Analysis of the Deflection, Bristle Splaying, and Abrasion of a Single Tuft of a Polybutylene Terephthalate Toothbrush after Use: A Randomized Controlled Trial

Abstract

:1. Introduction

2. Materials and Methods

2.1. Study Design

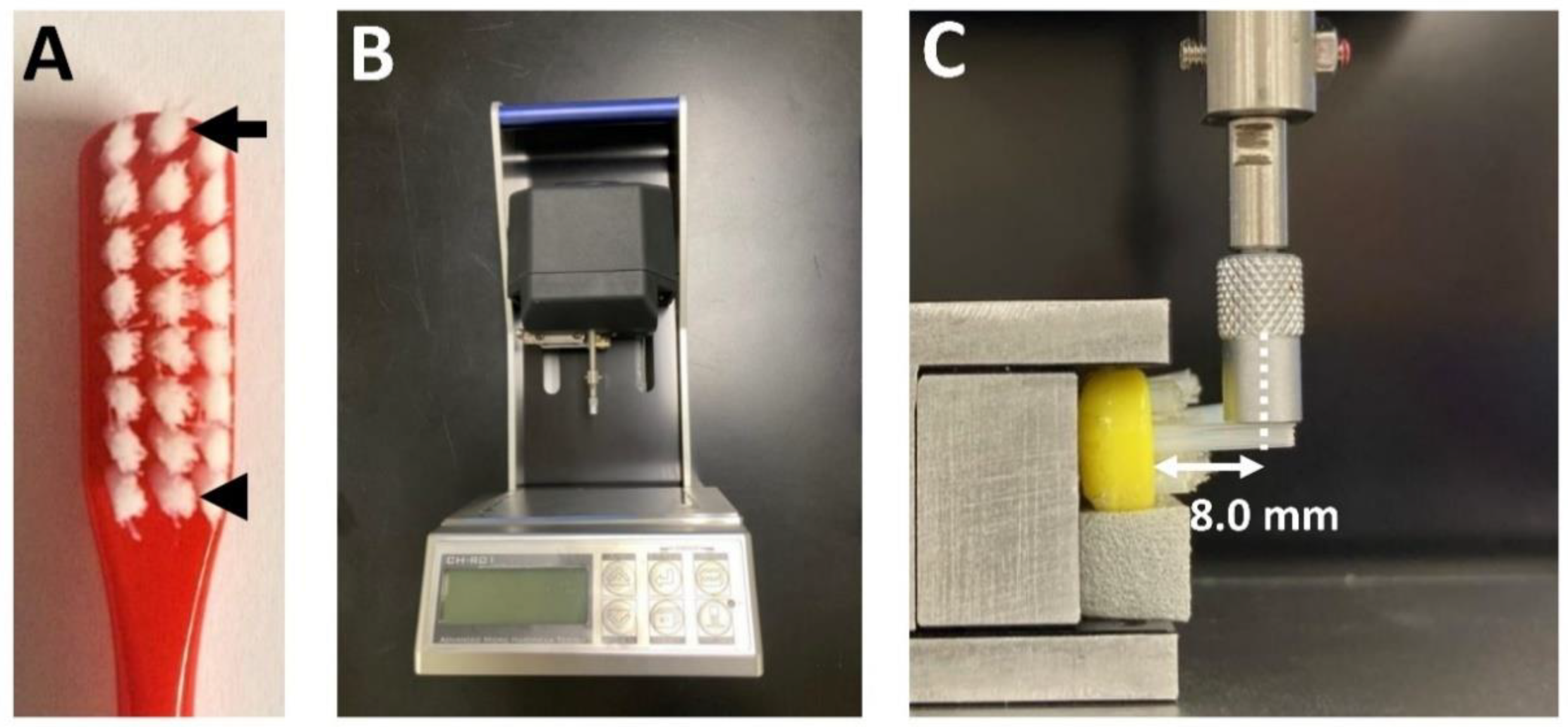

2.2. Measurement of Deflection of a Single Tuft

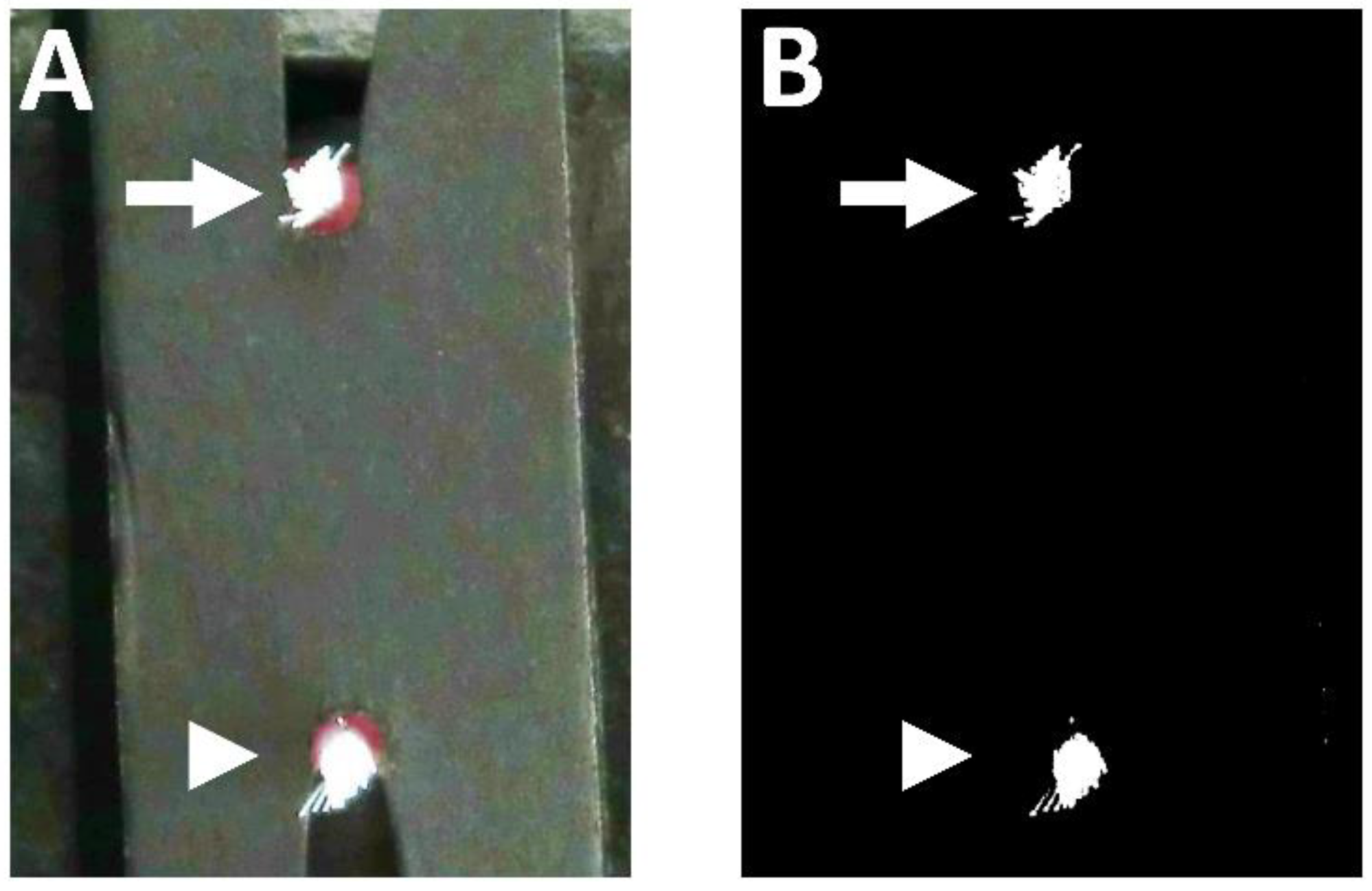

2.3. Measurement of Bristle Splaying Using Digital Software

2.4. Evaluation of Bristle Abrasion Using a SEM

2.5. Statistical Analysis

3. Results

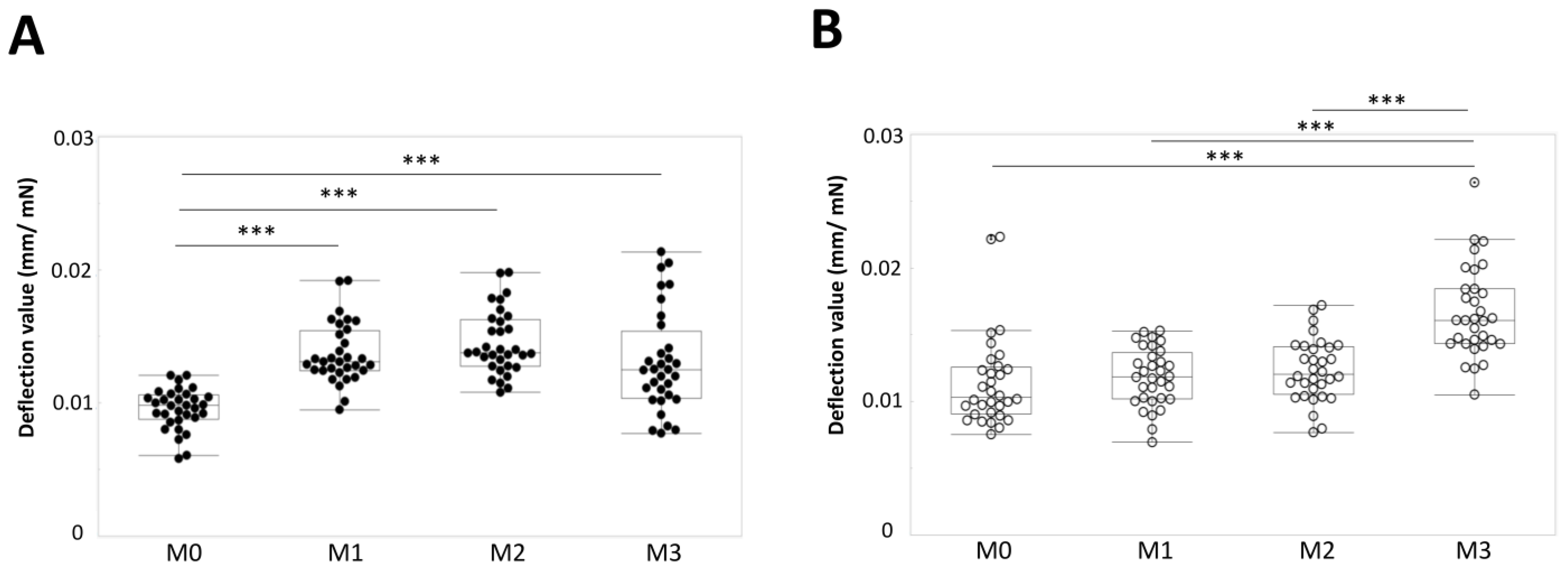

3.1. Changes in the Deflection of the Top– and Bottom–Middle Tufts of the PBT Toothbrushes

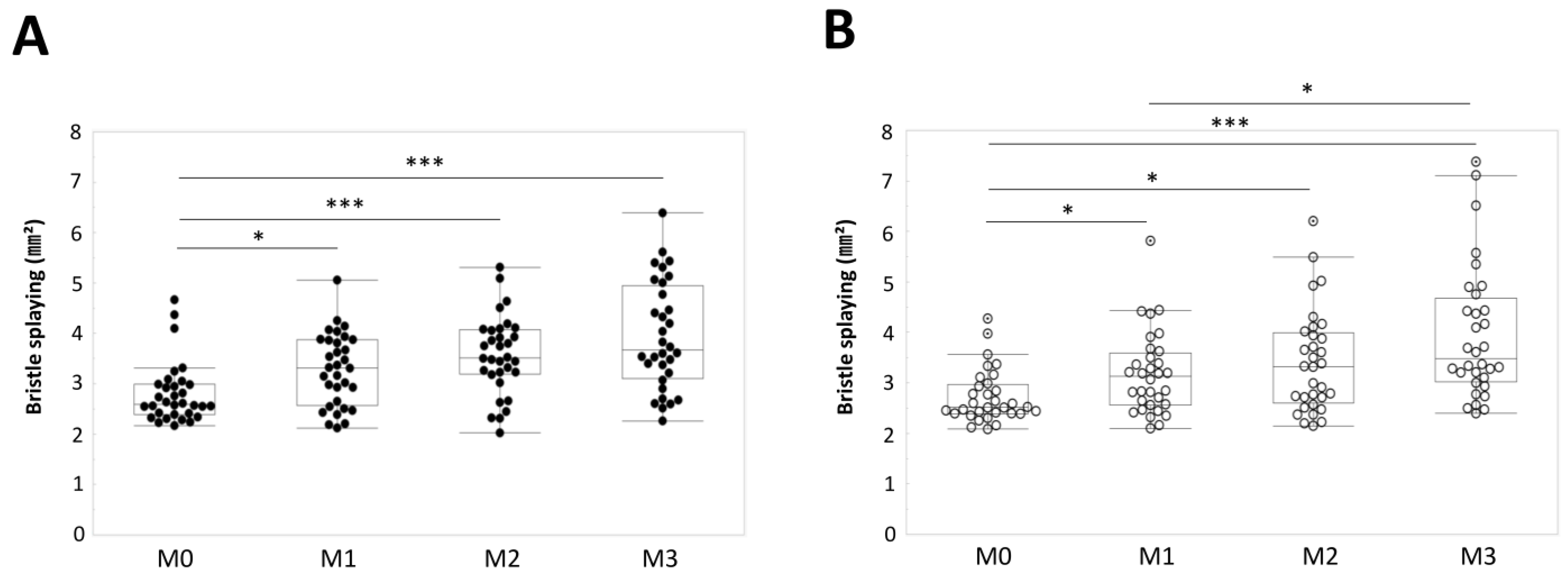

