Study on the Hydrogen Embrittlement of Nanograined Materials with Different Grain Sizes by Atomistic Simulation

Abstract

:1. Introduction

2. Materials and Methods

3. Results

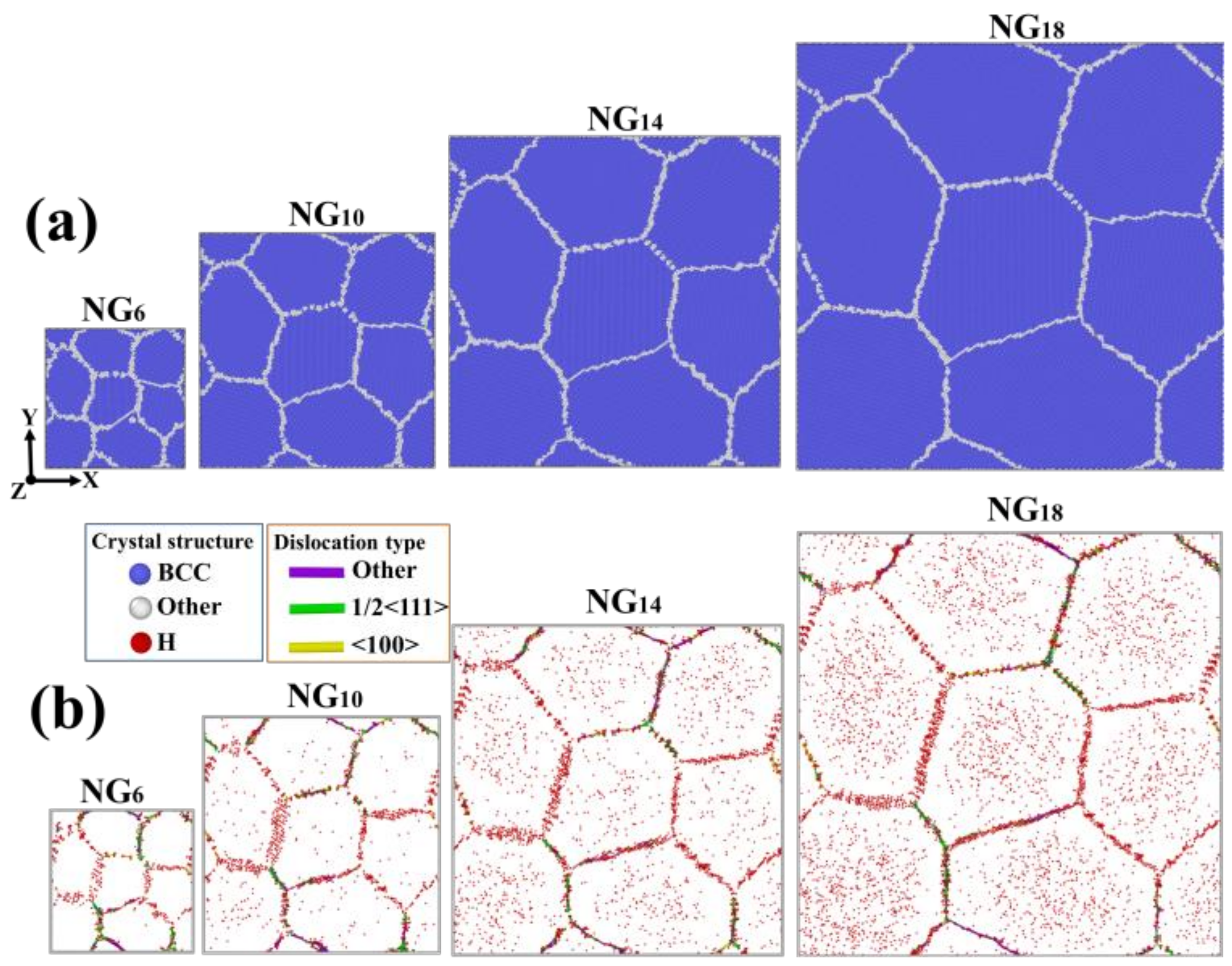

3.1. GB Structures and H Segregation in Nanograined Fe Models

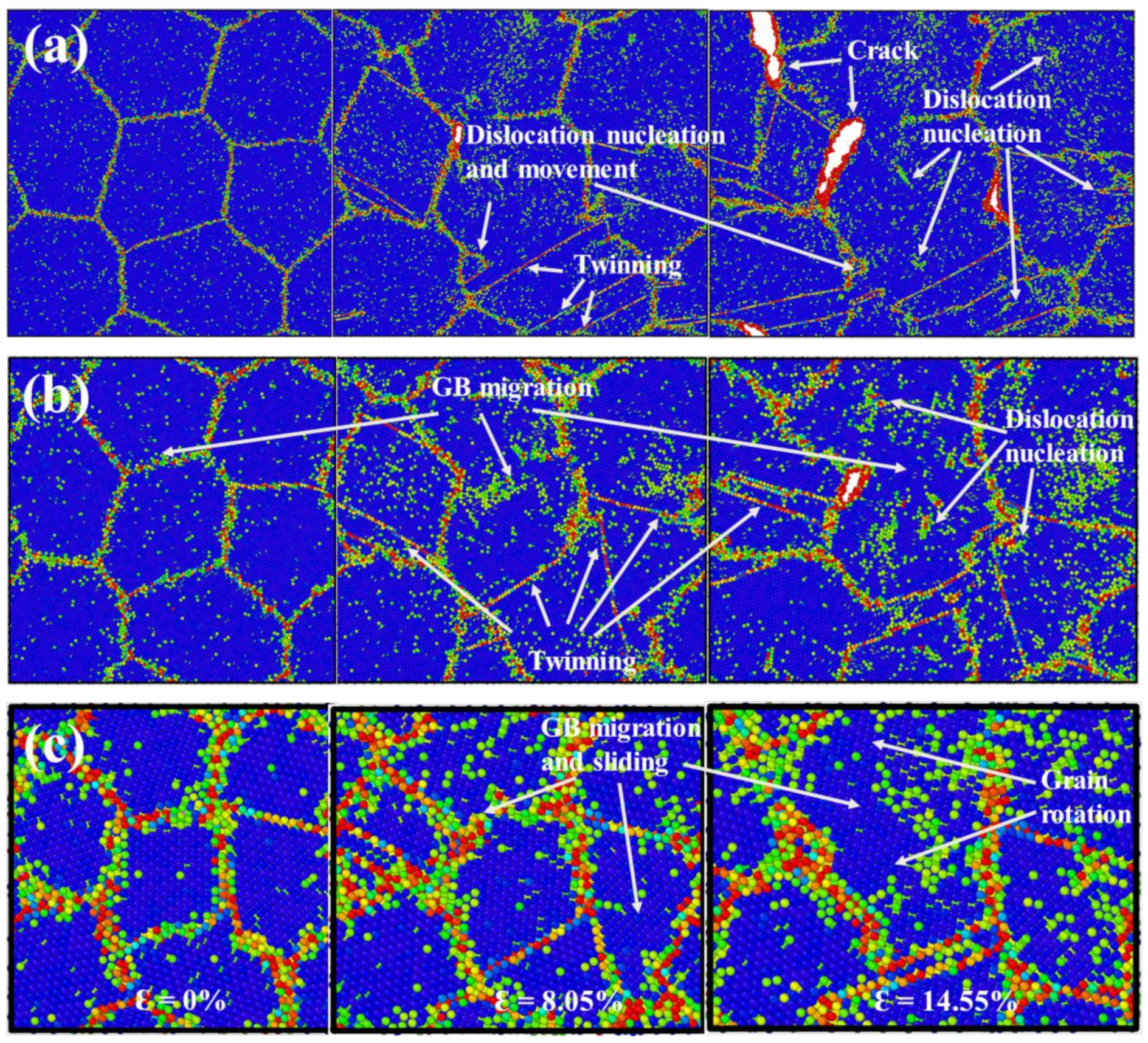

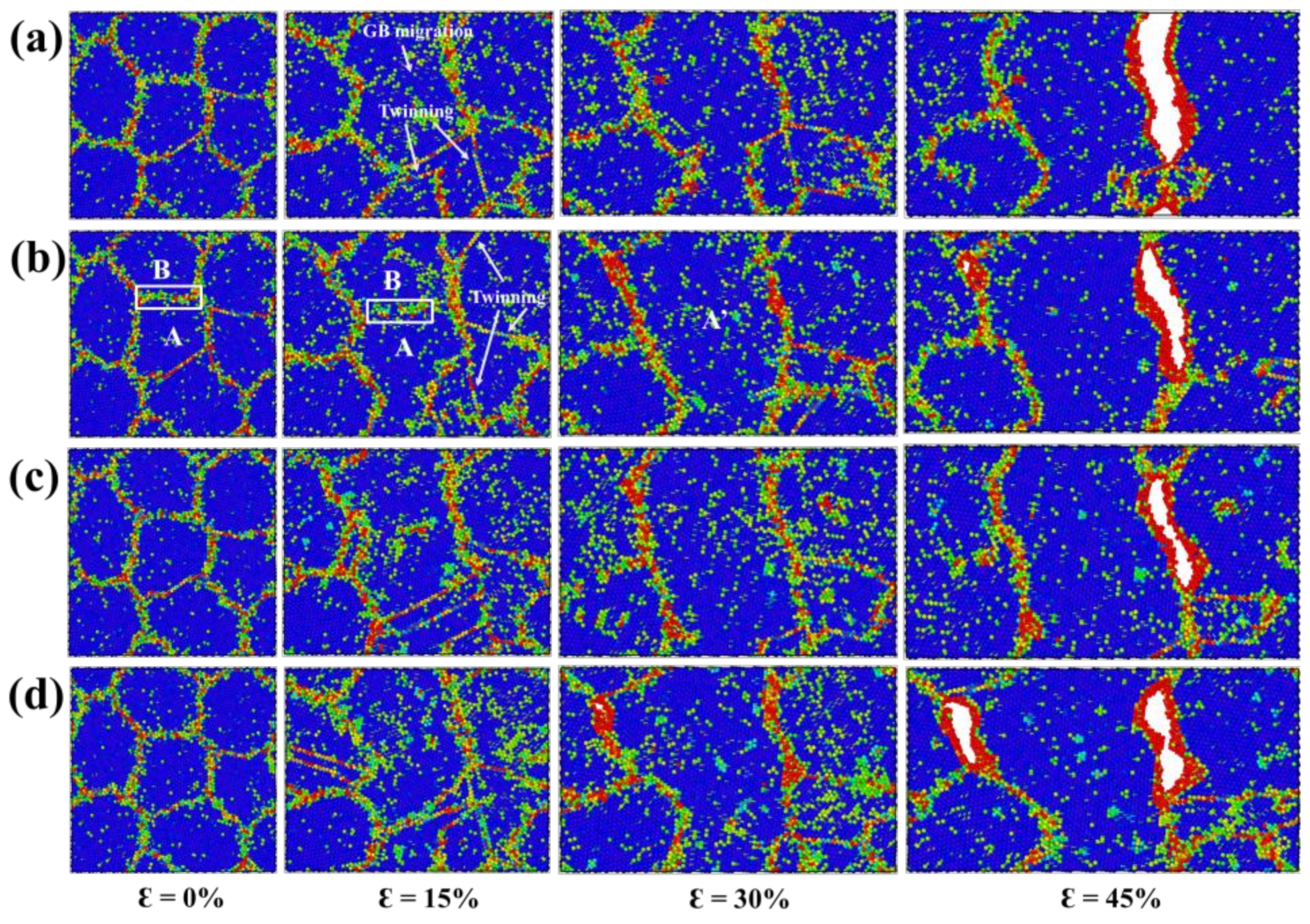

