Computational AI Models for Investigating the Radiation Shielding Potential of High-Density Concrete

Abstract

:1. Introduction

2. Experimental Program

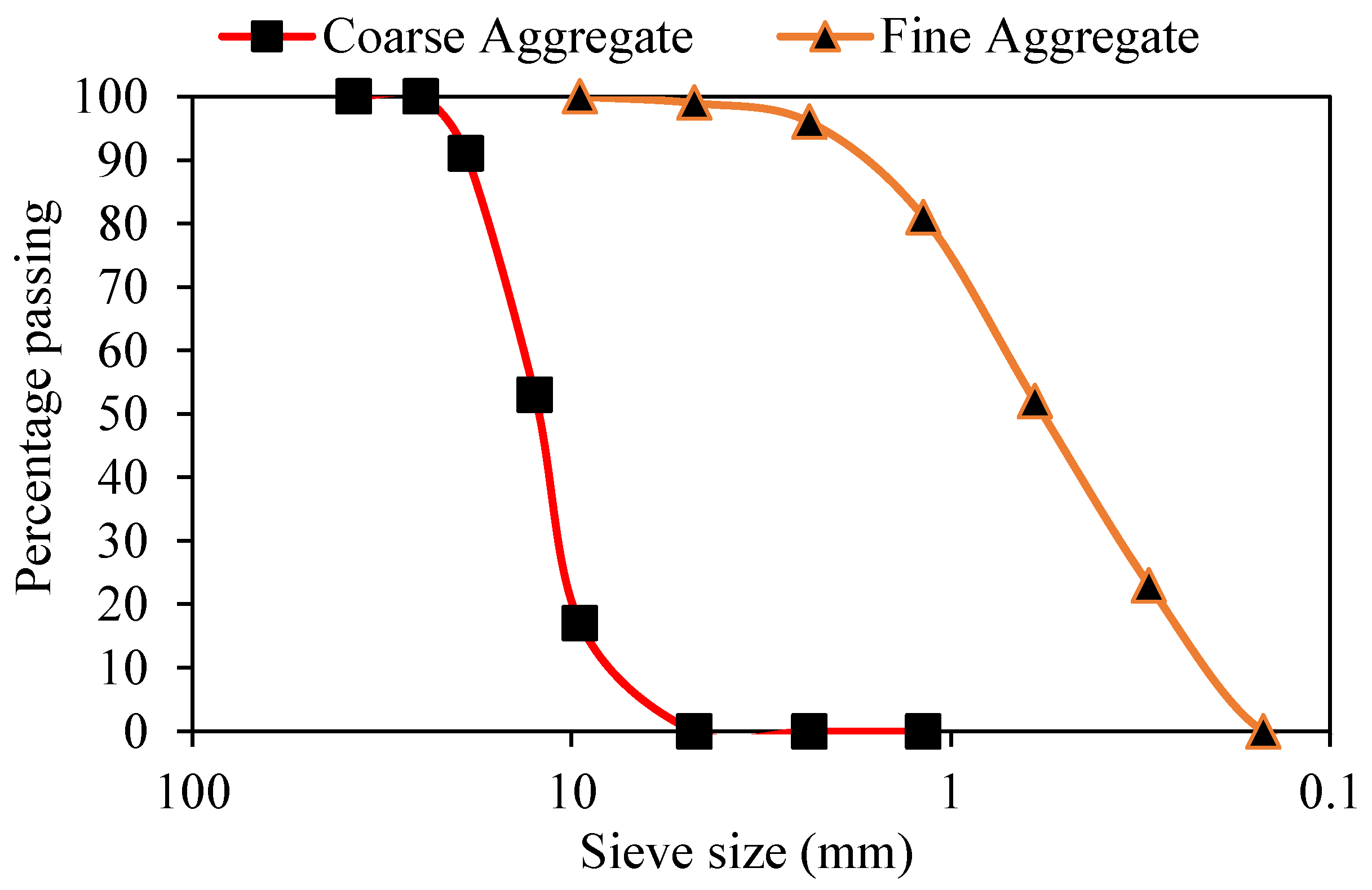

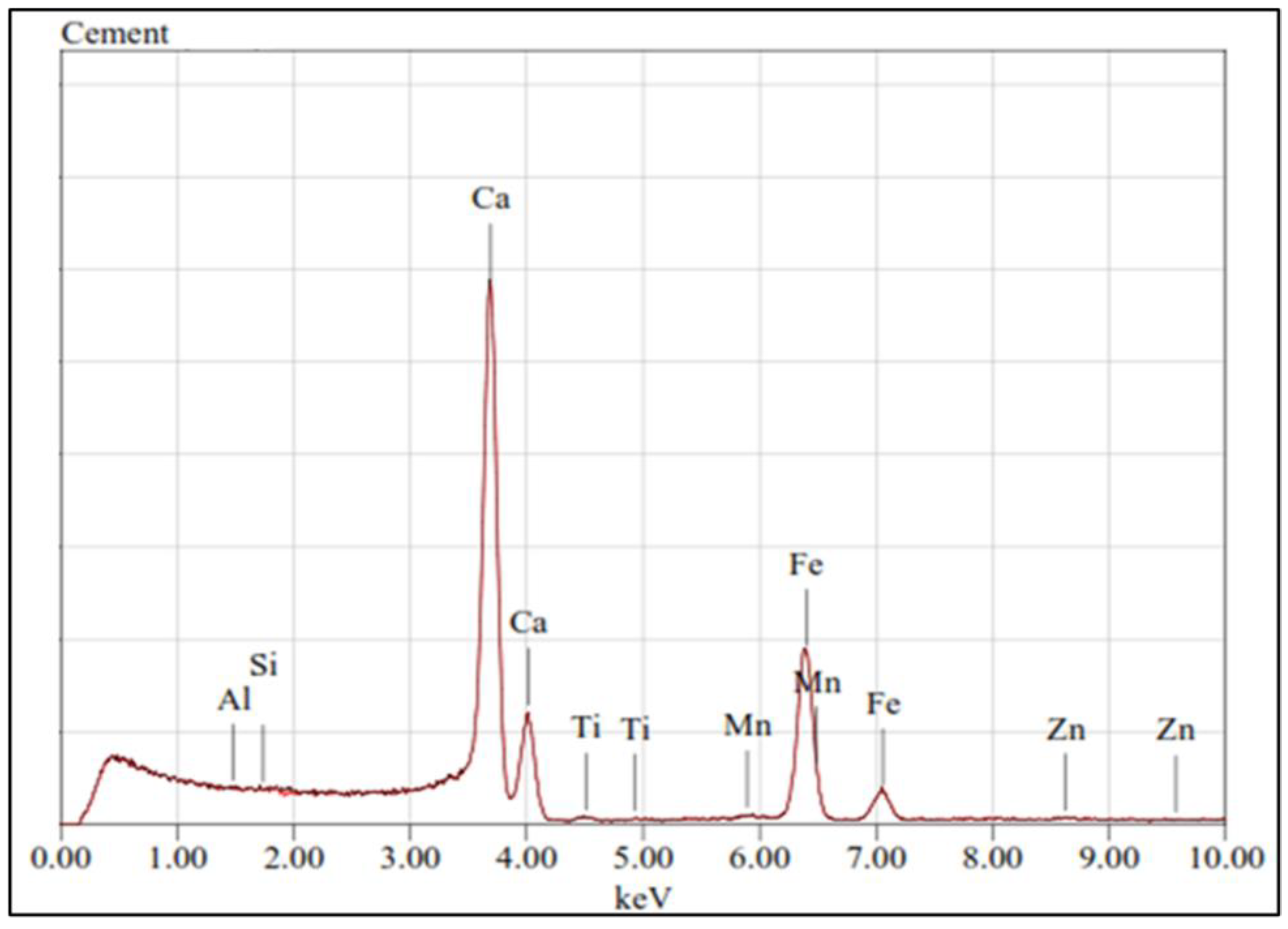

2.1. Materials

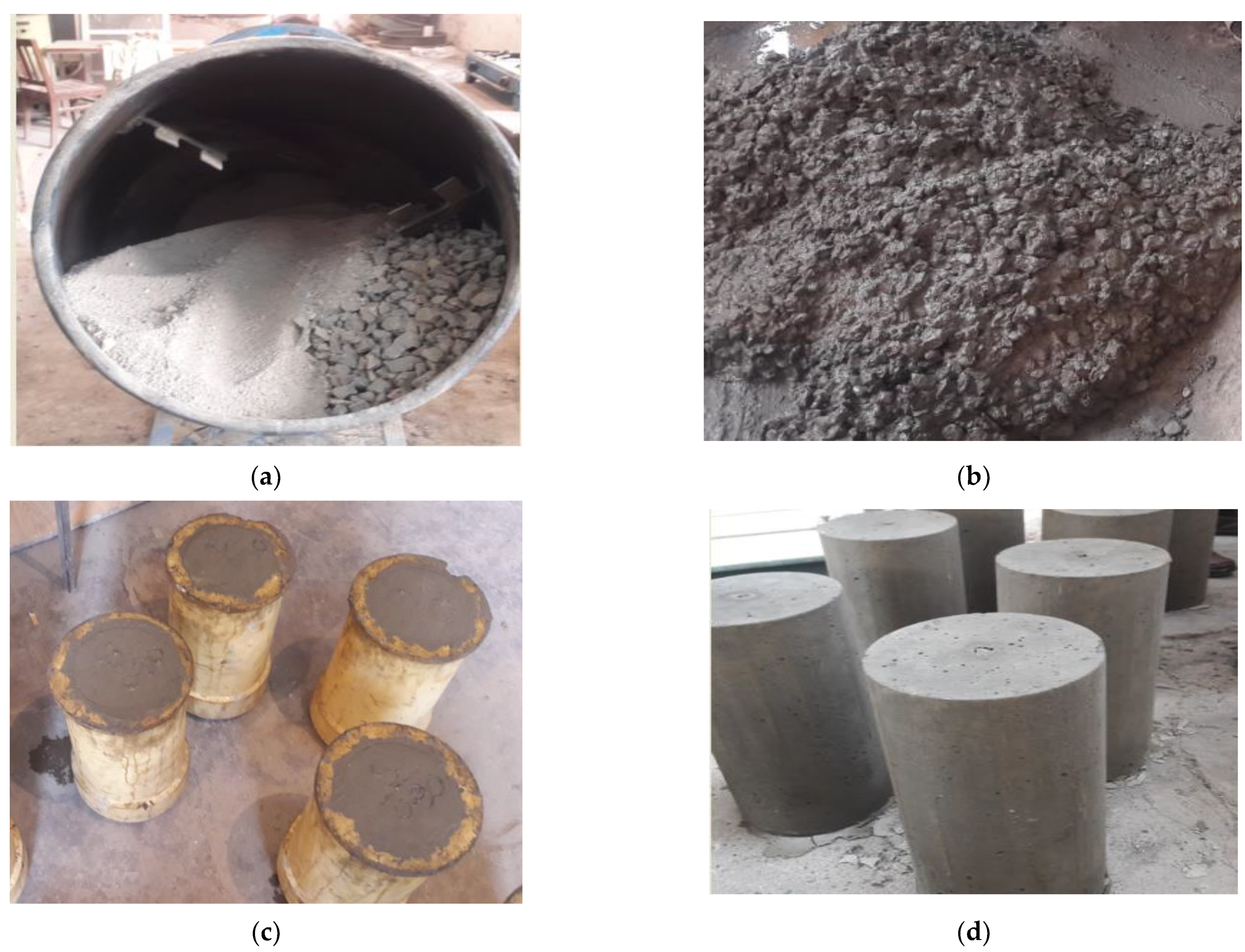

2.2. Mix Proportioning

2.3. Testing Program

2.4. Artificial Neural Network Modelling

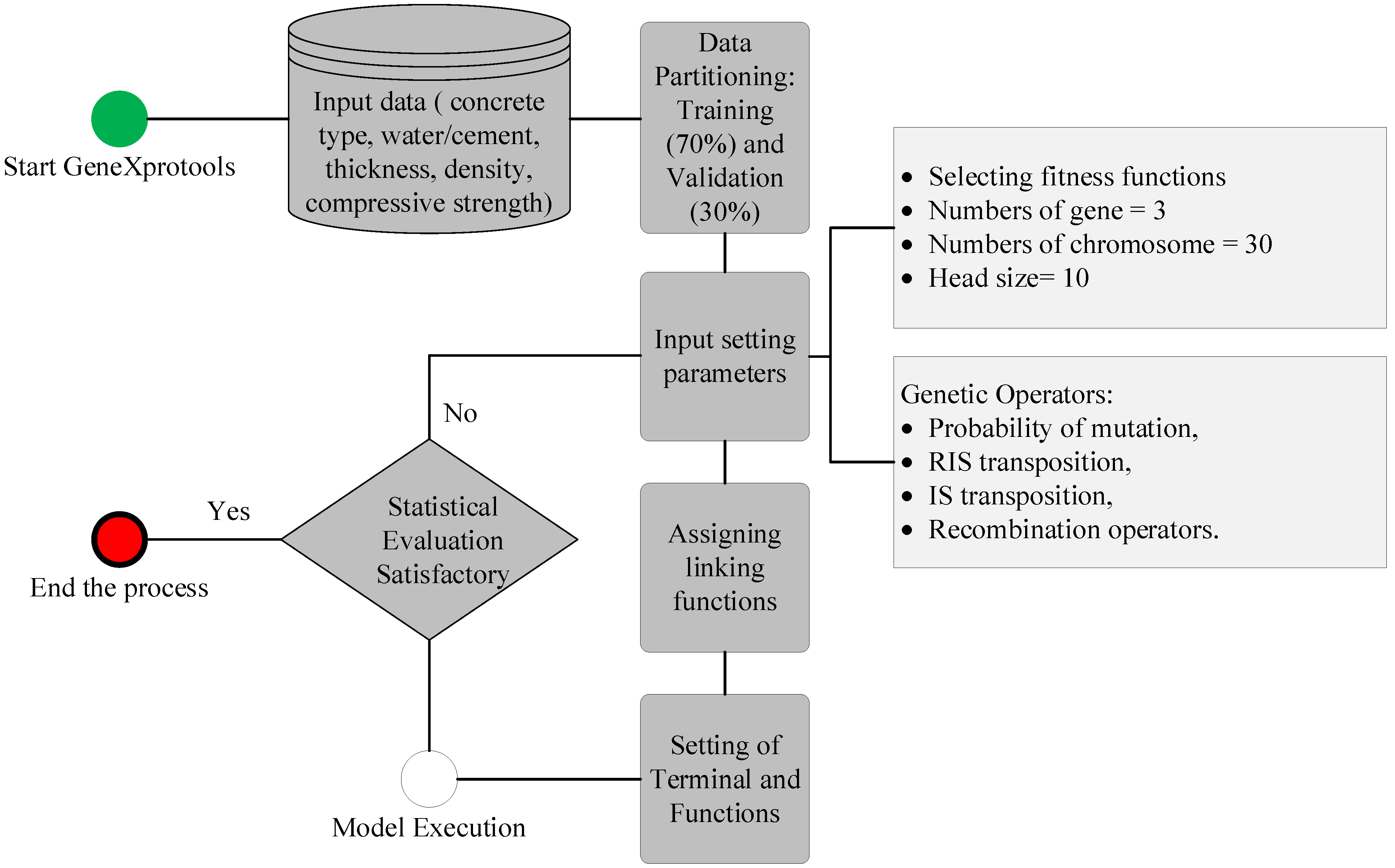

2.5. Gene Expression Programming Modelling

3. Results and Discussions

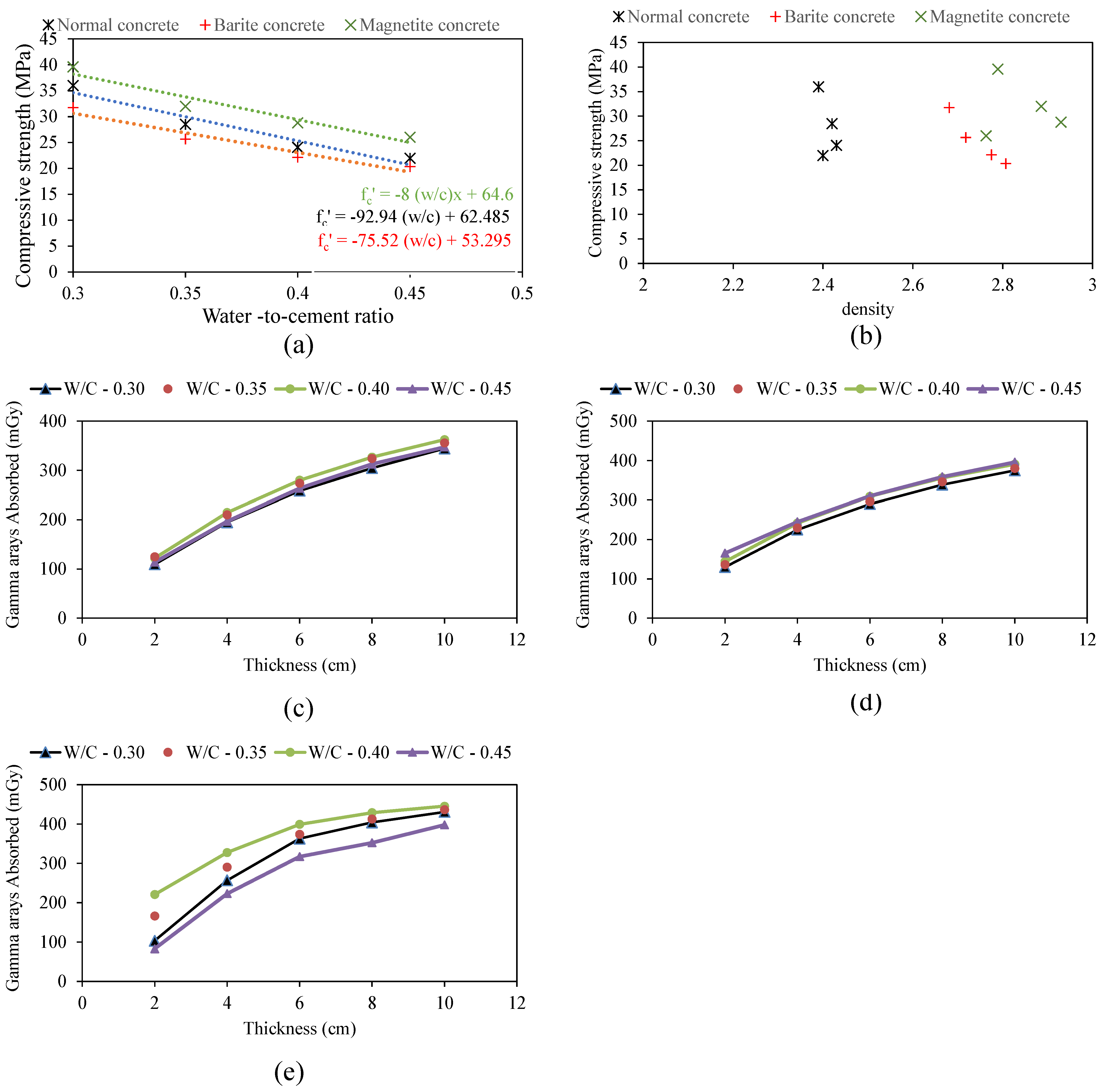

3.1. Experimental Results

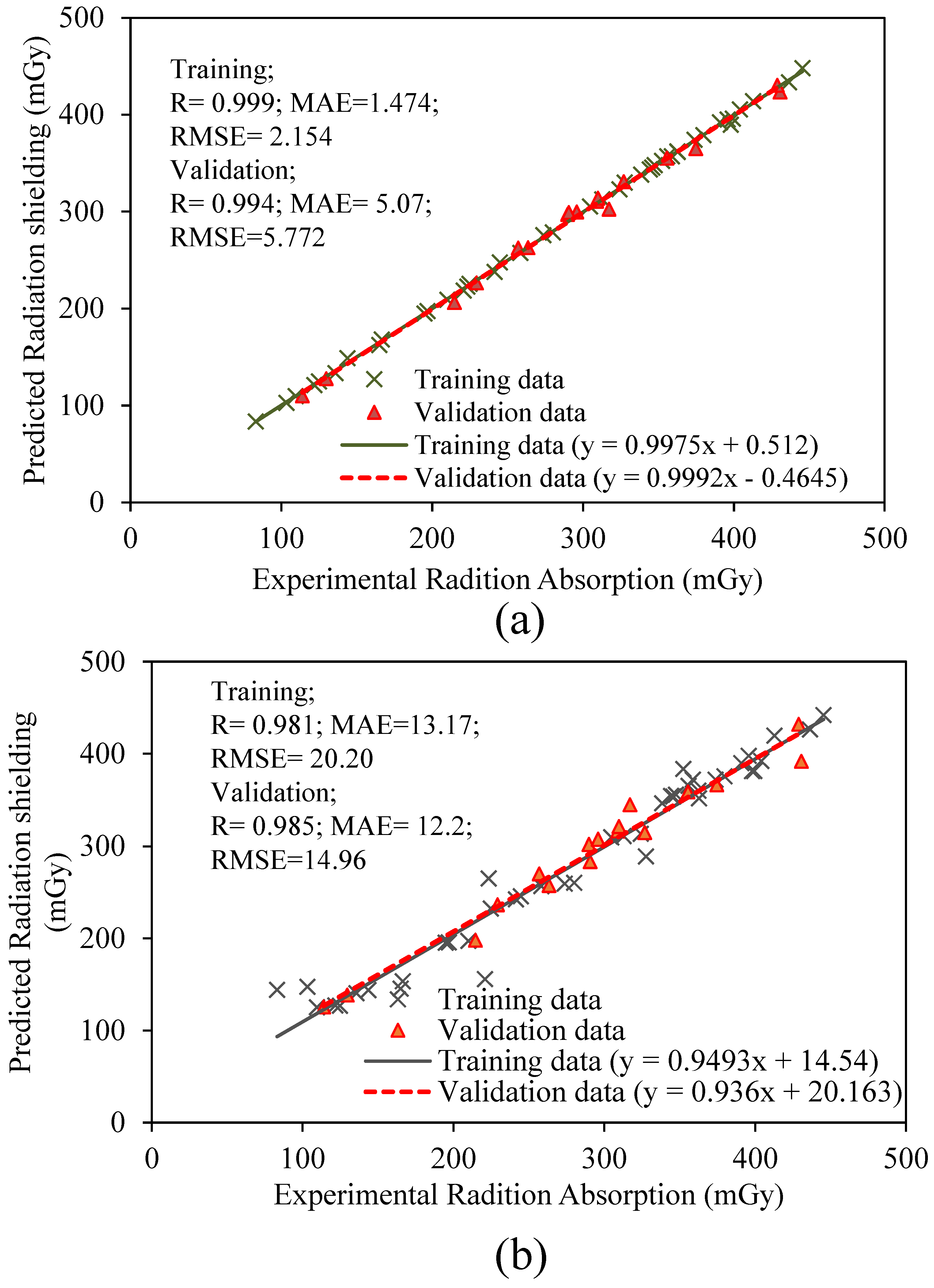

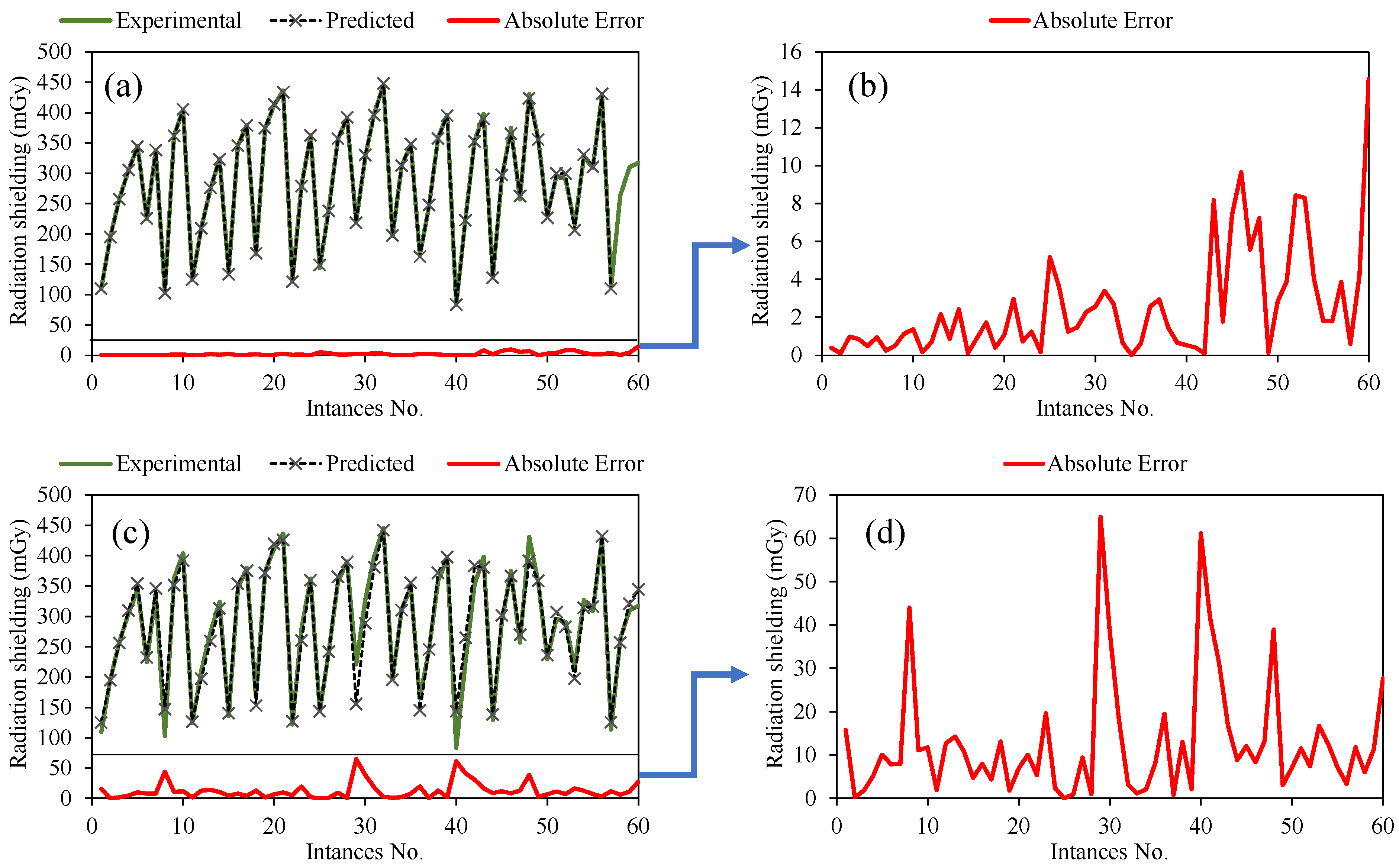

3.2. Performance of the Models

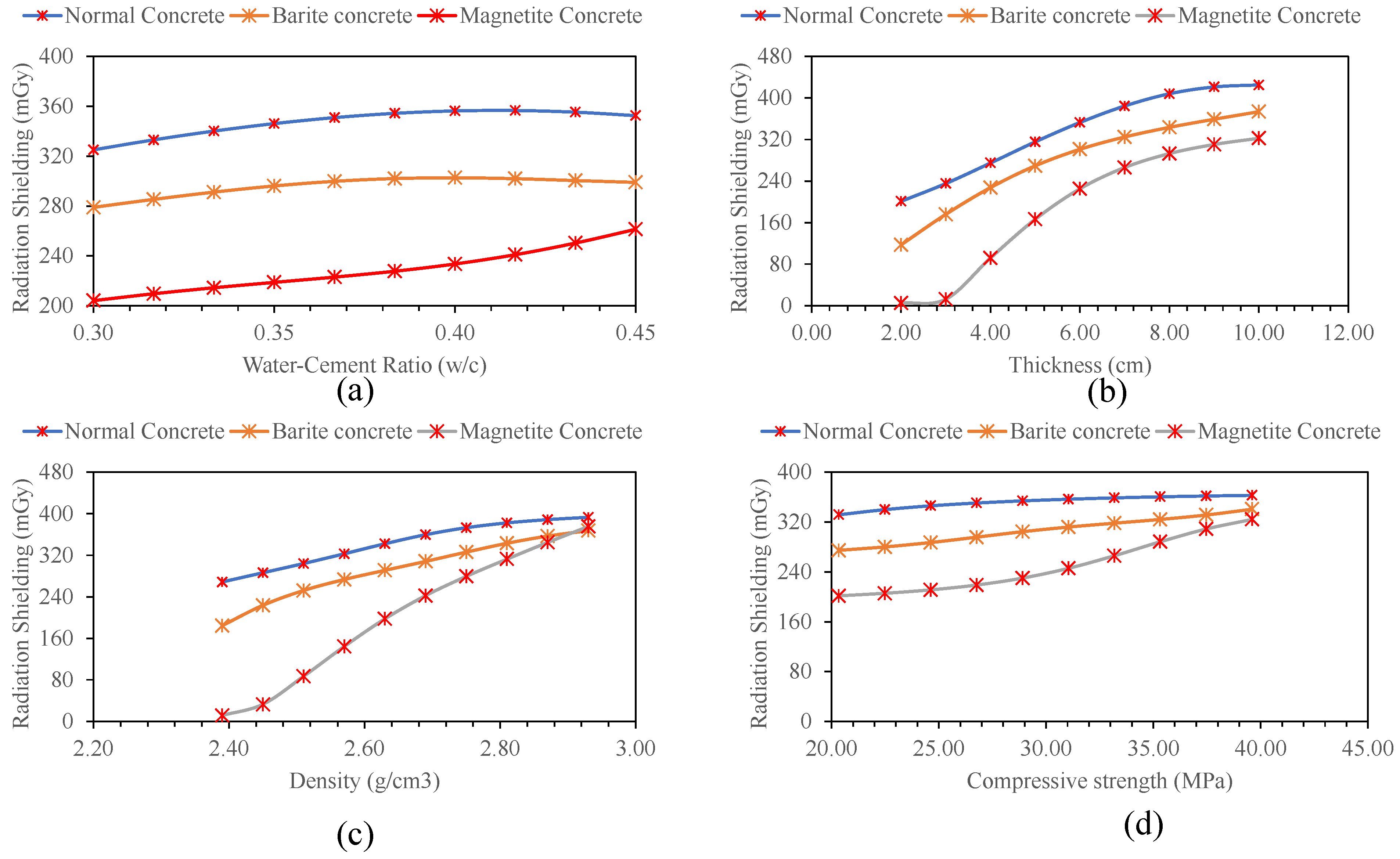

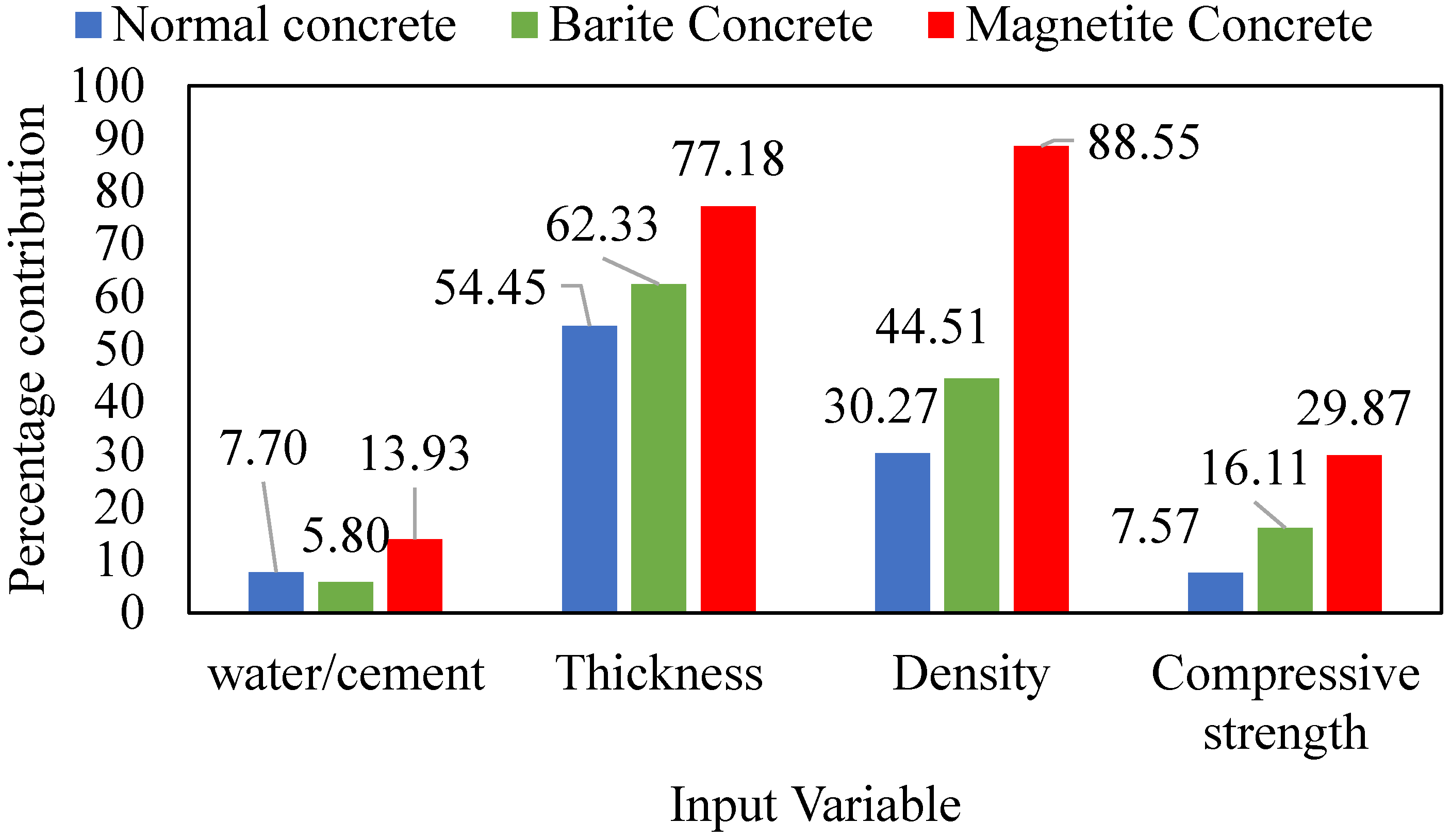

3.3. Sensitivity and Parametric Analysis

4. Conclusions

- The density of material and the thickness of concrete samples are the two important factors that attenuate the quantity of gamma radiation. Increasing the thickness and density of concrete improves its radiation shielding ability. Normal concrete is the most commonly used material in construction. Therefore, it is recommended to use such a w/c ratio in order to achieve a higher density without affecting strength properties. For normal and barite-containing concrete, the optimum water/cement ratio was observed as 0.40–0.42. Using