Abstract

In order to apply the concepts that allow the transition from a linear to a circular economy, waste generators and/or processors must identify those variants that generate products that can be used as secondary raw materials, thus also respecting the actions governing sustainable development. This paper presents such a variant, the briquetting of waste with high iron content, waste generated on current flows in steel enterprises or deposited in industrial sites. The obtained briquettes are analyzed for chemical and mechanical characteristics so that can be used as secondary materials in the steel production. An optimization of the chemical composition using generic algorithms is also proposed in order to obtain the mechanical characteristics necessary for the proper handling of these products.

1. Introduction

In the context of sustainable development, the resource efficiency, reuse, and recycling of the steel in question of ferrous waste is very important for the steel industry. The efficiency and quality of raw materials and auxiliary materials is an integral part of the steelmaking process [1]. The transition from the linear economy to the circular economy requires action at all stages of the manufacture of ferrous alloys: from the extraction and transport of raw materials to the design of materials and products according to the new market requirements, to the production, distribution, and consumption of steel products, to their recycling and to the integrated management of the resulting waste, but also the recovery of the elements still useful from them. The steel industry must use all raw materials to their full potential, tending to zero waste in steelmaking [2,3]. Each co-product formed during the manufacture of steel, in the context of the circular economy, must be used in new products. This approach minimizes the amount of waste sent to landfills, reduces emissions, and preserves raw materials [2,4]. Co-products resulting from the steel industry (dusts, slurries, slag, milling) are recycled and transformed into new products for the industry. For example, 97% is recovered from the total amount of slag (BOF slag, EAF slag) produced (78% is used for cement manufacturing, 21% in road construction and the rest in agriculture as fertilizer) [3,5]. Powdery ferrous waste comes from the various operations of cleaning exhaust gases and wastewater, in dry or sludge form. Given the granulation of the dusts captured when cleaning gases, their storage raises special problems regarding the protection of the environment, so that almost all the steel companies that own such waste are looking for solutions to reintroduce them into the steel circuit [6,7,8].

By using simple processing operations of this small and powdery waste (agglomeration, pelleting, briquetting [9,10,11,12,13,14,15]), by-products can be obtained and can be used in the steel industry, when developing cast iron (agglomerates, pellets) or steel (reduced agglomerates, metallic pellets, lighters with adequate mechanical strength–Figure 1). The condition that these products can be recovered in the steel industry is not to pollute cast iron or steel with residual elements such as Zn, Cu, Sn, Cr, Ni.

Figure 1.

By-products made from waste with high iron content [7].

If, through the repeated recycling of this waste, there is an increase in the content of residual elements, which would lead to the contamination of cast iron/steel, there must be applied methods of reducing the content of these elements [16,17,18] or this waste should be recovered by other industries and not by steel industry [13,19,20].

Powdery and small ferrous waste resulting from different phases of industrial processes (in most cases steel) represents an intrinsic value, which is determined by the ferrous content (chemically bound iron, sometimes metallic) that can properly replace the raw material, namely iron ore/cast iron/scrap iron, in steel processes [6,7,8]. In addition to iron, the main element, some wastes also have a high carbon content as well as basic or fluidifying component, which are useful in the recycling process. Recovery of these wastes and their reintroduction into the economic circuit is necessary both from an economic point of view, because it leads to the economy of raw materials and from an ecological point of view [11,12]. The share of the use of ferrous waste is expected to increase in the medium and long term as a secondary raw material in the load of steel-making aggregates (global ferrous scrap availability expected to increase to 1 bn tones in 2030 and 1.3 bn tones in 2050). Thus, large parts of the natural raw materials are replaced by waste or by-products, from the steel industry or from other industries, which have mineral content or similar properties [2,11].

By using by-products obtained from waste deposits or produced on current streams, both economic and ecological benefits are achieved, thus saving natural resources (iron ores). However, these by-products must meet conditions in terms of chemical composition and mechanical characteristics (during their use in processing aggregates).

2. Materials and Methods

2.1. Materials

The work presents the results obtained from the processing by briquetting of sludge (sintering sludge, sludge mill scale and ferrous sludge) resulting from the steel industry. From the point of view of the chemical and particle composition, the waste can be recovered by recycling, the choice of technology having to consider all its qualitative characteristics.

Powdery ferrous wastes were subjected to qualitative analysis, in order to determine the characteristics: chemical analyzes granulation and mineralogical and morphological analysis.