3.2. Mechanical Behavior and Deformation Mechanisms of Nanograined Fe Models without H

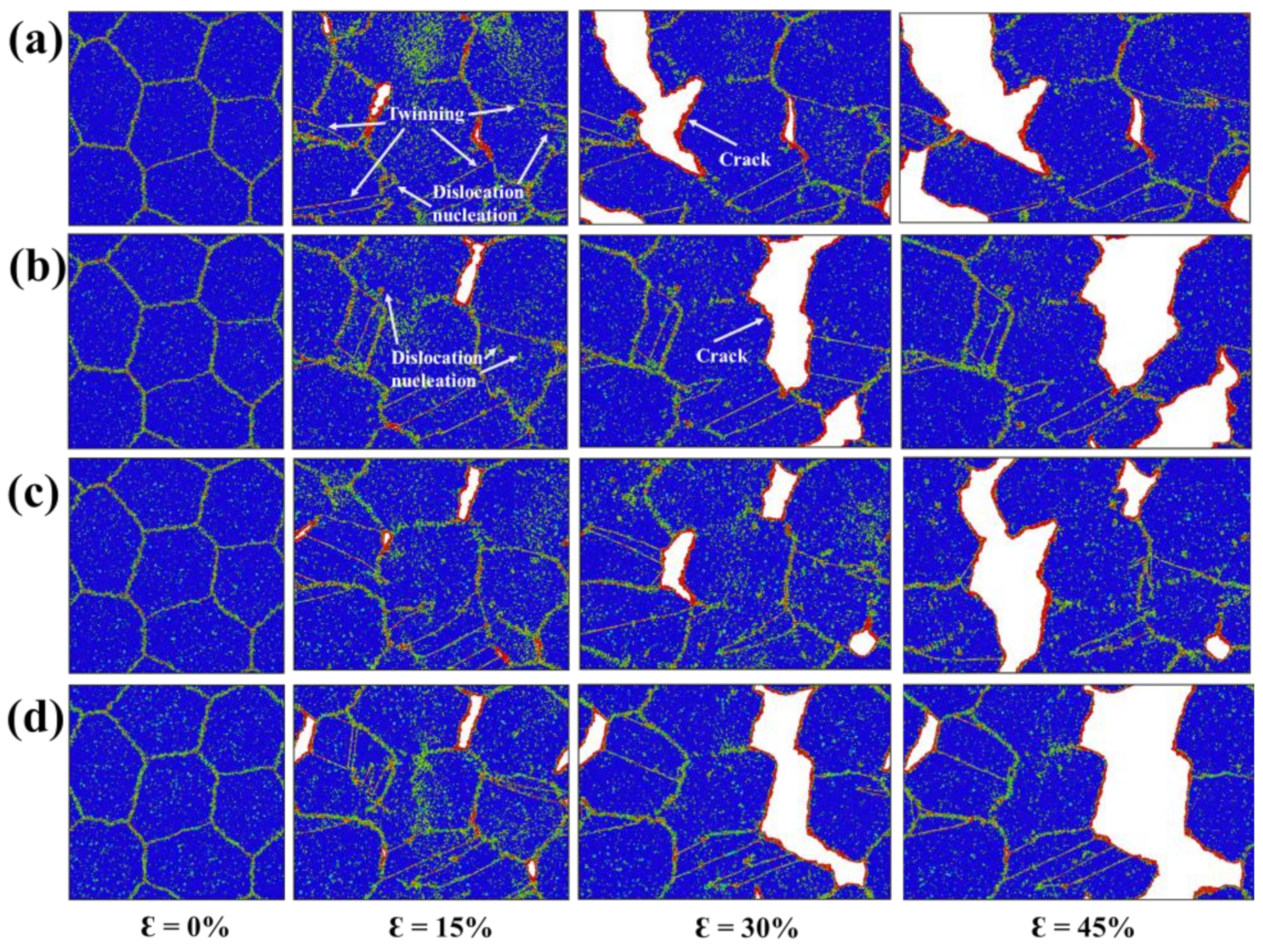

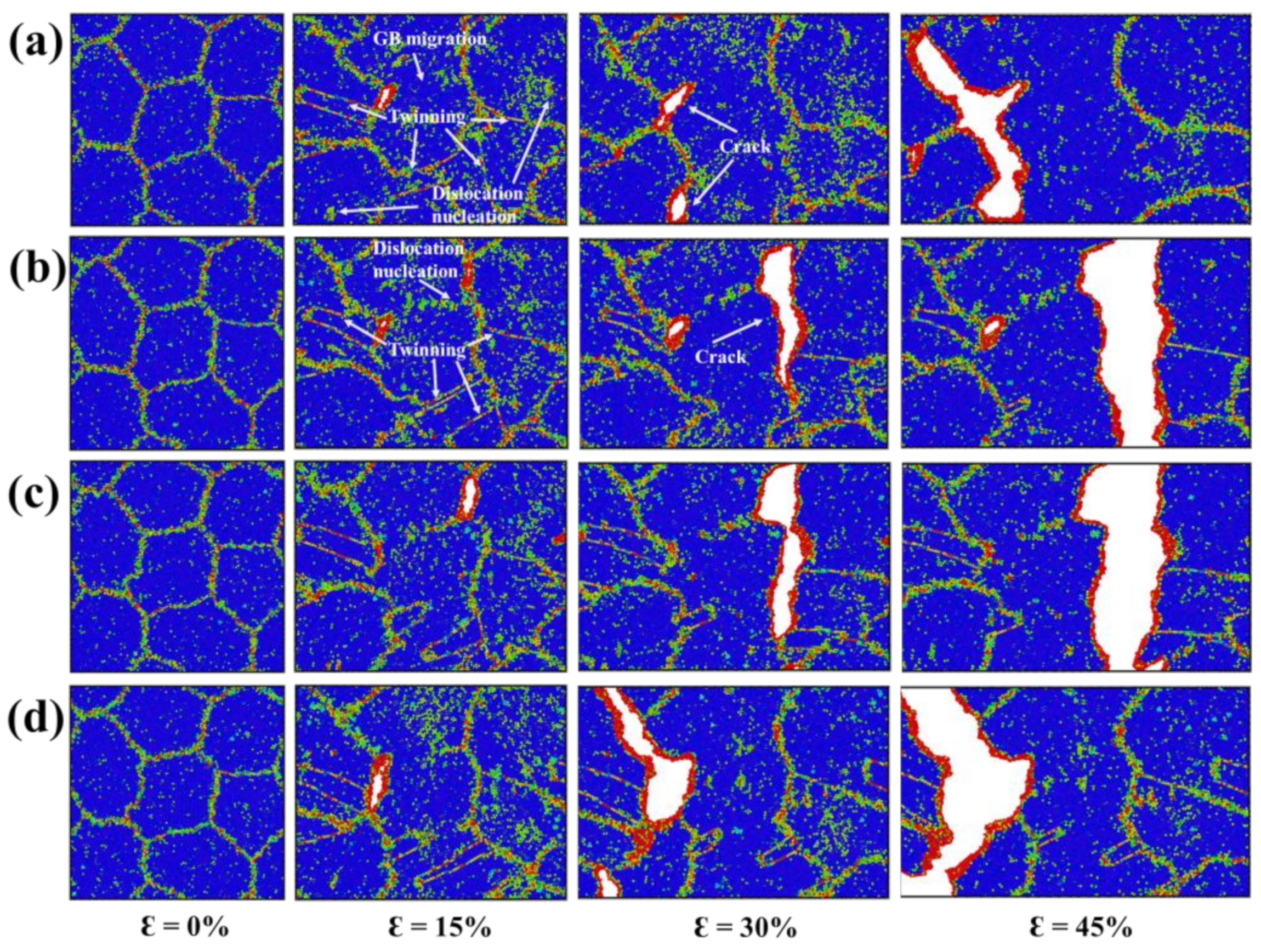

3.3. Deformation Mechanisms and the Fracture Response of Nanograined Fe Models with H

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| HE | hydrogen embrittlement |

| GBs | grain boundaries |

| HEDE | hydrogen-enhanced decohesion |

| HELP | hydrogen enhanced localized plasticity |

| SPD | severe plastic deformation |

| HPT | high pressure torsion |

| ARB | accumulative roll bonding |

| ECAP | equal channel angular pressing |

| DPD | dynamic plastic deformation |

| MD | molecular dynamics |

| LAMMPS | large-scale atomic/molecular massively parallel simulator |

| OVITO | open visualization tool |

| CNA | common neighbor analysis |

| CSP | centro-symmetry parameter |

| DXA | dislocation extraction algorithm |

| NPT | Isothermal–isobaric ensemble |

| MSD | mean-squared displacement |

References

- Andersson, J.; Grönkvist, S. Large-scale storage of hydrogen. Int. J. Hydrogen Energy 2019, 44, 11901–11919. [Google Scholar] [CrossRef]

