The Use of Miniature Specimens to Determine Local Properties and Fracture Behavior of LPBF-Processed Inconel 718 in as-Deposited and Post-Treated States

Abstract

:1. Introduction

2. Materials, Methods and Results

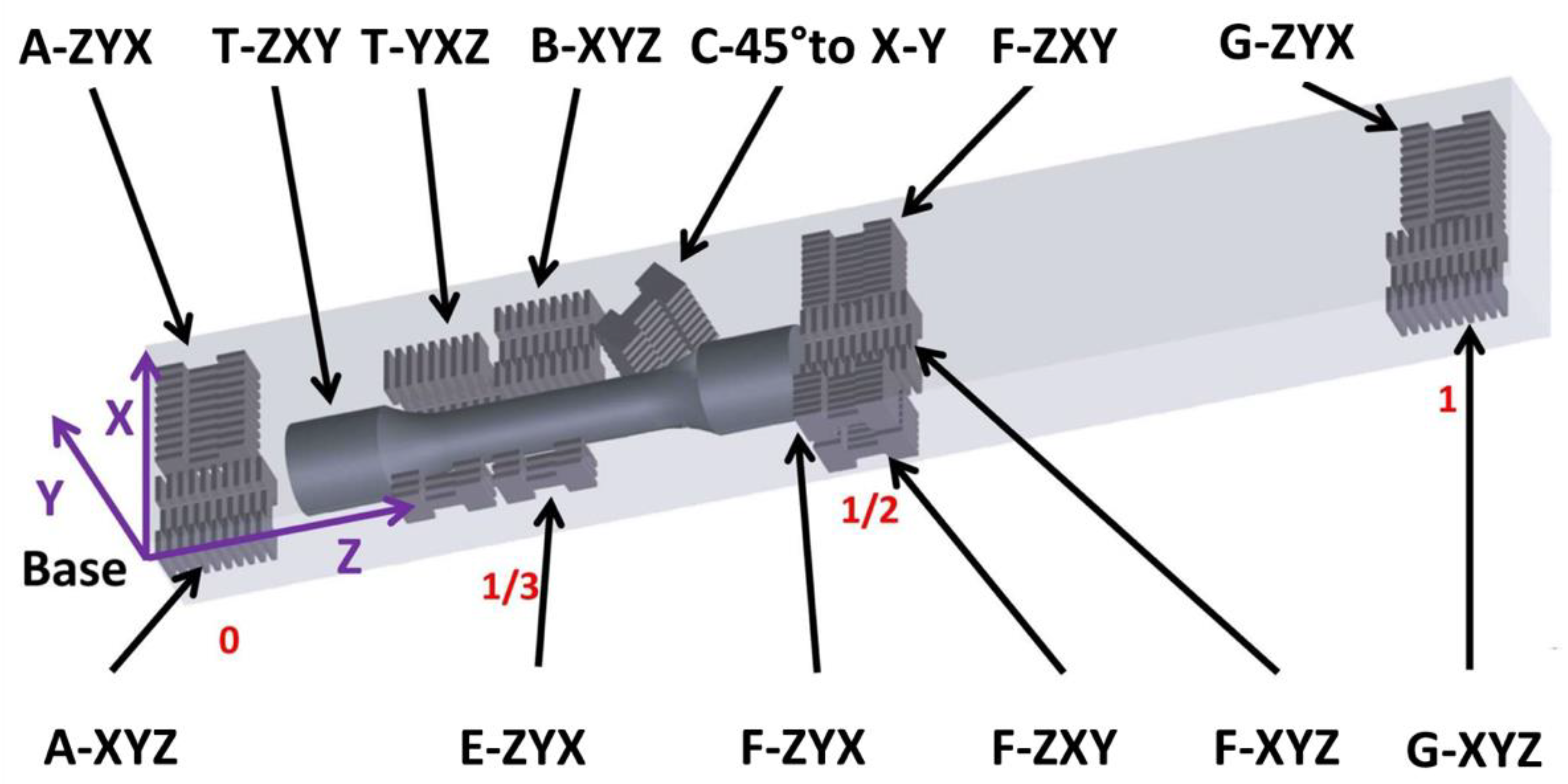

2.1. Processing and Specimen Preparation

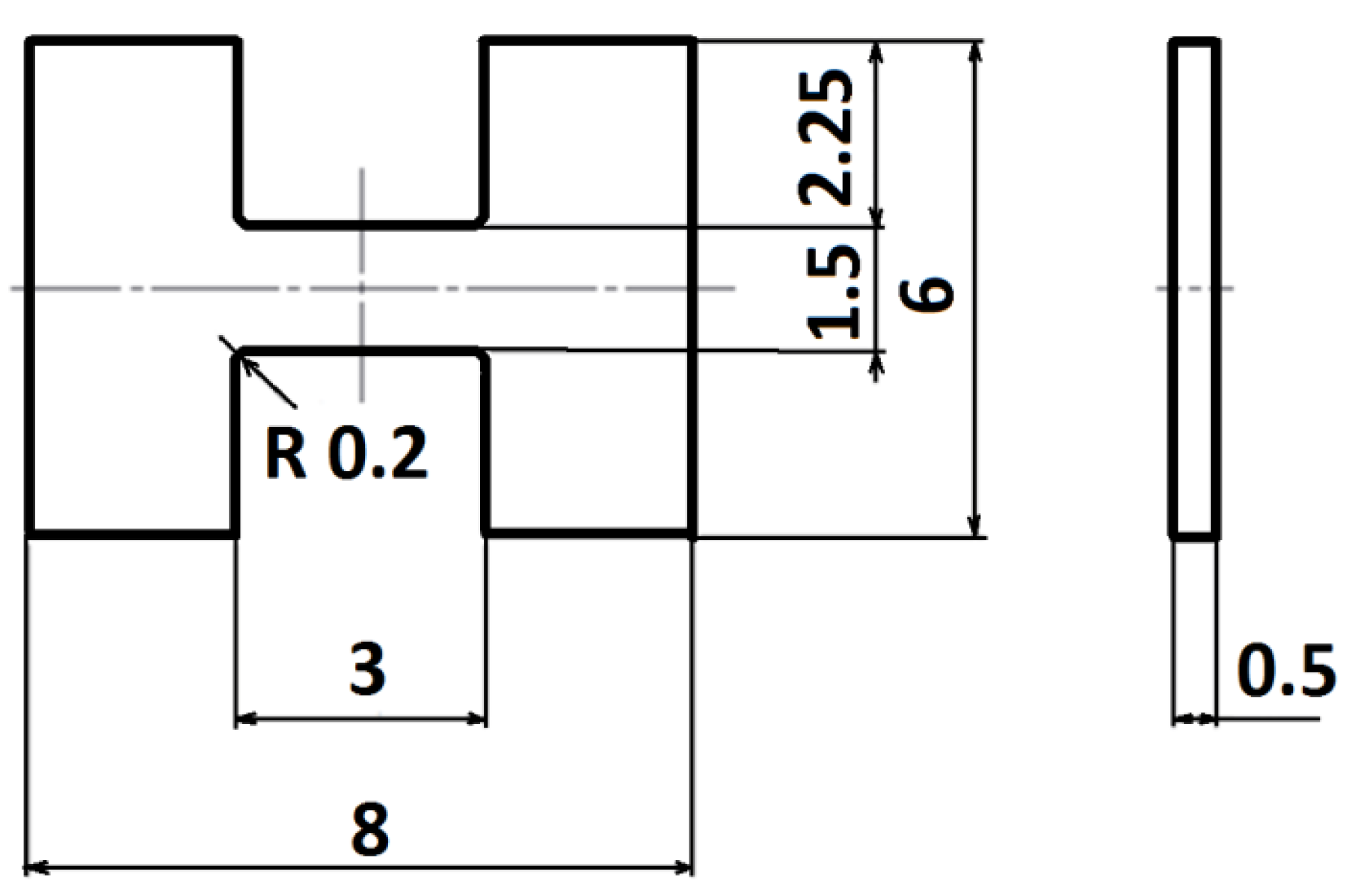

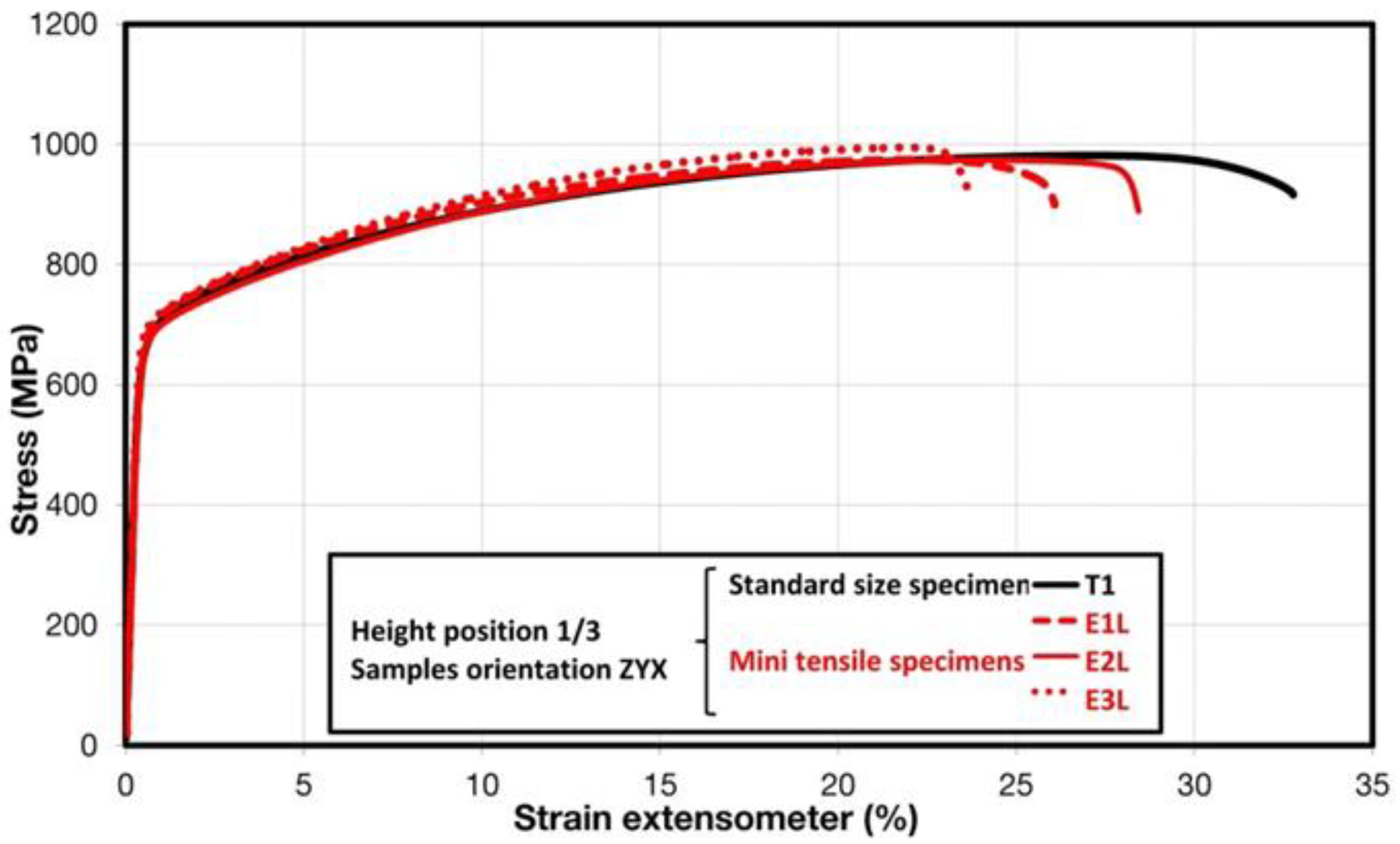

2.2. Mini-Tensile Testing (M-TT)

2.3. Microstructure Evaluation and Fractography

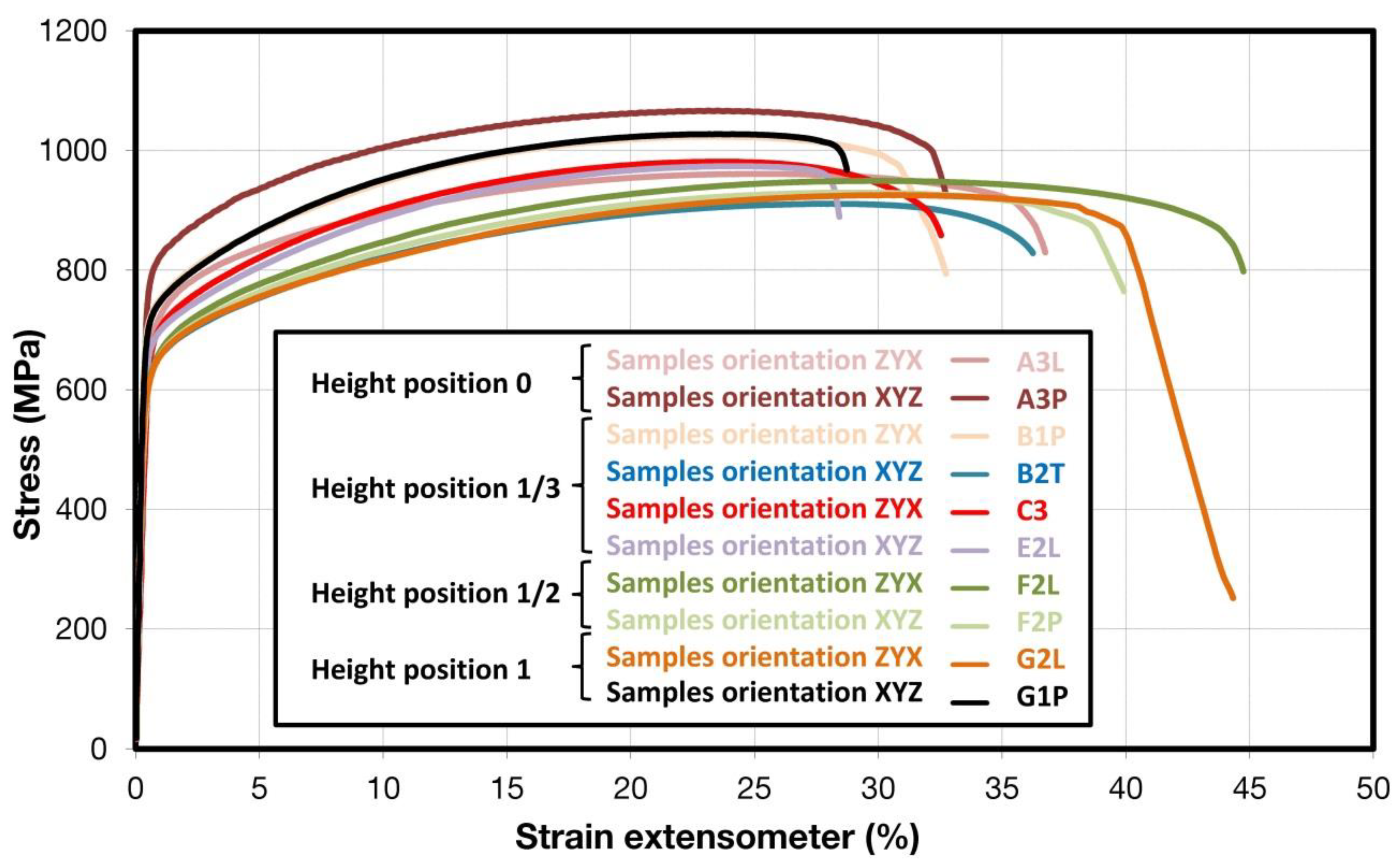

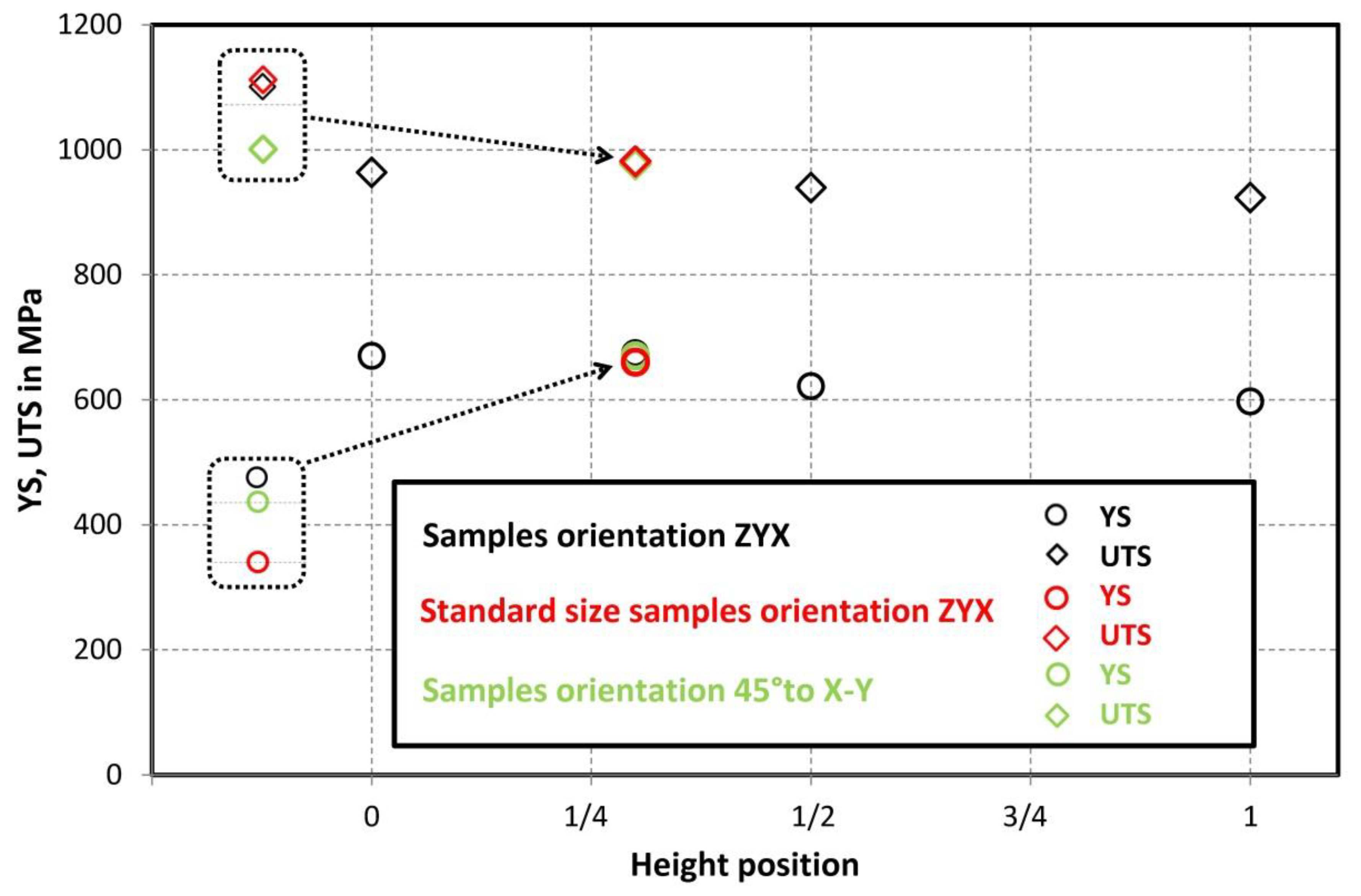

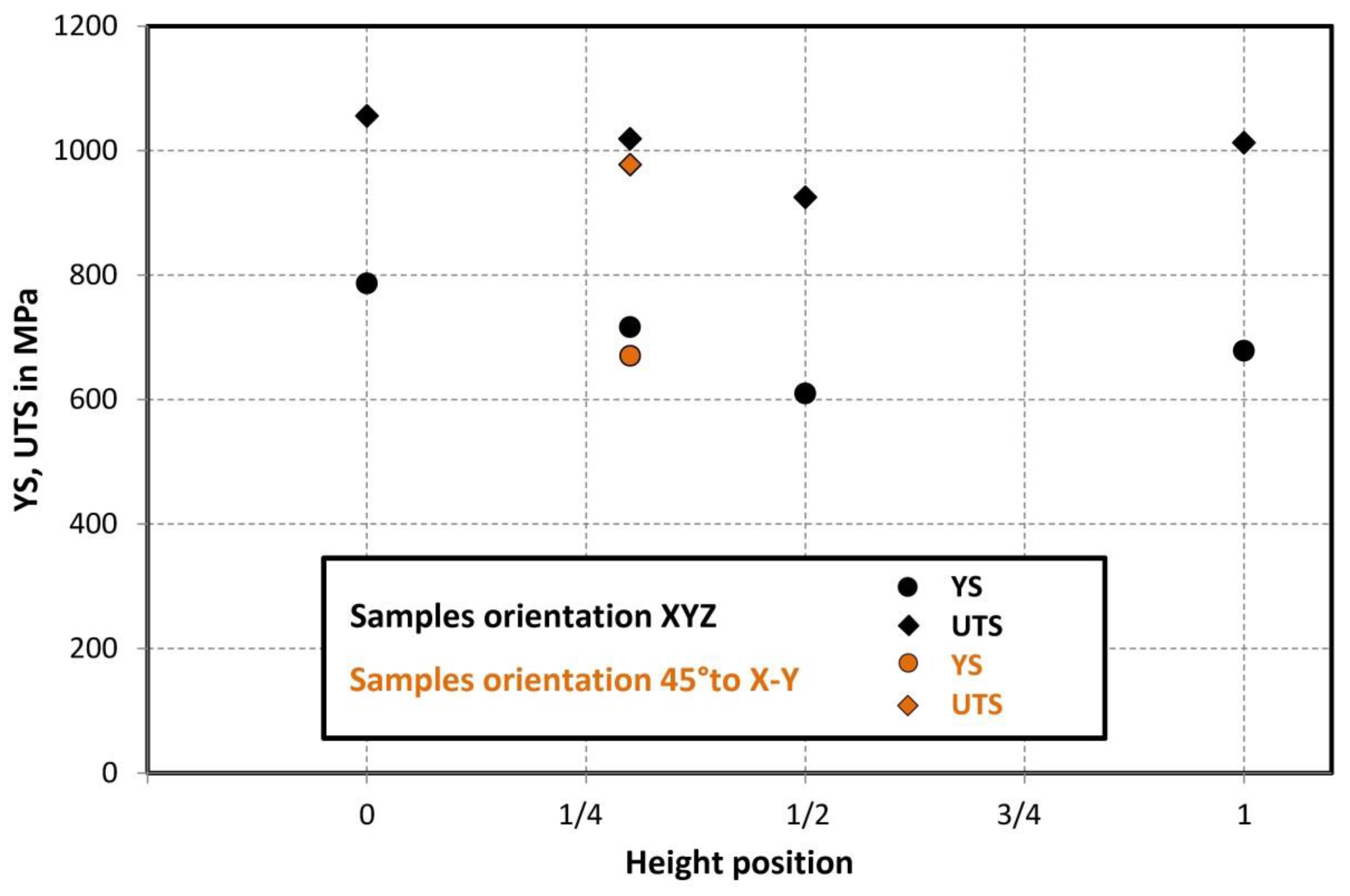

