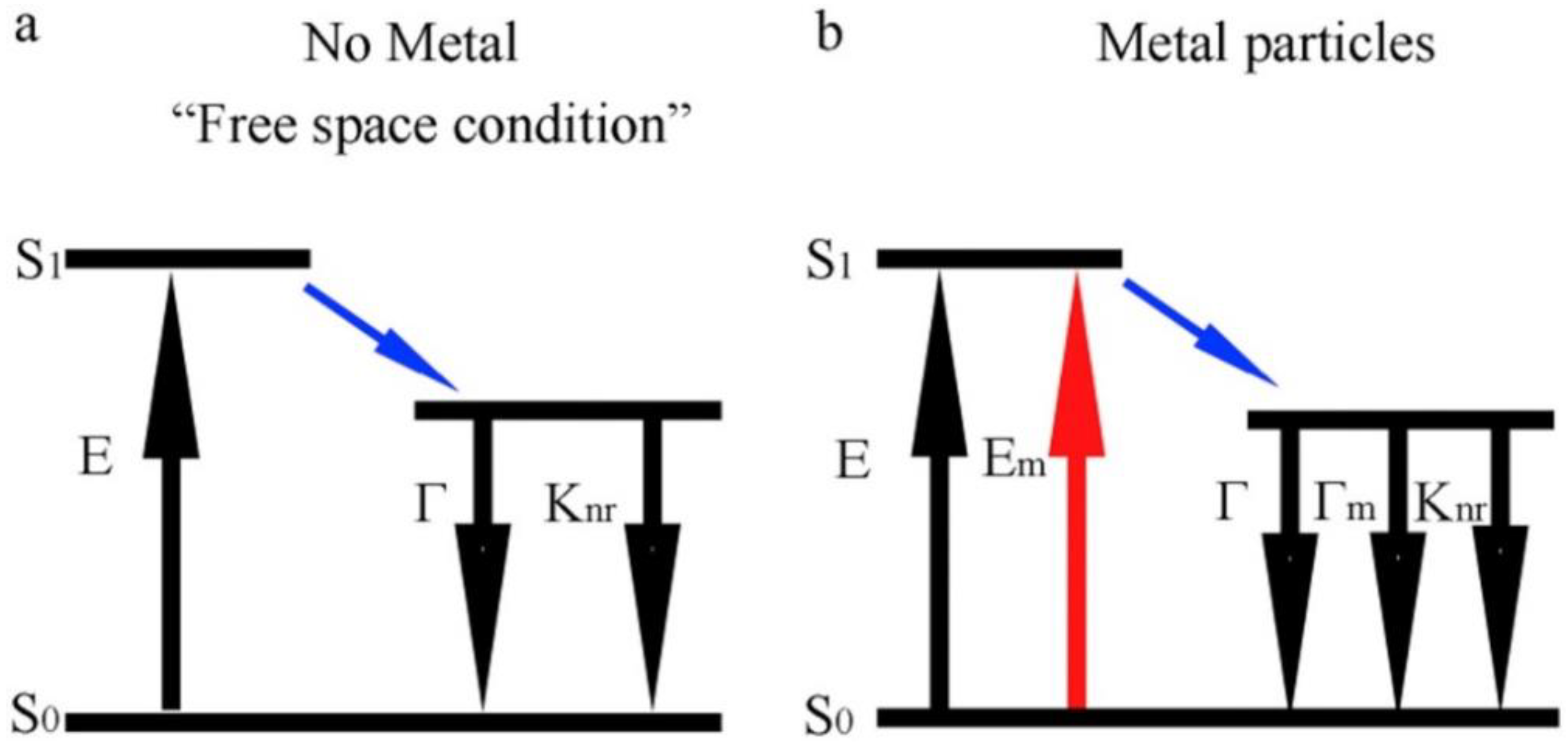

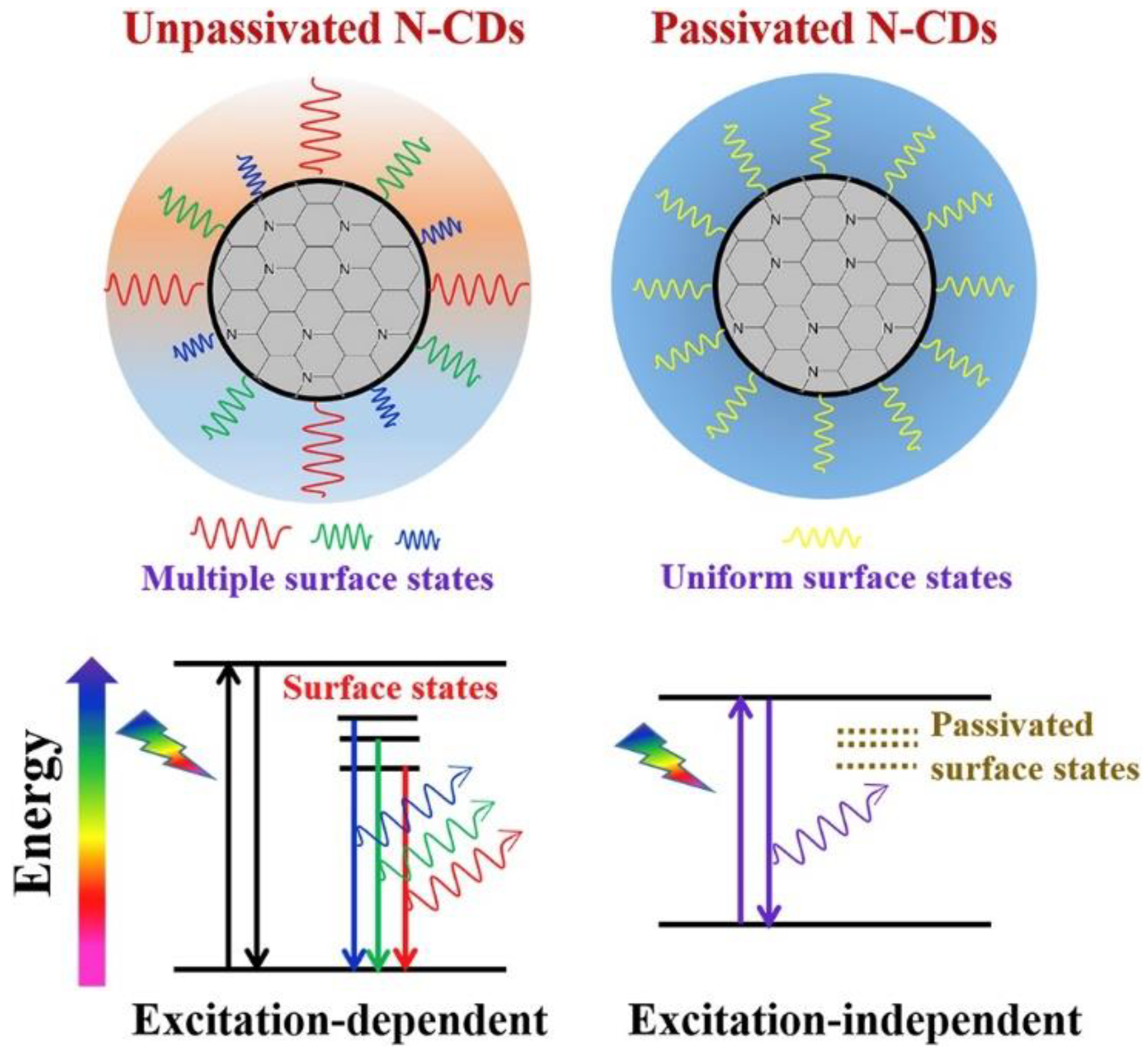

6.3. QY Improvement

6.4. Luminous Intensity and Luminous Efficiency

6.5. Stability

6.6. Biocompatibility

6.7. Applications of CD-Based LED in Telecommunications

6.8. Synoptic and Chronological Framework of Color Conversion CD-Based LEDs

7. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xu, X.; Ray, R.; Gu, Y.; Ploehn, H.J.; Gearheart, L.; Raker, K.; Scrivens, W.A. Electrophoretic Analysis and Purification of Fluorescent Single-Walled Carbon Nanotube Fragments. J. Am. Chem. Soc. 2004, 126, 12736–12737. [Google Scholar] [CrossRef] [PubMed]

- Jamaludin, N.; Rashid, S.A.; Tan, T. Chapter 5—Natural biomass as carbon sources for the synthesis of photoluminescent carbon dots. In Synthesis, Technology and Applications of Carbon Nanomaterials; Elsevier: Amsterdam, The Netherlands, 2019; pp. 109–134. [Google Scholar]

- Lim, S.Y.; Shen, W.; Gao, Z. Carbon quantum dots and their applications. Chem. Soc. Rev. 2015, 44, 362–381. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.; Park, E.; Lee, H.A.; Sugnaux, C.; Shin, M.; Jeong, C.J.; Lee, J.; Messersmith, P.B.; Park, S.Y.; Lee, H. Phenolic condensation and facilitation of fluorescent carbon dot formation: A mechanism study. Nanoscale 2017, 9, 16596–16601. [Google Scholar] [CrossRef]

- Zhu, S.; Meng, Q.; Wang, L.; Zhang, J.; Song, Y.; Jin, H.; Zhang, K.; Sun, H.; Wang, H.; Yang, B. Highly Photoluminescent Carbon Dots for Multicolor Patterning, Sensors, and Bioimaging. Angew. Chem. Int. Ed. 2013, 52, 3953–3957. [Google Scholar] [CrossRef]

- Wang, L.; Li, W.; Yin, L.; Liu, Y.; Guo, H.; Lai, J.; Han, Y.; Li, G.; Li, M.; Zhang, J.; et al. Full-color fluorescent carbon quantum dots. Sci. Adv. 2020, 6, eabb6772. [Google Scholar] [CrossRef]

- Essner, J.B.; Baker, G.A. The emerging roles of carbon dots in solar photovoltaics: A critical review. Environ. Sci. Nano 2017, 4, 1216–1263. [Google Scholar] [CrossRef]

- Wang, Q.; Huang, X.; Long, Y.; Wang, X.; Zhang, H.; Zhu, R.; Liang, L.; Teng, P.; Zheng, H. Hollow luminescent carbon dots for drug delivery. Carbon 2013, 59, 192–199. [Google Scholar] [CrossRef]

- Li, H.; Yan, X.; Kong, D.; Jin, R.; Sun, C.; Du, D.; Lin, Y.; Lu, G. Recent advances in carbon dots for bioimaging applications. Nanoscale Horiz. 2020, 5, 218–234. [Google Scholar] [CrossRef]

- Li, M.; Chen, T.; Gooding, J.J.; Liu, J. Review of Carbon and Graphene Quantum Dots for Sensing. ACS Sens. 2019, 4, 1732–1748. [Google Scholar] [CrossRef]

- Pricilla, R.B.; Skoda, D.; Urbanek, P.; Urbanek, M.; Suly, P.; Domincova Bergerova, E.; Kuritka, I. Unravelling the highly efficient synthesis of individual carbon nanodots from casein micelles and the origin of their competitive constant-blue-red wavelength shift luminescence mechanism for versatile applications. RSC Adv. 2022, 12, 16277–16290. [Google Scholar] [CrossRef]

- Yuan, F.; He, P.; Xi, Z.; Li, X.; Li, Y.; Zhong, H.; Fan, L.; Yang, S. Highly efficient and stable white LEDs based on pure red narrow bandwidth emission triangular carbon quantum dots for wide-color gamut backlight displays. Nano Res. 2019, 12, 1669–1674. [Google Scholar] [CrossRef]

- Zhang, Y.; Xiao, J.; Zhuo, P.; Yin, H.; Fan, Y.; Liu, X.; Chen, Z. Carbon Dots Exhibiting Concentration-Dependent Full-Visible-Spectrum Emission for Light-Emitting Diode Applications. ACS Appl. Mater. Interfaces 2019, 11, 46054–46061. [Google Scholar] [CrossRef] [PubMed]

- Zhu, H.; Wang, X.; Li, Y.; Wang, Z.; Yang, F.; Yang, X. Microwave synthesis of fluorescent carbon nanoparticles with electrochemiluminescence properties. Chem. Commun. 2009, 34, 5118–5120. [Google Scholar] [CrossRef]

- Liu, J.; Li, D.; Zhang, K.; Yang, M.; Sun, H.; Yang, B. One-Step Hydrothermal Synthesis of Nitrogen-Doped Conjugated Carbonized Polymer Dots with 31% Efficient Red Emission for In Vivo Imaging. Small 2018, 14, 1703919. [Google Scholar] [CrossRef] [PubMed]

- Doñate-Buendia, C.; Torres-Mendieta, R.; Pyatenko, A.; Falomir, E.; Fernández-Alonso, M.; Mínguez-Vega, G. Fabrication by Laser Irradiation in a Continuous Flow Jet of Carbon Quantum Dots for Fluorescence Imaging. ACS Omega 2018, 3, 2735–2742. [Google Scholar] [CrossRef]

- Zhang, Q.; Sun, X.; Ruan, H.; Yin, K.; Li, H. Production of yellow-emitting carbon quantum dots from fullerene carbon soot. Sci. China Mater. 2017, 60, 141–150. [Google Scholar] [CrossRef] [Green Version]

- Sciortino, A.; Marino, E.; van Dam, B.; Schall, P.; Cannas, M.; Messina, F. Solvatochromism Unravels the Emission Mechanism of Carbon Nanodots. J. Phys. Chem. Lett. 2016, 7, 3419–3423. [Google Scholar] [CrossRef]

- Zu, F.; Yan, F.; Bai, Z.; Xu, J.; Wang, Y.; Huang, Y.; Zhou, X. The quenching of the fluorescence of carbon dots: A review on mechanisms and applications. Microchim. Acta 2017, 184, 1899–1914. [Google Scholar] [CrossRef]

- Yoo, H.J.; Kwak, B.E.; Kim, D.H. Self-Quenching Origin of Carbon Dots and the Guideline for Their Solid-State Luminescence. J. Phys. Chem. C 2019, 123, 27124–27131. [Google Scholar] [CrossRef]

- Holonyak, N.; Bevacqua, S.F. Coherent (visible) light emission from Ga(As1−xPx) junctions. Appl. Phys. Lett. 1962, 1, 82–83. [Google Scholar] [CrossRef]

- Pearsall, T.P.; Miller, B.I.; Capik, R.J.; Bachmann, K.J. Efficient lattice-matched double-heterostructure LED’s at 1.1 μm from GaxIn1−xAsyP1−y. Appl. Phys. Lett. 1976, 28, 499–501. [Google Scholar] [CrossRef]

- Quaranta, M.; Borisov, S.M.; Klimant, I. Indicators for optical oxygen sensors. Bioanal. Rev. 2012, 4, 115–157. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Han, K.; Heo, J.; Chung, W.J. The effect of rare earth on color conversion properties of Cd–S–Se quantum dot embedded silicate glasses for white LED. Opt. Mater. 2021, 111, 110545. [Google Scholar] [CrossRef]

- Neikov, O.D.; Yefimov, N.A. Chapter 9 Nanopowders. In Handbook of Non-Ferrous Metal Powders; Elsevier: Amsterdam, The Netherlands, 2019; pp. 271–311. [Google Scholar] [CrossRef]

