New Aluminum Syntactic Foam: Synthesis and Mechanical Characterization

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Synthesis

2.2.2. Density and Porosity

2.2.3. Microstructural Analysis

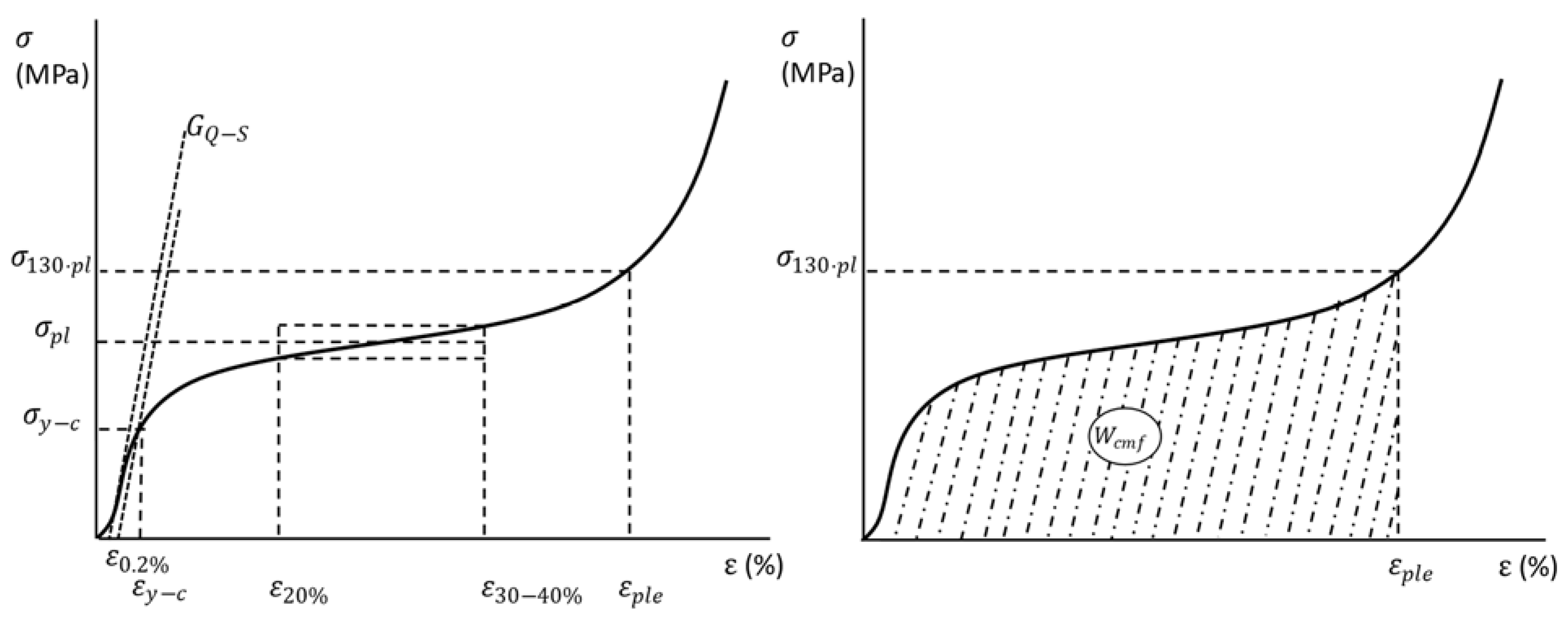

2.2.4. Mechanical Behavior

3. Results

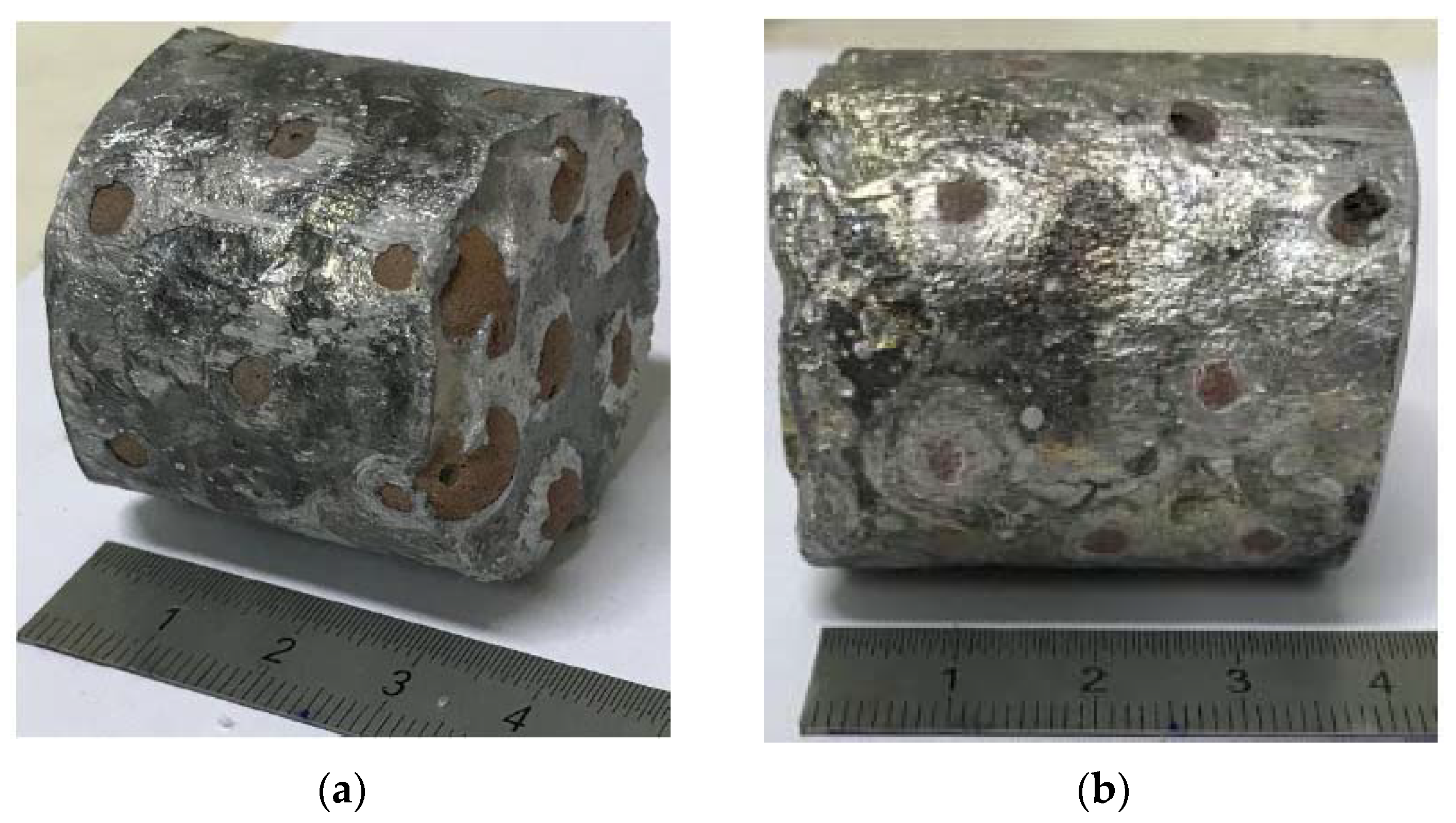

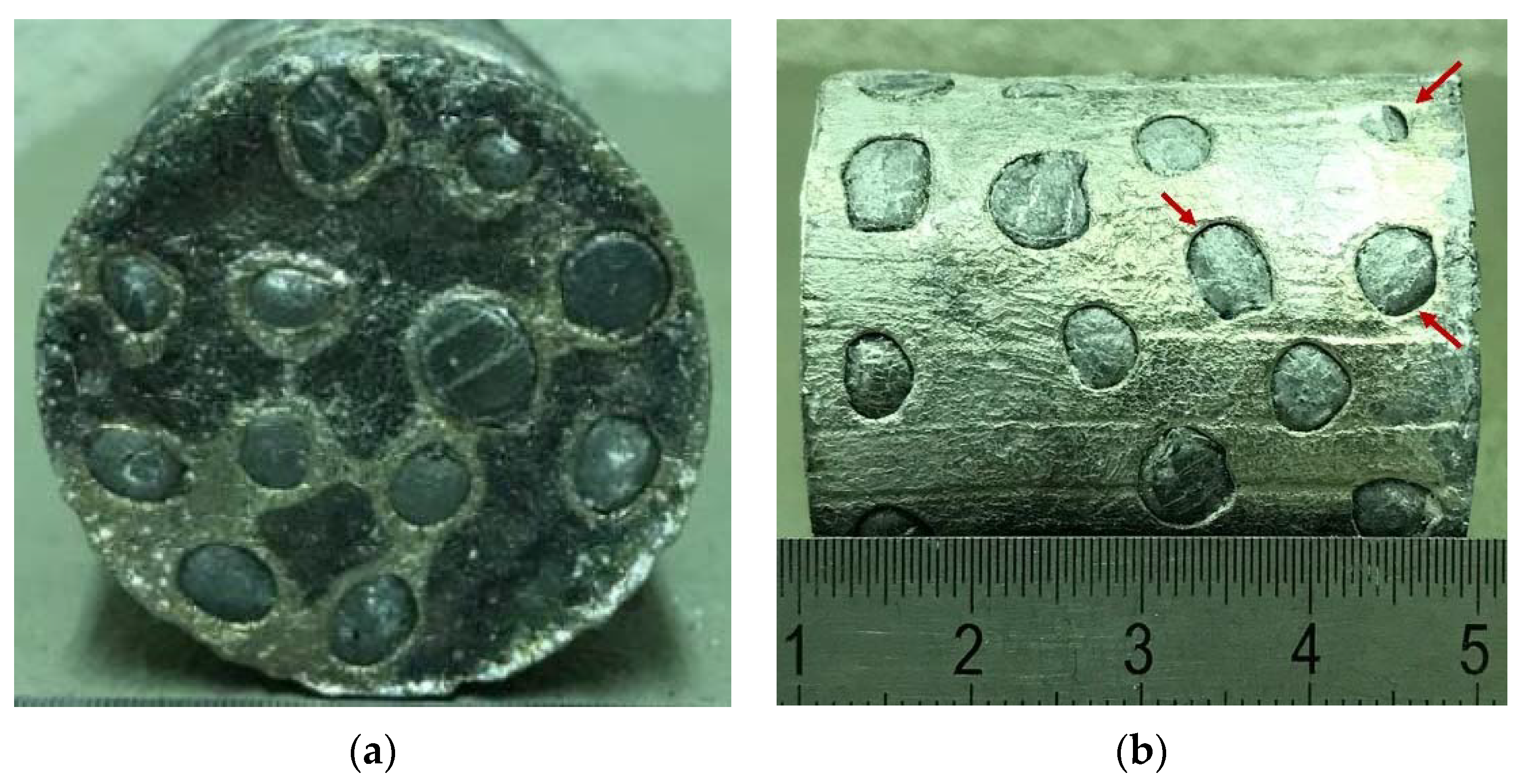

3.1. Manufacturing

3.2. Density and Porosity

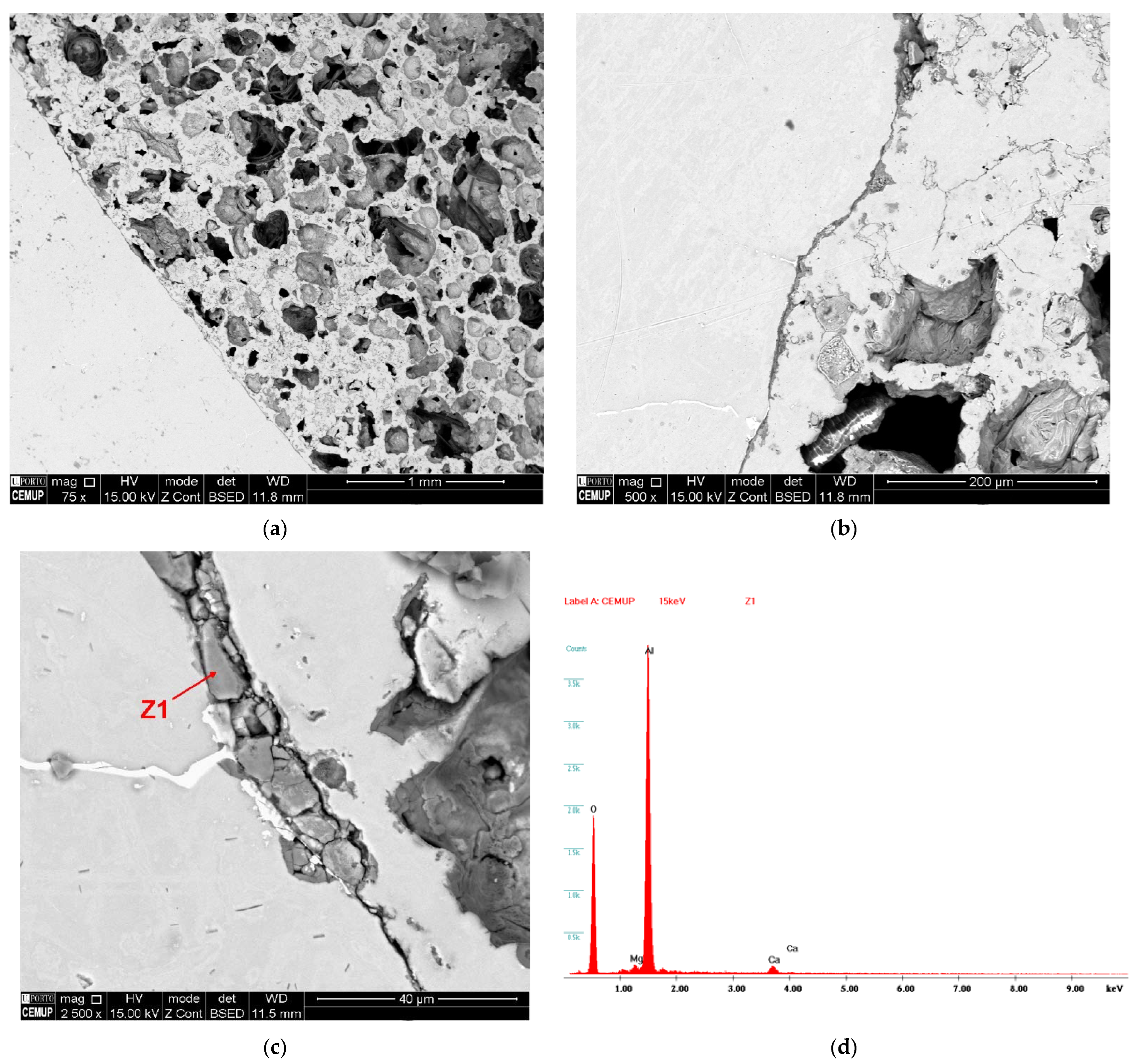

3.3. Microstructure

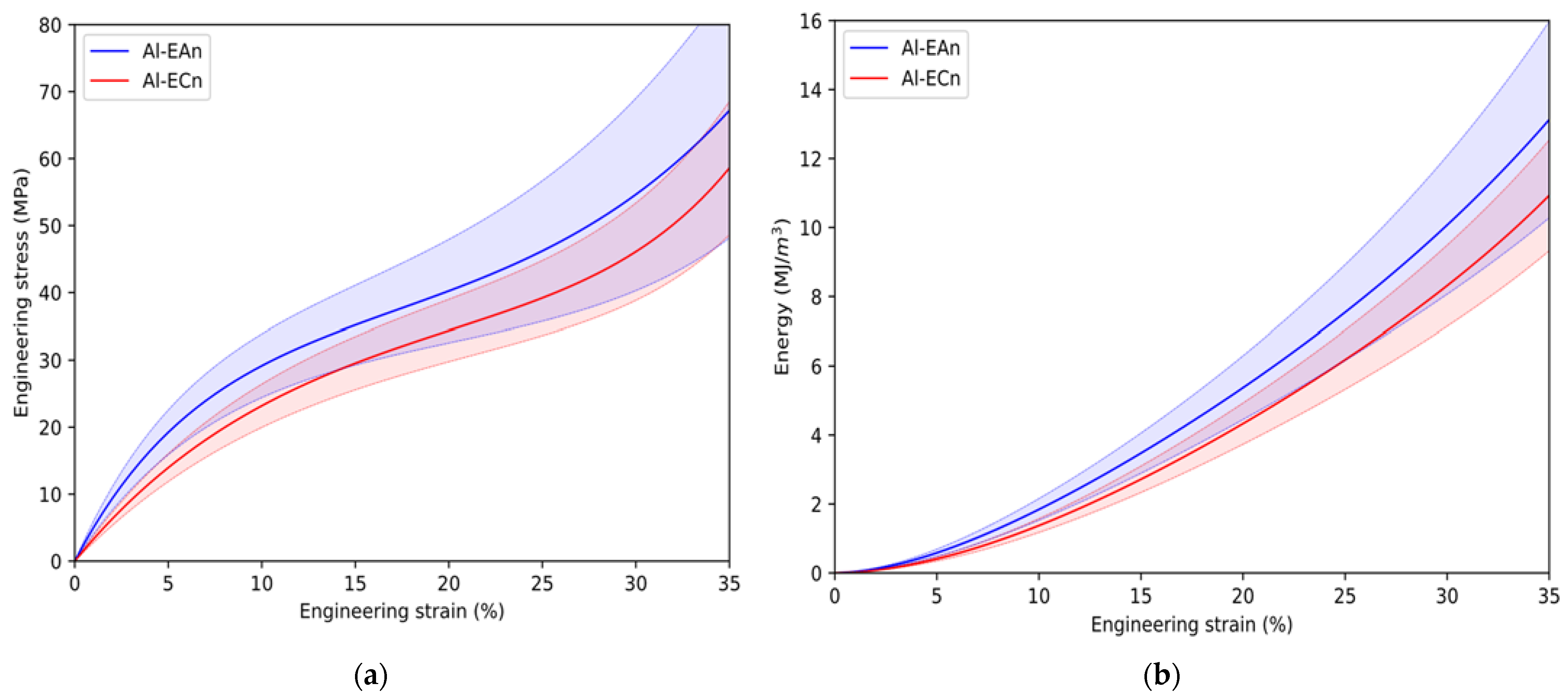

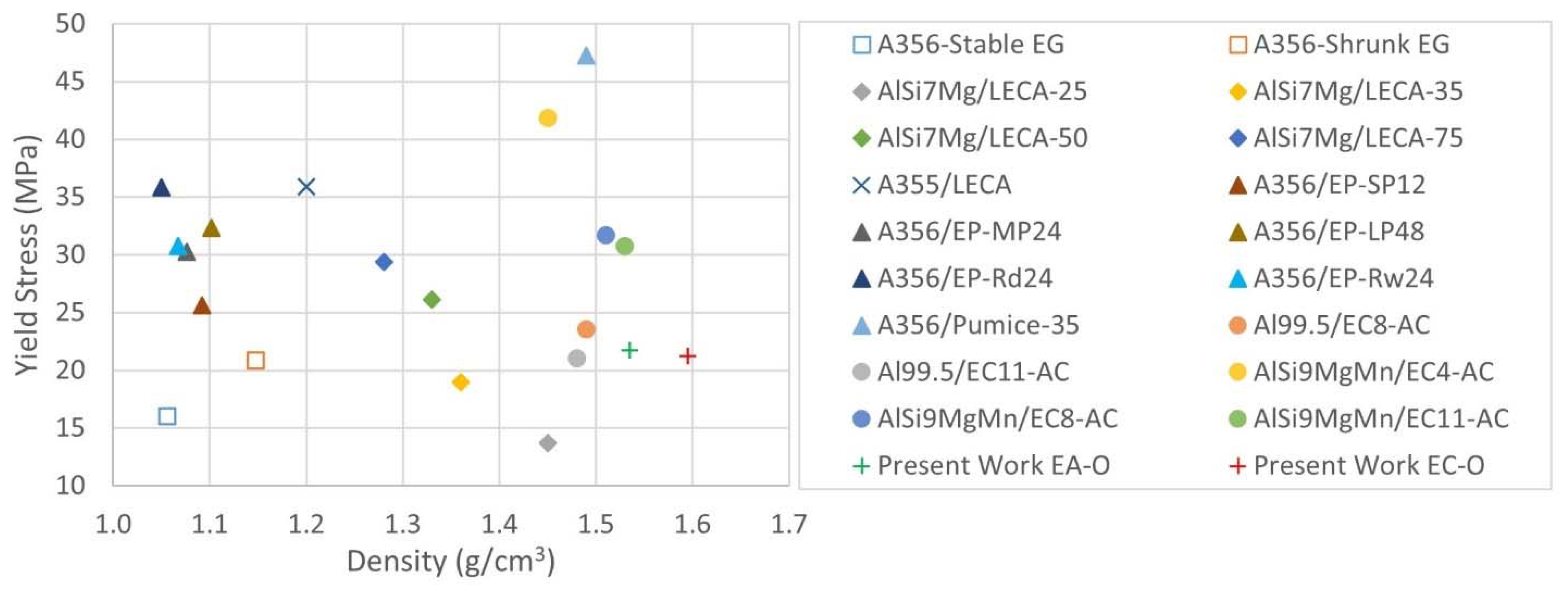

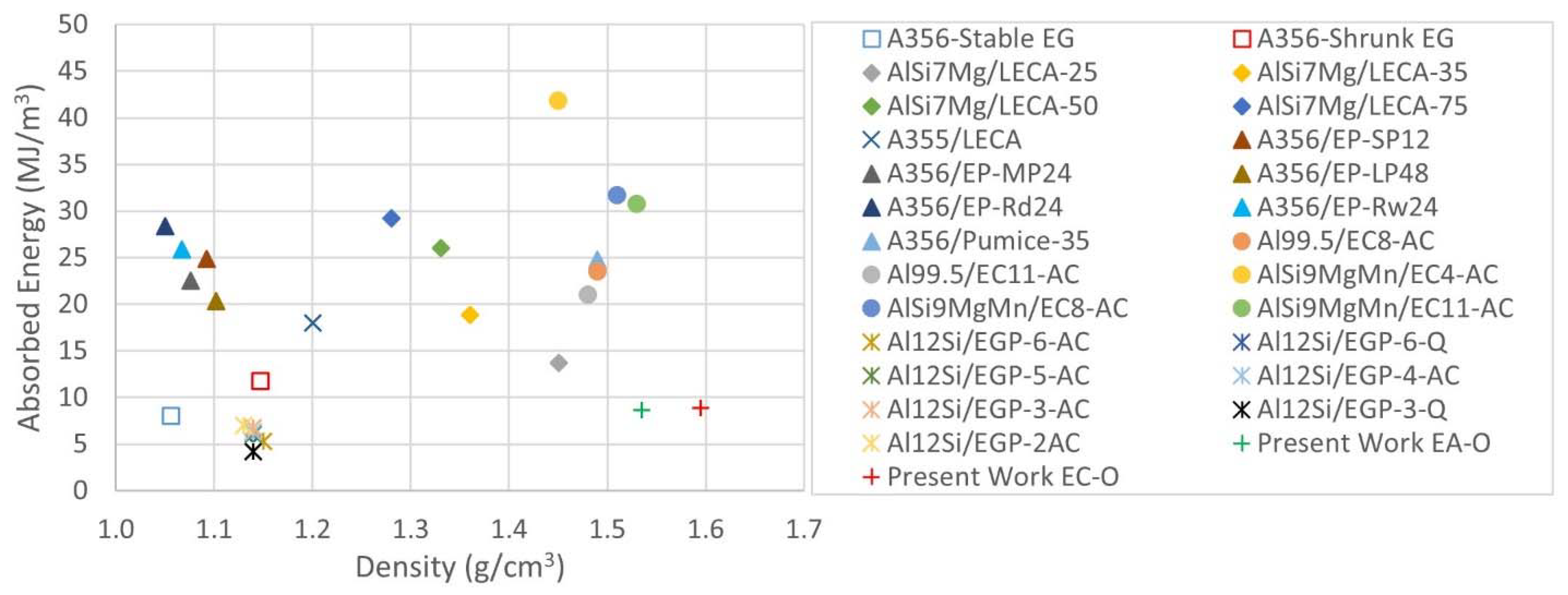

3.4. Mechanical Behavior