3.2. Changes in Bristle Splaying of the Top– and Bottom–Middle Tufts of the PBT Toothbrushes

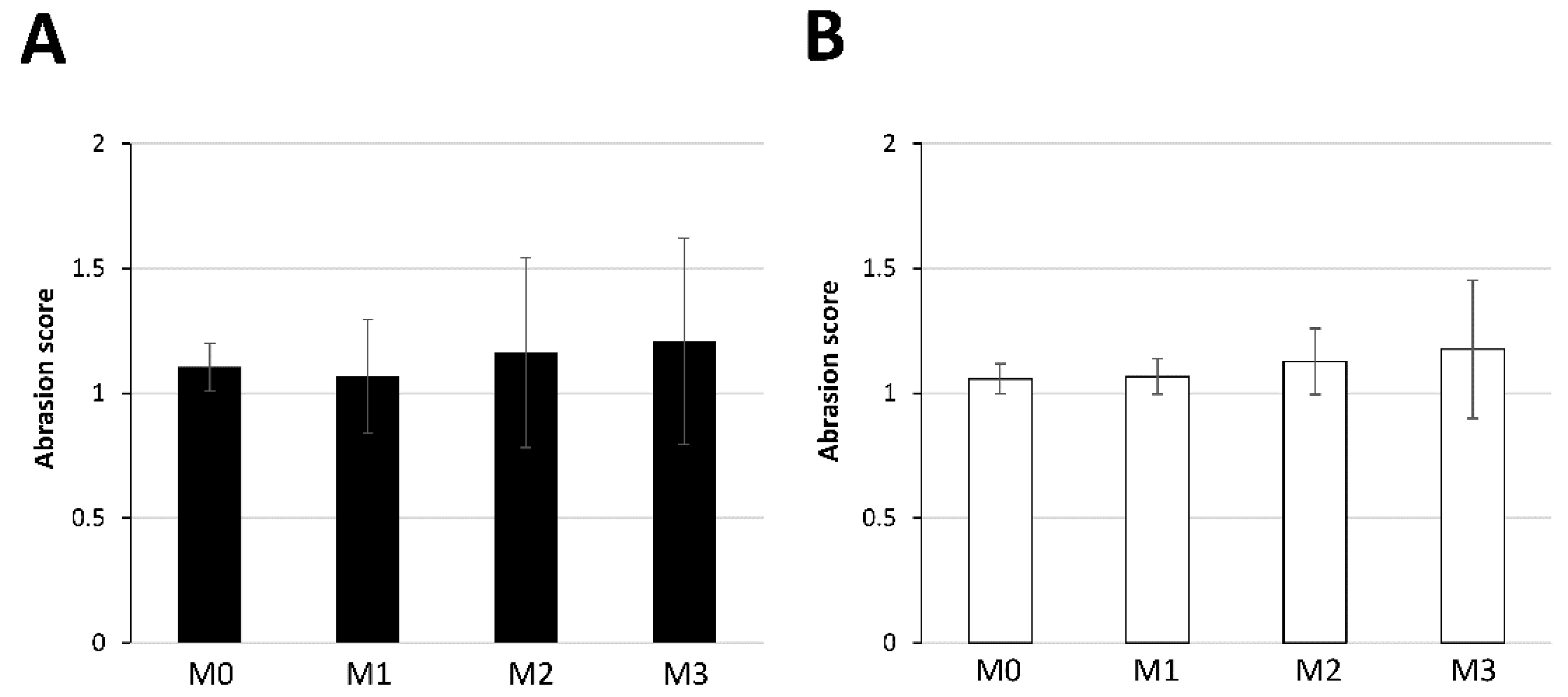

3.3. Changes in Bristle Abrasion of the Top– and Bottom–Middle Tufts of the PBT Toothbrushes

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Van Leeuwen, M.P.C.; Van der Weijden, F.A.; Slot, D.E.; Rosema, M.A.M. Toothbrush wear in relation to toothbrushing effectiveness. Int. J. Dent. Hyg. 2019, 17, 77–84. [Google Scholar] [CrossRef] [Green Version]

- Versteeg, P.A.; Piscaer, M.; Rosema, N.A.; Timmerman, M.F.; Van der Velden, U.; Van der Weijden, G.A. Tapered toothbrush filaments in relation to gingival abrasion, removal of plaque and treatment of gingivitis. Int. J. Dent. Hyg. 2008, 6, 174–182. [Google Scholar] [CrossRef]

