A Comparative Study to Evaluate the Essential Work of Fracture to Measure the Fracture Toughness of Quasi-Brittle Material

Abstract

1. Introduction

2. Analytical Model (Essential Work of Fracture)

3. Methods and Material

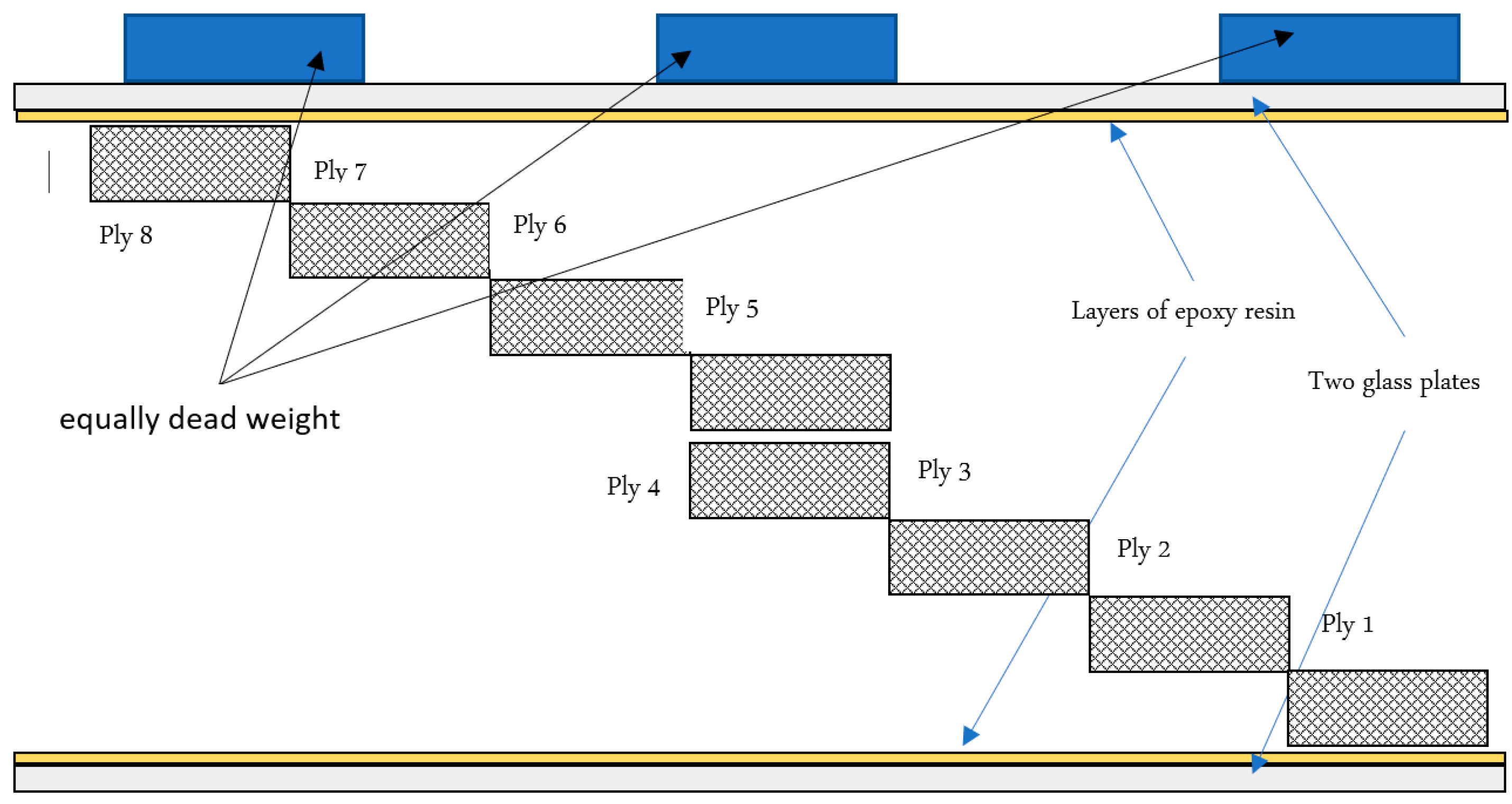

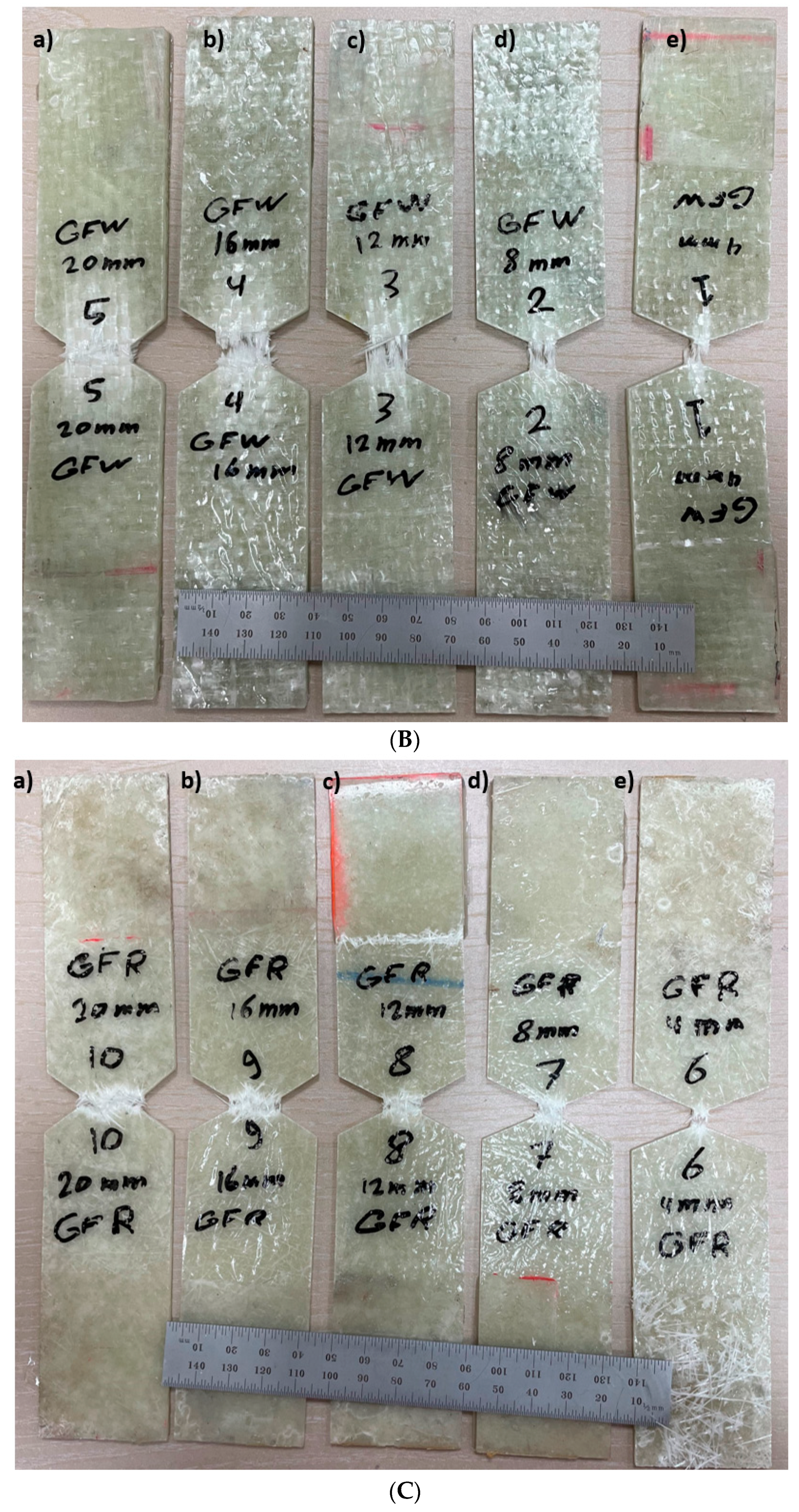

3.1. Material and Manufacturing

3.2. Un-Notch Tensile Test

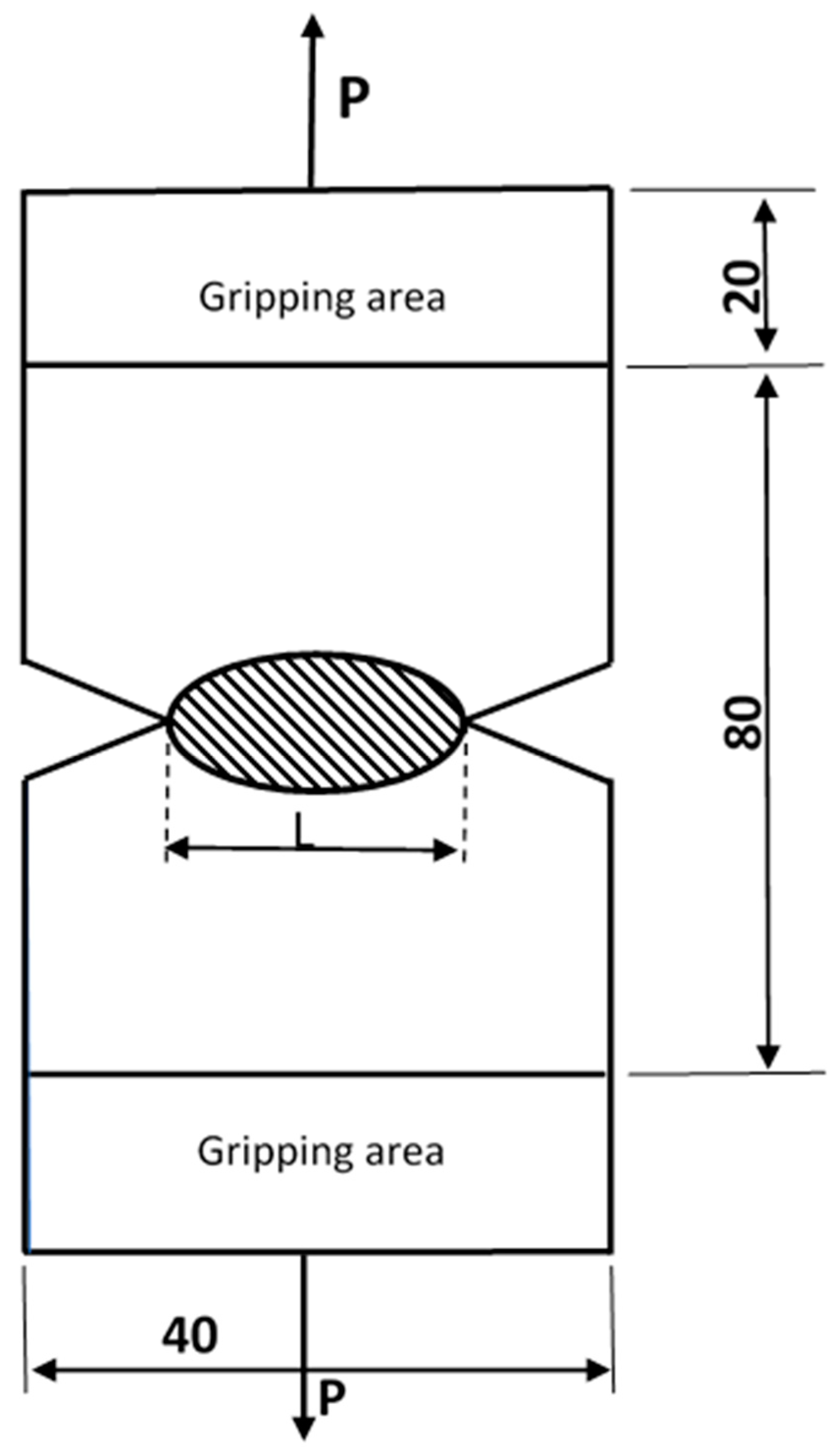

