Ceramic and Composite Polishing Systems for Milled Lithium Disilicate Restorative Materials: A 2D and 3D Comparative In Vitro Study

Abstract

:1. Introduction

2. Materials and Methods

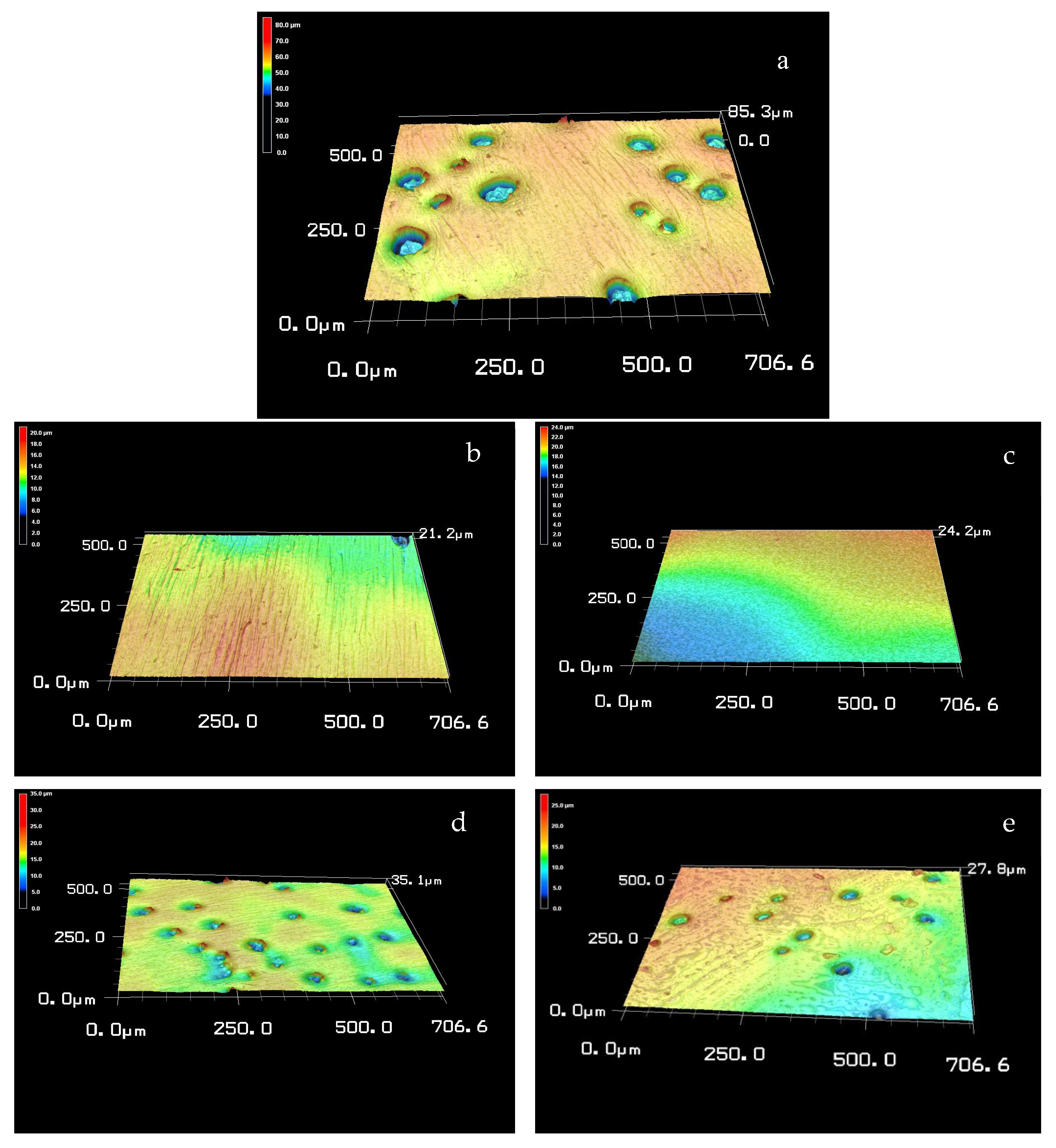

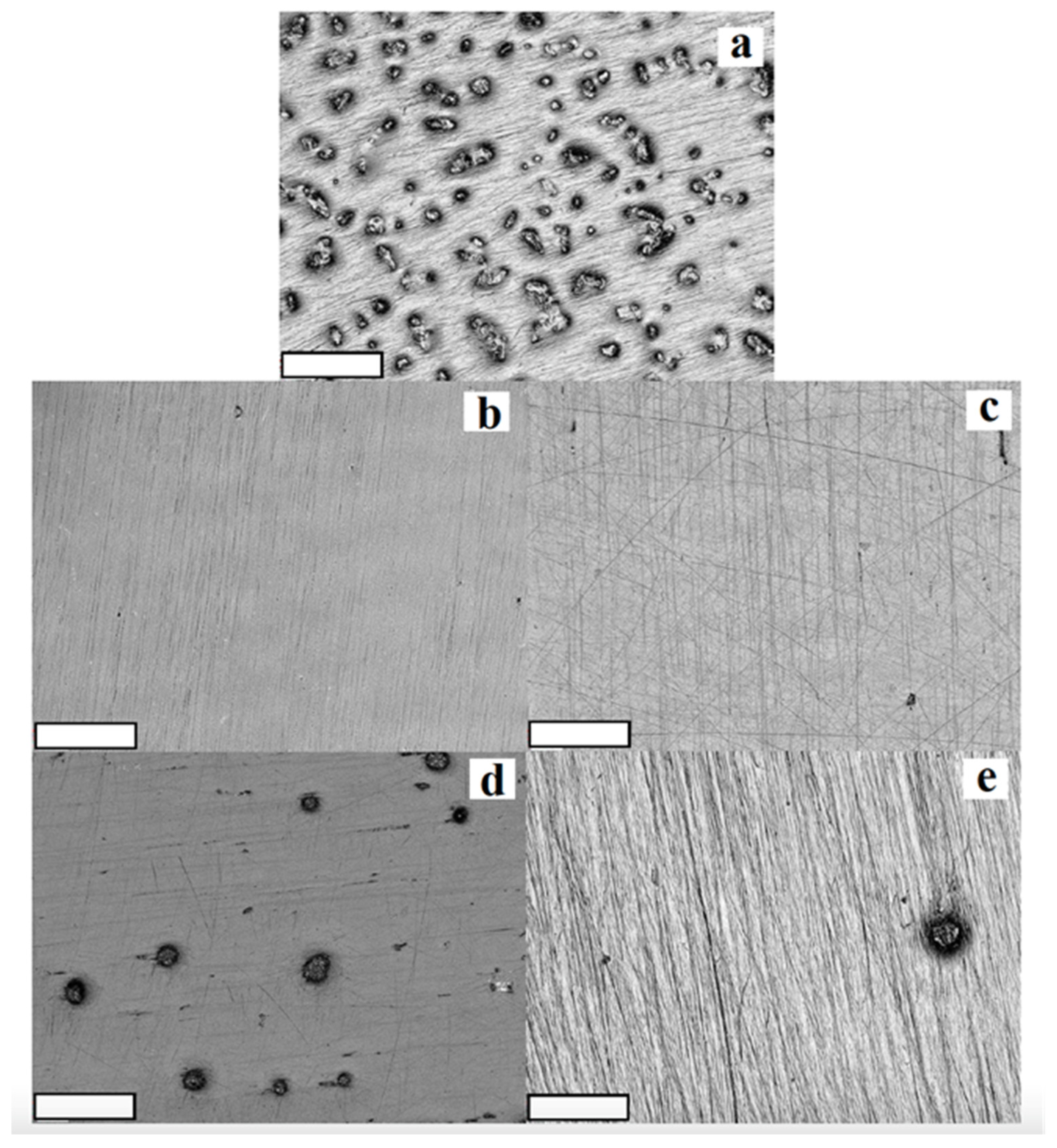

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Duret, F.; Preston, J.D. CAD/CAM imaging in dentistry. Curr. Opin. Dent. 1991, 1, 150–154. [Google Scholar] [PubMed]

- Priest, G. Virtual-designed and computer-milled implant abutments. J. Oral Maxillofac. Surg. 2005, 63, 22–32. [Google Scholar] [CrossRef]