- Dawood, F.; Anda, M.; Shafiullah, G.M. Hydrogen production for energy: An overview. Int. J. Hydrogen Energy 2020, 45, 3847–3869. [Google Scholar] [CrossRef]

- Parra, D.; Valverde, L.; Pino, F.J.; Patel, M.K. A review on the role, cost and value of hydrogen energy systems for deep decarbonisation. Renew. Sustain. Energy Rev. 2019, 101, 279–294. [Google Scholar] [CrossRef]

- Ghaib, K.; Ben-Fares, F.-Z. Power-to-methane: A state-of-the-art review. Renew. Sustain. Energy Rev. 2018, 81, 433–446. [Google Scholar] [CrossRef]

- Bechtle, S.; Kumar, M.; Somerday, B.; Launey, M.; Ritchie, R. Grain-boundary engineering markedly reduces susceptibility to intergranular hydrogen embrittlement in metallic materials. Acta Mater. 2009, 57, 4148–4157. [Google Scholar] [CrossRef] [Green Version]

- Koyama, M.; Akiyama, E.; Lee, Y.-K.; Raabe, D.; Tsuzaki, K. Overview of hydrogen embrittlement in high-Mn steels. Int. J. Hydrogen Energy 2017, 42, 12706–12723. [Google Scholar] [CrossRef]

- Zhou, C.; Fang, B.; Wang, J.; Tang, D.; Tao, H.; He, Y.; Zhou, Z.; Chen, C.; Zhang, L. Hydrogen embrittlement resistance of TWIP (twinning-induced plasticity) steel in high pressure hydrogen environment. Int. J. Fatigue 2021, 151, 106362. [Google Scholar] [CrossRef]

- Wasim, M.; Djukic, M.B.; Ngo, T.D. Influence of hydrogen-enhanced plasticity and decohesion mechanisms of hydrogen embrittlement on the fracture resistance of steel. Eng. Fail. Anal. 2021, 123, 105312. [Google Scholar] [CrossRef]

- Robertson, I.M.; Sofronis, P.; Nagao, A.; Martin, M.; Wang, S.; Gross, D.W.; Nygren, K.E. Hydrogen embrittlement understood. Metall. Mater. Trans. B 2015, 46, 1085–1103. [Google Scholar] [CrossRef]

- Nagumo, M.; Takai, K. The predominant role of strain-induced vacancies in hydrogen embrittlement of steels: Overview. Acta Mater. 2019, 165, 722–733. [Google Scholar] [CrossRef]

- Li, S.; Li, Y.; Lo, Y.C.; Neeraj, T.; Srinivasan, R.; Ding, X.; Sun, J.; Qi, L.; Gumbsch, P.; Li, J. The interaction of dislocations and hydrogen-vacancy complexes and its importance for deformation-induced proto nano-voids formation in α-Fe. Int. J. Plast. 2015, 74, 175–191. [Google Scholar] [CrossRef]

- Kapci, M.F.; Schön, J.C.; Bal, B. The role of hydrogen in the edge dislocation mobility and grain boundary-dislocation interaction in α-Fe. Int. J. Hydrogen Energy 2021, 46, 32695–32709. [Google Scholar] [CrossRef]

- Taketomim, S.; Matsumoto, R.; Miyazaki, N. Atomistic simulation of the effects of hydrogen on the mobility of edge dislocation in alpha iron. J. Mater. Sci. 2008, 43, 1166–1169. [Google Scholar] [CrossRef] [Green Version]

- Xing, X.; Deng, G.; Zhang, H.; Cui, G.; Liu, J.; Li, Z.; Wang, B.; Li, S.; Qi, C. Molecular dynamics studies of hydrogen effect on intergranular fracture in α-iron. Materials 2020, 13, 4949. [Google Scholar] [CrossRef]

- Chen, Y.-S.; Lu, H.; Liang, J.; Rosenthal, A.; Liu, H.; Sneddon, G.; McCarroll, I.; Zhao, Z.; Li, W.; Guo, A.; et al. Observation of hydrogen trapping at dislocations, grain boundaries, and precipitates. Science 2020, 367, 171–175. [Google Scholar] [CrossRef]

- Song, J.; Curtin, W.A. Atomic mechanism and prediction of hydrogen embrittlement in iron. Nat. Mater. 2012, 12, 145–151. [Google Scholar] [CrossRef]

- Song, J.; Curtin, W.A. A nanoscale mechanism of hydrogen embrittlement in metals. Acta Mater. 2011, 59, 1557–1569. [Google Scholar] [CrossRef]

- Peral, L.; Zafra, A.; Belzunce, J.; Rodríguez, C. Effects of hydrogen on the fracture toughness of CrMo and CrMoV steels quenched and tempered at different temperatures. Int. J. Hydrogen Energy 2019, 44, 3953–3965. [Google Scholar] [CrossRef]