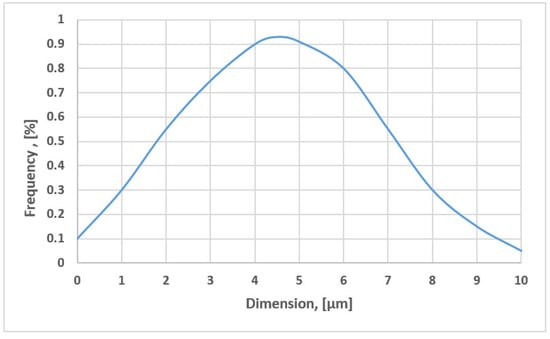

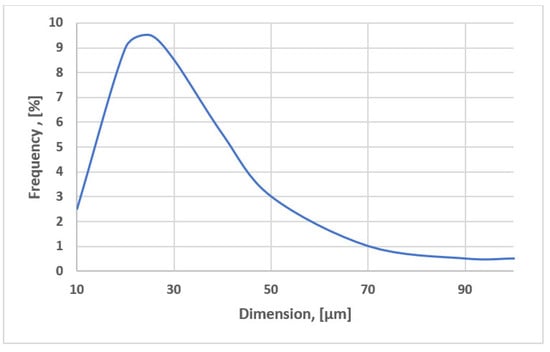

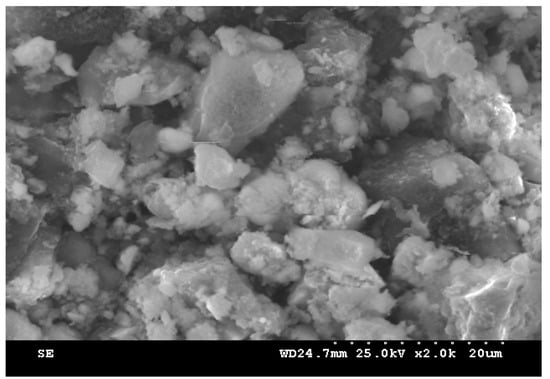

In the sintering sludge, samples were taken from the sludge warehouse in Bataga (Hunedoara, Romania). The chemical composition of the samples taken is shown in Table 1, and among the physical characteristics, we mention: the bulk density is 1.18 kg/dm3 and the natural slope angle is 16°. The distribution of the grading classes has two well-defined areas that differ essentially by the form of the class distribution and is shown in Figure 2 and Figure 3. Figure 4 shows the morphological aspects corresponding to the sintering sludge samples. In the analyzed samples, the particles have different sizes and shapes, some slightly rounded, others polyhedral.

Table 1.

Chemical composition of sintering sludge, [%].

Figure 2.

Distribution of particle size classes for sintering sludge, class 0–10 μm.

Figure 3.

Distribution of the particle size classes for sintering sludge, class 10–100 μm.

Figure 4.

Image of sintering sludge, 4000×.

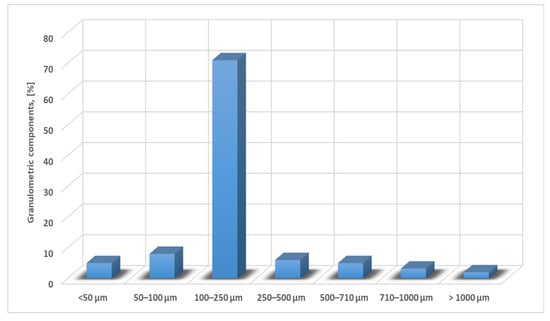

The sludge mill scale samples were taken from a steel plant, which were analyzed for the determination of the quality characteristics (the chemical composition was determined on the ARL 9400 XRF spectrometer—Thermo Fisher Scientific, Waltham, MA, USA). The data on the chemical analysis of the sludge mill scale under analysis are presented in Table 2 and the particle size distribution of the samples is shown in Figure 5.

Table 2.

Chemical composition of sludge mill scale, [%].

Figure 5.

Particle size composition of sludge mill scale.

