Numerical Simulation and Process Optimization on Hot Twist-Stretch Straightening of Ti-6Al-4V Alloy Profile

Abstract

:1. Introduction

2. Material and Methods

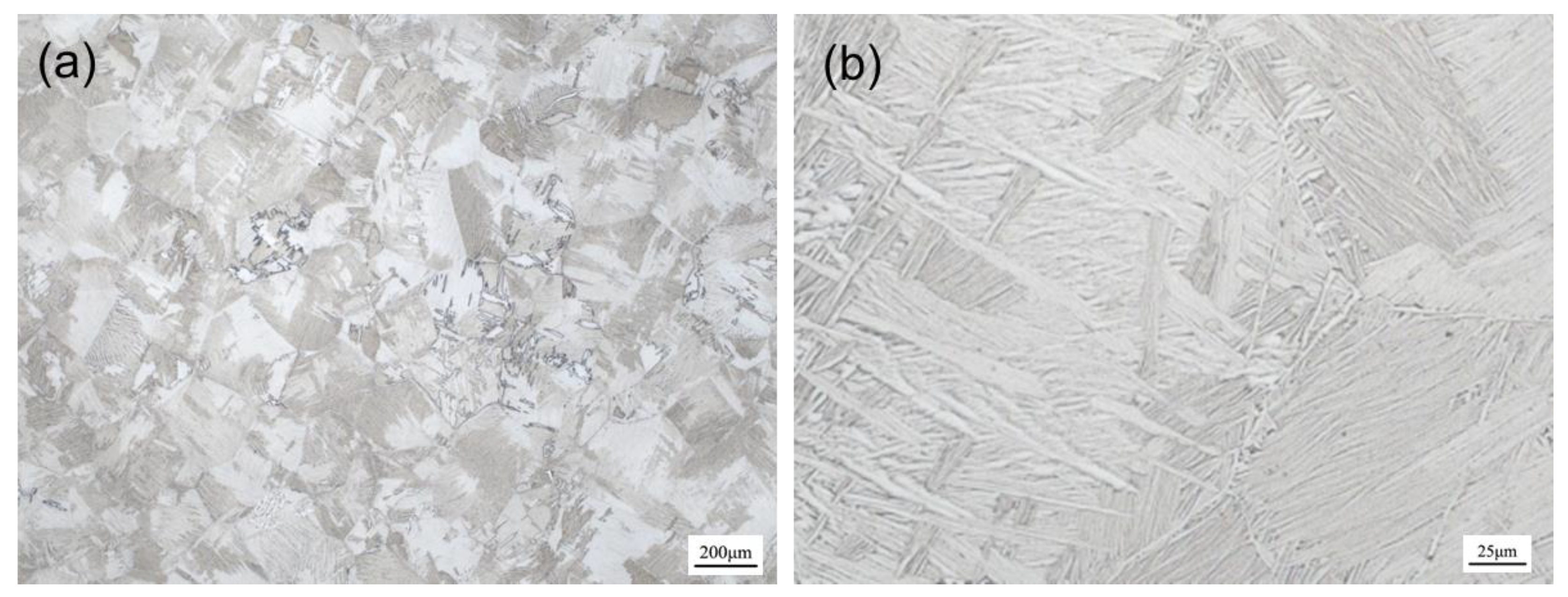

2.1. Experiment Material

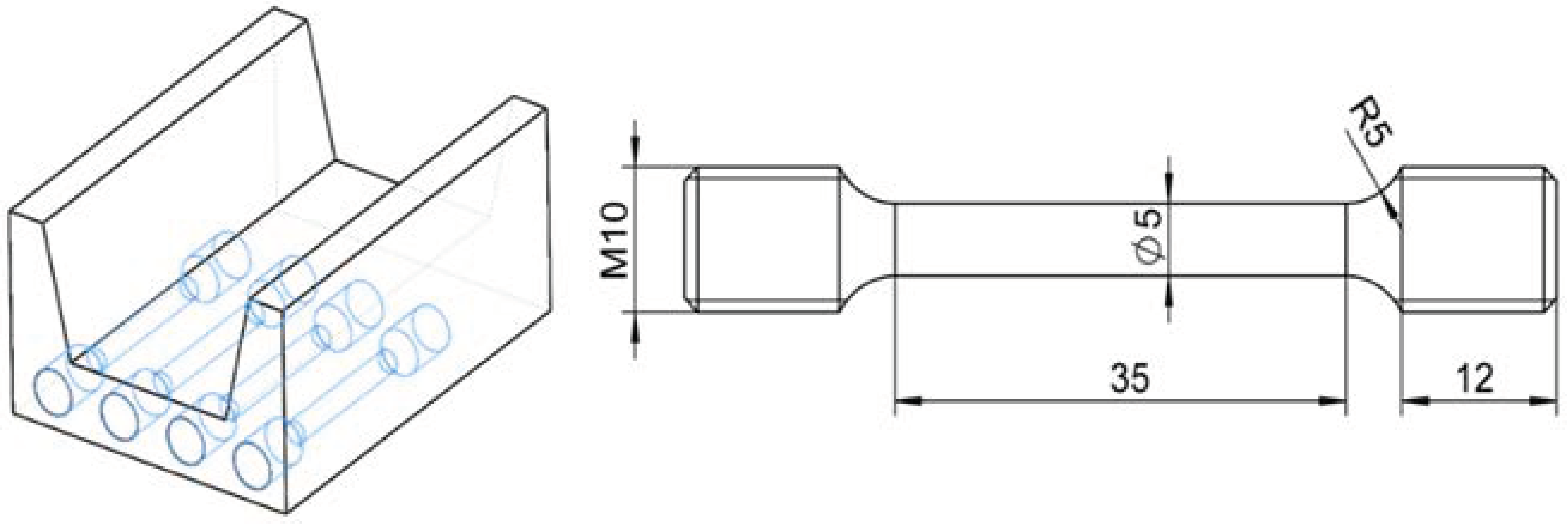

2.2. Uniaxial Tensile Tests

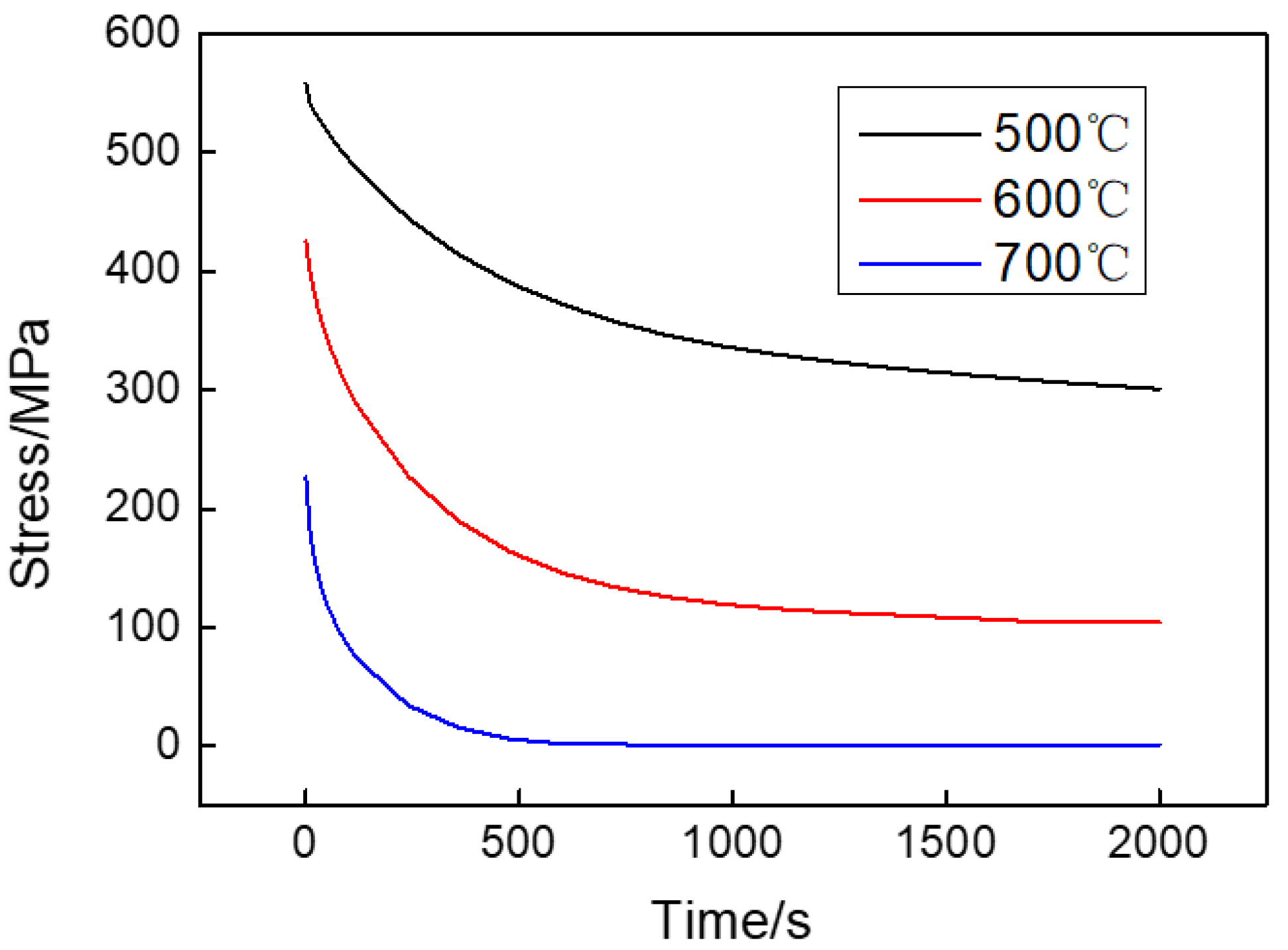

2.3. Stress Relaxation Tests

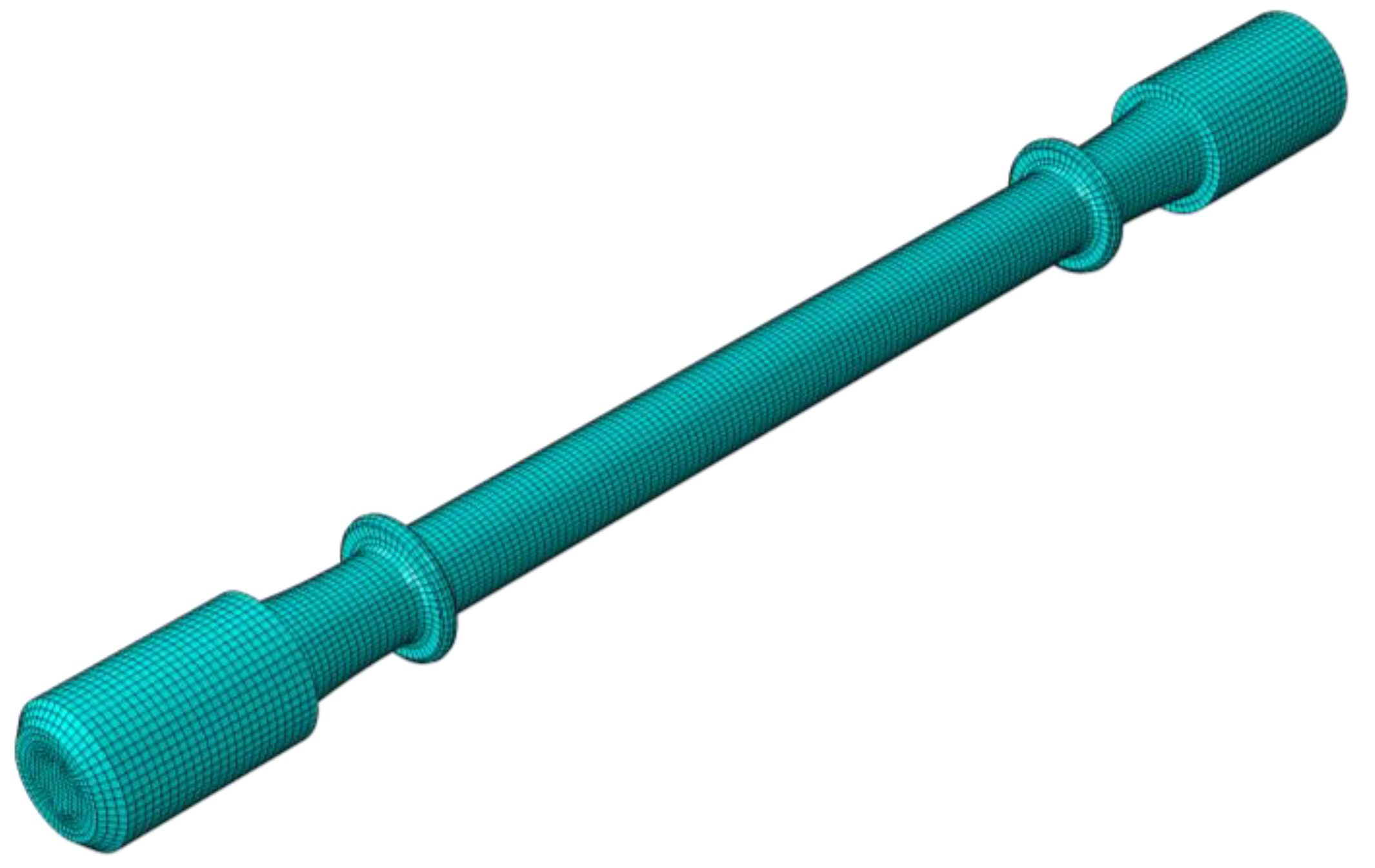

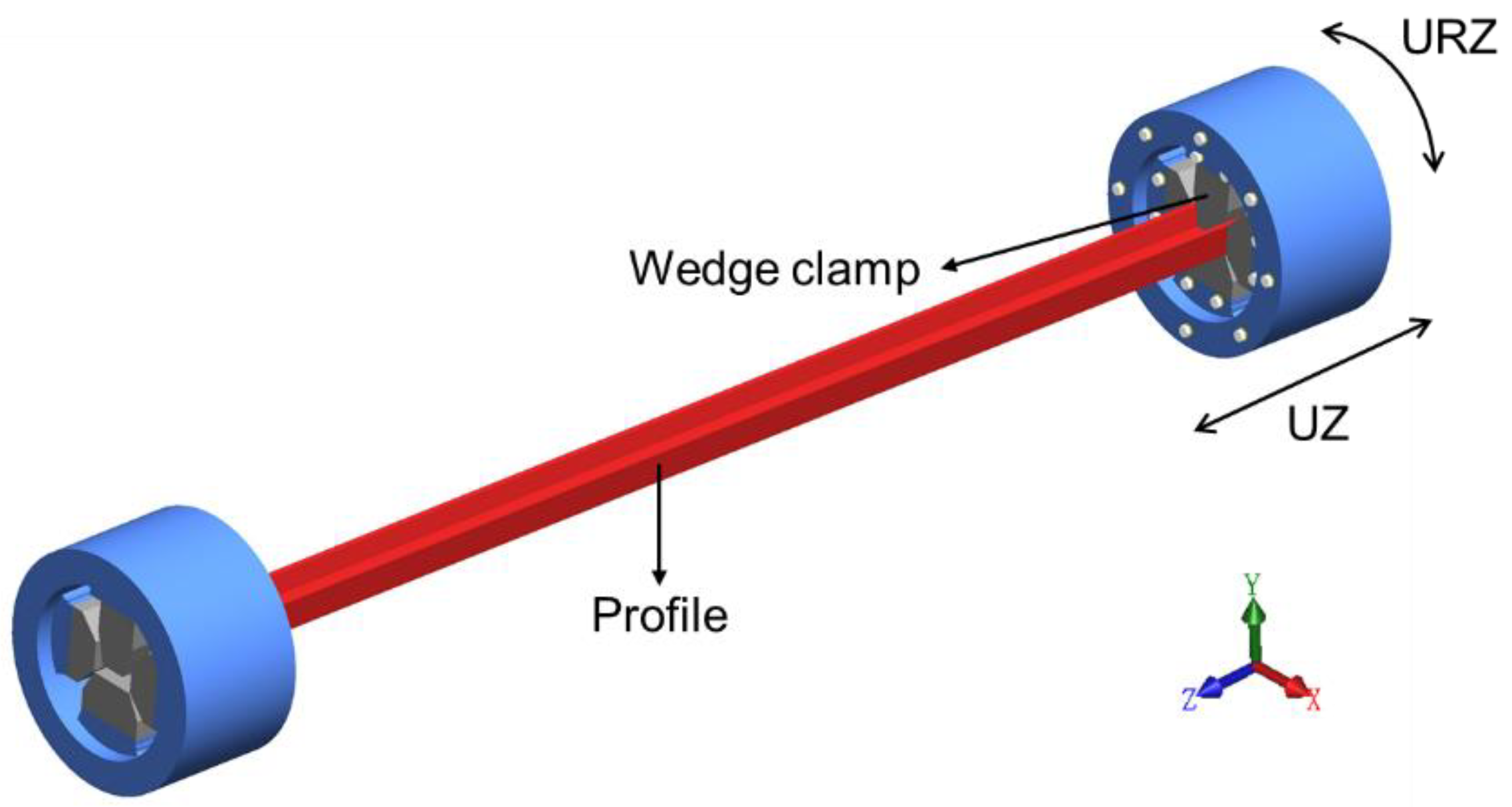

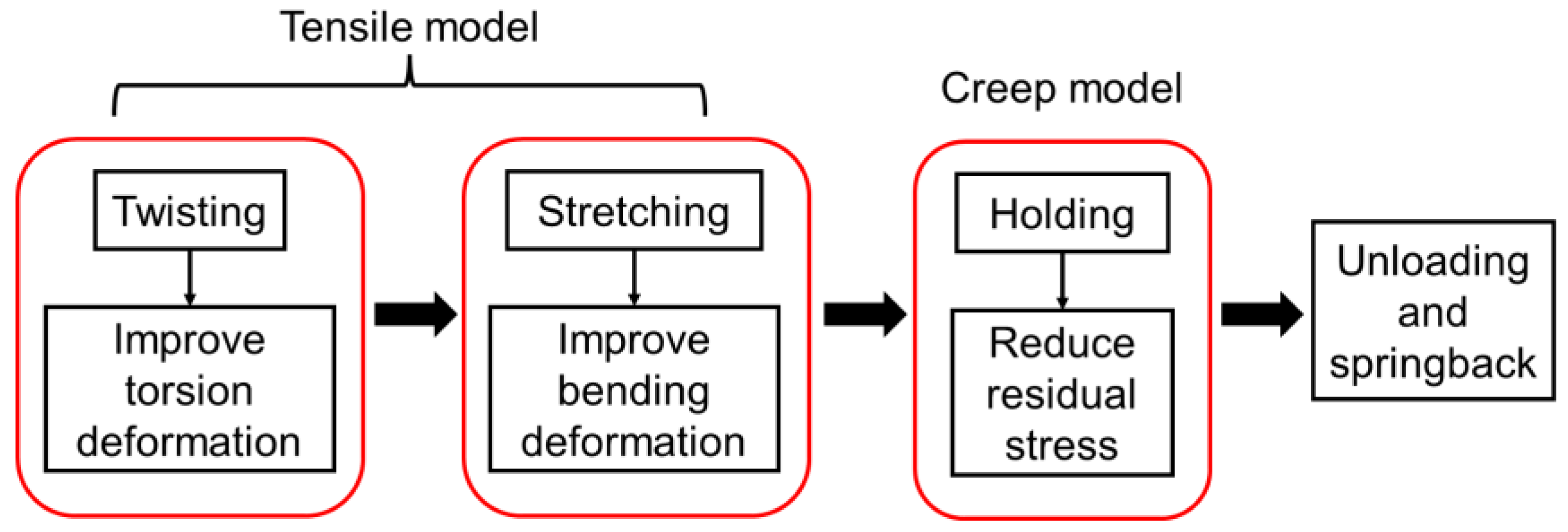

3. Numerical Simulation Model

3.1. Material Model

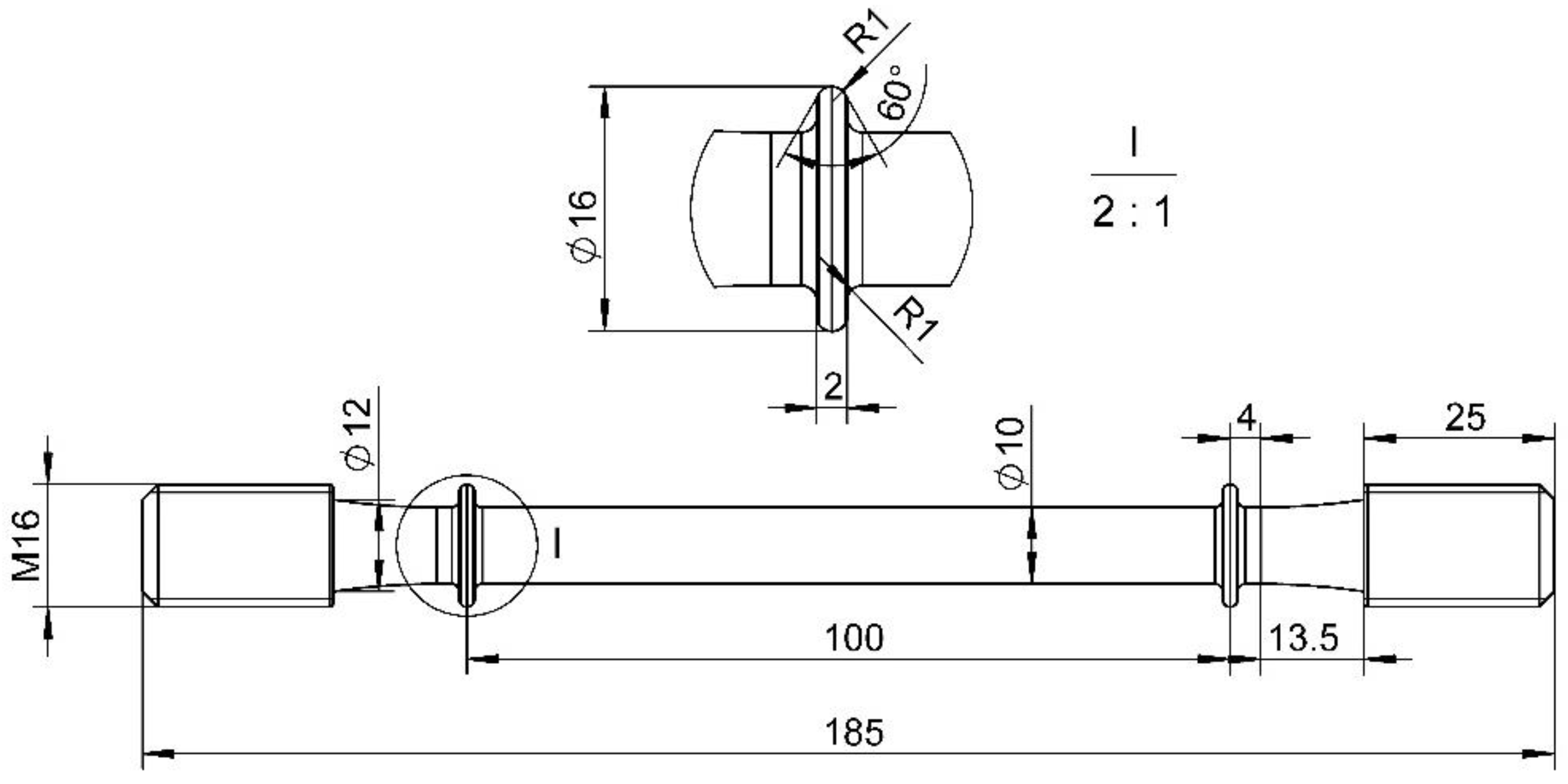