- Edvinsson, T. Optical quantum confinement and photocatalytic properties in two-, one- and zero-dimensional nanostructures. R. Soc. Open Sci. 2018, 5, 180387. [Google Scholar] [CrossRef] [Green Version]

- Rama Krishna, M.V.; Friesner, R.A. Quantum confinement effects in semiconductor clusters. J. Chem. Phys. 1991, 95, 8309–8322. [Google Scholar] [CrossRef]

- Alivisatos, A.P. Perspectives on the Physical Chemistry of Semiconductor Nanocrystals. J. Phys. Chem. 1996, 100, 13226–13239. [Google Scholar] [CrossRef]

- Brus, L.E. Electron–electron and electron-hole interactions in small semiconductor crystallites: The size dependence of the lowest excited electronic state. J. Chem. Phys. 1984, 80, 4403–4409. [Google Scholar] [CrossRef] [Green Version]

- Brus, L. Electronic wave functions in semiconductor clusters: Experiment and theory. J. Phys. Chem. 1986, 90, 2555–2560. [Google Scholar] [CrossRef]

- Saleh, B.E.A.; Teich, M.C. Fundamentals of Photonics, 2nd ed.; Wiley: Hoboken, NJ, USA, 2013; ISBN 978-1-118-58581-8. [Google Scholar]

- Hou, B.; Cho, Y.; Kim, B.-S.; Ahn, D.; Lee, S.; Park, J.B.; Lee, Y.-W.; Hong, J.; Im, H.; Morris, S.M.; et al. Red green blue emissive lead sulfide quantum dots: Heterogeneous synthesis and applications. J. Mater. Chem. C 2017, 5, 3692–3698. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Bai, X.; Wang, T.; Yan, L.; Zhang, T.; Zhang, Y.; Yu, W.W. Efficient near-infrared light-emitting diodes based on liquid PbSe quantum dots. Nanotechnology 2017, 28, 215703. [Google Scholar] [CrossRef]

- Crouch, D.J.; O’Brien, P.; Malik, M.A.; Skabara, P.J.; Wright, S.P. A one-step synthesis of cadmium selenide quantum dots from a novel single source precursor. Chem. Commun. 2003, 12, 1454–1455. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Li, Z.; Chen, M.; Cooper, H.M.; Lu, G.Q.; Xu, Z.P. One-pot preparation of highly fluorescent cadmium telluride/cadmium sulfide quantum dots under neutral-pH condition for biological applications. J. Colloid Interface Sci. 2013, 390, 3–10. [Google Scholar] [CrossRef] [PubMed]

- Rajh, T.; Micic, O.I.; Nozik, A.J. Synthesis and characterization of surface-modified colloidal cadmium telluride quantum dots. J. Phys. Chem. 1993, 97, 11999–12003. [Google Scholar] [CrossRef]

- Franke, D.; Harris, D.K.; Chen, O.; Bruns, O.T.; Carr, J.A.; Wilson, M.W.B.; Bawendi, M.G. Continuous injection synthesis of indium arsenide quantum dots emissive in the short-wavelength infrared. Nat. Commun. 2016, 7, 12749. [Google Scholar] [CrossRef] [Green Version]

- Ramasamy, P.; Kim, N.; Kang, Y.-S.; Ramirez, O.; Lee, J.-S. Tunable, Bright, and Narrow-Band Luminescence from Colloidal Indium Phosphide Quantum Dots. Chem. Mater. 2017, 29, 6893–6899. [Google Scholar] [CrossRef]

- Wageh, S.; Al-Ghamdi, A.; Jilani, A.; Iqbal, J. Facile Synthesis of Ternary Alloy of CdSe1-xSx Quantum Dots with Tunable Absorption and Emission of Visible Light. Nanomaterials 2018, 8, 979. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Li, X.; Song, J.; Xiao, L.; Zeng, H.; Sun, H. All-Inorganic Colloidal Perovskite Quantum Dots: A New Class of Lasing Materials with Favorable Characteristics. Adv. Mater. 2015, 27, 7101–7108. [Google Scholar] [CrossRef]

- Shiohara, A.; Hoshino, A.; Hanaki, K.-I.; Suzuki, K.; Yamamoto, K. On the cyto-toxicity caused by quantum dots. Microbiol. Immunol. 2004, 48, 669–675. [Google Scholar] [CrossRef]

- Ali, H.; Khan, E.; Ilahi, I. Environmental Chemistry and Ecotoxicology of Hazardous Heavy Metals: Environmental Persistence, Toxicity, and Bioaccumulation. J. Chem. 2019, 2019, 6730305. [Google Scholar] [CrossRef] [Green Version]

- Yang, P.; Zhao, J.; Zhang, L.; Li, L.; Zhu, Z. Intramolecular Hydrogen Bonds Quench Photoluminescence and Enhance Photocatalytic Activity of Carbon Nanodots. Chem. Eur. J. 2015, 21, 8561–8568. [Google Scholar] [CrossRef]

- Zhu, S.; Song, Y.; Zhao, X.; Shao, J.; Zhang, J.; Yang, B. The photoluminescence mechanism in carbon dots (graphene quantum dots, carbon nanodots, and polymer dots): Current state and future perspective. Nano Res. 2015, 8, 355–381. [Google Scholar] [CrossRef]

- Jiang, K.; Sun, S.; Zhang, L.; Lu, Y.; Wu, A.; Cai, C.; Lin, H. Red, Green, and Blue Luminescence by Carbon Dots: Full-Color Emission Tuning and Multicolor Cellular Imaging. Angew. Chem. Int. Ed. 2015, 54, 5360–5363. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.; Sun, J.; Li, X.; Zhou, W.; Wang, Z.; He, P.; Ding, G.; Xie, X.; Kang, Z.; Jiang, M. Large-scale fabrication of heavy doped carbon quantum dots with tunable-photoluminescence and sensitive fluorescence detection. J. Mater. Chem. A 2014, 2, 8660–8667. [Google Scholar] [CrossRef]

- Zhang, K.; Shi, Y.; Jia, Y.; Li, P.; Zhang, X.; Feng, X.; Zhu, L.; Sun, Y.; Hu, W.; Zhao, G. Tunable dual fluorescence emissions with high photoluminescence quantum yields modulated by Na ion dispersion method for purely solid state N-doped carbon dots. J. Photochem. Photobiol. Chem. 2020, 397, 112548. [Google Scholar] [CrossRef]

- Ma, P.; Sun, X.; Pan, W.; Yu, G.; Wang, J. Green and Orange Emissive Carbon Dots with High Quantum Yields Dispersed in Matrices for Phosphor-Based White LEDs. ACS Sustain. Chem. Eng. 2020, 8, 3151–3161. [Google Scholar] [CrossRef]

- Zhu, S.; Tang, S.; Zhang, J.; Yang, B. Control the size and surface chemistry of graphene for the rising fluorescent materials. Chem. Commun. 2012, 48, 4527–4539. [Google Scholar] [CrossRef]

- Yan, F.; Sun, Z.; Zhang, H.; Sun, X.; Jiang, Y.; Bai, Z. The fluorescence mechanism of carbon dots, and methods for tuning their emission color: A review. Microchim. Acta 2019, 186, 583. [Google Scholar] [CrossRef]

- Sk, M.A.; Ananthanarayanan, A.; Huang, L.; Lim, K.H.; Chen, P. Revealing the tunable photoluminescence properties of graphene quantum dots. J. Mater. Chem. C 2014, 2, 6954–6960. [Google Scholar] [CrossRef]

- Iqbal, A.; Tian, Y.; Wang, X.; Gong, D.; Guo, Y.; Iqbal, K.; Wang, Z.; Liu, W.; Qin, W. Carbon dots prepared by solid state method via citric acid and 1,10-phenanthroline for selective and sensing detection of Fe2+ and Fe3+. Sens. Actuators B Chem. 2016, 237, 408–415. [Google Scholar] [CrossRef]

- Kimball, J.; Chavez, J.; Ceresa, L.; Kitchner, E.; Nurekeyev, Z.; Doan, H.; Szabelski, M.; Borejdo, J.; Gryczynski, I.; Gryczynski, Z. On the origin and correction for inner filter effects in fluorescence Part I: Primary inner filter effect-the proper approach for sample absorbance correction. Methods Appl. Fluoresc. 2020, 8, 033002. [Google Scholar] [CrossRef]

- Doose, S.; Neuweiler, H.; Sauer, M. Fluorescence Quenching by Photoinduced Electron Transfer: A Reporter for Conformational Dynamics of Macromolecules. Chem. Phys. Chem. 2009, 10, 1389–1398. [Google Scholar] [CrossRef] [PubMed]

- So, Y.-H.; Zaleski, J.M.; Murlick, C.; Ellaboudy, A. Synthesis and Photophysical Properties of Some Benzoxazole and Benzothiazole Compounds. Macromolecules 1996, 29, 2783–2795. [Google Scholar] [CrossRef]

- Murphy, C.B.; Zhang, Y.; Troxler, T.; Ferry, V.; Martin, J.J.; Jones, W.E. Probing Förster and Dexter Energy-Transfer Mechanisms in Fluorescent Conjugated Polymer Chemosensors. J. Phys. Chem. B 2004, 108, 1537–1543. [Google Scholar] [CrossRef]

- Chen, Y.; O’Donoghue, M.B.; Huang, Y.-F.; Kang, H.; Phillips, J.A.; Chen, X.; Estevez, M.-C.; Yang, C.J.; Tan, W. A Surface Energy Transfer Nanoruler for Measuring Binding Site Distances on Live Cell Surfaces. J. Am. Chem. Soc. 2010, 132, 16559–16570. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wei, C.; Li, J.; Xiao, X.; Yue, T.; Zhao, D. The one-step preparation of green-emission carbon dots based on the deactivator-reducing reagent synergistic effect and the study on their luminescence mechanism. RSC Adv. 2018, 8, 20016–20024. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Guo, Y.; Wang, Z.; Shao, H.; Jiang, X. Hydrothermal synthesis of highly fluorescent carbon nanoparticles from sodium citrate and their use for the detection of mercury ions. Carbon 2013, 52, 583–589. [Google Scholar] [CrossRef]

- Yang, Z.-C.; Li, X.; Wang, J. Intrinsically fluorescent nitrogen-containing carbon nanoparticles synthesized by a hydrothermal process. Carbon 2011, 49, 5207–5212. [Google Scholar] [CrossRef]

- Zhang, B.; Liu, C.; Liu, Y. A Novel One-Step Approach to Synthesize Fluorescent Carbon Nanoparticles. Eur. J. Inorg. Chem. 2010, 2010, 4411–4414. [Google Scholar] [CrossRef]

- Li, H.; Ming, H.; Liu, Y.; Yu, H.; He, X.; Huang, H.; Pan, K.; Kang, Z.; Lee, S.-T. Fluorescent carbon nanoparticles: Electrochemical synthesis and their pH sensitive photoluminescence properties. New J. Chem. 2011, 35, 2666–2670. [Google Scholar] [CrossRef]

- He, C.; Yan, H.; Li, X.; Wang, X. Ultrafast preparation of polymer carbon dots with solid-state fluorescence for white light-emitting diodes. Mater. Res. Express 2019, 6, 065609. [Google Scholar] [CrossRef]

- Zhou, J.; Booker, C.; Li, R.; Zhou, X.; Sham, T.-K.; Sun, X.; Ding, Z. An Electrochemical Avenue to Blue Luminescent Nanocrystals from Multiwalled Carbon Nanotubes (MWCNTs). J. Am. Chem. Soc. 2007, 129, 744–745. [Google Scholar] [CrossRef] [PubMed]

- Dong, Y.; Zhou, N.; Lin, X.; Lin, J.; Chi, Y.; Chen, G. Extraction of Electrochemiluminescent Oxidized Carbon Quantum Dots from Activated Carbon. Chem. Mater. 2010, 22, 5895–5899. [Google Scholar] [CrossRef]

- Sun, Y.-P.; Zhou, B.; Lin, Y.; Wang, W.; Fernando, K.A.S.; Pathak, P.; Meziani, M.J.; Harruff, B.A.; Wang, X.; Wang, H.; et al. Quantum-Sized Carbon Dots for Bright and Colorful Photoluminescence. J. Am. Chem. Soc. 2006, 128, 7756–7757. [Google Scholar] [CrossRef]

- Kaczmarek, A.; Hoffman, J.; Morgiel, J.; Mościcki, T.; Stobiński, L.; Szymański, Z.; Małolepszy, A. Luminescent Carbon Dots Synthesized by the Laser Ablation of Graphite in Polyethylenimine and Ethylenediamine. Materials 2021, 14, 729. [Google Scholar] [CrossRef] [PubMed]

- Sun, M.; Qu, S.; Hao, Z.; Ji, W.; Jing, P.; Zhang, H.; Zhang, L.; Zhao, J.; Shen, D. Towards efficient solid-state photoluminescence based on carbon-nanodots and starch composites. Nanoscale 2014, 6, 13076–13081. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Javanbakht, S.; Namazi, H. Solid state photoluminescence thermoplastic starch film containing graphene quantum dots. Carbohydr. Polym. 2017, 176, 220–226. [Google Scholar] [CrossRef]

- He, Y.; He, J.; Yu, Z.; Zhang, H.; Liu, Y.; Hu, G.; Zheng, M.; Dong, H.; Zhuang, J.; Lei, B. Double carbon dot assembled mesoporous aluminas: Solid-state dual-emission photoluminescence and multifunctional applications. J. Mater. Chem. C 2018, 6, 2495–2501. [Google Scholar] [CrossRef]

- He, Y.; He, J.; Zhang, H.; Liu, Y.; Lei, B. Luminescent properties and energy transfer of luminescent carbon dots assembled mesoporous Al2O3: Eu3+ co-doped materials for temperature sensing. J. Colloid Interface Sci. 2017, 496, 8–15. [Google Scholar] [CrossRef]

- Mosconi, D.; Mazzier, D.; Silvestrini, S.; Privitera, A.; Marega, C.; Franco, L.; Moretto, A. Synthesis and Photochemical Applications of Processable Polymers Enclosing Photoluminescent Carbon Quantum Dots. ACS Nano 2015, 9, 4156–4164. [Google Scholar] [CrossRef]

- Gong, X.; Ma, W.; Li, Y.; Zhong, L.; Li, W.; Zhao, X. Fabrication of high-performance luminescent solar concentrators using N-doped carbon dots/PMMA mixed matrix slab. Org. Electron. 2018, 63, 237–243. [Google Scholar] [CrossRef]

- Li, Y.; Miao, P.; Zhou, W.; Gong, X.; Zhao, X. N-doped carbon-dots for luminescent solar concentrators. J. Mater. Chem. A 2017, 5, 21452–21459. [Google Scholar] [CrossRef]

- He, X.; Zhou, X.; Jia, K.; Zhang, D.; Shou, H.; Liu, X. Incorporation of polyethylene glycol into polyethylene terephthalate towards blue emitting co-polyester. Mater. Lett. 2016, 182, 367–371. [Google Scholar] [CrossRef]

