DMA Analysis of Plasma Modified PVC Films and the Nature of Initiated Surface Changes

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussions

3.1. Study of Surface Properties

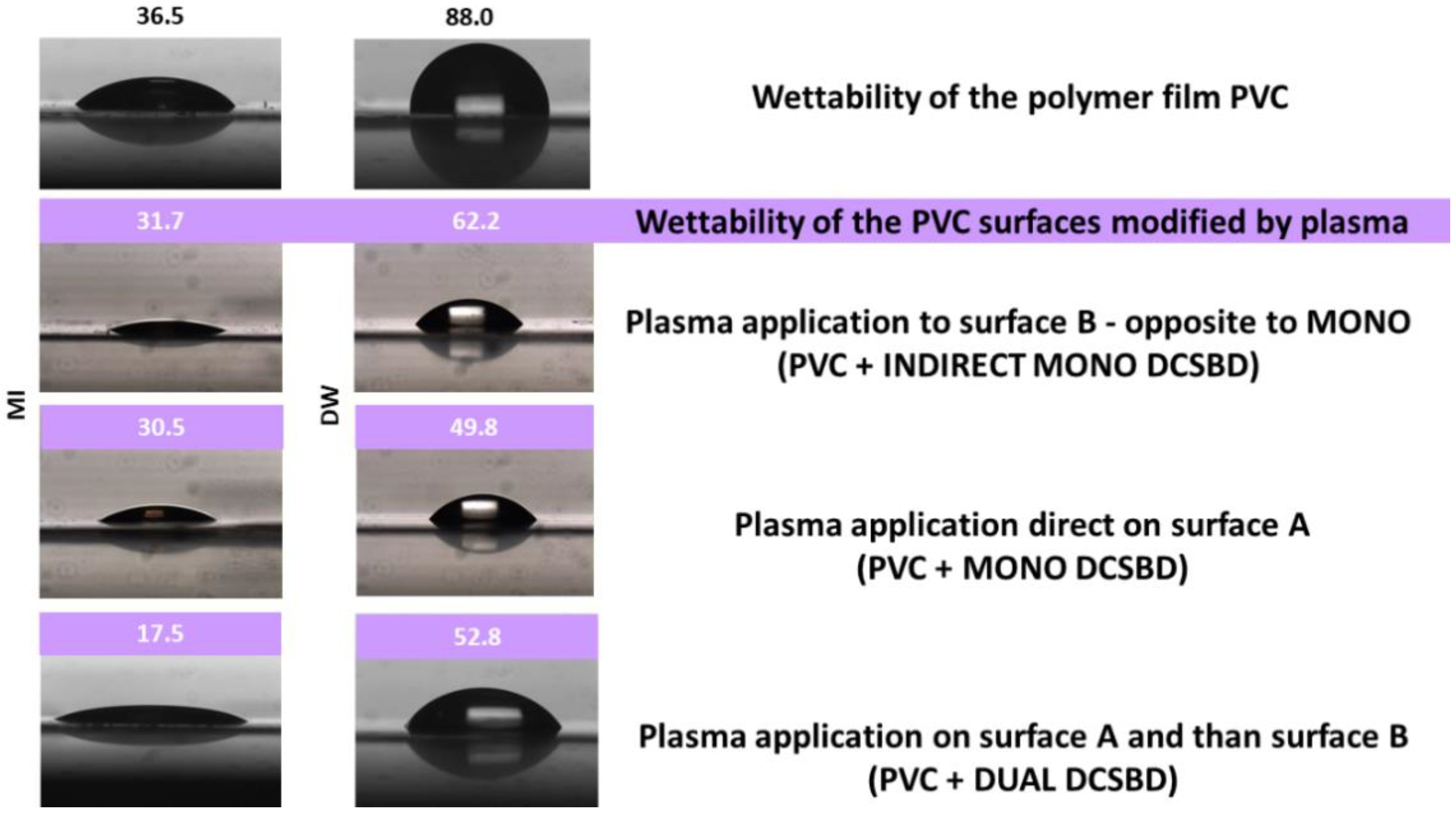

3.1.1. Contact Angles Observation

Comparison of Contact Angle Changes in PVC, I, II, III, IV Samples

Comparison of Contact Angle Changes in Type1/Type 2 Modifications

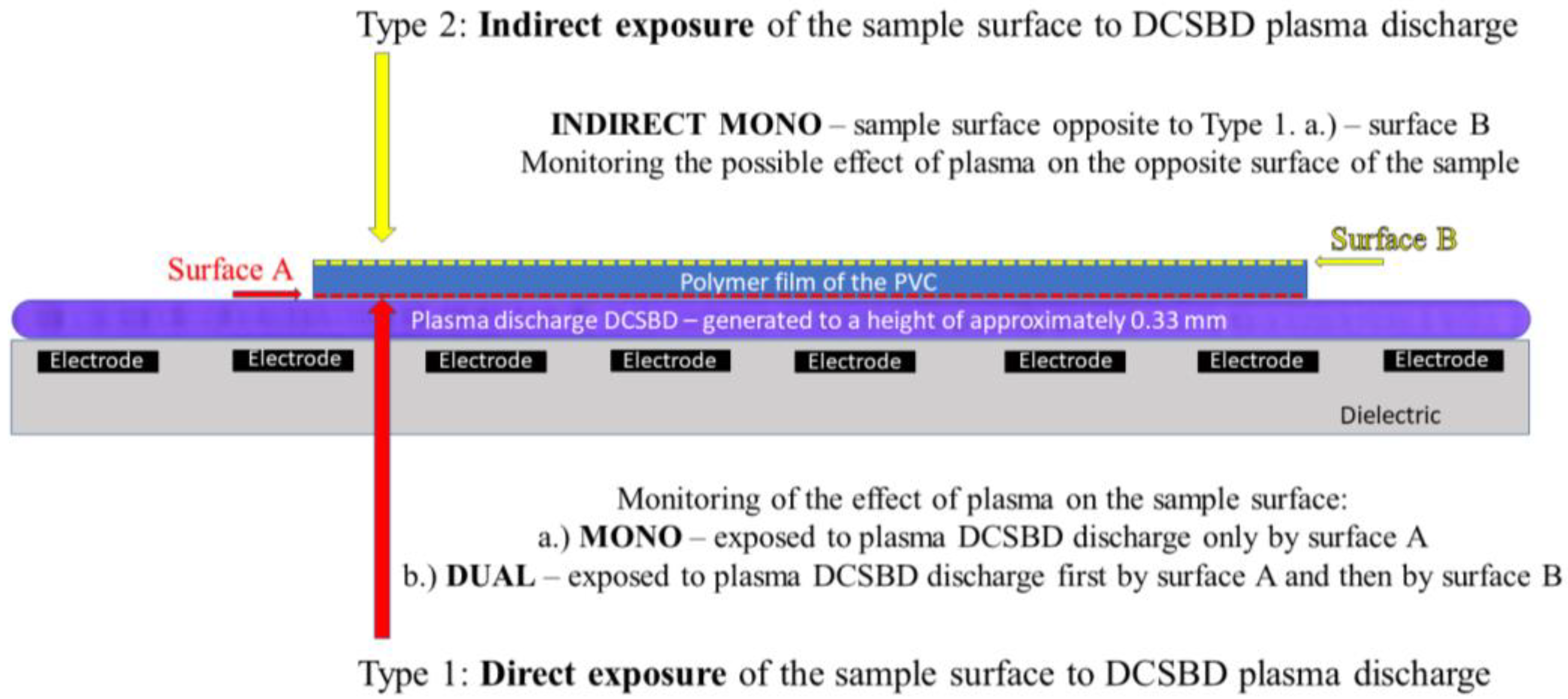

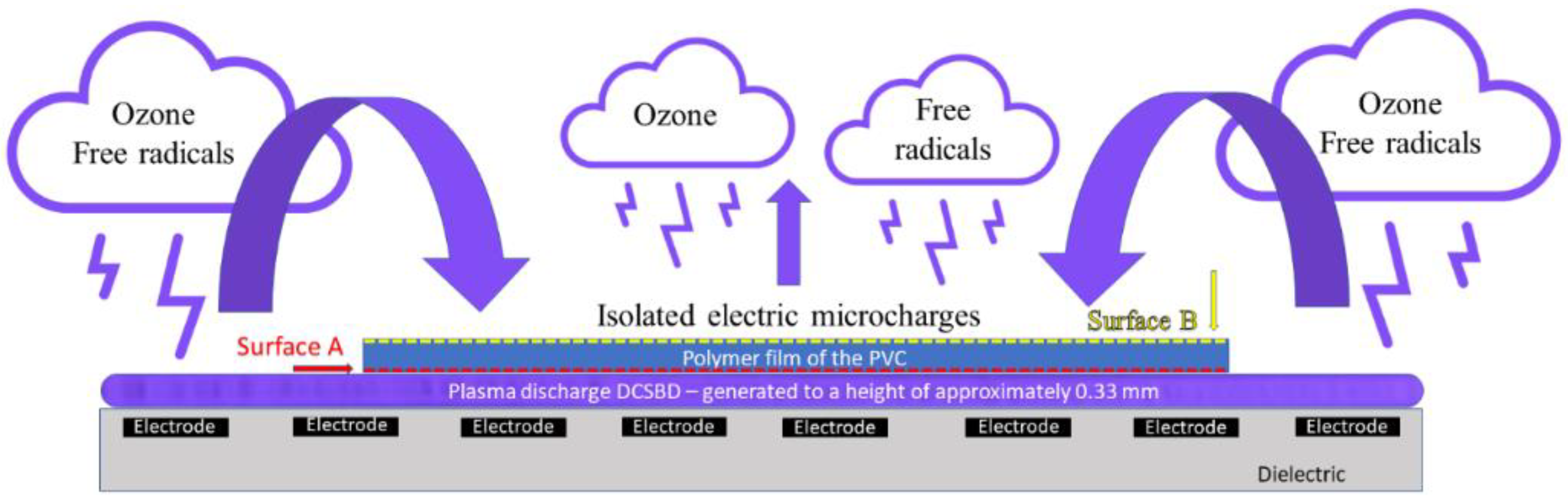

- DCSBD plasma burns on the entire ceramic dielectric, while atoms, ions and free radicals are excited into the atmosphere from the free, unoccupied part of the ceramic dielectric. These can be released in the vicinity of the ceramic dielectric and subsequently fall on the opposite surface of the investigated PVC polymer film. Thus, a kind of plasma cloud with a kinetic potential may form above the surface of the ceramic dielectric (Figure 5).

- Insulated micro-discharge breakthroughs contribute to surface modification (Figure 6).

- DCSBD plasma, as it is generated, penetrates through the structure of the (thin polymer) material and thus affects the opposite surface (possible with the support and in combination with the generated UV, ozone [55] and heat from the ceramic dielectric).

- The fourth option may be a combination of the two previous hypotheses.

