Derivation of Empirical Relationships to Predict Cambodian Masonry Strength

Abstract

:1. Introduction

2. Past Studies on Coefficient Values for Masonry Strength

3. Experimental Programme/Laboratory Testing

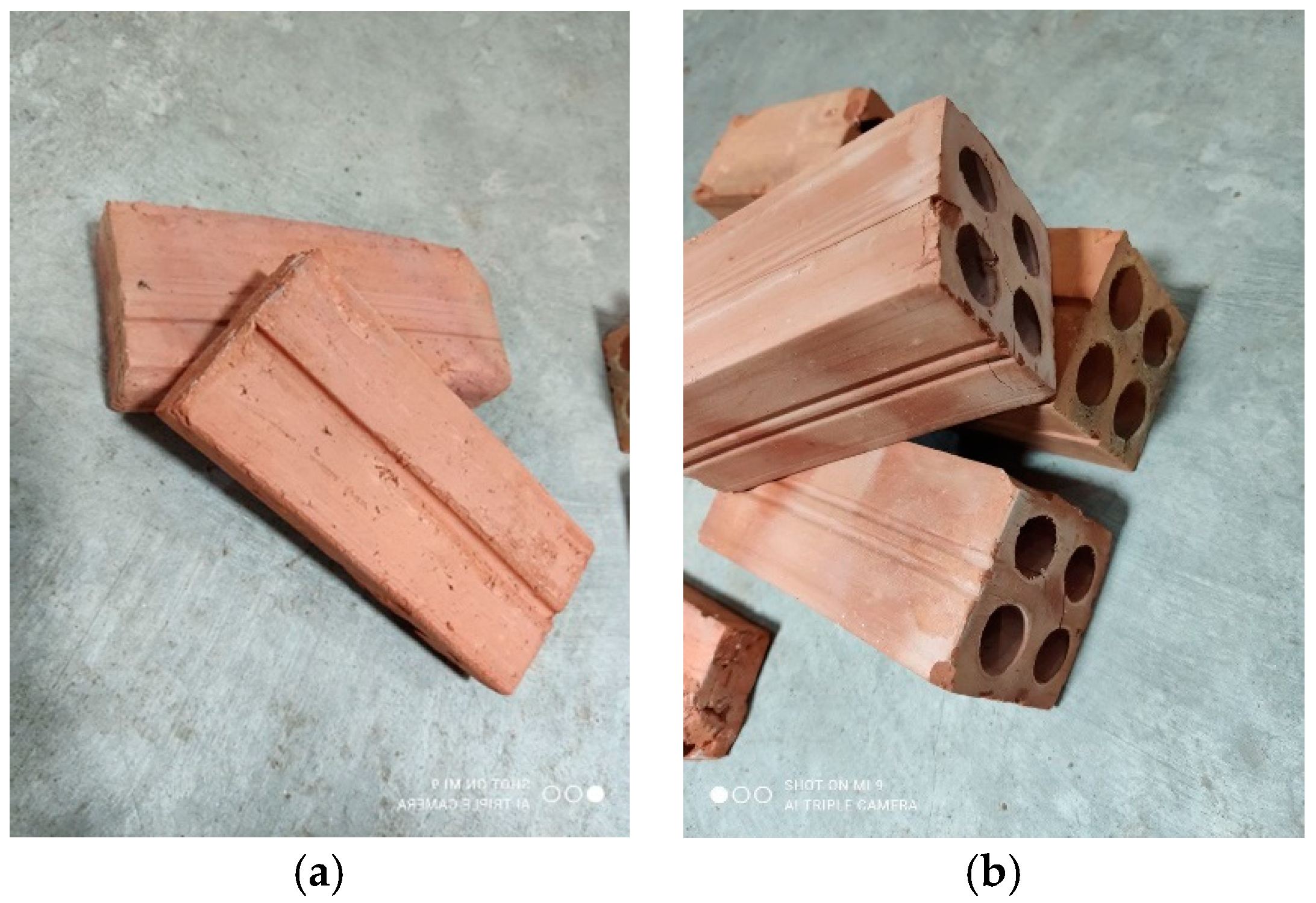