- Wang, B.; Yu, Y.; Zhang, H.; Xuan, Y.; Chen, G.; Ma, W.; Li, J.; Yu, J. Carbon Dots in a Matrix: Energy-Transfer-Enhanced Room-Temperature Red Phosphorescence. Angew. Chem. Int. Ed. 2019, 58, 18443–18448. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Zheng, M.; Xiao, Y.; Dong, H.; Zhang, H.; Zhuang, J.; Hu, H.; Lei, B.; Liu, Y. A Self-Quenching-Resistant Carbon-Dot Powder with Tunable Solid-State Fluorescence and Construction of Dual-Fluorescence Morphologies for White Light-Emission. Adv. Mater. 2016, 28, 312–318. [Google Scholar] [CrossRef] [PubMed]

- Shen, C.-L.; Zang, J.-H.; Lou, Q.; Su, L.-X.; Li, Z.; Liu, Z.-Y.; Dong, L.; Shan, C.-X. In-situ embedding of carbon dots in a trisodium citrate crystal matrix for tunable solid-state fluorescence. Carbon 2018, 136, 359–368. [Google Scholar] [CrossRef]

- Song, H.; Liu, X.; Wang, B.; Tang, Z.; Lu, S. High production-yield solid-state carbon dots with tunable photoluminescence for white/multi-color light-emitting diodes. Sci. Bull. 2019, 64, 1788–1794. [Google Scholar] [CrossRef] [Green Version]

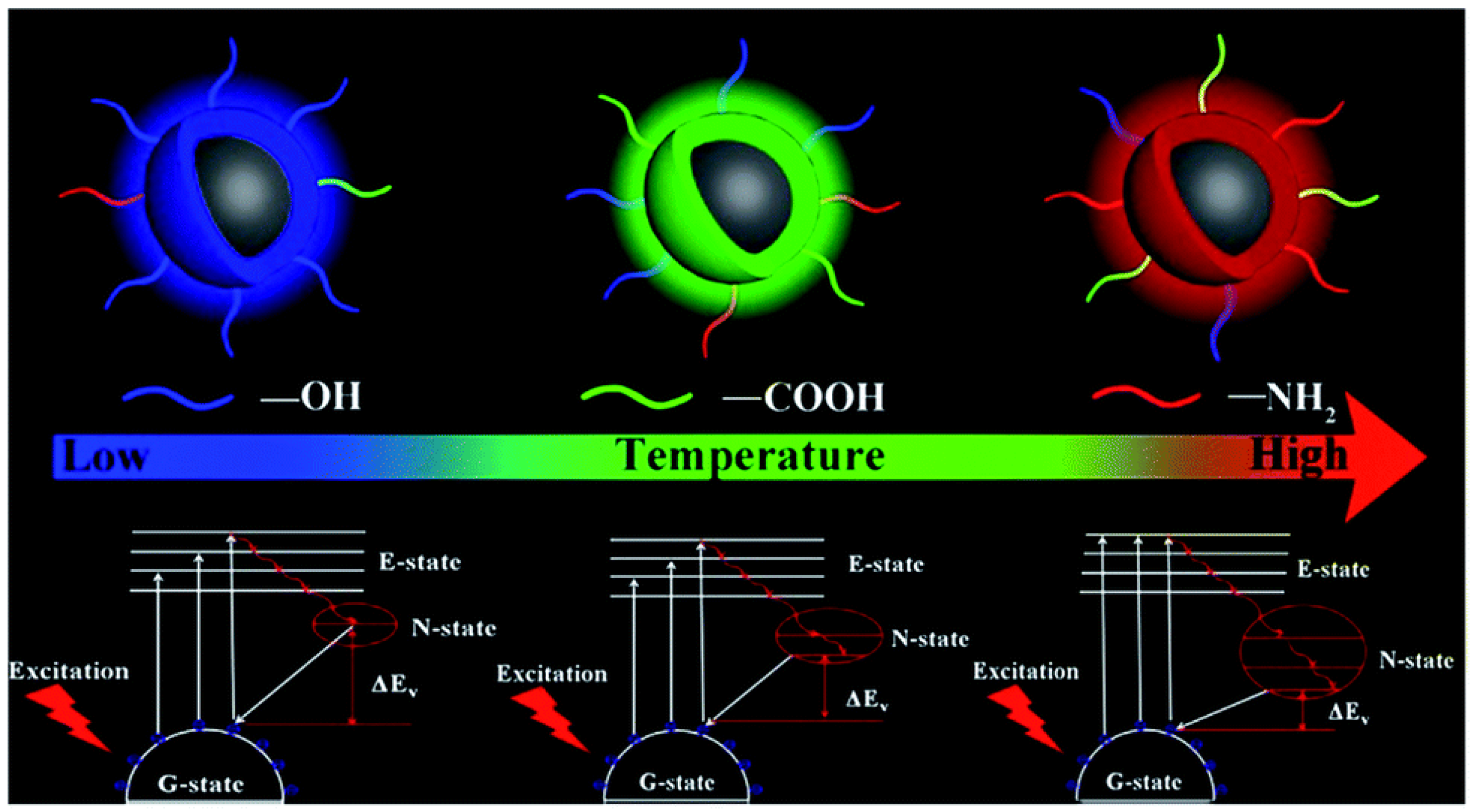

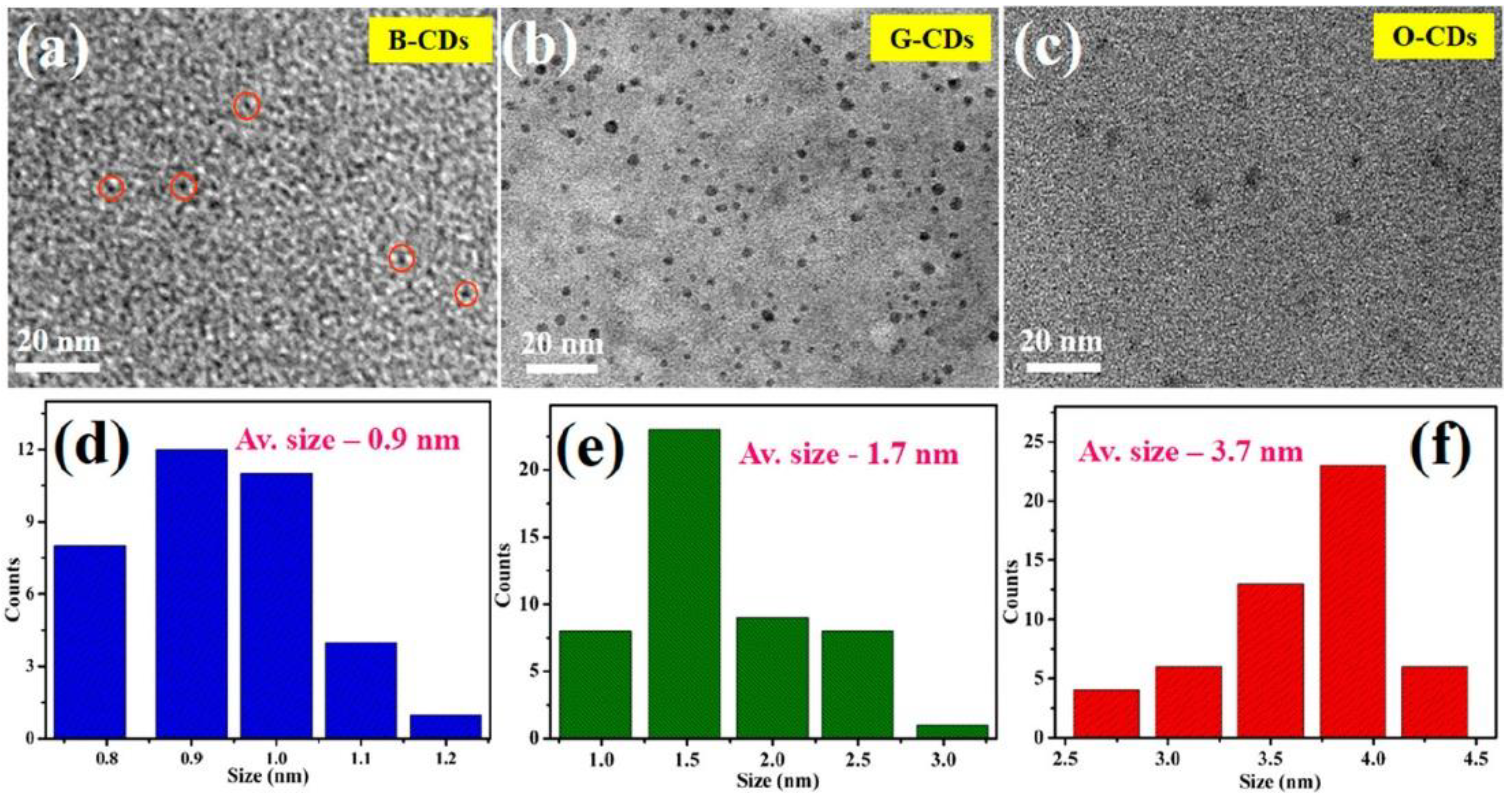

- Ding, H.; Yu, S.-B.; Wei, J.-S.; Xiong, H.-M. Full-Color Light-Emitting Carbon Dots with a Surface-State-Controlled Luminescence Mechanism. ACS Nano 2016, 10, 484–491. [Google Scholar] [CrossRef]

- Wang, H.-J.; Hou, W.-Y.; Hao, Y.-W.; Jiang, W.-S.; Chen, H.-L.; Zhang, Q.-Q. Novel yellow solid-state fluorescent-emitting carbon dots with high quantum yield for white light-emitting diodes. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2021, 250, 119340. [Google Scholar] [CrossRef]

- Zhou, Z.; Tian, P.; Liu, X.; Mei, S.; Zhou, D.; Li, D.; Jing, P.; Zhang, W.; Guo, R.; Qu, S.; et al. Hydrogen Peroxide-Treated Carbon Dot Phosphor with a Bathochromic-Shifted, Aggregation-Enhanced Emission for Light-Emitting Devices and Visible Light Communication. Adv. Sci. 2018, 5, 1800369. [Google Scholar] [CrossRef]

- Li, C.-X.; Yu, C.; Wang, C.-F.; Chen, S. Facile plasma-induced fabrication of fluorescent carbon dots toward high-performance white LEDs. J. Mater. Sci. 2013, 48, 6307–6311. [Google Scholar] [CrossRef]

- Chen, J.; Liu, W.; Mao, L.-H.; Yin, Y.-J.; Wang, C.-F.; Chen, S. Synthesis of silica-based carbon dot/nanocrystal hybrids toward white LEDs. J. Mater. Sci. 2014, 49, 7391–7398. [Google Scholar] [CrossRef]

- Sun, C.; Zhang, Y.; Wang, Y.; Liu, W.; Kalytchuk, S.; Kershaw, S.V.; Zhang, T.; Zhang, X.; Zhao, J.; Yu, W.W.; et al. High color rendering index white light emitting diodes fabricated from a combination of carbon dots and zinc copper indium sulfide quantum dots. Appl. Phys. Lett. 2014, 104, 261106. [Google Scholar] [CrossRef]

- Kim, T.H.; Wang, F.; McCormick, P.; Wang, L.; Brown, C.; Li, Q. Salt-embedded carbon nanodots as a UV and thermal stable fluorophore for light-emitting diodes. J. Lumin. 2014, 154, 1–7. [Google Scholar] [CrossRef]

- Ganiga, M.; Cyriac, J. Direct synthesis of highly stable nitrogen rich carbon dots toward white light emission. RSC Adv. 2015, 5, 101333–101337. [Google Scholar] [CrossRef]

- Ma, L.; Xiang, W.; Gao, H.; Pei, L.; Ma, X.; Huang, Y.; Liang, X. Carbon dot-doped sodium borosilicate gel glasses with emission tunability and their application in white light emitting diodes. J. Mater. Chem. C 2015, 3, 6764–6770. [Google Scholar] [CrossRef]

- Sun, C.; Zhang, Y.; Sun, K.; Reckmeier, C.; Zhang, T.; Zhang, X.; Zhao, J.; Wu, C.; Yu, W.W.; Rogach, A.L. Combination of carbon dot and polymer dot phosphors for white light-emitting diodes. Nanoscale 2015, 7, 12045–12050. [Google Scholar] [CrossRef]

- Othong, J.; Boonmak, J.; Promarak, V.; Kielar, F.; Youngme, S. Sonochemical Synthesis of Carbon Dots/Lanthanoid MOFs Hybrids for White Light-Emitting Diodes with High Color Rendering. ACS Appl. Mater. Interfaces 2019, 11, 44421–44429. [Google Scholar] [CrossRef]

- Li, X.; Liu, Y.; Song, X.; Wang, H.; Gu, H.; Zeng, H. Intercrossed Carbon Nanorings with Pure Surface States as Low-Cost and Environment-Friendly Phosphors for White-Light-Emitting Diodes. Angew. Chem. Int. Ed. 2015, 54, 1759–1764. [Google Scholar] [CrossRef]

- Lin, S.; Chen, M.; Wang, Z.; Zhang, Y.; Yuan, R.; Liang, X.; Xiang, W.; Zhou, Y. Construction of full-color light-emitting N-based carbon nanodots and their efficient solid-state materials via tape-casting technology for warm WLED. Chem. Eng. J. 2017, 324, 194–202. [Google Scholar] [CrossRef]

- Zheng, X.G.; Wang, H.L.; Ding, G.Q.; Cui, G.L.; Chen, L.; Zhang, P.H.; Gong, Q.; Wang, S.M. Facile synthesis of highly graphitized nitrogen-doped carbon dots and carbon sheets with solid-state white-light emission. Mater. Lett. 2017, 195, 58–61. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, F.; Wang, Y.; Yang, Y.; Liu, X. Efficient resistance against solid-state quenching of carbon dots towards white light emitting diodes by physical embedding into silica. Carbon 2018, 126, 426–436. [Google Scholar] [CrossRef]

- Zhu, J.; Bai, X.; Bai, J.; Pan, G.; Zhu, Y.; Zhai, Y.; Shao, H.; Chen, X.; Dong, B.; Zhang, H.; et al. Emitting color tunable carbon dots by adjusting solvent towards light-emitting devices. Nanotechnology 2018, 29, 085705. [Google Scholar] [CrossRef] [PubMed]

- Liu, E.; Li, D.; Zhou, X.; Zhou, G.; Xiao, H.; Zhou, D.; Tian, P.; Guo, R.; Qu, S. Highly Emissive Carbon Dots in Solid State and Their Applications in Light-Emitting Devices and Visible Light Communication. ACS Sustain. Chem. Eng. 2019, 7, 9301–9308. [Google Scholar] [CrossRef]

- Chen, L.; Zheng, J.; Du, Q.; Yang, Y.; Liu, X.; Xu, B. Orange-emissive carbon dot phosphors for warm white light-emitting diodes with high color rendering index. Opt. Mater. 2020, 109, 110346. [Google Scholar] [CrossRef]