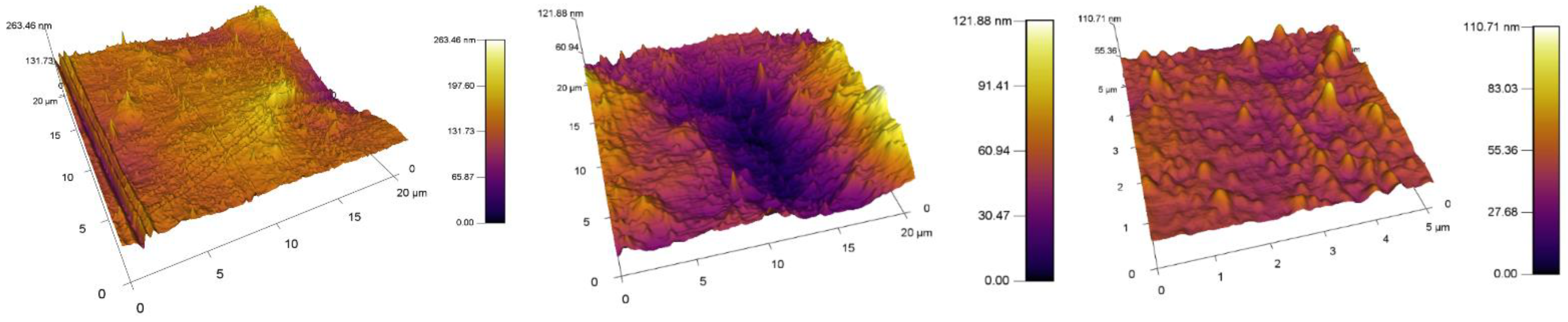

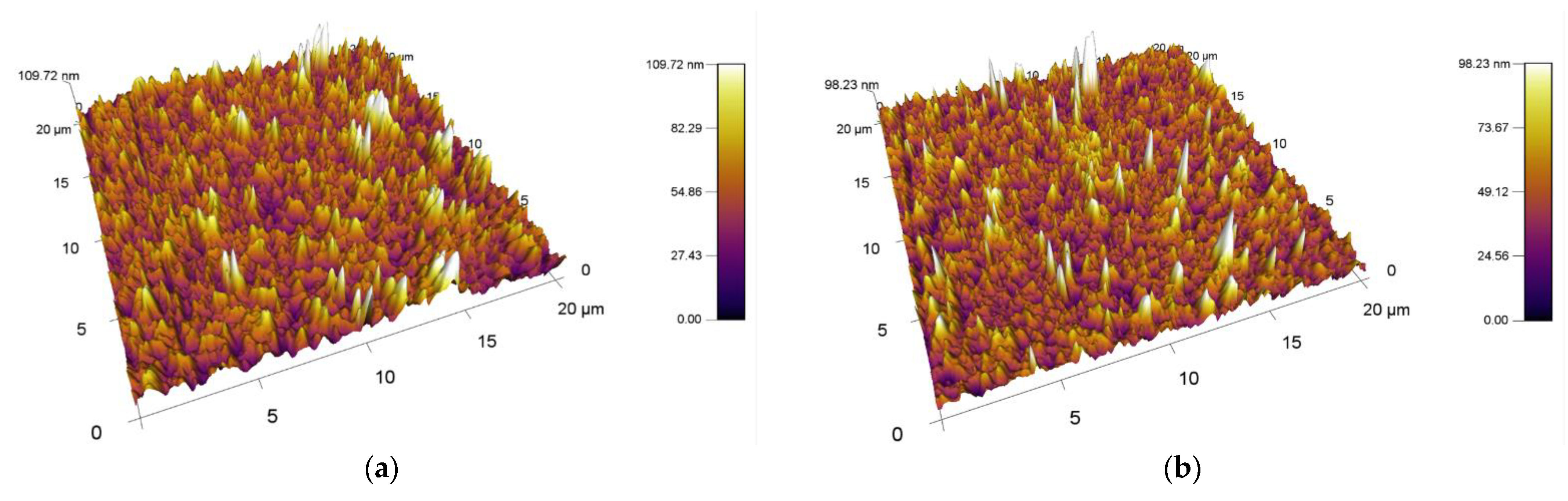

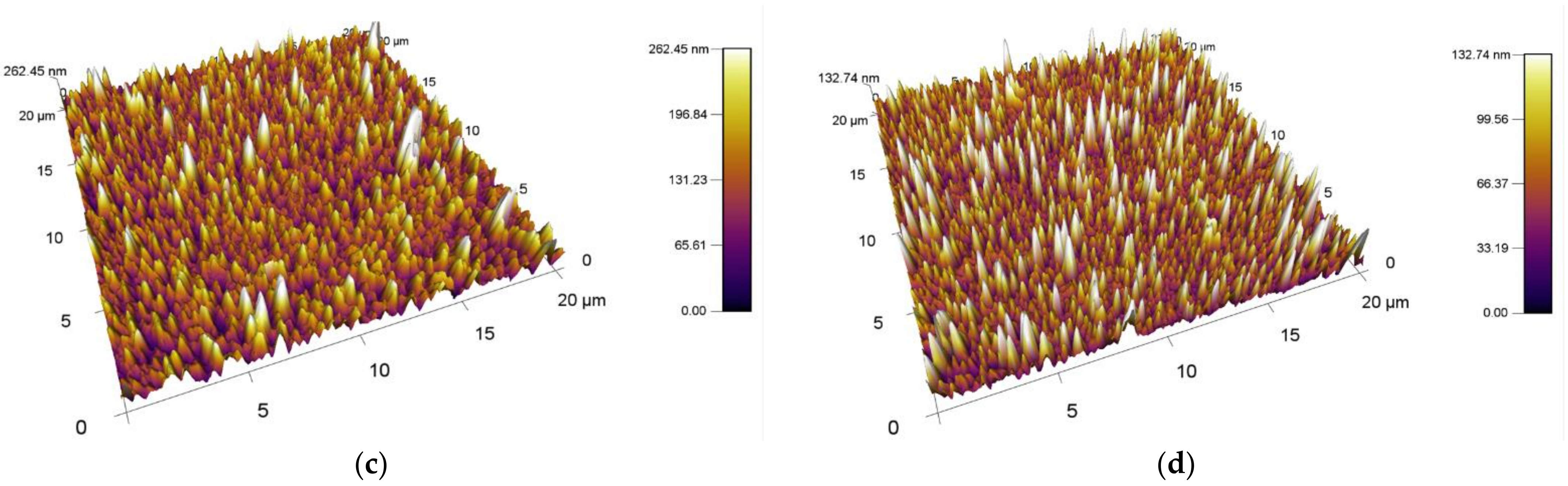

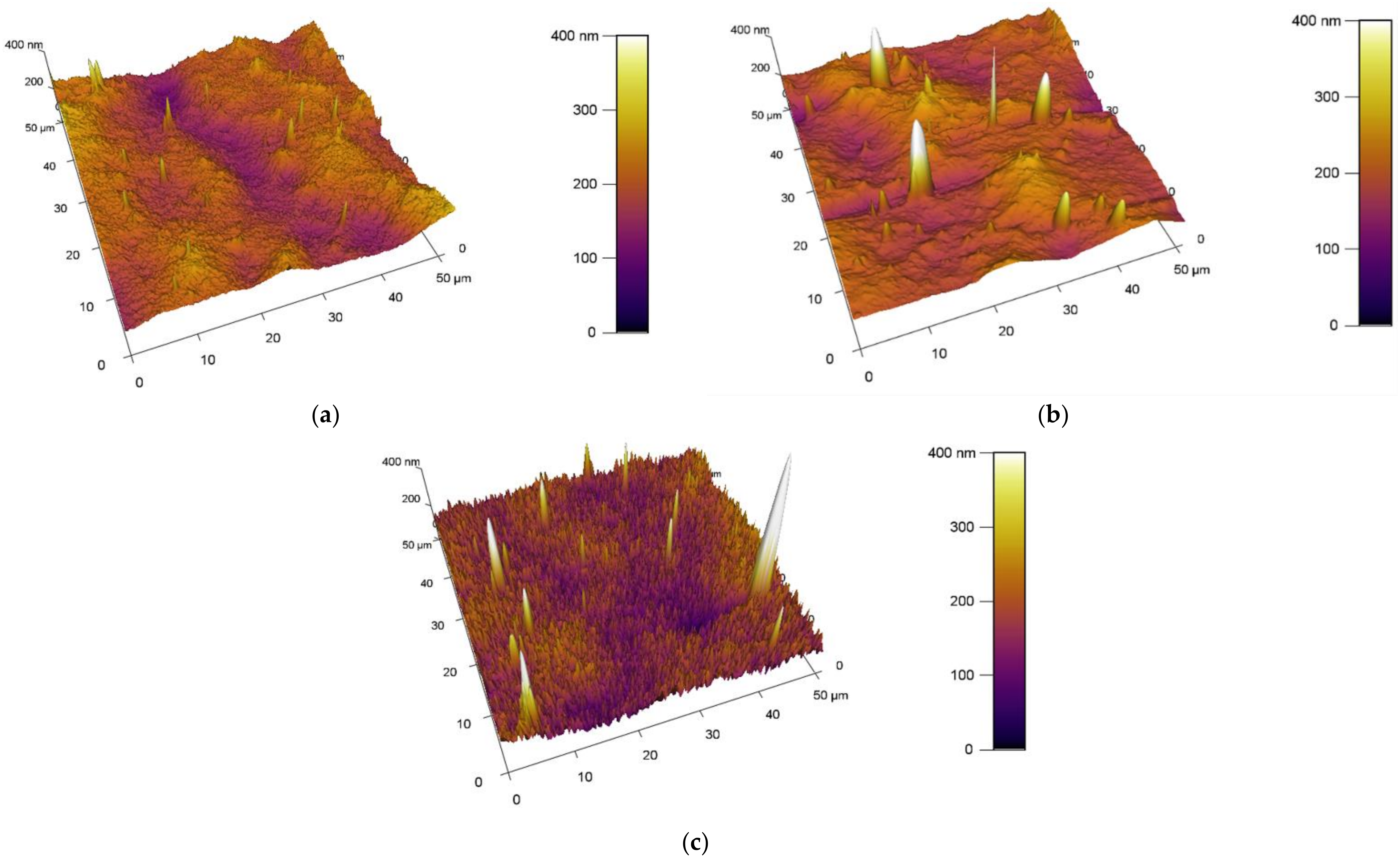

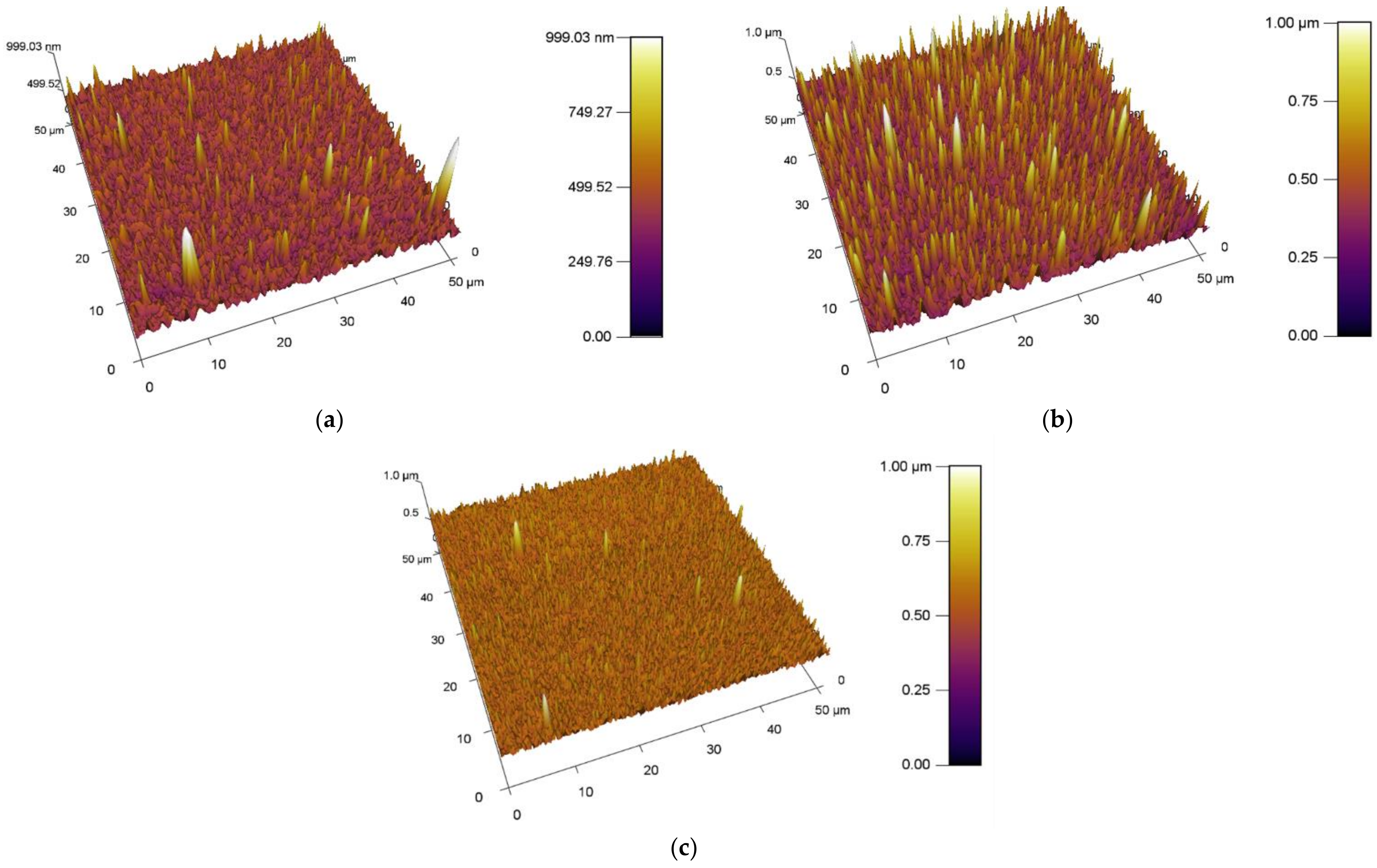

3.1.2. Observation of Surfaces Using AFM Method

Comparison of the Increase in Area and Roughness in PVC, I, II, III, IV Samples

Comparison of Surface Area and Roughness Increase with Type1/Type2 Modifications

3.1.3. Elemental Changes on Surfaces Detected by XPS Analysis

Comparison of Change in PVC, I, II, III, IV Samples

Comparison of Change in Type1/Type 2 Modifications