3.1. Materials/Brick–Mortar Properties

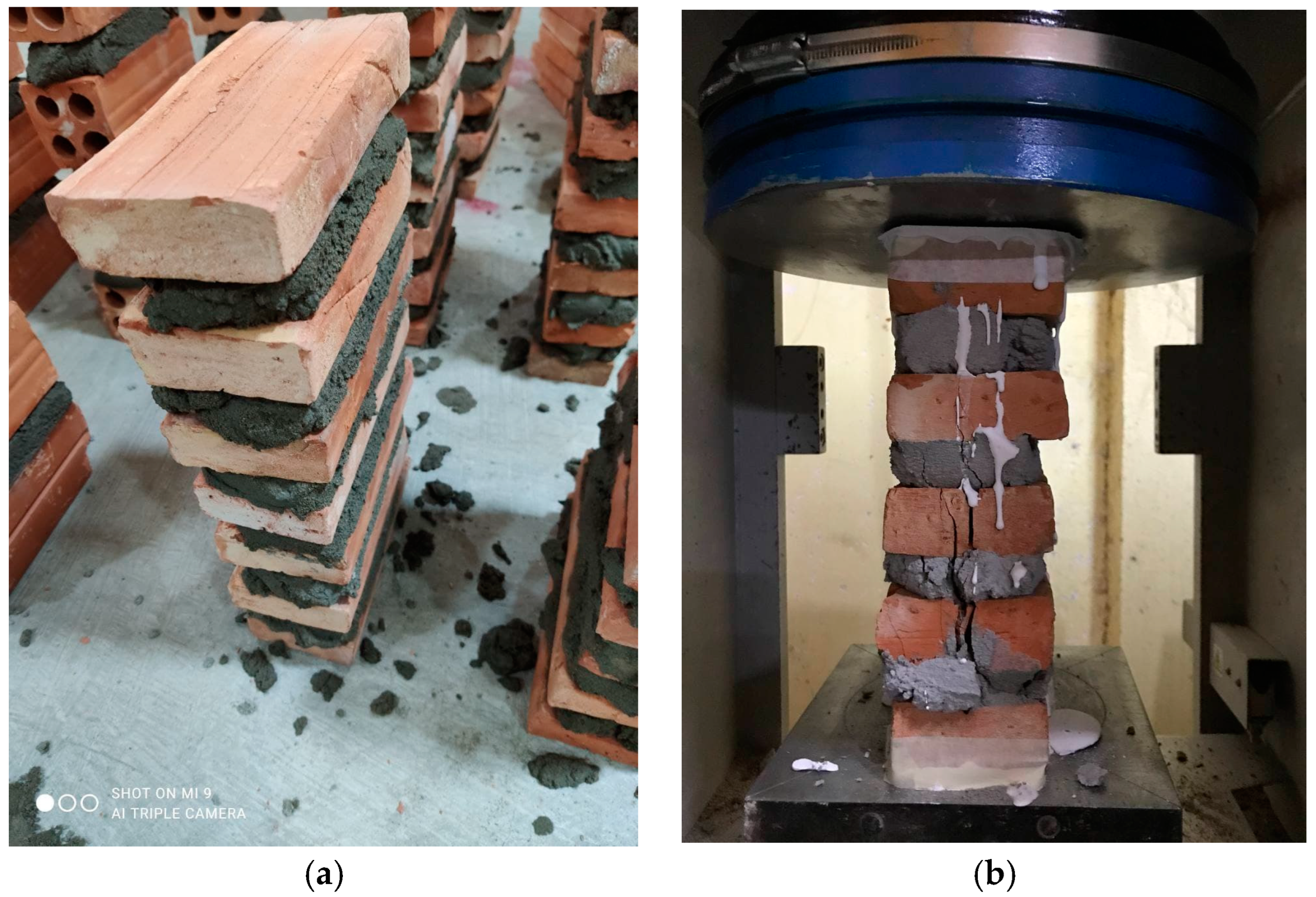

3.2. Testing Procedures

4. Results and Discussion

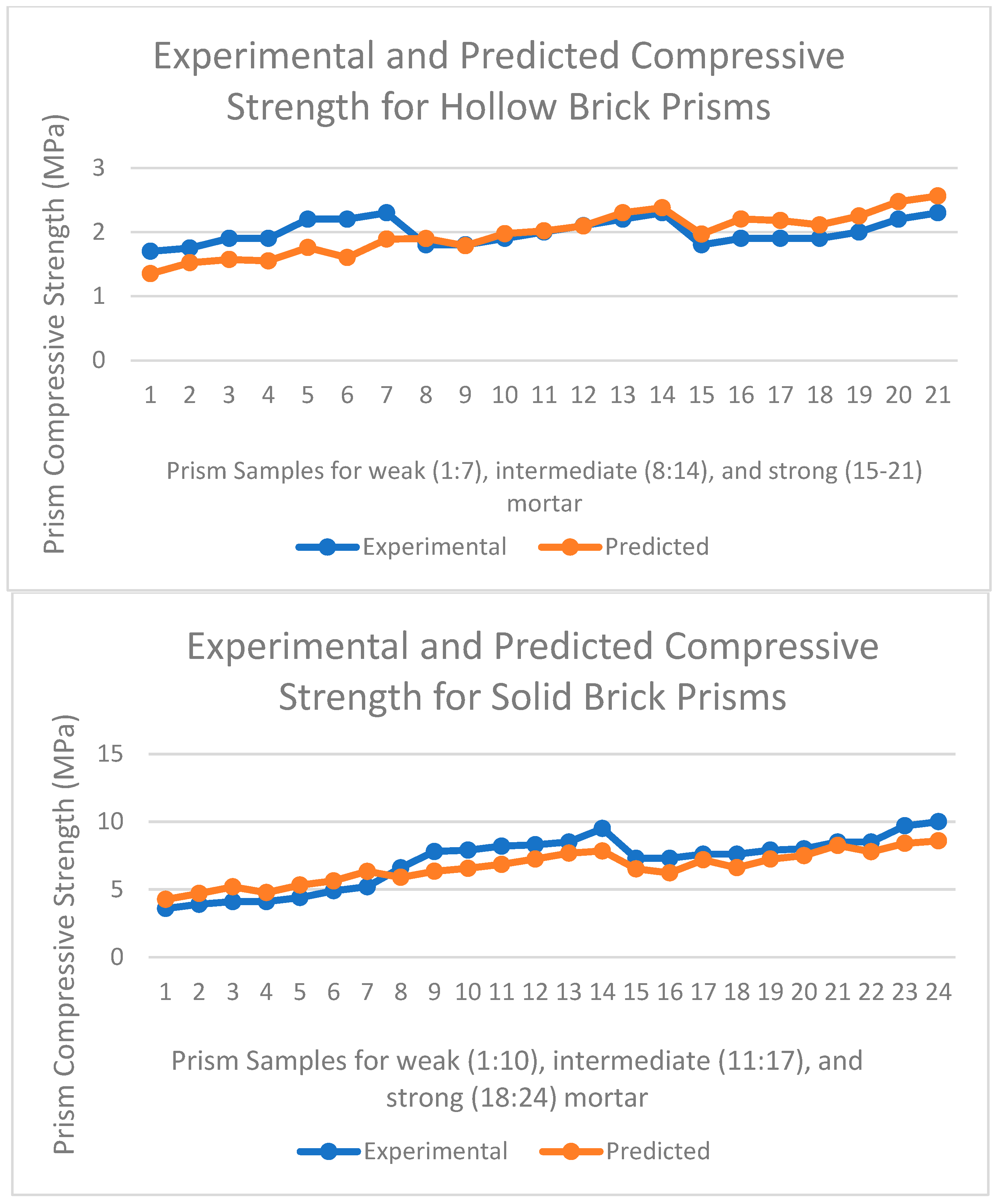

Estimation of Prism Strength of Masonry

5. Conclusions

- Significant variation has been observed in compressive strength of hollow and solid bricks. Physical properties, such as hole, height, and density, and production technology such as burning temperature could constitute the difference in variation of the compressive strength.