3.3. Centre Notch Test

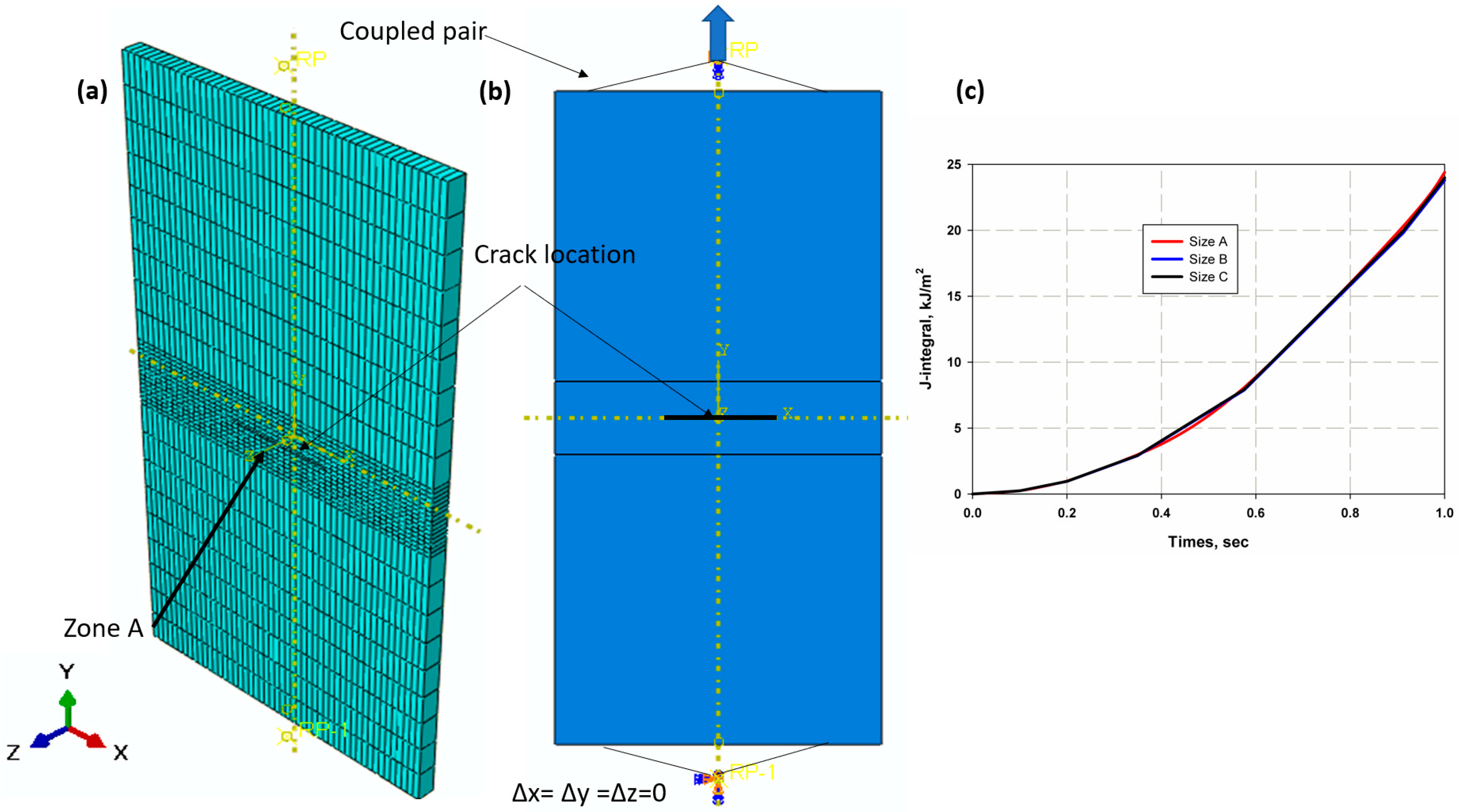

3.4. Extended Finite Element Method XFEM

XFEM Extraction

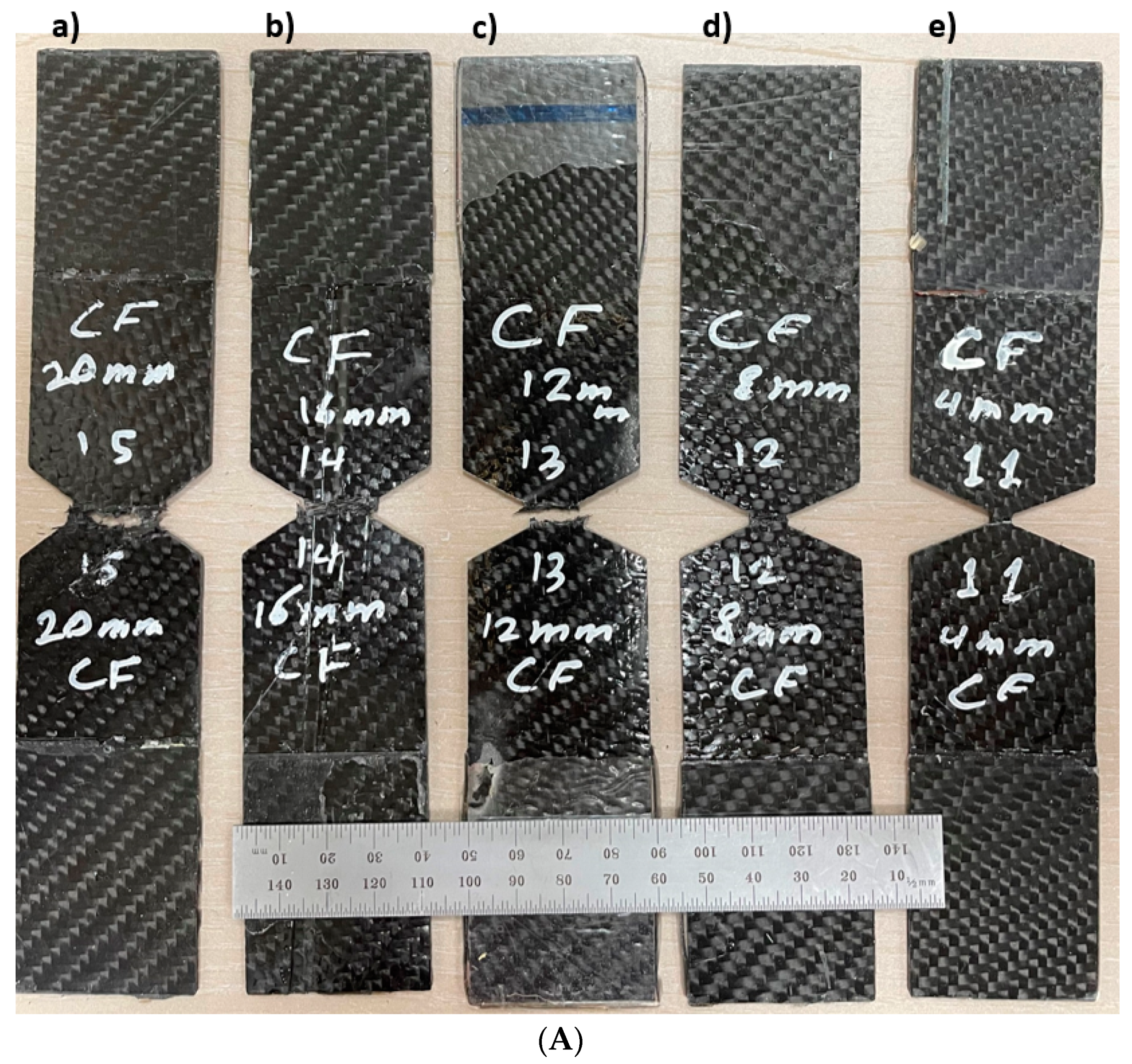

3.5. Essential Work of Fracture Test

4. Results and Discussion

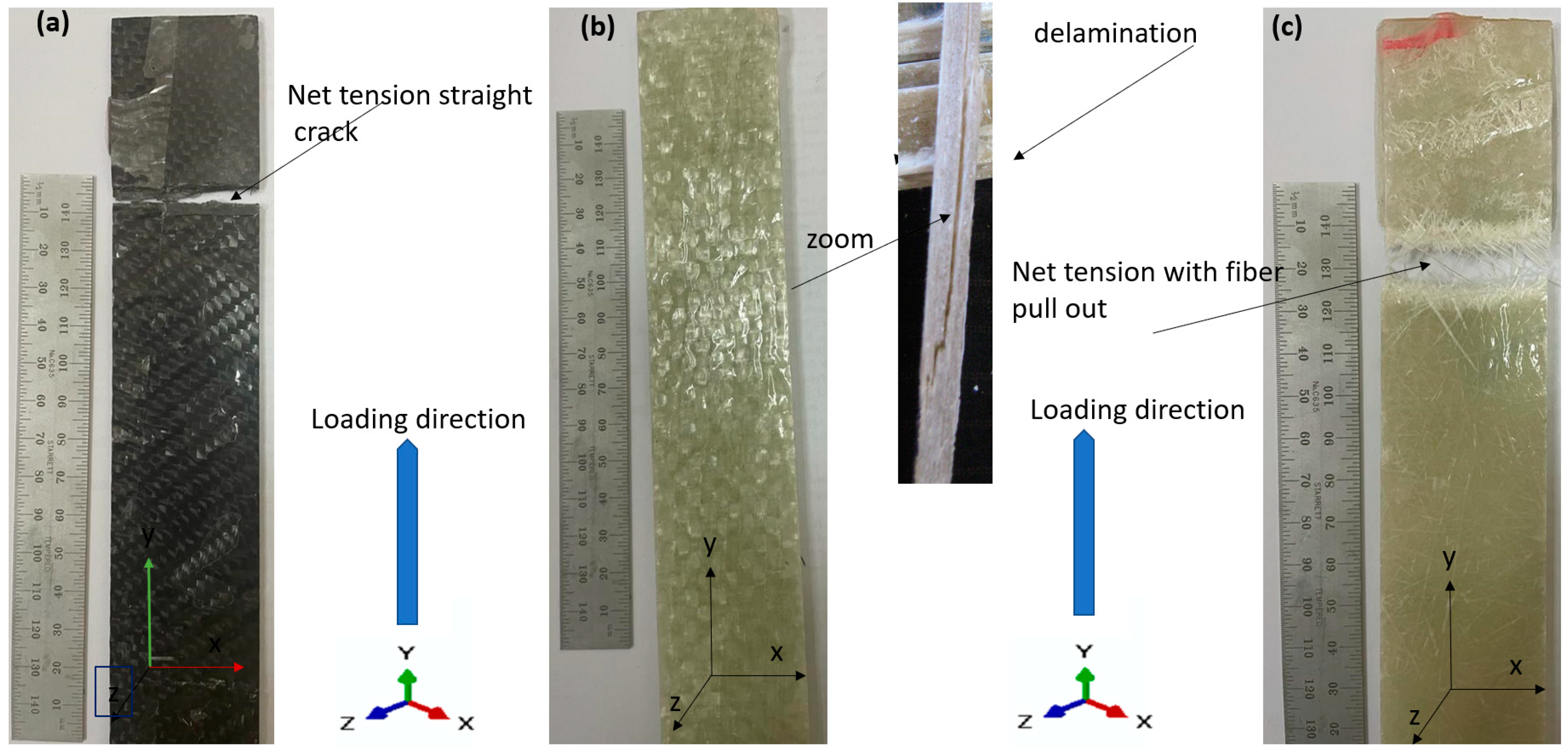

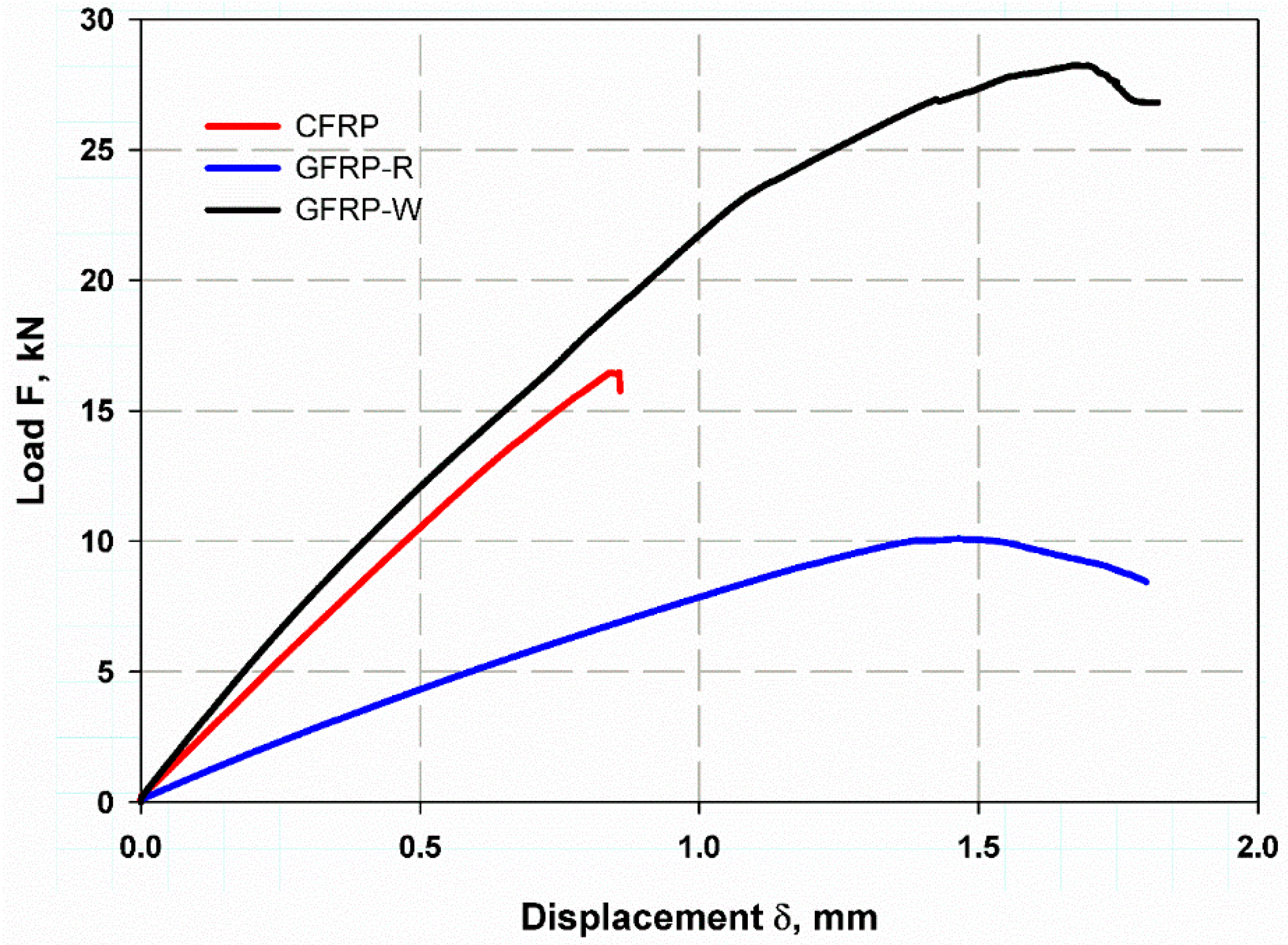

4.1. Centre Notch

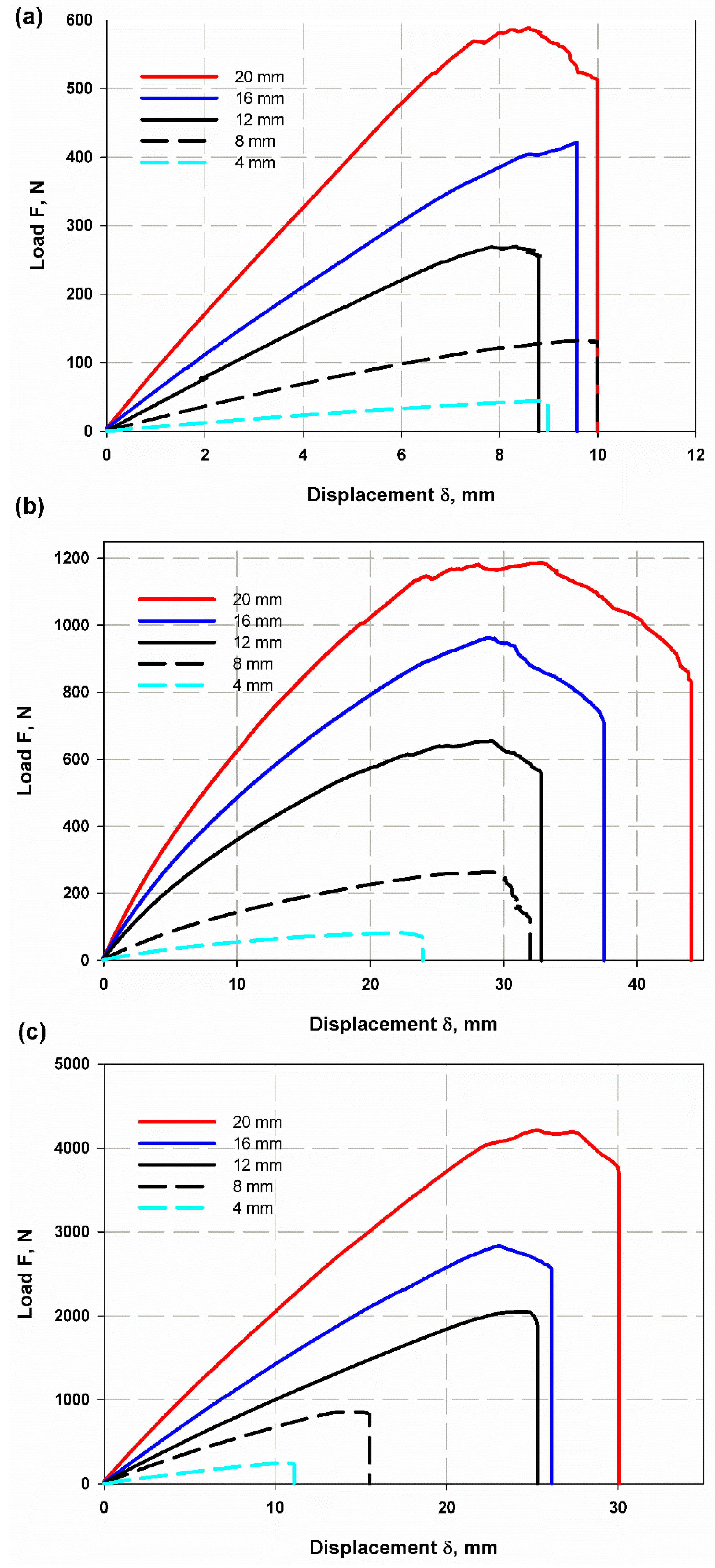

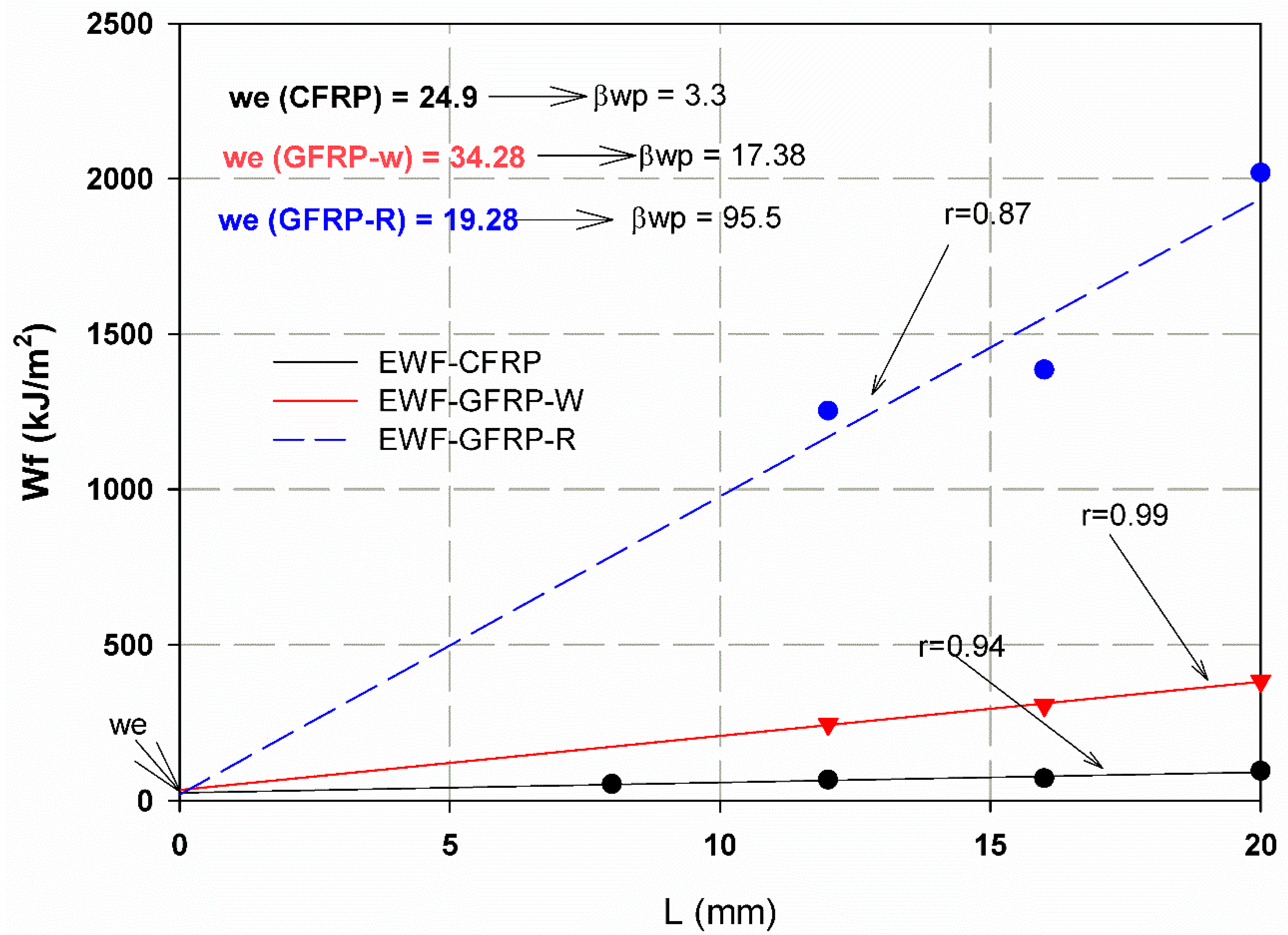

