Novel Surfactant-Induced MWCNTs/PDMS-Based Nanocomposites for Tactile Sensing Applications

Abstract

:1. Introduction

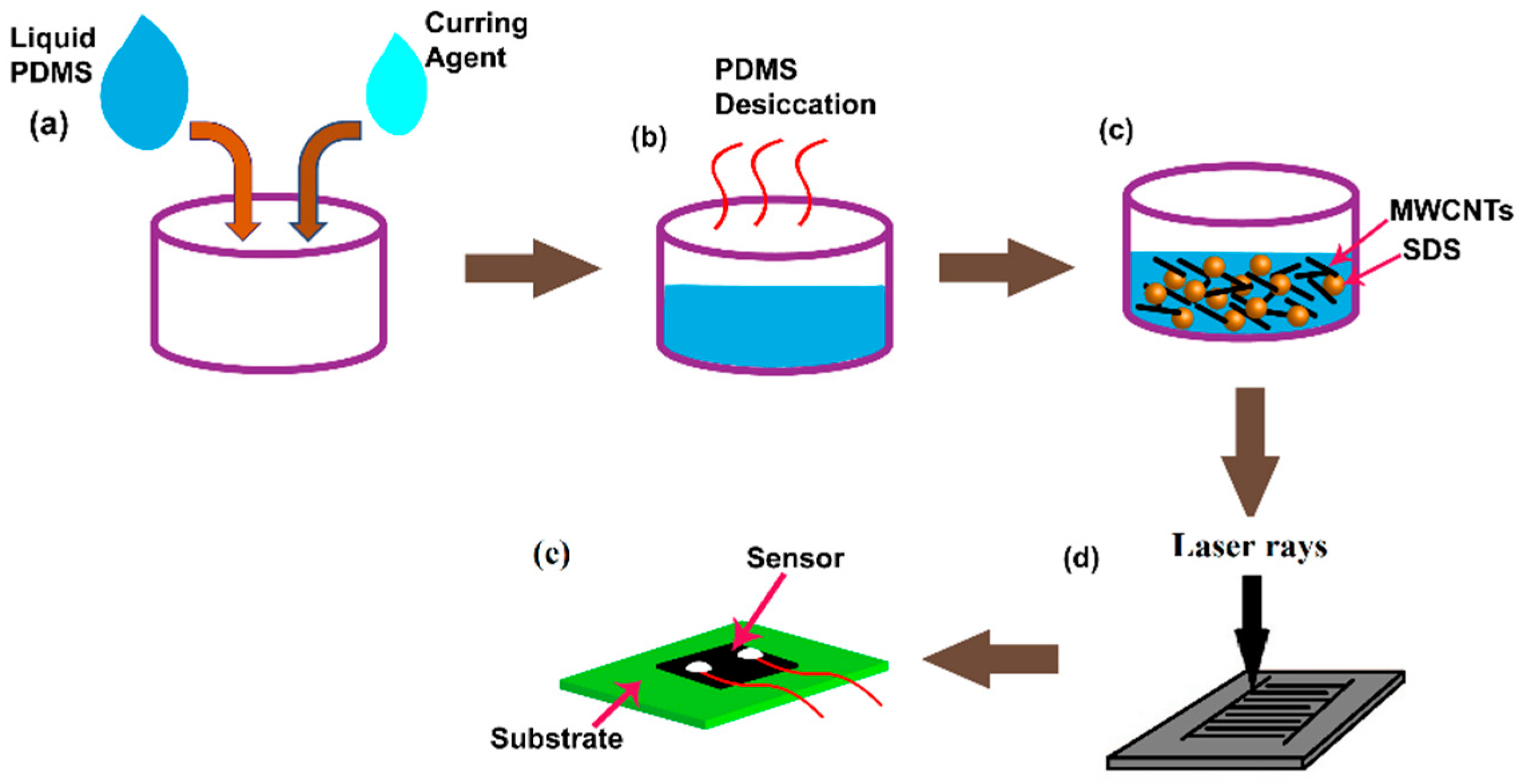

