Friction Performance Improvement of Phenolic/Rockwool Fibre Composites: Influence of Fibre Morphology and Distribution

Abstract

:1. Introduction

2. Materials and Methods

2.1. Investigated Materials

2.2. Microstructure Characterisation

2.3. Evaluation of Tribological Behaviour

2.3.1. Tribometer Description

2.3.2. Experimental Protocol

2.3.3. Thermal Phenomena Investigation

3. Results and Discussion

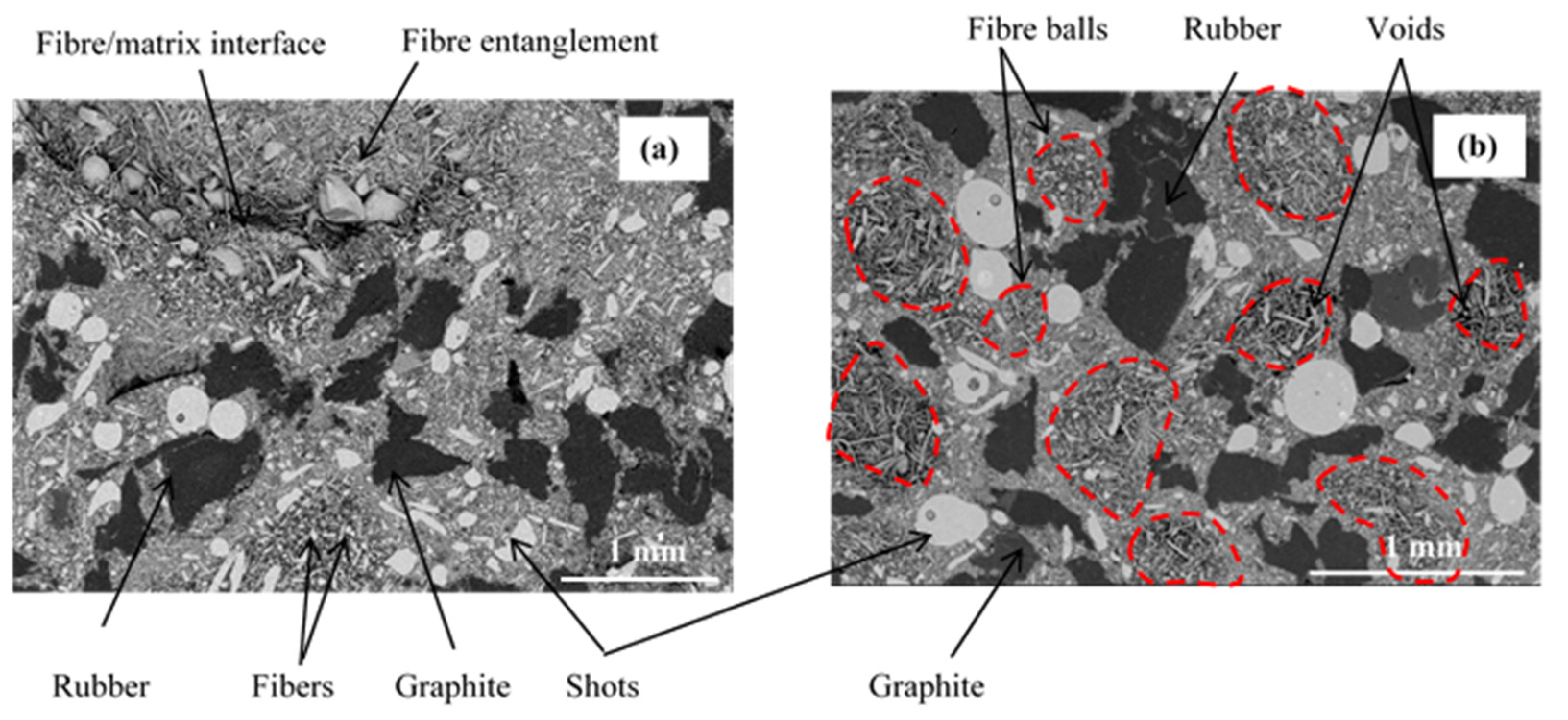

3.1. Microstructures

3.2. Friction Behaviour

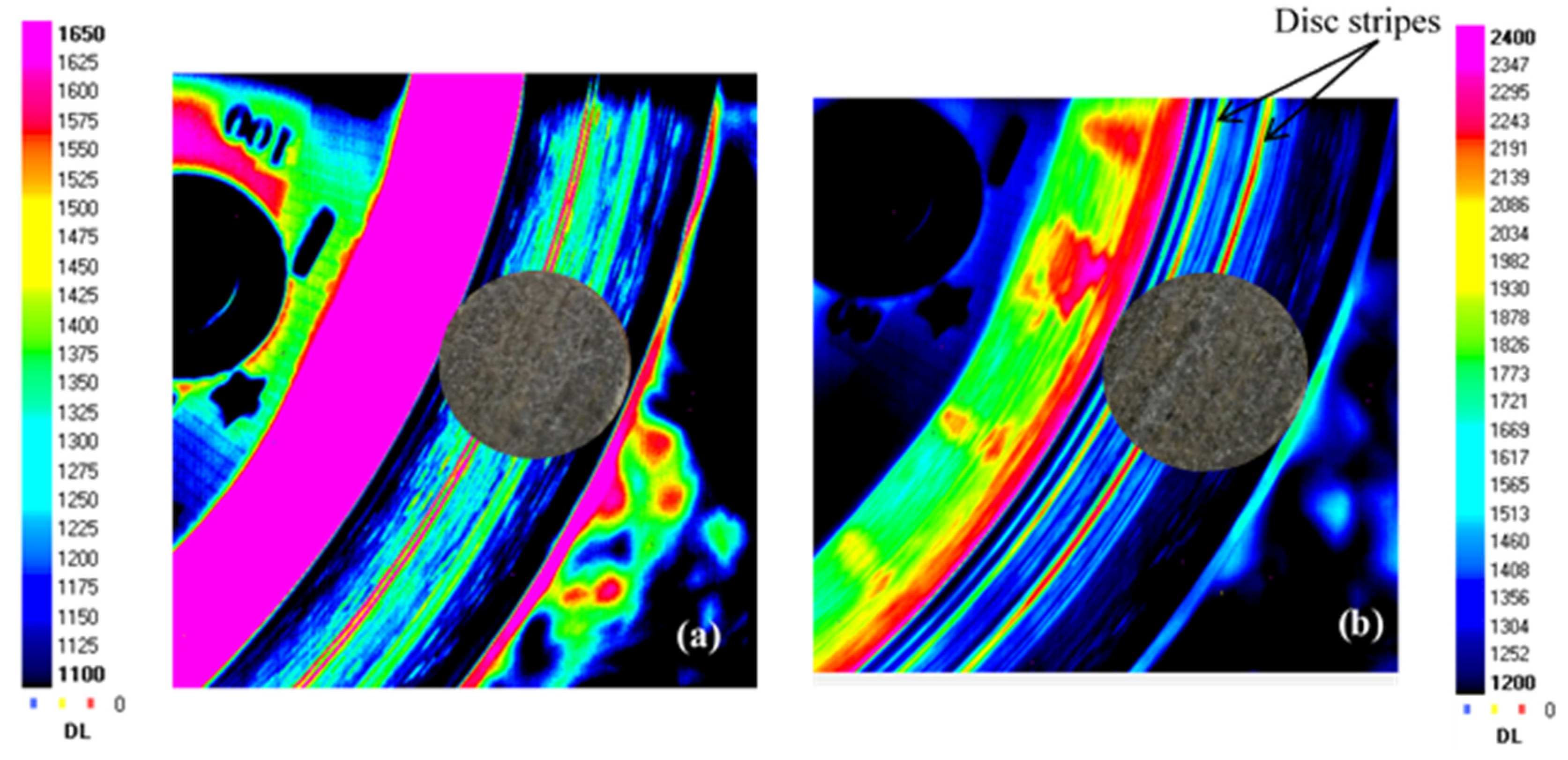

3.3. Thermal Phenomena Correlation

3.4. Friction and Wear Mechanisms

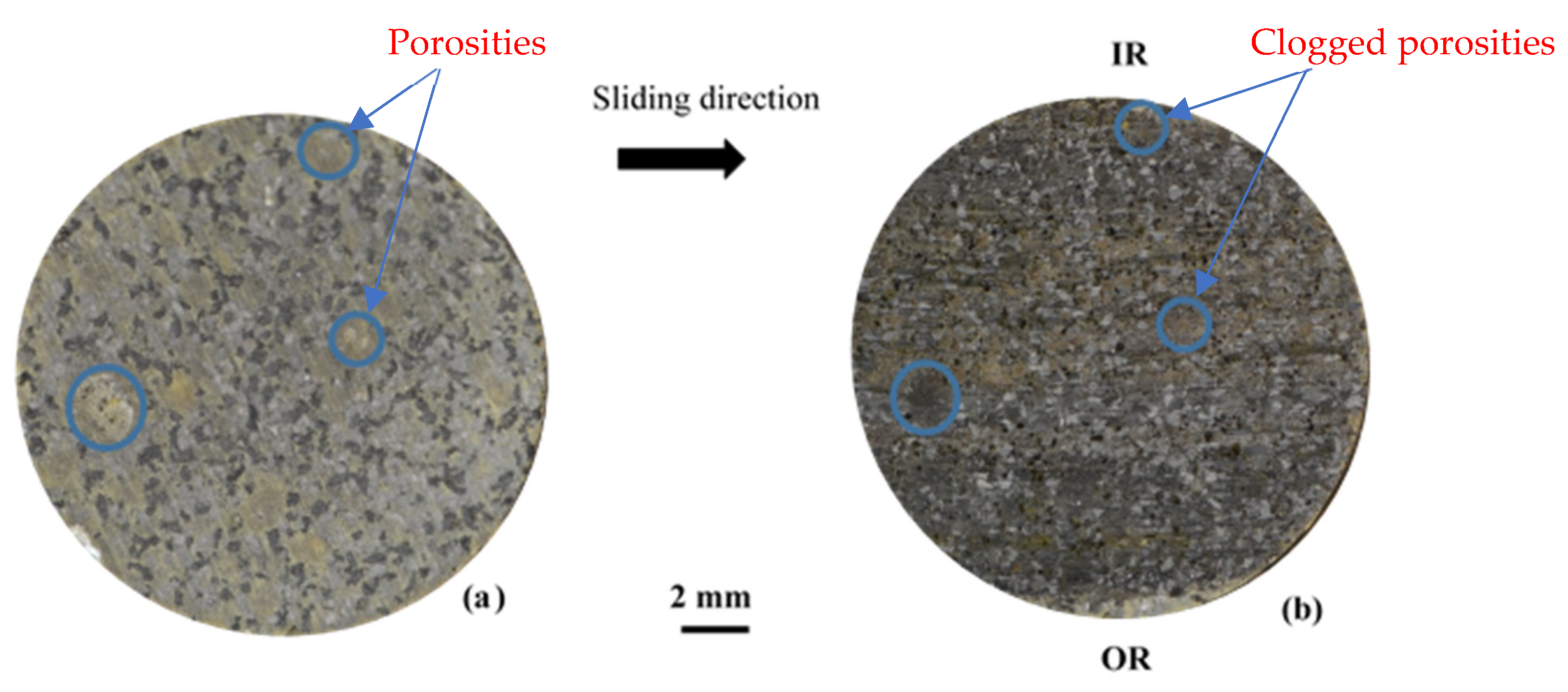

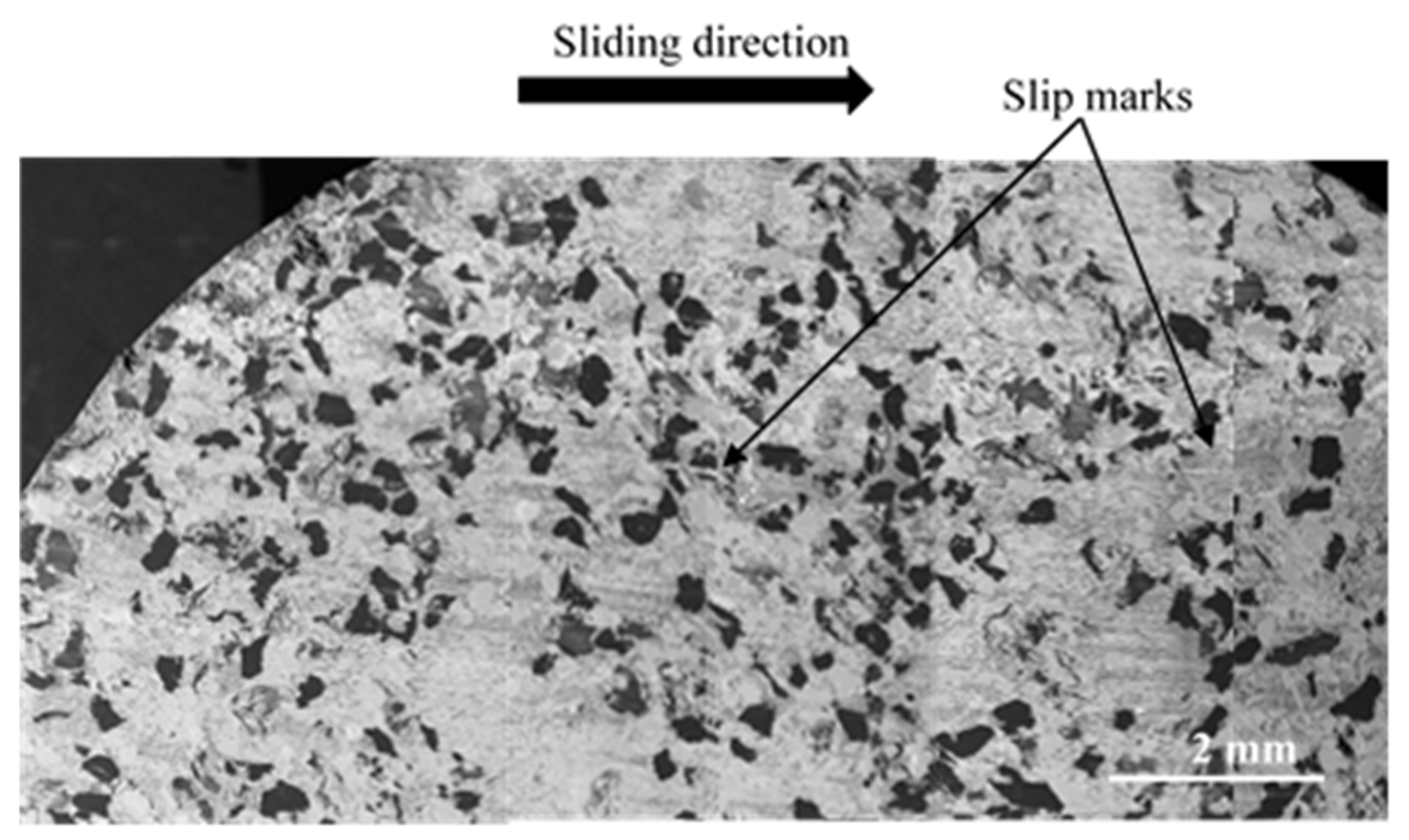

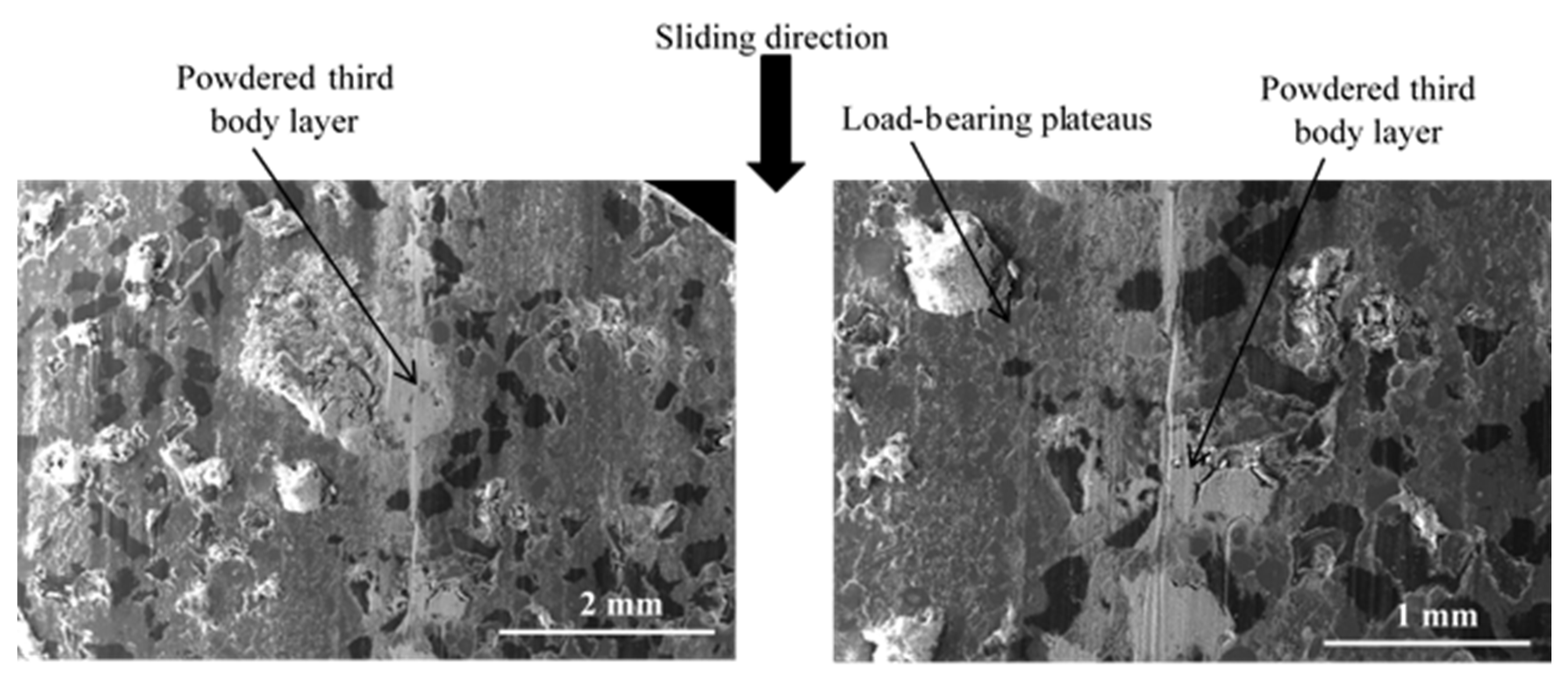

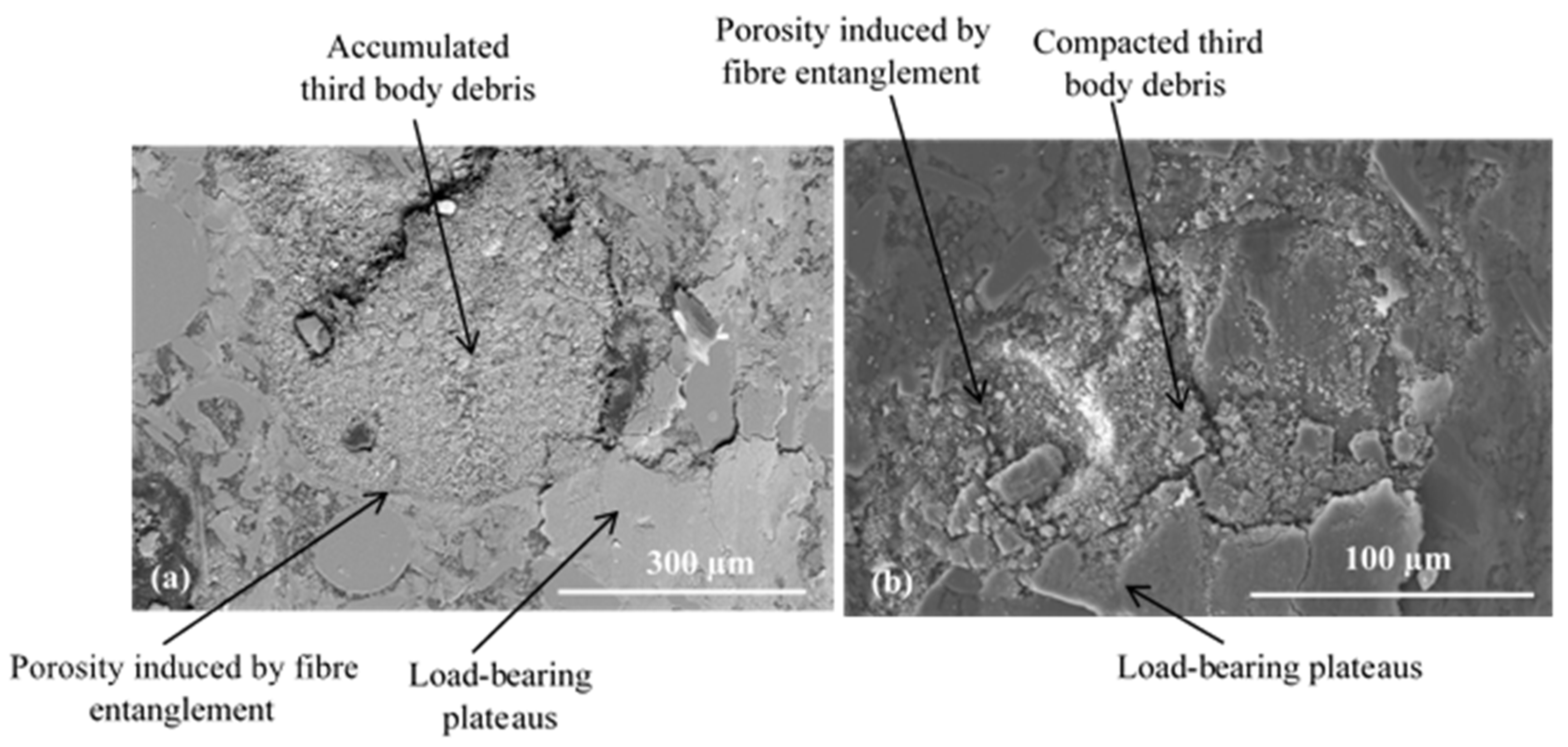

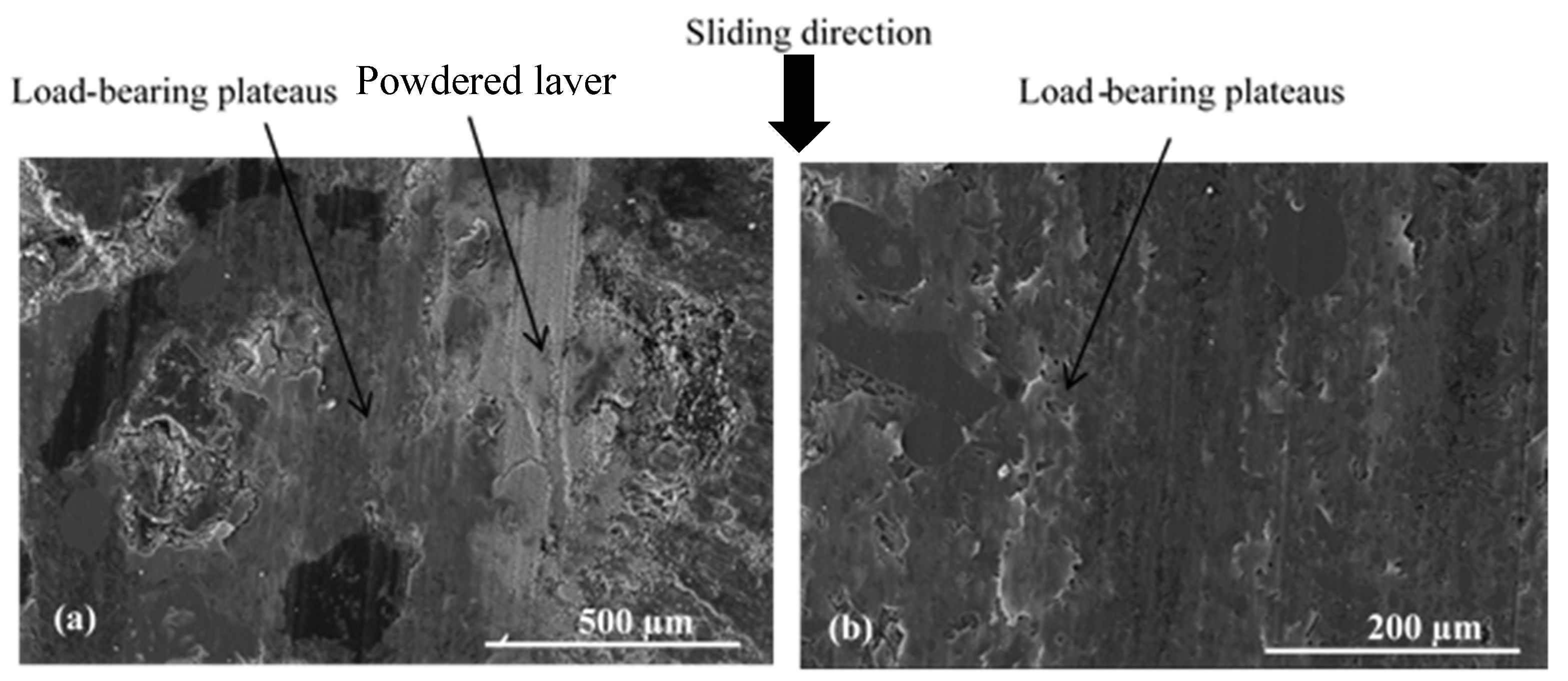

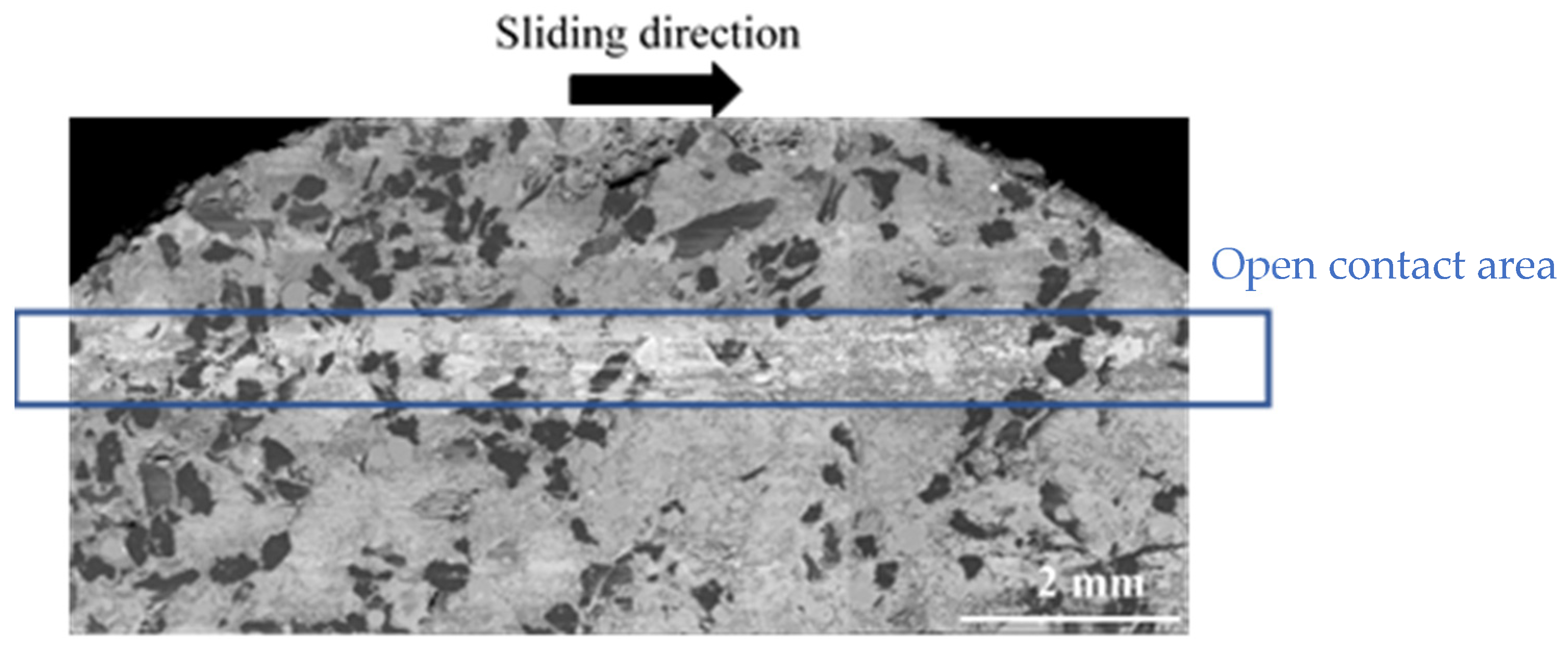

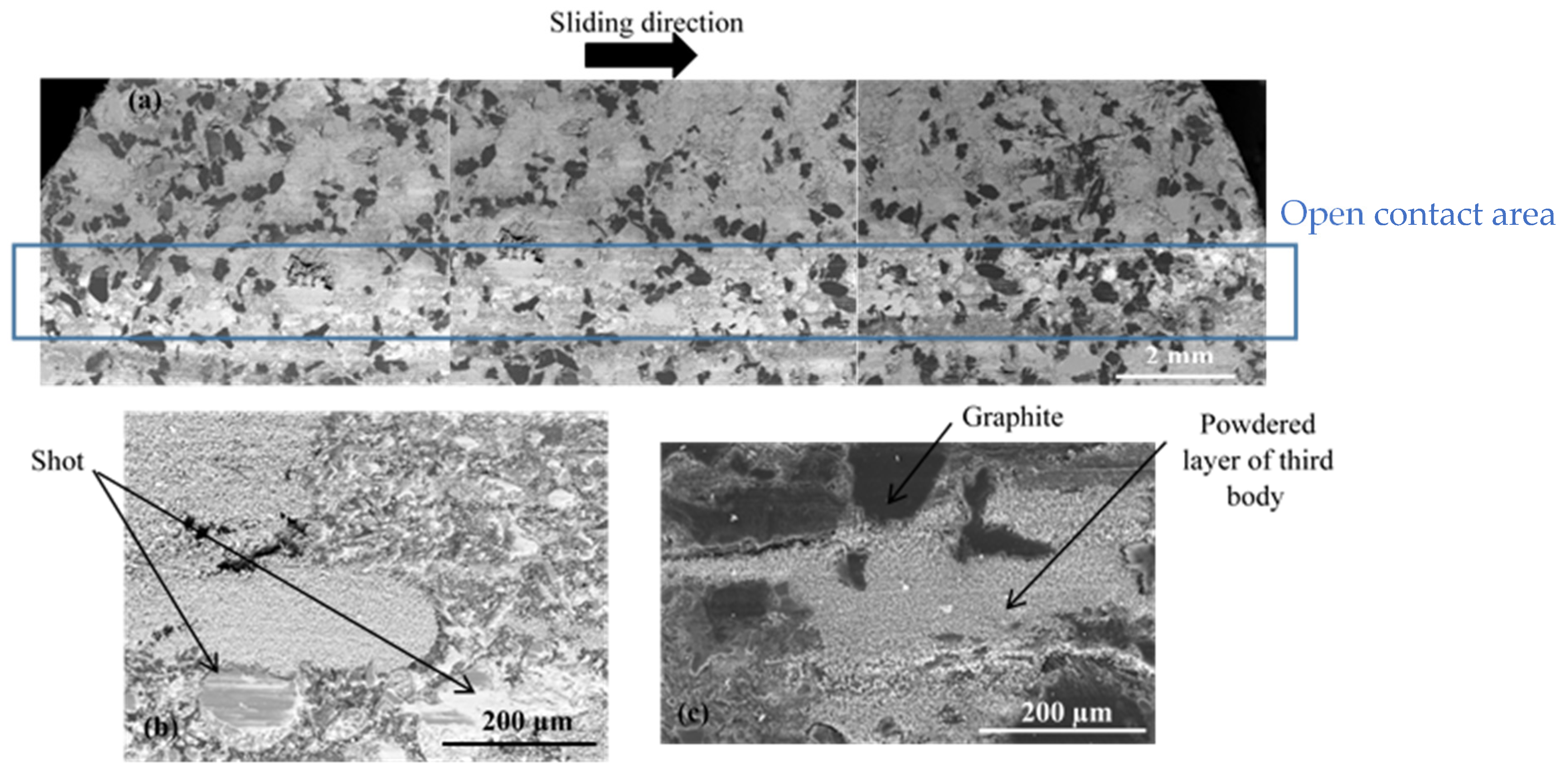