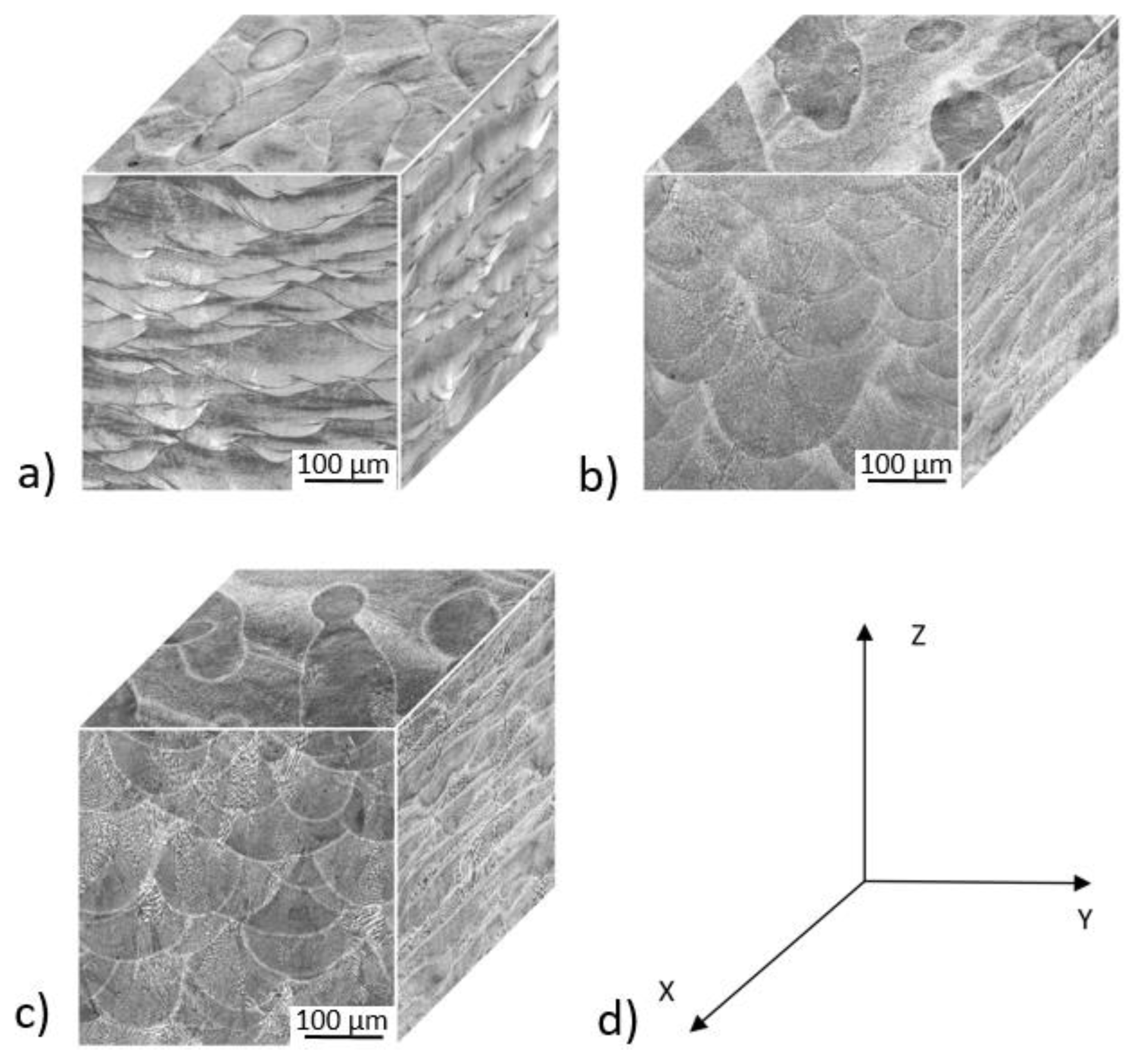

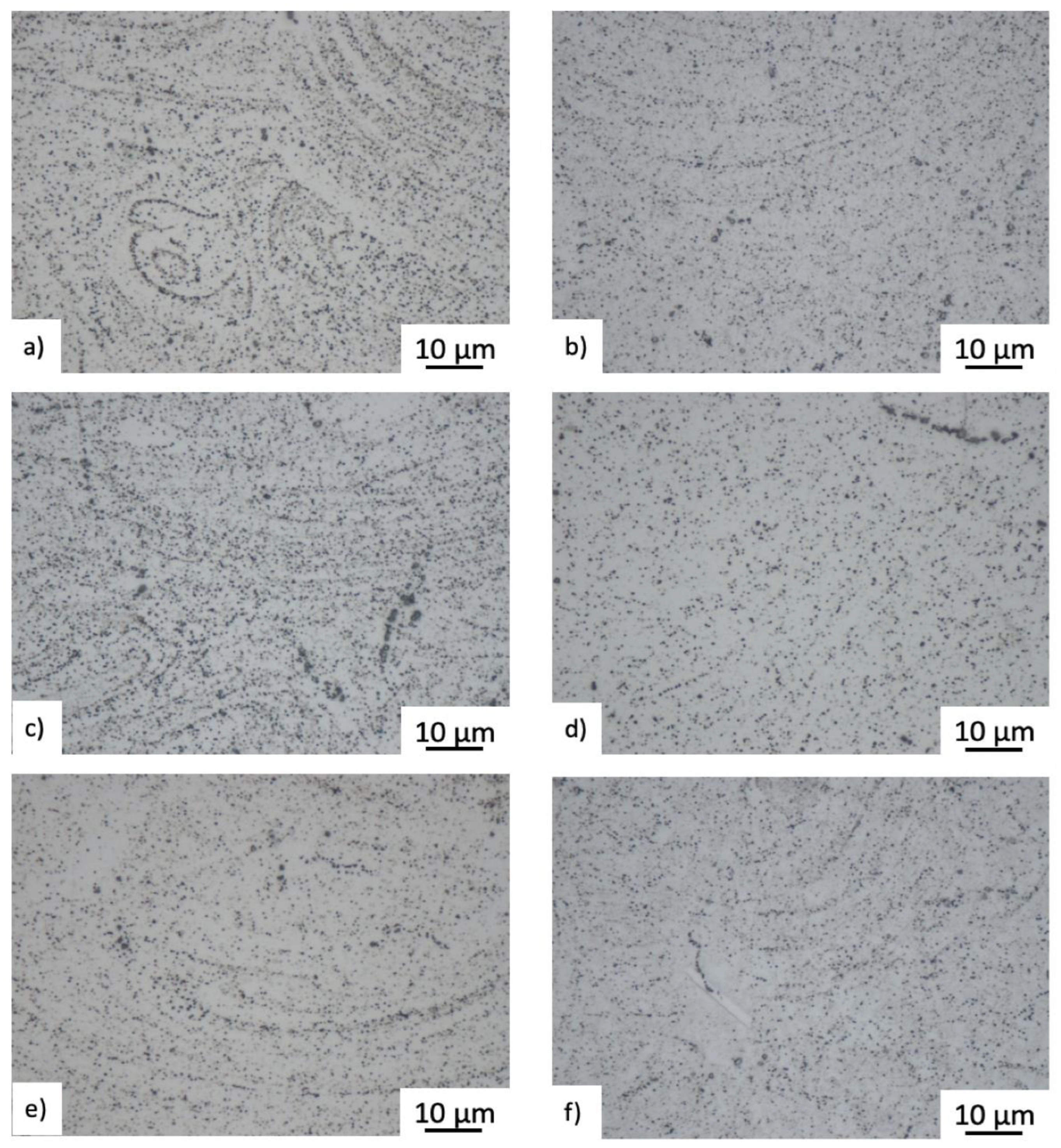

2.4. As-Deposited State

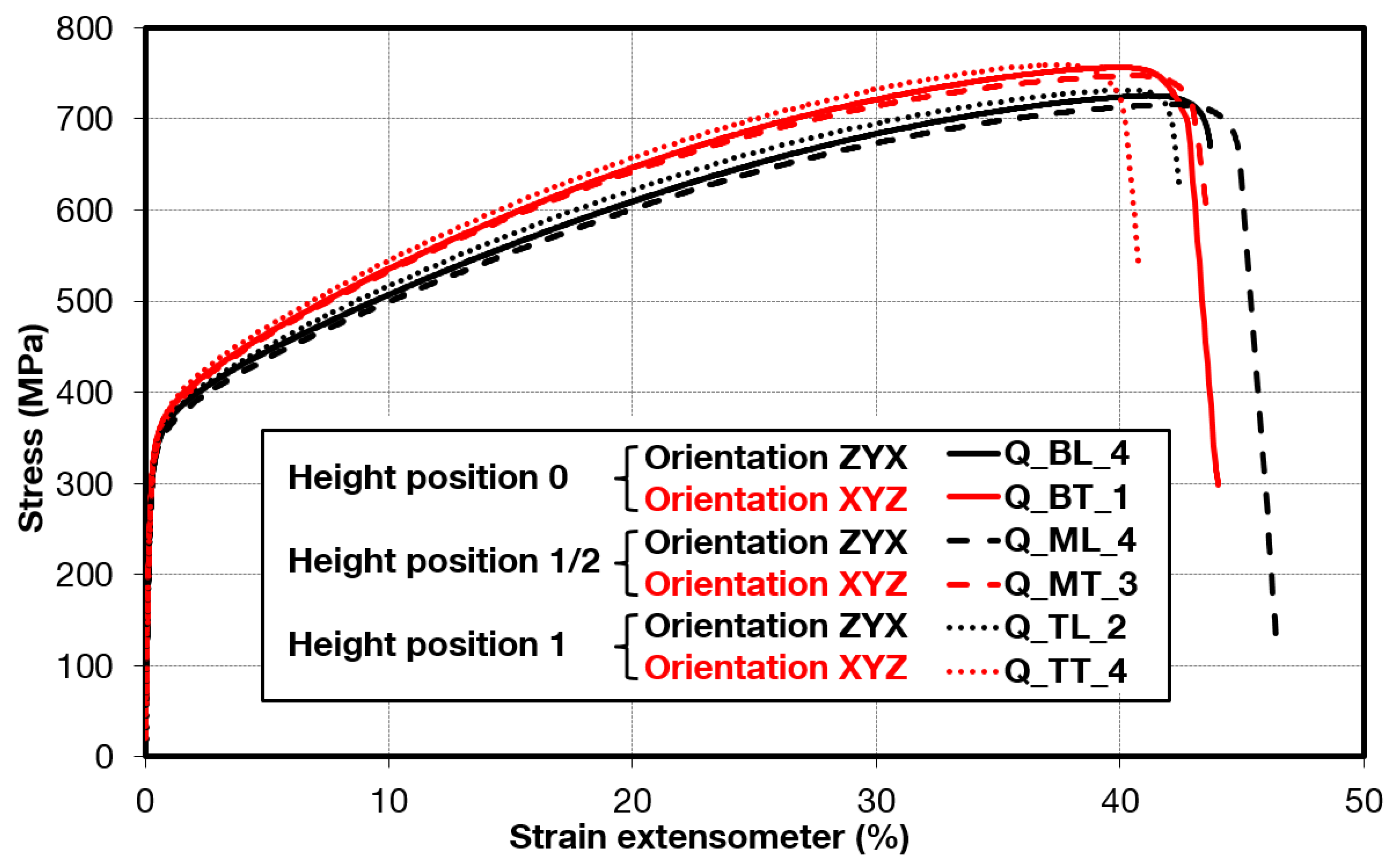

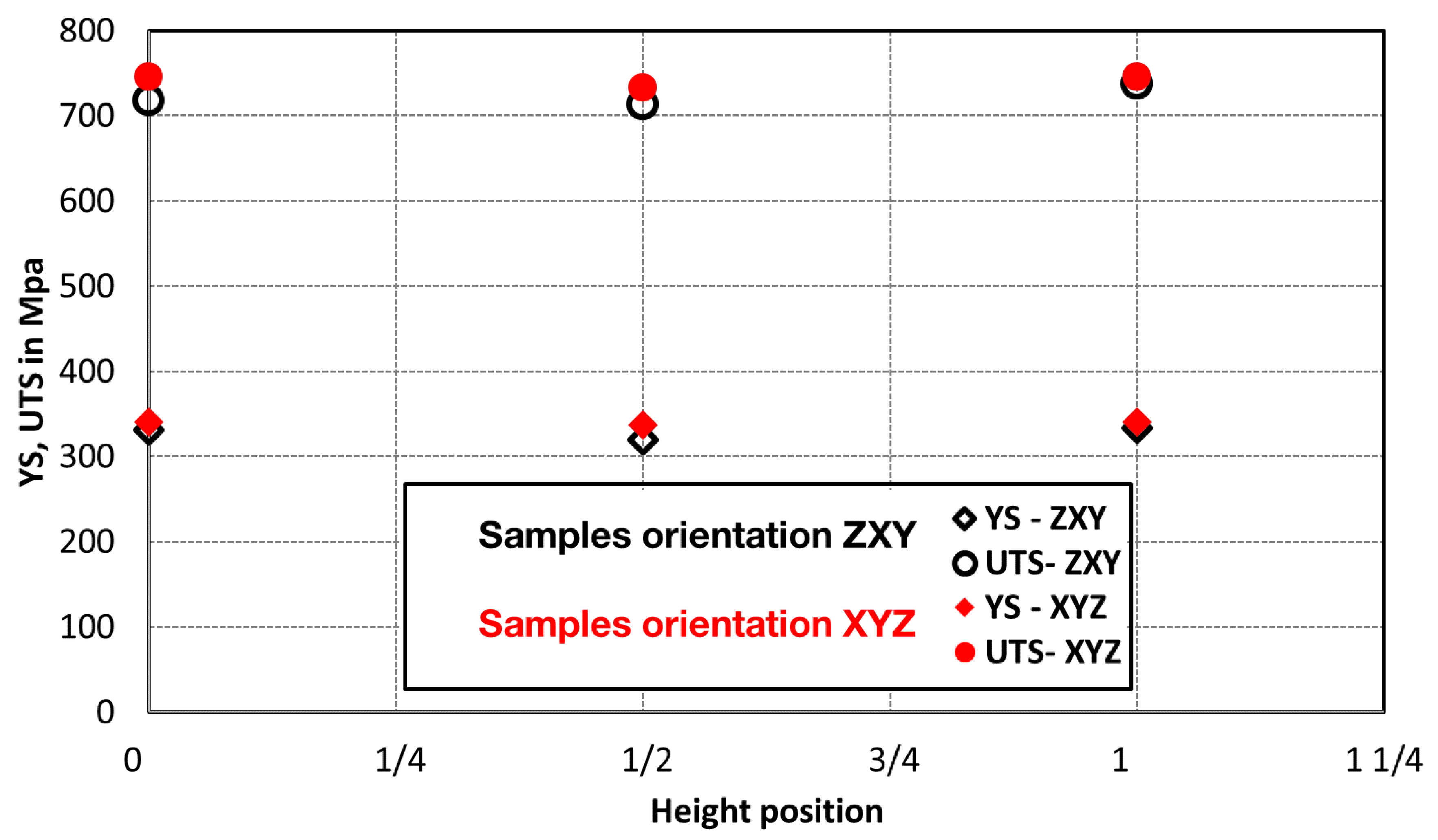

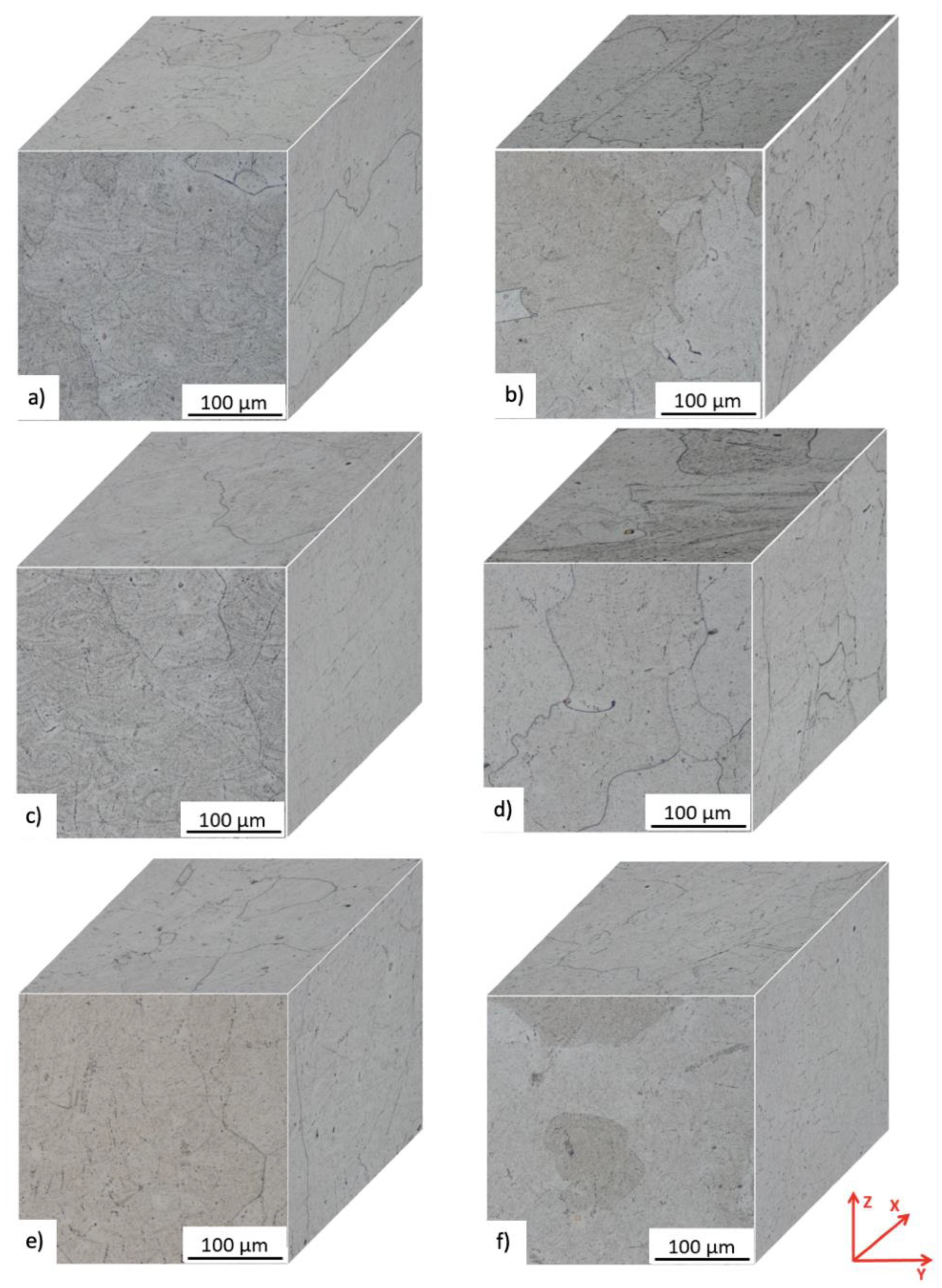

2.5. Post-Treated

3. Discussion

4. Conclusions

- The present work has successfully used miniature M-TT tension samples excised from bulk samples to investigate the location- and orientation-dependence of properties in comparison to bulk LPBF IN 718 in both as-deposited and post-treated conditions. This approach again provides a useful procedure to illustrate