- Mörmann, W.H.; Bindl, A. All-ceramic, chair-side computer-aided design/computer-aided machining restorations. Dent. Clin. N. Am. 2002, 46, 405–426. [Google Scholar] [CrossRef]

- Jurado, C.; Sayed, M.; Fu, C.-C.; Villalobos-Tinoco, J.; Tsujimoto, A. Computer-aided design and computer-aided manufacturing (cad/cam) complete dentures for atrophic alveolar ridges: Workflow combining conventional and novel techniques. Cureus 2022, 14, e21093. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.W.; Liu, Q.; Yue, Z.G.; Hou, J.; Afrashtehfar, K.I. Digital workflow for full-arch immediate implant placement using a stackable surgical guide fabricated using SLM technology. J. Prosthodont. 2021, 30, 645–650. [Google Scholar] [CrossRef] [PubMed]

- Alberto Jurado, C.; Kaleinikova, Z.; Tsujimoto, A.; Treviño, D.A.C.; Seghi, R.R.; Lee, D.J. Comparison of fracture resistance for chairside CAD/CAM lithium disilicate crowns and overlays with different designs. J. Prosthodont. 2022, 31, 341–347. [Google Scholar] [CrossRef]

- Hasanzade, M.; Aminikhah, M.; Afrashtehfar, K.I.; Alikhasi, M. Marginal and internal adaptation of single crowns and fixed dental prostheses by using digital and conventional workflows: A systematic review and meta-analysis. J. Prosthet. Dent. 2021, 126, 360–368. [Google Scholar] [CrossRef]

- Sulaiman, T.A. Materials in digital dentistry—A review. J. Esthet. Restor. Dent. 2020, 32, 171–181. [Google Scholar] [CrossRef]

- Fasbinder, D.J. Restorative material options for CAD/CAM restorations. Compend. Contin. Educ. Dent. 2002, 23, 911–924. [Google Scholar]

- Zandinejad, A.; Lin, W.S.; Atarodi, M.; Abdel-Azim, T.; Metz, M.; Morton, D. Digital workflow for virtually designing and milling ceramic lithium disilicate veneers: A clinical report. Oper. Dent. 2015, 40, 241–246. [Google Scholar] [CrossRef]

- Jurado, C.A.; El-Gendy, T.; Hyer, J.; Tsujimoto, A. Color stability of fully- and pre-crystalized chair-side CAD-CAM lithium disilicate restorations after required and additional sintering processes. J. Adv. Prosthodont. 2022, 14, 56–62. [Google Scholar] [CrossRef] [PubMed]

- Afrashtehfar, K.I.; de Souza, R.F. Comments regarding: Cooper LF, Stanford C, Feine J, McGuire M. Prospective assessment of CAD-CAM zirconia abutment and lithium disilicate crown restorations: 2.4 year results. J. Prosthet. Dent. 2016, 116, 33–39. [Google Scholar]

- Rauch, A.; Reich, S.; Schierz, O. Chair-side generated posterior monolithic lithium disilicate crowns: Clinical survival after 6 years. Clin. Oral Investig. 2017, 21, 2083–2089. [Google Scholar] [CrossRef] [PubMed]

- Albakry, M.; Guazzato, M.; Swain, M.V. Influence of hot pressing on the microstructure and fracture toughness of two pressable dental glass-ceramics. J. Biomed. Mater. Res. B Appl. Biomater. 2004, 71, 99–107. [Google Scholar] [CrossRef]

- Guazzato, M.; Albakry, M.; Ringer, S.P.; Swain, M.V. Strength, fracture toughness and microstructure of a selection of all ceramic materials. Part I. Pressable and alumina glass infiltrated ceramics. Dent. Mater. 2004, 20, 441–448. [Google Scholar] [CrossRef]

- Gehrt, M.; Wolfart, S.; Rafai, N.; Reich, S.M.; Edelhoff, D. Clinical results of lithium-disilicate crowns after up to 9 years of service. Clin. Oral Investig. 2013, 17, 275–284. [Google Scholar] [CrossRef]