- Shen, H.; Guo, J.; Ling, L.; Li, F.; Li, Q.; Wang, C.-F.; Wang, J.; Chen, S. Constructing honeycomb architectures from polymer carbon dot composites for luminous efficacy enhancement of LEDs. Appl. Phys. A 2019, 125, 91. [Google Scholar] [CrossRef]

- He, L.; Bai, Y.; Ge, C.; Yang, H.; Yu, X.; Zhang, X. Tunable luminescence and morphological evolution of facile synthesized zinc borate/carbon dots composites for NUV-WLEDs. J. Alloy. Compd. 2020, 834, 155021. [Google Scholar] [CrossRef]

- Mosca, M.; Macaluso, R.; Crupi, I. Hybrid Inorganic-Organic White Light Emitting Diodes. In Polymers for Light-Emitting Devices and Displays; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2020; pp. 197–262. ISBN 978-1-119-65464-3. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhuo, P.; Yin, H.; Fan, Y.; Zhang, J.; Liu, X.; Chen, Z. Solid-State Fluorescent Carbon Dots with Aggregation-Induced Yellow Emission for White Light-Emitting Diodes with High Luminous Efficiencies. ACS Appl. Mater. Interfaces 2019, 11, 24395–24403. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Yu, S.F.; Fei, L.; Jin, L.; Pan, S.; Lin, P. Large-area color controllable remote carbon white-light light-emitting diodes. Carbon 2015, 85, 344–350. [Google Scholar] [CrossRef]

- Sun, C.; Zhang, Y.; Kalytchuk, S.; Wang, Y.; Zhang, X.; Gao, W.; Zhao, J.; Cepe, K.; Zboril, R.; Yu, W.W.; et al. Down-conversion monochromatic light-emitting diodes with the color determined by the active layer thickness and concentration of carbon dots. J. Mater. Chem. C 2015, 3, 6613–6615. [Google Scholar] [CrossRef]

- Chen, D.; Gao, H.; Chen, X.; Fang, G.; Yuan, S.; Yuan, Y. Excitation-Independent Dual-Color Carbon Dots: Surface-State Controlling and Solid-State Lighting. ACS Photonics 2017, 4, 2352–2358. [Google Scholar] [CrossRef]

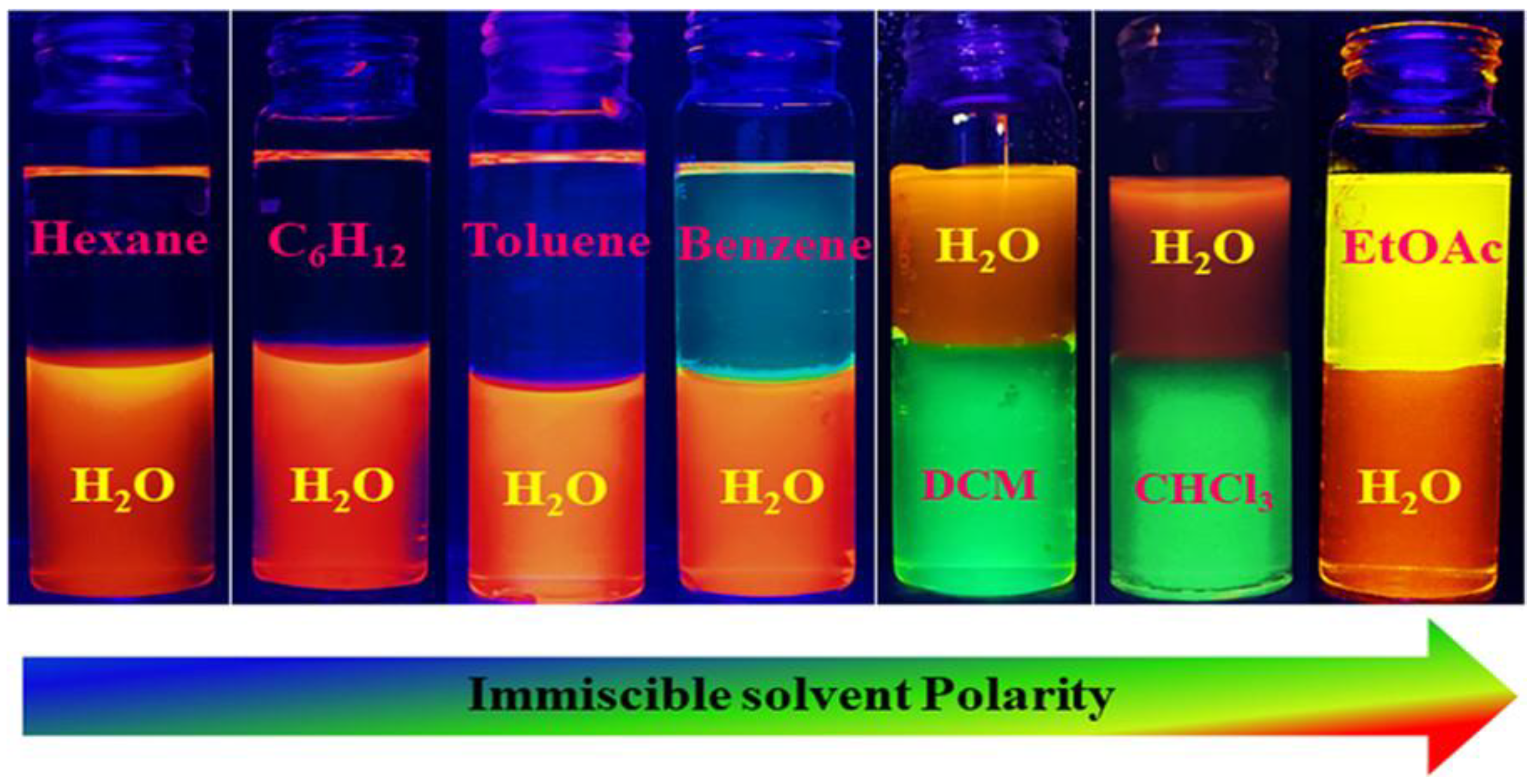

- Lin, S.; Lin, C.; He, M.; Yuan, R.; Zhang, Y.; Zhou, Y.; Xiang, W.; Liang, X. Solvatochromism of bright carbon dots with tunable long-wavelength emission from green to red and their application as solid-state materials for warm WLEDs. RSC Adv. 2017, 7, 41552–41560. [Google Scholar] [CrossRef] [Green Version]

- Tian, Z.; Zhang, X.; Li, D.; Zhou, D.; Jing, P.; Shen, D.; Qu, S.; Zboril, R.; Rogach, A.L. Full-Color Inorganic Carbon Dot Phosphors for White-Light-Emitting Diodes. Adv. Opt. Mater. 2017, 5, 1700416. [Google Scholar] [CrossRef]

- Wang, K.; Yin, Z.; Du, F. Green light–emitting diodes with high efficiency organosilane-functionalized carbon dots. Integr. Ferroelectr. 2017, 181, 70–77. [Google Scholar] [CrossRef]

- Yuan, R.; Liu, J.; Xiang, W.; Liang, X. Red-emitting carbon dots phosphors: A promising red color convertor toward warm white light emitting diodes. J. Mater. Sci. Mater. Electron. 2018, 29, 10453–10460. [Google Scholar] [CrossRef]

- Zhang, S.; Guo, Y.; Wang, Q. TiC2: A new two-dimensional sheet beyond MXenes. Nanoscale 2017, 8, 233–242. [Google Scholar] [CrossRef]

- Zhu, J.; Shao, H.; Bai, X.; Zhai, Y.; Zhu, Y.; Chen, X.; Pan, G.; Dong, B.; Xu, L.; Zhang, H.; et al. Modulation of the photoluminescence in carbon dots through surface modification: From mechanism to white light-emitting diodes. Nanotechnology 2018, 29, 245702. [Google Scholar] [CrossRef]

- Zhang, T.; Zhao, F.; Li, L.; Qi, B.; Zhu, D.; Lü, J.; Lü, C. Tricolor White-Light-Emitting Carbon Dots with Multiple-Cores@Shell Structure for WLED Application. ACS Appl. Mater. Interfaces 2018, 10, 19796–19805. [Google Scholar] [CrossRef]

- Ren, J.; Sun, J.; Sun, X.; Song, R.; Xie, Z.; Zhou, S. Precisely Controlled Up/Down-Conversion Liquid and Solid State Photoluminescence of Carbon Dots. Adv. Opt. Mater. 2018, 6, 1800115. [Google Scholar] [CrossRef]

- Zhai, Y.; Wang, Y.; Li, D.; Zhou, D.; Jing, P.; Shen, D.; Qu, S. Red carbon dots-based phosphors for white light-emitting diodes with color rendering index of 92. J. Colloid Interface Sci. 2018, 528, 281–288. [Google Scholar] [CrossRef]

- Wang, H.-J.; Yu, T.-T.; Chen, H.-L.; Nan, W.-B.; Xie, L.-Q.; Zhang, Q.-Q. A self-quenching-resistant carbon dots powder with tunable solid-state fluorescence and their applications in light-emitting diodes and fingerprints detection. Dye. Pigment. 2018, 159, 245–251. [Google Scholar] [CrossRef]

- Liu, C.; Wang, R.; Wang, B.; Deng, Z.; Jin, Y.; Kang, Y.; Chen, J. Orange, yellow and blue luminescent carbon dots controlled by surface state for multicolor cellular imaging, light emission and illumination. Microchim. Acta 2018, 185, 539. [Google Scholar] [CrossRef]

- Kumari, R.; Kumar Sahu, S. Synthesis of Longer-Wavelength-Emissive Carbon Quantum Dots for WLEDs and Investigation of Their Photoluminescence Properties. Chem. Sel. 2018, 3, 12998–13005. [Google Scholar] [CrossRef]

- Hu, T.; Wen, Z.; Wang, C.; Thomas, T.; Wang, C.; Song, Q.; Yang, M. Temperature-controlled spectral tuning of full-color carbon dots and their strongly fluorescent solid-state polymer composites for light-emitting diodes. Nanoscale Adv. 2019, 1, 1413–1420. [Google Scholar] [CrossRef] [Green Version]

- Kumari, R.; Pal, K.; Karmakar, P.; Sahu, S.K. pH-Responsive Mn-Doped Carbon Dots for White-Light-Emitting Diodes, Fingerprinting, and Bioimaging. ACS Appl. Nano Mater. 2019, 2, 5900–5909. [Google Scholar] [CrossRef]

- Liu, Y.; Li, W.; Wu, P.; Ma, C.; Wu, X.; Luo, S.; Liu, S. Organosilane-functionalized carbon quantum dots and their applications to “on-off-on” fluorometric determination of chromate and ascorbic acid, and in white light-emitting devices. Microchim. Acta 2019, 186, 516. [Google Scholar] [CrossRef]

- Su, R.; Guan, Q.; Cai, W.; Yang, W.; Xu, Q.; Guo, Y.; Zhang, L.; Fei, L.; Xu, M. Multi-color carbon dots for white light-emitting diodes. RSC Adv. 2019, 9, 9700–9708. [Google Scholar] [CrossRef] [Green Version]

- Song, X.; Guo, Q.; Cai, Z.; Qiu, J.; Dong, G. Synthesis of multi-color fluorescent carbon quantum dots and solid state CQDs@SiO2 nanophosphors for light-emitting devices. Ceram. Int. 2019, 45, 17387–17394. [Google Scholar] [CrossRef]

- Kumari, R.; Sahu, S.K. Effect of Solvent-Derived Highly Luminescent Multicolor Carbon Dots for White-Light-Emitting Diodes and Water Detection. Langmuir 2020, 36, 5287–5295. [Google Scholar] [CrossRef]

- Yang, X.; Sui, L.; Wang, B.; Zhang, Y.; Tang, Z.; Yang, B.; Lu, S. Red-emitting, self-oxidizing carbon dots for the preparation of white LEDs with super-high color rendering index. Sci. China Chem. 2021, 64, 1547–1553. [Google Scholar] [CrossRef]

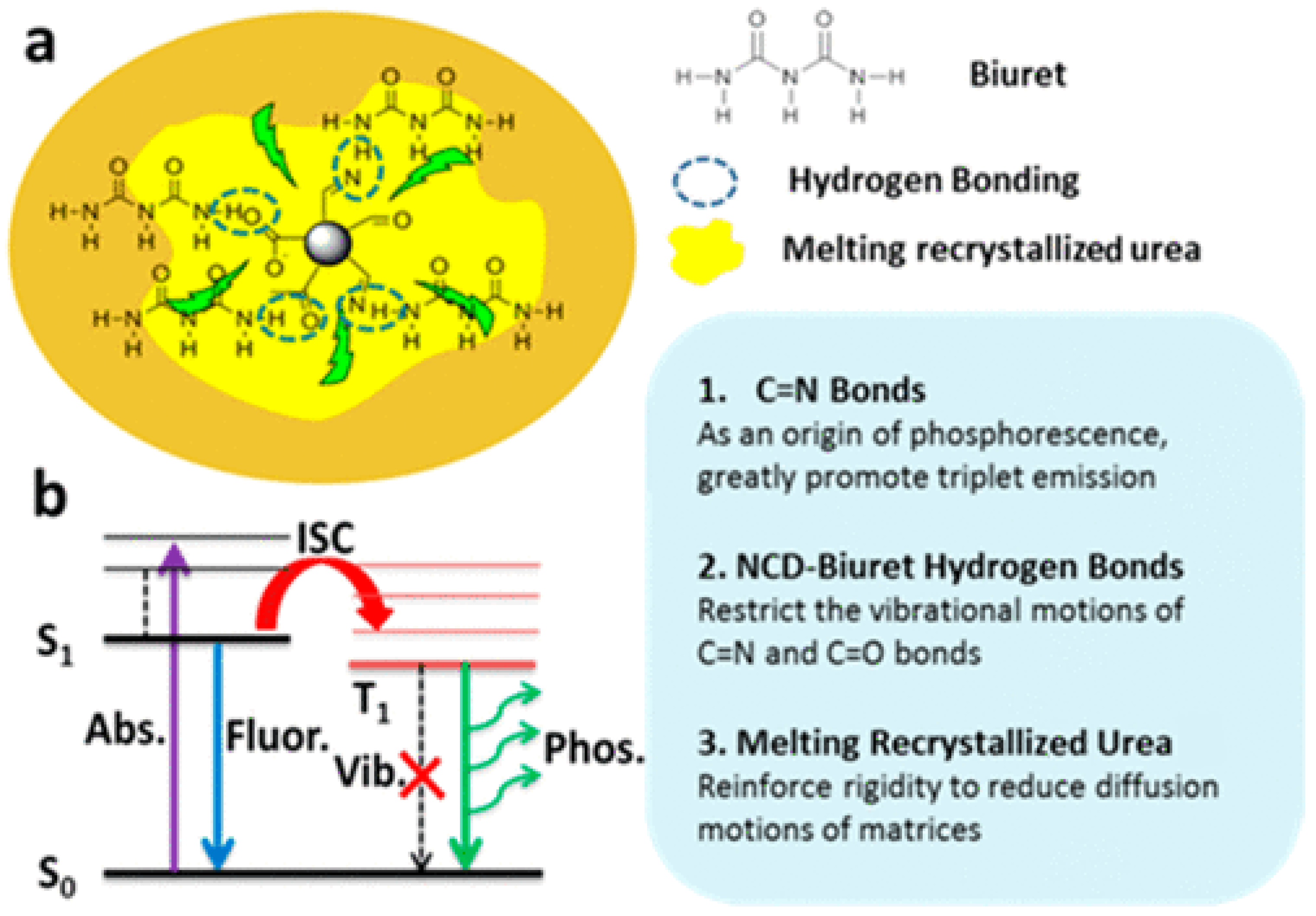

- Li, Q.; Zhou, M.; Yang, Q.; Wu, Q.; Shi, J.; Gong, A.; Yang, M. Efficient Room-Temperature Phosphorescence from Nitrogen-Doped Carbon Dots in Composite Matrices. Chem. Mater. 2016, 28, 8221–8227. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, Y.; Zhen, S.; Li, X.; Zhang, W.; Sun, X.; Xu, B.; Wang, X.; Gao, Z.; Meng, X. Gram-Scale Synthesis of 41% Efficient Single-Component White-Light-Emissive Carbonized Polymer Dots with Hybrid Fluorescence/Phosphorescence for White Light-Emitting Diodes. Adv. Sci. 2020, 7, 1902688. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lu, S.; Cong, R.; Zhu, S.; Zhao, X.; Liu, J.; S.Tse, J.; Meng, S.; Yang, B. pH-Dependent Synthesis of Novel Structure-Controllable Polymer-Carbon NanoDots with High Acidophilic Luminescence and Super Carbon Dots Assembly for White Light-Emitting Diodes. ACS Appl. Mater. Interfaces 2016, 8, 4062–4068. [Google Scholar] [CrossRef] [PubMed]