- Mechanical properties of masonry and its constituent materials were obtained by uniaxial compression testing according to the respective standards. The average compressive strengths of the masonry prisms constructed with 1:3, 1:4, and 1:6 cement-sand mortar were found to be in good agreement with past studies in the literature [5,7,8,12,14,15,21,22].

- The mean masonry compressive strength was found to increase with the increase in brick compressive strength, which was found to be in good agreement with previous researchers [7].

- It has been observed that increase in mortar strength increases the masonry’s compressive strength in solid bricks, in agreement with the literature [7]. However, that effect could not been observed in hollow bricks, and this observation could be due to the weak brick–mortar bond of hollow bricks, which has very smooth surfaces.

- A predictive equation relating brick and mortar compressive strengths with masonry compressive strength in the form of the Eurocode 6 [37] expression was derived, and constants were found to be 0.24, 0.59, and 0.32 for K, α, and β, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lumantarna, R.; Biggs, D.T.; Ingham, J.M. Uniaxial Compressive Strength and Stiffness of Field-Extracted and Laboratory-Constructed Masonry Prisms. J. Mater. Civ. Eng. 2014, 26, 567–575. [Google Scholar] [CrossRef]

- Barbosa, C.S.; Lourenço, P.B.; Hanai, J.B. On the compressive strength prediction for concrete masonry prisms. Mater. Struct. 2009, 43, 331–344. [Google Scholar] [CrossRef]

- Thamboo, J.A.; Dhanasekar, M. Characterisation of thin layer polymer cement mortared concrete masonry bond. Constr. Build. Mater. 2015, 82, 71–80. [Google Scholar] [CrossRef] [Green Version]

- Fortes, E.S.; Parsekian, G.A.; Fonseca, F.S. Relationship between the Compressive Strength of Concrete Masonry and the Compressive Strength of Concrete Masonry Units. J. Mater. Civ. Eng. 2015, 27, 04014238. [Google Scholar] [CrossRef]

- Gumaste, K.S.; Rao, K.S.N.; Reddy, B.V.V.; Jagadish, K.S. Strength and elasticity of brick masonry prisms and wallettes under compression. Mater. Struct. 2007, 40, 241–253. [Google Scholar] [CrossRef]

- Murthi, P.; Bhavani, M.; Musthaq, M.S.; Jauhar, M.O.; Devi, V.R. Development of relationship between compressive strength of brick masonry and brick strength. Mater. Today Proc. 2021, 39, 258–262. [Google Scholar] [CrossRef]

- Padalu, P.K.V.R.; Singh, Y. Variation in compressive properties of Indian brick masonry and its assessment using empirical models. Structures 2021, 33, 1734–1753. [Google Scholar] [CrossRef]

- Thaickavil, N.N.; Thomas, J. Behaviour and strength assessment of masonry prisms. Case Stud. Constr. Mater. 2018, 8, 23–38. [Google Scholar] [CrossRef]

- Calvi, G.M.; Kingsley, G.R.; Magenes, G. Testing of Masonry Structures for Seismic Assessment. Earthq. Spectra 1996, 12, 145–162. [Google Scholar] [CrossRef]

- Carpinteri, A.; Invernizzi, S.; Lacidogna, G. Historical brick-masonry subjected to double flat-jack test: Acoustic emissions and scale effects on cracking density. Constr. Build. Mater. 2009, 23, 2813–2820. [Google Scholar] [CrossRef]

- Kumavat, H.R. An Experimental Investigation of Mechanical Properties in Clay Brick Masonry by Partial Replacement of Fine Aggregate with Clay Brick Waste. J. Inst. Eng. Ser. A 2016, 97, 199–204. [Google Scholar] [CrossRef]

- Basha, S.H.; Kaushik, H.B. Evaluation of Nonlinear Material Properties of Fly Ash Brick Masonry under Compression and Shear. J. Mater. Civ. Eng. 2014, 27, 04014227. [Google Scholar] [CrossRef]