3.1.1. Uniaxial Tensile Test Results

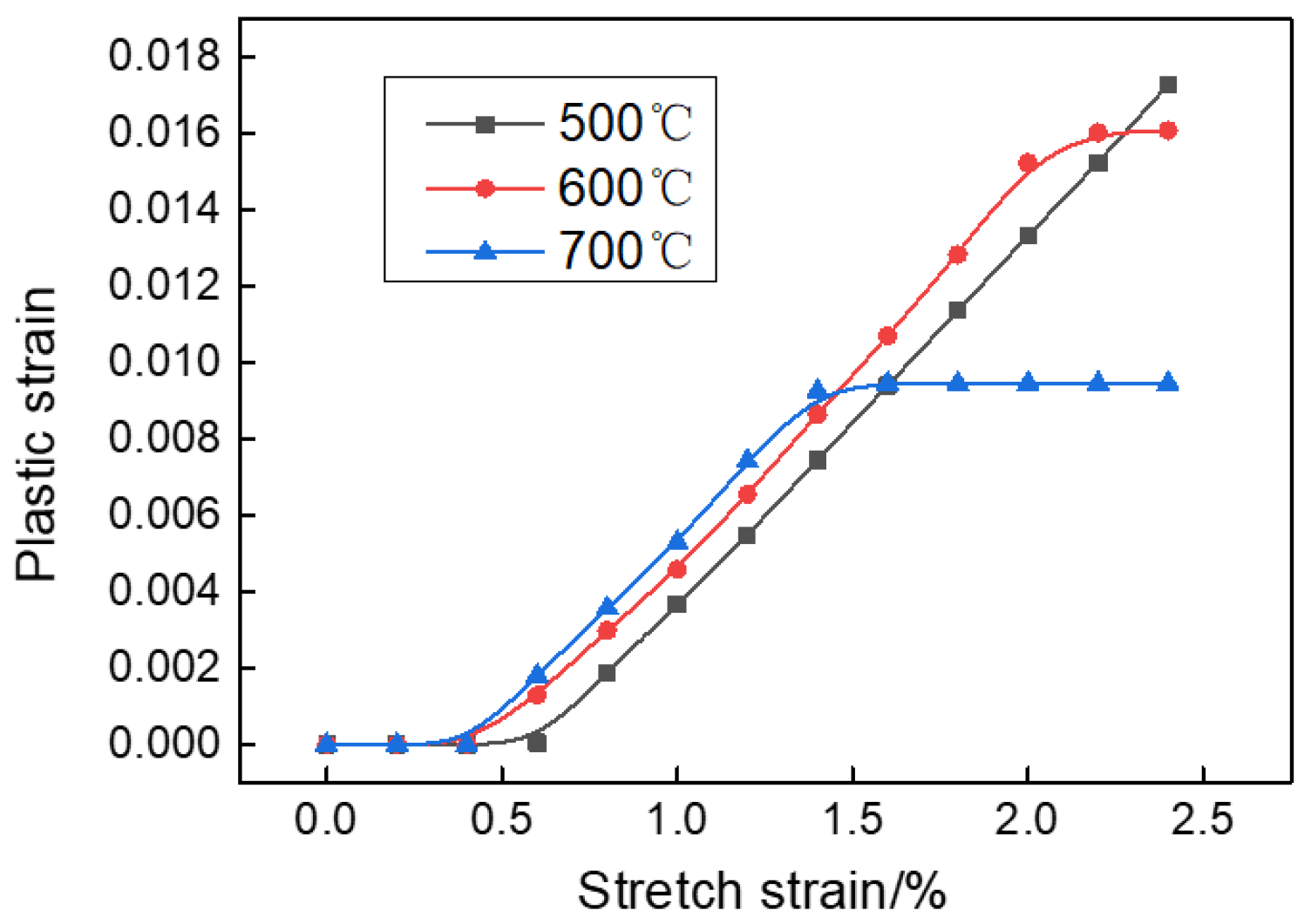

3.1.2. Stress Relaxation Test Results

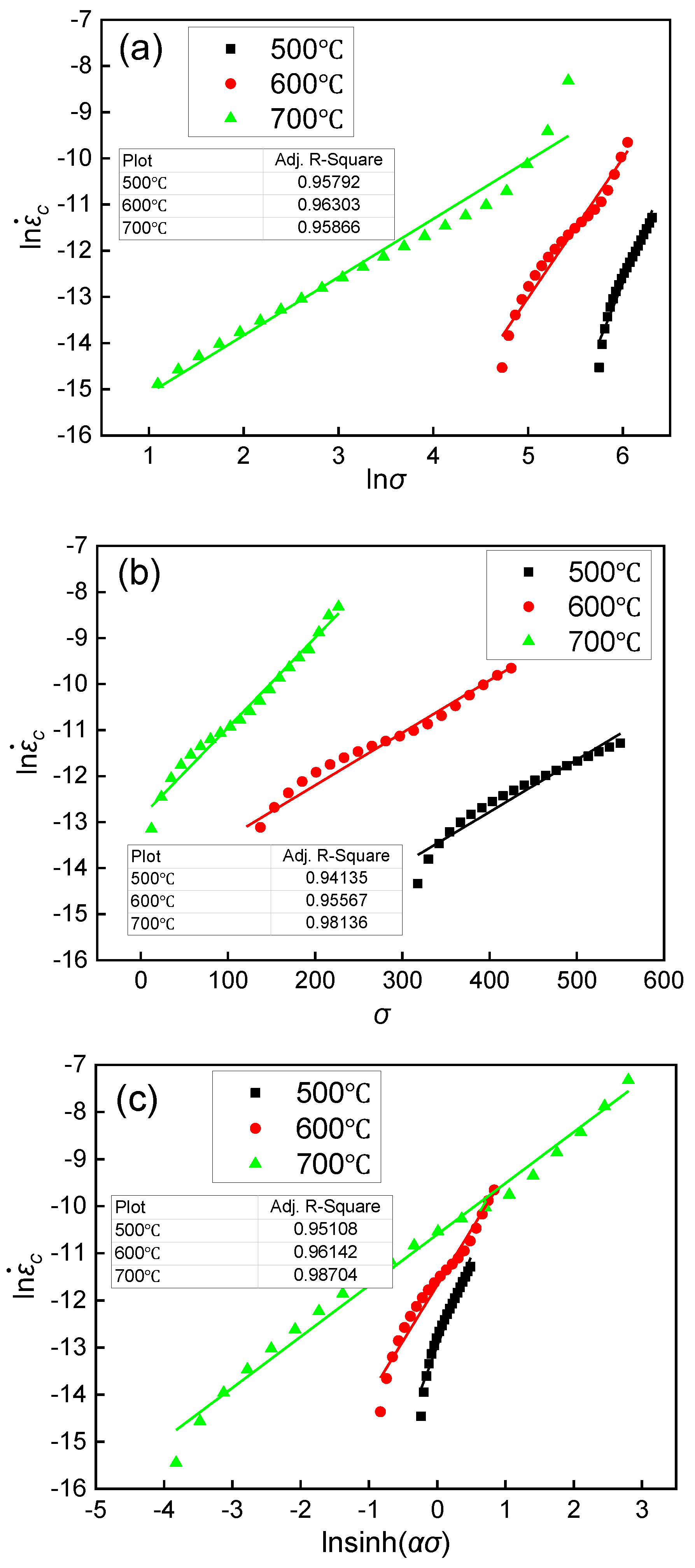

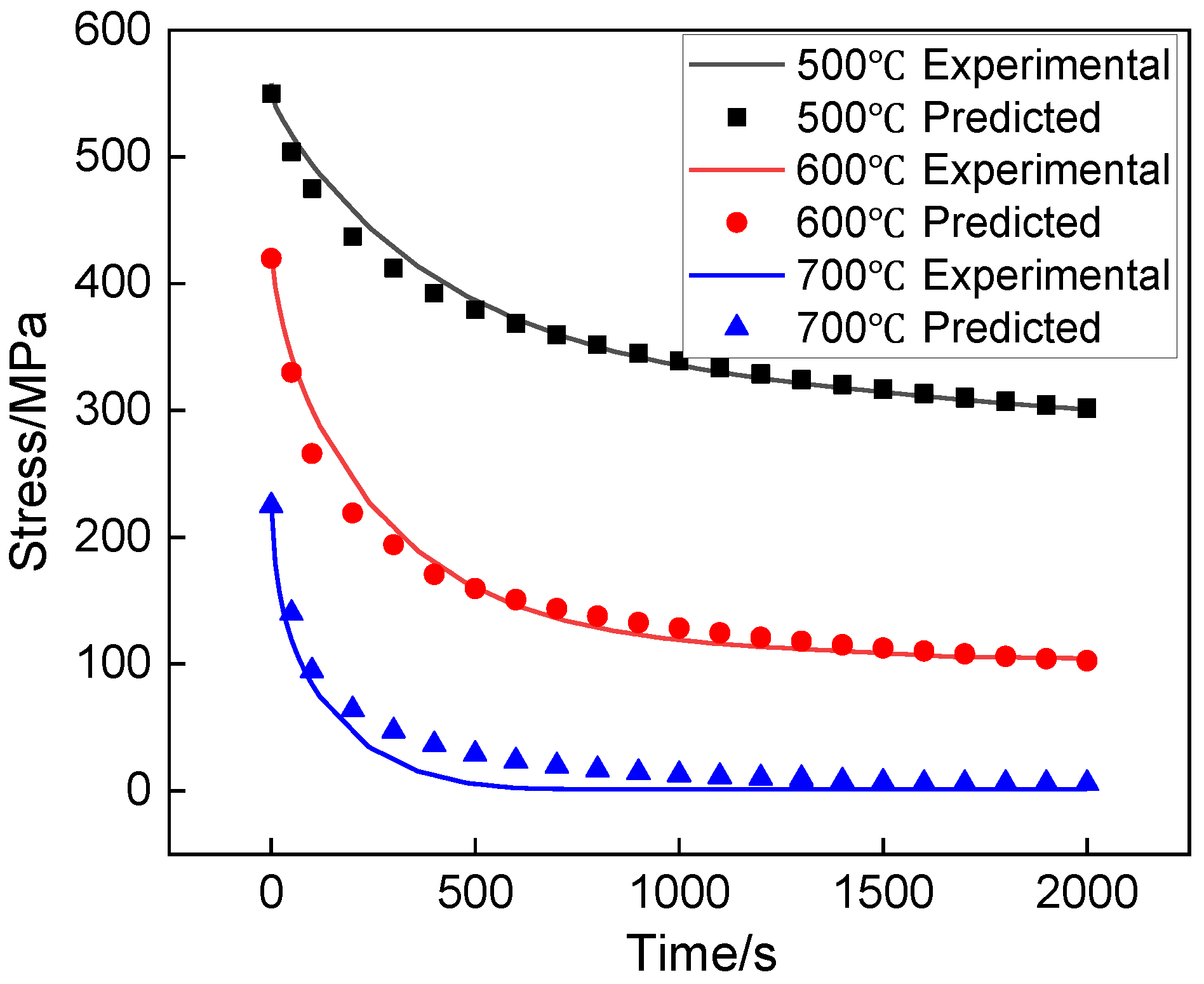

3.1.3. Creep Constitutive Modeling

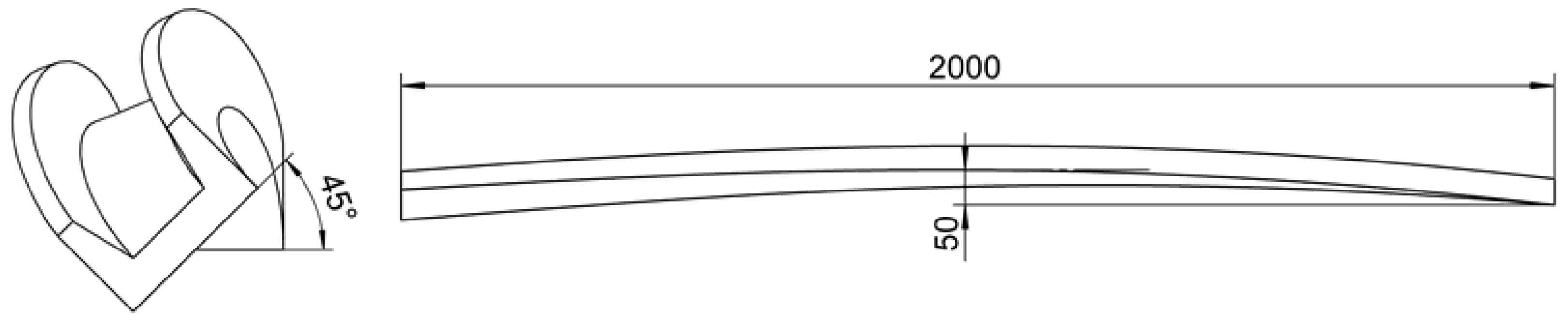

3.2. Geometric Model

3.3. Coupled Thermo-Mechanical Model

3.4. Orthogonal Experiment Scheme

4. Results and Discussion

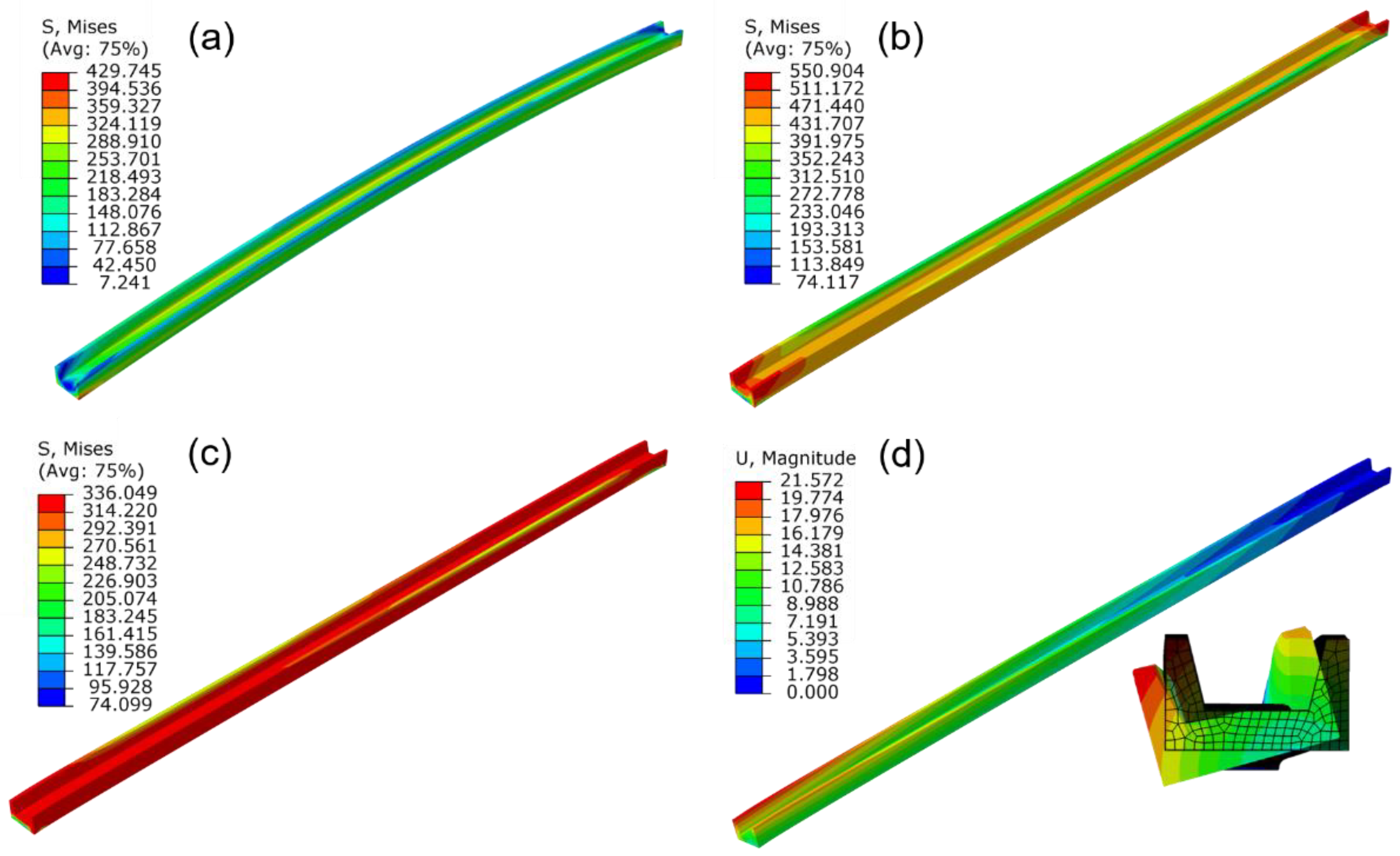

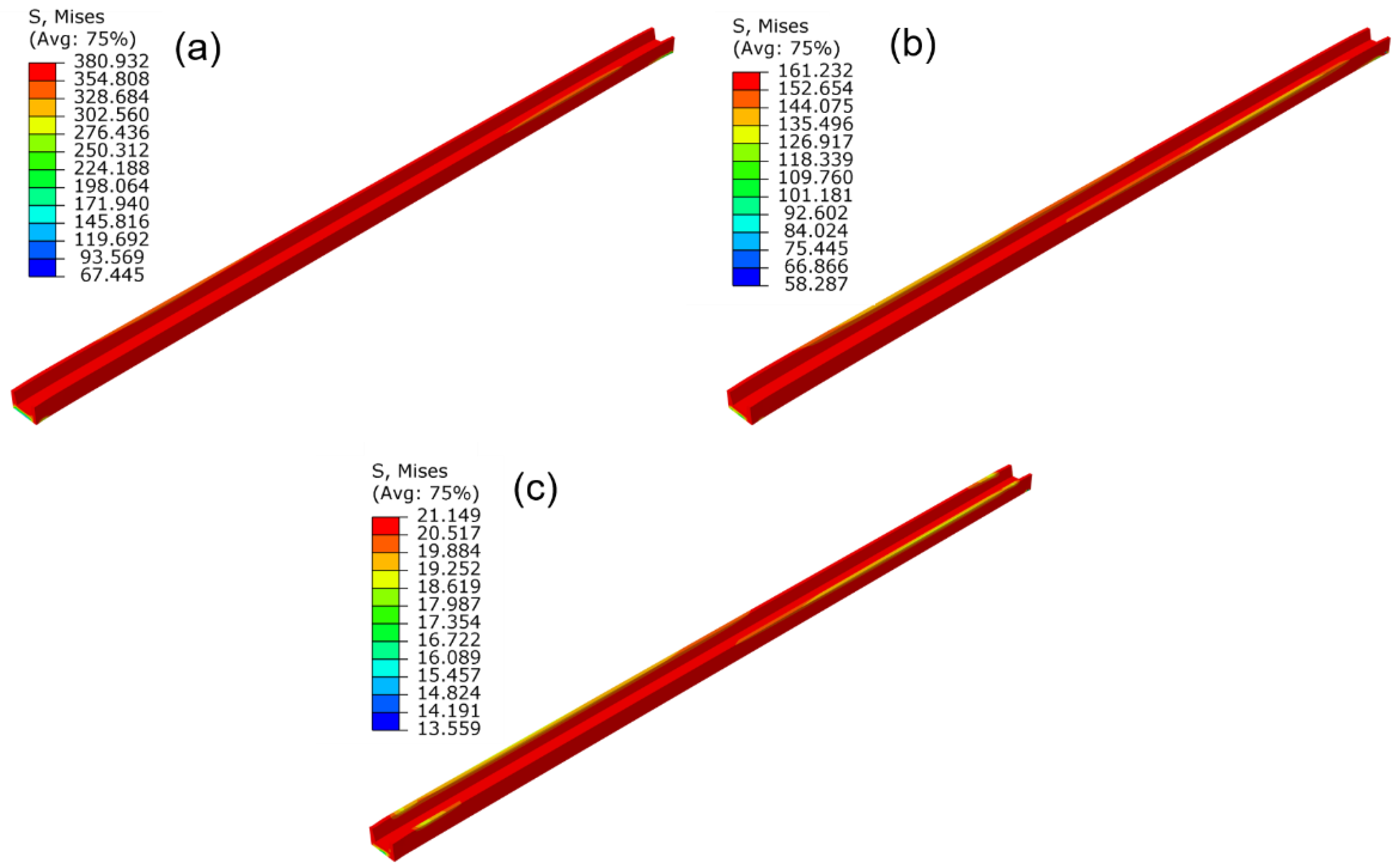

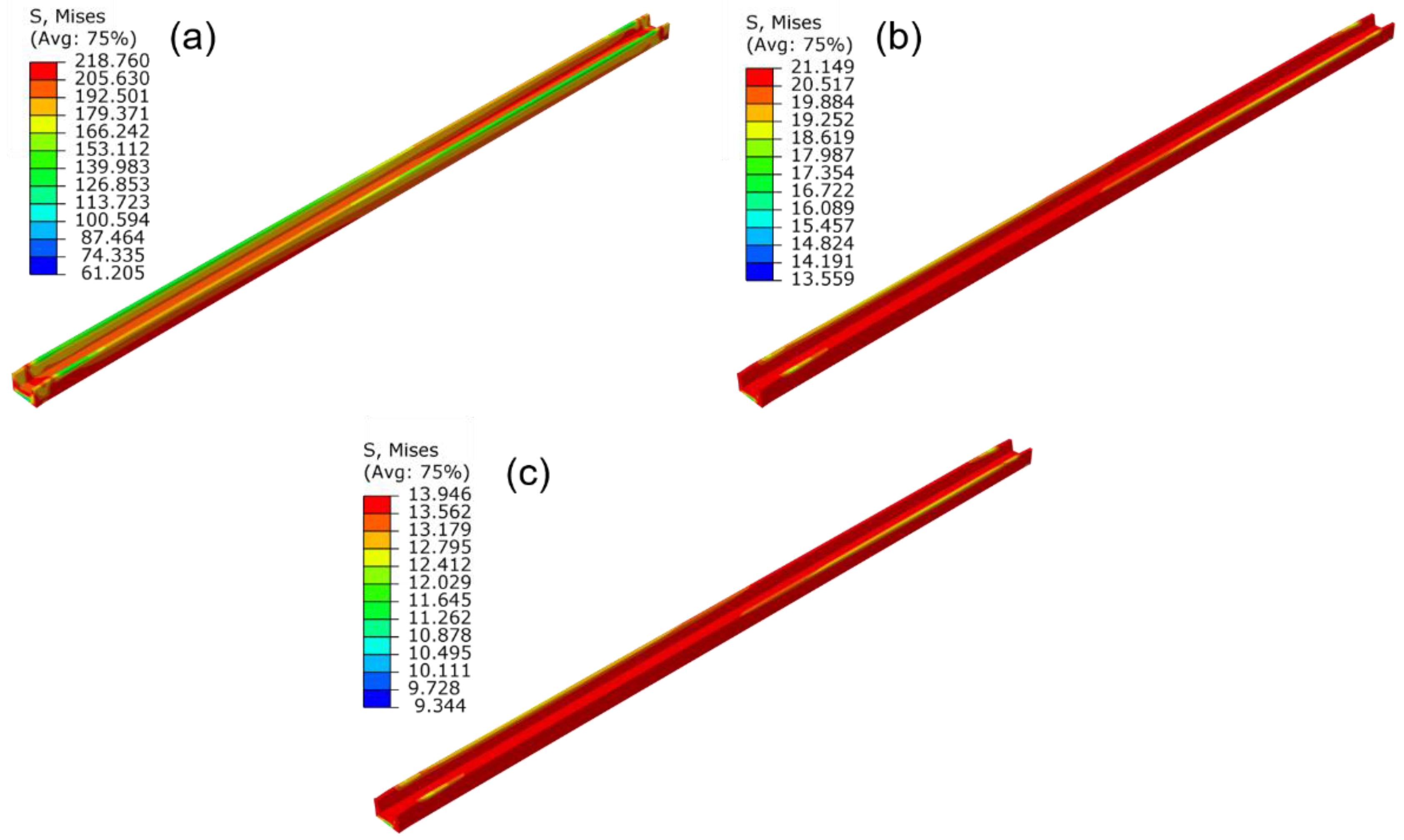

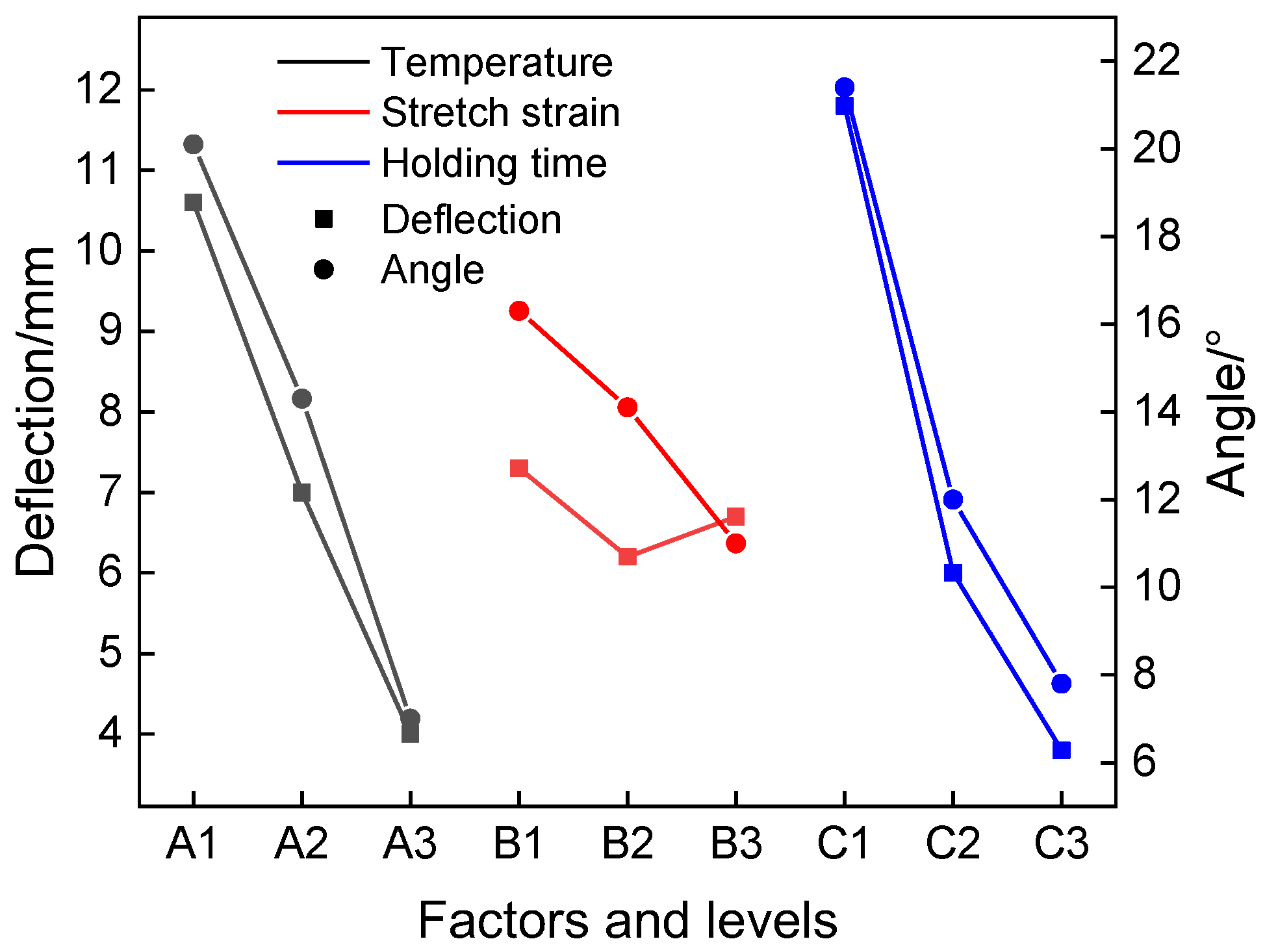

4.1. Discussion of Numerical Simulation Results

