Comparison between Piezoelectric and Piezoresistive Wearable Gait Monitoring Techniques

Abstract

1. Introduction

- -

- introducing the most advanced force sensitive materials and discussing their potential integration into the current insole PSD sensors;

- -

- conducting a detailed comparison of piezoresistive and piezoelectric based insole PSD architectures;

- -

- explaining diseases features and providing reasonable advice for insole PSD prototypes/products design for diverse neural-skeleton diseases.

2. Mechanisms of Piezoresistive and Piezoelectric Techniques

2.1. Piezoresistive Sensing Mechanisms and Suitable Materials

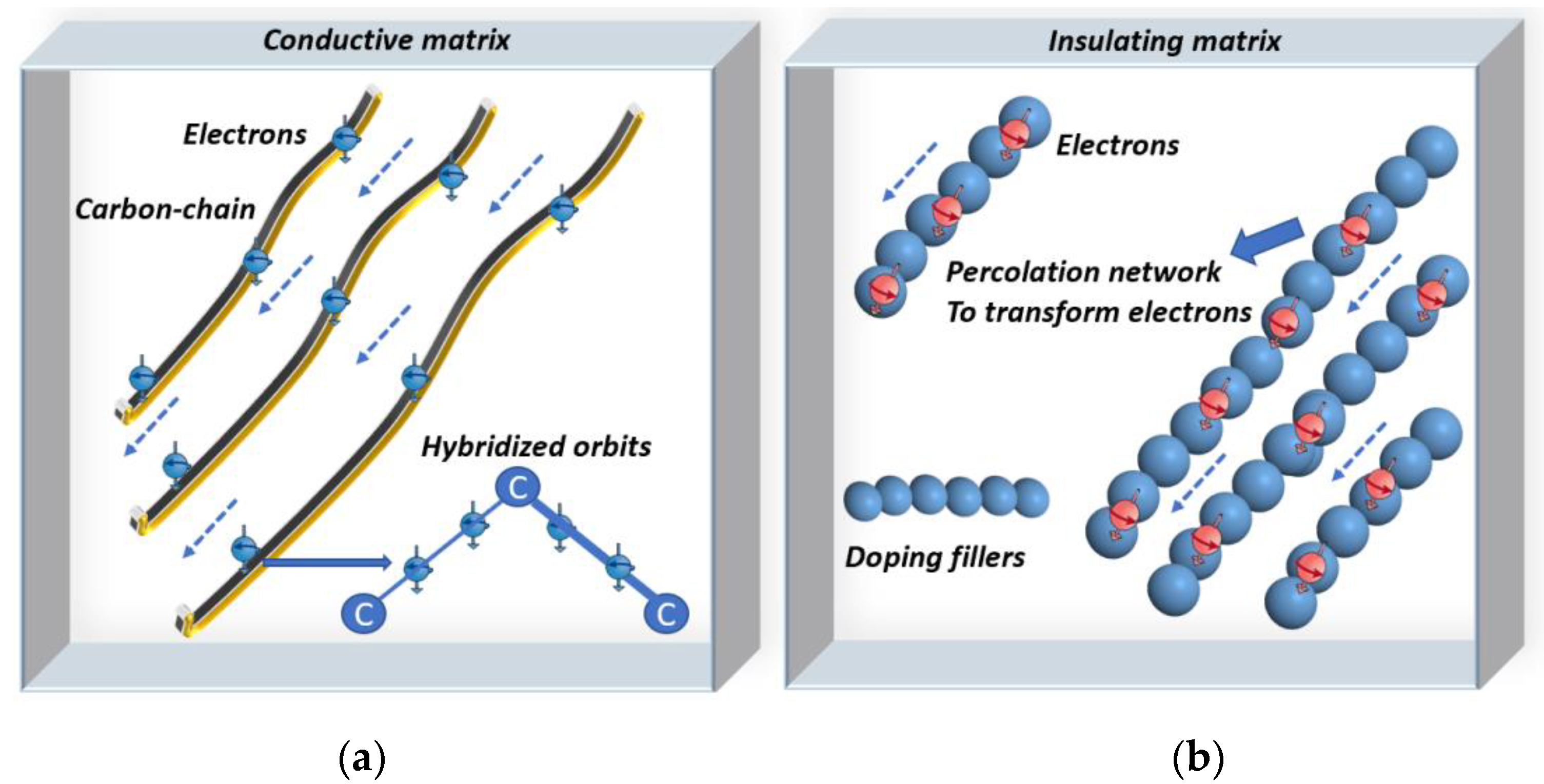

2.1.1. Piezoresistive Sensing Mechanism of Conductive Polymers

2.1.2. Piezoresistive Sensing Mechanism of Conductive Ink

2.1.3. Piezoresistive Sensing Mechanism of Metal Liquids

2.2. Piezoelectric Sensing Mechanisms and Suitable Materials

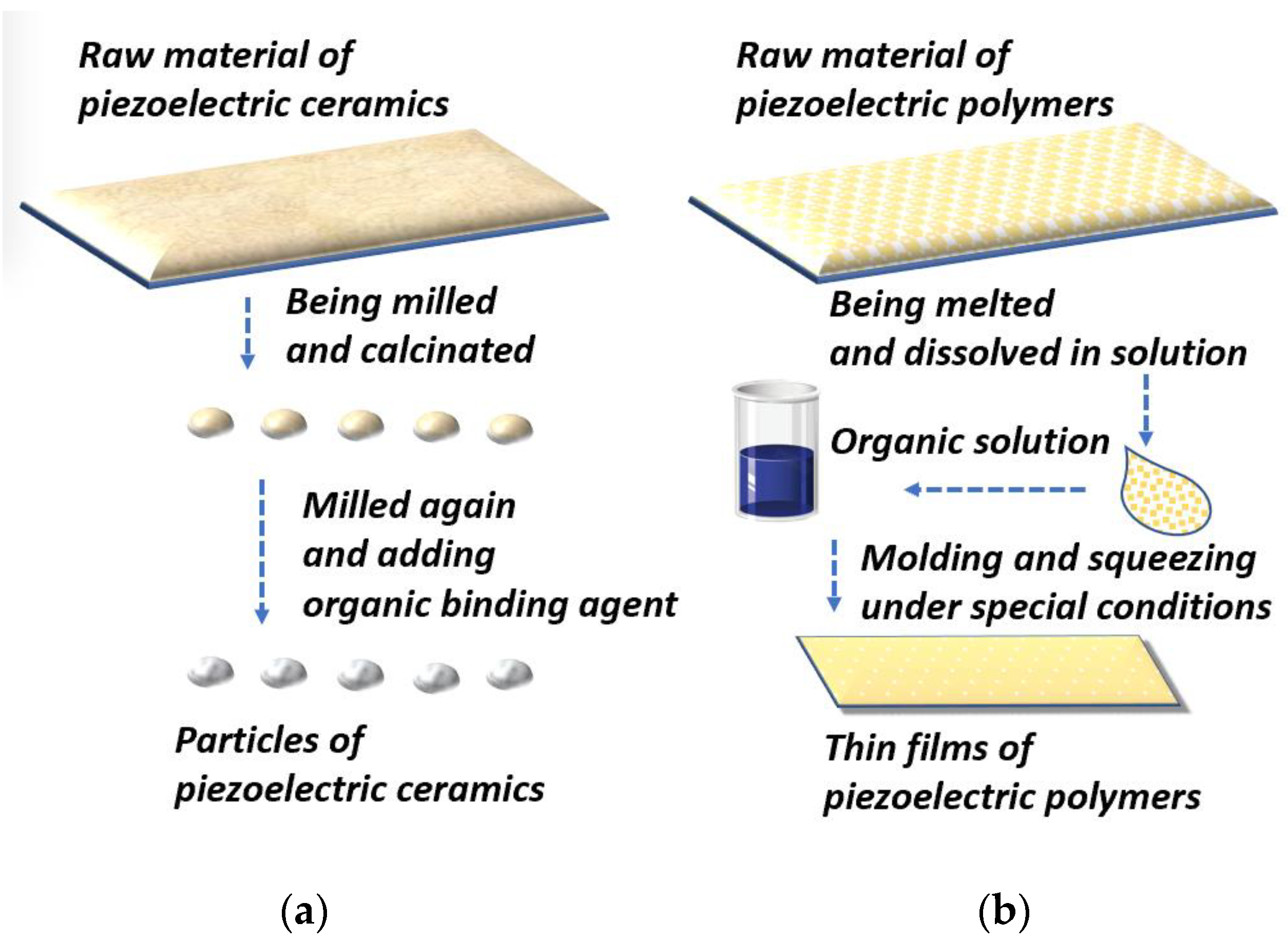

2.2.1. Piezoelectric Ceramics

2.2.2. Piezoelectric Polymers

3. Comparison and Review of Piezoresistive and Piezoelectric PSD Sensors

3.1. Review of Piezoresistive PSD Sensors for Gait Analysis

3.1.1. Conductive Foam and Related PSD Sensors