4.2. Essential Work of Fracture Approach

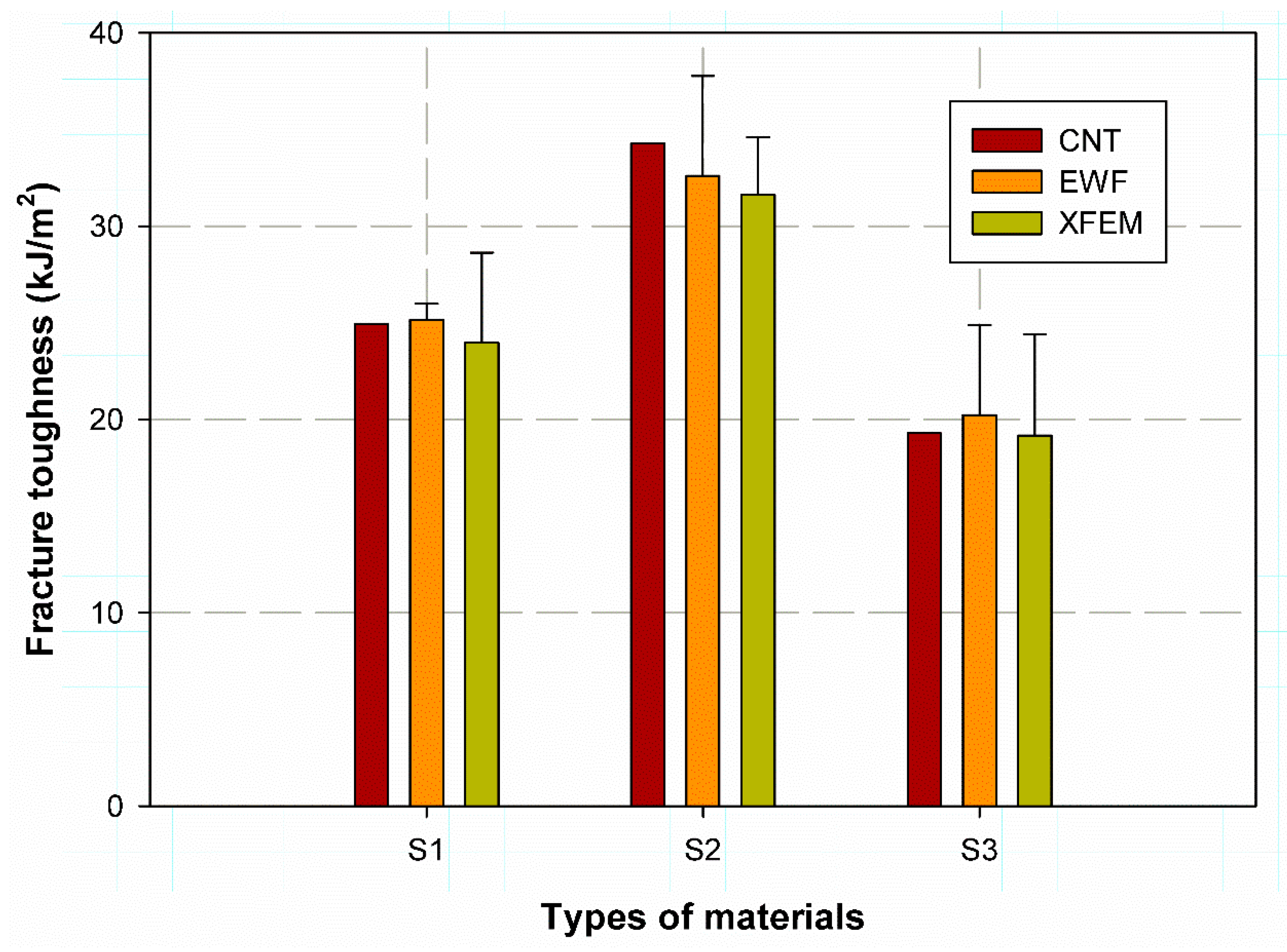

4.3. Comparison between Methods

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Displacement at failure | |

| Geometric shape factors related to the plastic zone during ligament yielding | |

| Geometric shape factors related to the plastic zone during tearing after necking | |

| Slope of linear fitting regression | |

| Plasticity shape factor | |

| Thickness of the specimen | |

| Applied load | |

| Displacement increment | |

| Ligament length | |

| a0 | Pre-crack length |

| Un-notched tensile strength | |

| 0.2% offset displacement | |

| Essential work of the fracture in the elastic zone | |

| Non-essential work of the fracture | |

| Essential work of the fracture | |

| Elastic energy of the elastic and yielding ligament length | |

| Relative energy in plastic and yielding of ligament length | |

| Relative plastic energy in tearing and necking | |

| Energy of the tearing and necking of the plastic zone | |

| Total strain energy attributed to the fracture | |

| Initiation J-integral in EPFM | |

| Finite element J-integral | |

| Critical J-integral or release energy in elastic plastic fracture mechanics (EPFM) | |