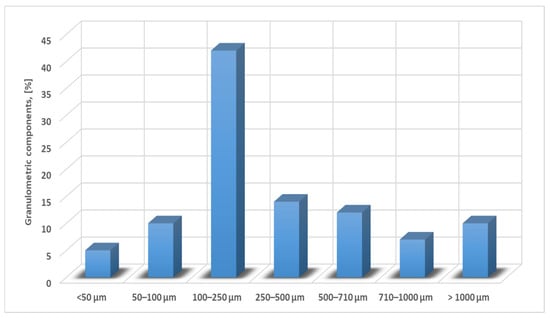

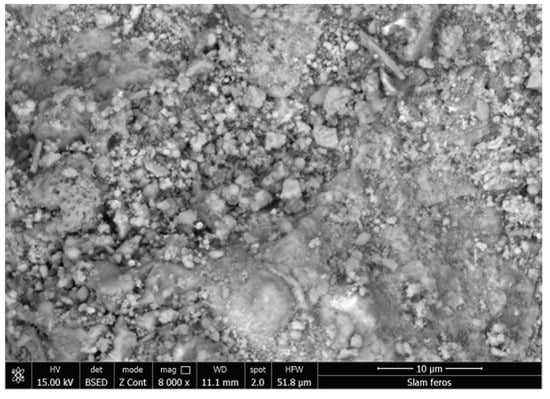

The ferrous sludge samples came from a steel plant producing raw iron powder. Moreover, for these, the chemical composition and the particle size composition were determined. In order to establish the particle size classes, the laboratory installation used is the vibrating sieving machine “Analysette 3” Fritsch (FRITSCH GmbH—Milling and Sizing, Idar-Oberstein, Germany) with a complete set of sieges (mesh sizes of the siege 450–25 μm). The slam sample was graded by refusal and the resulting particle size composition is shown in Figure 6. The chemical analysis of the samples taken is shown in Table 3 and the morphological analysis of ferrous sludge is shown in Figure 7.

Figure 6.

Particle size composition of ferrous sludge.

Table 3.

Chemical composition of ferrous sludge, [%].

Figure 7.

SEM images for ferrous sludge, 8000×.

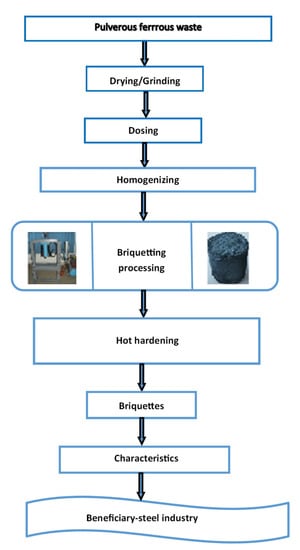

2.2. Method

The previously analyzed iron wastes were briquetted in order to obtain secondary materials that can be used in steelmaking—the experiments taking place only in the laboratory phase. The briquetting process was chosen because it is a simple, reliable process, to which the force required for compaction can be adjusted. Moreover, the process can be easily automated so that a certain productivity can be achieved.

The lighter processing option was chosen without the addition of binders, the briquettes obtained, being intended for the steel industry, being used as a raw material for the elaboration of steels.

The experimental technology of processing briquettes consists of the following steps:

- -

- Preparation of powdery ferrous waste (ferrous sludge, sintering sludge, sludge mill scale) for the formation of raw batch;

- -

- Determination of the chemical and granulometric composition on the batch of materials subjected to processing;

- -

- Dosing the materials according to the established recipe, for a lighter weight of 1 kg;

- -

- Homogenization of the batch in the homogenization drum, the time for this operation being about 10 min;

- -

- Briquetting the batch with the help of hydraulic press;

- -

- Hardening of briquettes in the oven;

- -

- Determination of the quality characteristics (chemical composition and compressive strength) for each batch of briquettes.

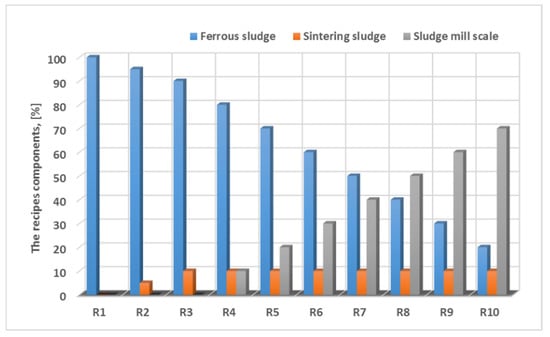

The technological process is shown in Figure 8. Lighters were manufactured after 10 prescriptions, the composition of which is shown in Figure 9.

Figure 8.

Technological stream of waste processing through briquetting.

Figure 9.