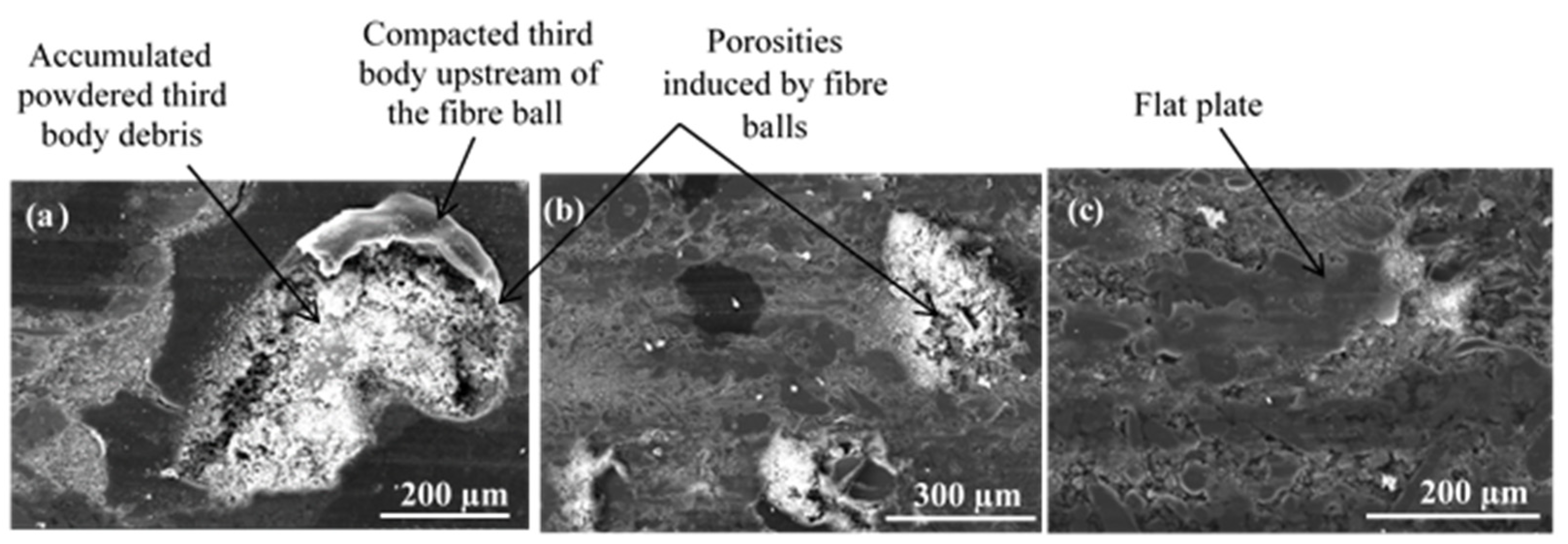

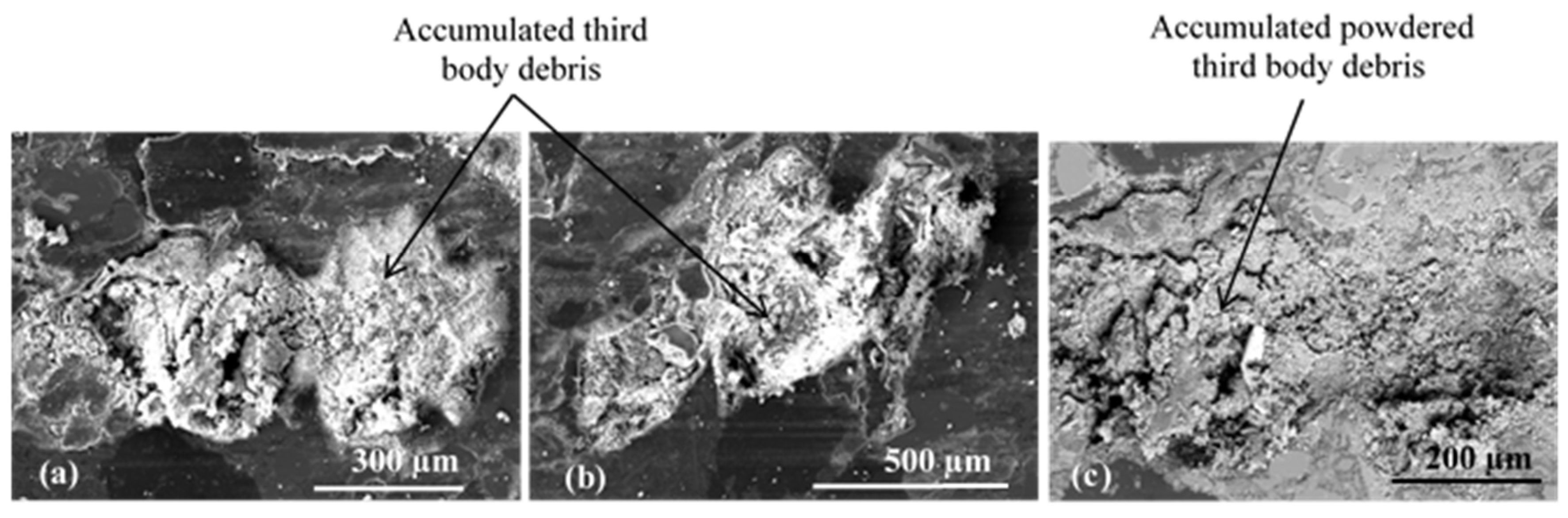

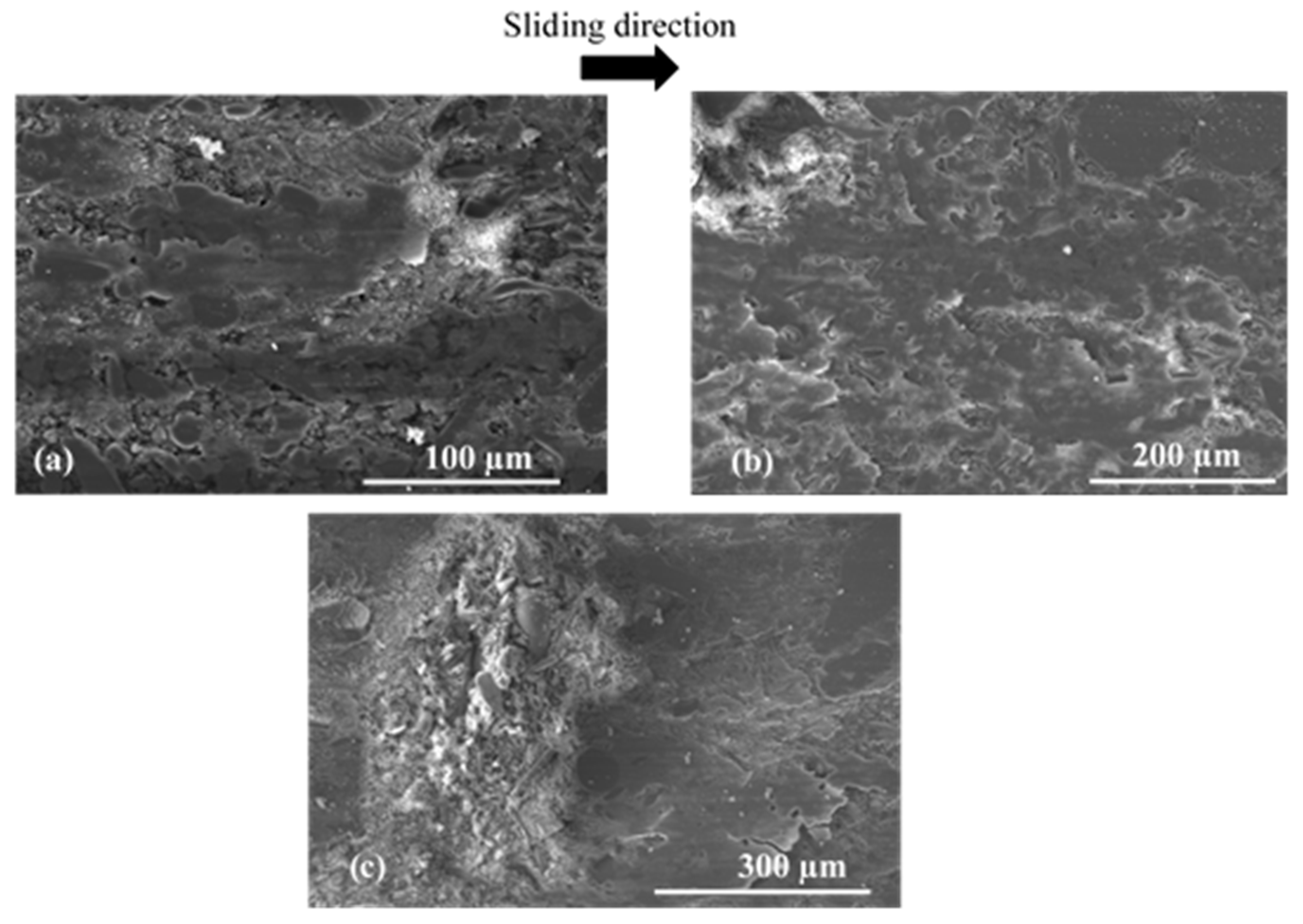

3.4.1. Wear Mechanisms of FMFS

3.4.2. Wear Mechanisms of FMFBs

3.5. Wear Behaviour

4. Conclusions

- A high source flow provided by homogeneous distribution of fibre balls leads to the rapid establishment of a third body in the interface capable of providing bearing capacity and velocity accommodation.

- Locally high surface porosity, due to the fibre entanglements, favours the accumulation of debris of a third body. These particle accumulations, periodically released into the tribological circuit, disrupt the load-bearing plateaus and thus the friction.

- A homogeneously distributed porosity, induced by fibre balls, in the contact favours the development, coalescence, and preservation of the load-bearing plateaus in the contact and thus a stable friction.