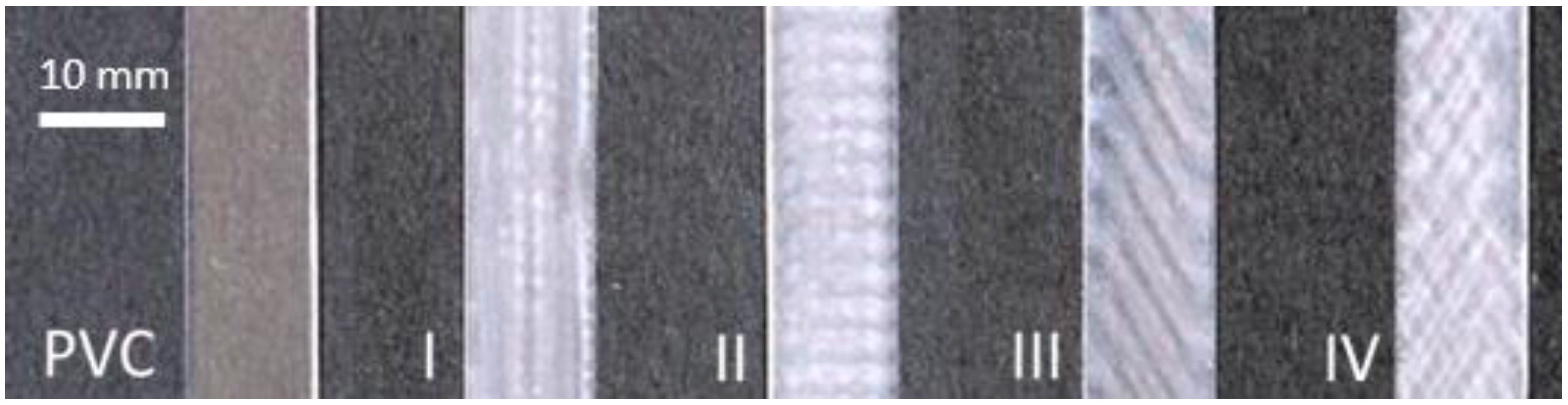

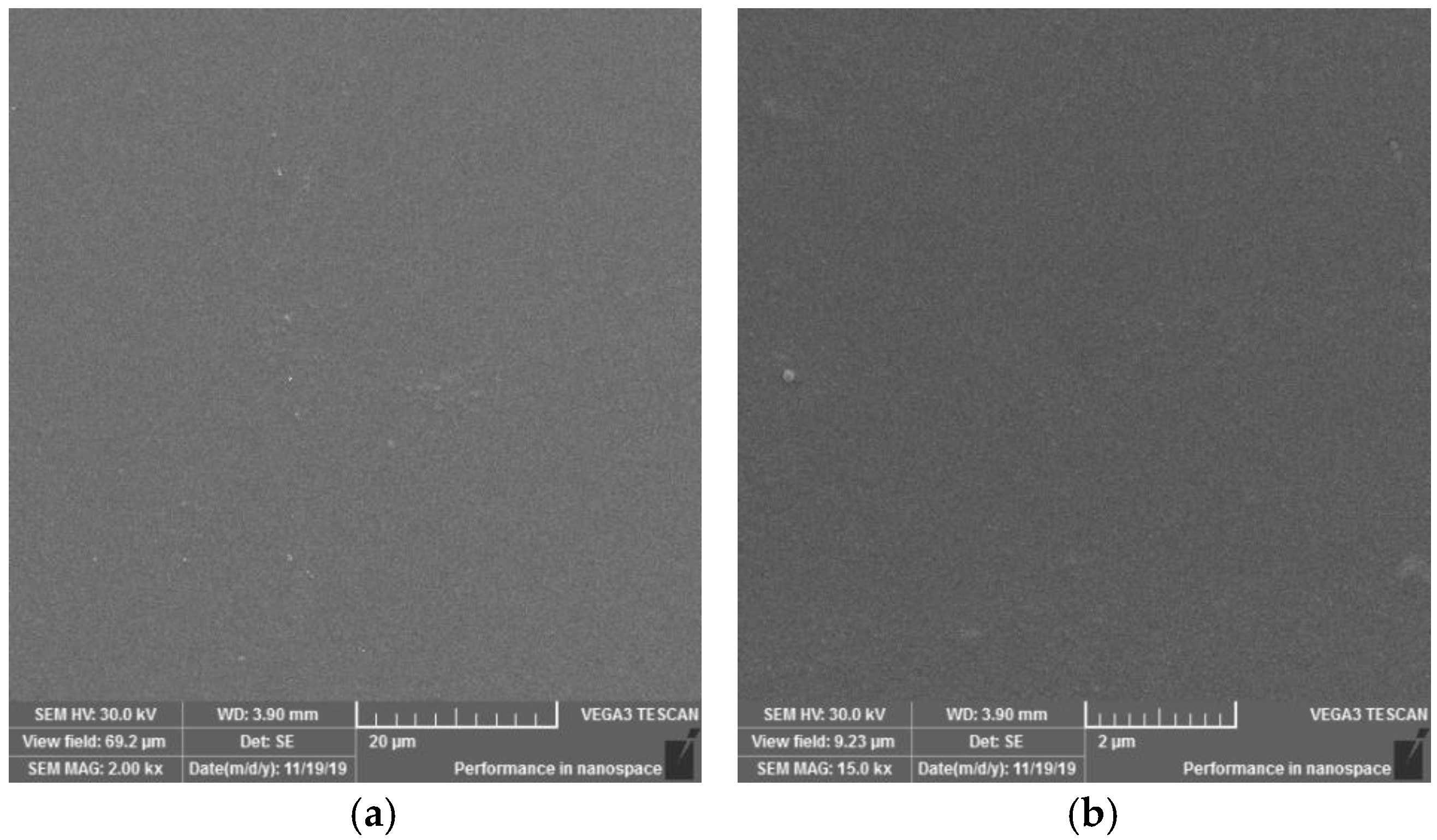

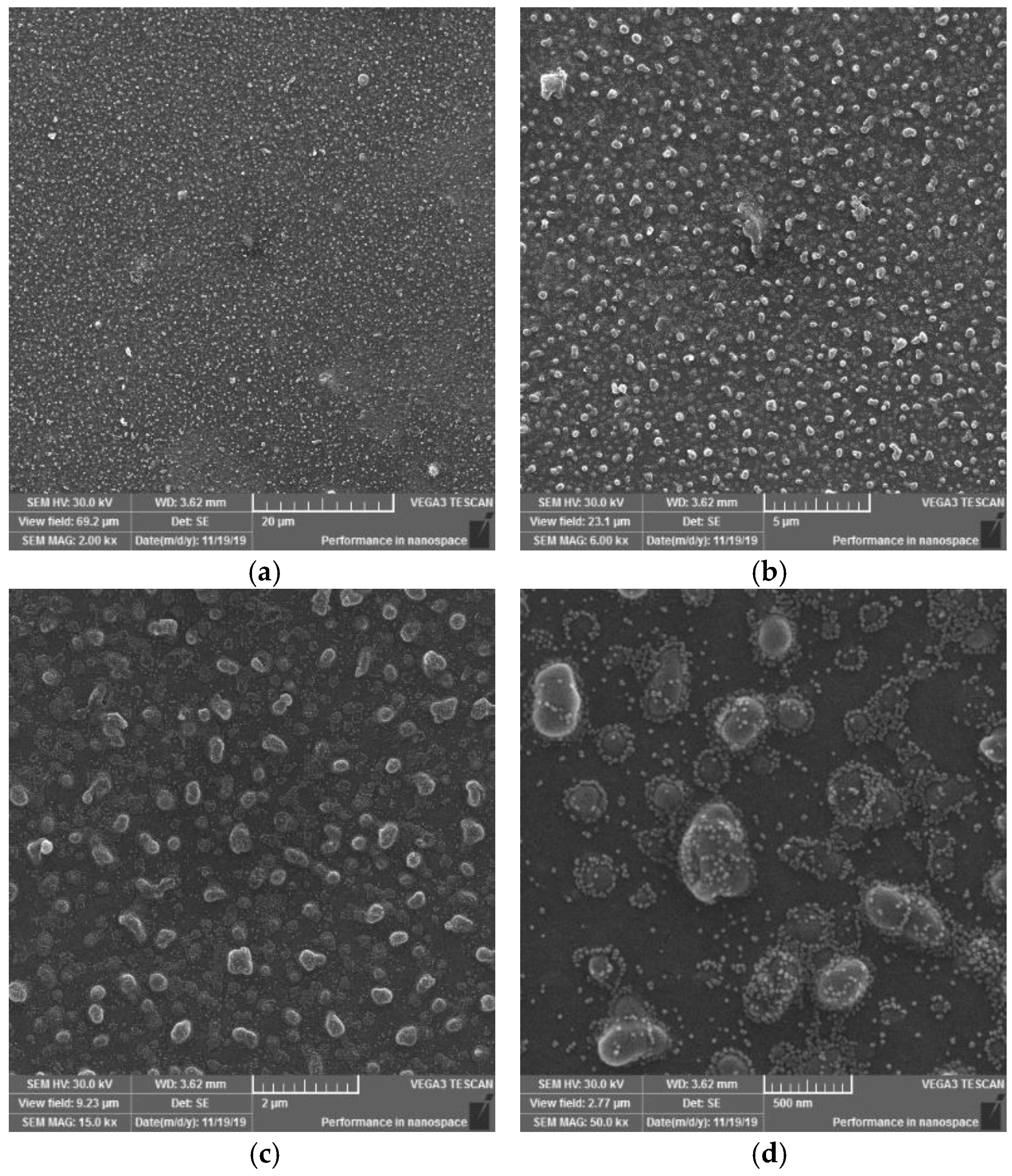

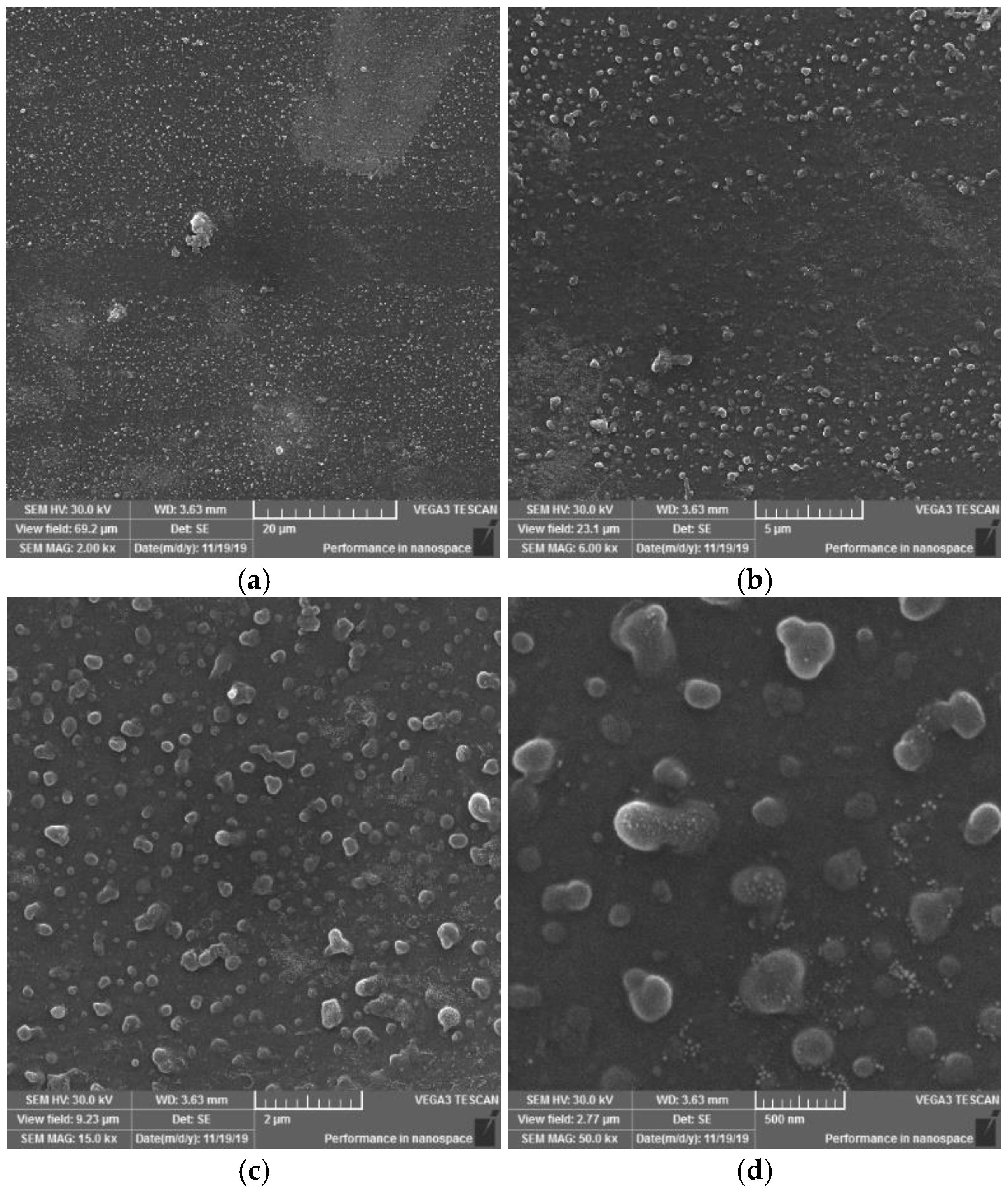

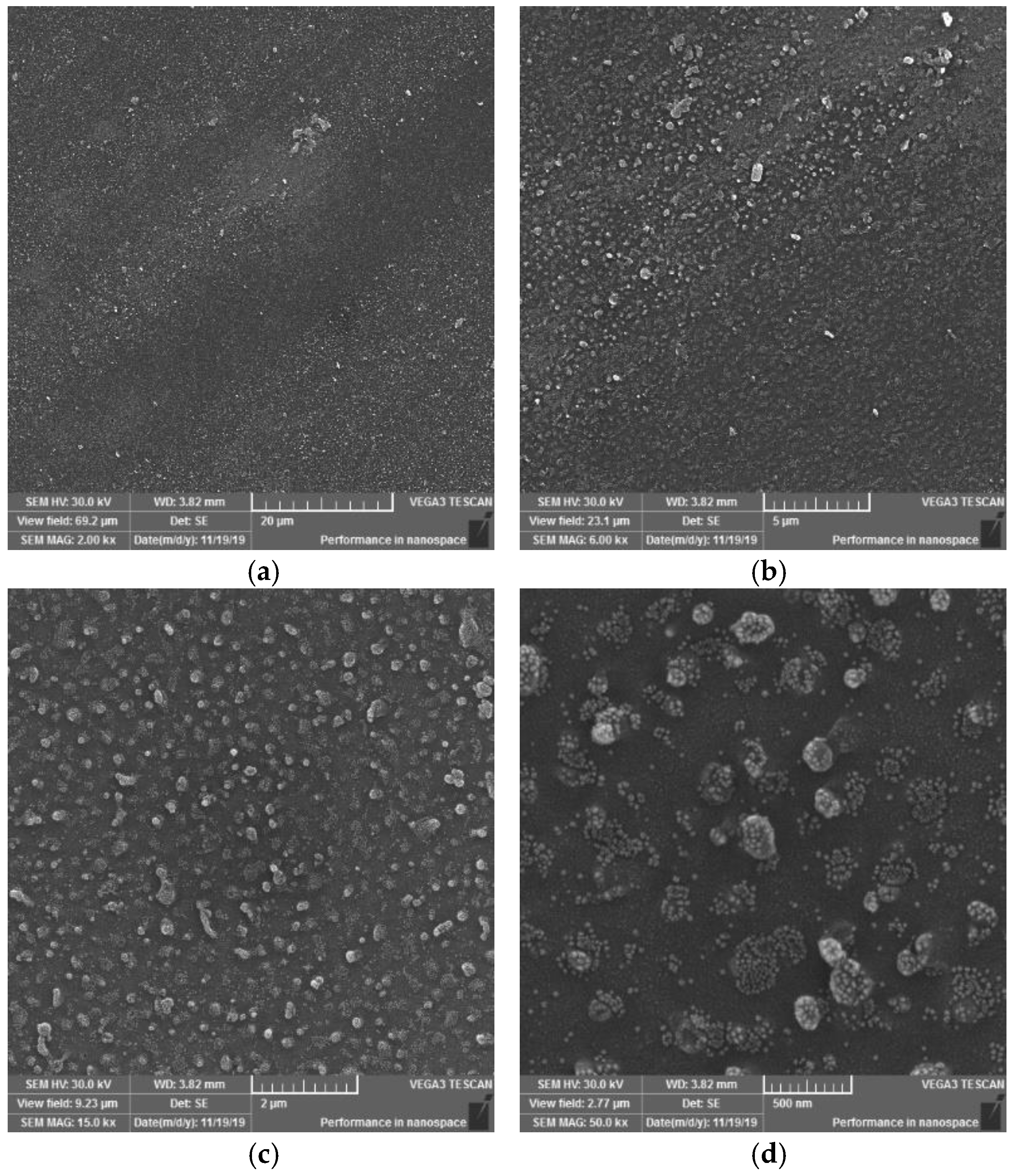

3.1.4. Surface Observation Using SEM Method

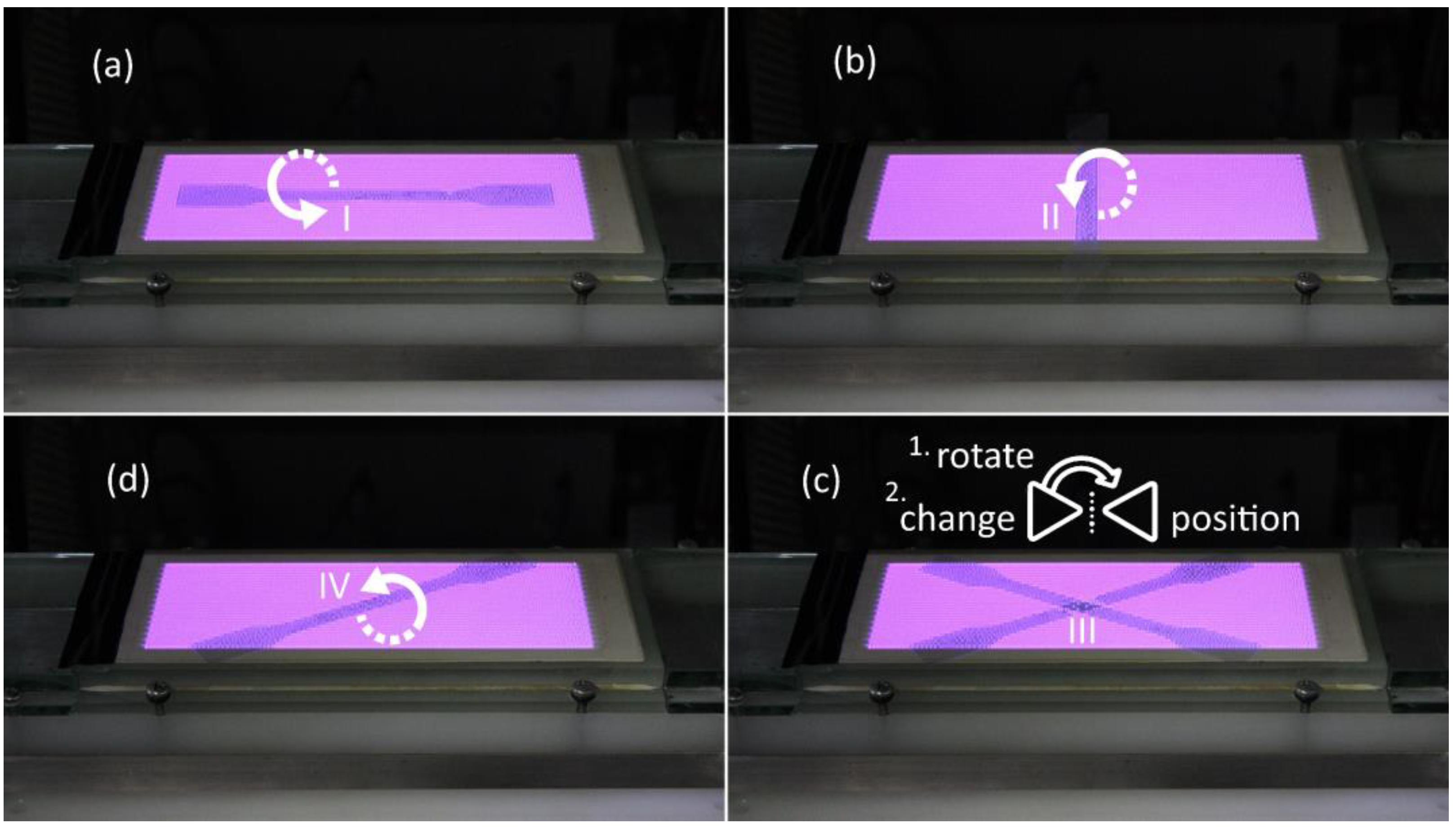

- Experimental setup:

- ○

- ○

- plasma exposure time—not investigated in this study,

- ○

- plasma reactor power—not investigated in this study,

- ○

- the distance of the material from the plasma-generating ceramic dielectric—not investigated in this study.