- Christy, F.C.; Shanthi, M.R. Experimental study on axial compressive strength and elastic modulus of the clay and fly ash brick masonry. J. Civ. Eng. Constr. Technol. 2013, 4, 134–141. [Google Scholar] [CrossRef]

- Kaushik, H.B.; Rai, D.C.; Jain, S.K. Stress-strain characteristics of clay brick masonry under uniaxial compression. J. Mater. Civ. Eng. 2007, 19, 728–739. [Google Scholar] [CrossRef]

- Kadam, S.B.; Singh, Y.; Li, B. Out-of-plane behaviour of unreinforced masonry strengthened using ferrocement overlay. Mater. Struct. 2014, 48, 3187–3203. [Google Scholar] [CrossRef]

- Kandymov, N.; Masha, A.; Durdyev, S.; Yardim, Y. Construction materials’ properties: Investigation of unreinforced masonry buildings in the cities of Tirana, Durres and Elbasan. Case Stud. Constr. Mater. 2020, 13, e00395. [Google Scholar] [CrossRef]

- Gumaste, K.S.; Venkatarama, R.B.; Nanjunda, R.K. Properties of burnt bricks and mortars in India. Mason. Int. 2004, 17, 45–52. [Google Scholar]

- Sarangapani, G.; Reddy, B.V.V.; Jagadish, K.S. Brick-mortar bond and masonry compressive strength. J. Mater. Civ. Eng. 2005, 17, 229–237. [Google Scholar] [CrossRef]

- Thamboo, J.A.; Dhanasekar, M. Correlation between the performance of solid masonry prisms and wallettes under compression. J. Build. Eng. 2019, 22, 429–438. [Google Scholar] [CrossRef]

- Singhal, V.; Rai, D.C. Suitability of Half-Scale Burnt Clay Bricks for Shake Table Tests on Masonry Walls. J. Mater. Civ. Eng. 2013, 26, 644–657. [Google Scholar] [CrossRef]

- Singh, S.B.; Munjal, P. Bond strength and compressive stress-strain characteristics of brick masonry. J. Build. Eng. 2017, 9, 10–16. [Google Scholar] [CrossRef]

- Shermi, C.; Dubey, R.N. Study on out-of-plane behaviour of unreinforced masonry strengthened with welded wire mesh and mortar. Constr. Build. Mater. 2017, 143, 104–120. [Google Scholar] [CrossRef]

- Ravula, M.B.; Subramaniam, K.V.L. Experimental investigation of compressive failure in masonry brick assemblages made with soft brick. Mater. Struct. Constr. 2017, 50, 19. [Google Scholar] [CrossRef]

- Engesser, F. Über weitgespannte wölbbrücken. Z. Archit. Ing. 1907, 53, 403–440. [Google Scholar]

- Garzón-Roca, J.; Marco, C.O.; Adam, J.M. Compressive strength of masonry made of clay bricks and cement mortar: Estimation based on Neural Networks and Fuzzy Logic. Eng. Struct. 2013, 48, 21–27. [Google Scholar] [CrossRef]

- Dymiotis, C.; Gutlederer, B.M. Allowing for uncertainties in the modelling of masonry compressive strength. Constr. Build. Mater. 2002, 16, 443–452. [Google Scholar] [CrossRef]

- Dayaratnam, P. Brick and Reinforced Brick Structures; Oxford & IBH Pub. Co.: Delhi, India, 1987. [Google Scholar]

- Rozza, M.; Martinez-Luengas, G.L.; Pardo, A.L. Intervention Techniques in Architectural Heritage: Course. Restructuring of Masonry Wall Buildings. Constr. Tech. Consult. 1995. Available online: https://scholar.google.com/scholar_lookup?title=CursoTécnicasdeIntervenciónenElPatrimonioArquitectonico&author=G.L.Rozza&publication_year=1995 (accessed on 18 May 2022).

