Numerical Investigation of FRCM-Strengthened Corroded RC Beams under Cathodic Protection

Abstract

:1. Introduction

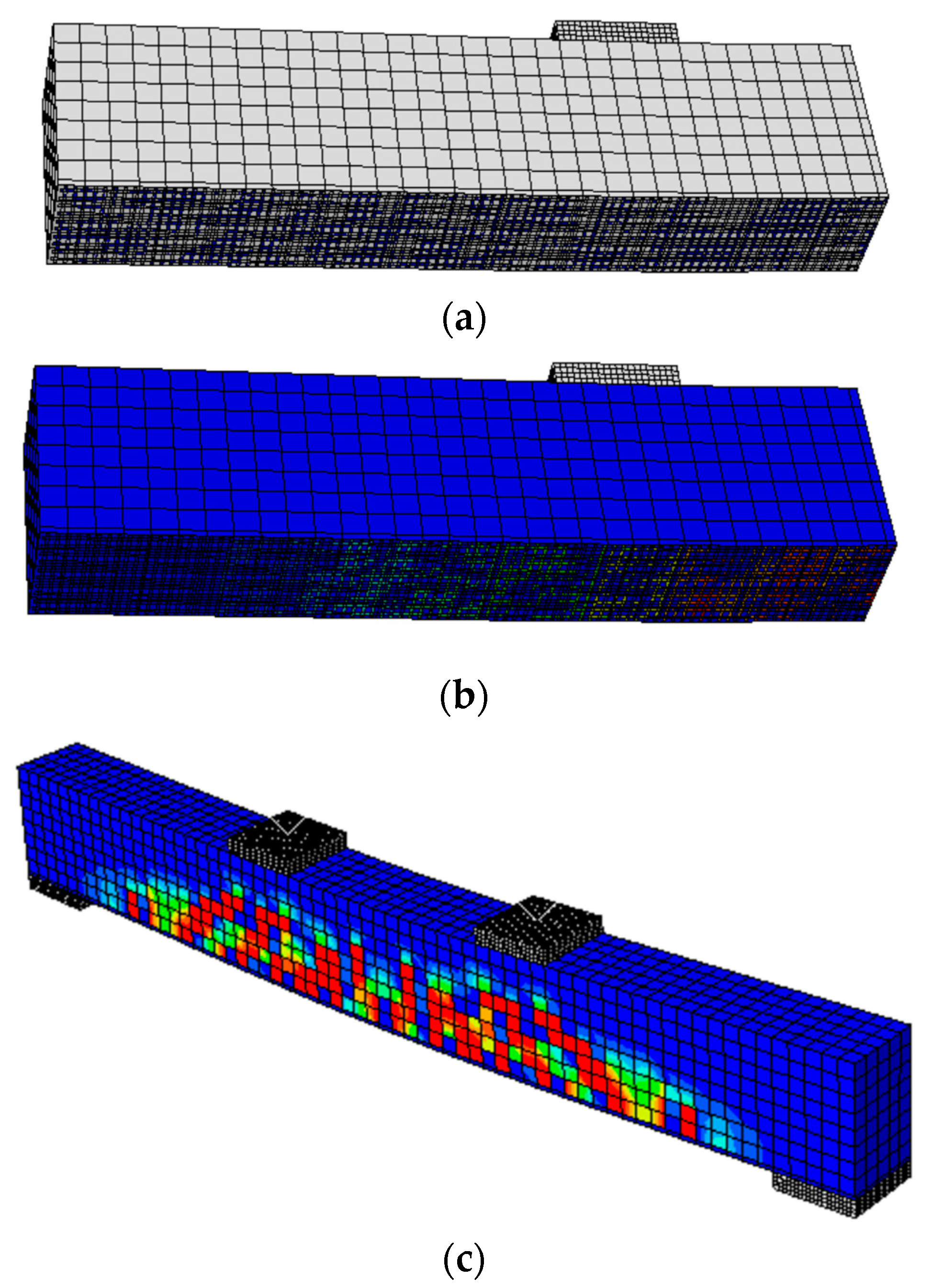

2. Experimental Results from the Literature

3. Numerical Modelling and Validation

4. Parametric Studies

5. Discussion

5.1. Effects of Degradation of Fibre/Cement Interface

5.2. Effects of Mechanical Anchorage

5.3. Effects of Corrosion

6. Comparison with Design Standards

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Samples, L.M.; Ramirez, J.A. Methods of Corrosion Protection and Durability of Concrete Bridge Decks Reinforced with Epoxy-Coated Bars, Phase I; Publication FHWA/IN/JTRP-98/15; Indiana Department of Transportation and Purdue University: West Lafayette, IN, USA, 1999. [Google Scholar] [CrossRef] [Green Version]

- Shi, X.; Xie, N.; Fortune, K.; Gong, J. Durability of steel reinforced concrete in chloride environments: An overview. Constr. Build. Mater. 2012, 30, 125–138. [Google Scholar] [CrossRef]

- Nguyen, K.; Le, T.A.; Lee, K. Evaluation of the mechanical properties of sea sand-based geopolymer concrete and the corrosion of embedded steel bar. Constr. Build. Mater. 2018, 169, 462–472. [Google Scholar] [CrossRef]

- Arya, E.K.; Dhanya, B.S. Corrosion control of reinforced concrete structures in construction industry: A review. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1114, 012006. [Google Scholar] [CrossRef]

- Lambert, P.; Van Nguyen, C.; Mangat, P.S.; O’Flaherty, F.J.; Jones, G. Dual function carbon fibre fabric strengthening and impressed current cathodic protection (ICCP) anode for reinforced concrete structures. Mater. Struct. 2015, 48, 2157–2167. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.; Wang, J.; Zhu, J.H.; Feng, Y.; Liu, C.B. Study on the Corroded Hollow Section RC Columns Strengthened by ICCP-SS System. Buildings 2021, 11, 197. [Google Scholar] [CrossRef]