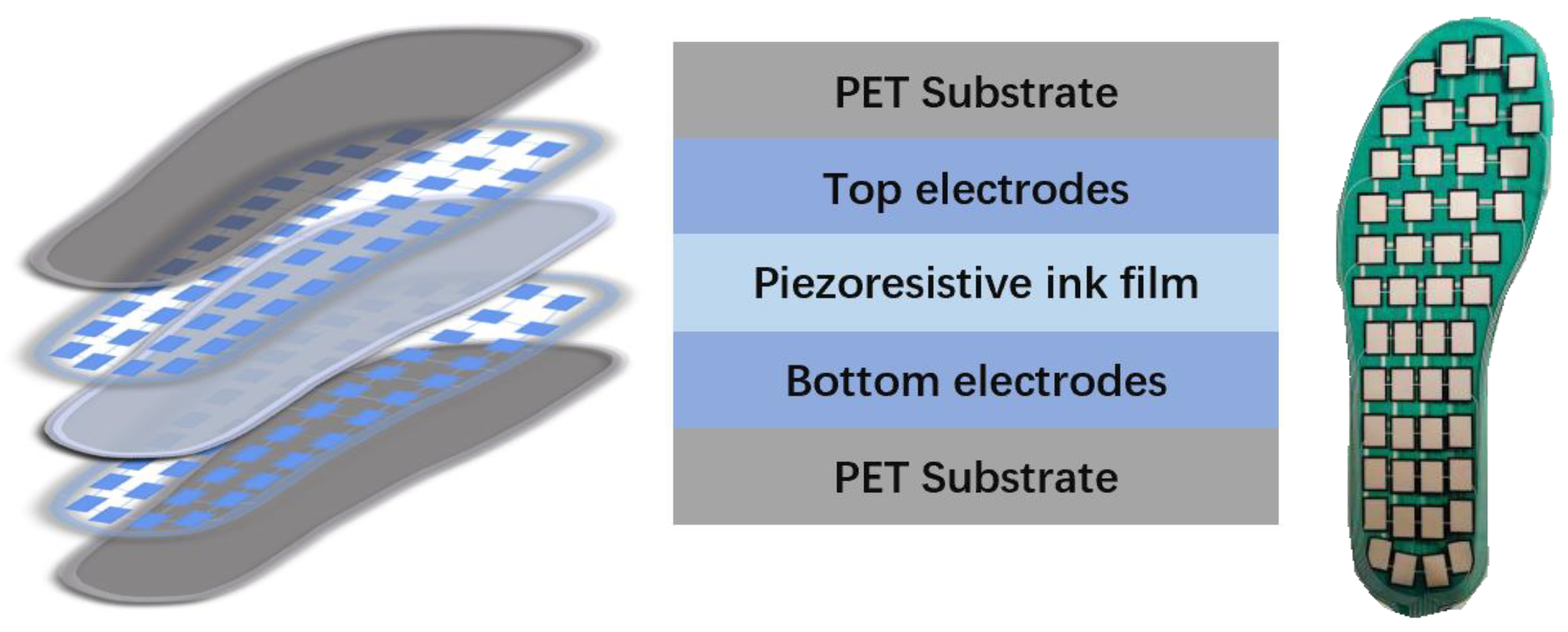

3.1.2. Conductive Ink and PSD Sensors

3.1.3. Metal Liquids and Related PSD Sensors

3.1.4. Current Commercial Piezoresistive PSD Sensors

3.1.5. Brief Summary of Piezoresistive PSD Sensors

3.2. Review of Piezoelectric PSD Sensors for Gait Analysis

3.2.1. Piezoelectric Ceramics and Related Piezoelectric PSD Sensors

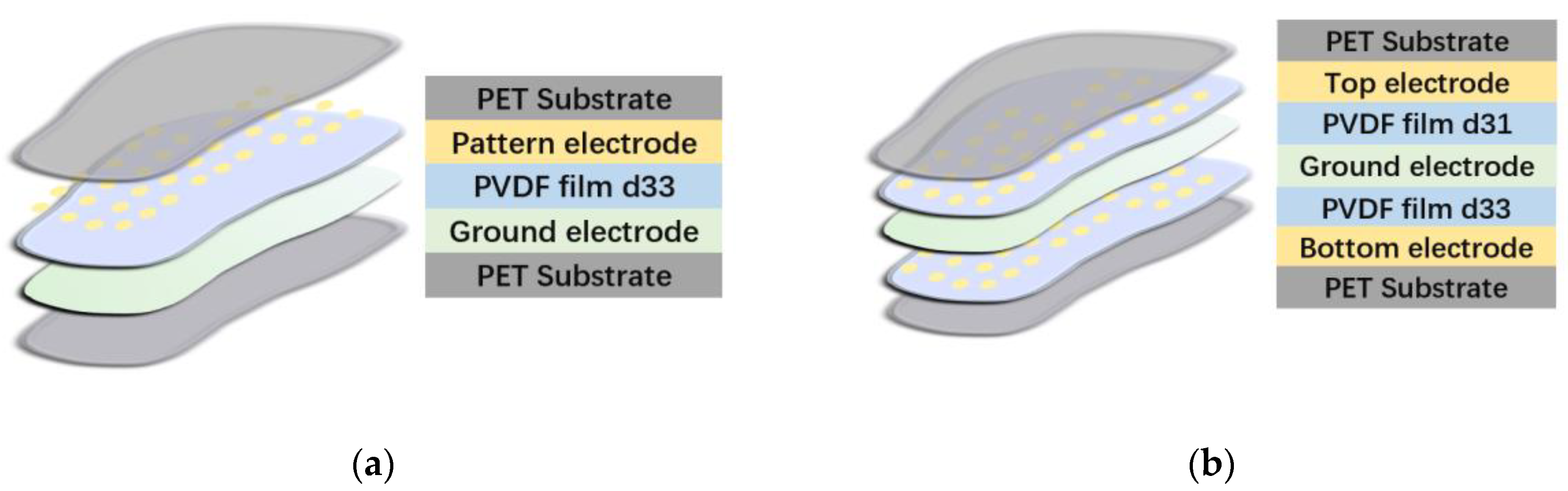

3.2.2. Piezoelectric Polymers and Related Piezoelectric PSD Sensors

3.2.3. Conclusions and Recent Commercial Progress of Piezoelectric PSD Sensors

3.3. Comparison of Piezoresistive and Piezoelectric Techniques

3.3.1. Mechanisms

3.3.2. Main Advantages and Drawbacks

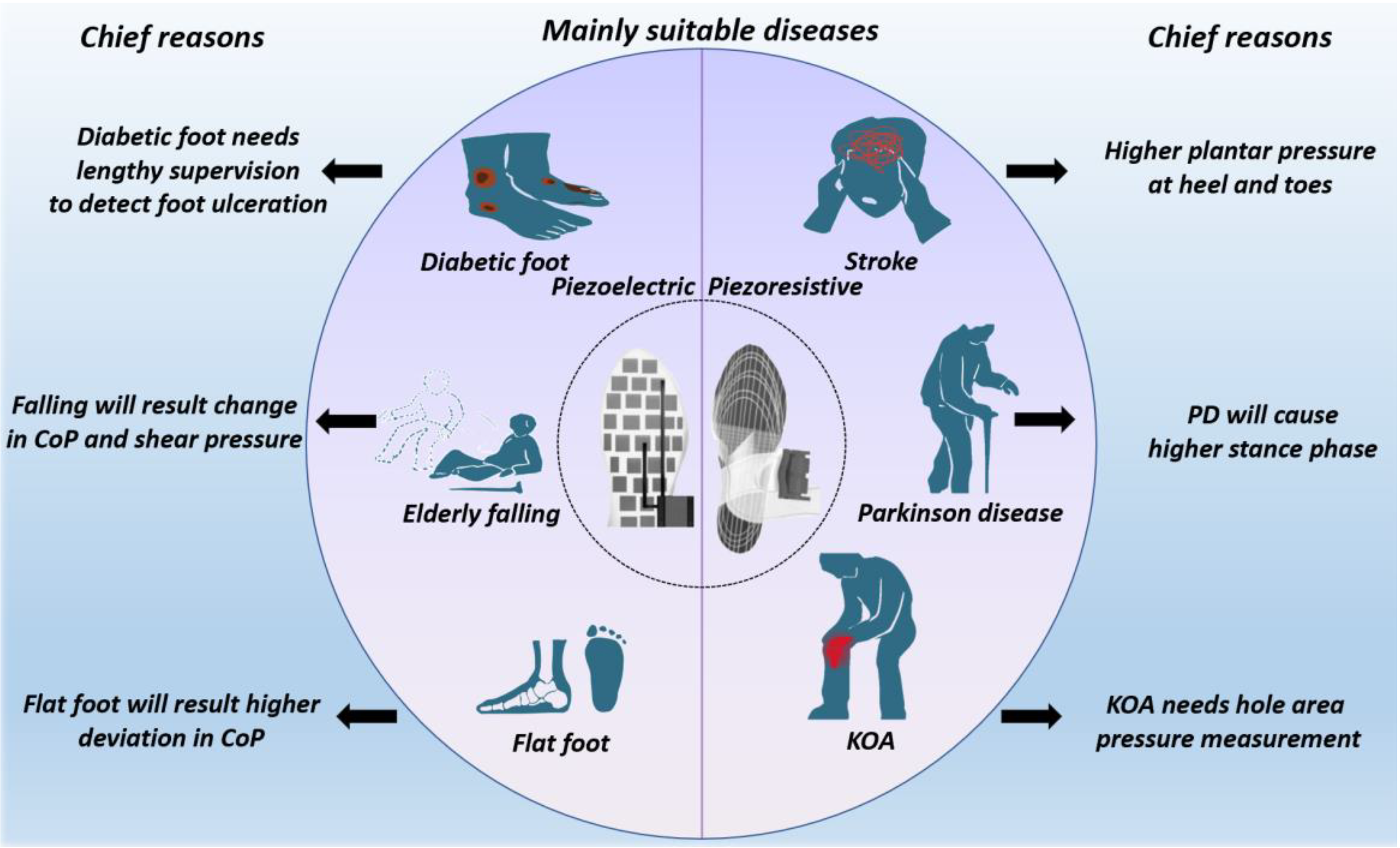

3.3.3. Chronic Diseases Suitable for Monitoring

4. Challenges

4.1. Application Challenges

4.2. Limitations of Sensing Materials

5. Future Research Directions

5.1. Multi-Sensing-Based Self-Calibration Function

5.2. Digital Twin (DT) Technology

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- International Diabetes Federation. Diabetes Atlas 5th Edition. 2011. Available online: http://www.idf.org/media-events/press-releases/2011/Diabetes-atlas-5th-edition (accessed on 26 April 2022).