- Nwofor, T.C. Experimental Determination of the Mechanical Properties of Clay Brick Masonry. Can. J. Environ. Constr. Civ. Eng. 2012, 3, 127–145. [Google Scholar]

- Llorens, J.; Llorens, M.; Chamorro, M.A.; Soler, J. Experimental Behavior of Brick Masonry under Uniaxial Compression on Parallel-to-Face Brick. Single-Leaf Case Study 2018, 14, 23–37. [Google Scholar] [CrossRef]

- Sarhat, S.R.; Sherwood, E.G. The prediction of compressive strength of ungrouted hollow concrete block masonry. Constr. Build. Mater. 2014, 58, 111–121. [Google Scholar] [CrossRef]

- Sajanthan, K.; Balagasan, B.; Sathiparan, N. Prediction of compressive strength of stabilized earth block masonry. Adv. Civ. Eng. 2019, 2019, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Hendry, A.W.; Malek, M.H. Characteristic compressive strength of brickwork walls from collected test results. Masonry Int. 1986, 7, 15. [Google Scholar]

- Rostampour, M. Aspects of the Design of the Multistory Buildings in Light-Weight Concrete. 1973. Available online: https://era.ed.ac.uk/handle/1842/16928 (accessed on 29 October 2020).

- Mann, W. Statistical evaluation of tests on masonry by potential functions. In Proceedings of the Sixth International Brick Masonry, Rome, Italy, 16–19 May 1982; pp. 86–98. [Google Scholar]

- Bröcker, O. Die auswertung von tragfähigkeitsversuchen an gemauerten wänden. Betonstein-Zeitung 1963, 10, 19–21. [Google Scholar]

- European Committe for Standardization (CEN). Eurocode 6: Design of Masonry Structures–Part 1-1: General Rules for Reinforced and Unreinforced Masonry Structures; European Committe for Standardization: Brussels, Belgium, 2005. [Google Scholar]

- BS EN 772-1:2011; BS EN 772-1:2011+A1:2015 Methods of Test for Masonry Units Determination of Compressive Strength-European Standards. BSI Standards Limited: London, UK, 2011. Available online: https://www.en-standard.eu/bs-en-772-1-2011-a1-2015-methods-of-test-for-masonry-units-determination-of-compressive-strength/ (accessed on 23 May 2022).

- MSZ EN 772-1: 2011; Test Methods for Masonry Units. Part 1: Determination of Compressive Strength (Hungarian Standards Board). 2011. Available online: http://www.mszt.hu/ (accessed on 22 May 2022).

- ASTM International. ASTM C109/C109M-20b Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50 mm] Cube Specimens). 2008. Available online: https://www.astm.org/Standards/C109.htm (accessed on 10 November 2020).

- ASTM International. ASTM C1314-03b Standard Test Method for Compressive Strength of Masonry Prisms. 2003. Available online: https://www.astm.org/DATABASE.CART/HISTORICAL/C1314-03B.htm (accessed on 10 November 2020).

- ASTM International. Standard Test Method for Compressive Strength of Masonry Prisms. 2016. Available online: https://www.astm.org/c1314-16.html (accessed on 23 May 2022).

- Fódi, A. Effects influencing the compressive strength of a solid, fired clay brick. Period. Polytech. Civ. Eng. 2011, 55, 117–128. [Google Scholar] [CrossRef]

- Chapagain, Y.P.; Sapkota, S.; Ghale, D.B.; Bohara, N.B.; Duwal, N.; Bhattarai, J. A case study on mineralogy and physico-mechanical properties of commercial bricks produced in Nepal. SN Appl. Sci. 2020, 2, 123AD. [Google Scholar] [CrossRef]

- Karaman, S.; Gunal, H.; Ersahin, S. Assesment of clay bricks compressive strength using quantitative values of colour components. Constr. Build. Mater. 2006, 20, 348–354. [Google Scholar] [CrossRef]