Composition of the experimental recipes.

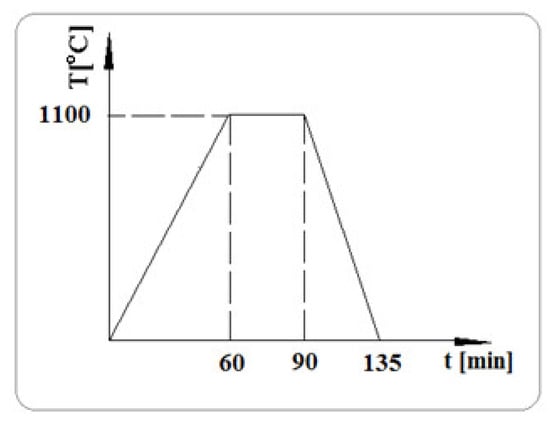

The test lighters were subjected to heat-resistance in an oven, in accordance with the diagram in Figure 10.

Figure 10.

Lighter hardening diagram (T-hardening temperature, [°C]; t-hardening time, [min]).

3. Results and Discussions

The iron content in the test lighters varied within 60–68.76%. Figure 11 shows the obtained lighters and their image (macro-structure) using the digital stereomicroscope model 520 Spin M-D.

Figure 11.

Experimental briquettes.

For the assessment of the quality characteristics of resistance to handling and transport of lighters, three technological characteristics were determined by experiments: resistance to cracking, resistance to crushing, and crushing interval. For good handling and transport behavior, the literature [7,11] indicates for resistance to cracking Rf > 2 N/mm2, for resistance to crushing Rs > 3 N/mm2, and the crush range Is = (0.2–0.35) Rf.

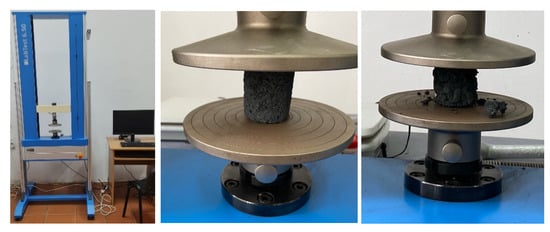

The determination of the technological resistance characteristics for the test lighters was carried out using the universal compression/traction test machine LabTest 6.50 as shown in Figure 12.

Figure 12.

Determination of the briquette’s resistance characteristics.

For the resistance specifications the values obtained are:

- Rf = 4–9 N/mm2,

- Rs = 9–18 N/mm2,

- Is ≥ 5 N/mm2.

To establish double correlation equations between the technology factors of resistance to compression of the test lighters, the data were processed in the Matlab calculation program, the optimization being made using genetic algorithms.

Genetic Algorithm (GA) is a search-based optimization technique based on the principles of Genetics and Natural Selection. It is frequently used to solve optimization problems, to find optimal or near-optimal solutions to difficult problems which otherwise would take a long time to solve. Genetic Algorithms is proven to have many parallel capabilities, optimizing both continuous and discrete functions and also multi-objective problems.

The following notations were taken into account:

- x1–Ferrous sludge, %

- x2–Sludge mill scale, %

- x3–Sintering sludge, %

- y1–Rf–resistance to cracking, N/mm2

- y2–Rs–resistance to crushing, N/mm2

- y3–Is = Rs − Rf-crush range, N/mm2

Using the response areas method [21,22,23] we will further determine the connection between the parameters of this process and its characteristic responses as areas in the multidimensional space of variables. In the experiments conducted according to this method, the independent variables are varied simultaneously, taking a limited number of values in the considered experimentation range, called levels. With the help of this method, although the three independent variables are varied simultaneously, their main and higher-order effects, as well as the interactions between them, can be determined separately. Changing the independent variables will automatically change the output data. The results thus obtained can be used to improve the performance of the studied process.

Considering the case of a process with three parameters x1, x2, x3 that can be varied within the limits, x1a ≤ x1 ≤ x1b, x2a ≤ x2 ≤ x2b and respectively x3a ≤ x3 ≤ x3b, the area in the plan of independent variables represents the experimental region, and the points of this surface, having different coordinates triplets of values (x1i, x2i, x3i) of the parameters, represent experimental points. The area on which the responses for each test point are located is the response surface of the considered characteristic of the process.