- Logroscino, G. The role of early life environmental risk factors in Parkinson’s disease: What is the evidence? Environ. Health Perspect. 2005, 113, 1234–1238. [Google Scholar] [CrossRef] [PubMed]

- Moissenet, F.; Bélaise, C.; Piche, E.; Michaud, B.; Begon, M. An optimization method tracking EMG, ground reactions forces and marker trajectories for musculo-tendon forces estimation in equinus gait. Front. Neurorobot. 2019, 13, 48. [Google Scholar] [CrossRef] [PubMed]

- Radwan, A.; Sucasas, V.; Rodriguez, J.; André, P.S.; Antunes, P.F. Insole optical fiber sensor architecture for remote gait analysis—An e-health solution. IEEE Internet Things J. 2017, 6, 207–214. [Google Scholar]

- Boulton, A.; Betts, R.; Franks, C.; Newrick, P.; Ward, J.; Duckworth, T. Abnormalities of foot pressure in early diabetic neuropathy. Diabet. Med. 1987, 4, 225–228. [Google Scholar] [CrossRef] [PubMed]

- Grandez, K.; Bustamante, P.; Solas, G.; Gurutzeaga, I.; García-Alonso, A. Wearable wireless sensor for the gait monitorization of Parkinsonian patients. In Proceedings of the 2009 16th IEEE International Conference on Electronics, Circuits and Systems—(ICECS 2009), Tunisia, Turkey, 13–16 December 2009; pp. 215–218. [Google Scholar] [CrossRef]