an optimal w/c ratio would decrease the wall thickness required for radiation shielding in therapy bunkers and atomic reactors, indirectly saving cost. Increasing the w/c ratio was found to reduce the compressive strength.

- The AI models developed in this study showed close agreement between experimental and predicted results; however, the ANN model developed for predicting radiation shielding manifests outperformed the GEP model. The simple mathematical relationship produced from the GEP model signifies its importance because it can be used in the future to predict radiation shielding of new data without using any computer program.

- The results obtained from the parametric analysis showed agreement with the experimental results. The thickness and density of concrete were found to be the most influential parameters in determining the shielding ability of concrete.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Golden, A.P.; Cohen, S.S.; Chen, H.; Ellis, E.D.; Boice, J.D., Jr. Evaluation of statistical modeling approaches for epidemiologic studies of low-dose radiation health effects. Int. J. Radiat. Biol. 2022, 98, 572–579. [Google Scholar] [CrossRef] [PubMed]

- Hasegawa, A.; Tanigawa, K.; Ohtsuru, A.; Yabe, H.; Maeda, M.; Shigemura, J.; Ohira, T.; Tominaga, T.; Akashi, M.; Hirohashi, N. Health effects of radiation and other health problems in the aftermath of nuclear accidents, with an emphasis on fukushima. Lancet 2015, 386, 479–488. [Google Scholar] [CrossRef]