2. Fabrication of the Nanocomposites

3. Experimental Setup

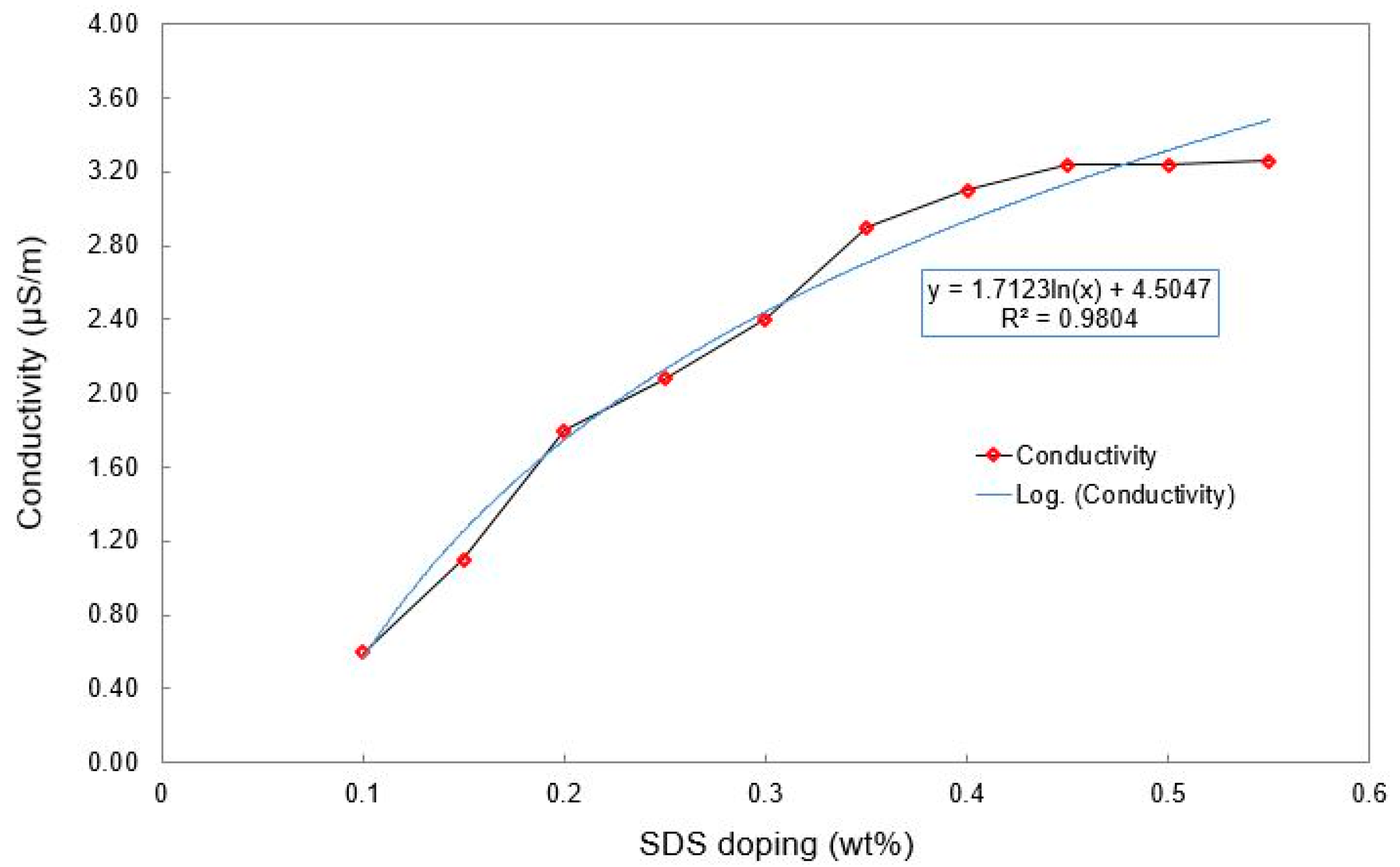

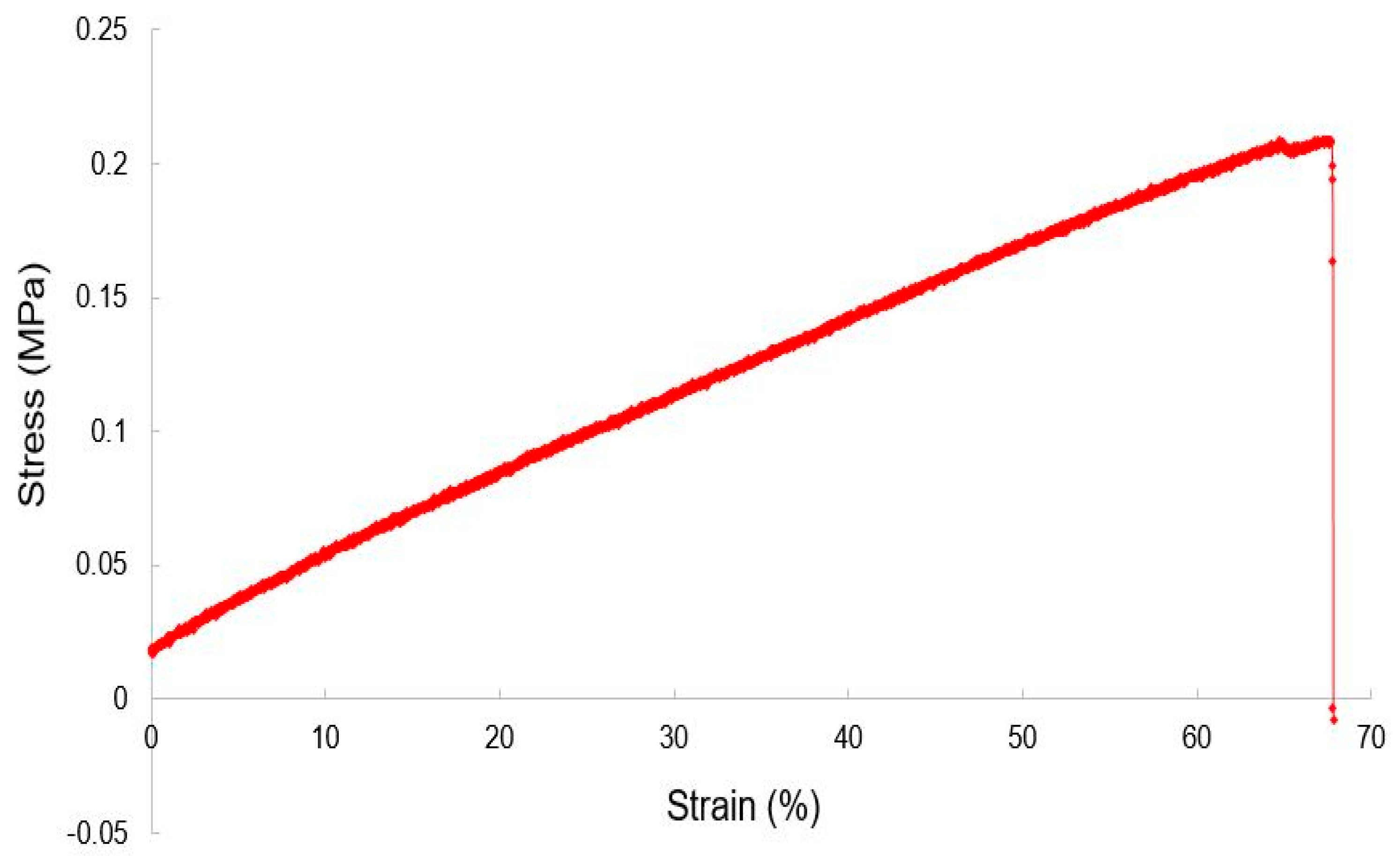

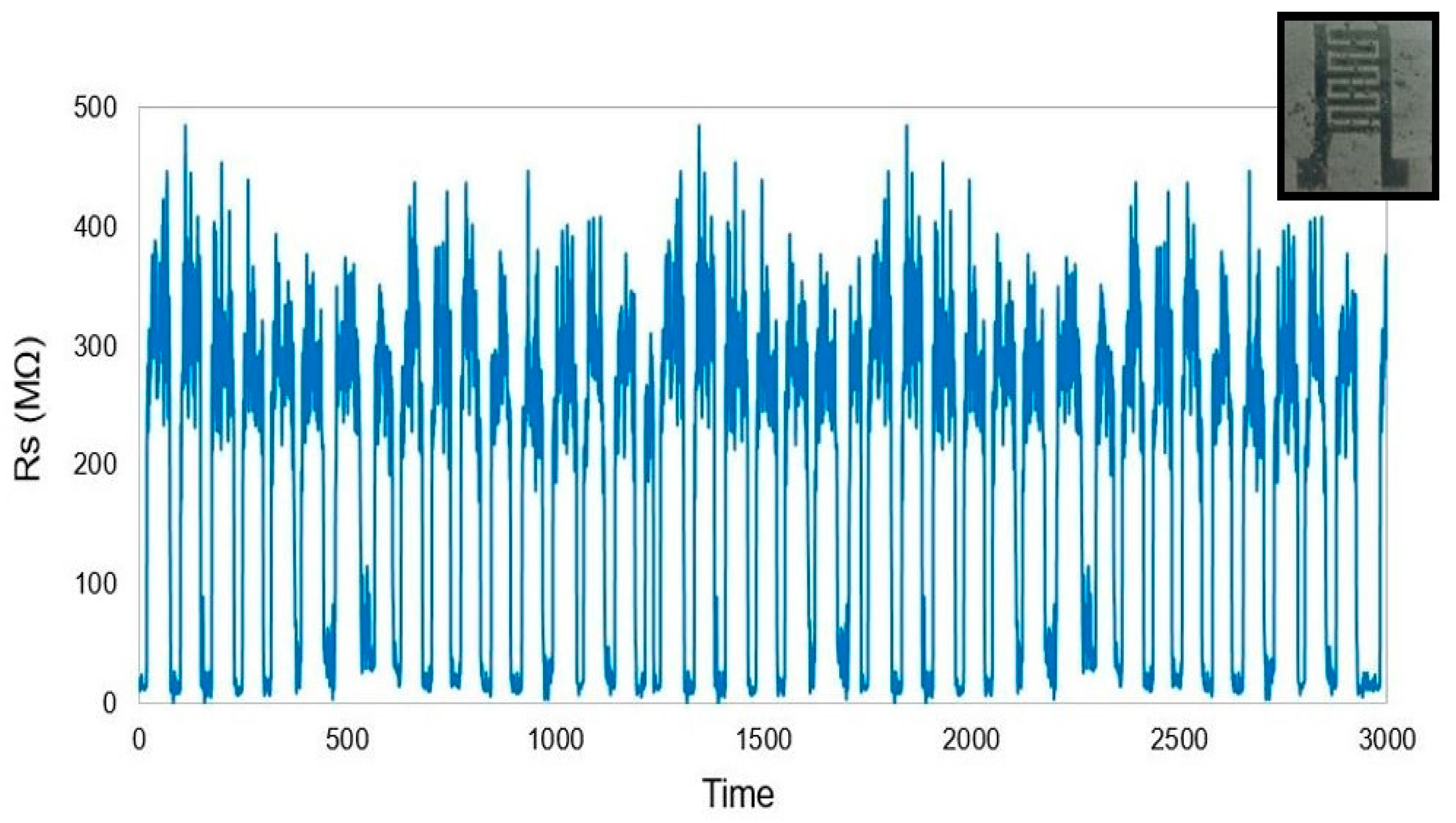

4. Performance of the Nanocomposite-Based Sensors

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mehmood, A.; Mubarak, N.; Khalid, M.; Walvekar, R.; Abdullah, E.; Siddiqui, M.; Baloch, H.A.; Nizamuddin, S.; Mazari, S. Graphene based nanomaterials for strain sensor application—A review. J. Environ. Chem. Eng. 2020, 8, 103743. [Google Scholar] [CrossRef]