- Porosity induced by fibre balls and entanglements constitute third-body supplies feeding of the tribological circuit.

- Fibre entanglements lead to a heterogeneous and poorly distributed porosity, which results in an irregular supply of the tribological system.

- Irregular third-body feeding, induced by fibre entanglements, disturbs load-bearing mechanisms and generates a high wear rate.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rajan, B.S.; Balaji, M.A.S.; Noorani, A.B.M.A.; Khateeb, M.U.H.; Hariharasakthisudan, P.; Doss, P.A. Tribological performance evaluation of newly synthesized silane treated shell powders in friction composites. Mater. Res. Express 2019, 6, 065317. [Google Scholar] [CrossRef]

- Singh, T.; Tiwari, A.; Patnaik, A.; Chauhan, R.; Ali, S. Influence of wollastonite shape and amount on tribo-performance of non-asbestos organic brake friction composites. Wear 2017, 386, 157–164. [Google Scholar] [CrossRef]

- Makni, F.; Cristol, A.-L.; Elleuch, R.; Desplanques, Y. Organic brake friction composite materials: Impact of mixing duration on microstructure, properties, tribological behavior and wear resistance. Polymers 2022, 14, 1692. [Google Scholar] [CrossRef] [PubMed]

- Makni, F.; Kchaou, M.; Cristol, A.-L.; Elleuch, R.; Desplanques, Y. A new method of mixing quality assessment for friction material constituents toward better mechanical properties. Powder Metall. Met. Ceram. 2017, 56, 1–13. [Google Scholar] [CrossRef]

- Satapathy, B.K.; Bijwe, J. Composite friction materials based on organic fibers: Sensitivity of friction and wear to operating variables. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1557–1567. [Google Scholar] [CrossRef]

- Lu, Y.; Tang, C.-F.; Wright, M.A. Optimization of a commercial brake pad formulation. J. Appl. Polym. Sci. 2002, 84, 2498–2504. [Google Scholar] [CrossRef]