- Du, W.; Zhang, L.; Li, X.; Ling, G.; Zhang, P. Nuclear Targeting Subcellular-delivery Nanosystems for Precise Cancer Treatment. Int. J. Pharm. 2022, 619, 121735. [Google Scholar] [CrossRef] [PubMed]

- Tanaka, S.; Hosokawa, M.; Tatsumi, A.; Asaumi, S.; Imai, R.; Ogawara, K. Improvement of resistance to oxaliplatin by vorinostat in human colorectal cancer cells through inhibition of Nrf2 nuclear translocation. Biochem. Biophys. Res. Commun. 2022, 607, 9–14. [Google Scholar] [CrossRef] [PubMed]

- Pinsky, R.; Sabharwall, P.; Hartvigsen, J.; O’Brien, J. Comparative review of hydrogen production technologies for nuclear hybrid energy systems. Prog. Nucl. Energy 2020, 123, 103317. [Google Scholar] [CrossRef]

- Parker, H.M.O.; Joyce, M.J. The use of ionising radiation to image nuclear fuel: A review. Prog. Nucl. Energy 2015, 85, 297–318. [Google Scholar] [CrossRef] [Green Version]

- Akkurt, I.; Akyildirim, H.; Mavi, B.; Kilincarslan, S.; Basyigit, C. Gamma-ray shielding properties of concrete including barite at different energies. Prog. Nucl. Energy 2010, 52, 620–623. [Google Scholar] [CrossRef]