- Tehranchi, A.; Curtin, W.A. Atomistic study of hydrogen embrittlement of grain boundaries in nickel: I. Fracture. J. Mech. Phys. Solids 2017, 101, 150–165. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Martin, M.L.; Sofronis, P.; Ohnuki, S.; Hashimoto, N.; Robertson, I.M. Hydrogen-induced intergranular failure of iron. Acta Mater. 2014, 69, 275–282. [Google Scholar] [CrossRef]

- Ogawa, Y.; Birenis, D.; Matsunaga, H.; Takakuwa, O.; Yamabe, J.; Prytz, Ø.; Thøgersen, A. The role of intergranular fracture on hydrogen-assisted fatigue crack propagation in pure iron at a low stress intensity range. Mater. Sci. Eng. A 2018, 733, 316–328. [Google Scholar] [CrossRef]

- Shibata, A.; Murata, T.; Takahashi, H.; Matsuoka, T.; Tsuji, N. Characterization of hydrogen-related fracture behavior in as-quenched low-carbon martensitic steel and tempered medium-carbon martensitic steel. Metall. Mater. Trans. A 2015, 46, 5685–5696. [Google Scholar] [CrossRef]

- Wang, S.; Martin, M.; Robertson, I.M.; Sofronis, P. Effect of hydrogen environment on the separation of Fe grain boundaries. Acta Mater. 2016, 107, 279–288. [Google Scholar] [CrossRef] [Green Version]

- Huang, S.; Chen, D.; Song, J.; McDowell, D.L.; Zhu, T. Hydrogen embrittlement of grain boundaries in nickel: An atomistic study. npj Comput. Mater. 2017, 3, 28. [Google Scholar] [CrossRef] [Green Version]

- Tehranchi, A.; Curtin, W.A. Atomistic study of hydrogen embrittlement of grain boundaries in nickel: II. Decohesion. Model. Simul. Mater. Sci. Eng. 2017, 25, 075013. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Lu, C.; Pei, L.; Zhang, C.; Wang, R. Atomistic investigation of hydrogen induced decohesion of Ni grain boundaries. Mech. Mater. 2020, 150, 103586. [Google Scholar] [CrossRef]

- Beachem, C.D. A new model for hydrogen-assisted cracking (hydrogen “embrittlement”). Metall. Mater. Trans. B 1972, 3, 441–455. [Google Scholar] [CrossRef]

- Birnbaum, H.K.; Sofronis, P. Hydrogen-enhanced localized plasticity—A mechanism for hydrogen-related fracture. Mater. Sci. Eng. A 1994, 176, 191–202. [Google Scholar] [CrossRef]

- Li, J.; Lu, C.; Pei, L.; Zhang, C.; Tieu, K. Influence of solute hydrogen on the interaction of screw dislocations with vicinal twin boundaries in nickel. Scrip. Mater. 2019, 173, 115–119. [Google Scholar] [CrossRef]

- Zhu, Y.; Li, Z.; Huang, M. Solute hydrogen effects on plastic deformation mechanisms of α-Fe with twist grain boundary. Int. J. Hydrogen Energy 2018, 43, 10481–10495. [Google Scholar] [CrossRef]

- Martin, M.L.; Dadfarnia, M.; Nagao, A.; Wang, S.; Sofronis, P. Enumeration of the hydrogen-enhanced localized plasticity mechanism for hydrogen embrittlement in structural materials. Acta Mater. 2019, 165, 734–750. [Google Scholar] [CrossRef]

- Mine, Y.; Matsumoto, S.; Horita, Z. Strengthening and hydrogen embrittlement of ultrafine-grained Fe–0.01mass% C alloy processed by high-pressure torsion. Corros. Sci. 2011, 53, 2969–2977. [Google Scholar] [CrossRef]

- Mine, Y.; Horita, N.; Horita, Z.; Takashima, K. Effect of ultrafine grain refinement on hydrogen embrittlement of metastable austenitic stainless steel. Int. J. Hydrogen Energy 2017, 42, 15415–15425. [Google Scholar] [CrossRef]

- Deng, G.; Zhao, X.; Su, L.; Wei, P.; Zhang, L.; Zhan, L.; Chong, Y.; Zhu, H.; Tsuji, N. Effect of high pressure torsion process on the microhardness, microstructure and tribological property of Ti6Al4V alloy. J. Mater. Sci. Technol. 2021, 94, 183–195. [Google Scholar] [CrossRef]

- Wei, P.; Lu, C.; Tieu, K.; Su, L.; Deng, G.; Huang, W. A study on the texture evolution mechanism of nickel single crystal deformed by high pressure torsion. Mater. Sci. Eng. A 2017, 684, 239–248. [Google Scholar] [CrossRef]

- Deng, G.; Chong, Y.; Su, L.; Zhan, L.; Wei, P.; Zhao, X.; Zhang, L.; Tian, Y.; Zhu, H.; Tsuji, N. Mechanisms of remarkable wear reduction and evolutions of subsurface microstructure and nano-mechanical properties during dry sliding of nano-grained Ti6Al4V alloy: A comparative study. Tribol. Int. 2022, 169, 107464. [Google Scholar] [CrossRef]