- Cao, M.; Xia, C.; Xia, J.; Jiang, D.; Yu, C.; Li, H. A yellow carbon dots-based phosphor with high efficiency for white light-emitting devices. J. Lumin. 2019, 206, 97–104. [Google Scholar] [CrossRef]

- Li, L.; Zhao, F.; Zhang, T.; Lü, C. A facile method to prepare polymer functionalized carbon dots inspired by the mussel chemistry for LED application. Dye. Pigment. 2019, 162, 845–854. [Google Scholar] [CrossRef]

- Perikala, M.; Bhardwaj, A. Excellent color rendering index single system white light emitting carbon dots for next generation lighting devices. Sci. Rep. 2021, 11, 11594. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Zhu, Z.; Chang, Y.; Wang, H.; Yuan, N.; Li, G.; Yu, D.; Jiang, Y. Ammonium hydroxide modulated synthesis of high-quality fluorescent carbon dots for white LEDs with excellent color rendering properties. Nanotechnology 2016, 27, 295202. [Google Scholar] [CrossRef]

- Schubert, E.F. Light-Emitting Diodes, 2nd ed.; Cambridge University Press: Cambridge, UK, 2006; ISBN 978-0-521-86538-8. [Google Scholar] [CrossRef]

- Chou, Y.-F.; Chen, C.-F.; Ying, S.-P.; Yeh, Y.-Y. The Effects of TiO2 Diffuser-Loaded Encapsulation on Corrected Color Temperature Uniformity of Remote Phosphor White LEDs. Appl. Sci. 2019, 9, 675. [Google Scholar] [CrossRef] [Green Version]

- Li, J.-S.; Tang, Y.; Li, Z.-T.; Li, Z.; Ding, X.-R.; Rao, L.-S. Investigation of the Emission Spectral Properties of Carbon Dots in Packaged LEDs Using TiO2 Nanoparticles. IEEE J. Sel. Top. Quantum Electron. 2017, 23, 1–7. [Google Scholar] [CrossRef]

- Lin, S.; Wang, Z.; Zhang, Y.; Huang, Y.; Yuan, R.; Xiang, W.; Zhou, Y. Easy synthesis of silver nanoparticles-orange emissive carbon dots hybrids exhibiting enhanced fluorescence for white light emitting diodes. J. Alloy. Compd. 2017, 700, 75–82. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, F.; Chen, Y.; Qian, S.; Hu, P.; Li, W.; Deng, Y.; Fang, Y.; Han, L.; Luqman, M.; et al. Core-shell Ag@SiO2@mSiO2 mesoporous nanocarriers for metal-enhanced fluorescence. Chem. Commun. 2011, 47, 11618–11620. [Google Scholar] [CrossRef]

- Aslan, K.; Huang, J.; Wilson, G.M.; Geddes, C.D. Metal-Enhanced Fluorescence-Based RNA Sensing. J. Am. Chem. Soc. 2006, 128, 4206–4207. [Google Scholar] [CrossRef] [PubMed]

- Aslan, K.; Holley, P.; Geddes, C.D. Metal-enhanced fluorescence from silver nanoparticle-deposited polycarbonate substrates. J. Mater. Chem. 2006, 16, 2846–2852. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, J.; Zhang, J.; Lin, S.; Huang, Y.; Yuan, R.; Liang, X.; Xiang, W. Intense enhancement of yellow luminescent carbon dots coupled with gold nanoparticles toward white LED. Dye. Pigment. 2017, 140, 122–130. [Google Scholar] [CrossRef]

- Cui, S.; Ji, X.; Qin, J.; Yang, G.; Wang, Y.; Zhu, Y.; Pan, G. Enhanced luminescence of solid blue carbon dots by the “Islands” Ag films for highly efficient light-emitting diodes. Appl. Phys. Express 2020, 13, 082010. [Google Scholar] [CrossRef]

- Wang, Y.; Zheng, J.; Wang, J.; Yang, Y.; Liu, X. Rapid microwave-assisted synthesis of highly luminescent nitrogen-doped carbon dots for white light-emitting diodes. Opt. Mater. 2017, 73, 319–329. [Google Scholar] [CrossRef]

- An, J.; Liu, G.; Chen, M.; Hu, Y.; Chen, R.; Lyu, Y.; Zhang, C.; Liu, Y. One-step synthesis of fluorescence-enhanced carbon dots for Fe (III) on−off−on sensing, bioimaging and light-emitting devices. Nanotechnology 2021, 32, 285501. [Google Scholar] [CrossRef] [PubMed]

- Caruso, F.; Mosca, M.; Rinella, S.; Macaluso, R.; Calì, C.; Saiano, F.; Feltin, E. Frequency-Downconversion Stability of PMMA Coatings in Hybrid White Light-Emitting Diodes. J. Electron. Mater. 2016, 45, 682–687. [Google Scholar] [CrossRef]

- Mosca, M.; Caruso, F.; Zambito, L.; Seminara, B.; Macaluso, R.; Calì, C.; Feltin, E. Warm white LED light by frequency down-conversion of mixed yellow and red Lumogen. In Proceedings of the Integrated Photonics: Materials, Devices, and Applications II; Fédéli, J.-M., Vivien, L., Smit, M.K., Eds.; SPIE Microtechnologies: Grenoble, France, 2013; Volume 8767, pp. 140–149. [Google Scholar] [CrossRef]

- Caruso, F.; Mosca, M.; Macaluso, R.; Feltin, E.; Calì, C. Generation of white LED light by frequency downconversion using perylene-based dye. Electron. Lett. 2012, 48, 1417–1419. [Google Scholar] [CrossRef]

- Wang, Z.; Yuan, F.; Li, X.; Li, Y.; Zhong, H.; Fan, L.; Yang, S. 53% Efficient Red Emissive Carbon Quantum Dots for High Color Rendering and Stable Warm White-Light-Emitting Diodes. Adv. Mater. 2017, 29, 1702910. [Google Scholar] [CrossRef]

- Jin, L.; Zhang, L.; Yang, L.; Wu, X.; Zhang, C.; Wei, K.; He, L.; Han, X.; Qiao, H.; Asiri, A.M.; et al. Orange-red, green, and blue fluorescence carbon dots for white light emitting diodes. J. Mater. Sci. Technol. 2020, 50, 184–191. [Google Scholar] [CrossRef]

- Zheng, J.; Liu, X.; Yang, Y.; Liu, X.; Xu, B. Rapid and green synthesis of fluorescent carbon dots from starch for white light-emitting diodes. New Carbon Mater. 2018, 33, 276–288. [Google Scholar] [CrossRef]

- Liu, X.; Zheng, J.; Yang, Y.; Chen, Y.; Liu, X. Preparation of N-doped carbon dots based on starch and their application in white LED. Opt. Mater. 2018, 86, 530–536. [Google Scholar] [CrossRef] [Green Version]

- Bi, Z.; Li, T.; Su, H.; Ni, Y.; Yan, L. Transparent Wood Film Incorporating Carbon Dots as Encapsulating Material for White Light-Emitting Diodes. ACS Sustain. Chem. Eng. 2018, 6, 9314–9323. [Google Scholar] [CrossRef]

- Isnaeni; Zufara, B.S.; Lewa, I.W.L.; Herbani, Y.; Shiddiq, M. Role of surface states on luminescence shift of caramelised sugar carbon dots for color conversion emitting devices. Adv. Nat. Sci. Nanosci. Nanotechnol. 2020, 11, 015003. [Google Scholar] [CrossRef]

- Ge, M.; Huang, X.; Ni, J.; Han, Y.; Zhang, C.; Li, S.; Cao, J.; Li, J.; Chen, Z.; Han, S. One-step synthesis of self-quenching-resistant biomass-based solid-state fluorescent carbon dots with high yield for white lighting emitting diodes. Dye. Pigment. 2021, 185, 108953. [Google Scholar] [CrossRef]

- Meng, W.; Wang, B.; Ai, L.; Song, H.; Lu, S. Engineering white light-emitting diodes with high color rendering index from biomass carbonized polymer dots. J. Colloid Interface Sci. 2021, 598, 274–282. [Google Scholar] [CrossRef]

- Xie, Y.; Geng, X.; Gao, J.; Shi, W.; Zhou, Z.; Wang, H.; Zhang, D.; Deng, B.; Yu, R. Synthesis of carbon dots@Mg(OH)2 solid-state composites with blue, red emitting for horticultural application. J. Alloy. Compd. 2021, 873, 159663. [Google Scholar] [CrossRef]

- Sajjad, M.T.; Manousiadis, P.P.; Orofino, C.; Cortizo-Lacalle, D.; Kanibolotsky, A.L.; Rajbhandari, S.; Amarasinghe, D.; Chun, H.; Faulkner, G.; O’Brien, D.C.; et al. Fluorescent Red-Emitting BODIPY Oligofluorene Star-Shaped Molecules as a Color Converter Material for Visible Light Communications. Adv. Opt. Mater. 2015, 3, 536–540. [Google Scholar] [CrossRef] [Green Version]

- Pathak, P.H.; Feng, X.; Hu, P.; Mohapatra, P. Visible Light Communication, Networking, and Sensing: A Survey, Potential and Challenges. IEEE Commun. Surv. Tutor. 2015, 17, 2047–2077. [Google Scholar] [CrossRef]

- Mao, L.-H.; Tang, W.-Q.; Deng, Z.-Y.; Liu, S.-S.; Wang, C.-F.; Chen, S. Facile Access to White Fluorescent Carbon Dots toward Light-Emitting Devices. Ind. Eng. Chem. Res. 2014, 53, 6417–6425. [Google Scholar] [CrossRef]

- Feng, X.; Zhang, F.; Wang, Y.; Zhang, Y.; Yang, Y.; Liu, X. Fluorescent Carbon Quantum Dots as Single Light Converter for White LEDs. J. Electron. Mater. 2016, 45, 2784–2788. [Google Scholar] [CrossRef]

- Joseph, J.; Anappara, A.A. White light emission of carbon dots by creating different emissive traps. J. Lumin. 2016, 178, 128–133. [Google Scholar] [CrossRef]

- Wang, Y.; Yin, Z.; Xie, Z.; Zhao, X.; Zhou, C.; Zhou, S.; Chen, P. Polysiloxane Functionalized Carbon Dots and Their Cross-Linked Flexible Silicone Rubbers for Color Conversion and Encapsulation of White LEDs. ACS Appl. Mater. Interfaces 2016, 8, 9961–9968. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Zhang, H.; Zhou, X.; Liu, Y.; Lei, B. A dual-emitting core–shell carbon dot–silica–phosphor composite for LED plant grow light. RSC Adv. 2017, 7, 16662–16667. [Google Scholar] [CrossRef] [Green Version]

- Wu, M.; Zhan, J.; Geng, B.; He, P.; Wu, K.; Wang, L.; Xu, G.; Li, Z.; Yin, L.; Pan, D. Scalable synthesis of organic-soluble carbon quantum dots: Superior optical properties in solvents, solids, and LEDs. Nanoscale 2017, 9, 13195–13202. [Google Scholar] [CrossRef]

- Xie, Z.; Yin, Z.; Wu, Y.; Liu, C.; Hao, X.; Du, Q.; Xu, X. White Light-Emitting Diodes Based on Individual Polymerized Carbon Nanodots. Sci. Rep. 2017, 7, 12146. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhu, J.; Bai, X.; Zhai, Y.; Chen, X.; Zhu, Y.; Pan, G.; Zhang, H.; Dong, B.; Song, H. Carbon dots with efficient solid-state photoluminescence towards white light-emitting diodes. J. Mater. Chem. C 2017, 5, 11416–11420. [Google Scholar] [CrossRef]

- Liu, Q.; Li, D.; Zhu, Z.; Yu, S.; Zhang, Y.; Yu, D.; Jiang, Y. N-doped carbon dots from phenol derivatives for excellent colour rendering WLEDs. RSC Adv. 2018, 8, 4850–4856. [Google Scholar] [CrossRef] [Green Version]

- Du, Q.; Zheng, J.; Wang, J.; Yang, Y.; Liu, X. The synthesis of green fluorescent carbon dots for warm white LEDs. RSC Adv. 2018, 8, 19585–19595. [Google Scholar] [CrossRef] [Green Version]

- Yuan, B.; Xie, Z.; Chen, P.; Zhou, S. Highly efficient carbon dots and their nanohybrids for trichromatic white LEDs. J. Mater. Chem. C 2018, 6, 5957–5963. [Google Scholar] [CrossRef]

- Chen, D.; Chen, X.; Gao, H.; Zhong, J. Red C-dots and C-dot films: Solvothermal synthesis, excitation-independent emission and solid-state-lighting. RSC Adv. 2018, 8, 29855–29861. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yuan, B.; Guan, S.; Sun, X.; Li, X.; Zeng, H.; Xie, Z.; Chen, P.; Zhou, S. Highly Efficient Carbon Dots with Reversibly Switchable Green–Red Emissions for Trichromatic White Light-Emitting Diodes. ACS Appl. Mater. Interfaces 2018, 10, 16005–16014. [Google Scholar] [CrossRef] [PubMed]

- Gao, H.; Chen, D.; Fang, G.; Yuan, S.; Chen, X.; Zhong, J. Excellent luminescence films of excitation-independent carbon quantum dots toward non-rare-earth phosphor-based white light-emitting diodes. J. Alloy. Compd. 2018, 764, 17–23. [Google Scholar] [CrossRef]