- Ahmad, I.; Shahzada, K.; Ahmad, M.I.; Khan, F.; Badrashi, Y.I.; Khan, S.W.; Muhammad, N.; Ahmad, H. Densification of concrete using barite as fine aggregate and its effect on concrete mechanical and radiation shielding properties. J. Eng. Res. 2019, 7, 81–95. [Google Scholar]

- Ouda, A.S. Development of high-performance heavy density concrete using different aggregates for gamma-ray shielding. Prog. Nucl. Energy 2015, 79, 48–55. [Google Scholar] [CrossRef] [Green Version]

- Maslehuddin, M.; Naqvi, A.; Ibrahim, M.; Kalakada, Z. Radiation shielding properties of concrete with electric arc furnace slag aggregates and steel shots. Ann. Nucl. Energy 2013, 53, 192–196. [Google Scholar] [CrossRef]

- González-Ortega, M.A.; Cavalaro, S.; Aguado, A. Influence of barite aggregate friability on mixing process and mechanical properties of concrete. Constr. Build. Mater. 2015, 74, 169–175. [Google Scholar] [CrossRef] [Green Version]

- Saidani, K.; Ajam, L.; Ouezdou, M.B. Barite powder as sand substitution in concrete: Effect on some mechanical properties. Constr. Build. Mater. 2015, 95, 287–295. [Google Scholar] [CrossRef]

- Gencel, O.; Brostow, W.; Ozel, C. An investigation on the concrete properties containing colemanite. Int. J. Phys. Sci. 2010, 5, 216–225. [Google Scholar]

- Demir, I.; Gümüş, M.; Gökçe, H. Gamma ray and neutron shielding characteristics of polypropylene fiber-reinforced heavyweight concrete exposed to high temperatures. Constr. Build. Mater. 2020, 257, 119596. [Google Scholar] [CrossRef]