- The process of plasma-chemical treatment, the result of which depends on:

- ○

- The ratio of diffuse and filamentary plasma that interacts with the material:

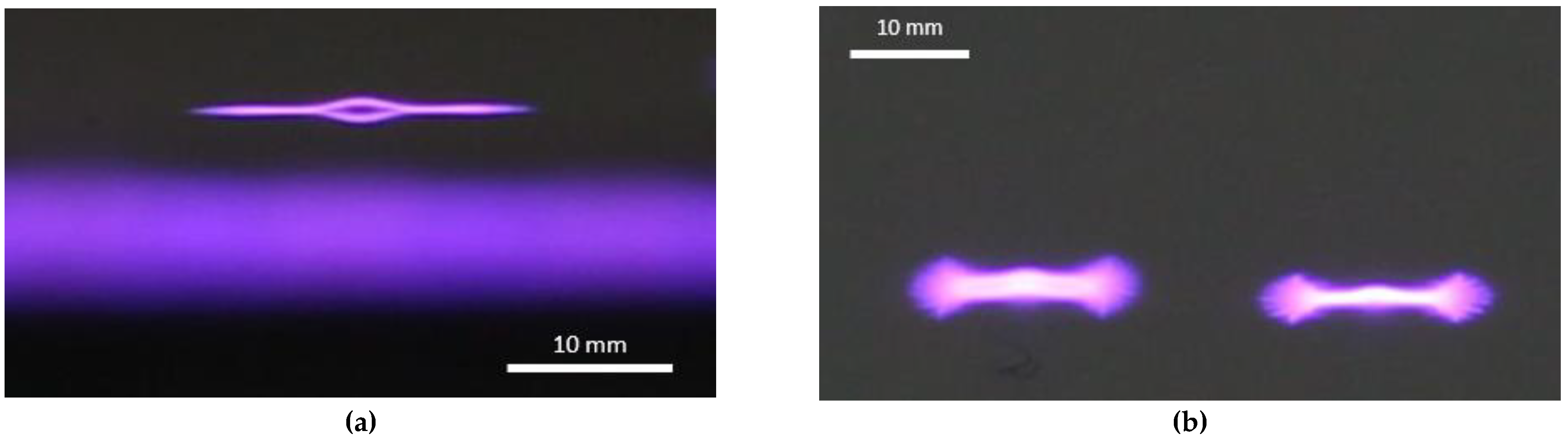

- PVC film exposed to DCSBD plasma loses insulating properties; thanks to the transparency of PVC, it was possible to observe a homogeneous plasma layer interacting with the PVC surface facing the ceramic dielectric during the modification/activation process, as well as individual micro-discharges—as insulated electric arcs breakthroughs turned away from the ceramic dielectric.