- Zheng, J.; Wang, J.; Wang, Y.; Yang, Y.; Liu, X.; Xu, B. Facile and Rapid Synthesis of Yellow-Emission Carbon Dots for White Light-Emitting Diodes. J. Electron. Mater. 2018, 47, 7497–7504. [Google Scholar] [CrossRef]

- Cai, W.; Zhang, T.; Xu, M.; Zhang, M.; Guo, Y.; Zhang, L.; Street, J.; Ong, W.-J.; Xu, Q. Full color carbon dots through surface engineering for constructing white light-emitting diodes. J. Mater. Chem. C 2019, 7, 2212–2218. [Google Scholar] [CrossRef]

- Guner, T.; Yuce, H.; Tascioglu, D.; Simsek, E.; Savaci, U.; Genc, A.; Turan, S.; Demir, M.M. Optimization and performance of nitrogen-doped carbon dots as a color conversion layer for white-LED applications. Beilstein J. Nanotechnol. 2019, 10, 2004–2013. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Zhang, Z.; Ding, J.; Xu, Y.; Chen, G.; Liu, J.; Zhao, L.; Huang, N.; He, Z.; Li, Y.; et al. Diamond-like carbon structure-doped carbon dots: A new class of self-quenching-resistant solid-state fluorescence materials toward light-emitting diodes. Carbon 2019, 149, 342–349. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, M.; Wu, Y.; Zhang, R.; Cao, Y.; Xu, X.; Chen, X.; Cai, L.; Xu, Q. Multicolor tunable highly luminescent carbon dots for remote force measurement and white light emitting diodes. Chem. Commun. 2019, 55, 12164–12167. [Google Scholar] [CrossRef]

- Madhu, M.; Chen, T.-H.; Tseng, W.-L. White-light emission of single carbon dots prepared by hydrothermal carbonization of poly(diallyldimethylammonium chloride): Applications to fabrication of white-light-emitting films. J. Colloid Interface Sci. 2019, 556, 120–127. [Google Scholar] [CrossRef]

- Wang, H.-J.; Hou, W.-Y.; Yu, T.-T.; Chen, H.-L.; Zhang, Q.-Q. Facile microwave synthesis of carbon dots powder with enhanced solid-state fluorescence and its applications in rapid fingerprints detection and white-light-emitting diodes. Dye. Pigment. 2019, 170, 107623. [Google Scholar] [CrossRef]

- Wang, B.; Li, J.; Tang, Z.; Yang, B.; Lu, S. Near-infrared emissive carbon dots with 33.96% emission in aqueous solution for cellular sensing and light-emitting diodes. Sci. Bull. 2019, 64, 1285–1292. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.; Hu, T.; Chen, Y.; Xu, Y.; Song, Q. Polymer-Assisted Self-Assembly of Multicolor Carbon Dots as Solid-State Phosphors for Fabrication of Warm, High-Quality, and Temperature-Responsive White-Light-Emitting Devices. ACS Appl. Mater. Interfaces 2019, 11, 22332–22338. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Wang, S.; Liu, S.; Ma, S.; Jing, G.; Hu, Y.; Wang, M.; Ye, Z.; Cheng, X. Facile one-pot synthesis of long-term thermally stable CDs@AlOOH toward white-light illumination. J. Mater. Chem. C 2019, 7, 14717–14724. [Google Scholar] [CrossRef]

- Yuan, T.; Yuan, F.; Li, X.; Li, Y.; Fan, L.; Yang, S. Fluorescence–phosphorescence dual emissive carbon nitride quantum dots show 25% white emission efficiency enabling single-component WLEDs. Chem. Sci. 2019, 10, 9801–9806. [Google Scholar] [CrossRef]

- Zhai, Y.; Shen, F.; Zhang, X.; Jing, P.; Li, D.; Yang, X.; Zhou, D.; Xu, X.; Qu, S. Synthesis of green emissive carbon dots@montmorillonite composites and their application for fabrication of light-emitting diodes and latent fingerprints markers. J. Colloid Interface Sci. 2019, 554, 344–352. [Google Scholar] [CrossRef]

- Zhao, K.; Zheng, X.; Zhang, H.; Xu, M.; Wang, S.; Yang, Q.; Xiong, C. Multi-color fluorescent carbon dots with single wavelength excitation for white light-emitting diodes. J. Alloy. Compd. 2019, 793, 613–619. [Google Scholar] [CrossRef]

- He, W.; Weng, W.; Sun, X.; Pan, Y.; Chen, X.; Liu, B.; Shen, J. Multifunctional Carbon Dots with Solid–Liquid State Orange Light Emission for Vitamin B12 Sensing, Cellular Imaging, and Red/White Light-Emitting Diodes. ACS Appl. Nano Mater. 2020, 3, 7420–7427. [Google Scholar] [CrossRef]

- Lan, X.; Ren, H.; Yang, X.; Wang, J.; Gao, P.; Zhang, Y. A facile microwave-assisted synthesis of highly crystalline red carbon dots by adjusting the reaction solvent for white light-emitting diodes. Nanotechnology 2020, 31, 215704. [Google Scholar] [CrossRef]

- Lin, H.; Yang, J.; Liu, Y.; Zeng, F.; Tang, X.-S.; Yao, Z.; Guan, H.; Xiong, Q.; Zhou, J.; Wu, D.; et al. Stable and efficient hybrid Ag-In-S/ZnS@SiO2-carbon quantum dots nanocomposites for white light-emitting diodes. Chem. Eng. J. 2020, 393, 124654. [Google Scholar] [CrossRef]

- Meng, L.; Ushakova, E.V.; Zhou, Z.; Liu, E.; Li, D.; Zhou, D.; Tan, Z.; Qu, S.; Rogach, A.L. Microwave-assisted in situ large scale synthesis of a carbon dots@g-C3N4 composite phosphor for white light-emitting devices. Mater. Chem. Front. 2020, 4, 517–523. [Google Scholar] [CrossRef]

- Qiao, G.; Chen, G.; Wen, Q.; Liu, W.; Gao, J.; Yu, Z.; Wang, Q. Rapid conversion from common precursors to carbon dots in large scale: Spectral controls, optical sensing, cellular imaging and LEDs application. J. Colloid Interface Sci. 2020, 580, 88–98. [Google Scholar] [CrossRef]

- Yan, F.; Jiang, Y.; Sun, X.; Wei, J.; Chen, L.; Zhang, Y. Multicolor carbon dots with concentration-tunable fluorescence and solvent-affected aggregation states for white light-emitting diodes. Nano Res. 2020, 13, 52–60. [Google Scholar] [CrossRef]

- Yao, Q.; Wang, H.; Wang, Y.; Zhang, L.; Zhang, W.; Zhang, Y. Tri-chromatic quantum-dot synthesized sun-like white light-emitting diodes reaching maximum spectral similarity of 0.98. Opt. Laser Technol. 2020, 121, 105828. [Google Scholar] [CrossRef]

- Zhang, X.; Sun, Z.; Zhu, Z.; Luo, J.; Wu, Z.; Wang, Z. High-efficient, spherical and thermal-stable carbon dots@silica fluorescent composite as rare earth-free phosphors for white LED. Ceram. Int. 2020, 46, 14706–14712. [Google Scholar] [CrossRef]

- An, Y.; Liu, C.; Li, Y.; Chen, M.; Zheng, Y.; Tian, H.; Shi, R.; He, X.; Lin, X. Application of high-efficiency green fluorescent carbon dots prepared by acid catalysis in multicolour LEDs. RSC Adv. 2021, 11, 38033–38039. [Google Scholar] [CrossRef]

- An, Y.; Lin, X.; Guo, Z.; Yin, Q.; Li, Y.; Zheng, Y.; Shi, Z.; Zhang, W.; Liu, C. Red Emission Carbon Dots Prepared by 1,4-Diaminonaphthalene for Light-Emitting Diode Application and Metal Ion Detection. Materials 2021, 14, 4716. [Google Scholar] [CrossRef]

- Park, S.J.; Yang, H.K.; Moon, B.K. Correlated color temperature alteration with changing the position of carbon dot film for warm WLEDs. Dye. Pigment. 2021, 186, 109063. [Google Scholar] [CrossRef]

- Han, B.; Jiang, J.; Yan, Q.; Xin, Z.; Yan, Q. One-step straightfoward solid synthesis of high yield white fluorescent carbon dots for white light emitting diodes. Chin. Chem. Lett. 2021, 32, 591–593. [Google Scholar] [CrossRef]

- Han, S.; Chen, X.; Hu, Y.; Han, L. Solid-state N,P-doped carbon dots conquer aggregation-caused fluorescence quenching and couple with europium metal-organic frameworks toward white light-emitting diodes. Dye. Pigment. 2021, 187, 109090. [Google Scholar] [CrossRef]

- He, L.; Liu, R.; Ge, C.; Yang, L.; Jia, K.; Zhang, X. Carbon dots optimize the luminescence and morphological of Tm3+ doped zinc borate composites for NUV-WLEDs. J. Alloys Compd. 2021, 872, 159665. [Google Scholar] [CrossRef]

- Hernández-Rivera, D.; Torres-Landa, S.D.; Rangel-Ayala, M.; Agarwal, V. Fluorescent films based on PVDF doped with carbon dots for evaluation of UVA protection of sunscreens and fabrication of cool white LEDs. RSC Adv. 2021, 11, 32604–32614. [Google Scholar] [CrossRef] [PubMed]

- Liu, B.; Chu, B.; Wang, Y.-L.; Hu, L.-F.; Hu, S.; Zhang, X.-H. Carbon dioxide derived carbonized polymer dots for multicolor light-emitting diodes. Green Chem. 2021, 23, 422–429. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, S.; Yu, K.; Yu, J.; Zhao, D.; Li, C. Encapsulating carbon quantum dot and organic dye in multi-shell nanostructured MOFs for use in white light-emitting diode. Microporous Mesoporous Mater. 2021, 319, 111062. [Google Scholar] [CrossRef]

- Vidya, T.; Anupama, M.; Muhammed, S.; Joseph, J.; Anappara, A.A. Multi-functional carbon dots for visual detection of picric acid and white-light emission. Mater. Res. Bull. 2021, 138, 111223. [Google Scholar] [CrossRef]

- Rao, L.; Zhang, Q.; Wen, M.; Mao, Z.; Wei, H.; Chang, H.-J.; Niu, X. Solvent regulation synthesis of single-component white emission carbon quantum dots for white light-emitting diodes. Nanotechnol. Rev. 2021, 10, 465–477. [Google Scholar] [CrossRef]

- Xavier, M.M.; Adarsh, N.N.; Nair, P.R.; Mathew, S. Carbon Nitride Quantum Dot-Embedded Poly(vinyl alcohol) Transparent Thin Films for Greenish-Yellow Light-Emitting Diodes. ACS Omega 2021, 6, 22840–22847. [Google Scholar] [CrossRef]

- Yan, F.; Zhang, H.; Xu, J.; Wu, Y.; Zang, Y.; Sun, J. Color Emission Carbon Dots with Quench-ResixAstant Solid-State Fluorescence for Light-Emitting Diodes. ACS Sustain. Chem. Eng. 2021, 9, 3901–3908. [Google Scholar] [CrossRef]

- Yin, L.; Yan, Y.; Guo, H.; Wang, L.; Xiu, H.; Zhang, J. Solid-State Carbon Dots-Based White Light-Emitting Diodes with Ultrahigh Color Rendering Index and Good Thermal Stability. IEEE Trans. Electron Devices 2021, 68, 3901–3906. [Google Scholar] [CrossRef]

- Yu, B.; Liu, Y.; Cao, M.; Zhu, M.; Chen, R.; Li, H. Multi-color carbon dots from cis-butenedioic acid and urea and highly luminescent carbon dots@Ca(OH)2 hybrid phosphors with excellent thermal stability for white light-emitting diodes. J. Lumin. 2021, 237, 118202. [Google Scholar] [CrossRef]

- Bao, S.; Yu, H.; Gao, G.; Zhu, H.; Wang, D.; Zhu, P.; Wang, G. Rare-earth single atom based luminescent composite nanomaterials: Tunable full-color single phosphor and applications in WLEDs. Nano Res. 2022, 15, 3594–3605. [Google Scholar] [CrossRef]

- Cao, W.; Wu, Y.; Li, X.; Jiang, X.; Zhang, Y.; Zhan, Y.; Sun, Z. One-pot synthesis of double silane-functionalized carbon dots with tunable emission and excellent coating properties for WLEDs application. Nanotechnology 2022, 33, 115703. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; Li, W.; Zhang, X.; Ma, C.; Xia, Z.; Lei, B. Carbon dots embedded in lead-free luminescent metal halide crystals toward single-component white emitters. Sci. China Mater. 2022. [Google Scholar] [CrossRef]

- Chen, M.; Liu, C.; An, Y.; Li, Y.; Zheng, Y.; Tian, H.; Shi, R.; He, X.; Lin, X. Red, green, and blue light-emitting carbon dots prepared from gallic acid for white light-emitting diode applications. Nanoscale Adv. 2022, 4, 14–18. [Google Scholar] [CrossRef]

- Da, X.; Han, Z.; Yang, Z.; Zhang, D.; Hong, R.; Tao, C.; Lin, H.; Huang, Y. Preparation of multicolor carbon dots with high fluorescence quantum yield and application in white LED. Chem. Phys. Lett. 2022, 794, 139497. [Google Scholar] [CrossRef]

- Dai, R.; Chen, X.; Ouyang, N.; Hu, Y. A pH-controlled synthetic route to violet, green, and orange fluorescent carbon dots for multicolor light-emitting diodes. Chem. Eng. J. 2022, 431, 134172. [Google Scholar] [CrossRef]

- Fang, M.; Neto, A.N.C.; Fu, L.; Ferreira, R.A.S.; deZeaBermudez, V.; Carlos, L.D. A Hybrid Materials Approach for Fabricating Efficient WLEDs Based on Di-Ureasils Doped with Carbon Dots and a Europium Complex. Adv. Mater. Technol. 2022, 7, 2100727. [Google Scholar] [CrossRef]

- Kaushal, N.; Sharma, A.L.; Saha, A. Visible LED-based photo-redox properties of sulfur and nitrogen-doped carbon dots designed by solid-state synthesis. Mater. Adv. 2022, 3, 355–361. [Google Scholar] [CrossRef]

- Kumari, R.; Sahu, S.K. A new insights into multicolor emissive carbon dots using Trachelospermum jasminoides leaves for the application of WLEDs. Colloids Surf. Physicochem. Eng. Asp. 2022, 647, 128959. [Google Scholar] [CrossRef]

- Lei, X.; Li, D.; Chen, Y.; Liu, Q.; Yan, Q.; Wang, J.; Han, B.; He, G.; An, B. RGB-multicolor fluorescent carbon dots by changing the reaction solvent type for white light-emitting diodes. New J. Chem. 2022, 46, 4979–4982. [Google Scholar] [CrossRef]

- Lv, Z.; Xu, H.; Wang, Z.; Jia, M.; Wei, Y.; Fu, Z. Tunable KLa(MoO4)2:Eu3+@CDs composite materials for white LED and multi-mode information encryption technology. J. Alloys Compd. 2022, 894, 162298. [Google Scholar] [CrossRef]