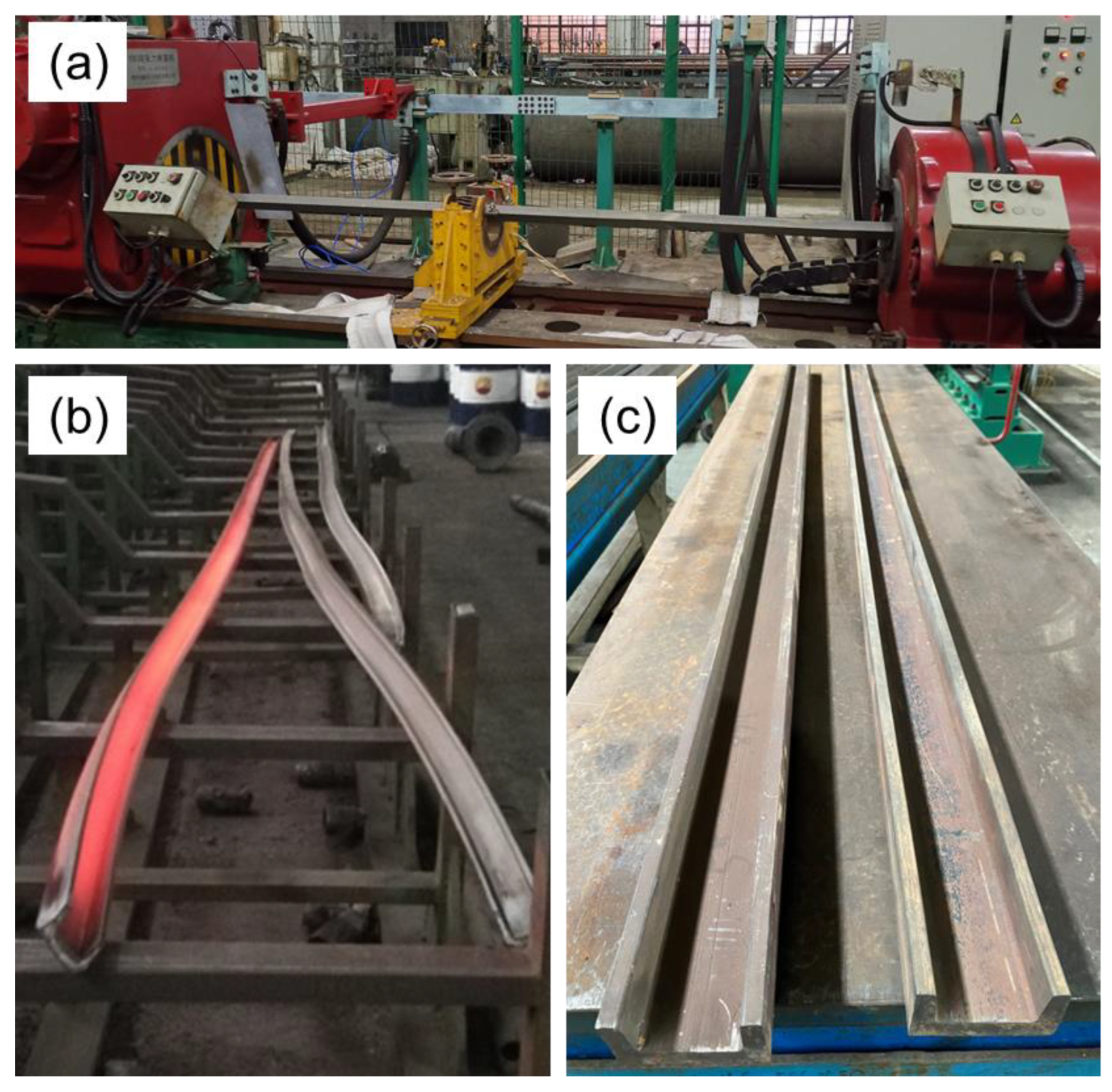

4.2. Experimental Verification

5. Conclusions

- The stress relaxation behavior is affected by temperature and time. The stress gradually decreases with the increases in time, and finally tends to the relaxation limit stress. The higher the temperature is, the lower the relaxation limit stress. Based on the stress relaxation curves, the Arrhenius creep constitutive model was established and verified, which could accurately describe the creep behavior of profile.

- The straightening temperature and holding time have significant influence on the straightening process