- The effect of DCSBD plasma was observed by changing the contact angles (Table 1, Figure 4), changes in roughness and surface area increase using the AFM method (Figure 8, Figure 9 and Figure 10, Table 2), XPS analysis (Table 3) and SEM microscopy (Figure 11, Figure 12, Figure 13, Figure 14 and Figure 15).

- ○

- The presence of ozone (Figure 5) generated during plasma modification and its concentration (this depends on all known variables listed in the experimental settings above + atmospheric conditions—atmospheric pressure, relative humidity in the laboratory/industrial application)—were not examined in this study.

- According to the available literature, ozone interacts with polymer double bonds. This reaction usually results in the breakdown of the polymer chain into fragments, which reduces the molecular weight of the individual chains. The material thus loses overall strength and other mechanical properties [39]. This fact is described below (Static tensile test—Table 4).

- ○

- The intensity of UV radiation (especially UV-B) generated by plasma, affects the material during exposure.

- According to the literature, due to the presence of abnormalities in the polymer matrix caused by the presence of C=O and O-O, PVC shows the ability of photo-oxidative degradation. Evidence of degradation by photooxidation is cracking, embrittlement, yellowing and opacity of the polymer.

3.2. Study of Thermal Properties

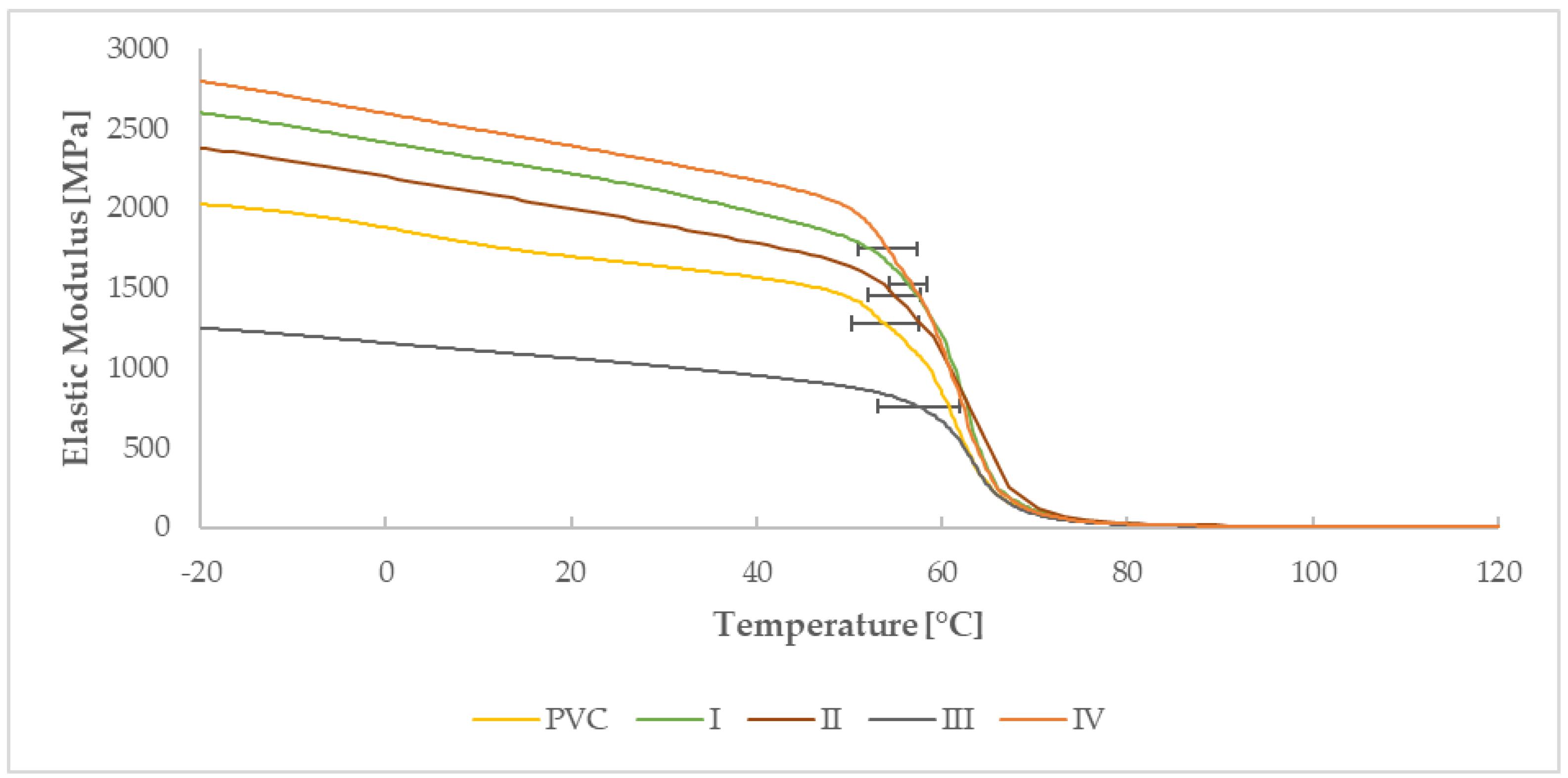

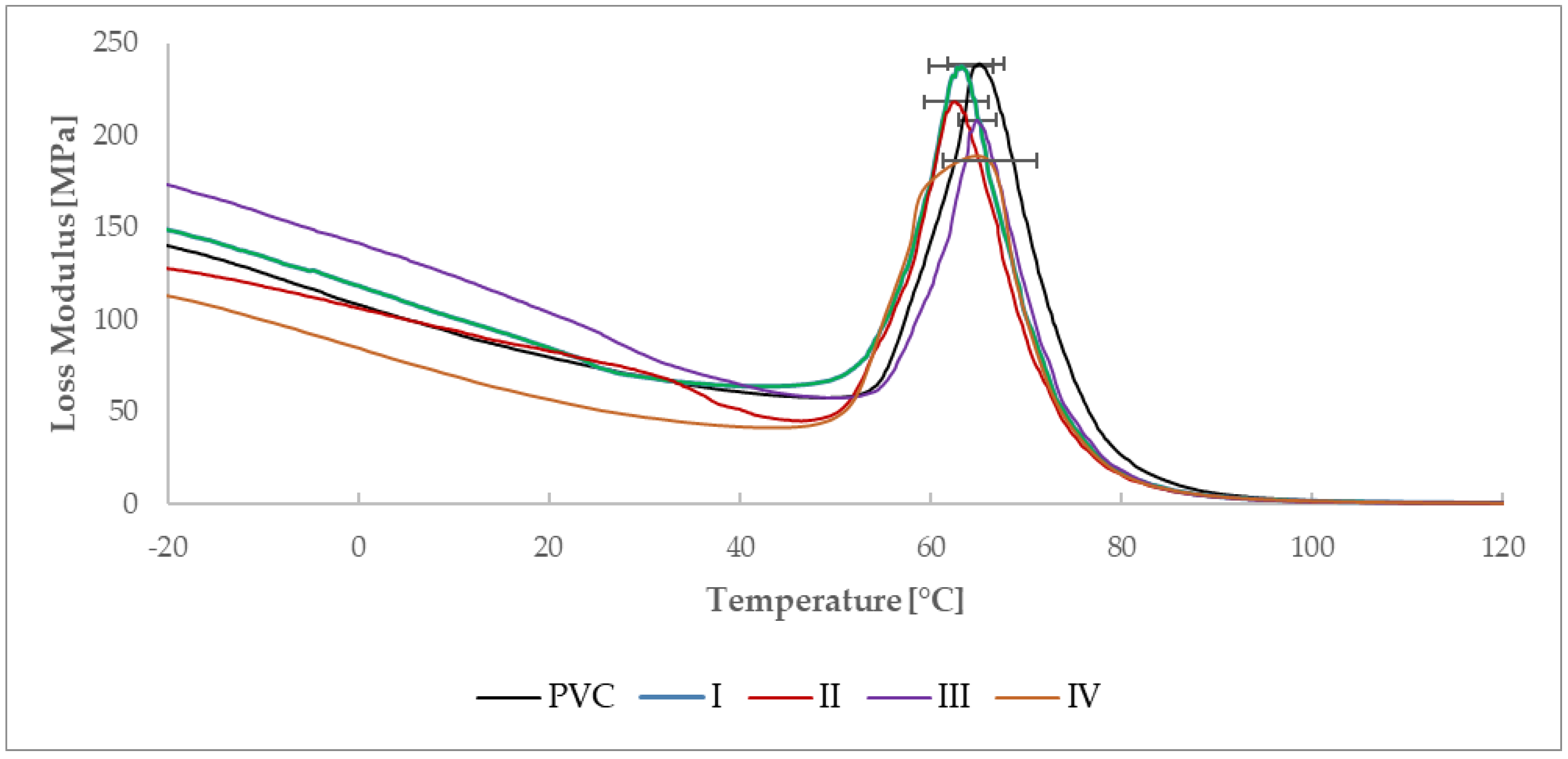

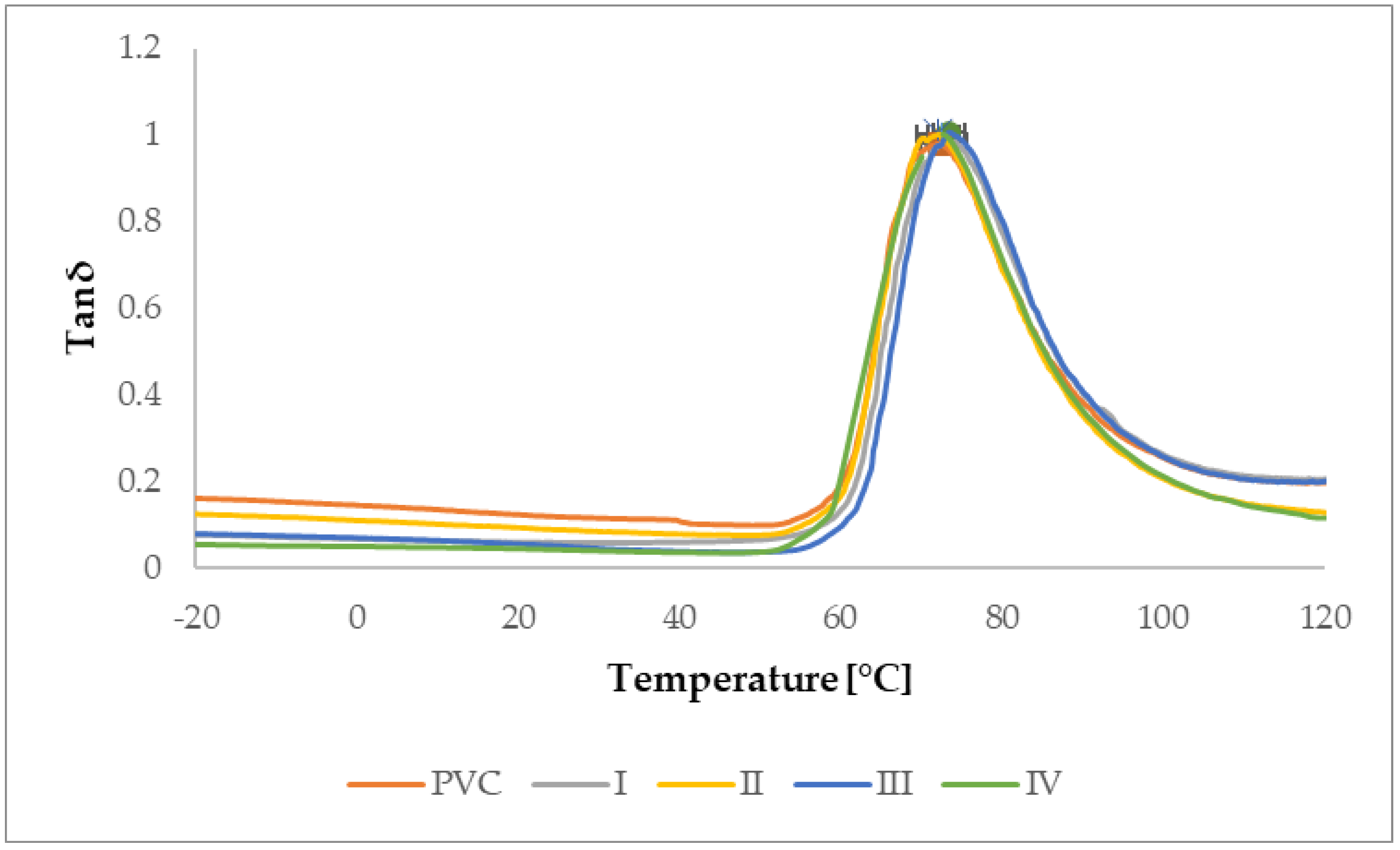

3.2.1. Determination of Glass Transition Temperature by DMA Analysis

- 8.5 times larger when comparing samples II vs. III, both of which were plasma modified (transverse and oblique),

- 3.9 times larger when comparing PVC x III samples

- 3.5 times larger when comparing PVC x I samples. Both series compare the unmodified PVC polymer film with the selected type of plasma modification.