- Kaneyasu, Y.; Shigeishi, H.; Maehara, T.; Fukada-Sambuichi, E.; Amano, H.; Sugiyama, M. Measurement of bristle splaying of toothbrushes using digital imaging and evaluation of plaque removal efficacy over 3 months: A randomized controlled trial (RCT). Int. J. Dent. Hyg. 2020, 18, 173–181. [Google Scholar] [CrossRef]

- Radusch, H.J. Poly (Butylene Terephthalate). In Handbook of Thermoplastic Polyesters: Homopolymers, Copolymers, Blends, and Composites; Fakirov, S., Ed.; Wiley-VCH: Weinheim, Germany, 2002; pp. 389–419. [Google Scholar]

- Draft International Standard ISO 22254; International Standard. Dentistry-Manual Toothbrushes-Resistance of Tufted Portion to Deflection. International Standards Organization for Standardization: Geneva, Switzerland, 2005; pp. 4–6.

- Kaneyasu, Y.; Shigeishi, H.; Ohta, K.; Sugiyama, M. Changes in the Bristle Stiffness of Polybutylene Terephthalate Manual Toothbrushes over 3 Months: A Randomized Controlled Trial. Materials 2020, 13, 2802. [Google Scholar] [CrossRef]

- Tebeta, R.T.; Fattahi, A.M.; Ahmed, N.A. Experimental and numerical study on HDPE/SWCNT nanocomposite elastic properties considering the processing techniques effect. Microsyst. Technol. 2020, 26, 2423–2441. [Google Scholar] [CrossRef]

- Lambart, A.L.; Xepapadeas, A.B.; Koos, B.; Li, P.; Spintzyk, S. Rinsing postprocessing procedure of a 3D-printed orthodontic appliance material: Impact of alternative post-rinsing solutions on the roughness, flexural strength and cytotoxicity. Dent. Mater. 2022; in press. [Google Scholar] [CrossRef]

- Babaier, R.; Watts, D.C.; Silikas, N. Effects of three food-simulating liquids on the roughness and hardness of CAD/CAM polymer composites. Dent. Mater. 2022, 38, 874–885. [Google Scholar] [CrossRef]

- Dyer, D.; Addy, M.; Newcombe, R.G. Studies in vitro of abrasion by different manual toothbrush heads and a standard toothpaste. J. Clin. Periodontol. 2000, 27, 99–103. [Google Scholar] [CrossRef]

- JIS S 3016:1995; Tooth Brushes. Japanese Standards Association: Tokyo, Japan, 1995; pp. 1–8. (In Japanese)