of the profile while the effect of stretch strain was relatively small. The combination of a straightening temperature at 700 °C, a stretch strain of 1.5%, and a holding time of 600 s is the optimal process parameter. The deflection/length and angle/length of profile after straightening are 1.5‰ and 1.7‰°/mm, respectively.

- The verification experiments were carried out through straightening processes optimized by the orthogonal experiment. The experiment results are consistent with simulation results, which verified the accuracy of the established numerical simulation model.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Leyens, C.; Peters, M.; Chen, Z.H. Translated. Titanium and Titanium Alloys; Chemical Industry Press: Beijing, China, 2005; ISBN 9787502564087. [Google Scholar]

- Boyer, R.R. An overview on the use of titanium in the aerospace industry. Mater. Sci. Eng. A 1996, 1–2, 103–114. [Google Scholar] [CrossRef]

- Cai, H.J.; Ye, W.J.; Hui, S.X.; Liu, R. Effects of hot extrusion on the microstructure and properties of Ti-6Al-4V titanium alloy. J. Univ. Sci. Technol. B 2013, 7, 895–900. [Google Scholar] [CrossRef]

- Noor, A.K.; Venneri, S.L.; Paul, D.B.; Hopkins, M.A. Structures technology for future aerospace systems. Comput. Struct. 2000, 5, 507–519. [Google Scholar] [CrossRef]

- Deng, T.S.; Li, S.; Lu, J.; Liu, X.; Li, D.S.; Li, X.Q. Research status of precision extrusion technology for titanium alloy profile. Forg. Stamp. Technol. 2018, 43, 1–9. [Google Scholar] [CrossRef]

- Bergamini, R.; Mapelli, C.; Venturini, R. Hot extrusion experiments performed on Ti-6Al-4V for the production of special cross sections. Metal. Sci. Technol. 2013, 2, 18–25. [Google Scholar]

- Liu, Y.T. Extrusion of titanium alloy profile with special shape. Rare Metal Mater. Eng. 1995, 6, 75–80. [Google Scholar]

- Damodaran, D.; Shivpuri, R. Prediction and control of part distortion during the hot extrusion of titanium alloys. J. Mater. Process. Technol. 2004, 150, 70–75. [Google Scholar] [CrossRef]

- Dai, C.; Zhang, P.P.; Wang, J.Q.; Li, B.X.; Xie, L.J. Analysis of straightening process for extruded TC4 titanium alloy U profile. World Nonferrous Met. 2018, 10, 4–5. [Google Scholar]

- Haddag, B.; Yameogo, D.; Nouari, M.; Makich, H. Multi-Physics Analysis of Machining Ti-6Al-4V Alloy: Experimental Characterization and a New Material Behavior Modeling. Metals 2022, 12, 581. [Google Scholar] [CrossRef]