- 5.8 times larger when comparing the loss modulus of plasma modified I x III samples.

- 3.6 times larger when comparing plasma modified II x III samples.

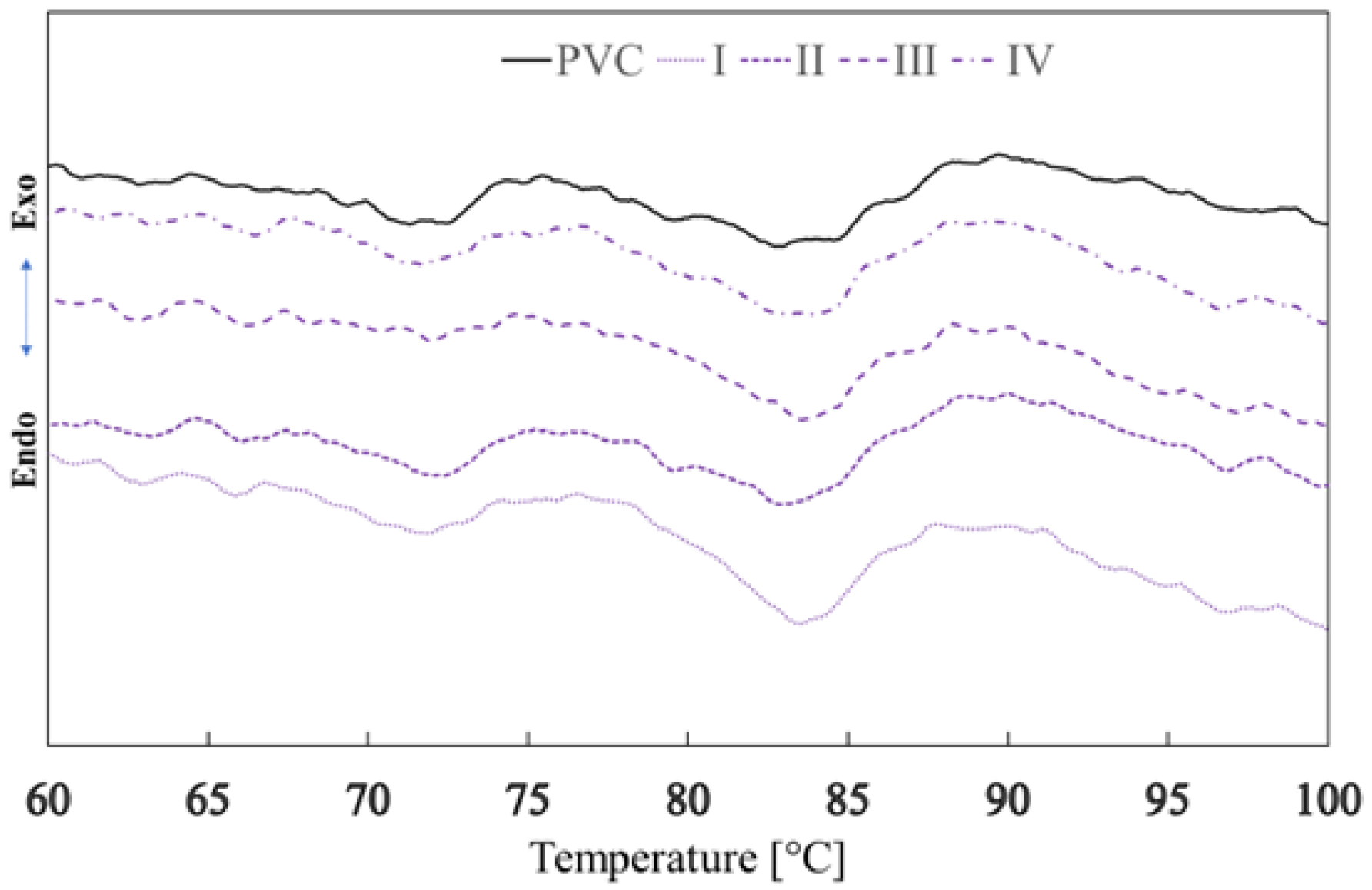

3.2.2. Determination of Glass Transition Temperature Using DSC Analysis

- ○

- using dynamic mechanical analysis, this change represented, on average, an increase in the glass transition temperature by 0.39 °C,

- ○

- using the DSC analysis, this change represented, on average, an increase of 0.49 °C.

3.3. Study of Mechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Leszczynska, A.; Pielichowski, K. Application of thermal analysis methods for characterization of polymer/montmorillonite nanocomposites. J. Therm. Anal. Calorim. 2008, 93, 677–687. [Google Scholar] [CrossRef]

- Papageorgiou, G.Z.; Palani, A.; Gilliopoulos, D.; Triantafylidis, K.S. Mechanical properties and crystallization of high-density polyethylene composites with mesostructured cellular silica foam. J. Therm. Anal. Calorim. 2013, 113, 1651–1665. [Google Scholar] [CrossRef]

- Teixeira, M.; Del Hoyo, I.; Wandrowelsti, F.; Swinka-Filho, V.; Munaro, M. Evaluation of thermal degradation in isotactic polypropylene films used in power capacitors. J. Therm. Anal. Calorim. 2017, 130, 997–1002. [Google Scholar] [CrossRef]

- Frone, A.N.; Panaitescu, D.M.; Chiulan, I.; Gabor, A.R.; Nicolae, C.A.; Oprea, M.; Ghiurea, M.; Gavrilescu, D.; Puitel, A.C. Thermal and mechanical behavior of biodegradable polyester films containing cellulose nanofibers. J. Therm. Anal. Calorim. 2019, 138, 2387–2398. [Google Scholar] [CrossRef]

- Kogelschatz, U. Collective phenomena in volume and surface barrier discharges. J. Phys. 2010, 257, 012015. [Google Scholar] [CrossRef] [Green Version]

- Ivanova, T.V.; Krumpolec, R.; Homola, T.; Musin, E.; Baier, G.; Landfester, K.; Cameron, D.C.; Černák, M. Ambient air plasma pre-treatment of non-woven fabrics for deposition of antibacterial poly (l-lactide) nanoparticles. Plasma Process Polym. 2017, 14, 10. [Google Scholar] [CrossRef]

- Černák, M.; Černáková, Ľ.; Hudec, I.; Kováčik, D.; Zahoranová, A. Diffuse Coplanar Surface Barrier Discharge and its applications for in-line processing of low-added-value materials. EPJ Appl. Phys. 2009, 47, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Simek, M.; Homola, T. Optical and electrical characteristics of Dielectric Coplanar Surface Barrier Discharge in nitrogen. In Proceedings of the ICPIG 2007, Prague, Czech Republic, 15–20 July 2007. [Google Scholar]

- Sihelník, D. Surface Treatment of Polymer Films in Plasma Excited at Atmospheric Pressure. Bachelor’s Thesis, Masaryk University, Brno, Czech Republic, 2016. [Google Scholar]

- Klébert, S.; Tilajka, S.; Románszki, L.; Mohai, M.; Csiszár, E.; Károly, Z. Degradation phenomena on atmospheric air plasma treatment of polyester fabrics. Surf. Interfaces 2021, 22, 100826. [Google Scholar] [CrossRef]

- Krbaťa, M.; Majerík, J.; Barényi, I.; Mikušová, I.; Kusmič, D. Mechanical and tribological features of the 90MnCrV8 steel after plasma nitriding. Manuf. Technol. 2019, 19, 238–242. [Google Scholar] [CrossRef]

- Károly, Z.; Kalácska, G.; Zsidai, L.; Mohai, M.; Klébert, S. Improvement of Adhesion Properties of Polyamide 6 and Polyoxymethylene-Copolymer by Atmospheric Cold Plasma Treatment. Polymers 2018, 10, 1380. [Google Scholar] [CrossRef] [Green Version]

- Murthy, V.S.M.D.; Vaidya, U. Improving the adhesion of glass/polypropylene (glass-PP) and high-density polyethylene (HDPE) surfaces by open air plasma treatment. Int. J. Adhes. Adhes. 2019, 95, 102435. [Google Scholar]

- Amorim, M.K.M.; Rangel, E.C.; Landers, R.; Durrant, S.F. Effects of cold SF6 plasma treatment on a-C:H, polypropylene and polystyrene. Surf. Coat. Technol. 2020, 385, 125398. [Google Scholar] [CrossRef]

- Bagiatis, V.; Critchlow, G.W.; Price, D.; Wang, S. The effect of atmospheric pressure plasma treatment (APPT) on the adhesive bonding of poly(methyl methacrylate) (PMMA)-to-glass using a polydimethylsiloxane (PDMS)-based adhesive. Int. J. Adhes. Adhes. 2019, 95, 102405. [Google Scholar] [CrossRef]

- Buček, A.; Brablec, A.; Kováčik, D.; Sťahel, P.; Černák, M. Glass bond adhesive strength improvement by DCSBD atmospheric-pressure plasma treatment. Int. J. Adhes. Adhes. 2017, 78, 1–3. [Google Scholar] [CrossRef]

- Homola, T.; Matoušek, J.; Kormunda, M.; Wu, L.Y.L.; Černák, M. Plasma Treatment of Glass Surfaces Using Diffuse Coplanar Surface Barrier Discharge in Ambient Air. Plasma Chem. Plasma Process 2013, 33, 881–894. [Google Scholar] [CrossRef]

- Rafailović, L.D.; Stupavska, M.; Prysiazhnyi, V.; Polt, G.; Rohr, O.; Nixon, S.; Rahel, J. Impact of atmospheric pressure plasma treatment on surface metallization of CFRP composites. Surf. Coat. Technol. 2021, 412, 127046. [Google Scholar] [CrossRef]

- Shepa, I.; Mudra, E.; Pavlinak, D.; Antal, V.; Bednarcik, J.; Mikovic, O.; Kovalcikova, A.; Dusza, J. Surface plasma treatment of the electrospun TiO2/PVP composite fibers in different atmospheres. Appl. Surf. Sci. 2020, 523, 146381. [Google Scholar] [CrossRef]

- Pavliňák, D.; Galmiz, O.; Pavliňáková, V.; Poláček, P.; Kelar, J.; Stupavská, M.; Černák, M. Application of dielectric barrier plasma treatment in the nanofiber processing. Mater. Today Commun. 2018, 16, 330–338. [Google Scholar]

- Trejbal, J.; Kopecký, L.; Tesárek, P.; Fládr, J.; Antoš, J.; Somr, M.; Nežerka, V. Impact of surface plasma treatment on the performance of PET fiber reinforcement in cementitious composites. Cem. Concr. Res. 2016, 89, 276–287. [Google Scholar] [CrossRef]

- Radić, N.; Obradović, B.M.; Kostić, M.; Dojčinović, B.; Kuraica, M.M.; Černák, M. Deposition of silver ions onto DBD and DCSBD plasma treated nonwoven polypropylene. Surf. Coat. Technol. 2012, 206, 5006–5011. [Google Scholar] [CrossRef]

- Naebe, M.; Haque, A.N.M.A.; Haji, A. Plasma-assisted antimicrobial finishing of textiles: A review. Engineering 2021, 89, 276–287. [Google Scholar] [CrossRef]

- Hasan, M.M.; Zhu, F.; Ahmed, A.; Khoso, N.A.; Deb, H.; Yuchao, L.; Islam, M.Z.; Sun, H.; Yu, B. Functionalization of polypropylene nonwoven fabrics using cold plasma (O2) for developing graphene-based wearable sensors. Sens. Actuator A Phys. 2019, 300, 111637. [Google Scholar] [CrossRef]

- Kawakami, R.; Yoshitani, Y.; Mitani, K.; Niibe, M.; Nakano, Y.; Azuma, C.; Mukai, T. Effects of air-based nonequilibrium atmospheric pressure plasma jet treatment on characteristics of polypropylene film surfaces. Appl. Surf. Sci. 2020, 509, 144910. [Google Scholar] [CrossRef]