| Initiation surface release energy in LEFM or crack initiation resistance | |

| Surface release energy or critical mode I fracture toughness |

Appendix A

| **PARTS *Preprint, echo=NO, model=NO, history=NO, contact=NO **PARTS *Part, name = Part-1 *Element, type=C3D8R * *Nset, nset=Part-1-RefPt_, internal *Nset, nset=Set-1 *Surface, type=ELEMENT, name=Surf-1 *Surface, type=ELEMENT, name=Surf-2 ** Section: Section-1 *Solid Section, elset=_PickedSet15, material=Material-1 *End Part *Part, name=crack *End Part ** ASSEMBLY *Assembly, name=Assembly *Instance, name = Part-1-1, part= Part-1 *End Instance *Instance, name = Part-2-1, part= Part-2 *End Instance ** Constraint: Constraint-1 *Coupling, constraint name=Constraint-1, ref node=_PickedSet12, surface= Part-1 *Kinematic -1.Surf-1 ** Constraint: Constraint-2 *Coupling, constraint name=Constraint-2, ref node=_PickedSet16, surface= Part-1-1.Surf-2 *Kinematic *Enrichment, name=Crack-1, type=STATIONARY CRACK, elset=_PickedSet19 *End Assembly ** MATERIALS *Material, name=Material-1 *Damage Initiation, criterion=MAXPS 303., *Damage Evolution, type=DISPLACEMENT 0.01, *Density 1.5e-09, *Elastic 27130., 0.3 Part-1-1.443, 3,Crack-1, -0.335333 Part-1-1.443, 4,Crack-1, -0.335333 Part-1-1.443, 5,Crack-1, 0.335333 Part-1-1.443, 6,Crack-1, 0.335333 Part-1-1.443, 7,Crack-1, -0.335333 Part-1-1.443, 8,Crack-1, -0.335333 Part-1-1.458, 1,Crack-1, 0.335333 Part-1-1.458, 2,Crack-1, 0.335333 Part-1-1.458, 3,Crack-1, -0.335333 Part-1-1.458, 4,Crack-1, -0.335333 Part-1-1.458, 5,Crack-1, 0.335333 Part-1-1.458, 6,Crack-1, 0.335333 Part-1-1.458, 7,Crack-1, -0.335333 Part-1-1.458, 8,Crack-1, -0.335333 Part-1-1.473, 1,Crack-1, 0.335333 Part-1-1.473, 2,Crack-1, 0.335333 Part-1-1.473, 3,Crack-1, -0.335333 Part-1-1.473, 4,Crack-1, -0.335333 Part-1-1.473, 5,Crack-1, 0.335333 Part-1-1.473, 6,Crack-1, 0.335333 Part-1-1.473, 7,Crack-1, -0.335333 Part-1-1.473, 8,Crack-1, -0.335333 Part-1-1.488, 1,Crack-1, 0.335333 Part-1-1.488, 2,Crack-1, 0.335333 Part-1-1.488, 3,Crack-1, -0.335333 Part-1-1.488, 4,Crack-1, -0.335333 ** BOUNDARY CONDITIONS ** Name: BC-1 Type: Symmetry/Antisymmetry/Encastre *Boundary _PickedSet22, ENCASTRE ** ---------------------------------------------------------------- ** STEP: Step-1 *Step, name=Step-1, inc=100000 *Static 1., 1., 1e-10, 1. ** BOUNDARY CONDITIONS ** Name: BC-2 Type: Displacement/Rotation *Boundary _PickedSet23, 1, 1 _PickedSet23, 3, 3 _PickedSet23, 5, 5 _PickedSet23, 6, 6 ** LOADS ** ** Name: Load-1 Type: Concentrated force *Cload _PickedSet20, 2, 16500. ** CONTROLS *Controls, reset *Controls, parameters=time incrementation , , 20, 20, 20, 20, 20, 20, , , ** OUTPUT REQUESTS *Restart, write, frequency=0 ** FIELD OUTPUT: F-Output-1 *Output, field *Node Output CF, PHILSM, PSILSM, RF, U *Element Output, directions=YES LE, PE, PEEQ, PEMAG, S, STATUSXFEM *Contact Output CDISP, CSTRESS *Output, history, frequency=0 ** HISTORY OUTPUT: H-Output-1 *Contour Integral, crack name=Crack-1, contours=5, xfem *End Step |

References

- Hassan, M.K.; Mohammed, Y.; Salem, T.; Hashem, A.M. Prediction of nominal strength of composite structure open hole specimen through cohesive laws. Int. J. Mech. Mechatron. Eng. 2012, 12, 1–9. [Google Scholar]

- Bažant, Z.P.; Planas, J. Fracture and Size Effect in Concrete and Other Quasibrittle Materials; Routledge: New York, NY, USA, 2019. [Google Scholar]

- Yu, C.; Lu, T. A damage-driven integration scheme in physically non-linear transient analysis for quasi-brittle materials. Eng. Fract. Mech. 2022, 269, 108531. [Google Scholar] [CrossRef]

- Abdellah, M.Y. An approximate analytical model for modification of size effect law for open-hole composite structure under biaxial load. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2020, 235, 3570–3583. [Google Scholar] [CrossRef]

- Maio, L.; Fromme, P. On ultrasound propagation in composite laminates: Advances in numerical simulation. Prog. Aerosp. Sci. 2022, 129, 100791. [Google Scholar] [CrossRef]

- Kalita, K.; Haldar, S.; Chakraborty, S. A Comprehensive Review on High-Fidelity and Metamodel-Based Optimization of Composite Laminates. Arch. Comput. Methods Eng. 2022, 29, 1–36. [Google Scholar] [CrossRef]

- Sateesh, N.; Subbiah, R.; Nookaraju, B.; Nagaraju, D.S. Achieving safety and weight reduction in automobiles with the application of composite material. Mater. Today Proc. 2022, 62, 4469–4472. [Google Scholar] [CrossRef]

- Anderson, T.L. Fracture Mechanics: Fundamentals and Applications; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Catalanotti, G.; Camanho, P.; Xavier, J.; Dávila, C.; Marques, A. Measurement of resistance curves in the longitudinal failure of composites using digital image correlation. Compos. Sci. Technol. 2010, 70, 1986–1993. [Google Scholar] [CrossRef]

- Dávila, C.G.; Rose, C.A.; Camanho, P. A procedure for superposing linear cohesive laws to represent multiple damage mechanisms in the fracture of composites. Int. J. Fract. 2009, 158, 211–223. [Google Scholar] [CrossRef]

- Soutis, C.; Curtis, P.; Fleck, N. Compressive failure of notched carbon fibre composites. Proc. R. Soc. Ser. A Math. Phys. Sci. 1993, 440, 241–256. [Google Scholar]

- Williams, J.; Rink, M. The standardisation of the EWF test. Eng. Fract. Mech. 2007, 74, 1009–1017. [Google Scholar] [CrossRef]

- Cotterell, B.; Reddel, J.K. The essential work of plane stress ductile fracture. Int. J. Fract. 1977, 13, 267–277. [Google Scholar] [CrossRef]

- Cotterell, B.; Atkins, A.G. A review of the J and I integrals and their implications for crack growth resistance and toughness in ductile fracture. Int. J. Fract. 1996, 81, 357–372. [Google Scholar] [CrossRef]

- Rice, J.R. A Path Independent Integral and the Approximate Analysis of Strain Concentration by Notches and Cracks. J. Appl. Mech. 1968, 35, 379–386. [Google Scholar] [CrossRef]

- Mai, Y.-W.; Powell, P. Essential work of fracture and j-integral measurements for ductile polymers. J. Polym. Sci. Part B Polym. Phys. 1991, 29, 785–793. [Google Scholar] [CrossRef]

- Gobbi, G.; Colombo, C.; Vergani, L. Sensitivity analysis of a 2D cohesive model for hydrogen embrittlement of AISI 4130. Eng. Fract. Mech. 2016, 167, 101–111. [Google Scholar] [CrossRef]

- Barany, T.; Czigány, T.; Karger-Kocsis, J. Application of the essential work of fracture (EWF) concept for polymers, related blends and composites: A review. Prog. Polym. Sci. 2010, 35, 1257–1287. [Google Scholar] [CrossRef]

- Heidari, F.; Aghalari, M.; Tehran, A.C.; Shelesh-Nezhad, K. Study on the fluidity, mechanical and fracture behavior of ABS/TPU/CNT nanocomposites. J. Thermoplast. Compos. Mater. 2021, 34, 1037–1051. [Google Scholar] [CrossRef]

- Clutton, E. Essential Work of Fracture, in European Structural Integrity Society; Elsevier: Berkeley, CA, USA, 2001; pp. 177–195. [Google Scholar]