the potential differences in local properties from global properties obtained on bulk samples/parts.

- M-TT samples excised from the gage length locations of the bulk samples exhibited comparable results to standard bulk samples printed at the same time. The resulting offset yield strengths/UTS obtained for M-TT and standard specimens were 182/674 MPa and 182/660 MPa, respectively. These findings are consistent with previous work of this type on other AM-processed materials.

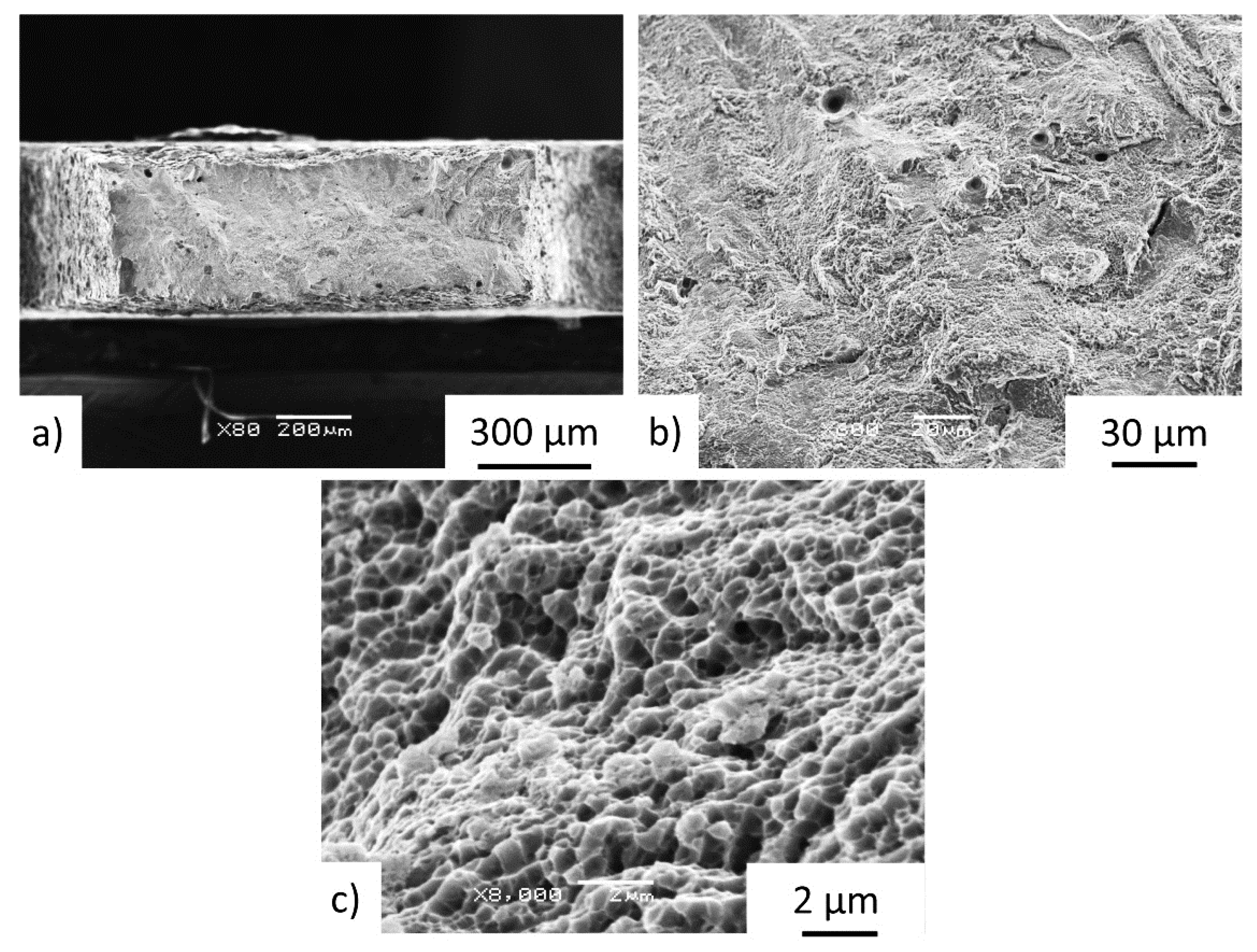

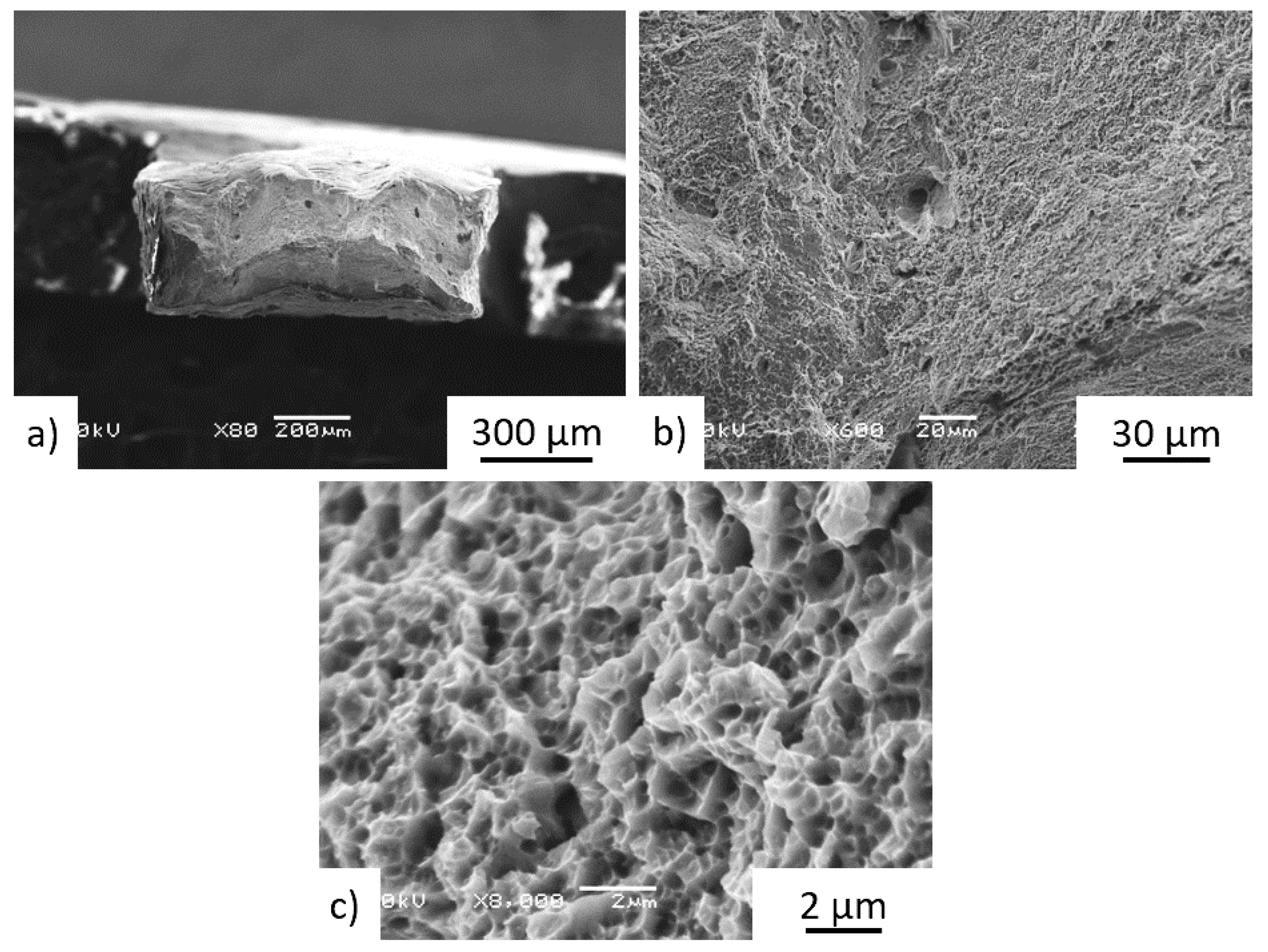

- The as-deposited material exhibited significant property anisotropy in the different orientations in addition to both location- and orientation-dependent properties. Difference between the tensile properties along the build direction and perpendicular to the build direction reached 15% for some locations, while samples excised along the build direction generally produced lower properties compared to those excised perpendicularly. Microstructure examination of the as-deposited material revealed coarsening of the columnar microstructure along the build direction, suggestive of heat accumulation during the build. This partially contributed to the differences in M-TT properties both along the build and in different orientations, although relatively homogeneous properties were obtained in the middle of the build. Fracture surface examinations revealed multiple examples of process-induced porosity at various locations on the fracture surface, although the remainder of the fracture surface exhibited very fine (e.g., <1 micron) dimples.

- Metallurgical examinations of the post-treated samples revealed preferential carbide precipitation along grain boundaries and removal of the columnar microstructure.