Applying the design method of experiments (Design of Experiments) [24,25,26] a scheme of the experiments necessary to be performed in the case of three parameters (factors) was generated, in which the factors take the extremes and central values in their fields of variation. This scheme of experiments is called the central experimental design or of the Box-Behnken type [24,25,26], and the factors considered for our experiment fall within the following limits: 20 ≤ x1 ≤ 100; 0 ≤ x2 ≤ 70; and 0 ≤ x3 ≤ 10.

The second-order models best approximate the response areas also called regression surfaces:

In matrix notation the relation (1) becomes:

where [x] is the vector of their factors and contributions on the model;

[y] represents the vector of the observations of the N response in the experiments;

[ε] represents the vector of the measurement errors;

[β] is the vector of the coefficients of the regression surface, to be determined.

For the determination of the β coefficients of the response surface with the help of experimental data, the most appropriate is the method of the smallest squares [21,23,25], which ensures a minimum dispersion of the coefficients determined.

For this purpose, the objective function of the form is considered:

It follows that the determination of the coefficients of the response area is equivalent to the following problem of minimizing the objective function:

which leads to a system of algebraic equations of the type:

The coefficients of the response area that shape the process in the study are given by the expression:

In order to validate the regression model, it is necessary to calculate the correlation coefficient R2, which measures the “proximity” of the response surface from the experimental points and has the expression:

where: is the sum of squares of errors in relation to experimental observations

measures the total variation of the N observations.

The problem of determining the optimal parameters that maximize the response surface was solved using genetic algorithms [27,28,29]

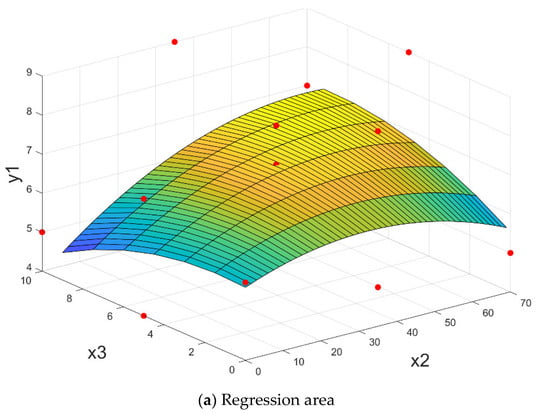

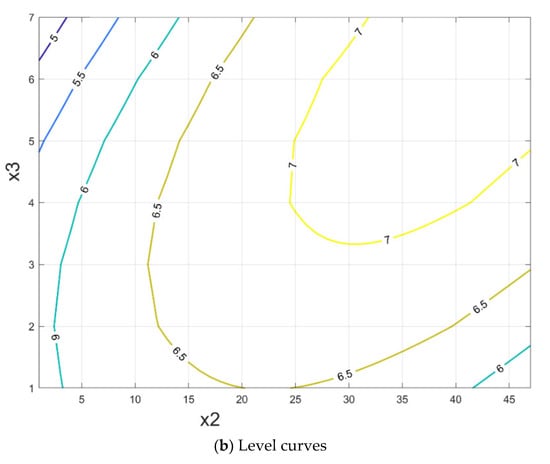

The response surface that shapes the resistance to cracking y1 according to the parameters: x1–ferrous sludge; x2–sludge mill scale; x3–sintering sludge, has the expression:

having a correlation coefficient R2 = 88.62%.

The results of the optimization problem (11) are shown in Table 4. The response area (12) and related contour lines are shown in Figure 13 for the average value of parameter x1.

Table 4.

The results of the optimization problem for y1.

Figure 13.

The briquettes resistance to cracking depending on the proportion of sludge mill scale and sintering sludge, for a medium value of ferrous sludge y1 = f (x1med, x2, x3).

The response surface that shapes the crushing resistance y2 according to parameters: x1–ferrous sludge; x2–sludge mill scale; x3–sintering sludge, has the expression:

having a correlation coefficient R2 = 88.50%.

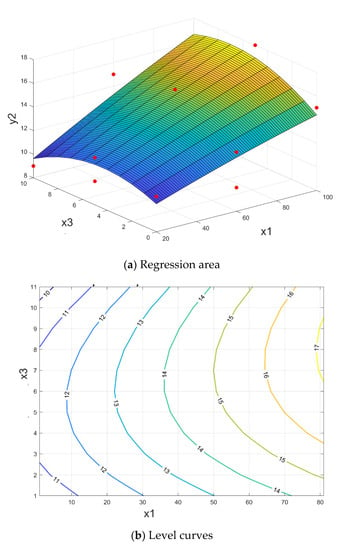

The results of the optimization problem (11) are presented in Table 5. The response area (13) and related contour lines are shown in Figure 14 for the average value of parameter x2.