- Martinez, A.; Gamez-Perez, J.; Sanchez-Soto, M.; Velasco, J.; Santana, O.; Maspoch, M.L. The Essential Work of Fracture (EWF) method—Analyzing the Post-Yielding Fracture Mechanics of polymers. Eng. Fail. Anal. 2009, 16, 2604–2617. [Google Scholar] [CrossRef]

- Pegoretti, A.; Castellani, L.; Franchini, L.; Mariani, P.; Penati, A. On the essential work of fracture of linear low-density-polyethylene. I. Precision of the testing method. Eng. Fract. Mech. 2009, 76, 2788–2798. [Google Scholar] [CrossRef]

- Pardoen, T.; Marchal, Y.; Delannay, F. Thickness dependence of cracking resistance in thin aluminium plates. J. Mech. Phys. Solids 1999, 47, 2093–2123. [Google Scholar] [CrossRef]

- Pardoen, T. A method for determining the CTOD at cracking initiation-application to the characterization of the fracture toughness of copper. In Proceedings of the ECF13, San Sebastian 2000, San Sebastian, Spain, 6–9 September 2013. [Google Scholar]

- Marchal, Y.; Walhin, J.-F.; Delannay, F. Statistical procedure for improving the precision of the measurement of the essential work of fracture of thin sheets. Int. J. Fract. 1997, 87, 189–199. [Google Scholar] [CrossRef]

- Mouzakis, D.E.; Stricker, F.; Mulhaupt, R.; Karger-Kocsis, J. Fracture behaviour of polypropylene/glass bead elastomer composites by using the essential work-of-fracture method. J. Mater. Sci. 1998, 33, 2551–2562. [Google Scholar] [CrossRef]

- Elmeguenni, M.; Naït-Abdelaziz, M.; Zaïri, F.; Gloaguen, J.M. Fracture characterization of high-density polyethylene pipe materials using the $$J$$ J -integral and the essential work of fracture. Int. J. Fract. 2013, 183, 119–133. [Google Scholar] [CrossRef]

- Ching, E.C.Y.; Poon, W.K.Y.; Li, R.; Mai, Y.-W. Effect of strain rate on the fracture toughness of some ductile polymers using the essential work of fracture (EWF) approach. Polym. Eng. Sci. 2000, 40, 2558–2568. [Google Scholar] [CrossRef]

- Tehran, A.C.; Heidari, F.; Chakherlou, T.N.; Najjar, R. Fracture toughness and fractographic investigation of polybutylene terephthalate/thermoplastic polyurethane binary blends reinforced by multi-walled carbon nanotubes using essential work of fracture approach. J. Compos. Mater. 2022, 56, 743–759. [Google Scholar] [CrossRef]

- Karger-Kocsis, J.; Khumalo, V.; Bárány, T.; Meszaros, L.; Pegoretti, A. On the toughness of thermoplastic polymer nanocomposites as assessed by the essential work of fracture (EWF) approach. Compos. Interfaces 2013, 20, 395–404. [Google Scholar] [CrossRef]

- Yang, J.-L.; Zhang, Z.; Zhang, H. The essential work of fracture of polyamide 66 filled with TiO2 nanoparticles. Compos. Sci. Technol. 2005, 65, 2374–2379. [Google Scholar] [CrossRef]

- Hassan, M.K.; Abdellah, M.Y.; ElAbiadi, T.S.; Mohamed, A.F.; Azam, S.; Marzouk, W. Essential Work of Fracture and Size Effect in Copper/Glass-Reinforced Epoxy Laminate Composites Used as MEMS Devices. Am. J. Mech. Eng. 2017, 5, 234–238. [Google Scholar] [CrossRef][Green Version]

- Abdellah, M.Y. Essential work of fracture assessment for thin aluminium strips using finite element analysis. Eng. Fract. Mech. 2017, 179, 190–202. [Google Scholar] [CrossRef]

- Chandra, N. Evaluation of interfacial fracture toughness using cohesive zone model. Compos. Part A Appl. Sci. Manuf. 2002, 33, 1433–1447. [Google Scholar] [CrossRef]

- Xia, Z.; Curtin, W.; Sheldon, B. A new method to evaluate the fracture toughness of thin films. Acta Mater. 2004, 52, 3507–3517. [Google Scholar] [CrossRef]

- Lee, S.; Ji, W. Measurement of pure mode I fracture toughness at a sandwich interface and parametrization of the R-curve for a cohesive element. Compos. Struct. 2022, 291, 115599. [Google Scholar] [CrossRef]

- Huang, Y.; Zolfaghari, N.; Bunger, A.P. Cohesive element simulations capture size and confining stress dependence of rock fracture toughness obtained from burst experiments. J. Mech. Phys. Solids 2022, 160, 104799. [Google Scholar] [CrossRef]

- Lee, J.; Gao, Y.; Johanns, K.; Pharr, G. Cohesive interface simulations of indentation cracking as a fracture toughness measurement method for brittle materials. Acta Mater. 2012, 60, 5448–5467. [Google Scholar] [CrossRef]

- Abdellah, M.Y. Delamination Modeling of Double Cantilever Beam of Unidirectional Composite Laminates. J. Fail. Anal. Prev. 2017, 17, 1011–1018. [Google Scholar] [CrossRef]

- Shao, Y.; Duan, Q.; Qiu, S. Consistent element-free Galerkin method for three-dimensional crack propagation based on a phase-field model. Comput. Mater. Sci. 2020, 179, 109694. [Google Scholar] [CrossRef]

- Kabir, H.; Aghdam, M.M. A generalized 2D Bézier-based solution for stress analysis of notched epoxy resin plates reinforced with graphene nanoplatelets. Thin-Walled Struct. 2021, 169, 108484. [Google Scholar] [CrossRef]

- Mai, Y.-W.; Cotterell, B. On the essential work of ductile fracture in polymers. Int. J. Fract. 1986, 32, 105–125. [Google Scholar] [CrossRef]

- Broberg, K. On stable crack growth. J. Mech. Phys. Solids 1975, 23, 215–237. [Google Scholar] [CrossRef]

- Kuno, T. Deformation mechanism under essential work of fracture process in polycyclo-olefin materials. Express Polym. Lett. 2008, 2, 404–412. [Google Scholar] [CrossRef]

- Wu, J.; Mai, Y.-W. The essential fracture work concept for toughness measurement of ductile polymers. Polym. Eng. Sci. 1996, 36, 2275–2288. [Google Scholar] [CrossRef]

- Ward, I.M.; Hadley, D.W. An Introduction to the Mechanical Properties of Solid Polymers; John Wiley & Sons, Inc.: San Francisco, CA, USA, 1993. [Google Scholar]

- Jones, R.M. Mechanics of Composite Materials; CRC Press: Boca Raton, FL, USA, 1998. [Google Scholar]

- Mallick, P.K. Composites Engineering Handbook; CRC Press: Boca Raton, FL, USA, 1997. [Google Scholar]

- Khashaba, U.A. In-plane shear properties of cross-ply composite laminates with different off-axis angles. Compos. Struct. 2004, 65, 167–177. [Google Scholar] [CrossRef]

- Mohammed, Y.; Hassan, M.K.; El-Ainin, H.A.; Hashem, A. Effect of stacking sequence and geometric scaling on the brittleness number of glass fiber composite laminate with stress raiser. Sci. Eng. Compos. Mater. 2014, 21, 281–288. [Google Scholar] [CrossRef]

- Khashaba, U.; Aldousari, S.; Najjar, I. Behavior of [0]8 woven composites under combined bending and tension loading: Part I experimental and analytical. J. Compos. Mater. 2012, 46, 1345–1355. [Google Scholar] [CrossRef]

- Petrie, E.M. Epoxy Adhesive Formulations; McGraw Hill Professional: New York, NY, USA, 2005. [Google Scholar]

- ASTM D3171; Standard Test Methods for Constituent Content of Composite Materials. ASTM: West Conshohocken, PA, USA, 2011.