- Deng, G.; Bhattacharjee, T.; Chong, Y.; Zheng, R.; Bai, Y.; Shibata, A.; Tsuji, N. Influence of Fe addition in CP titanium on phase transformation, microstructure and mechanical properties during high pressure torsion. J. Alloys Compd. 2020, 822, 153604. [Google Scholar] [CrossRef]

- Su, L.; Lu, C.; Deng, G.; Tieu, K. Microstructure and mechanical properties of AA5005/AA6061 laminated composite processed by accumulative roll bonding. Metall. Mater. Trans. B 2014, 45, 515–522. [Google Scholar] [CrossRef]

- Nie, N.; Su, L.; Deng, G.; Li, H.; Yu, H.; Tieu, A.K. A review on plastic deformation induced surface/interface roughening of sheet metallic materials. J. Mater. Res. Technol. 2021, 15, 6574–6607. [Google Scholar] [CrossRef]

- Su, L.; Lu, C.; Deng, G.; Tieu, A.K.; Sun, X. Microstructure and mechanical properties of 1050/6061 laminated composite processed by accumulative roll bonding. Rev. Adv. Mater. Sci. 2013, 33, 33–37. [Google Scholar]

- Deng, G.; Lu, C.; Su, L.; Tieu, A.; Yu, H.; Liu, X. Investigation of sample size effect on the deformation heterogeneity and texture development during equal channel angular pressing. Comput. Mater. Sci. 2013, 74, 75–85. [Google Scholar] [CrossRef]

- Deng, G.; Lu, C.; Su, L.; Tieu, A.K.; Li, J.; Liu, M.; Zhu, H.; Liu, X. Influence of outer corner angle (OCA) on the plastic deformation and texture evolution in equal channel angular pressing. Comput. Mater. Sci. 2014, 81, 79–88. [Google Scholar] [CrossRef]

- Su, L.; Deng, G.; Luzin, V.; Wang, H.; Wang, Z.; Yu, H.; Li, H.; Tieu, A.K. Effect of cryogenic temperature equal channel angular pressing on microstructure, bulk texture and tensile properties of AA1050. Mater. Sci. Eng. A 2020, 780, 139190. [Google Scholar] [CrossRef]

- Fan, Y.H.; Cui, F.; Lu, L. A nanotwinned austenite stainless steel with high hydrogen embrittlement resistance. J. Alloy. Comp. 2019, 788, 1066–1075. [Google Scholar] [CrossRef]

- Ding, Y.; Yu, H.; Zhao, K.; Lin, M.; Xiao, S.; Ortiz, M.; He, J.; Zhang, Z. Hydrogen-induced transgranular to intergranular fracture transition in bi-crystalline nickel. Scrip. Mater. 2021, 204, 114122. [Google Scholar] [CrossRef]

- Li, J.; Pei, L.; Lu, C.; Godbole, A.; Michal, G. Hydrogen effects on the mechanical behaviour and deformation mechanisms of inclined twin boundaries. Int. J. Hydrogen Energy 2021, 46, 16127–16140. [Google Scholar] [CrossRef]

- Hüter, C.; Shanthraj, P.; McEniry, E.; Spatschek, R.; Hickel, T.; Tehranchi, A.; Guo, X.; Roters, F. Multiscale modelling of hydrogen transport and segregation in polycrystalline steels. Metals 2018, 8, 430. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.; Shibuta, Y.; Lu, C.; Huang, X. Interaction between nano-voids and migrating grain boundary by molecular dynamics simulation. Acta Mater. 2019, 173, 206–224. [Google Scholar] [CrossRef]

- Zhang, L.; Lu, C.; Tieu, K.; Shibuta, Y. Dynamic interaction between grain boundary and stacking fault tetrahedron. Scripta Mater. 2018, 144, 78–83. [Google Scholar] [CrossRef] [Green Version]

- Dupraz, M.; Sun, Z.; Brandl, C.; Van Swygenhoven, H. Dislocation interactions at reduced strain rates in atomistic simulations of nanocrystalline Al. Acta Mater. 2018, 144, 68–79. [Google Scholar] [CrossRef]

- Zhu, Y.; Li, Z.; Huang, M.; Liu, Y. Strengthening mechanisms of the nanolayered polycrystalline metallic multilayers assisted by twins. Int. J. Plast. 2015, 72, 168–184. [Google Scholar] [CrossRef]

- Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO—The open visualization tool. Model. Simul. Mater. Sci. Eng. 2010, 18, 015012. [Google Scholar] [CrossRef]

- Li, J.; Lu, C.; Wang, L.; Pei, L.; Godbole, A.; Michal, G. The role of hydrogen on the behavior of intergranular cracks in bicrystalline α-Fe nanowires. Nanomaterials 2021, 11, 294. [Google Scholar] [CrossRef]

- Li, X.; Wei, Y.; Lu, L.; Lu, K.; Gao, H. Dislocation nucleation governed softening and maximum strength in nano-twinned metals. Nature 2010, 464, 877–880. [Google Scholar] [CrossRef] [Green Version]