- Morefield, S.W.; Hock, V.F.; Weiss, C.A., Jr.; Malone, P.G. Application of Electrokinetic Nanoparticle Migration in the Production of Novel Concrete-Based Composites. 2008. Available online: http://www.oai.dtic.mil/oai/oai?verb=getRecordmetadataPrefix=htmlidentifier=ADA504199 (accessed on 1 December 2008).

- Png, W.; Lin, H.; Pua, C.; Lim, J.; Lim, S.; Lee, Y.; Rahman, F. Feasibility use of in-line Mach–Zehnder interferometer optical fibre sensor in lightweight foamed concrete structural beam on curvature sensing and crack monitoring. Struct. Health Monit. 2018, 17, 1277–1288. [Google Scholar] [CrossRef]

- Corrosion Protection of Fiber-Reinforced Polymer-Wrapped Reinforced Concrete. ACI Mater. J. 2010, 107, 349–356. [CrossRef]

- Bahekar, P.V.; Gadve, S.S. Impressed current cathodic protection of rebar in concrete using Carbon FRP laminate. Constr. Build. Mater. 2017, 156, 242–251. [Google Scholar] [CrossRef]

- Walraven, J. Synthesized intervention method to prolong service life of reinforced concrete structures: ICCP-SS. Struct. Concr. 2020, 22, 590–592. [Google Scholar] [CrossRef]

- Zhu, J.-H.; Su, M.-N.; Huang, J.-Y.; Ueda, T.; Xing, F. The ICCP-SS technique for retrofitting reinforced concrete compressive members subjected to corrosion. Constr. Build. Mater. 2018, 167, 669–679. [Google Scholar] [CrossRef] [Green Version]

- Su, M.-N.; Wei, L.; Zhu, J.-H.; Ueda, T.; Guo, G.-P.; Xing, F. Combined Impressed Current Cathodic Protection and FRCM Strengthening for Corrosion-Prone Concrete Structures. J. Compos. Constr. 2019, 23, 04019021. [Google Scholar] [CrossRef]