- Gencel, O.; Bozkurt, A.; Kam, E.; Korkut, T. Determination and calculation of gamma and neutron shielding characteristics of concretes containing different hematite proportions. Ann. Nucl. Energy 2011, 38, 2719–2723. [Google Scholar] [CrossRef]

- Akyüz, S. Heavyweight concrete with barite aggregate for protecting structures against gamma rays. ITU J. 1977, 35, 59–69. [Google Scholar]

- Rezaei-Ochbelagh, D.; Azimkhani, S.; Mosavinejad, H.G. Shielding and strength tests of silica fume concrete. Ann. Nucl. Energy 2012, 45, 150–154. [Google Scholar] [CrossRef]

- Abo-El-Enein, S.A.; El-Sayed, H.A.; Ali, A.H.; Mohammed, Y.T.; Khater, H.M.; Ouda, A.S. Physico-mechanical properties of high performance concrete using different aggregates in presence of silica fume. HBRC J. 2014, 10, 43–48. [Google Scholar]

- Mostofinejad, D.; Reisi, M.; Shirani, A. Mix design effective parameters on γ-ray attenuation coefficient and strength of normal and heavyweight concrete. Constr. Build. Mater. 2012, 28, 224–229. [Google Scholar] [CrossRef]

- Özen, S.; Şengül, C.; Erenoğlu, T.; Çolak, Ü.; Reyhancan, I.A.; Taşdemir, M.A. Properties of heavyweight concrete for structural and radiation shielding purposes. Arab. J. Sci. Eng. 2016, 41, 1573–1584. [Google Scholar] [CrossRef]