- Galli, M.; Cimolin, V.; Crugnola, V.; Priano, L.; Menegoni, F.; Trotti, C.; Milano, E.; Mauro, A. Gait pattern in myotonic dystrophy (Steinert disease): A kinematic, kinetic and EMG evaluation using 3D gait analysis. J. Neurol. Sci. 2012, 314, 83–87. [Google Scholar] [CrossRef] [PubMed]

- Lim, E.; Tan, T.M.; Seet, R. LASER-Assisted Device (LAD) for start hesitation and freezing in Parkinson disease. Case Rep. Clin. Pract. Rev. 2006, 7, 92–95. [Google Scholar]

- Caliò, R.; Rongala, U.B.; Camboni, D.; Milazzo, M.; Stefanini, C.; De Petris, G.; Oddo, C.M. Piezoelectric energy harvesting solutions. Sensors 2014, 14, 4755–4790. [Google Scholar] [CrossRef]

- Kyeong, S.; Shin, W.; Yang, M.; Heo, U.; Feng, J.-R.; Kim, J. Recognition of walking environments and gait period by surface electromyography. Front. Inf. Technol. Electron. Eng. 2019, 20, 342–352. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, J.; Zhang, Y.; Liu, H.; Chen, Z.A.; Lu, Y.; Gao, S. Flexible and Wearable EMG and PSD Sensors Enabled Locomotion Mode Recognition for IoHT-Based In-Home Rehabilitation. IEEE Sens. J. 2021, 21, 26311–26319. [Google Scholar] [CrossRef]

- Gao, S.; Chen, J.-L.; Dai, Y.-N.; Wang, R.; Kang, S.-B.; Xu, L.-J. Piezoelectric-Based Insole Force Sensing for Gait Analysis in the Internet of Health Things. IEEE Consum. Electron. Mag. 2020, 10, 39–44. [Google Scholar] [CrossRef]

- Huang, H.; Wang, Z.; Zhao, W.; Zhu, Z.; Lin, W.; Peng, Z. A Facile Low-Cost Wireless Self-Powered Footwear System for Monitoring Plantar Pressure. In Proceedings of the 2021 IEEE 16th International Conference on Nano/Micro Engineered and Molecular Systems (NEMS), Xiamen, China, 25–29 April 2021. [Google Scholar]

- Fei, F.; Leng, Y.; Yang, M.; Wu, C.; Yang, D. Development of A Wearable Human Gait Analysis System Based on Plantar Pressure Sensors. In Proceedings of the 2019 The 2nd International Conference on Micro/Nano Sensors for AI, Healthcare, and Robotics (NSENS), Shenzhen, China, 31 October–2 November 2019. [Google Scholar]

- Noda, K.; Iwase, E.; Matsumoto, K.; Shimoyama, I. Stretchable liquid tactile sensor for robot-joints. In Proceedings of the 2010 IEEE International Conference on Robotics and Automation, Anchorage, Alaska, 3–8 May 2010. [Google Scholar]

- Jung, K.C.; Son, J.H.; Chang, S.H. Self-Powered Smart Shoes with Tension-Type Ribbon Harvesters and Sensors. Adv. Mater. Technol. 2021, 6, 2000872. [Google Scholar] [CrossRef]

- Zhao, Z.; Li, Q.; Dong, Y.; Gong, J.; Li, Z.; Qiao, X.; Zhang, J. A wearable sensor based on gold nanowires/textile and its integrated smart glove for motion monitoring and gesture expression. Energy Technol. 2021, 9, 2100166. [Google Scholar] [CrossRef]

- Chen, C.-T.; Lee, W.-Y.; Shen, T.-L.; Wu, H.-C.; Shih, C.-C.; Ye, B.-W.; Lin, T.-Y.; Chen, W.-C.; Chen, Y.-F. Highly reliable and sensitive tactile transistor memory. Adv. Electron. Mater. 2017, 3, 1600548. [Google Scholar] [CrossRef]

- Shi, X.; Cheng, C.H.; Zheng, Y.; Wai, P.K.A. An EGaIn-based flexible piezoresistive shear and normal force sensor with hysteresis analysis in normal force direction. J. Micromech. Microeng. 2016, 26, 105020. [Google Scholar] [CrossRef]

- Son, Y.H.; Kweon, S.Y.; Kim, S.J.; Kim, Y.M.; Hong, T.W.; Lee, Y.G. Fabrication and electrical properties of PZT-PVDF 0–3 type composite film. Integr. Ferroelectr. 2007, 88, 44–50. [Google Scholar] [CrossRef]

- Almusallam, A.; Luo, Z.; Komolafe, A.; Yang, K.; Robinson, A.; Torah, R.; Beeby, S. Flexible piezoelectric nano-composite films for kinetic energy harvesting from textiles. Nano Energy 2017, 33, 146–156. [Google Scholar] [CrossRef]

- Dai, Y.; Xie, Y.; Chen, J.; Kang, S.; Xu, L.; Gao, S. A lamination-based piezoelectric insole gait analysis system for massive production for Internet-of-health things. Int. J. Distrib. Sens. Netw. 2020, 16, 1550147720905431. [Google Scholar] [CrossRef]

- Zhao, G.; Zhang, X.; Cui, X.; Wang, S.; Liu, Z.; Deng, L.; Li, L. Piezoelectric polyacrylonitrile nanofiber film-based dual-function self-powered flexible sensor. ACS Appl. Mater. Interfaces 2018, 10, 15855–15863. [Google Scholar] [CrossRef]

- Chen, J.; Dai, Y.; Grimaldi, N.S.; Lin, J.; Hu, B.; Wu, Y.; Gao, S. Risk of falling assessment on different types of ground using the instrumented TUG. In Proceedings of the 2015 IEEE International Conference on Systems, Man, and Cybernetics, Hong Kong, China, 9–12 October 2015. [Google Scholar]

- Chen, J.-L.; Dai, Y.-N.; Grimaldi, N.S.; Lin, J.-J.; Hu, B.-Y.; Wu, Y.-F.; Gao, S. Plantar Pressure-Based Insole Gait Monitoring Techniques for Diseases Monitoring and Analysis: A Review. Adv. Mater. Technol. 2022, 7, 2100566. [Google Scholar] [CrossRef]

- Shuo, G.; Dai, Y.; Nathan, A. Tactile and Vision Perception for Intelligent Humanoids. Adv. Intell. Syst. 2022, 4, 2100074. [Google Scholar]

- Nauman, S. Piezoresistive sensing approaches for structural health monitoring of polymer composites—A review. Energy 2021, 2, 197–226. [Google Scholar] [CrossRef]

- Yakhmi, J.V.; Saxena, V.; Aswal, D.K. 2—Conducting Polymer Sensors, Actuators and Field-Effect Transistors. In Functional Materials; Banerjee, S., Tyagi, A.K., Eds.; Elsevier: London, UK, 2012; pp. 61–110. [Google Scholar]

- Ma, Z.; Shi, W.; Yan, K.; Pan, L.; Yu, G. Doping engineering of conductive polymer hydrogels and their application in advanced sensor technologies. Chem. Sci. 2019, 10, 6232–6244. [Google Scholar] [CrossRef] [PubMed]