- Yu, J.H.; Park, J.H. Compressive and Diagonal Tension Strengths of Masonry Prisms Strengthened with Amorphous Steel Fiber-Reinforced Mortar Overlay. Appl. Sci. 2021, 11, 5974. [Google Scholar] [CrossRef]

| Research | Year | K | α | β |

|---|---|---|---|---|

| [19] | 2019 | 0.2 | 1.26 | 0.15 |

| [32] | 2019 | 0.25 | 1.03 | 0.28 |

| [30] | 2018 | 0.1 | 0.34 | 1.93 |

| [11] | 2016 | 0.69 | 0.6 | 0.35 |

| [12] | 2014 | 1.34 | 0.1 | 0.33 |

| [1] | 2014 | 0.75 | 0.75 | 0.31 |

| [13] | 2013 | 0.35 | 0.65 | 0.25 |

| [29] | 2012 | 0.61 | 0.51 | 0.36 |

| [14] | 2007 | 0.63 | 0.49 | 0.32 |

| [5] | 2007 | 0.32 | 0.86 | 0.13 |

| [5] | 2007 | 0.22 | 0.85 | 0.14 |

| [27] | 1987 | 0.27 | 0.5 | 0.5 |

| [33] | 1986 | 0.32 | 0.53 | 0.21 |

| [35] | 1982 | 0.83 | 0.66 | 0.33 |

| [34] | 1973 | 0.9 | 0.67 | 0.33 |

| [36] | 1963 | 0.68 | 0.5 | 0.33 |

| Type | Name | Brick Type | Mortar Type | h (mm) | l (mm) | w (mm) |

|---|---|---|---|---|---|---|

| Prism | S3 | Solid | A | 360 | 170 | 75 |

| Prism | H3 | Hollow | A | 370 | 170 | 75 |

| Prism | S4 | Solid | C | 360 | 170 | 75 |

| Prism | H4 | Hollow | C | 370 | 170 | 75 |

| Prism | S6 | Solid | B | 360 | 170 | 75 |

| Prism | H6 | Hollow | B | 370 | 170 | 75 |

| Unit Type | Dimension (L × W × H) (mm) | Density/(kg/m3) (ASTM C90-16a) | Compressive Strength/(MPa) (BS EN 772-1:2011) |

|---|---|---|---|

| Hollow (10 specimens) | 170 × 75 × 75 | 1256 (10.4%) | 10.20 (10.3%) |

| Solid (10 specimens) | 170 × 75 × 30 | 2484 (7.7%) | 77.75 (15%) |

| Mortar Type (Cement: Sand) | Density/(kg/m3) BS EN 1015-10 | Compressive Strength/(MPa) ASTM C109 |

|---|---|---|

| A (1:3) | 1895 (0.5%) | 13.8 (8.3%) |

| B (1:6) | 1783 (1.6%) | 4.81 (14%) |

| C (1:4) | 1870 (1.7%) | 10.56 (12.4%) |

| Brick Type | f’m (MPa) | Normalised f’m (MPa) |

|---|---|---|

| Prisms with weak mortar (1:6) | ||

| Hollow | 1.99 (11.9%) | 2.41 |

| Solid | 4.31 (13%) | 5.19 |

| Prisms with intermediate mortar (1:4) | ||

| Hollow | 2.01 (9%) | 2.44 |

| Solid | 8.11 (10.7%) | 9.78 |

| Prisms with strong mortar (1:3) | ||

| Hollow | 2 (9%) | 2.42 |

| Solid | 8.23 (12.9%) | 9.92 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kandymov, N.; Mohd Hashim, N.F.; Ismail, S.; Durdyev, S. Derivation of Empirical Relationships to Predict Cambodian Masonry Strength. Materials 2022, 15, 5030. https://doi.org/10.3390/ma15145030

Kandymov N, Mohd Hashim NF, Ismail S, Durdyev S. Derivation of Empirical Relationships to Predict Cambodian Masonry Strength. Materials. 2022; 15(14):5030. https://doi.org/10.3390/ma15145030

Chicago/Turabian StyleKandymov, Nurmurat, Nor Fazilah Mohd Hashim, Syuhaida Ismail, and Serdar Durdyev. 2022. "Derivation of Empirical Relationships to Predict Cambodian Masonry Strength" Materials 15, no. 14: 5030. https://doi.org/10.3390/ma15145030

APA StyleKandymov, N., Mohd Hashim, N. F., Ismail, S., & Durdyev, S. (2022). Derivation of Empirical Relationships to Predict Cambodian Masonry Strength. Materials, 15(14), 5030. https://doi.org/10.3390/ma15145030