- Wei, L.; Zhu, J.-H.; Dong, Z.; Liu, J.; Liu, W.; Su, M.; Xing, F. Anodic and Mechanical Behavior of Carbon Fiber Reinforced Polymer as a Dual-Functional Material in Chloride-Contaminated Concrete. Materials 2020, 13, 222. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhu, J.-H.; Wang, Z.; Su, M.-N.; Ueda, T.; Xing, F. C-FRCM Jacket Confinement for RC Columns under Impressed Current Cathodic Protection. J. Compos. Constr. 2020, 24, 04020001. [Google Scholar] [CrossRef] [Green Version]

- Feng, R.; Zhang, J.; Li, Y.; Zhu, J.H. Experimental study on hysteretic behavior for corroded circular RC columns retrofitted by ICCP-SS. Structures (Oxford) 2022, 35, 421–435. [Google Scholar] [CrossRef]

- Su, M.-N.; Wei, L.-L.; Zeng, Z.-W.; Ueda, T.; Xing, F.; Zhu, J.-H. A solution for sea-sand reinforced concrete beams. Constr. Build. Mater. 2019, 204, 586–596. [Google Scholar] [CrossRef]

- Zhu, J.-H.; Zeng, C.; Su, M.-N.; Zeng, Z.-W.; Zhu, A. Effectiveness of a dual-functional intervention method on the durability of reinforced concrete beams in marine environment. Constr. Build. Mater. 2019, 222, 633–642. [Google Scholar] [CrossRef]

- Su, M.-N.; Zeng, C.; Li, W.-Q.; Zhu, J.-H.; Lin, W.-H.; Ueda, T.; Xing, F. Flexural performance of corroded continuous RC beams rehabilitated by ICCP-SS. Compos. Struct. 2019, 232, 111556. [Google Scholar] [CrossRef]

- Feng, R.; Liu, Y.; Zhu, J.-H.; Xing, F. Flexural behaviour of C-FRCM strengthened corroded RC continuous beams. Compos. Struct. 2020, 245, 112200. [Google Scholar] [CrossRef]

- Wei, L.L. Characterizations of RC Beams Intervened by ICCP-SS System with Externally Bonded Carbon-FRCM Composites. Ph.D. Thesis, Hokkaido University, Sapporo, Japan, 2020. Available online: http://hdl.handle.net/2115/78927 (accessed on 11 June 2022).

- Su, M.-N.; Wei, L.-L.; Liang, H.-S.; Zhu, J.-H.; Ueda, T.; Xing, F. Fatigue behaviour and design of corroded reinforced concrete beams intervened by ICCP-SS. Compos. Struct. 2020, 261, 113295. [Google Scholar] [CrossRef]

- Feng, R.; Wang, J.; Zhu, J.-H.; Dong, Z. Fatigue behavior of corroded reinforced concrete continuous beams with multi-intervention system. Eng. Struct. 2021, 231, 111748. [Google Scholar] [CrossRef]

- Wei, L.; Zhu, J.-H.; Ueda, T.; Matsumoto, K. Performance of FRCM composites and FRCM-strengthened RC beams subjected to anodic polarization and cyclic loading. Eng. Struct. 2022, 250, 113475. [Google Scholar] [CrossRef]

- Wei, L.; Ueda, T.; Matsumoto, K.; Zhu, J.-H. Experimental and analytical study on the behavior of RC beams with externally bonded carbon-FRCM composites. Compos. Struct. 2021, 273, 114291. [Google Scholar] [CrossRef]

- Zhang, E.Q.; Abbas, Z.; Tang, L. Predicting degradation of the anode–concrete interface for impressed current cathodic protection in concrete. Constr. Build. Mater. 2018, 185, 57–68. [Google Scholar] [CrossRef]

- Zhang, E.Q.; Tang, L.P. Carbon Fiber as Anode Material for Cathodic Prevention in Cementitious Materials. In Proceedings of the 5th International Conference on Durability of Concrete Structures, Shenzhen, China, 30 June–1 July 2016. [Google Scholar]

- Zhu, M.C. Bond Behavior and Degradation Mechanisms of Multi-Functional FRCM Composites Used for ICCP-SS. Ph.D. Thesis, Hokkaido University, Sapporo, Japan, 2020. Available online: http://hdl.handle.net/2115/79413 (accessed on 11 June 2022).