- Fabbri, G.; Zarone, F.; Dellificorelli, G.; Cannistraro, G.; De Lorenzi, M.; Mosca, A.; Sorrentino, R. Clinical evaluation of 860 anterior and posterior lithium disilicate restorations: Retrospective study with a mean follow-up of 3 years and a maximum observational period of 6 years. Int. J. Periodont. Restor. Dent. 2014, 34, 165–177. [Google Scholar] [CrossRef]

- Vivadent Ivoclar. Scientific Documentation IPS e.max CAD; Vivadent Ivoclar: Schaan, Liechtenstein, 2011. [Google Scholar]

- Li, R.W.; Chow, T.W.; Matinlinna, J.P. Ceramic dental biomaterials and CAD/CAM technology: State of the art. J. Prosthodont. Res. 2014, 58, 208–216. [Google Scholar] [CrossRef] [Green Version]

- Willard, A.; Gabriel Chu, T.M. The science and application of IPS e.Max dental ceramic. Kaohsiung J. Med. Sci. 2018, 34, 238–242. [Google Scholar] [CrossRef] [Green Version]

- Marchesi, G.; Camurri Piloni, A.; Nicolin, V.; Turco, G.; Di Lenarda, R. Chairside CAD/CAM Materials: Current Trends of Clinical Uses. Biology 2021, 10, 1170. [Google Scholar] [CrossRef]

- Lubauer, J.; Belli, R.; Peterlik, H.; Hurle, K.; Lohbauer, U. Grasping the Lithium hype: Insights into modern dental Lithium Silicate glass-ceramics. Dent. Mater. 2022, 38, 318–332. [Google Scholar] [CrossRef]

- Scherrer, D.; Bragger, U.; Ferrari, M.; Mocker, A.; Joda, T. In-vitro polishing of CAD/CAM ceramic restorations: An evaluation with SEM and confocal profilometry. J. Mech. Behav. Biomed. Mater. 2020, 107, 103761. [Google Scholar] [CrossRef] [PubMed]

- Jurado, C.A.; Tsujimoto, A.; Watanabe, H.; Fischer, N.G.; Hasslen, J.A.; Tomeh, H.; Baruth, A.G.; Barkmeier, W.W.; Garcia-Godoy, F. Evaluation of polishing systems for CAD/CAM polymer-infiltrated ceramic-network restorations. Oper. Dent. 2021, 46, 219–225. [Google Scholar] [CrossRef] [PubMed]

- Rashid, H. The effect of surface roughness on ceramics used in dentistry: A review of literature. Eur. J. Dent. 2014, 8, 571–579. [Google Scholar] [CrossRef] [PubMed]

- Quirynen, M.; Bollen, C.M. The influence of surface roughness and surface free energy on supra and subgingival plaque formation in man. A review of the literature. J. Clin. Periodontol. 1995, 22, 1–14. [Google Scholar] [CrossRef]

- Augusto, M.G.; de Andrade, G.S.; Mathias-Santamaria, I.F.; Dal Piva, A.M.d.O.; Tribst, J.P.M. Comparison of Polishing Systems on the Surface Roughness of Resin Based Composites Containing Different Monomers. J. Compos. Sci. 2022, 6, 146. [Google Scholar] [CrossRef]

- Dal Piva, A.; Contreras, L.; Ribeiro, F.C.; Anami, L.C.; Camargo, S.; Jorge, A.; Bottino, M.A. Monolithic Ceramics: Effect of Finishing Techniques on Surface Properties, Bacterial Adhesion and Cell Viability. Oper. Dent. 2018, 43, 315–325. [Google Scholar] [CrossRef]

- Alikhasi, M.; Yousefi, P.; Afrashtehfar, K.I. Smile design: Mechanical considerations. Dent. Clin. N. Am. 2022, 66, 477–487. [Google Scholar] [CrossRef]

- Sagsoz, O.; Demirci, T.; Demirci, G.; Sagsoz, N.P.; Yildiz, M. The effects of different polishing techniques on the staining resistance of CAD/CAM resin-ceramics. J. Adv. Prosthodont. 2016, 8, 417–422. [Google Scholar] [CrossRef] [Green Version]

- Jung, M.; Wehlen, O.; Klimek, J. Finishing and polishing of indirect composite and ceramic inlays in-vivo: Occlusal surfaces. Oper. Dent. 2004, 29, 131–141. [Google Scholar]