- Hourmand, M.; Sarhan, A.A.D.; Sayuti, M.; Hamdi, M. A Comprehensive Review on Machining of Titanium Alloys. Arab. J. Sci. Eng. 2021, 46, 7087–7123. [Google Scholar] [CrossRef]

- Xiao, J.J.; Li, D.S.; Li, X.Q.; Ding, P.; Zhao, K.; Huang, X.Z.; Xu, M.J. Process parameters optimization of Ti-6Al-4V alloy sheet during hot stretch-creep forming. Trans. Nonferr. Metal Soc. 2015, 25, 420–428. [Google Scholar] [CrossRef]

- Astarita, A.; Armentani, E.; Ceretti, E.; Giorleo, L.; Mastrilli, P.; Paradiso, V.; Scherillo, F.; Squillace, A.; Velotti, C. Hot stretch forming of a titanium alloy component for aeronautic: Mechanical and modeling. Key Eng. Mater. 2013, 554–557, 647–656. [Google Scholar] [CrossRef]

- Astarita, A.; Giorleo, L.; Scherillo, F.; Squillace, A.; Ceretti, E.; Carrino, L. Titanium hot stretch forming: Experimental and modeling residual stress analysis. Key Eng. Mater. 2014, 611–612, 149–161. [Google Scholar] [CrossRef]

- Deng, T.S.; Li, D.S.; Li, X.Q.; Ding, P.; Zhao, K. Hot stretch bending and creep forming of titanium alloy profile. Pro. Eng. 2014, 81, 1792–1798. [Google Scholar] [CrossRef] [Green Version]

- Deng, T.S.; Li, D.S.; Li, X.Q.; Ding, P.; Zhao, K. Material characterization, constitutive modeling and validation in hot stretch bending of Ti-6Al-4V profile. Proc. Inst. Mech. Eng. B-J. Eng. 2016, 3, 505–516. [Google Scholar] [CrossRef]

- Guo, G.Q.; Li, D.S.; Li, X.Q.; Deng, T.S.; Wang, S. Finite element simulation and process optimization for hot stretch bending of Ti-6Al-4V thin-walled extrusion. Int. J. Adv. Manuf. Technol. 2017, 92, 1707–1719. [Google Scholar] [CrossRef]

- Zhao, P.; Wu, W.; Fu, X.S.; Zeng, Y.S.; Chen, G.Q.; Zhou, W.L. Numerical simulation of high temperature bending creep of TC4 titanium alloy L profile. Rare Metal. Mat. Eng. 2022, 51, 211–216. [Google Scholar]

- Zhang, S.Y.; Wu, Y.X.; Gong, H. A modeling of residual stress in stretched aluminum alloy plate. J. Mater. Process. Technol. 2012, 212, 2463–2473. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, X.M. A critical review of experimental results and constitutive descriptions for metals and alloys in hot working. Mater. Des. 2011, 32, 1733–1759. [Google Scholar] [CrossRef]

- Kotkunde, N.; Deole, A.D.; Gupta, A.K.; Singh, S.K. Comparative study of constitutive modeling for Ti–6Al–4V alloy at low strain rates and elevated temperatures. Mater. Des. 2014, 55, 999–1005. [Google Scholar] [CrossRef]

- Tao, Z.J.; Fan, X.G.; Yang, H.; Ma, J.; Li, H. A modified Johnson-Cook model for NC warm bending of large diameter thin-walled Ti-6Al-4V tube in wide ranges of strain rates and temperatures. Trans. Nonferr Metal. Soc. 2018, 28, 298–308. [Google Scholar] [CrossRef]

- Safyari, M.; Moshtaghi, M.; Kuramoto, S. Effect of strain rate on environmental hydrogen embrittlement susceptibility of a severely cold-rolled Al-Cu alloy. Vacuum 2020, 172, 109057. [Google Scholar] [CrossRef]

- Liu, P.; Zong, Y.Y.; Shan, D.B.; Guo, B. Relationship between constant-load creep, decreasing-load creep and stress relaxation of titanium alloy. Mater. Sci. Eng. A 2015, 638, 106–113. [Google Scholar] [CrossRef]

- Ji, G.L.; Li, F.G.; Li, Q.H.; Li, H.Q.; Li, Z. A comparative study on Arrhenius-type constitutive model and artificial neural network model to predict high-temperature deformation behaviour in Aermet100 steel. Mater. Sci. Eng. A 2011, 528, 4774–4782. [Google Scholar] [CrossRef]

- Cai, J.; Li, F.G.; Liu, T.Y.; Chen, B.; He, M. Constitutive equations for elevated temperature flow stress of Ti-6Al-4V alloy considering the effect of strain. Mater. Des. 2011, 32, 1144–1151. [Google Scholar] [CrossRef]

- Han, X.N.; Yang, J.Z.; Li, J.S.; Wu, J.J. Constitutive Modeling on the Ti-6Al-4V Alloy during Air Cooling and Application. Metals 2022, 12, 513. [Google Scholar] [CrossRef]

| Al | V | Fe | C | H | O | N | Ti |

|---|---|---|---|---|---|---|---|

| 6.17 | 4.12 | 0.036 | 0.0044 | 0.0048 | 0.12 | 0.0073 | Balance |

| T/°C | A | α | n | Q (J/mol) |

|---|---|---|---|---|

| 500 | 4.05 × 10−4 | 0.0023 | 5.07 | 21,450 |

| 600 | 0.0046 | 3.02 | 19,255 | |

| 700 | 0.0155 | 1.26 | 21,998 |

| Factors | Symbol | 1 | 2 | 3 |

|---|---|---|---|---|

| Straightening temperature/°C | A | 500 | 600 | 700 |

| Stretch strain/% | B | 1 | 1.5 | 2 |

| Holding time/s | C | 0 | 600 | 1200 |

| No. | Temperature/°C (A) | Stretch Strain/% (B) | Holding Time/s (C) | Deflection/mm | Angle/° |

|---|---|---|---|---|---|

| 1 | 500 | 1 | 0 | 17.4 | 30.7 |

| 2 | 500 | 1.5 | 600 | 8.7 | 17.9 |

| 3 | 500 | 2 | 1200 | 5.8 | 11.6 |

| 4 | 600 | 1 | 600 | 6.4 | 15.5 |

| 5 | 600 | 1.5 | 1200 | 3.2 | 9.2 |

| 6 | 600 | 2 | 0 | 11.3 | 18.3 |

| 7 | 700 | 1 | 1200 | 2.4 | 2.7 |

| 8 | 700 | 1.5 | 0 | 6.8 | 15.2 |

| 9 | 700 | 2 | 600 | 2.9 | 3.1 |

| X1 | 10.6/20.1 | 7.3/16.3 | 11.8/21.4 | The average value of deflection and angle corresponding to each parameter (deflection mm/angle°) | |

| X2 | 7.0/14.3 | 6.2/14.1 | 6.0/12.1 | ||

| X3 | 4.0/7.0 | 6.7/11.0 | 3.8/7.8 | ||

| R | 6.6/13.1 | 1.1/5.3 | 8.0/13.6 | The variation range of deflection and angle corresponding to each parameter (deflection mm/angle°) | |

| No. | Length/mm | Before Straightening | After Straightening | ||

|---|---|---|---|---|---|

| Deflection/mm | Angle/° | Deflection/mm | Angle/° | ||

| 1 | 2350 | 12 | 35 | 2 | 3 |

| 2 | 2760 | 38 | 42 | 3 | 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, X.; Hui, S.; Ye, W.; Liu, R.; Huang, L. Numerical Simulation and Process Optimization on Hot Twist-Stretch Straightening of Ti-6Al-4V Alloy Profile. Materials 2022, 15, 4522. https://doi.org/10.3390/ma15134522

Deng X, Hui S, Ye W, Liu R, Huang L. Numerical Simulation and Process Optimization on Hot Twist-Stretch Straightening of Ti-6Al-4V Alloy Profile. Materials. 2022; 15(13):4522. https://doi.org/10.3390/ma15134522

Chicago/Turabian StyleDeng, Xuwen, Songxiao Hui, Wenjun Ye, Rui Liu, and Liang Huang. 2022. "Numerical Simulation and Process Optimization on Hot Twist-Stretch Straightening of Ti-6Al-4V Alloy Profile" Materials 15, no. 13: 4522. https://doi.org/10.3390/ma15134522

APA StyleDeng, X., Hui, S., Ye, W., Liu, R., & Huang, L. (2022). Numerical Simulation and Process Optimization on Hot Twist-Stretch Straightening of Ti-6Al-4V Alloy Profile. Materials, 15(13), 4522. https://doi.org/10.3390/ma15134522