- Zhu, M.; Zhu, J.-H.; Ueda, T.; Su, M.; Xing, F. A method for evaluating the bond behavior and anchorage length of embedded carbon yarn in the cementitious matrix. Constr. Build. Mater. 2020, 255, 119067. [Google Scholar] [CrossRef]

- Zhu, M.; Zhu, J.-H.; Ueda, T.; Matsumoto, K.; Su, M. Bond behavior of carbon fabric reinforced cementitious matrix (FRCM) composites considering matrix impregnation. Compos. Struct. 2021, 262, 113350. [Google Scholar] [CrossRef]

- Kyaure, M.; Abed, F. Finite element parametric analysis of RC columns strengthened with FRCM. Compos. Struct. 2021, 275, 114498. [Google Scholar] [CrossRef]

- Jawdhari, A.; Adheem, A.H.; Kadhim, M.M. Parametric 3D finite element analysis of FRCM-confined RC columns under eccentric loading. Eng. Struct. 2020, 212, 110504. [Google Scholar] [CrossRef]

- Khattak, N.; Mansour, M.; El-Maaddawy, T.; Ismail, N. Continuous Reinforced Concrete Beams Strengthened with Fabric-Reinforced Cementitious Matrix: Experimental Investigation and Numerical Simulation. Buildings 2021, 12, 27. [Google Scholar] [CrossRef]

- Feng, R.; Liu, P.P.; Zhang, J.Z.; Ying, X.; Zhu, J.H. Finite element analysis and design of C-FRCM strengthened corroded RC continuous beams. Compos. Struct. 2022, in press. [Google Scholar] [CrossRef]

- ABAQUS. Analysis User’s Manual. Dassault Systemes; Dassault Systèmes SIMULIA: Johnston, RI, USA, 2021. [Google Scholar]

- Peng, G.; Niu, D.; Hu, X.; Pan, B.; Zhong, S. Experimental study of the interfacial bond strength between cementitious grout and normal concrete substrate. Constr. Build. Mater. 2021, 273, 122057. [Google Scholar] [CrossRef]

- ACI 318R-19; Building Code Requirements for Structural Concrete and Commentary. American Concrete Institute: Farmington Hills, MI, USA, 2019.

- ACI 549.4R-13; Guide to Design and Construction of Externally Bonded Fabric- Reinforced Cementitious Matrix (FRCM) Systems for Repair and Strengthening Concrete and Masonry Structures. American Concrete Institute: Farmington Hills, MI, USA, 2013.

- ACI 440.2R-17; Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures. American Concrete Institute: Farmington Hills, MI, USA, 2017.

- AC434R-16; Acceptance Criteria for Masonry and Concrete Strengthening using Fabric-Reinforced Cementitious Matrix (FRCM) and Steel Reinforced Grout (SRG) Composite Systems. American Concrete Institute: Farmington Hills, MI, USA, 2016.