- Michael, Z.; Grainger, L. Additive manufacturing of metallic materials. In Additive Manufacturing; Butterworth-Heinemann: Oxford, UK, 2018; pp. 53–103. [Google Scholar]

- Yoo, J.; Kim, D.-Y.; Kim, H.; Hur, O.-N.; Park, S.-H. Comparison of Pressure Sensing Properties of Carbon Nanotubes and Carbon Black Polymer Composites. Materials 2022, 15, 1213. [Google Scholar] [CrossRef] [PubMed]

- Cheung, Y.-N.; Zhu, Y.; Cheng, C.-H.; Chao, C.; Leung, W.W.-F. A novel fluidic strain sensor for large strain measurement. Sens. Actuators A 2008, 147, 401–408. [Google Scholar] [CrossRef]

- Shi, X.; Ching, H.S.; Chen, C.; Like, W.; Yongping, Z. A piezoresistive normal and shear force sensor using liquid metal alloy as gauge material. In Proceedings of the 2012 7th IEEE International Confenrence on Nano/Micro Engineered and Molecular Systems (NEMS), Kyoto, Japan, 5–8 March 2012; pp. 483–486. [Google Scholar]

- Shi, X.; Cheng, C.-H. Artificial hair cell sensors using liquid metal alloy as piezoresistors. In Proceedings of the 2013 8th IEEE International Conference on Nano/Micro Engineered and Molecular Systems (NEMS), Suzhou, China, 7–10 April 2013; pp. 978–981. [Google Scholar]

- Goldacker, T.; Abetz, V.; Stadler, R.; Erukhimovich, I.; Leibler, L.J.N. Non-centrosymmetric superlattices in block copolymerlends. Nature 1999, 398, 137–139. [Google Scholar] [CrossRef]

- Briscoe, J.; Jalali, N.; Woolliams, P.; Stewart, M.; Weaver, P.M.; Cain, M.; Dunn, S. Measurement techniques for piezoelectric nanogenerators. Energy Environ. Sci. 2013, 6, 3035–3045. [Google Scholar] [CrossRef]

- Gao, S. A Multi-Functional Touch Panel for Multi-Dimensional Sensing in Interactive Displays. Master’s Thesis, University of Cambridge, Cambridge, UK, 2017. [Google Scholar]

- Berlincourt, D.; Jaffe, H.; Shiozawa, L.R. Electroelastic Properties of the Sulfides, Selenides, and Tellurides of Zinc and Cadmium. Phys. Rev. 1963, 129, 1009–1017. [Google Scholar] [CrossRef]

- Mariani, B.; Rouhani, H.; Crevoisier, X.; Aminian, K. Quantitative estimation of foot-flat and stance phase of gait using foot-worn inertial sensors. Gait Posture 2013, 37, 229–234. [Google Scholar] [CrossRef]

- Navneet, S.; Anand, S.C.; Shah, T.H. Energy harvesting and storage textiles. In Handbook of Technical Textiles; Woodhead Publishing: Sawston, UK, 2016; pp. 357–396. [Google Scholar]

- Soin, N.; Shah, T.H.; Anand, S.C.; Geng, J.; Pornwannachai, W.; Mandal, P.; Siores, E. Novel 3-D spacer all fibre piezoelectric textiles for energy harvesting applications. Energy Environ. Sci. 2014, 7, 1670–1679. [Google Scholar] [CrossRef]

- Qi, Y.; McAlpine, M.C. Nanotechnology-enabled flexible and biocompatible energy harvesting. Energy Environ. Sci. 2010, 3, 1275–1285. [Google Scholar] [CrossRef]

- Almusallam, A.; Torah, R.N.; Zhu, D.; Tudor, M.J.; Beeby, S.P. Screen-printed piezoelectric shoe-insole energy harvester using an improved flexible PZT-polymer composites. J. Phys. Conf. Ser. 2013, 476, 012108. [Google Scholar] [CrossRef]

- PZT about PZT-Properties. Available online: https://www.americanpiezo.com/piezo-theory/pzt.html (accessed on 18 April 2022).

- Sepehri, A. Development of Micro 3D Structured Polyvinylidene Fluoride (PVDF) Thin Film. Master’s Thesis, San Diego State University, San Diego, CA, USA, 2012. [Google Scholar]

- Polyvinylidene Fluoride (PVDF): Properties, Production, & Applications. Available online: https://matmatch.com/learn/material/polyvinylidene-fluoride-pvdf (accessed on 18 April 2022).

- Roopa, T.S.; Murty, N.; Swathi, H.S.; Angadi, G.; Harish, D.V.N. Synthesis and characterization of spin-coated clay/PVDF thin films. Bull. Mater. Sci. 2019, 42, 1–8. [Google Scholar] [CrossRef]

- Solvay, Processing Guide for Polymer Membranes, Technical Bulletin, Special Polymers. Available online: https://www.solvay.com/sites/g/files/srpend221/files/2018-08/Membranes-Processing-Guide_EN-v4.6_0.pdf. (accessed on 5 May 2022).

- Cho, D.; Park, J.; Kim, J.; Kim, T.; Kim, J.; Park, I.; Jeon, S. Three-dimensional continuous conductive nanostructure for highly sensitive and stretchable strain sensor. ACS Appl. Mater. Interfaces 2017, 9, 17369–17378. [Google Scholar] [CrossRef]

- Yan, X.; Bowen, C.R.; Yuan, C.; Hao, Z.; Pan, M. Carbon fibre based flexible piezoresistive composites to empower inherent sensing capabilities for soft actuators. Soft Matter 2019, 15, 8001–8011. [Google Scholar] [CrossRef]

- Ramalingame, R.; Hu, Z.; Gerlach, C.; Rajendran, D.; Zubkova, T.; Baumann, R.; Kanoun, O. Flexible piezoresistive sensor matrix based on a carbon nanotube PDMS composite for dynamic pressure distribution measurement. J. Sens. Sens. Syst. 2019, 8, 1–7. [Google Scholar] [CrossRef]

- Zhai, W.; Xia, Q.; Zhou, K.; Yue, X.; Ren, M.; Zheng, G.; Dai, K.; Liu, C.; Shen, C. Multifunctional flexible carbon black/polydimethylsiloxane piezoresistive sensor with ultrahigh linear range, excellent durability and oil/water separation capability. Chem. Eng. J. 2019, 372, 373–382. [Google Scholar] [CrossRef]

- Howell, A.M.; Kobayashi, T.; Hayes, H.A.; Foreman, K.B.; Bamberg, S.J.M. Kinetic gait analysis using a low-cost insole. IEEE Trans. Biomed. Eng. 2013, 60, 3284–3290. [Google Scholar] [CrossRef]

- Pineda-Lopez, F.; Guerra, A.; Montes, E.; Benítez, D. A low cost baropodometric system for children’s postural and gait analysis. In Proceedings of the IEEE Colombian Conference on Communication and Computing, Cartagena, Colombia, 19–27 April 2016; pp. 1–4. [Google Scholar]