- Gönüldaş, F.; Öztürk, C.; Atalay, P.; Öztaş, D. Influence of different surface finishing techniques on machinable feldspathic and leucite-reinforced ceramics. Dent. Mater. J. 2019, 38, 317–322. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Barakah, H.M.; Taher, N.M. Effect of polishing systems on stain susceptibility and surface roughness of nanocomposite resin material. J. Prosthet. Dent. 2014, 112, 625–631. [Google Scholar] [CrossRef] [PubMed]

- Nagura, Y.; Tsujimoto, A.; Fischer, N.G.; Baruth, A.G.; Barkmeier, W.W.; Takamizawa, T.; Latta, M.A.; Miyazaki, M. Effect of reduced universal adhesive application time on enamel bond fatigue and surface morphology. Oper. Dent. 2019, 44, 42–52. [Google Scholar]

- Fischer, N.G.; Tsujimoto, A.; Baruth, A.G. Effects of polishing bur application force and reuse on sintered zirconia surface topography. Oper. Dent. 2018, 45, 80–91. [Google Scholar]

- Kournetas, N.; Spintzyk, S.; Schweizer, E.; Sawada, T.; Said, F.; Schmid, P.; Geis-Gerstorfer, J.; Eliades, G.; Rupp, F. Comparative evaluation of topographical data of dental implant surfaces applying optical interferometry and scanning electron microscopy. Dent Mater. 2017, 33, e317–e327. [Google Scholar] [CrossRef]

- Fischer, N.G.; Dang, J.; Takamizawa, T.; Tsujimoto, A.; Barkmeier, W.W.; Baruth, A.G. The role of spatial frequency analysis in correlating atomic force microscopy and optical profilometry with self-etch adhesive enamel bond fatigue durability. Microsc. Res. Tech. 2019, 82, 1419–1429. [Google Scholar] [CrossRef]

- Mullan, F.; Austin, R.S.; Parkinson, C.R.; Hasan, A.; Bartlett, D.W. Measurement of surface roughness changes of unpolished and polished enamel following erosion. PLoS ONE 2017, 12, e0182406. [Google Scholar] [CrossRef] [Green Version]

- Suter, F.; Zinelis, S.; Patcas, R.; Schätzle, M.; Eliades, G.; Eliades, T. Roughness and wettability of aligner materials. J. Orthod. 2020, 47, 223–231. [Google Scholar] [CrossRef]

- Lubauer, J.; Belli, R.; Petschelt, A.; Cicconi, M.R.; Hurle, K.; Lohbauer, U. Concurrent kinetics of crystallization and toughening in multicomponent biomedical SiO2-Li2O-P2O5-ZrO2 glass- ceramics. J. Non-Cryst. Solids 2021, 554, 120607. [Google Scholar] [CrossRef]

- Botta, A.C.; Duarte, S., Jr.; Paulin Filho, P.I.; Gheno, S.M.; Powers, J.M. Surface roughness of enamel and four resin composites. Am. J. Dent. 2009, 22, 252–254. [Google Scholar] [PubMed]

- Ashe, M.J.; Tripp, G.A.; Eichmiller, F.C.; George, L.A.; Meiers, J.C. Surface roughness of glass-ceramic insert-composite restorations: Assessing several polishing techniques. J. Am. Dent. Assoc. 1996, 127, 1495–1500. [Google Scholar] [CrossRef] [PubMed]

| Group | Polishing System | Manufacturer | Components | Manufacturer Instructions |

|---|---|---|---|---|

| Group 1 (NoP) | No polishing | None | None | None |

| Group 2 Ceramic System (CeDi) | Dialite LD for lithium disilicate (Brasseler USA) | Brasseler USA, Savannah, GA, USA. | Medium (red) and fine (yellow) grits (red) for:

| Medium grifts (red) for pre-polishing and fine grifts (yellow) for final polishing. Speed: 5000–7000 rpms. May be used dry with a feather touch or wet. |

| Group 3 Ceramic System (CeOp) | OptraFine (Ivoclar Vivadent) | Ivoclar Vivadent, Schaan, Liechtenstein. |