- Correia, D.M.; Nunes-Pereira, J.; Alikin, D.; Kholkin, A.L.; Carabineiro, S.A.C.; Rebouta, L.; Rodrigues, M.S.; Vaz, F.; Costa, C.M.; Lanceros-Méndez, S. Surface wettability modification of poly(vinylidene fluoride) and copolymer films and membranes by plasma treatment. Polymer 2019, 169, 138–147. [Google Scholar] [CrossRef]

- Talviste, R.; Galmiz, O.; Stupavská, M.; Tučeková, Z.; Kaarna, K.; Kováčik, D. Effect of DCSBD plasma treatment on surface properties of thermally modified wood. Surf. Interfaces 2019, 16, 8–14. [Google Scholar] [CrossRef]

- Macedo, M.J.P.; Silva, G.S.; Feitor, M.C.; Costa, T.H.C.; Ito, E.N.; Melo, J.D.D. Surface modification of kapok fibers by cold plasma surface treatment. J. Mater. Res. Technol. 2020, 9, 2467–2476. [Google Scholar] [CrossRef]

- Bulbul, V.J.; Bhushette, P.R.; Zambare, R.S.; Deshmukh, R.R.; Annapure, U.S. Effect of cold plasma treatment on Xanthan gum properties. Polym. Test. 2019, 79, 106056. [Google Scholar] [CrossRef]

- Limnaios, A.; Pathak, N.; Bovi, G.G.; Fröhling, A.; Valdramidis, V.P.; Taoukis, P.S.; Schlüter, O. Effect of cold atmospheric pressure plasma processing on quality and shelf life of red currants. LWT 2021, 151, 112213. [Google Scholar] [CrossRef]

- Hu, X.; Sun, H.; Yang, X.; Cui, D.; Wang, Y.; Zhuang, J.; Wang, X.; Ma, R.; Jiao, Z. Potential use of atmospheric cold plasma for postharvest preservation of blueberries. Postharvest Biol. Technol. 2021, 179, 111564. [Google Scholar] [CrossRef]

- Hou, Y.; Wang, R.; Gan, Z.; Shao, T.; Zhang, X.; Hem, M.; Sun, A. Effect of cold plasma on blueberry juice quality. Food Chem. 2019, 290, 79–86. [Google Scholar] [CrossRef]

- Misra, N.N.; Yepez, X.; Xu, L.; Keener, K. In-package cold plasma technologies. J. Food Eng. 2019, 244, 21–31. [Google Scholar] [CrossRef]

- Krumpolec, R.; Richter, V.; Zemánek, M.; Homola, T. Multi-hollow surface dielectric barrier discharge for plasma treatment of patterned silicon surfaces. Surf. Interfaces 2019, 16, 181–187. [Google Scholar] [CrossRef]

- Hvojnik, M.; Vida, J.; Homola, T.; Pavličková, M.; Hatala, M.; Tomanová, K.; Mikula, M.; Gemeiner, P. The effect of rapid atmospheric plasma treatment of FTO substrates on the quality of TiO2 blocking layers for printed perovskite solar cells. Mater. Sci. Semicond. Process. 2021, 131, 105850. [Google Scholar] [CrossRef]

- Medvecká, V.; Kováčik, D.; Stupavská, M.; Roch, T.; Kromka, A.; Fajgar, R.; Zahoranová, A.; Černák, M. Preparation and characterization of alumina submicron fibers by plasma assisted calcination. Ceram. Int. 2020, 46, 22774–22780. [Google Scholar] [CrossRef]

- Liu, P.; Song, Y.; Zhang, Z. A Novel Dielectric Barrier Discharge (DBD) Reactor with Streamer and Glow Corona Discharge for Improved Ozone Generation at Atmospheric Pressure. Micromachines 2021, 12, 1287. [Google Scholar] [CrossRef]

- Štěpánová, V.; Šrámková, P.; Sihelník, S.; Stupavská, M.; Jurmanová, J.; Kováčik, D. The effect of ambient air plasma generated by coplanar and volume dielectric barrier discharge on the surface characteristics of polyamide foils. Vacuum 2021, 183, 109887. [Google Scholar] [CrossRef]

- Crawford, C.B.; Quinn, B. 4—Physiochemical properties and degradation. Microplast. Pollut. 2017, 2017, 57–100. [Google Scholar]

- Janík, R.; Kohutiar, M.; Pajtášová, M.; Ondrušová, D.; Skalková, P.; Eckert, M. Application of diffuse coplanar surface barrier plasma discharge to polymeric materials. Mater. Werkst. 2022, 53, 494–502. [Google Scholar] [CrossRef]

- Chlupová, S.; Kelar, J.; Slavicek, P. Changing the Surface Properties of ABS Plastic by Plasma. Plasma Sci. Technol. 2017, 4, 32–35. [Google Scholar] [CrossRef]

- Šrámková, P.; Zahoranová, A.; Kelar, J.; Tučeková, Z.K.; Stupavská, M.; Krumpolec, R.; Jurmanová, J.; Kováčik, D.; Černák, M. Cold atmospheric pressure plasma: Simple and efficient strategy for preparation of poly(2-oxazoline)-based coatings designed for biomedical applications. Sci. Rep. 2020, 10, 9478. [Google Scholar] [CrossRef]

- Skácelová, D.; Haničinec, M.; Sťahel, P.; Černák, M. Oxidation of Silicon Surface by DCSBD. In Proceedings of the 4th International Conference on NANOCON, Brno, Czech Republic, 23–25 October 2012; Available online: http://konsys-t.tanger.cz/files/proceedings/04/reports/772.pdf (accessed on 22 September 2021).

- Skácelová, D.; Sládek, P.; Sťahel, P.; Pawera, L.; Hanicinec, M.; Meichsner, J.; Černák, M. Properties of atmospheric pressure plasma oxidized layers on silicon wafers. Open Chem. 2014, 13, 376–381. [Google Scholar] [CrossRef]

- Krumpolec, R.; Čech, J.; Jurmanová, J.; Ďurina, P.; Černák, M. Atmospheric pressure plasma etching of silicon dioxide using diffuse coplanar surface barrier discharge generated in pure hydrogen. Surf. Coat. Technol. 2017, 309, 301–308. [Google Scholar] [CrossRef]

- Papučová, I.; Šulcová, J.; Plško, A.; Pagáčová, J. Surface Properties of Corroded SiO2 Films. In Hutnícke Listy. 2016. Available online: https://www.hutnickelisty.cz/wp-content/uploads/2019/10/PapucovaHL5-2016.pdf (accessed on 15 October 2021).

- Goldírová, K. Influence of Segmentation of Textiles to Surface Wettability. Diploma Thesis, Technical University of Liberec, Liberec, Czech Republic, 2006. [Google Scholar]

- Patra, N.; Hladik, J.; Martinova, L. Investigating the thermal properties of polyethylene plasma modified by using unconventional chemical vapors. J. Therm. Anal. Calorim. 2014, 117, 229–234. [Google Scholar] [CrossRef]

- ISO 527-3:2018; Plastics—Determination of Tensile Properties—Part 3: Test Conditions for Films and Sheets. ISO: Geneva, Switzerland, 2018.

- McGinty, K.; Brittain, W. Hydrophilic surface modification of poly(vinyl chloride) film and tubing using physisorbed free radical grafting technique. Polymer 2008, 49, 4350–4357. [Google Scholar] [CrossRef]

- Bento, W.C.A.; Honda, R.Y.; Kayama, M.E.; Schreiner, W.H.; Cruz, N.C.; Rangel, E.C. Hydrophilization of PVC Surfaces by Argon Plasma Immersion Ion Implantation. Plasmas Polym. 2003, 8, 1–11. [Google Scholar] [CrossRef]

- Farag, O.F. The Influence of DC Glow Discharge Plasma on the Hydrophilic Properties of Polyvinyl Chloride Films. Adv. Appl. Sci. Res. 2017, 8, 49–54. [Google Scholar]

- Thurston, R.M.; Clay, J.D.; Schulte, M.D. Effect of Atmospheric Plasma Treatment on Polymer Surface Energy and Adhesion. J. Plast. Film Sheeting 2007, 23, 63–78. [Google Scholar] [CrossRef]

- Hansen, F.K. The Measurement of Surface Energy of Polymers by Means of Contact Angles of Liquids on Solid Surfaces: A Short Overview of Frequently Used Methods; University of Oslo: Oslo, Norway, 2004; Available online: http://www.ramehart.com/surface_energy_finn.pdf (accessed on 28 October 2021).

- Homola, T.; Pongrác, B.; Zemánek, M.; Simek, M. Efficiency of Ozone Production in Coplanar Dielectric Barrier Discharge. Plasma Chem. Plasma Process. 2019, 39, 1227–1242. [Google Scholar] [CrossRef]

- Kucherenko, O.B.; Kohlert, C.; Sosnov, E.A.; Malygin, A.A. Synthesis and properties of polyvinyl chloride films with modified surface. Russ. J. Appl. Chem. 2006, 79, 1316–1320. [Google Scholar] [CrossRef]

- Joseph, J.; Deshmukh, K.; Chidambaram, K.; Faisal, M.; Selvarajan, E.; Sadasivuni, K.K.; Ahamed, M.B.; Pasha, S.K.K. Dielectric and electromagnetic interference shielding properties of germanium dioxide nanoparticle reinforced poly(vinyl chloride) and poly(methylmethacrylate) blend nanocomposites. J. Mater. Sci. Mater. Electron. 2018, 29, 20172–20188. [Google Scholar] [CrossRef]

- Demirci, N.; Demirel, M.; Dilsiz, N. Surface Modification of PVC Film with Allylamine Plasma Polymers. Adv. Polym. Technol. 2014, 33, 21435. [Google Scholar] [CrossRef]

- Zhao, E.; Wang, L.; Yan, L.; Torimoto, Y.; Li, Q. Surface modification of medical poly(vinyl chloride) with O−water. J. Appl. Polym. Sci. 2008, 110, 39–48. [Google Scholar] [CrossRef]

- Jawad, H.M.; Shallal, I.H.; Hassoni, M.H. Experimental and theoretical study of (PVC) nanoparticles prepared by laser ablation in ethanol. AIP Conf. Proc. 2019, 2123, 020101. [Google Scholar]

- El-Hiti, G.A.; Ahmed, D.S.; Yousif, E.; Alotaibi, M.H.; Satar, H.A.; Ahmed, A.A. Influence of Polyphosphates on the Physicochemical Properties of Poly (Vinyl Chloride) after Irradiation with Ultraviolet Light. Polymers 2020, 12, 193. [Google Scholar] [CrossRef] [Green Version]

- D’yakova, A.K.; Trifonov, S.A.; Sosnov, E.A.; Malygin, A.A. Effect of chemical modification on structural and energy characteristics of the surface of polyethylene and polyvinyl chloride films. Russ. J. Appl. Chem. 2009, 82, 622–629. [Google Scholar] [CrossRef]

- Dvořáková, H.; Čech, J.; Stupavská, M.; Prokeš, L.; Jurmanová, J.; Buršíková, V.; Ráheľ, J.; Sťahel, P. Fast Surface Hydrophilization via Atmospheric Pressure Plasma Polymerization for Biological and Technical Applications. Polymers 2019, 11, 1613. [Google Scholar] [CrossRef] [Green Version]

- Merchán, M.; Sedlarikova, J.; Vesel, A.; Sedlarik, V.; Pastorek, M.; Saha, P. Characterization of Antibacterial, Mechanical, and Structural Properties of Polyvinyl Chloride/Silver Nitrate Composites Prepared by Thermoplastic Compounding. Int. J. Polym. Anal. Charact. 2010, 15, 360–369. [Google Scholar] [CrossRef]

- Čech, J.; Hanusová, J.; Sťahel, P.; Černák, M. Diffuse Coplanar Surface Barrier Discharge in Artificial Air: Statistical Behaviour of Microdischarges. Open Chem. 2014, 13, 528–540. [Google Scholar] [CrossRef]

- Belinger, A.; Naudé, N.; Ghérardi, N. Transition from diffuse to self-organized discharge in a high frequency dielectric barrier discharge. Eur. Phys. J. Appl. Phys. 2017, 79, 10802. [Google Scholar]

- Khorasani, M.T.; Mirzadeh, H. Effect of oxygen plasma treatment on surface charge and wettability of PVC blood bag—In vitro assay. Radiat. Phys. Chem. 2007, 76, 1011–1016. [Google Scholar] [CrossRef]

- Liptáková, T.; Alexy, P.; Gondár, E.; Khunová, V. Polymeric Construction Materials; EDIS: Žilina, Slovakia, 2012. [Google Scholar]

- Pedrosa, A.; Del Rio, M. Comparative scanning electron microscope study of the degradation of a plasticized polyvinyl chloride waterproofing membrane in different conditions. Mater. Constr. 2017, 67, e109. [Google Scholar] [CrossRef] [Green Version]

- TA Instruments. Frequency Dependence of Glass Transition Temperatures. Available online: https://www.tainstruments.com/pdf/literature/TA423.pdf (accessed on 10 September 2021).