- Hentati, N.; Kchaou, M.; Cristol, A.-L.; Najjar, D.; Elleuch, R. Impact of post curing duration on the mechanical, thermal and tribological behavior of an organic friction material. Mater. Des. 2014, 63, 699–709. [Google Scholar] [CrossRef]

- Baklouti, M.; Cristol, A.-L.; Desplanques, Y.; Elleuch, R. Impact of the glass fiber addition on tribological behavior and breaking performances of organic matrix composites for brake lining. Wear 2015, 330, 507–514. [Google Scholar] [CrossRef]

- Ji, Z.; Luo, W.; Zhou, K.; Hou, S.; Zhang, Q.; Li, J.; Jin, H. Effects of the shapes and dimensions of mullite whisker on the friction and wear behaviors of resin-based friction materials. Wear 2018, 406, 118–125. [Google Scholar] [CrossRef]

- Öztürk, B.Ü.; Öztürk, S.U.; Adigüzel, A.A. Effect of Type and Relative Amount of Solid Lubricants and Abrasives on the Tribological Properties of Brake Friction Materials. Tribol. Trans. 2013, 56, 428–441. [Google Scholar] [CrossRef]

- Vineeth Kumar, V.; Senthil Kumaran, S. Friction material composite: Types of brake friction material formulations and effects of various ingredients on brake performance—A review. Mater. Res. Express 2019, 6, 082005. [Google Scholar] [CrossRef]

- Jae Hyun, G.; Byung, S.J.; Ho, J. The effect of short glass fiber dispersion on the friction and vibration of brake friction materials. Wear 2016, 362, 61–67. [Google Scholar] [CrossRef]

- Wu, S.; Zhao, J.; Guo, M.; Zhuang, J.; Wu, Q. Effect of Fiber Shape on the Tribological, Mechanical, and Morphological Behaviors of Sisal Fiber-Reinforced Resin-Based Friction Materials: Helical, Undulated, and Straight Shapes. Materials 2021, 14, 5410. [Google Scholar] [CrossRef] [PubMed]

- Matejka, V.; Fu, Z.; Kukutschova, J.; Qi, S.; Jiang, S.; Zhang, X.; Yun, R.; Vaculik, M.; Heliova, M.; Lu, Y. Jute fibers and powderized hazelnut shells as natural fillers in non-asbestos organic non-metallic friction composites. Mater. Des. 2013, 51, 847–853. [Google Scholar] [CrossRef]

- Baklouti, M.; Elleuch, R.; Cristol, A.-L.; Najjar, D.; Desplanques, Y. Relationships between the heterogeneous microstructure, the mechanical properties and the braking behavior of an organic brake lining material. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2013, 227, 549–560. [Google Scholar] [CrossRef]

- Makni, F.; Cristol, A.-L.; Kchaou, M.; Elleuch, R.; Desplanques, Y. Synergistic effects of fiber arrangements on the microstructure and properties of organic composite materials. J. Compos. Mater. 2020, 54, 4621–4634. [Google Scholar] [CrossRef]

- Lei, H.F.; Zhang, Z.Q.; Liu, B. Effect of fiber arrangement on mechanical properties of short fiber reinforced composites. Compos. Sci. Technol. 2012, 72, 506–514. [Google Scholar] [CrossRef]