- Zhou, X.-Y.; Zhu, J.-H.; Wu, H.-H. Molecular dynamics studies of the grain-size dependent hydrogen diffusion coefficient of nanograined Fe. Int. J. Hydrogen Energy 2021, 46, 5842–5851. [Google Scholar] [CrossRef]

- Nagano, M.; Hayashi, Y.; Ohtani, N.; Isshiki, M.; Igaki, K. Hydrogen diffusivity in high-purity alpha-iron. Scr. Metall. 1982, 16, 973–976. [Google Scholar] [CrossRef]

- Grabke, H.J.; Riecke, E. Absorption and diffusion of hydrogen in steels. Mater. Tehnol. 2000, 34, 331. [Google Scholar]

- Zhang, Y.; Millett, P.C.; Tonks, M.; Biner, S.B. Deformation twins in nanocrystalline body-centered cubic mo as predicted by molecular dynamics simulations. Acta Mater. 2012, 60, 6421–6428. [Google Scholar] [CrossRef]

- Luo, X.-M.; Zhu, X.-F.; Zhang, G.-P. Nanotwin-assisted grain growth in nanocrystalline gold films under cyclic loading. Nat. Commun. 2014, 5, 3021. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Lu, C.; Pei, L.; Zhang, C.; Wang, R.; Tieu, K. Effects of H segregation on shear-coupled motion of 〈110〉 grain boundaries in α-Fe. Int. J. Hydrogen Energy 2019, 44, 18616–18627. [Google Scholar] [CrossRef]

- Bai, Y.; Momotani, Y.; Chen, M.; Shibata, A.; Tsuji, N. Effect of grain refinement on hydrogen embrittlement behaviors of high-Mn TWIP steel. Mater. Sci. Eng. A 2016, 651, 935–944. [Google Scholar] [CrossRef] [Green Version]

- Zan, N.; Ding, H.; Guo, X.; Tang, Z.; Bleck, W. Effects of grain size on hydrogen embrittlement in a Fe-22Mn-0.6C TWIP steel. Int. J. Hydrogen Energy 2015, 40, 10687–10696. [Google Scholar] [CrossRef]

- Takakuwa, O.; Mano, Y.; Soyama, H. Increase in the local yield stress near surface of austenitic stainless steel due to invasion by hydrogen. Int. J. Hydrogen Energy 2014, 39, 6095–6103. [Google Scholar] [CrossRef]

- Murakami, Y.; Kanezaki, T.; Mine, Y. Hydrogen effect against hydrogen embrittlement. Metall. Mater. Trans. A 2010, 41, 2548–2562. [Google Scholar] [CrossRef] [Green Version]

- Song, J.; Curtin, W.A. Mechanisms of hydrogen-enhanced localized plasticity: An atomistic study using α-Fe as a model system. Acta Mater. 2014, 68, 61–69. [Google Scholar] [CrossRef]

- Nibur, K.A.; Bahr, D.F.; Somerday, B.P. Hydrogen effects on dislocation activity in austenitic stainless steel. Acta Mater. 2006, 54, 2677–2684. [Google Scholar] [CrossRef]

| Grain Size (nm) | (%) | GB Atom Ratio (%) | fseg, C0 = 0.5% | fseg, C0 = 1% | CH-GB, C0 = 0.5% | CH-GB, C0 = 1% |

|---|---|---|---|---|---|---|

| 6 | 0.63 | 14.71 | 0.862 | 0.860 | 0.012 | 0.023 |

| 10 | 0.39 | 8.60 | 0.841 | 0.837 | 0.017 | 0.035 |

| 14 | 0.28 | 6.42 | 0.835 | 0.821 | 0.023 | 0.048 |

| 18 | 0.23 | 5.51 | 0.785 | 0.780 | 0.025 | 0.052 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Wu, Z.; Wang, F.; Zhang, L.; Zhou, C.; Lu, C.; Teng, L.; Lin, Q. Study on the Hydrogen Embrittlement of Nanograined Materials with Different Grain Sizes by Atomistic Simulation. Materials 2022, 15, 4589. https://doi.org/10.3390/ma15134589

Li J, Wu Z, Wang F, Zhang L, Zhou C, Lu C, Teng L, Lin Q. Study on the Hydrogen Embrittlement of Nanograined Materials with Different Grain Sizes by Atomistic Simulation. Materials. 2022; 15(13):4589. https://doi.org/10.3390/ma15134589

Chicago/Turabian StyleLi, Jiaqing, Ziyue Wu, Fang Wang, Liang Zhang, Chilou Zhou, Cheng Lu, Lin Teng, and Qifeng Lin. 2022. "Study on the Hydrogen Embrittlement of Nanograined Materials with Different Grain Sizes by Atomistic Simulation" Materials 15, no. 13: 4589. https://doi.org/10.3390/ma15134589

APA StyleLi, J., Wu, Z., Wang, F., Zhang, L., Zhou, C., Lu, C., Teng, L., & Lin, Q. (2022). Study on the Hydrogen Embrittlement of Nanograined Materials with Different Grain Sizes by Atomistic Simulation. Materials, 15(13), 4589. https://doi.org/10.3390/ma15134589