- Janík, R.; Kohutiar, M.; Pajtášová, M.; Dubec, A.; Pagáčová, J.; Šulcová, J. The impact of DCSBD plasma discharge on polypropylene. IOP Conf. Ser. Mater. Sci. Eng. 2020, 776, 012090. [Google Scholar] [CrossRef]

- Pajtášová, M.; Mičicová, Z.; Ondrušová, D.; Božeková, S.; Janík, R.; Pecušová, B.; Raník, L. Use of waste materials in rubber matrix. MATEC Web Conf. 2018, 157, 07009. [Google Scholar] [CrossRef] [Green Version]

- Kohutiar, M.; Janík, R.; Pajtášová, M.; Ondrušová, D.; Labaj, I.; Mezencevová, V.Z. Study of structural changes in thermoplastics using dynamic mechanical analysis. IOP Conf. Ser. Mater. Sci. Eng. 2020, 776, 012092. [Google Scholar] [CrossRef] [Green Version]

- Kohutiar, M.; Pajtášová, M.; Janík, R.; Papučová, I.; Pagáčová, J.; Pecušová, B.; Labaj, I. Study of selected thermoplastics using dynamic mechanical analysis. MATEC Web Conf. 2018, 157, 07002. [Google Scholar] [CrossRef]

- Asadinezhad, A.; Lehotský, M.; Sáha, P.; Mozetič, M. Recent Progress in Surface Modification of Polyvinyl Chloride. Materials 2012, 5, 2937–2959. [Google Scholar] [CrossRef] [Green Version]

- Wypych, G. PVC Degradation and Stabilization, 3rd ed.; Elsevier: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Liau, W.B.; Tseng, F.P. The effect of long-term ultraviolet light irradiation on polymer matrix composites. Polym. Compos. 1998, 19, 440–445. [Google Scholar] [CrossRef]

- Yousif, E.; Haddad, R. Photodegradation and photostabilization of polymers, especially polystyrene: Review. SpringerPlus 2013, 2, 398. [Google Scholar] [CrossRef] [Green Version]

- Rangel, E.C.; Dos Santos, N.M.; Bortoleto, J.R.R.; Durrant, S.F.; Schreiner, W.H.; Honda, R.Y.; Rangel, R.D.C.C.; Cruz, N.C. Treatment of PVC using an alternative low energy ion bombardment procedure. Appl. Surf. Sci. 2011, 258, 1854–1864. [Google Scholar] [CrossRef]

- Oravcova, A.; Hudec, I. The Influence of Atmospheric Pressure Plasma Treatment on Surface Properties of Polypropylene Films. Acta Chim. Slovaca 2010, 3, 57–62. [Google Scholar]

| Sample Type Sample Designation | Test Liquid | |||||||

|---|---|---|---|---|---|---|---|---|

| MI | DW | MI | DW | MI | DW | |||

| Modification Type | ||||||||

| Type 1: Direct Exposure | Type 2: Indirect Exposure | |||||||

| MONO | DUAL | INDIRECT MONO | ||||||

| Contact Angle (°) | ||||||||

| Unmodified | PVC | 36.5 ± 2.7 | 88.0 ± 1.7 | 36.5 ± 2.7 | 88.0 ± 1.7 | 36.5 ± 2.7 | 88.0 ± 1.7 | |

| DCSBD plasma modified | By exposure type | I | 30.2 ± 4.9 | 49.4 ± 4.7 | 20.3 ± 2.6 | 51.8 ± 1.9 | 30.7 ± 7.5 | 64.9 ± 8.1 |

| II | 28.9 ± 4.2 | 50.2 ± 3.0 | 20.1 ± 1.8 | 50.0 ± 2.0 | 33.2 ± 4.9 | 62.9 ± 4.5 | ||

| III | 32.4 ± 3.3 | 49.9 ± 5.4 | 16.0 ± 1.1 | 55.3 ± 0.7 | 31.2 ± 4.1 | 58.9 ± 6.3 | ||

| IV | * | * | 13.5 ± 2.0 | 53.9 ± 1.6 | * | * | ||

| Average ** | 30.5 | 49.8 | 17.5 | 52.8 | 31.7 | 62.2 | ||

| Difference *** | 6.0 | 38.2 | 19.1 | 35.3 | 4.8 | 25.8 | ||

| Difference **** [%] | Reference modification | −54.7% | −57.8% | 3.8% | 24.9% | |||

| Type 1: Direct Exposure | Type 2: Indirect Exposure | |||||||

|---|---|---|---|---|---|---|---|---|

| Sample Type Sample Designation | MONO | DUAL | INDIRECT MONO | |||||

| Increase in Area [%] | Roughness Sa [nm] | Increase in Area [%] | Roughness Sa [nm] | Increase in Area [%] | Roughness Sa [nm] | |||

| Unmodified | PVC | 0.04 ± 0.00 | 5.98 ± 0.15 | 0.04 ± 0.00 | 5.98 ± 0.15 | 0.04 ± 0.00 | 5.98 ± 0.15 | |

| DCSBD plasma modified | by exposure type | I | 3.91 ± 1.38 | 37.02 ± 3.18 | 0.81 ± 0.03 | 10.28 ± 0.29 | 0.49 ± 0.56 | 24.93 ± 2.89 |

| II | 4.66 ± 1.29 | 38.69 ± 3.50 | 1.12 ± 0.02 | 15.11 ± 0.47 | 0.25 ± 0.20 | 22.014 ± 4.28 | ||

| III | 4.05 ± 1.03 | 36.36 ± 3.35 | 9.37 ± 0.39 | 37.38 ± 2.72 | 0.06 ± 0.01 | 4.28 ± 0.57 | ||

| IV | * | 12.05 ± 1.17 | 52.98 ± 4.66 | * | ||||

| Average ** | 4.21 | 37.36 | 5.84 | 28.94 | 0.27 | 17.7 | ||

| Difference *** | 4.17 | 31.38 | 5.80 | 22.96 | 0.23 | 11.9 | ||

| Sample Type Sample Designation | Type 1: Direct Exposure (DUAL) | |||||||

|---|---|---|---|---|---|---|---|---|

| Element (%) | ||||||||

| C 1s | O 1s | Cl 2p | ||||||

| Observed Area | ||||||||

| Clear | Matte | Clear | Matte | Clear | Matte | |||

| Unmodified | PVC | 77.6 | * | 12.6 | * | 7.1 | * | |

| DCSBD plasma modified | By exposure type | I | 60.8 | 60 | 17.2 | 20.4 | 19.2 | 17.2 |

| II | 62.1 | 60.4 | 18.1 | 19.2 | 18.2 | 17.1 | ||

| III | 61.2 | 60.2 | 17.8 | 19.1 | 17.9 | 17.4 | ||

| IV | 60.5 | 59.9 | 19.1 | 19.4 | 18.5 | 17.6 | ||

| Average ** | 61.2 | 60.1 | 18.1 | 19.5 | 18.5 | 17.3 | ||

| Difference *** | −16.5 | - | 5.5 | - | 11.4 | - | ||

| Type 2: Indirect exposure | ||||||||

| By exposure type | I | 61.8 | 61.3 | 18.9 | 18.6 | 17.3 | 17.2 | |

| Difference **** | 0.6 | 1.2 | 0.9 | −0.9 | −1.2 | −0.1 | ||

| Dynamic-Mechanical Analysis (DUAL) | Static Tensile Test (DUAL) | |||||||

|---|---|---|---|---|---|---|---|---|

| Sample Type Sample Designation | Glass Transition Temperature-Tg [°C] | Tan δvalue | Tensile Strength [MPa] | Elongation [%] | ||||

| E′ Onset Point | E″ Peak | Tan δmax | ||||||

| Unmodified | PVC | 54.5 ± 3.6 | 64.4 ± 3.0 | 72.5 ± 2.3 | 0.9880 ± 0.019 | 54.9 ± 2.1 | 3.5 ± 0.2 | |

| DCSBD plasma modified | By exposure type | I | 54.7 ± 2.8 | 63.0 ± 3.3 | 72.0 ± 2.4 | 0.9790 ± 0.015 | 54.9 ± 1.6 | 3.5 ± 0.1 |

| II | 56.5 ± 2.1 | 62.6 ± 3.4 | 73.2 ± 2.6 | 0.9832 ± 0.008 | 54.5 ± 1.7 | 3.7 ± 0.2 | ||

| III | 58.1 ± 4.4 | 65.0 ± 2.0 | 73.8 ± 2.0 | 0.9782 ± 0.033 | 54.0 ± 2.2 | 3.5 ± 0.1 | ||

| IV | 54.9 ± 3.2 | 65.0 ± 4.9 | 72.7 ± 1.9 | 0.9915 ± 0.019 | 51.7 ± 1.6 | 3.5 ± 0.1 | ||

| Average * | 56.1 | 63.9 | 72.9 | 0.9829 | 53.8 | 3.6 | ||

| Difference ** | 1.6 | −0.5 | 0.4 | −0.0051 | −1.1 | 0.05 | ||

| One Way ANOVA Test (p < 0.10) for Glass Transition Temperatures (PVC) and after Plasma Modification (I, II, III, IV) Mutual Comparison (x) | ||||||

| Sample | E′ | E″ | Tan δmax | |||

| F | p | F | p | F | p | |

| PVC x I | 3.49 | 0.10 | 0.98 | 0.35 | 0.77 | 0.40 |

| PVC x II | 0.02 | 0.90 | 1.71 | 0.23 | 0.86 | 0.38 |

| PVC x III | 3.90 | 0.08 | 0.20 | 0.67 | 0.97 | 0.97 |

| PVC x IV | 0.01 | 0.92 | 0.05 | 0.84 | 0.27 | 0.62 |

| One Way ANOVA Test (p < 0.10) for Glass Transition Temperatures of Plasma Modified Samples I, II, III, IV Mutual Comparison (x) | ||||||

| I x II | 2.10 | 0.18 | 0.06 | 0.82 | 0.77 | 0.40 |

| I x III | 0.80 | 0.40 | 5.80 | 0.04 | 0.14 | 0.72 |

| I x IV | 1.37 | 0.27 | 1.07 | 0.33 | 0.12 | 0.74 |

| II x III | 8.48 | 0.02 | 3.07 | 0.12 | 3.58 | 0.09 |

| II x IV | 0.05 | 0.83 | 0.90 | 0.37 | 0.50 | 0.50 |

| III x IV | 2.08 | 0.18 | 0.21 | 0.66 | 2.24 | 0.17 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Janík, R.; Kohutiar, M.; Dubec, A.; Eckert, M.; Moricová, K.; Pajtášová, M.; Ondrušová, D.; Krbata, M. DMA Analysis of Plasma Modified PVC Films and the Nature of Initiated Surface Changes. Materials 2022, 15, 4658. https://doi.org/10.3390/ma15134658

Janík R, Kohutiar M, Dubec A, Eckert M, Moricová K, Pajtášová M, Ondrušová D, Krbata M. DMA Analysis of Plasma Modified PVC Films and the Nature of Initiated Surface Changes. Materials. 2022; 15(13):4658. https://doi.org/10.3390/ma15134658

Chicago/Turabian StyleJaník, Róbert, Marcel Kohutiar, Andrej Dubec, Maroš Eckert, Katarína Moricová, Mariana Pajtášová, Darina Ondrušová, and Michal Krbata. 2022. "DMA Analysis of Plasma Modified PVC Films and the Nature of Initiated Surface Changes" Materials 15, no. 13: 4658. https://doi.org/10.3390/ma15134658

APA StyleJaník, R., Kohutiar, M., Dubec, A., Eckert, M., Moricová, K., Pajtášová, M., Ondrušová, D., & Krbata, M. (2022). DMA Analysis of Plasma Modified PVC Films and the Nature of Initiated Surface Changes. Materials, 15(13), 4658. https://doi.org/10.3390/ma15134658