- Bamberg, S.J.M.; LaStayo, P.; Dibble, L.; Musselman, J.; Raghavendra, S.K.D. Development of a quantitative in-shoe measurement system for assessing balance: Sixteen-sensor insoles. In Proceedings of the Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), New York, NY, USA, 30 August–3 September 2006; pp. 6041–6044. [Google Scholar]

- Koiva, R.; Zenker, M.; Schürmann, C.; Haschke, R.; Ritter, H.J. A highly sensitive 3D-shaped tactile sensor. In Proceedings of the 2013 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Wollongong, Australia, 9–12 July 2013. [Google Scholar]

- Grice, P.M.; Killpack, M.D.; Jain, A.; Vaish, S.; Hawke, J.; Kemp, C.C. Whole-arm tactile sensing for beneficial and acceptable contact during robotic assistance. In Proceedings of the 2013 IEEE 13th International Conference on Rehabilitation Robotics (ICORR), Seattle, WA, USA, 24–26 June 2013. [Google Scholar]

- Pang, G.; Deng, J.; Wang, F.; Zhang, J.; Pang, Z.; Yang, G. Development of flexible robot skin for safe and natural human–robot collaboration. Micromachines 2018, 9, 576. [Google Scholar] [CrossRef]

- Wang, Z.; Guan, X.; Huang, H.; Wang, H.; Lin, W.; Peng, Z. Full 3D Printing of Stretchable Piezoresistive Sensor with Hierarchical Porosity and Multimodulus Architecture. Adv. Funct. Mater. 2018, 29, 1807569. [Google Scholar] [CrossRef]

- Zhu, Q.; Zhang, Z.; Sun, Z.; Cai, B.; Cai, W. Importance of cations and anions from control agents in the synthesis of silver nanowires by polyol method. Appl. Phys. A 2016, 122, 1–7. [Google Scholar] [CrossRef]

- Akbar, A.A.; Derakhshi, M. The effect of FeCl3 in the shape control polyol synthesis of silver nanospheres and nanowires. J. Clust. Sci. 2015, 26, 1901–1910. [Google Scholar]

- Zhang, H.M.; Zhang, Y.; Zhang, J.W.; Ye, X.; Li, Y.Y.; Wang, P. Preparation and characterization of flexible pressure sensor based on silver nanowires/nonwoven fabric. Polym. Compos. 2021, 42, 2523–2530. [Google Scholar] [CrossRef]

- Deng, C.; Zhao, S.; Su, E.; Li, Y.; Wu, F. Trilayer MXene Fabric for Integrated Ultrasensitive Pressure Sensor and Wearable Heater. Adv. Mater. Technol. 2021, 6, 2100574. [Google Scholar] [CrossRef]

- Morley, R.E.; Richter, E.J.; Klaesner, J.W.; Maluf, K.S.; Mueller, M.J. In-Shoe Multisensory Data Acquisition System. IEEE Trans. Biomed. Eng. 2001, 48, 815–820. [Google Scholar] [CrossRef]

- Urry, S. Plantar pressure-measurement sensors. Meas. Sci. Technol. 1999, 10, R16–R32. [Google Scholar] [CrossRef]

- Yin, M.J.; Yin, Z.; Zhang, Y.; Zheng, Q.; Zhang, A.P. Micropatterned elastic ionic polyacrylamide hydrogel for low-voltage capacitive and organic thin-film transistor pressure sensors. Nano Energy 2019, 58, 96–104. [Google Scholar] [CrossRef]

- Hewson, D.J.; Singh, N.K.; Snoussi, H.; Duchêne, J. Classification of elderly as fallers and non-fallers using Centre of Pressure velocity. In Proceedings of the Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBS), Buenos Aires, Argentina, 31 August–4 September 2010; pp. 3678–3681. [Google Scholar]

- Miraoui, A.; Snoussi, H.; Duchêne, J.; Azzaoui, N. On the detection of elderly equilibrium degradation using multivariate-EMD. In Proceedings of the IEEE Globecom 2010 Workshop on Advances in Communications and Networks, Miami, FL, USA, 6–10 December 2010; pp. 2049–2053. [Google Scholar]

- Saito, I.; Okada, K.; Nishi, T.; Wakasa, M.; Saito, A.; Sugawara, K.; Takahashi, Y.; Kinoshita, K. Foot pressure pattern and its correlation with knee range of motion limitations for individuals with medial knee osteoarthritis. Arch. Phys. Med. Rehabil. 2013, 94, 2502–2508. [Google Scholar] [CrossRef]

- Morris, M.E.; Huxham, F.; McGinley, J.; Dodd, K.; Iansek, R. The biomechanics and motor control of gait in Parkinson disease. Clin. Biomech. 2001, 16, 459–470. [Google Scholar] [CrossRef]

- Downton, H.; Andrews, K. Prevalence, characteristics and factors associated with falls among the elderly living at home, Aging. Clin. Experim. Res. 1991, 3, 219–228. [Google Scholar]

- Wu, H.; Zhang, L.; Jiang, S.; Zhang, Y.; Zhang, Y.; Xin, C.; Ji, S.; Zhu, W.; Li, J.; Hu, Y.; et al. Ultrathin and high-stress-resolution liquid-metal-based pressure sensors with simple device structures. ACS Appl. Mater. Interfaces 2020, 12, 55390–55398. [Google Scholar] [CrossRef]

- Jovanov, E.; Wang, E.; Verhagen, L.; Fredrickson, M.; Fratangelo, R. deFOG—A real time system for detection and unfreezing of gait of Parkinsons patients. In Proceedings of the 2009 Annual International Conference of the IEEE Engineering in Medicine and Biology Society, Minneapolis, MN, USA, 2–6 September 2009; pp. 5151–5154. [Google Scholar] [CrossRef]

- Bachlin, M.; Plotnik, M.; Roggen, D.; Maidan, I.; Hausdorff, J.M.; Giladi, N.; Troster, G. Wearable Assistant for Parkinson’s Disease Patients with the Freezing of Gait Symptom. IEEE Trans. Inf. Technol. Biomed. 2010, 14, 436–446. [Google Scholar] [CrossRef] [PubMed]

- Tekscan Inc. Pressure Mapping, Force Measurement & Tactile Sensors. Available online: https://www.tekscan.com/products-solutions/systems/f-scan-system (accessed on 6 August 2020).

- Gerlach, C.; Krumm, D.; Illing, M.; Lange, J.; Kanoun, O.; Odenwald, S.; Hübler, A. Printed MWCNT-PDMS-composite pressure sensor system for plantar pressure monitoring in ulcer prevention. IEEE Sens. J. 2015, 15, 3647–3656. [Google Scholar] [CrossRef]

- Amemiya, A.; Noguchi, H.; Oe, M.; Sanada, H.; Mori, T. Establishment of a measurement method for in-shoe pressure and shear stress in specific regions for diabetic ulcer prevention. In Proceedings of the 2016 38th Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), Orlando, FL, USA, 16–20 August 2016; pp. 2291–2294. [Google Scholar]

- Orpyx, About Orpyx-Si. Available online: https://www.orpyx.com/about-orpyx-si (accessed on 16 April 2022).