4. Conclusions

- It is feasible to synthesize Al–Al syntactic foams using nodules with porous closed-cells and fine internal morphology by melt infiltration routes. These nodules are made of aluminum of commercial purity and were foamed with wastes of marble from ornamental rock quarries as a low-cost substitute for conventional titanium hydride.

- Al-EAn have an average relative density of 56% and an average total porosity of 43%. The average residual porosity is approximately 5%. No significant chemical interaction is observed at the nodule–matrix interface; thus, the bonding in the interface is purely mechanical.

- The Al-EAn samples exhibit similar mechanical properties to the Al-ECn samples, although slightly higher due to EA nodules exhibiting a higher crush load than EC nodules. The low volume fraction of EAn compensates for the higher crush load concerning ECn. The 5% residual porosity of the Al-EAn samples manifests itself in a higher standard deviation of the porosity-governed properties: plateau stress and densification strain. Samples with Al-Ean have approximately the same energy absorption capacity as samples with Al-ECn.

- The stress–strain curves demonstrate the ductile nature of the matrix. The samples with nodules of EC show slight stress spikes along with the transition between the elastic stage and the plateau, demonstrating the brittle nature of the ECn. The Ean series does not experience any spikes, evidencing the ductile nature of the dispersed phase, and the effect of the alumina film coating of the nodules on the mechanical behavior is negligible.

- The deformation mechanism that governs both materials is ductile because both exhibit a uniform and continuous deformation layer-by-layer and a slight barreling phenomenon.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Duarte, I.; Ferreira, J. Composite and Nanocomposite Metal Foams. Materials 2016, 9, 79. [Google Scholar] [CrossRef] [Green Version]

- Gupta, N.; Rohatgi, P.K. Metal Matrix Syntactic Foams: Processing, Microstructure, Properties and Applications; Gupta, N., Rohatgi, P.K., Eds.; DEStech Publications Inc.: Lancaster, PA, USA, 2014; ISBN 9781932078831. [Google Scholar]

- Bolat, Ç.; Akgün, İ.C.; Göksenli, A. On the Way to Real Applications: Aluminum Matrix Syntactic Foams. Eur. Mech. Sci. 2020, 4, 131–141. [Google Scholar] [CrossRef]

- Marx, J.; Rabiei, A. Overview of Composite Metal Foams and Their Properties and Performance. Adv. Eng. Mater. 2017, 19, 1–13. [Google Scholar] [CrossRef]