- The post-treated samples exhibited isotropic properties as well as significant reductions (e.g., >30%) in the strength (Yield, UTS) along with significant increases in the reduction in area at fracture for all of the M-TT samples in comparison to as-build state. The HIP post-treatment reduced the number of process-induced defects exhibited in the fractured samples, while the fracture surfaces continued to exhibit very fine (<1 micron) dimples.

Author Contributions

Funding

Conflicts of Interest

References

- Lewandowski, J.J.; Seifi, M. Metal Additive Manufacturing: A Review of Mechanical Properties. Annu. Rev. Mater. 2016, 46, 151–186. [Google Scholar] [CrossRef] [Green Version]

- Palanivel, S.; Dutt, A.K.; Faierson, E.J.; Mishra, R.S. Spatially dependent properties in a laser additive manufactured Ti–6Al–4V component. Mater. Sci. Eng. A 2016, 654, 39–52. [Google Scholar] [CrossRef]

- Melzer, D.; Džugan, J.; Koukolíková, M.; Rzepa, S.; Vavřík, J. Structural integrity and mechanical properties of the functionally graded material based on 316L/IN718 processed by DED technology. Mater. Sci. Eng. A 2021, 811, 141038. [Google Scholar] [CrossRef]

- Popovich, V.A.; Borisov, E.V.; Popovich, A.A.; Sufiiarov, V.S.; Masaylo, D.V.; Alzina, L. Functionally graded Inconel 718 processed by additive manufacturing: Crystallographic texture, anisotropy of microstructure and mechanical properties. Mater. Des. 2017, 114, 441–449. [Google Scholar] [CrossRef]

- Máthis, K.; Köver, M.; Stráská, J.; Džugan, J.; Halmešová, K. Micro-tensile behavior of Mg-Al-Zn alloy processed by equal channel angular pressing (ECAP). Materials 2018, 11, 1644. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chlebus, E.; Gruber, K.; Kuznicka, B.; Kurzac, J.; Kurzynowski, T. Effect of heat treatment on the microstructure and mechanical properties of Inconel 718 processed by selective laser melting. Mater. Sci. Eng. A-Struct. Mater. Prop. 2015, 639, 647–655. [Google Scholar] [CrossRef]

- Džugan, J.; Prochazka, R.; Konopik, P. Micro-Tensile Test Technique Development and Application to Mechanical Property Determination; ASTM Special Technical Publication: West Conshohocken, PA, USA, 2015; Volume STP 1576. [Google Scholar]

- Džugan, J.; Konopik, P.; Rund, M.; Prochazka, R. Determination of local tensile and fatigue properties with the use of sub-sized specimens. In Pressure Vessels and Piping Division (VP); American Society of Mechanical Engineers: New York, NY, USA, 2015; Volume 1A. [Google Scholar]

- Procházka, R.; Džugan, J. Low cycle fatigue properties assessment for rotor steels with the use of miniaturized specimens. Int. J. Fatigue 2022, 154, 106555. [Google Scholar] [CrossRef]

- Dzugan, J.; Sibr, M.; Konopík, P.; Procházka, R.; Rund, M. Mechanical properties determination of AM components. In Proceedings of the 4th International Conference Recent Trends in Structural Materials, Pilsen, Czech Republic, 9–11 November 2016; Volume 179, pp. 1–7. [Google Scholar]

- Konopík, P.; Džugan, J.; Rund, M. Dynamic tensile and micro-tensile testing using DIC method. In Proceedings of the METAL 2014—23rd International Conference on Metallurgy and Materials, sv., Brno, Czech Republic, 21–23 May 2014. [Google Scholar]

- ASTM WK49229; Standard Guide for Orientation and Location Dependence Mechanical Properties for Metal Additive Manufacturing. ASTM International: West Conshohocken, PA, USA, 2017.

- Kohyama, A.; Hamada, K.; Matsui, H. Specimen size effects on tensile properties of neutron-irradiated steels. J. Nucl. Mater. 1991, 179, 417–420. [Google Scholar] [CrossRef]

- Kohno, Y.; Kohyama, A.; Hamilton, M.L.; Hirose, T.; Katoh, Y.; Garner, F.A. Specimen size effects on the tensile properties of JPCA and JFMS. J. Nucl. Mater. 2000, 283, 1014–1017. [Google Scholar] [CrossRef]

- Gussev, M.N.; Busby, J.T.; Field, K.G.; Sokolov, M.A.; Gray, S.E. Role of Scale Factor during Tensile Testing of Small Specimens; ASTM Special Technical Publication: West Conshohocken, PA, USA, 2015; Volume STP 1576, pp. 31–49. [Google Scholar]

- Kumar, K.; Pooleery, A.; Madhusoodanan, K.; Singh, R.N.; Chakravartty, J.K.; Dutta, B.K.; Sinha, R.K. Use of miniature tensile specimen for measurement of mechanical properties. Procedia Eng. 2014, 86, 899–909. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Chu, D. Mechanical characterization of post-buckled micro-bridge beams by micro-tensile testing. Microsyst. Technol. 2010, 16, 375–380. [Google Scholar] [CrossRef]

- Yuan, W.; Zhang, W.; Su, Z.; Qiao, Y.; Chu, L. Influence of specimen thickness with rectangular cross-section on the tensile properties of structural steels. Mater. Sci. Eng. A 2012, 532, 601–605. [Google Scholar] [CrossRef]

- Wang, G.; Wang, C.; Guo, C.; Shan, B.; Huang, D. Size effect on flow stress in uniaxial compression of pure nickel cylinders with a few grains across thickness. Mater. Lett. 2013, 106, 294–296. [Google Scholar] [CrossRef]

- Poling, W.A. Grain Size Effects in Micro-Tensile Testing of Austenitic Stainless Steel; Colorado School of Mines: Golden, CO, USA, 2012. [Google Scholar]

- Henning, H.; Vehoff, M. Statistical size effects based on grain size and texture in thin sheets. Mater. Sci. Eng. A 2017, 452, 603–613. [Google Scholar] [CrossRef]

- Brandt, M. Laser Additive Manufacturing: Materials, Design, Technologies and Applications; Elsevier Ltd.: Amsterdam, The Netherlands, 2017; ISBN 978-0-08-100434-0. [Google Scholar]

- Moore, P. Nondestructive Testing Handbook: Volume 4. Radiographic Testing, 3rd ed.; American Society for Nondestructive Testing: Columbus, OH, USA, 2002. [Google Scholar]

| Ni | Cr | Fe | Ta + Nb | Mo | Ti | Al | Cu | C | Si | Mn | B | Co | P | S |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 50.0–55.0 | 17.0–21.0 | Bal. | 4.75–5.5 | 2.8–3.3 | 0.65–1.15 | 0.2–0.8 | 0.3 | 0.08 | 0.35 | 0.35 | 0.006 | 1.00 | 0.015 | 0.015 |