- Singh, B.S.; Ramana, K. Mechanical properties of heavy weight concrete using heavy weight coarse-aggregate as hematite (Fe58 high grade iron ore). PAN 2014, 15, 100. [Google Scholar]

- Khalaf, M.A.; Ban, C.C.; Ramli, M.; Ahmed, N.M.; Sern, L.J.; Khaleel, H.A. Physicomechanical and gamma-ray shielding properties of high-strength heavyweight concrete containing steel furnace slag aggregate. J. Build. Eng. 2020, 30, 101306. [Google Scholar] [CrossRef]

- Lai, M.H.; Wu, K.J.; Cheng, X.; Ho, J.C.M.; Wu, J.P.; Chen, J.H.; Zhang, A.J. Effect of fillers on the behaviour of heavy-weight concrete made by iron sand. Constr. Build. Mater. 2022, 332, 127357. [Google Scholar] [CrossRef]

- Iffat, S. Relation between density and compressive strength of hardened concrete. Concr. Res. Lett. 2015, 6, 182–189. [Google Scholar]

- Daungwilailuk, T.; Yenchai, C.; Rungjaroenkiti, W.; Pheinsusom, P.; Panwisawas, C.; Pansuk, W. Use of barite concrete for radiation shielding against gamma-rays and neutrons. Constr. Build. Mater. 2022, 326, 126838. [Google Scholar] [CrossRef]

- Öz, A.; Bayrak, B.; Kavaz, E.; Kaplan, G.; Çelebi, O.; Alcan, H.G.; Aydın, A.C. The radiation shielding and microstructure properties of quartzic and metakaolin based geopolymer concrete. Constr. Build. Mater. 2022, 342, 127923. [Google Scholar] [CrossRef]

- Libeesh, N.K.; Naseer, K.A.; Arivazhagan, S.; El-Rehim, A.F.A.; Misned, G.A.L.; Tekin, H.O. Characterization of Ultramafic–Alkaline–Carbonatite complex for radiation shielding competencies: An experimental and Monte Carlo study with lithological mapping. Ore Geol. Rev. 2022, 142, 104735. [Google Scholar] [CrossRef]

- Abdalla, A.M.; Al-Naggar, T.I.; Bashiri, A.M.; Alsareii, S.A. Radiation shielding performance for local granites. Prog. Nucl. Energy 2022, 150, 104294. [Google Scholar] [CrossRef]

- Esen, Y.; Doğan, Z.M. Evaluation of physical and mechanical characteristics of siderite concrete to be used as heavy-weight concrete. Cem. Concr. Compos. 2017, 82, 117–127. [Google Scholar] [CrossRef]

- Ban, C.C.; Khalaf, M.A.; Ramli, M.; Ahmed, N.M.; Ahmad, M.S.; Ali, A.M.A.; Dawood, E.T.; Ameri, F. Modern heavyweight concrete shielding: Principles, industrial applications and future challenges; review. J. Build. Eng. 2021, 39, 102290. [Google Scholar] [CrossRef]

- Azeez, M.O.; Ahmad, S.; Al-Dulaijan, S.U.; Maslehuddin, M.; Naqvi, A.A. Radiation shielding performance of heavy-weight concrete mixtures. Constr. Build. Mater. 2019, 224, 284–291. [Google Scholar] [CrossRef]

- Marvila, M.T.; de Azevedo, A.R.G.; de Matos, P.R.; Monteiro, S.N.; Vieira, C.M.F. Materials for production of high and ultra-high performance concrete: Review and perspective of possible novel materials. Materials 2021, 14, 4304. [Google Scholar] [CrossRef]

- Baalamurugan, J.; Kumar, V.G.; Chandrasekaran, S.; Balasundar, S.; Venkatraman, B.; Padmapriya, R.; Raja, V.K.B. Recycling of steel slag aggregates for the development of high density concrete: Alternative & environment-friendly radiation shielding composite. Compos. Part B Eng. 2021, 216, 108885. [Google Scholar]

- Mahmood, A.H.; Foster, S.J.; Castel, A. Development of high-density geopolymer concrete with steel furnace slag aggregate for coastal protection structures. Constr. Build. Mater. 2020, 248, 118681. [Google Scholar] [CrossRef]

- Al-Jabri, K.S.; Hisada, M.; Al-Saidy, A.H.; Al-Oraimi, S.K. Performance of high strength concrete made with copper slag as a fine aggregate. Constr. Build. Mater. 2009, 23, 2132–2140. [Google Scholar] [CrossRef]

- Anastasiou, E.; Filikas, K.G.; Stefanidou, M. Utilization of fine recycled aggregates in concrete with fly ash and steel slag. Constr. Build. Mater. 2014, 50, 154–161. [Google Scholar] [CrossRef]

- Lv, Y.; Qin, Y.; Wang, J.; Li, G.; Zhang, P.; Liao, D.; Xi, Z.; Yang, L. Effect of incorporating hematite on the properties of ultra-high performance concrete including nuclear radiation resistance. Constr. Build. Mater. 2022, 327, 126950. [Google Scholar] [CrossRef]

- Ibrahim, A.M.; Mohamed, A.R.; El-Khatib, A.M.; Alabsy, M.T.; Elsalamawy, M. Effect of hematite and iron slag as aggregate replacement on thermal, mechanical, and gamma-radiation shielding properties of concrete. Constr. Build. Mater. 2021, 310, 125225. [Google Scholar] [CrossRef]

- Piotrowski, T.; Tefelski, D.; Polański, A.; Skubalski, J. Monte Carlo simulations for optimization of neutron shielding concrete. Open Eng. 2012, 2, 296–303. [Google Scholar] [CrossRef]

- Alwaeli, M.; Nadziakiewicz, J. Recycling of scale and steel chips waste as a partial replacement of sand in concrete. Constr. Build. Mater. 2012, 28, 157–163. [Google Scholar] [CrossRef]

- Coskun, A. Use of Barite Aggregate in Heavy-Weight Concrete and Study of Concrete Properties. Master’s Thesis, Afyon Kocatepe University, Afyonkarahisar, Turkey, 2010. [Google Scholar]

- Al-Humaiqani, M.M.; Shuraim, A.B.; Hussain, R.R. Γ-radiation shielding properties of high strength high performance concretes prepared with different types of normal and heavy aggregates. Asian Trans. Eng. 2013, 3, 18–28. [Google Scholar]

- Shams, T.; Eftekhar, M.; Shirani, A. Investigation of gamma radiation attenuation in heavy concrete shields containing hematite and barite aggregates in multi-layered and mixed forms. Constr. Build. Mater. 2018, 182, 35–42. [Google Scholar] [CrossRef]

- Akkurt, I.; Akyıldırım, H.; Mavi, B.; Kilincarslan, S.; Basyigit, C. Radiation shielding of concrete containing zeolite. Radiat. Meas. 2010, 45, 827–830. [Google Scholar] [CrossRef]

- Lotfi-Omran, O.; Sadrmomtazi, A.; Nikbin, I.M. A comprehensive study on the effect of water to cement ratio on the mechanical and radiation shielding properties of heavyweight concrete. Constr. Build. Mater. 2019, 229, 116905. [Google Scholar] [CrossRef]

- Yang, K.-H.; Mun, J.-S.; Lee, H. Workability and mechanical properties of heavyweight magnetite concrete. ACI Mater. J. 2014, 111, 273. [Google Scholar] [CrossRef]

- Zheng, Z.; Tian, C.; Wei, X.; Zeng, C. Numerical investigation and ANN-based prediction on compressive strength and size effect using the concrete mesoscale concretization model. Case Stud. Constr. Mater. 2022, 16, e01056. [Google Scholar] [CrossRef]

- Moradi, M.J.; Khaleghi, M.; Salimi, J.; Farhangi, V.; Ramezanianpour, A.M. Predicting the compressive strength of concrete containing metakaolin with different properties using ANN. Measurement 2021, 183, 109790. [Google Scholar] [CrossRef]

- Amiri, M.; Hatami, F. Prediction of mechanical and durability characteristics of concrete including slag and recycled aggregate concrete with artificial neural networks (ANNs). Constr. Build. Mater. 2022, 325, 126839. [Google Scholar] [CrossRef]