- Nygaard-Ostby, P.; Spydevold, B.; Edvardsen, S. Suggestion for a definition, measuring method and classification system of bristle stiffness of toothbrushes. Scand J. Dent. Res. 1979, 87, 159–170. [Google Scholar] [CrossRef]

- Yankell, S.L.; Shi, X.; Emling, R.C.; Loudin, S.; Homan, G.; Nelson, C.F. Laboratory evaluations of a toothbrush with diamond-shaped filaments for stiffness and efficacy. J. Clin. Dent. 2001, 12, 112–115. [Google Scholar] [PubMed]

- Rawls, H.R.; Mkwayi-Tulloch, N.J.; Krull, M.E. A mathematical model for predicting toothbrush stiffness. Dent. Mater. 1990, 6, 111–117. [Google Scholar] [CrossRef]

- Broitman, E. Indentation hardness measurements at micro-, macro-, and nanoscale: A critical overview. Tribol. Lett. 2017, 65, 23. [Google Scholar] [CrossRef] [Green Version]

- Colombo, M.; Gallo, S.; Poggio, C.; Ricaldone, V.; Arciola, C.R.; Scribante, A. New Resin-Based Bulk-Fill Composites: In vitro Evaluation of Micro-Hardness and Depth of Cure as Infection Risk Indexes. Materials 2020, 13, 1308. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Turgut, M.D.; Keçeli, T.I.; Tezel, B.; Cehreli, Z.C.; Dolgun, A.; Tekçiçek, M. Number, length and end-rounding quality of bristles in manual child and adult toothbrushes. Int. J. Paediatr. Dent. 2011, 21, 232–239. [Google Scholar] [CrossRef] [PubMed]

- Zanatta, F.B.; Bergoli, A.D.; Werle, S.B.; Antoniazzi, R.P. Biofilm removal and gingival abrasion with medium and soft toothbrushes. Oral Health Prev Dent. 2011, 9, 177–183. [Google Scholar]

- Ranzan, N.; Muniz, F.W.M.G.; Rösing, C.K. Are bristle stiffness and bristle end-shape related to adverse effects on soft tissues during toothbrushing? A systematic review. Int. Dent. J. 2019, 69, 171–182. [Google Scholar] [CrossRef] [Green Version]

- Danser, M.M.; Timmerman, M.F.; IJzerman, Y.; Bulthuis, H.; van der Velden, U.; van der Weijden, G.A. Evaluation of the incidence of gingival abrasion as a result of toothbrushing. J. Clin. Periodontol. 1998, 25, 701–706. [Google Scholar] [CrossRef]

- Silverstone, L.M.; Featherstone, M.J. A scanning electron microscope study of the end rounding of bristles in eight toothbrush types. Quintessence Int. 1988, 19, 87–107. [Google Scholar]

- Lee, H.S.; Jung, H.I.; Kang, S.M.; Kim, H.E.; Kim, B.I. Evaluation of the bristle end-rounding patterns of children’s toothbrushes using scanning electron microscopy and stereomicroscopy. Int. J. Dent. Hyg. 2017, 15, 120–127. [Google Scholar] [CrossRef]

- Van Nüss, K.; Friedl, K.H.; Hiller, K.A.; Hornecker, E.; Mausberg, R.F.; Ziebolz, D. Investigation of wear in manual toothbrushes from different price categories. Schweiz Monatsschr Zahnmed. 2010, 120, 750–763. (In German) [Google Scholar]

- Jung, M.; Koçkapan, C.; Wetzel, W.E. Bristle end rounding of manual toothbrushes and reproducibility of end rounding classification. Am. J. Dent. 2003, 16, 299–304. [Google Scholar] [PubMed]

- Jung, M.; Soydan, N.; Rubbert, F.; Wetzel, W.E. Quality of bristle end-rounding on replaceable heads of powered toothbrushes. J. Clin. Periodontol. 2005, 32, 604–609. [Google Scholar] [CrossRef] [PubMed]

- Meyer-Lueckel, H.; Kielbassa, A.M.; Renz, H.; Hopfenmuller, W. Bristle end-rounding in toothbrushes: A comparison of different evaluation techniques, bristle position and viewing angle. J. Clin. Dent. 2004, 15, 22–27. [Google Scholar] [PubMed]