- Szlancsik, A.; Katona, B.; Kemény, A.; Károly, D. On the Filler Materials of Metal Matrix Syntactic Foams. Materials 2019, 12, 2023. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- S-de-la-Muela, A.M.; Cambronero, L.E.G.; Ruiz-Román, J.M. Molten Metal Infiltration Methods to Process Metal Matrix Syntactic Foams. Metals 2020, 10, 149. [Google Scholar] [CrossRef] [Green Version]

- Sánchez de la Muela, A.M.; Duarte, J.; Santos Baptista, J.; García Cambronero, L.E.; Ruiz-Román, J.M.; Elorza, F.J. Stir Casting Routes for Processing Metal Matrix Syntactic Foams: A Scoping Review. Processes 2022, 10, 478. [Google Scholar] [CrossRef]

- Rohatgi, P.K.; Gupta, N.; Schultz, B.F.; Luong, D.D. The Synthesis, Compressive Properties, and Applications of Metal Matrix Syntactic Foams. JOM 2011, 63, 36–42. [Google Scholar] [CrossRef]

- Taherishargh, M.; Belova, I.V.; Murch, G.E.; Fiedler, T. Low-Density Expanded Perlite-Aluminium Syntactic Foam. Mater. Sci. Eng. A 2014, 604, 127–134. [Google Scholar] [CrossRef]

- Broxtermann, S.; Taherishargh, M.; Belova, I.V.; Murch, G.E.; Fiedler, T. On the Compressive Behaviour of High Porosity Expanded Perlite-Metal Syntactic Foam (P-MSF). J. Alloys Compd. 2017, 691, 690–697. [Google Scholar] [CrossRef]

- Taherishargh, M.; Belova, I.V.; Murch, G.E.; Fiedler, T. The Effect of Particle Shape on Mechanical Properties of Perlite/Metal Syntactic Foam. J. Alloys Compd. 2017, 693, 55–60. [Google Scholar] [CrossRef]

- Taherishargh, M.; Belova, I.V.; Murch, G.E.; Fiedler, T. Pumice/Aluminium Syntactic Foam. Mater. Sci. Eng. A 2015, 635, 102–108. [Google Scholar] [CrossRef]

- Taherishargh, M.; Sulong, M.A.; Belova, I.V.; Murch, G.E.; Fiedler, T. On the Particle Size Effect in Expanded Perlite Aluminium Syntactic Foam. Mater. Des. 2015, 66, 294–303. [Google Scholar] [CrossRef]

- Al-Sahlani, K.; Taherishargh, M.; Kisi, E.; Fiedler, T. Controlled Shrinkage of Expanded Glass Particles in Metal Syntactic Foams. Materials 2017, 10, 1073. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wright, A.; Kennedy, A. The Processing and Properties of Syntactic Al Foams Containing Low Cost Expanded Glass Particles. Adv. Eng. Mater. 2017, 19, 1600467. [Google Scholar] [CrossRef] [Green Version]

- Linul, E.; Lell, D.; Movahedi, N.; Codrean, C.; Fiedler, T. Compressive Properties of Zinc Syntactic Foams at Elevated Temperatures. Compos. Part B Eng. 2019, 167, 122–134. [Google Scholar] [CrossRef]

- Movahedi, N.; Conway, S.; Belova, I.V.; Murch, G.E.; Fiedler, T. Influence of Particle Arrangement on the Compression of Functionally Graded Metal Syntactic Foams. Mater. Sci. Eng. A 2019, 764, 138242. [Google Scholar] [CrossRef]

- Movahedi, N.; Murch, G.E.; Belova, I.V.; Fiedler, T. Functionally Graded Metal Syntactic Foam: Fabrication and Mechanical Properties. Mater. Des. 2019, 168, 107652. [Google Scholar] [CrossRef]

- Movahedi, N.; Orbulov, I.N.; Kemény, A.; Belova, I.V.; Murch, G.E.; Fiedler, T. Fatigue Characterization of Functionally Graded ZA27 Alloy Syntactic Foams. Mater. Sci. Eng. A 2020, 798, 140255. [Google Scholar] [CrossRef]

- Bazzaz Bonabi, S.; Kahani Khabushan, J.; Kahani, R.; Honarbakhsh Raouf, A. Fabrication of Metallic Composite Foam Using Ceramic Porous Spheres “Light Expanded Clay Aggregate” via Casting Process. Mater. Des. 2014, 64, 310–315. [Google Scholar] [CrossRef]

- Puga, H.; Carneiro, V.H.; Jesus, C.; Pereira, J.; Lopes, V. Influence of Particle Diameter in Mechanical Performance of Al Expanded Clay Syntactic Foams. Compos. Struct. 2018, 184, 698–703. [Google Scholar] [CrossRef]

- Orbulov, I.N.; Szlancsik, A.; Kemény, A.; Kincses, D. Compressive Mechanical Properties of Low-Cost, Aluminium Matrix Syntactic Foams. Compos. Part A Appl. Sci. Manuf. 2020, 135, 105923. [Google Scholar] [CrossRef]

- Orbulov, I.N.; Szlancsik, A.; Kemény, A.; Kincses, D. Low-Cost Light-Weight Composite Metal Foams for Transportation Applications. J. Mater. Eng. Perform. 2022. [Google Scholar] [CrossRef]

- Kemény, A.; Leveles, B.; Károly, D. Functional Aluminium Matrix Syntactic Foams Filled with Lightweight Expanded Clay Aggregate Particles. Mater. Today Proc. 2021, 45, 4229–4232. [Google Scholar] [CrossRef]