- Golafshani, E.M.; Behnood, A. Predicting the mechanical properties of sustainable concrete containing waste foundry sand using multi-objective ANN approach. Constr. Build. Mater. 2021, 291, 123314. [Google Scholar] [CrossRef]

- Chou, J.-S.; Pham, A.-D. Enhanced artificial intelligence for ensemble approach to predicting high performance concrete compressive strength. Constr. Build. Mater. 2013, 49, 554–563. [Google Scholar] [CrossRef]

- El-Sayed, A.A.; Fathy, I.N.; Tayeh, B.A.; Almeshal, I. Using artificial neural networks for predicting mechanical and radiation shielding properties of different nano-concretes exposed to elevated temperature. Constr. Build. Mater. 2022, 324, 126663. [Google Scholar] [CrossRef]

- Yadollahi, A.; Nazemi, E.; Zolfaghari, A.; Ajorloo, A.M. Optimization of thermal neutron shield concrete mixture using artificial neural network. Nucl. Eng. Des. 2016, 305, 146–155. [Google Scholar] [CrossRef]

- Yadollahi, A.; Nazemi, E.; Zolfaghari, A.; Ajorloo, A. Application of artificial neural network for predicting the optimal mixture of radiation shielding concrete. Prog. Nucl. Energy 2016, 89, 69–77. [Google Scholar] [CrossRef]

- Xu, J.; Ren, Q.; Shen, Z. Prediction of the strength of concrete radiation shielding based on ls-svm. Ann. Nucl. Energy 2015, 85, 296–300. [Google Scholar]

- Isfahani, H.S.; Abtahi, S.M.; Roshanzamir, M.A.; Shirani, A.; Hejazi, S.M. Investigation on gamma-ray shielding and permeability of clay-steel slag mixture. Bull. Eng. Geol. Environ. 2019, 78, 4589–4598. [Google Scholar] [CrossRef]

- Mehmannavaz, T.; Khalilikhorram, V.; Sajjadi, S.M.; Samadi, M. Presenting an appropriate neural network for optimal mix design of roller compacted concrete dams. Res. J. Appl. Sci. Eng. Technol. 2014, 7, 1872–1877. [Google Scholar] [CrossRef]

- Khan, M. Predicting properties of high performance concrete containing composite cementitious materials using artificial neural networks. Autom. Constr. 2012, 22, 516–524. [Google Scholar] [CrossRef]

- Sobhani, J.; Najimi, M.; Pourkhorshidi, A.R.; Parhizkar, T. Prediction of the compressive strength of no-slump concrete: A comparative study of regression, neural network and anfis models. Constr. Build. Mater. 2010, 24, 709–718. [Google Scholar] [CrossRef]

- Bardhan, A.; Samui, P.; Ghosh, K.; Gandomi, A.H.; Bhattacharyya, S. Elm-based adaptive neuro swarm intelligence techniques for predicting the california bearing ratio of soils in soaked conditions. Appl. Soft Comput. 2021, 110, 107595. [Google Scholar] [CrossRef]

- Bardhan, A.; Kardani, N.; GuhaRay, A.; Burman, A.; Samui, P.; Zhang, Y. Hybrid ensemble soft computing approach for predicting penetration rate of tunnel boring machine in a rock environment. J. Rock Mech. Geotech. Eng. 2021, 13, 1398–1412. [Google Scholar] [CrossRef]

- Iqbal, M.; Zhang, D.; Jalal, F.E.; Javed, M.F. Computational ai prediction models for residual tensile strength of gfrp bars aged in the alkaline concrete environment. Ocean. Eng. 2021, 232, 109134. [Google Scholar] [CrossRef]

- Amin, M.N.; Iqbal, M.; Khan, K.; Qadir, M.G.; Shalabi, F.I.; Jamal, A. Ensemble tree-based approach towards flexural strength prediction of frp reinforced concrete beams. Polymers 2022, 14, 1303. [Google Scholar] [CrossRef] [PubMed]

- Iqbal, M.; Zhao, Q.; Zhang, D.; Jalal, F.E.; Jamal, A. Evaluation of tensile strength degradation of gfrp rebars in harsh alkaline conditions using non-linear genetic-based models. Mater. Struct. 2021, 54, 1–20. [Google Scholar] [CrossRef]

- Felekoğlu, B.; Türkel, S.; Baradan, B. Effect of water/cement ratio on the fresh and hardened properties of self-compacting concrete. Build. Environ. 2007, 42, 1795–1802. [Google Scholar] [CrossRef]

- Bheel, N.; Meghwar, S.L.; Abbasi, S.A.; Marwari, L.C.; Mugeri, J.A.; Abbasi, R.A. Effect of rice husk ash and water-cement ratio on strength of concrete. Civ. Eng. J. 2018, 4, 2373–2382. [Google Scholar] [CrossRef]

- Bardhan, A.; Gokceoglu, C.; Burman, A.; Samui, P.; Asteris, P.G. Efficient computational techniques for predicting the california bearing ratio of soil in soaked conditions. Eng. Geol. 2021, 291, 106239. [Google Scholar] [CrossRef]

- Biswas, R.; Bardhan, A.; Samui, P.; Rai, B.; Nayak, S.; Armaghani, D.J. Efficient soft computing techniques for the prediction of compressive strength of geopolymer concrete. Comput. Concr. 2021, 28, 221–232. [Google Scholar]

- Kardani, N.; Bardhan, A.; Kim, D.; Samui, P.; Zhou, A. Modelling the energy performance of residential buildings using advanced computational frameworks based on rvm, gmdh, anfis-bbo and anfis-ipso. J. Build. Eng. 2021, 35, 102105. [Google Scholar] [CrossRef]

- Kardani, N.; Bardhan, A.; Roy, B.; Samui, P.; Nazem, M.; Armaghani, D.J.; Zhou, A. A novel improved harris hawks optimization algorithm coupled with elm for predicting permeability of tight carbonates. Eng. Comput. 2021, 1–24. [Google Scholar] [CrossRef]

- Bardhan, A.; Biswas, R.; Kardani, N.; Iqbal, M.; Samui, P.; Singh, M.P.; Asteris, P.G. A novel integrated approach of augmented grey wolf optimizer and ann for estimating axial load carrying-capacity of concrete-filled steel tube columns. Constr. Build. Mater. 2022, 337, 127454. [Google Scholar] [CrossRef]

- Bardhan, A.; GuhaRay, A.; Gupta, S.; Pradhan, B.; Gokceoglu, C. A novel integrated approach of elm and modified equilibrium optimizer for predicting soil compression index of subgrade layer of dedicated freight corridor. Transp. Geotech. 2022, 32, 100678. [Google Scholar] [CrossRef]

- Khan, M.I.; Sutanto, M.H.; Khan, K.; Iqbal, M.; Napiah, M.B.; Zoorob, S.E.; Klemeš, J.J.; Bokhari, A.; Rafiq, W. Effective use of recycled waste pet in cementitious grouts for developing sustainable semi-flexible pavement surfacing using artificial neural network. J. Clean. Prod. 2022, 340, 130840. [Google Scholar] [CrossRef]

- Jalal, F.E.; Xu, Y.; Li, X.; Jamhiri, B.; Iqbal, M. Fractal approach in expansive clay-based materials with special focus on compacted gmz bentonite in nuclear waste disposal: A systematic review. Environ. Sci. Pollut. Res. 2021, 28, 43287–43314. [Google Scholar] [CrossRef] [PubMed]

| Ingredient | Physical properties | |||||

|---|---|---|---|---|---|---|

| Specific Gravity | Bulk Density | Absorption Capacity | Max. Aggregate Size | Fineness Modulus | ||

| Cement | 3.15 | - | - | - | - | |

| Coarse Aggregates | 2.65 | 1602 kg/m3 | 1.30% | 25.44 mm | - | |

| Fine Aggregates | 2.38 | - | 1.88% | - | 2.34 | |

| Barite | 3.10 | - | 3.05% | - | 2.31 | |

| Magnetite | 3.20 | - | 0.91% | - | 3.20 | |

| Constituents | Mass Percentage (%) |

|---|---|

| CaO | 77.2 |

| SiO2 | 15.8 |

| Al2O3 | 5.82 |

| Fe2O3 | 1.06 |

| ZnO | 0.07 |

| MnO + TiO2 + K2O | 0.05 |

| S. No. | Properties | Value |

|---|---|---|

| 1 | Slump range | 25–50 mm |

| 2 | Maximum size of coarse aggregate | 25 mm down |

| 3 | Bulk density of coarse aggregate | 591.1 kg/m3 |

| 4 | Specific gravity of coarse aggregate | 2.65 |

| 5 | Absorption capacity of coarse aggregate | 1.3% |

| 6 | Specific gravity of sand | 2.38 |

| 7 | Fineness modulus of sand | 2.34 |

| 8 | Absorption capacity of sand | 2% |

| 9 | Specific gravity of cement | 3.15 |

| Water/Cement (w/c) | Weight of Concrete Ingredients (Kg/m3) | Chemical Admixture (%) | |||||