- Meyer-Lueckel, H.; Rieben, A.S.; Kielbassa, A.M. Filament end-rounding quality in electric toothbrushes. J. Clin. Periodontol. 2005, 32, 29–32. [Google Scholar] [CrossRef]

- Rawls, H.R.; Smith, N.K.; Lentz, D.L.; Cobb, G.W., Jr.; Bailey, M.S. An electron microscopic comparison of bristle end-rounding of three commercial toothbrushes. J. Clin. Dent. 1993, 4, 96–100. [Google Scholar]

- Hamza, B.; Tanner, M.; Körner, P.; Attin, T.; Wegehaupt, F.J. Effect of toothbrush bristle stiffness and toothbrushing force on the abrasive dentine wear. Int. J. Dent. Hyg. 2021, 19, 355–359. [Google Scholar] [CrossRef]

- Watanabe, T.; Kobayashi, K. Recent toothbrush circumstances―Why is it wide flocking toothbrush now? J. Jpn. Soc. Periodontol. 2018, 60, 87–94. (In Japanese) [Google Scholar] [CrossRef] [Green Version]

| Top Tuft | Bottom Tuft | ||

|---|---|---|---|

| Mean ± SD (mm/mN) | Mean ± SD (mm/mN) | p-Value † | |

| M0 | 0.010 ± 0.002 | 0.011 ± 0.003 | <0.05 |

| M1 | 0.014 ± 0.002 | 0.012 ± 0.002 | <0.01 |

| M2 | 0.015 ± 0.002 | 0.012 ± 0.002 | <0.01 |

| M3 | 0.013 ± 0.004 | 0.017 ± 0.003 | <0.001 |

| Top Tuft | Bottom Tuft | ||

|---|---|---|---|

| Mean ± SD (mm2) | Mean ± SD (mm2) | p-Value † | |

| M0 | 2.80 ± 0.60 | 2.72 ± 0.52 | N.S. |

| M1 | 3.28 ± 0.72 | 3.18 ± 0.81 | N.S. |

| M2 | 3.56 ± 0.78 | 3.41 ± 1.01 | N.S. |

| M3 | 3.94 ± 1.07 | 3.95 ± 1.31 | N.S. |

| Top Tuft | Bottom Tuft | ||

|---|---|---|---|

| Mean ± SD | Mean ± SD | p-Value † | |

| M0 | 1.10 ± 0.09 | 1.06 ± 0.06 | N.S. |

| M1 | 1.07 ± 0.23 | 1.07 ± 0.07 | N.S. |

| M2 | 1.16 ± 0.38 | 1.13 ± 0.13 | N.S. |

| M3 | 1.21 ± 0.41 | 1.18 ± 0.28 | N.S. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaneyasu, Y.; Shigeishi, H.; Ohta, K.; Sugiyama, M. Analysis of the Deflection, Bristle Splaying, and Abrasion of a Single Tuft of a Polybutylene Terephthalate Toothbrush after Use: A Randomized Controlled Trial. Materials 2022, 15, 4890. https://doi.org/10.3390/ma15144890

Kaneyasu Y, Shigeishi H, Ohta K, Sugiyama M. Analysis of the Deflection, Bristle Splaying, and Abrasion of a Single Tuft of a Polybutylene Terephthalate Toothbrush after Use: A Randomized Controlled Trial. Materials. 2022; 15(14):4890. https://doi.org/10.3390/ma15144890

Chicago/Turabian StyleKaneyasu, Yoshino, Hideo Shigeishi, Kouji Ohta, and Masaru Sugiyama. 2022. "Analysis of the Deflection, Bristle Splaying, and Abrasion of a Single Tuft of a Polybutylene Terephthalate Toothbrush after Use: A Randomized Controlled Trial" Materials 15, no. 14: 4890. https://doi.org/10.3390/ma15144890

APA StyleKaneyasu, Y., Shigeishi, H., Ohta, K., & Sugiyama, M. (2022). Analysis of the Deflection, Bristle Splaying, and Abrasion of a Single Tuft of a Polybutylene Terephthalate Toothbrush after Use: A Randomized Controlled Trial. Materials, 15(14), 4890. https://doi.org/10.3390/ma15144890