- Leveles, B.; Kemény, A.; Szijártó, A. Mechanical Investigation of In-Situ Produced Aluminium Matrix Syntactic Foam-Filled Tubes. Mater. Today Proc. 2021, 45, 4221–4224. [Google Scholar] [CrossRef]

- Kemény, A.; Leveles, B.; Kincses, D.B.; Károly, D. Manufacturing and Investigation of In Situ and Ex Situ Produced Aluminum Matrix Foam-Filled Tubes. Adv. Eng. Mater. 2022, 24, 2100365. [Google Scholar] [CrossRef]

- Movahedi, N.; Linul, E. Mechanical Properties of Light Expanded Clay Aggregated (LECA) Filled Tubes. Mater. Lett. 2018, 217, 194–197. [Google Scholar] [CrossRef]

- Rabiei, A.; Vendra, L.; Reese, N.; Young, N.; Neville, B.P. Processing and Characterization of a New Composite Metal Foam. Mater. Trans. 2006, 47, 2148–2153. [Google Scholar] [CrossRef] [Green Version]

- Neville, B.P.; Rabiei, A. Composite Metal Foams Processed through Powder Metallurgy. Mater. Des. 2008, 29, 388–396. [Google Scholar] [CrossRef]

- Rabiei, A.; Vendra, L.J. A Comparison of Composite Metal Foam’s Properties and Other Comparable Metal Foams. Mater. Lett. 2009, 63, 533–536. [Google Scholar] [CrossRef]

- Marx, J.; Portanova, M.; Rabiei, A. A Study on Blast and Fragment Resistance of Composite Metal Foams through Experimental and Modeling Approaches. Compos. Struct. 2018, 194, 652–661. [Google Scholar] [CrossRef]

- Garcia-Avila, M.; Portanova, M.; Rabiei, A. Ballistic Performance of Composite Metal Foams. Compos. Struct. 2015, 125, 202–211. [Google Scholar] [CrossRef]

- Vesenjak, M.; Krstulovic-Opara, L. Experimental Testing of Single APM Spheres. EPJ Web Conf. 2010, 6, 02005. [Google Scholar] [CrossRef] [Green Version]

- Ulbin, M.; Borovinšek, M.; Higa, Y.; Shimojima, K.; Vesenjak, M.; Ren, Z. Internal Structure Characterization of AlSi7 and AlSi10 Advanced Pore Morphology (APM) Foam Elements. Mater. Lett. 2014, 136, 416–419. [Google Scholar] [CrossRef]

- Borovinsek, M.; Koudelka, P.; Sleichrt, J.; Vopalensky, M.; Kumpova, I.; Vesenjak, M.; Kytyr, D. Analysis of Advanced Pore Morphology (Apm) Foam Elements Using Compressive Testing and Time-lapse Computed Microtomography. Materials 2021, 14, 5897. [Google Scholar] [CrossRef] [PubMed]

- Vesenjak, M.; Gačnik, F.; Krstulović-Opara, L.; Ren, Z. Behavior of Composite Advanced Pore Morphology Foam. J. Compos. Mater. 2011, 45, 2823–2831. [Google Scholar] [CrossRef]

- Duarte, I.; Vesenjak, M.; Krstulović-Opara, L.; Ren, Z. Compressive Performance Evaluation of APM (Advanced Pore Morphology) Foam Filled Tubes. Compos. Struct. 2015, 134, 409–420. [Google Scholar] [CrossRef]

- Vesenjak, M.; Duarte, I.; Baumeister, J.; Göhler, H.; Krstulović-Opara, L.; Ren, Z. Bending Performance Evaluation of Aluminium Alloy Tubes Filled with Different Cellular Metal Cores. Compos. Struct. 2020, 234, 111748. [Google Scholar] [CrossRef]

- Hydro Data Sheet of AA-6063. Available online: https://www.hydro.com/globalassets/08-about-hydro/hydro-worldwide/germany/extrusion-germany/alloy-data-sheets/hydro-en-aw-6063.pdf (accessed on 19 April 2022).

- Cambronero, L.E.G.; Ruiz-Roman, J.M.; Corpas, F.A.; Ruiz Prieto, J.M. Manufacturing of Al-Mg-Si Alloy Foam Using Calcium Carbonate as Foaming Agent. J. Mater. Process. Technol. 2009, 209, 1803–1809. [Google Scholar] [CrossRef]

- Ruiz-Román, J.M.; de la Muela, A.S.; Cambronero, L.E.G.; Ruiz-Bustinza, Í. Quasi-Static and Dynamic Analysis of Single-Layer Sandwich Structures of APM Foam Spheroid Elements in-Situ Foamed with Marble. Rev. Metal. 2020, 56, 159. [Google Scholar] [CrossRef]

- Leca Declaration of Performance: G Rain Size 10–20. Mm. Available online: https://www.leca.co.uk/downloads?filter=Declaration-of-Performance-Docs (accessed on 5 January 2022).

- ISO 13314:2011; Mechanical Testing of Metals—Ductility Testing—Compression Test for Porous and Cellular Metals. International Organization for Standardization: Geneva, Switzerland, 2011; pp. 1–7.

- Coker, E.N. The Oxidation of Aluminum at High Temperature Studied by Thermogravimetric Analysis and Differential Scanning Calorimetry; Sandia National Laboratories: Albuquerque, NM, USA, 2013.