|---|---|---|---|---|---|---|---|

| Water | Cement | Fine Aggregates | Coarse Aggregates | ||||

| Sand | Barite | Magnatite | |||||

| 0.30 | 178 | 593 | 491 | 639.5 | 660.2 | 1117 | 1.5 |

| 0.35 | 208 | 593 | 462 | 601.8 | 621 | 1117 | 1 |

| 0.40 | 237 | 593 | 432 | 562.7 | 580.8 | 1117 | 0.8 |

| 0.45 | 267 | 593 | 402 | 523.6 | 540.5 | 1117 | 0.5 |

| w/c | Slump Type | Slump Values (mm) |

|---|---|---|

| 0.30 | True | 36 |

| 0.35 | True | 63 |

| 0.40 | True | 74 |

| 0.45 | True | 89 |

| Input Variables | Output Variable | ||||

|---|---|---|---|---|---|

| Concrete Type | w/c | Thickness (cm) | Density (g/cm3) | Compressive Strength (MPa) | Gamma Rays Absorption (mGy) |

| 1 | 0.30 | 2 | 2.39 | 35.99 | 109.47 |

| 1 | 0.30 | 4 | 2.39 | 35.99 | 194.77 |

| 1 | 0.30 | 6 | 2.39 | 35.99 | 258.37 |

| 1 | 0.30 | 8 | 2.39 | 35.99 | 304.57 |

| 1 | 0.30 | 10 | 2.39 | 35.99 | 344.27 |

| 2 | 0.30 | 4 | 2.68 | 31.76 | 224.67 |

| 2 | 0.30 | 8 | 2.68 | 31.76 | 338.47 |

| 3 | 0.30 | 2 | 2.79 | 39.60 | 103.24 |

| 3 | 0.30 | 6 | 2.79 | 39.60 | 362.78 |

| 3 | 0.30 | 8 | 2.79 | 39.60 | 403.99 |

| 1 | 0.35 | 2 | 2.42 | 28.50 | 124.77 |

| 1 | 0.35 | 4 | 2.42 | 28.50 | 209.97 |

| 1 | 0.35 | 6 | 2.42 | 28.50 | 273.67 |

| 1 | 0.35 | 8 | 2.42 | 28.50 | 324.077 |

| 2 | 0.35 | 2 | 2.72 | 25.65 | 135.77 |

| 2 | 0.35 | 8 | 2.72 | 25.65 | 345.77 |

| 2 | 0.35 | 10 | 2.72 | 25.65 | 379.77 |

| 3 | 0.35 | 2 | 2.89 | 32.00 | 166.46 |

| 3 | 0.35 | 6 | 2.89 | 32.00 | 373.82 |

| 3 | 0.35 | 8 | 2.89 | 32.00 | 412.79 |

| 3 | 0.35 | 10 | 2.89 | 32.00 | 436.400 |

| 1 | 0.40 | 2 | 2.43 | 24.06 | 121.77 |

| 1 | 0.40 | 6 | 2.43 | 24.06 | 279.97 |

| 1 | 0.40 | 10 | 2.43 | 24.06 | 362.47 |

| 2 | 0.40 | 2 | 2.78 | 22.15 | 143.67 |

| 2 | 0.40 | 4 | 2.78 | 22.15 | 241.37 |

| 2 | 0.40 | 8 | 2.78 | 22.15 | 355.87 |

| 2 | 0.40 | 10 | 2.78 | 22.15 | 390.77 |

| 3 | 0.40 | 2 | 2.93 | 28.80 | 220.83 |

| 3 | 0.40 | 4 | 2.93 | 28.80 | 327.57 |

| 3 | 0.40 | 6 | 2.93 | 28.80 | 399.34 |

| 3 | 0.40 | 10 | 2.93 | 28.80 | 445.35 |

| 1 | 0.45 | 4 | 2.40 | 21.98 | 196.87 |

| 1 | 0.45 | 8 | 2.40 | 21.98 | 312.77 |

| 1 | 0.45 | 10 | 2.40 | 21.98 | 347.47 |

| 2 | 0.45 | 2 | 2.81 | 20.34 | 164.97 |

| 2 | 0.45 | 4 | 2.81 | 20.34 | 244.77 |

| 2 | 0.45 | 8 | 2.81 | 20.34 | 358.77 |

| 2 | 0.45 | 10 | 2.81 | 20.34 | 395.77 |

| 3 | 0.45 | 2 | 2.76 | 26.00 | 83.04 |

| 3 | 0.45 | 4 | 2.76 | 26.00 | 223.24 |

| 3 | 0.45 | 8 | 2.76 | 26.00 | 352.41 |

| 3 | 0.45 | 10 | 2.76 | 26.00 | 397.88 |

| 2 | 0.30 | 2 | 2.68 | 31.76 | 129.67 |

| 2 | 0.30 | 6 | 2.68 | 31.76 | 289.77 |

| 2 | 0.30 | 10 | 2.68 | 31.76 | 374.67 |

| Concrete type | w/c | Thickness (cm) | Density (g/cm3) | Compressive Strength (MPa) | Gamma Rays Absorption (mGy) |

|---|---|---|---|---|---|

| 3 | 0.30 | 4 | 2.79 | 39.60 | 256.89 |

| 3 | 0.30 | 10 | 2.79 | 39.60 | 430.69 |

| 1 | 0.35 | 10 | 2.42 | 28.50 | 355.57 |

| 2 | 0.35 | 4 | 2.72 | 25.65 | 229.27 |

| 2 | 0.35 | 6 | 2.72 | 25.65 | 295.87 |

| 3 | 0.35 | 4 | 2.89 | 32.00 | 290.61 |

| 1 | 0.40 | 4 | 2.43 | 24.06 | 214.67 |

| 1 | 0.40 | 8 | 2.43 | 24.06 | 326.87 |

| 2 | 0.40 | 6 | 2.78 | 22.15 | 308.97 |

| 3 | 0.40 | 8 | 2.93 | 28.80 | 428.79 |

| 1 | 0.45 | 2 | 2.40 | 21.98 | 113.87 |

| 1 | 0.45 | 6 | 2.40 | 21.98 | 263.40 |

| 2 | 0.45 | 6 | 2.81 | 20.34 | 309.77 |

| 3 | 0.45 | 6 | 2.76 | 26.00 | 317.10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amin, M.N.; Ahmad, I.; Iqbal, M.; Abbas, A.; Khan, K.; Faraz, M.I.; Alabdullah, A.A.; Ullah, S. Computational AI Models for Investigating the Radiation Shielding Potential of High-Density Concrete. Materials 2022, 15, 4573. https://doi.org/10.3390/ma15134573

Amin MN, Ahmad I, Iqbal M, Abbas A, Khan K, Faraz MI, Alabdullah AA, Ullah S. Computational AI Models for Investigating the Radiation Shielding Potential of High-Density Concrete. Materials. 2022; 15(13):4573. https://doi.org/10.3390/ma15134573

Chicago/Turabian StyleAmin, Muhammad Nasir, Izaz Ahmad, Mudassir Iqbal, Asim Abbas, Kaffayatullah Khan, Muhammad Iftikhar Faraz, Anas Abdulalim Alabdullah, and Shahid Ullah. 2022. "Computational AI Models for Investigating the Radiation Shielding Potential of High-Density Concrete" Materials 15, no. 13: 4573. https://doi.org/10.3390/ma15134573

APA StyleAmin, M. N., Ahmad, I., Iqbal, M., Abbas, A., Khan, K., Faraz, M. I., Alabdullah, A. A., & Ullah, S. (2022). Computational AI Models for Investigating the Radiation Shielding Potential of High-Density Concrete. Materials, 15(13), 4573. https://doi.org/10.3390/ma15134573