- Hagnestål, A.; Sellgren, U.; Andersson, K. Durable winch-based point absorbers. In Proceedings of the Ewtec 2017: The 12th European Wave and Tidal Energy Conference, Cork, Ireland, 27 August–1 September 2017. [Google Scholar]

- Shukla, M.J.; Kumar, D.S.; Mahato, K.K.; Rathore, D.; Prusty, R.K.; Ray, B.C. A comparative study of the mechanical performance of Glass and Glass/Carbon hybrid polymer composites at different temperature environments. IOP Conf. Ser. Mater. Sci. Eng. 2015, 75, 012002. [Google Scholar] [CrossRef]

- MInus, M.; Kumar, S. The processing, properties, and structure of carbon fibers. JOM 2005, 57, 52–58. [Google Scholar] [CrossRef]

- ASTM D3039/D 3039M; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM: West Conshohocken, PA, USA, 1995.

- Available online: https://www.zwickroell.com/products/static-materials-testing-machines/universal-testing-machines-for-static-applications/materials-testing-machine-with-hydraulic-drive/ (accessed on 15 May 2022).

- Newman, J., Jr.; Haines, M.J. Verification of stress-intensity factors for various middle-crack tension test specimens. Eng. Fract. Mech. 2005, 72, 1113–1118. [Google Scholar] [CrossRef]

- Belytschko, T.; Black, T. Elastic crack growth in finite elements with minimal remeshing. Int. J. Numer. Methods Eng. 1999, 45, 601–620. [Google Scholar] [CrossRef]

- Melenk, J.; Babuška, I. The partition of unity finite element method: Basic theory and applications. Comput. Methods Appl. Mech. Eng. 1996, 139, 289–314. [Google Scholar] [CrossRef]

- Datta, D. Introduction to extended finite element (XFEM) method. arXiv 2013, arXiv:1308.5208. [Google Scholar]

- Abdellah, M.Y.; Alsoufi, M.S.; Hassan, M.K.; Ghulman, H.A.; Mohamed, A.F. Extended Finite Element Numerical Analysis of Scale Effect in Notched Glass Fiber Reinforced Epoxy Composite. Arch. Mech. Eng. 2015, 62, 217–236. [Google Scholar] [CrossRef]

- Li, X.; Hallett, S.R.; Wisnom, M.R.; Zobeiry, N.; Vaziri, R.; Poursartip, A. Experimental study of damage propagation in Over-height Compact Tension tests. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1891–1899. [Google Scholar] [CrossRef]

- Yang, D.; Karimi, H.; Aliha, M. Comparison of Testing Method Effects on Cracking Resistance of Asphalt Concrete Mixtures. Appl. Sci. 2021, 11, 5094. [Google Scholar] [CrossRef]

- Hahn, G.; Rosenfield, A. Local yielding and extension of a crack under plane stress. Acta Met. 1965, 13, 293–306. [Google Scholar] [CrossRef]

- Perez, N. Crack Tip Plasticity. In Fracture Mechanics; Springer: Dordrecht, The Netherlands, 2017; pp. 187–225. [Google Scholar]

- Abdellah, M.Y. Comparative study on prediction of fracture toughness of CFRP laminates from size effect law of open hole specimen using cohesive zone model. Eng. Fract. Mech. 2018, 191, 277–285. [Google Scholar] [CrossRef]

- Abdellah, M.Y.; Hassan, M.K.; Mohamed, A.F.; Backar, A.H. Cyclic Relaxation, Impact Properties and Fracture Toughness of Carbon and Glass Fiber Reinforced Composite Laminates. Materials 2021, 14, 7412. [Google Scholar] [CrossRef] [PubMed]

- Narasimhachary, S.; Saxena, A.; Newman, J. A double edge notch specimen design for tension–compression fatigue crack growth testing. Eng. Fract. Mech. 2012, 92, 126–136. [Google Scholar] [CrossRef]

- Yilmaz, S.; Yilmaz, T.; Kahraman, B. Essential work of fracture analysis of short glass fiber and/or calcite reinforced ABS/PA6 composites. Polym. Eng. Sci. 2014, 54, 540–550. [Google Scholar] [CrossRef]

- Yilmaz, S.; Yilmaz, T.; Arici, A.A. Effect of annealing process in water on the essential work of fracture response of ultra high molecular weight polyethylene. J. Mater. Sci. 2011, 46, 1758–1766. [Google Scholar] [CrossRef]

- Hashemi, S. Work of fracture of high impact polystyrene (HIPS) film under plane stress conditions. J. Mater. Sci. 2003, 38, 3055–3062. [Google Scholar] [CrossRef]

- Peres, F.M.; Tarpani, J.R.; Schön, C.G. An assessment of essential work of fracture testing method applied to medium density polyethylene (MDPE). Eng. Fract. Mech. 2013, 105, 136–151. [Google Scholar] [CrossRef]

| Properties | E-Glass | AS4-Carbon Fibre | Kemapoxy (150RGL) |

|---|---|---|---|

| Density (kg/m3) | 2600 | 1790 | 1.2 |

| Tensile strength (MPa) | 3450 | 4270 | 85 |

| Tensile modulus (GPa) | 80 | 228 | 2.5 |

| Passion ratio | 0.25 | 0.34 | 0.35 |

| In plane shear modulus (GPa) | 30.8 | 25 | 1.24 |

| Material | Young Modulus (GPa) | Tensile Strength, (MPa) | Passion Ratio [69] | Applied Load (B.C) kN | Element Type | Number of Elements | Evolution Dis. |

|---|---|---|---|---|---|---|---|

| CFRP (S1) | 27.13 | 303 | 0.34 | 16.5 | C3D8R | 1650 | 0.03 |

| GFRP-w (S2) | 15.36 | 187.5 | 0.34 | 29 | C3D8R | 1650 | 0.125 |

| GFRP-R (S3) | 501 | 125 | 0.34 | 10.2 | C3D8R | 1650 | 0.03 |

| Specimens | Load (kN) | Stress (MPa) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ligament length (mm) | 4 | 8 | 12 | 16 | 20 | 4 | 8 | 12 | 16 | 20 |

| CFRP (s1) | 39 | 134 | 267 | 418 | 585 | 0.48 | 1.66 | 3.34 | 5.225 | 7.313 |

| GFRP-W (s2) | 82 | 257 | 644 | 962 | 1171 | 0.41 | 1.29 | 3.22 | 4.81 | 5.85 |

| GFRP-R (s3) | 244 | 853 | 2028 | 2835 | 4205 | 3.26 | 3.05 | 10.66 | 25.35 | 35.44 |

| Material Type | Fracture Toughness, | Fracture Toughness, | % Error | Fracture Toughness, | % Error |

|---|---|---|---|---|---|

| CFRP (s1) | 25.14 | 23.97 | 4.65 | 24.936 | 0.83 |

| GFRP-W (s2) | 32.59 | 31.62 | 2.97 | 34.28 | 5.16 |

| GFRP-R (s3) | 20.22 | 19.16 | 5.25 | 19.28 | 4.64 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdellah, M.Y.; Zuwawi, A.-R.; Azam, S.A.; Hassan, M.K. A Comparative Study to Evaluate the Essential Work of Fracture to Measure the Fracture Toughness of Quasi-Brittle Material. Materials 2022, 15, 4514. https://doi.org/10.3390/ma15134514

Abdellah MY, Zuwawi A-R, Azam SA, Hassan MK. A Comparative Study to Evaluate the Essential Work of Fracture to Measure the Fracture Toughness of Quasi-Brittle Material. Materials. 2022; 15(13):4514. https://doi.org/10.3390/ma15134514

Chicago/Turabian StyleAbdellah, Mohammed Y., Abdul-Rahman Zuwawi, Sufyan A. Azam, and Mohamed K. Hassan. 2022. "A Comparative Study to Evaluate the Essential Work of Fracture to Measure the Fracture Toughness of Quasi-Brittle Material" Materials 15, no. 13: 4514. https://doi.org/10.3390/ma15134514

APA StyleAbdellah, M. Y., Zuwawi, A.-R., Azam, S. A., & Hassan, M. K. (2022). A Comparative Study to Evaluate the Essential Work of Fracture to Measure the Fracture Toughness of Quasi-Brittle Material. Materials, 15(13), 4514. https://doi.org/10.3390/ma15134514