- Sun, Z.; Yan, F.; Xu, J.; Zhang, H.; Chen, L. Solvent-controlled synthesis strategy of multicolor emission carbon dots and its applications in sensing and light-emitting devices. Nano Res. 2022, 15, 414–422. [Google Scholar] [CrossRef]

- Wang, B.; Song, H.; Tang, Z.; Yang, B.; Lu, S. Ethanol-derived white emissive carbon dots: The formation process investigation and multi-color/white LEDs preparation. Nano Res. 2022, 15, 942–949. [Google Scholar] [CrossRef]

- Wang, J.; Zheng, J.; Yang, Y.; Liu, X.; Qiu, J.; Tian, Y. Tunable full-color solid-state fluorescent carbon dots for light emitting diodes. Carbon 2022, 190, 22–31. [Google Scholar] [CrossRef]

- Yan, Y.; Yin, L.; Guo, H.; Wang, L.; Zhang, J. High Stability Carbon Dots Phosphor and Ultra-High Color Rendering Index White Light-Emitting Diodes. IEEE Photonics J. 2022, 14, 1–6. [Google Scholar] [CrossRef]

- Zhang, G.; Bai, Y.; Yu, C.; Xuan, T. Highly stable carbon nanodot-based phosphor as a color converter for WLED. J. Lumin. 2022, 246, 118836. [Google Scholar] [CrossRef]

| Year | Precursors | Preparation Method | QY (%) | LED λexc (nm) | LED λemis (nm) | CIE (x,y) | CCT (K) | CRI | Luminous Efficacy (lm/W) | Encapsulant | LED Emission Color | Notes | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2013 | acrylamide, cadmium chloride, N-acetyl- L-cysteine (NAC), sodium borohydride, tellurium powder, sodium hydroxide | plasma-induced method (150 W) | ~6% | 380 | 490 (FWHM: 110 nm) | (0.20, 0.18) CDs (0.38, 0.36) mix | NR | 87 | 30 (@350 mA) | silicone (OE-6550A: OE-6550B) | blue (CDs), white (mix) | CDs mixed with CdTe QDs | [83] |

| 2014 | citric acid, (3-aminopropyl) triethoxysilane (APTES) (1:1) | hydrothermal method (180 °C, 4 h) | 20 | 380 | broadband (two peaks at 470 and 550) | (0.27, 0.32) mix | 9051 | 71 | NR | silicone | white (mix) | CDs mixed with CDs nanocrystals | [84] |

| citric acid, AAPMS | heating from a solution (240 °C, 1 min) | NR | 400 | 490 | (0.22–0.24, 0.38–0.43) | NR | NR | NR | silicone | bluish white | CDs embedded in silica, KCl, KBr, NaCl | [86] | |

| poly(acrylic acid) (PAA), glycerol | one-step pyrolysis | 9 | 380 | broadband (two peaks at 440 and 470) | (0.27, 0.32) | NR | NR | NR | silicone | white | CDs dispersed in a thermocurable resin (silicone) | [156] | |

| [3–(2-aminoethylamino)propyl]trimethoxysilane (AEATMS), citric acid | pyrolysis (240 °C, 2 min) | NR | 385 | 450 | (0.321, 0.312) at 10 mA (0.351, 0.322) at 30 mA | 3825–6452 | 93 | NR | PMMA | cold and warm white | CDs with zinc copper indium sulfide core–shell QDs | [85] | |

| 2015 | EDA | exothermic reaction between P2O5 and H2O | 28.5 | 360 (48 W) | broad band | (0.22, 0.33) at 360 nm of excitation | NR | NR | NR | PVA | bluish white | single precursor; stability after 16 h of irradiation | [87] |

| PVA | one-step hydrothermal process | NR | 460 | 550 | (0.28, 0.27) | NR | NR | NR | bluish white | intercrossed carbon nanorings (with relatively pure hydroxy surface states); AIQ is reduced | [91] | ||

| N-(β-aminoethyl)-γ-aminopropyl methyldimethoxy silane (AEAPMS), citric acid | pyrolysis (220 °C, 10 min) | 78 | 460 | 570 | (0.32, 0.33) | ~6190 | 78.9 | 58.1 | epoxy-resin | white | CD-doped sodium borosilicate gel (CD-NBS gel) | [88] | |

| citric acid, EDA | hydrothermal method | NR | 385 | ~460 | (0.326, 0.343) at 50 mA | 2805–7786 | 85–96 | 4.9 | silicone | high CRI WLEDs | phosphors based on the combination of CDs and polymer dots | [89] | |

| organic acid, silane | decomposing organic acid in silane coupling agent | NR | 460 (10 W) | broad band (two main peaks at 550 and 600) | (0.376, 0.374) for thickness of 400 μm | 2500–10,000 | NR | NR | epoxy matrix deposited on polystyrene substrate | white | different colors depends on the thickness of the film where CDs are dispersed | [102] | |

| AEAPMS, citric acid | pyrolysis (240 °C, 1 min) | 47 | 385 | 455, 550, 575, 585, 610 | (0.22, 0.22) (0.34, 0.43) (0.42, 0.51) (0.46, 0.50) (0,52, 0.46) | NR | NR | 1.21 cd/A | PMMA | blue, green, yellow, orange, red | five monochrome LEDs obtained by varying the CD concentration | [103] | |

| 2016 | glucose, polyethylene glycol (PEG) 200 | one-step hydrothermal method | 3.5 | 365 | broad band centered at 544 | (0.32, 0.37) | 5584 | NR | NR | epoxy resin | cool white light | glucose is first used as a carbon source | [157] |

| EDA, tetra-acetic acid (EDTA), ethylene glycol(EG) | microwave-assisted hydrothermal method | NR | 365 | broad band centered at 550 | (0.34, 0.38) | 5078 | 84 | NR | PMMA | white | CDs with different functional groups | [158] | |

| folic acid, chloridric acid | hydrothermal treatment | 36 (phosphorescence + fluorescence) | 360 | NR | (0.213, 0.204) (0.338, 0.363) | NR | NR | NR | melting recrystallization urea and biuret from the heating urea | blue white | phosphorescent N-doped CDs (NCDs) | [124] | |

| L-serine and L-tryptophan (molar ratio 3:1) at different pH values | one-pot aqueous synthesis controlled by pH | 16.3 (pH ≈ 8.1) 26.99 (3 < pH < 7) 46.83 (1 < pH < 3) | 365 | broad band (410−700) | (0.29, 0.31) | 6786 | 81 | NR | DMMA | cool white | crosslinked polymer carbon film (pH > 7, 200 °C) polymer carbon nanosheets (3 < pH < 7, 200 °C), amorphous carbon structures (1 < pH < 3, 200 °C) supersmall CDs (pH = 0.5, 300 °C) | [126] | |

| citric acid, ammonium hydroxide | ammonium hydroxide modulated hydrothermal method | 40 | 360 (1 W) | broad band centered at 450 (only CDs) | (0.18, 0.19) CDs’ LED (0.33, 0.37) RGB white | 5447 (at 100 mA) | 95.1 (at 100 mA) | NR | silicone, ethanol | white | mix of blue emission CDs, green emission SrSi2O2N2:Eu, red emission Sr2Si5N8:Eu | [130] | |

| aminopropyl methyl polysiloxane (AMS), citric acid | one-step solvothermal method | 16 | 460 | 590 | (0.33, 0.28) | NR | 66.6 | 14 | AMS-CDs crosslinked silicone rubbers (SRs) | white | AMS-CDs have a dual role of luminescence and encapsulation layer | [159] | |

| 2017 | p-phenylenediamine (p-PD), formamide (FA) | solvothermal method (200 °C, 1 h) | 10–15 (orange CDs) 20–30 (blue CDs) | 465 (350 mA) | 480−780 | (0.283, 0.246) - (0.470, 0.358) only CDs (0.323, 0.326) - (0.419, 0.376) CDs + Ce:YAG | 14,570 - 2158 only CDs 5977 - 3089 CDs + Ce:YAG | 73.3 (only CDs) 85 (CDs + Ce:YAG) | 60–80 | polyvinylpyrrolidone (PVP) | white | mix of orange-emitting CDs and Ce:YAG | [104] |

| NR (CDs produced by Nanjing JANUS) | NR | 40 (reported by CD manufacturer) | UV (λ NR) | 433–600 | vary in a large gamut with TiO2 nanoparticles concentrations (at a fixed CD concentration of 10 wt%) | from 3000 to 19,000 | from 40 to 85 | ~1.4 (increased by 31% with TiO2 nanoparticles) | silicone (mixed in a CDs-chloroform solution) | from cool to warm white | TiO2 nanoparticles used for enhancing the light scattering ability of the encapsulant | [133] | |

| citric acid, urea (dissolved in N,N-dimethylformamide -DMF) | hydrothermal method | 48.5 | 460 | broad band | (0.4595, 0.3925) (0.03 g CDs in 4 g OSi) | 2561 (0.03 g CDs in 4 g OSi) | 92.6 (0.03 g CDs in 4 g OSi) | 30.6 (0.03 g CDs in 4 g Osi) | N-(b-aminoethyl)-c-amin-o-propyl methyl dimethoxy silane (Osi) | warm white | red emission CDs (casted on Ce3+: YAG phosphor in glass (Ce: PiG) | [92] | |

| citric acid, AEAPMS, nitrogen | one-pot hot injecting method | 24.5 | 460 | broad band 500–700 | (0.33, 0.35) (0.6 mm-thick) | 5435 (0.6 mm-thick) | 74.6 (0.6 mm-thick) | 41.26 (0.6 mm-thick) | Ag nanoparticle solution | from bluish to neutral white | surface plasmon resonance from Ag nanoparticles enhances CD fluorescence | [134] | |

| o-phenylenediamine, pPD, N,N-dimethyl formamide (DMF) (solvent) | hydrothermal method | 52.4 | 460 | broad band | (0.3943, 0.3869) (CDs + Ce:PiG) | 3722 (CDs + Ce:PiG) | 83 (CDs + Ce:PiG) | 66.17 (CDs + Ce:PiG) | polyvinyl butyral (PVB) | warm white (CDs + Ce:PiG) | CDs shift gradually from 520 nm to 630 nm increasing their concentration in solution or changing the solvent polarity (solvatochromism) | [105] | |

| citric acid, urea (solvents: water, glycerol, DMF) | solvothermal synthesis | 30–40 | 395, 440 | 448, 515, 540, 570, 603, 622, 638 | (0.34, 0.31) (WLED) | 5048 (WLED) | 82.4 (WLED) | 8.34 (WLED) | silica | blue, cyan, green, yellow, orange, red, white | realization of full-color emissive CDs by exploiting the solvatochromism of three different (water, glycerol, DMF) | [106] | |

| 1,3-Dihydroxynaphthalene, KIO4 (dissolved in ethanol) | dehydrative condensation and dehydrogenative planarization (DCDP) method and solvothermally treatment | 53 | 365 | 430, 510, 620 | (0.3924, 0.3912) | 3875 | 97 | 31.3 (at 20 mA) | PMMA | warm white | three layers of blue-, green-, and red-emitting CDs | [145] | |

| citric acid, Silane Coupler KH-602, nitrogen | one-pot method using CTAB as the cationic surfactant, NaSal as the structure-directing agent, TEA as a catalyst, and BTEE and TEOS as the silica source | 29.8 | 362 | 470, 612 | (0.294, 0.280) (0.356, 0.343) | NR | 85–86 | NR | silica | white | dual-emitting CDs/CaAlSiN3:Eu2+-silica powder; applicability as a lighting source for plant growth | [160] | |

| citric acid, N-(2-aminoethyl)-3- aminopropyltrimethoxysilane (KH792) | one-step solvothermal method | 450 | 530 | 60,96 | polymer | green | CDs converting blue light to green light | [107] | |||||

| citric acid, EDA | one-step microwave- assisted hydrothermal method | 75.96 | 365 | weak peak at 442, strong peak at 572 | (0.42, 0.40) | 3416 | NR | NR | silicone | warm white | N-passivated CDs show record QY values | [140] | |

| oil-soluble 1,3,6-trinitropyrene (TNP) (as C and N sources), various solvents: toluene, acetone, EA, DMF) | solvothermal synthesis | 65.93 | 460 | broad band between 540 and 610 | (0.32, 0.31) | 6300 | NR | NR | PMMA | white | mix of long-wavelength emitting CDs and green phosphors; effect of the solvents on the CD emission | [161] | |

| citric acid, organosilane | one-pot pyrolysis method | 25–55 | ~450 | ~550 | (0.24, 0.28)–(0.31, 0.43) | 5030 (for x = 0.33 and y = 0.21) | 74 (for x = 0.33 and y = 0.21) | 79.4 (at 350 mA) | polymerized silane prefunctionalized carbon dots (SiCDs) | white | SiCDs individually polymerized one-component system, drip-coated and bulk polymerized on GaN LEDs | [162] | |

| citric acid, AEAPMS, nitrogen | pyrolysis | 39 | 460 | broad band centered at 560 | (0.33, 0.36) | 5653 | 78.2 | 43.75 | colloidal Au nanoparticles | white | gold-carbon dots (GCDs) with high luminescence | [138] | |

| ammonium citrate, EDTA; solvent: DMF | solvothermal syn-thesis | 67 | 460 | from 450 to 600 | (0.32, 0.33) (white) | 6565 (white) | 68.4 (white) | 32.26 (white) | Polyamideresin-650 (P-650) | red, orange, yellow, white, cyan, blue, and dark blue | white and multicolor N-doped CDs; color depends on molar ratio between the precursors | [109] | |

| ammonium citrate (in DMF), ethyl alcohol or ammonium citrate (in DMF), AEAPMS | solvothermal syn-thesis | 51 | 395 | ~560 | (0.33, 0.34) | 6735 | 51 | 25.63 | glass matrix | white | white CD-based glass thin films fabricated by screen printing technology | [160] | |

| glucose, ammonia | hydrothermal synthesis | 10.2 | ~395 | ~590 | (0.28, 0.37) | NR | NR | NR | PVA | white | synthesis of nitrogen-doped carbon dots (NCDs) and carbon sheets (NCSs); PVA used to prevent AIQ | [93] | |

| hexadecyltrimethyl ammonium bromide | 38.7 | ~385 | two broad bands at 495 and 660 | 3623–8121 | PVP | white | modulation of the emitting states of colloidal CDs | [163] | |||||

| 2018 | p-PD, ethanol, N-(3-(trimethoxysilyl) propyl) ethylenediamine (KH-792) | solvothermal syn-thesis | 41.72 | 400 | 480–720 | (0.44, 0.42) | 2951 | NR | NR | silica | warm white | embedding of CDs into a silica matrix overcomes the AIQ | [94] |

| phenol derivative, EDA | hydrothermal method | 24.4 in water; 53.3 in ethanol | 360 | broad band | (0.3316, 0.3373) | 5538 | 93.3 | NR | transparent epoxy JH-6800MA and JH-6800MB | yellow–green, white | WLEDs fabricated by mixing yellow–green N-doped CDs, blue CDs, and red emission (Sr, Ca) AlSiN3:Eu powders | [164] | |