- Organero, M.M.; Littlewood, C.; Parker, J.; Powell, L.; Grindell, C.; Mawson, S. Identification of Walking Strategies of People with Osteoarthritis of the Knee Using Insole Pressure Sensors. IEEE Sens. J. 2017, 17, 3909–3920. [Google Scholar] [CrossRef]

- Howell, A.M.; Kobayashi, T.; Chou, T.R.; Daly, W.; Orendurff, M.; Bamberg, S.J.M. A laboratory insole for analysis of sensor placement to determine ground reaction force and ankle moment in patients with stroke. In Proceedings of the 2012 Annual International Conference of the IEEE Engineering in Medicine and Biology Society, San Diego, CA, USA, 28 August–1 September 2012; pp. 6394–6397. [Google Scholar]

- Abdul-Razak, A.H.; Zayegh, A.; Begg, R.K.; Wahab, Y. Foot Plantar Pressure Measurement System: A Review. Sensors 2012, 12, 9884–9912. [Google Scholar] [CrossRef] [PubMed]

- Ferraresi, G.; Manca, M.; Leardini, A.; Marchi, P.; Cavazza, S.; Venturini, E.; Benedetti, M. Gait pattern classification in hemiplegic patients with equinus deformity. Gait Posture 2011, 33, S14–S15. [Google Scholar] [CrossRef]

- Zheng, E.; Manca, S.; Yan, T.; Parri, A.; Vitiello, N.; Wang, Q. Gait phase estimation based on noncontact capacitive sensing and adaptive oscillators. IEEE Trans. Biomed. Eng. 2017, 64, 2419–2430. [Google Scholar] [CrossRef]

- Bus, S.A.; Ulbrecht, J.S.; Cavanagh, P.R. Pressure relief and load redistribution by custom-made insoles. Clin. Biomech. 2004, 19, 629–638. [Google Scholar] [CrossRef]

- Chen, Q.; Britto, R.; Erill, I.; Jeffery, C.J.; Liberzon, A.; Magrane, M.; Onami, J.-I.; Robinson-Rechavi, M.; Sponarova, J.; Zobel, J.; et al. Quality Matters: Biocuration Experts on the Impact of Duplication and Other Data Quality Issues in Biological Databases. Genom. Proteom. Bioinform. 2020, 18, 91. [Google Scholar] [CrossRef]

- Zhu, D.; Almusallam, A.; Beeby, S.P.; Tudor, J.; Harris, N.R. A Bimorph multi-layer piezoelectric vibration energy harvester. In Proceedings of the PowerMEMS 2010, Leuven, Belgium, 1–3 December 2010. [Google Scholar]

- Dietze, M.; Es-Souni, M. Structural and functional properties of screen-printed PZTPVDF-TrFE composites. Sens. Actuators 2008, 143, 329–334. [Google Scholar] [CrossRef]

- Armstrong, D.G.; Peters, E.J.; Athanasiou, K.A.; Lavery, L.A. Is there a critical level of plantar foot pressure to identify patients at risk for neuropathic foot ulceration? J. Foot Ankle Surg. 1998, 37, 303–307. [Google Scholar] [CrossRef]

- Wahab, Y.; Zayegh, A.; Begg, R.K.; Veljanovski, R. Design of MEMS biomedical pressure sensor for gait analysis. In Proceedings of the 2008 IEEE International Conference on Semiconductor Electronics, Johor Bahru, Malaysia, 25–27 November 2008; pp. 166–169. [Google Scholar] [CrossRef]

- Merve, A.; Yıldız, A.F.; Bazzaz, F.H. Development of a soft PZT based tactile sensor array for force localization. In Proceedings of the 2017 XXVI International Conference on Information, Communication and Automation Technologies (ICAT), Sarajevo, Bosnia & Herzegovina, 26–28 October 2017. [Google Scholar]

- Edmonds, M.E.; Blundell, M.P.; Morris, M.E.; Thomas, E.M.; Cotton, L.T.; Watkins, P.J. Improved survival of the diabetic foot: The role of a specialized foot clinic. Q. J. Med. 1986, 60, 763–771. [Google Scholar] [PubMed]

- Rajala, S.; Mattila, R.; Kaartinen, I.; Lekkala, J. Designing, manufacturing and testing of a piezoelectric polymer film insole sensor for plantar pressure distribution measurements. IEEE Sens. J. 2017, 17, 6798–6805. [Google Scholar] [CrossRef]

- Gao, S.; Huang, C.-Y.; Wu, L. Piezoelectric material-based technique for concurrent force sensing and energy harvesting for interactive displays. In Proceedings of the 2017 IEEE Sensors, Glasgow, UK, 29 October–1 November 2018; pp. 1–3. [Google Scholar]

- Xin, Y.; Li, X.; Tian, H.; Guo, C.; Qian, C.; Wang, S.; Wang, C. Shoes-equipped piezoelectric transducer for energy harvesting: A brief review. Ferroelectrics 2016, 493, n12–n24. [Google Scholar] [CrossRef]

- Zhou, H.; Hu, H. Inertial sensors for motion detection of human upper limbs. Sens. Rev 2007, 27, 151–158. [Google Scholar] [CrossRef]

- Kärki, S.; Lekkala, J.; Kuokkanen, H.; Halttunen, J. Development of a piezoelectric polymer film sensor for plantar normal and shear stress measurements. Sens. Actuat. A Phys. 2009, 154, 57–64. [Google Scholar] [CrossRef]

- Yu, B.; Kang, S.Y.; Akthakul, A.; Ramadurai, N.; Pilkenton, M.; Patel, A.; Langer, R. An elastic second skin. Nat. Mater. 2016, 15, 911–918. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, Y.; Liu, Q.; Cheng, W.; Wang, X.; Pan, L.; Xu, H. A self-healable, highly stretchable, and solution processable conductive polymer composite for ultrasensitive strain and pressure sensing. Adv. Funct. Mater. 2018, 28, 1705551. [Google Scholar] [CrossRef]

- Oh, H.; Yi, G.-C.; Yip, M.; Dayeh, S.A. Scalable tactile sensor arrays on flexible substrates with high spatiotemporal resolution enabling slip and grip for closed-loop robotics. Sci. Adv. 2020, 6, eabd7795. [Google Scholar] [CrossRef]

- Li, H.; Song, H.; Long, M.; Saeed, G.; Lim, S. Mortise–tenon joint structured hydrophobic surface-functionalized barium titanate/polyvinylidene fluoride nanocomposites for printed self-powered wearable sensors. Nanoscale 2021, 13, 2542–2555. [Google Scholar] [CrossRef]

- Meng, X.; Li, Q.; Hu, Z.; Guo, M. Microfluidic fabrication of β-phase enriched poly (vinylidene fluoride) microfibers toward flexible piezoelectric sensor. J. Polym. Sci. 2022, 60, 1718–1726. [Google Scholar] [CrossRef]

- Choi, W.; Lee, J.; Kyoung Yoo, Y.; Kang, S.; Kim, J.; Hoon Lee, J. Enhanced sensitivity of piezoelectric pressure sensor with micro-structured polydimethylsiloxane layer. Appl. Phys. Lett. 2014, 104, 123701. [Google Scholar] [CrossRef]