| Parameters | Concrete | Cementitious Layer |

|---|---|---|

| Elastic modulus (MPa) | 34,215 | 76,000 |

| Poisson’s ratio | 0.2 | 0.2 |

| Tensile strength (MPa) | 3 | 2.06 |

| Compressive strength (MPa) | 53 | 20.69 |

| Elastic modulus (MPa) | 190,000 |

| Poisson’s ratio | 0.3 |

| Yield stress (MPa) | 541.69 |

| Strain at yield point | 0.00157 |

| Stress at failure (MPa) | 642.84 |

| Strain at failure | 0.07887 |

| Parameters | Concrete–Cementitious Layer Interface | Cementitious Layer–FRP Mesh Interface |

|---|---|---|

| Stiffness in normal direction (N/mm3) | 15,000 (empirical) | 20 [29] |

| Stiffness in shear directions (N/mm3) | 10,000 (empirical) | 15 [29] |

| Strength in normal direction (N/mm2) | 2 [36] | 0.01 [29] |

| Strength in shear directions (N/mm2) | 3 [36] | 0.64 [29] |

| Fracture energy (N/mm) | 0.2 (empirical) | 2 (empirical) |

| Model ID | Mesh Size (mm) | Computational Time (s) | |

|---|---|---|---|

| Beam | Cement | ||

| Model 1 | 100 | 100 | 39 |

| Model 2 | 50 | 50 | 208 |

| Model 3 | 25 | 25 | 1456 |

| Model 4 | 20 | 20 | 2925 |

| Model 5 | 15 | 15 | 6699 |

| Model 6 | 10 | 10 | 20,800 |

| Specimens | Ultimate Loads (kN) | Deflection at Ultimate (mm) | |||

|---|---|---|---|---|---|

| C0 | 48.96 | 8.44 | 1.15 | ⸺ | ⸺ |

| C10 | 33.02 | 6.36 | 1.26 | ⸺ | ⸺ |

| C20 | 28.38 | 5.25 | 1.29 | ⸺ | ⸺ |

| C30 | 24.40 | 4.10 | 1.38 | ⸺ | ⸺ |

| C40 | 21.38 | 3.74 | 1.60 | ⸺ | ⸺ |

| C0-Pt | 56.33 | 12.80 | ⸺ | 1.24 | 1.31 |

| C10-Pt | 41.69 | 14.93 | ⸺ | 1.37 | 1.39 |

| C20-Pt | 37.24 | 13.08 | ⸺ | 1.37 | 1.40 |

| C30-Pt | 31.67 | 13.61 | ⸺ | 1.33 | 1.36 |

| C40-Pt | 28.87 | 12.86 | ⸺ | 1.41 | 1.44 |

| C0-Pt-D10 | 56.18 | 13.18 | ⸺ | 1.24 | 1.30 |

| C0-Pt-D20 | 55.96 | 13.37 | ⸺ | 1.23 | 1.30 |

| C0-Pt-D30 | 55.53 | 10.90 | ⸺ | 1.23 | 1.29 |

| C0-Pt-D30-Y | 64.15 | 14.33 | ⸺ | 1.42 | 1.49 |

| C0-Pt-D40 | 54.73 | 10.67 | ⸺ | 1.21 | 1.27 |

| C0-Pt-D40-Y | 63.02 | 13.59 | ⸺ | 1.39 | 1.46 |

| Mean, Pm | 1.34 | 1.31 | 1.36 | ||

| COV, VP | 0.114 | 0.060 | 0.054 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdulla, K.; Zhu, X.; Su, M. Numerical Investigation of FRCM-Strengthened Corroded RC Beams under Cathodic Protection. Materials 2022, 15, 5334. https://doi.org/10.3390/ma15155334

Abdulla K, Zhu X, Su M. Numerical Investigation of FRCM-Strengthened Corroded RC Beams under Cathodic Protection. Materials. 2022; 15(15):5334. https://doi.org/10.3390/ma15155334

Chicago/Turabian StyleAbdulla, Kurdo, Xiaoming Zhu, and Meini Su. 2022. "Numerical Investigation of FRCM-Strengthened Corroded RC Beams under Cathodic Protection" Materials 15, no. 15: 5334. https://doi.org/10.3390/ma15155334

APA StyleAbdulla, K., Zhu, X., & Su, M. (2022). Numerical Investigation of FRCM-Strengthened Corroded RC Beams under Cathodic Protection. Materials, 15(15), 5334. https://doi.org/10.3390/ma15155334