| pyrogallic acid, DMF | solvothermal syn-thesis | 8 (in KH-792); 16.82 (in DMF solution) | 365 | 560 | (0.38, 0.48) (at 3.5 V) | 4503 (at 3.5 V) | NR | NR | KH-792 | white | green CD emission due to large conjugated sp2-domain promoted by DMF; high-stability | [165] | |

| amino silane (red CDs), N-(2-aminoethyl)-3-aminopropyltrimethoxysilane (green CDs) | alkali-induced method | 80 (red); 49 (green) | 90.2 | 68.58 | trichromatic warm white | optical properties of red-emitting CDs modulated by the alkali-induced surface electronic states; mix of red- and green-emitting CDs | [166] | ||||||

| p-PD; solvent: isopropanol | solvothermal synthesis | 20.6 | 450 | broad band (peak at 580–600) | (0.335, 0.319) 0.5 nm-thick; (0.348, 0.324) 1.0 nm-thick; (0.371, 0.341) 1.5 nm-thick | 5359 (0.5 nm) 4772 (1.0 nm) 3994 (1.5 nm) | 81 (0.5 nm) 84 (1.0 nm) 85 (1.5 nm) | NR | PVA | white | combination of red CD solid film and yellow Ce:YAG PiG (0.5, 1.0, 1.5 nm film thickness) | [167] | |

| citric acid, urea; solvents: water, DMF, ethanol, NaOH | hydrothermal method | 34 (blue); 19 (green); 47 (red) | 365 | 442 (blue); 545 (green); 620 (red) | (0.38, 0.34) | 3913 | 91 | 10.2 | PVA | warm white | tunable emissions from blue, green, and red CDs (by changing the reaction solvent) | [95] | |

| Substituted derivatives from perylene (3,4,9,10-nitroperylene) (refluxed with HNO3) | solvothermal treatment in an alkaline solution | 81 (green); 80 (red) | 460 | 508 615 | 92.9 | 71.75 | methyltriethoxysilane (MTES) and APTES | trichromatic white | photoluminescent CDs with green and red emission switching using perylene as the precursor | [168] | |||

| 1,2,4-triaminobenzene, polyethylene glycol 200 (PEG 200); solvents: ethyl acetate, ethanediamine, oleylamine, DMSO | solvothermal method | from 10.8 to 25 | 460 | from 473 to 624 | (0.4557, 0.3840) (YAG/red CDs: 0.50) | 2514 (YAG/red CDs: 0.50) | 89.6 (YAG/red CDs: 0.50) | NR | silica | warm white (red CDs mixed with Ce3+:YAG) | CDs can be well-tuned from 473 to 624 nm in different solvents | [108] | |

| potato starch, EDS | microwave-assisted hydrothermal method | 2.46 (only starch; non-doped CDs); 5.71 (starch + EDS; N-doped CDs) | 375 | 560 (non-doped CDs); 430, 560 (N-doped CDs) | (0.38, 0.45) non-doped CDs; (0.33, 0.35) N-doped CDs | 4329 (non-doped CDs); 5437 (N-doped CDs) | NR | NR | starch | white | potato starch is used as a carbon source for CD and as an encapsulant | [147] | |

| citric acid, 5-amino-1,10- phenanthroline (Aphen) | one-pot hydrothermal method | 67 (red); 29 (white) | 400 | triple emission bands: 430 (blue), 500 (green), 630 (red) | (0.33, 0.33) | NR | 92 | 30.5 | poly(2-hydroxyethyl methacrylate) (PHEMA) | pure white | multicolor emissive CDs with multiple core@shell structure | [111] | |

| citric acid, urea | hydrothermal method | 53.82 (blue CDs); 36.18 (green CDs); 12.73 (red CDs) | 365 | 445 (blue CDs); 510 (green CDs); 600 (red CDs); from 400 to 800 (white) | (0.33, 0.32) | 5237 | 83 | NR | transparent wood (lignin removed by oxalic acid and choline chloride), PAA | trichromatic pure white | green preparation of transparent wood as encapsulant; stability tested for 7 days | [149] | |

| p-PD, 3-isocyanatopropyltriethoxysilane (IPTS) | pyrolysis | NR | 460 | 570 (dichromatic LED); 500, 605 (trichromatic LED); @50 mA | (0.397, 0.428) (dichromatic LED); (0.385, 0.345) (trichromatic LED); @50 mA | 3949 (dichromatic LED); 4494 (trichromatic LED); @50 mA | 70 (dichromatic LED); 85 (trichromatic LED); @50 mA | 15.88 (dichromatic LED); 22.00 (trichromatic LED); @50 mA | PMMA (dichromatic LED); APTES-gel (trichromatic LED) | dichromatic and trichromatic white | a novel approach to achieve up/down-conversion photoluminescence of CDs based on polarity dependence | [112] | |

| o-phenylenediamine (o-PD); solvent: water | hydrothermal method | 25–35 | InGaN blue LED (λ NR) | broad band | (0.353,0.371) @100–150 mA | ~5400 @100–150 mA | ~78 @100–150 mA | ~45 @100–150 mA | PVA, silica gel | white | yellow-emitting N-doped CDs | [169] | |

| citric acid, urea | microwave-assisted heating method | 25 (red CDs); 36 (green CDs) | 450 | broad band (peaks at 532, 630) | (0.33, 0.33) | 5610 | 92 | 12 | PVP (for red CDs); starch (for green CDs) | pure white | enhanced red emissive CDs-based phosphors with high QY | [113] | |

| citric acid, piperazine; (different mass ratio: 1:0.5, 1:1, 1:2 w/w) | microwave-assisted heating method | NR | 395 | broad band centered at ~560 | (0.25, 0.28); mass ratio: 1:1 w/w | 13601 | NR | NR | silicone | bluish white | the mass ratio of the precursors not only has a great influence on the CD sizes, but can also affect their luminescence properties | [114] | |

| o-PD, urea | one-pot microwave-assisted hydrothermal method | 4.23 | 420 | 440–700 (peak: 563) | (0.30, 0.30) | 7915 | NR | NR | PVA | white | rapid synthesis of yellow fluorescent CDs | [170] | |

| starch, EDA | one-step hydrothermal method | 9.65 | 365 | two peaks at 420 and 555 | (0.33, 0.37) | 5462 | NR | NR | starch, PVA | white | starch used as a carbon source for CDs | [148] | |

| phenylenediamine isomers (o-PD, m-PD, p-PD) formamide solution | microwave heating | in ethanol: 14 m-CDs; 45 o-CDs; 8 p-CDs; in water: 11 m-CDs; 38 o-CDs; 6 p-CDs | 390 (m-CDs); 450 (o-CDs, or p-CDs) | 470 m-CDs; 550 o-CDs; 600 p-CDs | (0.2678, 0.2945) m-CDs; (0.3613, 0.3851) o-CDs; (0.2423, 0.1283) p-CDs | 10,967 m-CDs; 4589 o-CDs; 3247 p-CDs | 83 m-CDs; 87 o-CDs; 81 p-CDs | 18.3 m-CDs; 21.0 o-CDs; 17.7 p-CDs | starch, silicone | cool, neutral, and warm white | phenylenediamine isomers (oPD, mPD, and pPD) used as precursors for producing multicolor emissive CDs | [115] | |

| pyromellitic acid (PA), diethylenetriamine (DETA) and thiourea. | one-pot solvothermal method | 16.7 | InGaN blue LED (λ NR) | 611 | (0.57, 0.42) (orange LED) | 1745 (orange LED) | 56 (orange LED) | NR | PMMA chloroform solution | orange, white | solvothermal route for the synthesis of nitrogen and sulfur co-doped CDs; orange emissive CDs | [116] | |

| 2019 | p-PD, amino acetic acid, ethanol, EDA | solvothermal method | 24.7 (red CDs) | 360 | broad band (peaks at 400, 465, 600) | (0.33, 0.33) | 5612 | 89 | NR | PVP | pure white | synthesis of blue-, green-, and red-emitting CDs with high dispersity both in aqueous and organic solvent; WLED obtained by mixing the three types of CDs | [171] |

| o-PD, starch | one-step hydrothermal method | 66.9 | 455 | broad band centered at around 600 | (0.3429, 0.2817) | 4613 | 83 | 30.54 | silicone | daylight white | highly efficient solid-state yellow-emitting CDs phosphors | [127] | |

| diammonium hydrogen citrate, urea | pyrolysis | NR | 450 | broad band | (0.31, 0.36) (composite fibers); (0.33, 0.34) (mix red phosphor and CDs) | 6000 (composite fibers) | 90 (composite fibers) | 63.5 (mix red phosphor and CDs) | PVP | white | WLED fabricated by a commercial red phosphor (Sr2Si5N8:Eu2+) and N-doped CDS embedded in PVP; fabrication of electrospun composite fibers | [172] | |

| citric acid, urea | one-step gaseous detonation method (within milliseconds) | 11.2 | 365 | broad band centered at 534 | (0.31, 0.42) | 6249 | NR | NR | water solution dripped on an optical lens and dried | white | rapid CD preparation by a one-step gaseous detonation approach | [63] | |

| citric acid, urea; solvent: DMF | one-step solvothermal treatment | 5.3 (blue CD); 12.4 (green CD); 8.9 (yellow CD); 6.9 (orange-red) | 365 | 450 (blue); 550 (green); 575 (yellow); 610 (orange-red); 440, 540–590 flat band (white) | (0.18, 0.21) blue; (0.34, 0.54) green; (0.49, 0.46) yellow; (0.58, 0.38) orange-red; (0.32, 0.33) white | 4820 | 82.7 | NR | PVA | blue, green, yellow, orange–red, white | study of temperature on the evolution of CD surface states and on the emissive properties of CD-based LEDs | [117] | |

| pyromellitic acid, pentaethylenehexamine (PEHA); (solvent: DMF; dopant: manganese chloride tetrahydrate) | solvothermal method | 28.5 (orange Mn-doped CDs); 83 (green CDs); 70 (blue CDs) | 365 | NR | (0.15, 0.19) blue; (0.25, 0.50) green; (0.55, 0.44) orange; (0.32, 0.31) white | 6216 | NR | NR | PVA | blue, green, orange, white | orange, green, and blue emissive CDs have synthesized; orange CDs doped with Mn to improve QY | [118] | |

| citric acid, tri(hydroxymethyl) amino methane hydrochloride (Tris-HMA) | one-step pyrolysis | 15 (CD@PS); 23 (CD@PEGMA) | 365 | ~440 (only blue CD@PS) | (0.32, 0.31) (mix of blue CD@PS, green 8-quinolinol, red CdSe/ZnS QDs) | NR | NR | NR | styrene, azobisisobutyronitrile (AIBN) | white | CDs prepared via mussel-inspired chemistry; CDs decorated by catechol-terminated hydrophilic poly(poly(ethylene glycol) methyl ether methacrylate (PPEGMA) and hydrophobic polystyrene (PS) | [128] | |

| KHP, NaN3, boric acid (BA); solvent: formaldehyde | one-step microwave-assisted pyrolysis | 67.8 | 365 | broad band centered at 432 | (0.17, 0.14) (15% mass ratio of D-CDs and resin) | >100,000 | 37 (15% mass ratio of D-CDs and resin) | 1.37 (15% mass ratio of D-CDs and resin) | epoxy silicone resin | bluish white | preparation of diamond-like carbon (sp3C) structure-doped carbon dots (D-CDs) powder for WLEDs | [173] | |

| citric acid, branched poly(ethylenimine) (b-PEI; molecular weight: 2000) | one-step hydrothermal method | 26 | 450 | 565 (WLED); 590 (yellow LED) | (0.34, 0.34) white; (0.56, 0.43) yellow | 4850 (white); 1849 (yellow) | 70.5 (white) | 8.9 (white) | NR | yellow, white | 4 ns of CD luminescence lifetime enabling the fabrication of WLEDs and high-performance visible light communication system | [96] | |

| Tobias acid, o-PD; solvents: formamide (blue CDs), ethanol (yellow CDs), sulfuric acid (red CDs) | one-step solvothermal method | 50.8 (red); 25.4 (yellow); 65.1 (blue); 50 (white) | 365 | 410–460 flat band, 560 | (0.31, 0.32) | 6135 | NR | NR | hydrogel | white | multicolor tunable highly luminescent CDs; N, S-CDs with red dual emission | [174] | |

| glucosamine, 3-[2-(2- aminoethylamino)ethylamino] propyl-trimethoxysilane (NQ-62); solvent: acetone | one-pot solvothermal treatment | 460 | broad band 380–780, centered at 600 | (0.269, 0.184) (CD concentration: 50 g/L); (0.340, 0.255) (CD concentration: 100 g/L); (0.355, 0.268) (CD concentration: 120 g/L); (0.427, 0.327) (CD concentration: 200 g/L); (0.547, 0.383) (CD concentration: 250 g/L) | 100,000 (CD concentration: 50 g/L); 4615 (CD concentration: 100 g/L); 3647 (CD concentration: 120 g/L); 2345 (CD concentration: 200 g/L); 1675 (CD concentration: 250 g/L) | 42.3 (CD concentration: 50 g/L); 67.5 (CD concentration: 100 g/L); 68.1 (CD concentration: 120 g/L); 78.0 (CD concentration: 200 g/L); 81.9 (CD concentration: 250 g/L) | NR | no | white | synthesis of organosilane-functionalized carbon quantum dots (Si-CDs) | [119] | ||

| poly(diallyldimethylammonium chloride) (PDDA) | microwave-assisted hydrothermal carbonization | ~11.0 in water; 7.3 in acetonitrile; 8.1 in DMF; 7.3 in methanol; 1.4 in acetone; 1.3 in PVA | 350 | broad band | (0.303, 0.332) in PVA; (0.307, 0.354) in water | 7023 in PVA; 5999 in water | NR | NR | PVA | white | CDs prepared starting from hydrothermal carbonization of PDDA; WLEDs fabricated by CD dispersion in water solution or in PVA | [175] | |

| citric acid, EDA | sonochemical synthesis | 9–11 | 365 | 450−850 | (0.334, 0.334) (optimized) | 4290–6606 | 88–94 | NR | lanthanoid metal–organic frameworks (Ln-MOFs) | white | fabrication of CDs/Ln-MOFs hybrids for WLEDs and as luminescent security inks | [90] | |

| poly(methyl methacrylate-co-dimethyl diallyl ammonium chloride) (PMMA-co-DMDAAC) | pyrolysis | NR | 360 | 450 | (0.1506, 0.0290) 1:5 molar ratios of DMDACC to MMA | NR | NR | 11.24 (1:5 DMDACC:MMA) | patterned PMMA-co-DMDAAC composite | blue | honeycomb-patterned films of different pore sizes as a matrix increases luminous efficiency | [98] | |

| citric acid, urea; solvents: water, ethyl alcohol, DMF | hydrothermal method | NR | 365 | broad band (peaks located at 441, 536, and 622) | (0.3497, 0.3045) (white) | 4878 | 85.2 | NR | silica | blue, green, yellow, orange, red, white | multicolor emission CDs synthesized by varying the ratio of precursors, the solvents, the temperature, and reaction time | [121] | |