Table 5.

The results of the optimization problem for y2.

Figure 14.

The briquettes resistance to crushing depending on the proportion of ferrous sludge and sintering sludge, for a medium value of sludge mill scale y2 = f (x1, x2 med, x3).

The response surface that shapes the crushing range y3 according to parameters: x1–ferrous sludge; x2–sludge mill scale; x3–sintering sludge, has the expression:

having a correlation coefficient R2 = 76.51%.

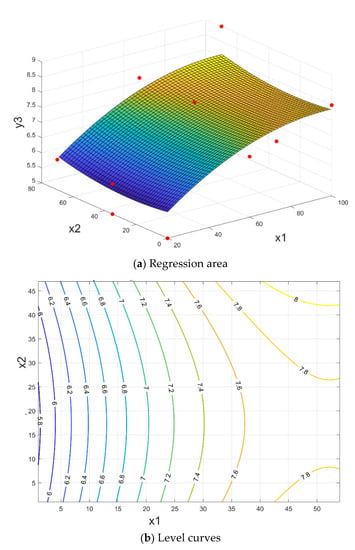

The results of the optimization problem (11) are shown in Table 6. The response area (14) and contour lines are shown in Figure 15 for the average value of parameter x3.

Table 6.

The results of the optimization problem for y3.

Figure 15.

The briquettes crush range depending on the proportion of ferrous sludge and sludge mill scale, for a medium value of sintering sludge y3 = f (x1, x2, x3 med).

From the correlation analysis shown in Figure 13 (level curves) it is noted that for sludge mill scale x2 = 33–37% and sintered sludge x3 = 3–7% (for x2 + x3 = 40%), for the crack resistance, the better accurate Rf ≥ 6.5 N/mm2 are obtained.

By analyzing the correlation shown in Figure 14 it is noted that for ferrous sludge x1 = 55–62% and sintering sludge x3 = 3–10% (for x1 + x3 = 65%) very good values are obtained for shattering resistance, i.e., Rs ≥ 14 N/mm2.

A technological analysis of the correlation presented in Figure 15 allows the identification of optimal variation ranges for ferrous sludge x1 = 58–62% and sludge mill scale x2 = 33–37% (for x1 + x2 = 95%) so that very good values are obtained for shattering resistance, i.e., Is ≥ 7.8 N/mm2.

4. Conclusions

In the “EU Action Plan for the Circular economy” presented in 2015, the European Commission supported the reasons why an appropriate, efficient, and rational use of resources, including through re-use/recycling/re-use of waste generated on current flows as secondary raw materials, can generate new and sustainable competitive advantages for the EU. Replacing the linear economy model and “closing the loop” of product life cycles through greater re-use and recycling–thus achieving a circular economy, can bring benefits for both the environment and the economy [30].

In the paper, the experiments carried out are aimed at identifying a technology and optimized alternatives whereby waste, generated on current flows or stored historically in areas where steel companies have operated, can be recovered by the industry where it originated, according to the concepts of the circular economy.

Experimental results lead to the conclusion that the waste analyzed (ferrous sludge, sludge mill scale, sintering sludge) can be processed by briquetting (with mechanical strength characteristics higher than the minimum values for this process), which allows the recovery of waste with large particle size variation limits (desirable below 2 mm).

The composition of the recipes can be determined based on the availability of small and powdery waste and the destination of the processed material: steelworks. By using a mathematical modeling with generic algorithms, optimal ranges of variation of the briquetting recipe components can be obtained (in the case of the three types of waste with the average composition presented in the paper: 33–37% sludge mill scale, 3–10% sintered sludge, 55–62% ferrous sludge).

Genetic algorithms are a modern tool used in artificial intelligence to look for a space for potential solutions to find a solution. They are faster and more efficient compared to traditional methods and help to find optimal solutions to difficult problems, while the traditional algorithm provides a step-by-step methodical procedure to solve a problem.

In order to obtain higher quality indicators for the products obtained (lighters), optimization of the kind described in the work may be used or some other changes to the raw batch recipes may be made, including by using a binder to eliminate hot hardening—in this case, much more rigorous control of the chemical composition is needed, especially from the point of view of the useful element: iron.