| State | Batch | Height Position | Orientation | Samples Designation |

|---|---|---|---|---|

| As deposited | A_L | 0 | ZYX | AxL |

| A_P | 0 | XYZ | AxP | |

| B_P | 1/3 | XYZ | BxP | |

| B_T | 1/3 | YXZ | BxT | |

| C | 1/3 | 45° to X-Y | Cx | |

| E_L | 1/3 | ZYX | ExL | |

| F_L | 1/2 | ZYX | F1_xL, F2_xL, F3_xL | |

| F_P | 1/2 | XYZ | FxP | |

| G_L | 1 | ZYX | GxL | |

| G_P | 1 | XYZ | GxP | |

| T | 1/3 | ZYX | Tx | |

| P- post-treated | P_B_L | 0 | ZYX | PBxL |

| P_B_P | 0 | XYZ | PBxP | |

| P_M_L | 1/2 | ZYX | PMxL | |

| P_M_P | 1/2 | XYZ | PMxP | |

| P_T_L | 1 | ZYX | PTxL | |

| P_T_P | 1 | XYZ | PTxP | |

| Q- post-treated | Q_B_L | 0 | ZYX | QBxL |

| Q_B_P | 0 | XYZ | QBxP | |

| Q_M_L | 1/2 | ZYX | QMxL | |

| Q_M_P | 1/2 | XYZ | QMxP | |

| Q_T_L | 1 | ZYX | QTxL | |

| Q_T_P | 1 | XYZ | QTxP |

| Specimen | Geometry | E | OYS | UTS | UE | EL | RA |

|---|---|---|---|---|---|---|---|

| GPa | MPa | MPa | % | % | % | ||

| E1_3L_1 | M-TT | 183.4 | 670.4 | 974.4 | 21.2 | 26.0 | 37.1 |

| E1_3L_2 | M-TT | 177.6 | 662.4 | 973.8 | 23.7 | 28.5 | 36.4 |

| E1_3L_3 | M-TT | 185.1 | 689.6 | 994.9 | 21.2 | 23.5 | 28.4 |

| Average | 182.0 | 674.1 | 981.0 | 22.1 | 26.0 | 34.0 | |

| St Dev. | 3.9 | 14.0 | 12.0 | 1.4 | 2.5 | 4.8 | |

| T1 | Standard | 182.4 | 660.1 | 981.5 | 26.5 | 31.6 | 44.0 |

| Values | Batch | Orientation | Height Position | YS | UTS | UE | A3mm | RA |

|---|---|---|---|---|---|---|---|---|

| MPa | MPa | % | % | % | ||||

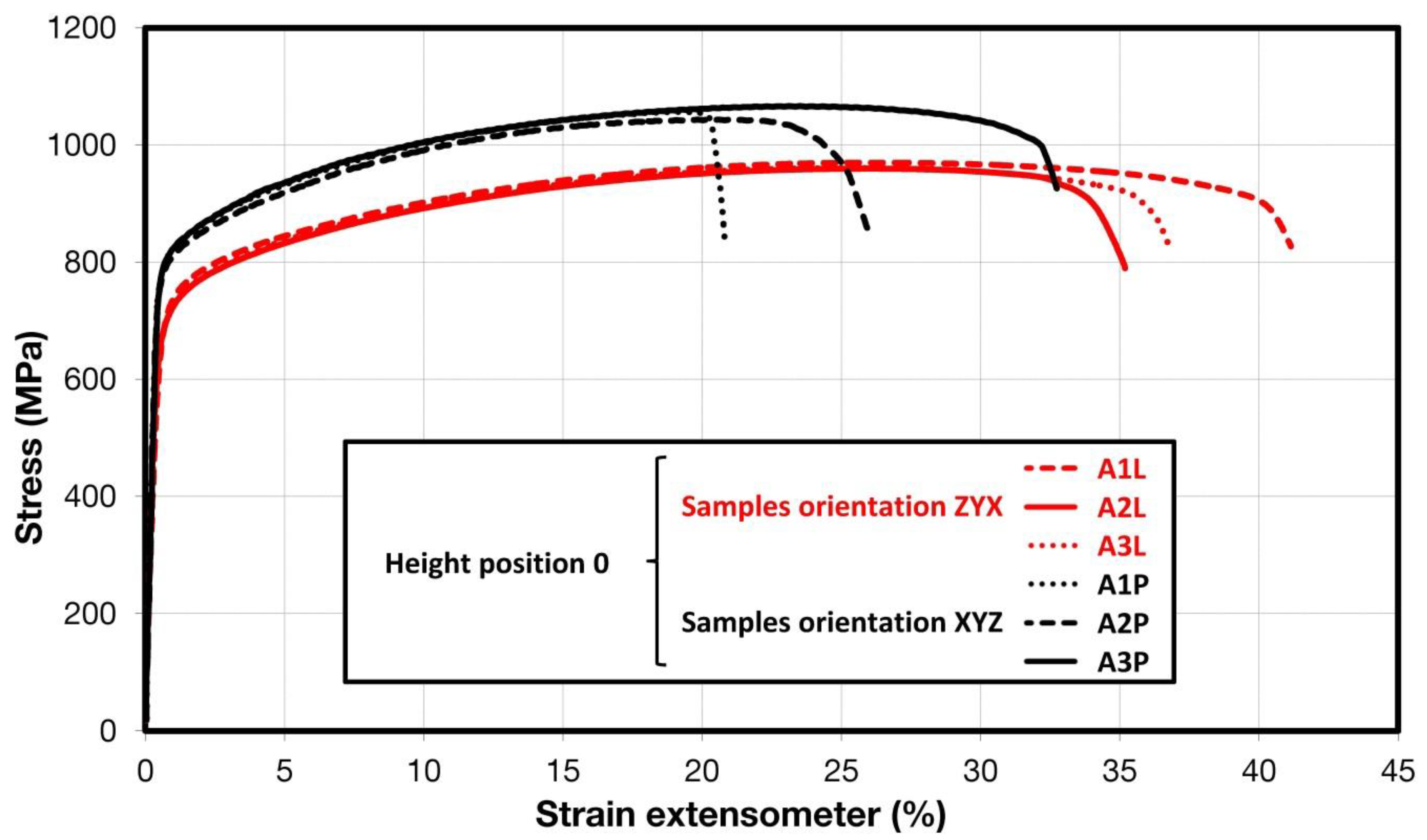

| Average | A_L | ZYX | 0 | 669.8 | 963.6 | 25.1 | 37.5 | 41.6 |

| ST. Dev. | 5.4 | 5.5 | 0.8 | 3.1 | 6.5 | |||

| Average | A_P | XYZ | 0 | 786.3 | 1055.5 | 20.4 | 26.3 | 34.5 |

| ST. Dev. | 7.1 | 11.5 | 2.3 | 6 | 2.4 | |||

| Average | B_T | XYZ | 1/3 | 609.8 | 904.4 | 27.2 | 36.2 | 45.8 |

| ST. Dev. | 7.7 | 14.5 | 1.7 | 3.3 | 2.6 | |||

| Average | B_P | YXZ | 1/3 | 716.2 | 1018.7 | 22.2 | 29.7 | 37.7 |

| ST. Dev. | 14.6 | 17.5 | 1.2 | 4.5 | 6.3 | |||

| Average | C | 45°X-Y | 1/3 | 670.2 | 977.4 | 21.7 | 29.2 | 32.7 |

| ST. Dev. | 5.6 | 5 | 1.2 | 4.9 | 5.7 | |||

| Average | E_L | ZYX | 1/3 | 674.1 | 981 | 22.1 | 26 | 34 |

| ST. Dev. | 14 | 12 | 1.4 | 2.5 | 4.8 | |||

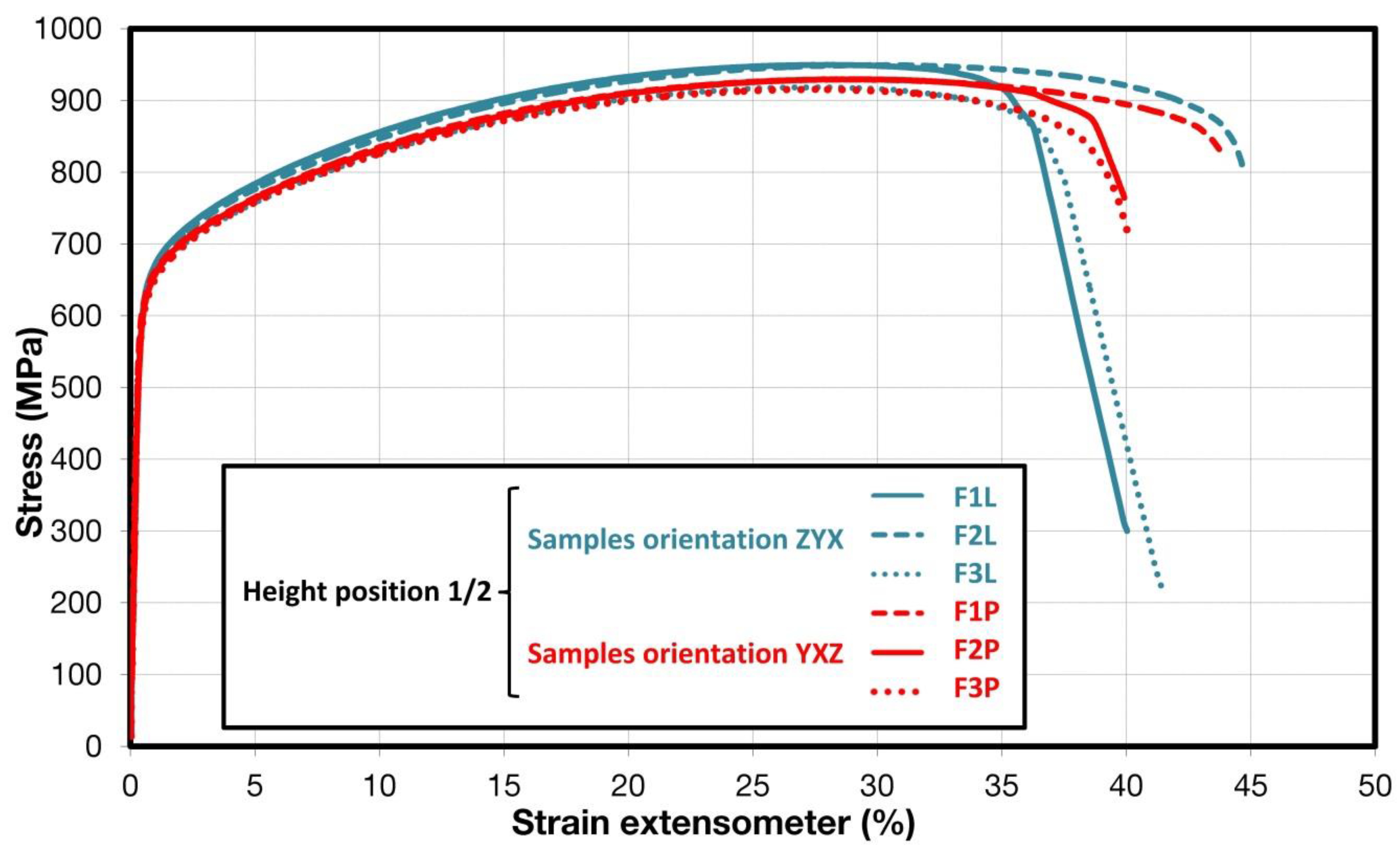

| Average | F_L | ZYX | ½ | 621.4 | 939.2 | 27.7 | 42 | 63.5 |

| ST. Dev. | 5.9 | 17.9 | 1.3 | 2.3 | 26.8 | |||

| Average | F_P | XYZ | ½ | 609.5 | 924.8 | 28 | 41.3 | 48.7 |

| ST. Dev. | 9.6 | 8.1 | 0.7 | 2.3 | 3.3 | |||

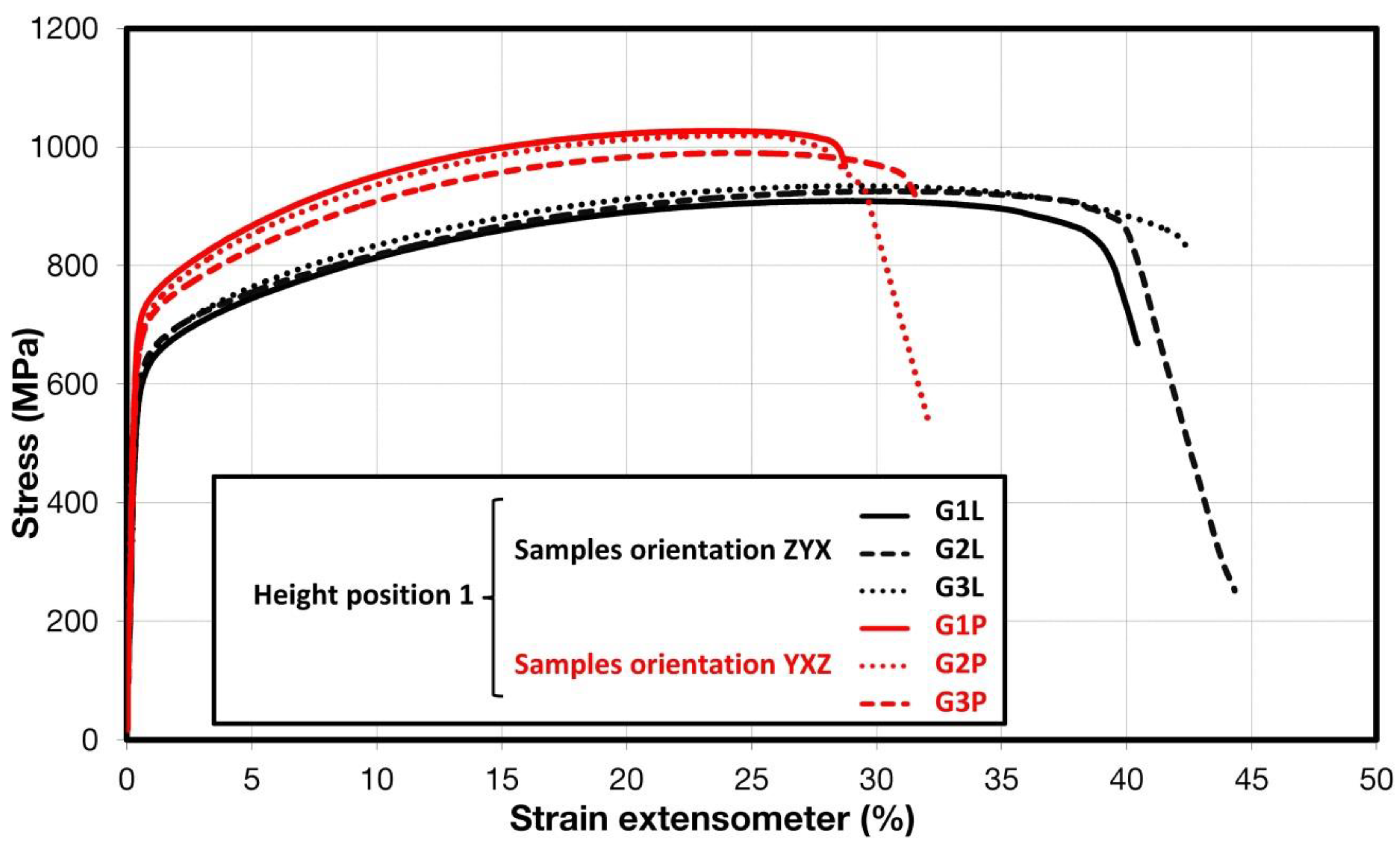

| Average | G_L | ZYX | 1 | 597.2 | 923.1 | 29 | 42.5 | 47.8 |

| ST. Dev. | 5.9 | 12.8 | 0.8 | 2 | 2.3 | |||

| Average | G_P | XYZ | 1 | 677.8 | 1012.4 | 23.9 | 31.3 | 40.1 |

| ST. Dev. | 28.4 | 19.6 | 0.2 | 2.8 | 4.3 | |||

| T1 | T | Z | 1/3 | 660.1 | 981.5 | 26.5 | 31.6 | 44.0 |