- Horovistiz, A.; Laranjeira, S.; Davim, J.P. Influence of sliding velocity on the tribological behavior of PA66GF30 andPA66 + MoS2: An analysis of morphology of sliding surface by digital image processing. Polym. Bull. 2018, 75, 5113–5131. [Google Scholar] [CrossRef]

- Maciel, M.M.; Ribeiro, S.; Ribeiro, C.; Francesko, A.; Maceiras, A.; Vilas, J.L.; Lanceros-Méndez, S. Relation between fiber orientation and mechanical properties of nano-engineered poly(vinylidene fluoride) electrospun composite fiber mats. Compos. Part B 2018, 139, 146–154. [Google Scholar] [CrossRef]

- Sharma, M.; Bijwe, J. Influence of fiber–matrix adhesion and operating parameters wear on sliding wear performance of carbon fabric polyethersulphone composites. Wear 2011, 271, 2919–2927. [Google Scholar] [CrossRef]

- Makni, F. Hétérogénéité Microstructurale de Garniture de Frein: Lien Avec les Proprietés Thermo Physiques et Mécaniques et le Comportement Tribologique. Ph.D. Thesis, Université de Sfax, Sfax, Tunisia, 2017. [Google Scholar]

- Bauer, W.; Oertel, H.; Rink, M. Spectral emissivity of bright and oxided metals at high temperatures. In Proceedings of the Fifteen Symposium on Thermophysical Properties, Boulder, CO, USA, 22–27 June 2003. [Google Scholar]

- Österle, W.; Dörfel, I.; Prietzel, C. A comprehensive microscopic study of third body formation at the interface between a brake pad and brake disc during the final stage of a pin-on-disc test. Wear 2009, 267, 781–788. [Google Scholar] [CrossRef]

- Thevenet, J.; Siroux, M.; Desmet, B. Measurements of brake disc surface temperature and emissivity by two-colour pyrometry. Appl. Therm. Eng. 2010, 30, 753–759. [Google Scholar] [CrossRef] [Green Version]

- Roussette, O. Etude Tribologique de Couples de Matériaux Sous Sollicitations de Freinage Très Sévères, Application à un Frein à Performance Améliorées. Ph.D. Thesis, Ecole Centrale de Lille, Villeneuve-d’Ascq, France, 2005. [Google Scholar]

- Filip, P.; Weiss, Z.; Rafaja, D. On friction layer formation in polymer matrix composite materials for brake applications. Wear 2002, 252, 189–198. [Google Scholar] [CrossRef]

- Desplanques, Y.; Degallaix, G. Interactions between third-body flows and localisation phenomena during high-energy railways stop-braking. SAE Int. J. Passeng. Cars—Mech. Syst. 2009, 1, 1267–1275. [Google Scholar] [CrossRef]

- Desplanques, Y.; Degallaix, G. Genesis of the Third-Body at the Pad-Disc Interface: Case Study of Sintered Metal Matrix Composite Lining Material. SAE Int. J. Mater. Manuf. 2010, 2, 25–32. [Google Scholar] [CrossRef]

- Blau, P.J. Microstructure and detachment mechanism of friction layers on the surface of brake shoes. J. Mater. Eng. Perform. 2003, 12, 56–60. [Google Scholar] [CrossRef]

- Duan, J.; Zhang, M.; Chen, P.; Li, Z.; Pang, L.; Xiao, P.; Li, Y. Tribological behavior and applications of carbon fiber reinforced ceramic composites as high-performance frictional materials. Ceram. Int. 2021, 47, 19271–19281. [Google Scholar] [CrossRef]

- Jara, D.C.; Jang, H. Synergistic effects of the ingredients of brake friction materials on friction and wear: A case study on phenolic res and potassium titanate. Wear 2019, 430, 222–232. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Y.; Pei, Z.; Li, W.; Shi, W.; Gong, J.; Sun, C. Influence of particle size and content on the friction and wear behaviors of as-annealed Ni–Mo/diamond composite coatings. Wear 2020, 452, 203300. [Google Scholar] [CrossRef]

- Kurt, A.; Ates, H. Effect of porosity on thermal conductivity of powder metal materials. Mater. Des. 2007, 28, 230–233. [Google Scholar] [CrossRef]

- Yang, Y.; Liang, L.-X.; Wu, H.; Liu, B.-W.; Qu, H.; Fang, Q.-H. Effect of zinc powder content on tribological behaviors of brake friction materials. Trans. Nonferrous Met. Soc. China 2020, 30, 3078–3092. [Google Scholar] [CrossRef]

- Elzayady, N.; Elsoeudy, R. Microstructure and wear mechanisms investigation on the brake pad. J. Mater. Res. Technol. 2021, 11, 2314–2335. [Google Scholar] [CrossRef]

- Bernard, S.; Jayakumari, L.S. Effect of Rockwool and Steel fiber on the Friction Performance of Brake Lining Materials. Matéria 2016, 21, 656–665. [Google Scholar] [CrossRef] [Green Version]

| Classification | Constituents of Simplified Formulation | Weight Proportion (%) | Selected Particle Size (µm) |

|---|---|---|---|

| Binder | Phenolic resin | 15.3 | <20 |

| Fibres | Rockwool fibres | 39.1 | Material FMFS: Fiber balls: 400–1000 |

| Material FMFBs: Fibres < 400 | |||

| Lubricant | Graphite | 11.9 | 212–300 |

| Abrasive | Alumina | 1.2 | <20 |

| Friction modifier | Rubber | 11.3 | 325–400 |

| Filler | Calcium carbonate | 21.3 | <20 |

| ΔT Disc (°C) | ΔT Pin (°C) | |

|---|---|---|

| FMFS | 20 | 17.1 |

| FMFBs | 22.3 | 16 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Makni, F.; Cristol, A.-L.; Desplanques, Y.; Elleuch, R. Friction Performance Improvement of Phenolic/Rockwool Fibre Composites: Influence of Fibre Morphology and Distribution. Materials 2022, 15, 5381. https://doi.org/10.3390/ma15155381

Makni F, Cristol A-L, Desplanques Y, Elleuch R. Friction Performance Improvement of Phenolic/Rockwool Fibre Composites: Influence of Fibre Morphology and Distribution. Materials. 2022; 15(15):5381. https://doi.org/10.3390/ma15155381

Chicago/Turabian StyleMakni, Fatma, Anne-Lise Cristol, Yannick Desplanques, and Riadh Elleuch. 2022. "Friction Performance Improvement of Phenolic/Rockwool Fibre Composites: Influence of Fibre Morphology and Distribution" Materials 15, no. 15: 5381. https://doi.org/10.3390/ma15155381

APA StyleMakni, F., Cristol, A.-L., Desplanques, Y., & Elleuch, R. (2022). Friction Performance Improvement of Phenolic/Rockwool Fibre Composites: Influence of Fibre Morphology and Distribution. Materials, 15(15), 5381. https://doi.org/10.3390/ma15155381