Author Contributions

Conceptualization, E.A., A.S. and O.L.; methodology, E.A., D.B. and C.D.; soft-ware, A.S., E.A., D.B. and N.C.; validation, O.L., D.B., C.D. and N.C.; formal analysis O.L., E.A. and A.S.; investigation, E.A. and O.L.; writing—original draft preparation, E.A.; writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the University Politechnica of Bucharest-PubArt Programme supporting scientific articles and communications publication.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

This work was supported by research grants from the Romanian National Authority for Scientific Research and Innovation, CNCS/CCCDI–UEFISCDI, project numbers: ERANET-M-COM℗TRANS-1, within PNCDI III and PN-III-P2-2.1-PED-2019–2022, within PNCDI III and the authors would want to thank University “Politechnica” of Bucharest for the chance to publish this paper.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Environment and Climate Change. Available online: https://www.worldsteel.org/steel-by-topic/environment-climate-change.html (accessed on 15 May 2022).

- Rohan, M. Cement and concrete industry integral part of the circular economy. Roman. J. Mater. 2016, 46, 253–258. [Google Scholar]

- World Steel Association Life Cycle Inventory Study. 2019. Available online: https://www.worldsteel.org/steel-by-topic/life-cycle-thinking.html (accessed on 15 May 2022).

- Steel—The Permanent Material in the Circular Economy, World Steel Association. 2020. Available online: http://circulareconomy.worldsteel.org/ (accessed on 17 May 2022).

- Costoiu, M.; Ioana, A.; Semenescu, A.; Constantin, N.; Florea, B.; Rucai, V.; Dobrescu, C.; Polifroni, M.; Păunescu, L. Environmental performance indicators for decision making and stakeholder interests. Environ. Eng. Manag. J. 2016, 15, 2279–2284. [Google Scholar]

- Mititelu, C.P.; Hritac, M.; Constantin, N. Laboratory experiments for determination of optimal characteristics of ultrafine ferrous waste briquettes to be used in cupola furnace. Sci. Bull. Ser. B Chem. Mater. Sci. 2015, 77, 157–164. [Google Scholar]

- CNMP. Research Project No.31-098/2007: Prevention and Fighting Pollution in the Steelmaking, Energetic and Mining Industrial Areas through the Recycling of Small-Size and Powdery Wastes. In Program 4 Partnerships in Priority Areas, 2007–2010; CO Responsable Heput T; CNMP Romania: Bucharest, Romania, 2007. [Google Scholar]

- Crisan, E. Research on the Valorization of Pulverulent Waste Containing Iron and Carbon in Siderurgy. Ph.D. Thesis, University Politehnica, Timisoara, Romania, 2013. [Google Scholar]

- Branca, T.A.; Colla, V.; Algermissen, D.; Granbom, H.; Martini, U.; Morillon, A.; Pietruck, R.; Rosendahl, S. Reuse and Recycling of By-Products in the Steel Sector: Recent Achievements Paving the Way to Circular Economy and Industrial Symbiosis in Europe. Metals 2020, 10, 345. [Google Scholar] [CrossRef] [Green Version]

- Matino, I.; Colla, V.; Branca, T.A.; Romaniello, L. Optimization of by-products reuse in the steel industry: Valorization of secondary resources with a particular attention on their pelletization. Waste Biomass Valoriz. 2017, 8, 2569–2581. [Google Scholar] [CrossRef]

- Serban, S.; Kiss, I. Identifying possibilities for superior recovery by pelletization of industry related small and powdery iron containing waste. Acta Polytehnica Hung. 2021, 18, 79–104. [Google Scholar] [CrossRef]

- Todorut, A.S. Management Research and Recovery of Small and Powdery Wastes, Resulted from Materials Industry, for Sustainable Development of Hunedoara. Ph.D. Thesis, University Politehnica, Timisoara, Romania, 2013. [Google Scholar]

- Rieger, J.; Colla, V.; Matino, I.; Branca, T.A.; Stubbe, G.; Panizza, A.; Brondi, C.; Falsafi, M.; Hage, J.; Wang, X.; et al. Residue Valorization in the Iron and Steel Industries: Sustainable Solutions for a Cleaner and More Competitive Future Europe. Metals 2021, 11, 1202. [Google Scholar] [CrossRef]