- Trunov, M.A.; Schoenitz, M.; Dreizin, E.L. Effect of Polymorphic Phase Transformations in Alumina Layer on Ignition of Aluminium Particles. Combust. Theory Model. 2006, 10, 603–623. [Google Scholar] [CrossRef]

- Orbulov, I.N.; Dobránszky, J. Producing Metal Matrix Syntactic Foams by Pressure Infiltration. Period. Polytech. Mech. Eng. 2008, 52, 35–42. [Google Scholar] [CrossRef] [Green Version]

- Su, M.; Wang, H.; Hao, H.; Fiedler, T. Compressive Properties of Expanded Glass and Alumina Hollow Spheres Hybrid Reinforced Aluminum Matrix Syntactic Foams. J. Alloys Compd. 2020, 821, 153233. [Google Scholar] [CrossRef]

- Licitra, L.; Luong, D.D.; Strbik, O.M.; Gupta, N. Dynamic Properties of Alumina Hollow Particle Filled Aluminum Alloy A356 Matrix Syntactic Foams. Mater. Des. 2015, 66, 504–515. [Google Scholar] [CrossRef]

- Echarri, J.M.; Jodra, S.; Culcasi, J.D.; Echarri, T. Tratamiento de Homogeneizado En La Extrudabilidad de La Aleación AA-6063. Segundas Jorn. Investig. 2013, 6, 654–659. [Google Scholar]

- Birol, Y. The Effect of Homogenization Practice on the Microstructure of AA6063 Billets. J. Mater. Process. Technol. 2004, 148, 250–258. [Google Scholar] [CrossRef]

- Májlinger, K.; Orbulov, I.N. Characteristic Compressive Properties of Hybrid Metal Matrix Syntactic Foams. Mater. Sci. Eng. A 2014, 606, 248–256. [Google Scholar] [CrossRef]

- Orbulov, I.N. Compressive Properties of Aluminium Matrix Syntactic Foams. Mater. Sci. Eng. A 2012, 555, 52–56. [Google Scholar] [CrossRef]

| Space Holder | Density kg/m3 | Height mm | Diameter mm | Crush Load N | Porosity % |

|---|---|---|---|---|---|

| Aluminum (EAn) | 820 | 7–8 | 8.5 | 365 | 70 |

| Clay (ECn) | 800 | NA | 11.5–12.5 | 308 | 80 |

| Alloy and Heat Treatment | Temperature (°C) | Time (min) | Cooling Rate (°C/Hour) | Temperature (°C) | Rate (°C/Hour) | Temperature (°C) |

|---|---|---|---|---|---|---|

| 6063-O | 415 | 180 | −28 | 260 | Natural | Room |

| Set of Samples | Weight (g) | H/D Ratio (-) | Experimental Density (g/cm3) | Volume Fraction of Fillers (%) | Theoretical Density (g/cm3) |

|---|---|---|---|---|---|

| Al-EAn | 60.65 +/− 3.591 | 0.954 +/− 0.029 | 1.535 +/− 0.086 | 54.464 +/− 0.687 | 1.680 +/− 0.013 |

| Al-ECn | 52.838 +/− 2.736 | 0.8 +/− 0.027 | 1.595 +/− 0.039 | 58.294 +/− 2.629 | 1.586 +/− 0.051 |

| Set of Samples | Relative Density (%) | Experimental Porosity (%) | Theoretical Porosity (%) | Residual Porosity (%) |

|---|---|---|---|---|

| Al-EAn | 56.836 +/− 3.167 | 43.164 +/− 3.167 | 38.021 +/− 0.479 | 5.142 +/− 3.086 |

| Al-ECn | 59.074 +/− 1.431 | 40.926 +/− 1.431 | 44.758 +/− 2.018 | −3.832 +/− 1.084 |

| Set of Samples | Elastic Gradient (MPa) | Yield Stress (MPa) | Yield Strain (%) | Plateau Stress (MPa) | Densification Stress (MPa) | Densification Strain (%) | Absorption of Energy (MJ/m3) |

|---|---|---|---|---|---|---|---|

| Al-ECn | 343.309 +/−51.012 | 21.247 +/−5.083 | 6.883 +/−0.918 | 35.84 +/−6.599 | 46.592 +/−8.579 | 30.136 +/−2.254 | 8.865 +/−2.067 |

| Al-EAn | 521.030 +/−60.802 | 21.742 +/−5.181 | 4.282 +/−0.371 | 37.647 +/−2.957 | 48.942 +/−3.844 | 27.206 +/−5.359 | 8.615 +/−0.676 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sánchez de la Muela, A.M.; García Cambronero, L.E.; Malheiros, L.F.; Ruiz-Román, J.M. New Aluminum Syntactic Foam: Synthesis and Mechanical Characterization. Materials 2022, 15, 5320. https://doi.org/10.3390/ma15155320

Sánchez de la Muela AM, García Cambronero LE, Malheiros LF, Ruiz-Román JM. New Aluminum Syntactic Foam: Synthesis and Mechanical Characterization. Materials. 2022; 15(15):5320. https://doi.org/10.3390/ma15155320

Chicago/Turabian StyleSánchez de la Muela, A. M., L. E. García Cambronero, L. F. Malheiros, and J. M. Ruiz-Román. 2022. "New Aluminum Syntactic Foam: Synthesis and Mechanical Characterization" Materials 15, no. 15: 5320. https://doi.org/10.3390/ma15155320

APA StyleSánchez de la Muela, A. M., García Cambronero, L. E., Malheiros, L. F., & Ruiz-Román, J. M. (2022). New Aluminum Syntactic Foam: Synthesis and Mechanical Characterization. Materials, 15(15), 5320. https://doi.org/10.3390/ma15155320