| Step 1: Prep polishing using “light blue”. Step 2: Polishing using “dark blue”. Step 3: High-gloss polishing with brushes and polishing paste. Speed: 1000 up to max 1500 rpm for diamond finishers (F) and polishers (P) with copious water spray (>50 mL/min). 7000 up to max 1000 rpm for brushes (HP) and polishing paste without water spray. |

| Group 4 Composite System (CoDi) | DiaComp (Brasseler USA) | Brasseler USA, Savannah, GA, USA. | Medium (green) and fine (gray) grits for:

| Green medium grit is used to remove scratches and satin shine surfaces. Gray fine grit leaves a high shine finish. Speed: 5000 to 6000 rpm. May be used dry with a feather touch or wet. |

| Group 5 Composite System (CoAs) | Astropol (Ivoclar Vivadent) | Ivoclar Vivadent, Schaan, Liechtenstein. | Astropol F (grey), P (green) and HP (pink).Shapes:

| Astropol F (grey) for removal of excess composite material. Astropol P (green) for polishing. Astropol HP (pink) for final high-gloss. Speed: 7000 to 10,000 rpm. Only used with copious water spray (>50 mL/min). Use without polishing paste. |

| Factors | Groups | ||||

|---|---|---|---|---|---|

| Group 1 No Polishing (μm) | Ceramic | Composite | |||

| Group 2 Dialite LD (μm) | Group 3 OptraFine (μm) | Group 4 DiaComp (μm) | Group 5 Astropol (μm) | ||

| Sa (Surface arithmetical mean height) | 1.15 (0.81, 1.29) | 0.32 (0.20, 0.50) | 0.34 (0.25, 0.40) | 0.66 (0.39, 0.85) | 0.52 (0.45, 0.67) |

| Sz (Surface maximum height) | 11.41 (5.23, 11.89) | 3.59 (3.27, 4.57) | 2.81 (2.39, 3.44) | 6.43 (2.70, 10.90) | 4.08 (3.19, 7.64) |

| Str (Surface texture aspect ratio) | 0.57 (0.44, 0.73) | 0.37 (0.20, 0.47) | 0.46 (0.35, 0.53) | 0.52 (0.40, 0.66) | 0.39 (0.31, 0.54) |

| Spc (Surface arithmetic mean peak curvature) | 2861 (2536, 3132) | 3314 (2926, 3528) | 2342 (2128, 2512) | 2851 (2622, 3204) | 2845 (2705, 3085) |

| Sdr (Surface developed interfacial area ratio) | 0.04 (0.03, 0.05) | 0.05 (0.04, 0.07) | 0.02 (0.02, 0.03) | 0.03 (0.03, 0.06) | 0.03 (0.03, 0.03) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jurado, C.A.; Amarillas-Gastelum, C.; Afrashtehfar, K.I.; Argueta-Figueroa, L.; Fischer, N.G.; Alshabib, A. Ceramic and Composite Polishing Systems for Milled Lithium Disilicate Restorative Materials: A 2D and 3D Comparative In Vitro Study. Materials 2022, 15, 5402. https://doi.org/10.3390/ma15155402

Jurado CA, Amarillas-Gastelum C, Afrashtehfar KI, Argueta-Figueroa L, Fischer NG, Alshabib A. Ceramic and Composite Polishing Systems for Milled Lithium Disilicate Restorative Materials: A 2D and 3D Comparative In Vitro Study. Materials. 2022; 15(15):5402. https://doi.org/10.3390/ma15155402

Chicago/Turabian StyleJurado, Carlos A., Clarisa Amarillas-Gastelum, Kelvin I. Afrashtehfar, Liliana Argueta-Figueroa, Nicholas G. Fischer, and Abdulrahman Alshabib. 2022. "Ceramic and Composite Polishing Systems for Milled Lithium Disilicate Restorative Materials: A 2D and 3D Comparative In Vitro Study" Materials 15, no. 15: 5402. https://doi.org/10.3390/ma15155402

APA StyleJurado, C. A., Amarillas-Gastelum, C., Afrashtehfar, K. I., Argueta-Figueroa, L., Fischer, N. G., & Alshabib, A. (2022). Ceramic and Composite Polishing Systems for Milled Lithium Disilicate Restorative Materials: A 2D and 3D Comparative In Vitro Study. Materials, 15(15), 5402. https://doi.org/10.3390/ma15155402