| Values | Batch | Orientation | Height Position | YS | UTS | UE | A3mm | RA |

|---|---|---|---|---|---|---|---|---|

| MPa | MPa | % | % | % | ||||

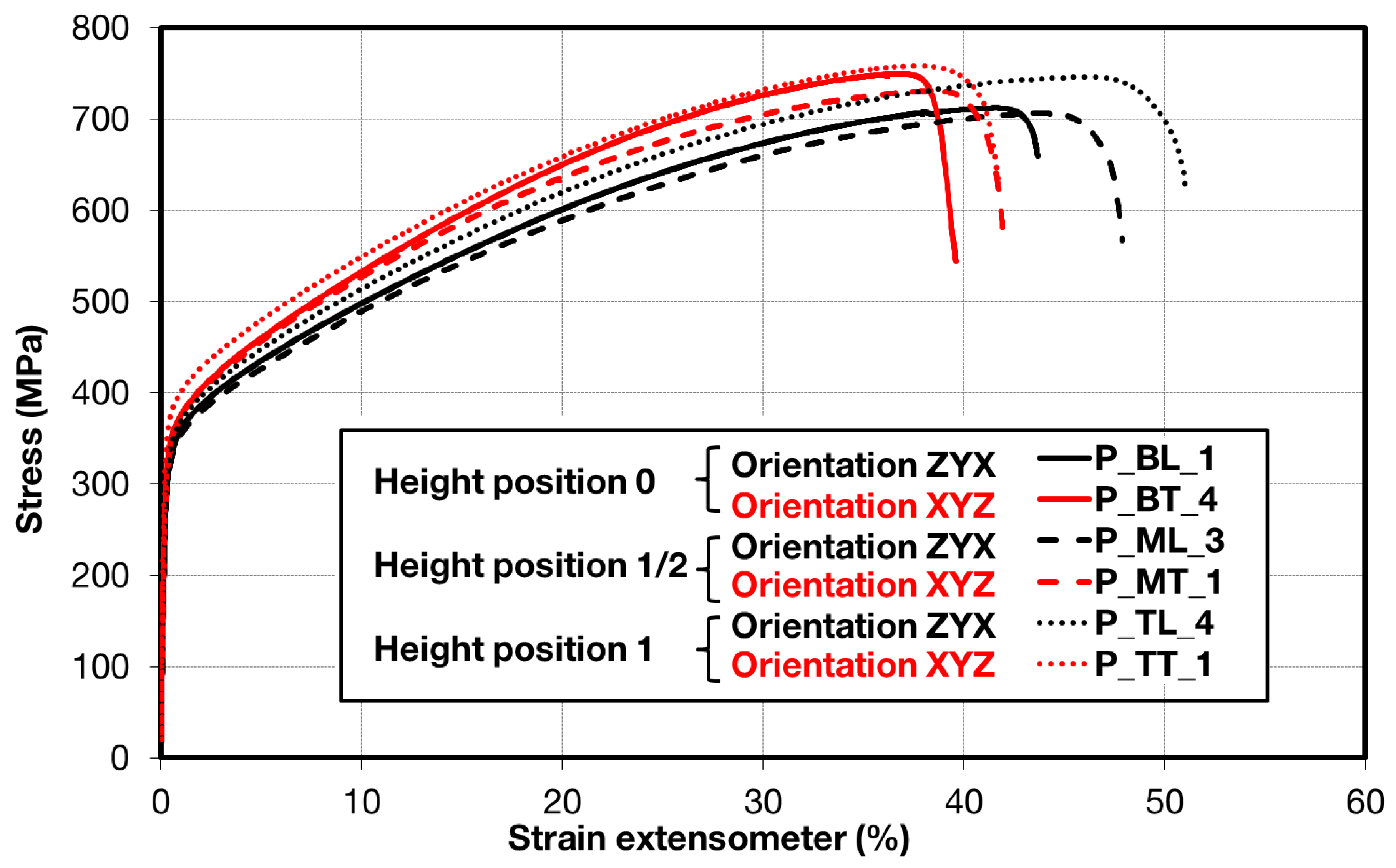

| Average | P_BL | ZXY | 0 | 330.9 | 718.5 | 41.0 | 43.2 | 56.2 |

| St.Dev. | 5.2 | 8.9 | 4.2 | 4.2 | 3.4 | |||

| Average | P_BT | XYZ | 0 | 340.2 | 745.6 | 36.6 | 39.6 | 61.1 |

| St.Dev. | 4.6 | 4.4 | 1.2 | 1.2 | 4.5 | |||

| Average | P_ML | ZXY | 1/2 | 319.8 | 713.0 | 43.4 | 47.0 | 61.3 |

| St.Dev. | 1.6 | 8.2 | 1.4 | 2.2 | 1.7 | |||

| Average | P_MT | XYZ | 1/2 | 336.8 | 733.3 | 37.9 | 40.8 | 61.6 |

| St.Dev. | 6.6 | 21.1 | 1.7 | 2.4 | 0.8 | |||

| Average | P_TL | ZXY | 1 | 333.3 | 737.8 | 44.6 | 49.4 | 57.7 |

| St.Dev. | 4.3 | 11.5 | 1.6 | 2.2 | 3.8 | |||

| Average | P_TT | XYZ | 1 | 340.6 | 745.6 | 36.2 | 39.4 | 58.2 |

| St.Dev. | 19.2 | 15.4 | 1,3 | 2.0 | 2.3 | |||

| Average | Q_BL | ZXY | 0 | 331.2 | 721.9 | 42.0 | 44.7 | 53.6 |

| St.Dev. | 5.7 | 13.5 | 2.9 | 3.9 | 4.3 | |||

| Average | Q_BT | XYZ | 0 | 337.5 | 740.2 | 40.0 | 43.2 | 60.3 |

| St.Dev. | 10.8 | 16.0 | 3.3 | 3.8 | 2.3 | |||

| Average | Q_ML | ZXY | 1/2 | 320.7 | 704.1 | 40.3 | 43.5 | 58.2 |

| St.Dev. | 4.0 | 9.0 | 2.8 | 2.8 | 6.0 | |||

| Average | Q_MT | XYZ | 1/2 | 327.0 | 739.4 | 40.0 | 43.1 | 54.4 |

| St.Dev. | 4.7 | 5.7 | 0.6 | 1.5 | 2.4 | |||

| Average | Q_TL | ZXY | 1 | 343.5 | 728.3 | 39.5 | 42.1 | 57.0 |

| St.Dev. | 12.7 | 11.5 | 2.4 | 2.7 | 2.2 | |||

| Average | Q_TT | XYZ | 1 | 324.4 | 737.5 | 37.1 | 39.4 | 57.5 |

| St.Dev. | 14.7 | 23.4 | 2.9 | 3.0 | 6.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dzugan, J.; Seifi, M.; Rund, M.; Podany, P.; Grylls, R.; Lewandowski, J.J. The Use of Miniature Specimens to Determine Local Properties and Fracture Behavior of LPBF-Processed Inconel 718 in as-Deposited and Post-Treated States. Materials 2022, 15, 4724. https://doi.org/10.3390/ma15134724

Dzugan J, Seifi M, Rund M, Podany P, Grylls R, Lewandowski JJ. The Use of Miniature Specimens to Determine Local Properties and Fracture Behavior of LPBF-Processed Inconel 718 in as-Deposited and Post-Treated States. Materials. 2022; 15(13):4724. https://doi.org/10.3390/ma15134724

Chicago/Turabian StyleDzugan, Jan, Mohsen Seifi, Martin Rund, Pavel Podany, Richard Grylls, and John J. Lewandowski. 2022. "The Use of Miniature Specimens to Determine Local Properties and Fracture Behavior of LPBF-Processed Inconel 718 in as-Deposited and Post-Treated States" Materials 15, no. 13: 4724. https://doi.org/10.3390/ma15134724

APA StyleDzugan, J., Seifi, M., Rund, M., Podany, P., Grylls, R., & Lewandowski, J. J. (2022). The Use of Miniature Specimens to Determine Local Properties and Fracture Behavior of LPBF-Processed Inconel 718 in as-Deposited and Post-Treated States. Materials, 15(13), 4724. https://doi.org/10.3390/ma15134724