- Rieger, J.; Reiter, W.; Raupenstrauch, H.; Lohmeier, L.; Schröder, H.-W.; Thaler, C. Solutions for internal recycling of steelmaking dusts and sludges. In Proceedings of the Residue Valorization in Iron and Steel Industry—Sustainable Solutions for A Cleaner and More Competitive Future Europe, Virtual Workshop, ESTEP, Brussels, Belgium, 13 November 2020. [Google Scholar]

- Lohmeier, L.; Thaler, C.; Harris, C.; Wollenberg, R.; Schröder, H.-W. Briquetting of fine-grained residues from iron and steel production using organic and inorganic binders. St. Res. Int. 2020, 91. [Google Scholar] [CrossRef]

- Popescu, D.A. Research on the Valorization of Powdering and Small Waste in the Metallurgical Industry. Ph.D. Thesis, University Politehnica, Timisoara, Romania, 2018. [Google Scholar]

- Panasiuk, D.; Daigo, I.; Hoshino, T.; Hayashi, H.; Yamasue, E.; Tran, D.H.; Sprecher, B.; Shi, F.; Shatokha, V. International comparison of impurities mixing and accumulation in steel scrap. J. Ind. Ecol. 2022, 26, 1040–1050. [Google Scholar] [CrossRef]

- Dworak, S.; Fellner, J. Steel scrap generation in the EU-28 since 1946—Sources and composition. Resour. Conserv. Recycl. 2021, 173, 105692. [Google Scholar] [CrossRef]

- Hage, J.; Wang, X.; Ho, H.T.; Ouwehand, M.; Blaffart, F.; Vanderheyden, B. Metal recovery from secondary raw materials through the HIsarna process—The ReclaMet project. In Proceedings of the Residue Valorization in Iron and Steel Industry—Sustainable Solutions for a Cleaner and more Competitive Future Europe, Virtual Workshop, ESTEP, Brussels, Belgium, 13 November 2020. [Google Scholar]

- Kumara, N.; Amritphaleb, S.S.; Matthewsb, J.C.; Lynama, J.G.; Alamb, S.; Abdulkareem, O.A. Synergistic utilization of diverse industrial wastes for reutilization in steel production and their geopolymerization potential. Waste Manag. 2021, 126, 728–736. [Google Scholar] [CrossRef] [PubMed]

- Bistrian, D.A. Numerical Methods; PIM Publishing House: Iasi, Romania, 2017; ISBN 978-606-13-4090-3. [Google Scholar]

- Bistrian, D.A. Mathematical Models, and Numerical Algorithms for Stability Investigation of Swirling Hydrodynamic Systems. Ph.D. Thesis, Series 14 Nr. 2. Politehnica Publishing House, Bucharest, Romania, 2011. [Google Scholar]

- Conslik, J. Optimal Response Surface Design in Monte Carlo Sampling Experiments. Ann. Econ. Soc. Meas. 1974, 3, 463–473. [Google Scholar]

- Bistrian, D.A. Parabolized Navier–Stokes model for study the interaction between roughness structures and concentrated vortices. Phys. Fluids 2013, 25, 104103. [Google Scholar] [CrossRef]

- Myers, R.; Montgomery, D.; Anderson-Cook, C.M. Response Surface Methodology: Process and Product Optimization Using Designed Experiments; Wiley: Hoboken, NJ, USA, 2009; ISBN 978-1-118-91601-8. [Google Scholar]

- Miller, S. The Method of Least Squares; From the book The Probability Lifesaver: All the Tools You Need to Understand Chance; Princeton University Press: Princeton, NJ, USA, 2017. [Google Scholar]

- Nocedal, J.; Wright, S. Numerical Optimization; Springer: Berlin/Heidelberg, Germany, 2006; ISBN 10: 0-387-30303-0. [Google Scholar]

- Boyd, S.; Vandenberghe, L. Convex Optimization; Cambridge University Press: Cambridge, UK, 2004. [Google Scholar]

- Banzhaf, W.; Nordon, P.; Keller, R.E.; Francone, F.D. Genetic Programming—An Introduction; Morgan Kaufmann Publishiers: San Francisco, CA, USA, 1998. [Google Scholar]

- European Semester Thematic Factsheet Public Procurement. Available online: https://ec.europa.eu/info/sites/info/files/file_import/european-semester_thematic-factsheet_resource-efficiency_ro.pdf (accessed on 26 May 2022).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).