- Chen, J.; Zhao, Y.; Lin, J.; Dai, Y.; Hu, B.; Gao, S. A Flexible Insole Gait Monitoring Technique for the Internet of Health Things. IEEE Sens. J. 2021, 21, 26397–26405. [Google Scholar] [CrossRef]

- Van Meulen, F.B.; Weenk, D.; Buurke, J.H.; van Beijnum, B.-J.F.; Veltink, P.H. Ambulatory assessment of walking balance after stroke using instrumented shoes. J. Neuroeng. Rehabil. 2016, 13, 48. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Mariani, B.; Jiménez, M.C.; Vingerhoets, F.J.G.; Aminian, K. On-shoe wearable sensors for gait and turning assessment of patients with Parkinson’s disease. IEEE Trans. Biomed. Eng. 2013, 60, 155–158. [Google Scholar] [CrossRef] [PubMed]

- Alam, U.; Riley, D.R.; Jugdey, R.S.; Azmi, S.; Rajbhandari, S.; D’Août, K.; Malik, R.A. Diabetic neuropathy and gait: A review. Diabetes Ther. 2017, 8, 1253–1264. [Google Scholar] [CrossRef] [PubMed]

- Lam, Y.-H.; Ki, W.-H.; Tsui, C.-Y. Integrated low-loss CMOS active rectifier for wirelessly powered devices. IEEE Trans. Circuits Syst. II Exp. Briefs 2006, 53, 1378–1382. [Google Scholar] [CrossRef]

- Yanning, D.; Wang, J.; Gao, S. Advanced Electronics and Artificial Intelligence: Must-Have Technologies Toward Human Body Digital Twins. Adv. Intell. Syst. 2022, 2100263. [Google Scholar] [CrossRef]

- Lee, G.-H.; Moon, H.; Kim, H.; Lee, G.H.; Kwon, W.; Yoo, S.; Myung, D.; Yun, S.H.; Bao, Z.; Hahn, S.K. Multifunctional materials for implantable and wearable photonic healthcare devices. Nat. Rev. Mater. 2020, 5, 149–165. [Google Scholar] [CrossRef]

- Jordan, M.I.; Mitchell, T.M. Machine learning: Trends, perspectives, and prospects. Science 2015, 349, 255–260. [Google Scholar] [CrossRef]

| Type of Material | Sensing Material | Parameters | Main Advantages and Drawbacks |

|---|---|---|---|

| Conductive foam [13] | TPU | Range: 20 Pa–1.2 Mpa | Simpler fabrication |

| CB | 32 sensors in a matrix | Higher stretchability | |

| NaCl | Sensor size: 7.57.5 mm2 | Higher conductivity | |

| Conductive fabrics [14] | RFP film | Range: 0–400 N | Higher repeatability |

| 8 round sensors | Lower hysteresis | ||

| Sensor diameter: 8 mm | Potential toxicity | ||

| Conductive ink [16] | PDMS | Sensitivity: 0.5–2.5 Kg | Wider use |

| MWCNT | 4 sensors in a matrix | Higher sensitivity | |

| Sensor size: 2015 mm2 | Higher plasticity | ||

| Conductive ink [17] | PDMS | Sensitivity: 0.29 Kpa | Higher sensitivity |

| Au-NWS | Range: 0–15 Kpa | Higher stretchability | |

| Metal liquids [19] | EGaIn PDMS | Sensitivity: 2N Sensor size: 22 mm2 | Higher hysteresis Higher sensitivity Shear force detection |

| Type of Material | Utilized Material | Parameter | Main Advantages and Drawbacks |

|---|---|---|---|

| Ceramics [20] | Diameters of particles: ≥ 0.3 μm | High conductivity | |

| ECS-PolyPZT Al | = 29 Pc/N | Medium flexibility Larger particle diameters | |

| Ceramics [21] | PZT Ferroperm | Diameters of particles < 0.3 μm = 36 Pcma/N Sensitivity: 0.4 Mv/N | High flexibility More complex production Smaller particle diameters |

| Polymers [22] | Copper | Sensitivity: 0.056 N | Only normal stress |

| PVDF Patterned electrodes | around 60 Pc/N | Higher sensitivity Simpler fabrication | |

| Polymers [12] | Copper | Normal sensitivity: 0.056 N | Higher and wider sensitivity |

| 2 layers of PVDF Patterned electrodes | Shear sensitivity: 0.174 N and around 60 Pc/N | Higher stability Simpler use | |

| Micro-structure Materials [98] | ZnO/PZT PDMS as substrate layer | Sensitivity: 0.293 Kpa = 69 Pc/N Sensing range: 0.2–500 Kpa | Higher coefficients Simpler fabrication Higher sensing range |

| Technique | Basic Mechanisms | Main Advantages | Main Drawbacks |

|---|---|---|---|

| Changing resistivity under external force. [25,26] | Near linear correlation; | Changing modulus decreases accuracy in walking. [14] | |

| Piezoresistive | static force measurement. [16,17] | ||

| Sensing | Adjusting conductivity to form piezoresistive material. [4,24] | Higher sensing range; higher sensitivity. [16,17,19] | Potential hysteresis; [14,19] sensitive to temperature. [26,27] |

| Polarization under external force in each direction. [34,37] | Shear force measurement; | Complex fabrication | |

| Piezoelectric | simpler structure. [22,98] | sensitive to small forces. [20,21] | |

| Sensing | Reversal charges accumulation under impact of force. [35,36] | Feasible charges harvest; | Potential current leakage under static force. [102] |

| less energy consumed. [12] |

| Technique | Challenges | Reasons |

|---|---|---|

| Piezoresistive | Decreasing sensitivity in utilization [4,30] | Hysteresis will decrease accuracy during utilization [30] |

| Sensing | Sensitive to temperature change [26,27,28]; | Temperature changes conductivity [26,28] |

| limited detecting directions [31,32] | Materials cannot detect shear force [31,32] | |

| Piezoelectric | Influencing accuracy in static PSD [12,22] | both exist in one PVDF layer [12,22] |

| Sensing | Sensitive to temperature change [95] | The pyroelectric effect will decrease the charges on the surface [95] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Xu, Z.; Chen, W.; Gao, S. Comparison between Piezoelectric and Piezoresistive Wearable Gait Monitoring Techniques. Materials 2022, 15, 4837. https://doi.org/10.3390/ma15144837

Zhang Z, Xu Z, Chen W, Gao S. Comparison between Piezoelectric and Piezoresistive Wearable Gait Monitoring Techniques. Materials. 2022; 15(14):4837. https://doi.org/10.3390/ma15144837

Chicago/Turabian StyleZhang, Zhiyuan, Zhenyu Xu, Wenbin Chen, and Shuo Gao. 2022. "Comparison between Piezoelectric and Piezoresistive Wearable Gait Monitoring Techniques" Materials 15, no. 14: 4837. https://doi.org/10.3390/ma15144837

APA StyleZhang, Z., Xu, Z., Chen, W., & Gao, S. (2022). Comparison between Piezoelectric and Piezoresistive Wearable Gait Monitoring Techniques. Materials, 15(14), 4837. https://doi.org/10.3390/ma15144837