- Vimbela, G.V.; Ngo, S.M.; Fraze, C.; Yang, L.; Stout, D.A. Antibacterial properties and toxicity from metallic nanomaterials. Int. J. Nanomed. 2017, 12, 3941. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jaaniso, R.; Tan, O.K. Semiconductor Gas Sensors; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Sze, S.M. Semiconductor Sensors; John Wiley & Sons: Hoboken, NJ, USA, 1994. [Google Scholar]

- Xu, Y.; Hu, X.; Kundu, S.; Nag, A.; Afsarimanesh, N.; Sapra, S.; Mukhopadhyay, S.C.; Han, T. Silicon-based sensors for biomedical applications: A review. Sensors 2019, 19, 2908. [Google Scholar] [CrossRef] [Green Version]

- Afsarimanesh, N.; Alahi, M.E.E.; Mukhopadhyay, S.C.; Kruger, M. Development of IoT-based impedometric biosensor for point-of-care monitoring of bone loss. IEEE J. Emerg. Sel. Top. Circuits Syst. 2018, 8, 211–220. [Google Scholar] [CrossRef]

- Nag, A.; Zia, A.I.; Li, X.; Mukhopadhyay, S.C.; Kosel, J. Novel sensing approach for LPG leakage detection: Part I—Operating mechanism and preliminary results. IEEE Sens. J. 2015, 16, 996–1003. [Google Scholar] [CrossRef] [Green Version]

- Nag, A.; Zia, A.I.; Li, X.; Mukhopadhyay, S.C.; Kosel, J. Novel sensing approach for LPG leakage detection—Part II: Effects of particle size, composition, and coating layer thickness. IEEE Sens. J. 2015, 16, 1088–1094. [Google Scholar] [CrossRef] [Green Version]

- Tilli, M.; Paulasto-Krockel, M.; Petzold, M.; Theuss, H.; Motooka, T.; Lindroos, V. Handbook of Silicon Based MEMS Materials and Technologies; Elsevier: Amsterdam, The Netherlands, 2020. [Google Scholar]

- Alahi, M.E.E.; Xie, L.; Mukhopadhyay, S.; Burkitt, L. A temperature compensated smart nitrate-sensor for agricultural industry. IEEE Trans. Ind. Electron. 2017, 64, 7333–7341. [Google Scholar] [CrossRef]

- Chaisriratanakul, W.; Bunjongpru, W.; Pankiew, A.; Srisuwan, A.; Jeamsaksiri, W.; Chaowicharat, E.; Thornyanadacha, N.; Pengpad, P.; Phromyothin, D. Effect of amino-, mercapto-silane coupling as a molecular bridge of polyvinyl chloride ion-selective membrane on silicon nitride for nitrate ISFET sensors. Jpn. J. Appl. Phys. 2020, 59, SIIJ10. [Google Scholar] [CrossRef]

- Anbia, M.; Kamel, L. Preparation of pyramids structured silicon as a support for nano sized zero valent iron particles for nitrate removal from water. Silicon 2018, 10, 1851–1859. [Google Scholar] [CrossRef]

- Nag, A.; Zia, A.I.; Mukhopadhyay, S.; Kosel, J. Performance enhancement of electronic sensor through mask-less lithography. In Proceedings of the 2015 9th International Conference on Sensing Technology (ICST), Auckland, New Zealand, 8–10 December 2015; pp. 374–379. [Google Scholar]

- Song, P.; Ma, Z.; Ma, J.; Yang, L.; Wei, J.; Zhao, Y.; Zhang, M.; Yang, F.; Wang, X. Recent progress of miniature MEMS pressure sensors. Micromachines 2020, 11, 56. [Google Scholar] [CrossRef] [Green Version]

- Khan, S.; Lorenzelli, L.; Dahiya, R.S. Technologies for printing sensors and electronics over large flexible substrates: A review. IEEE Sens. J. 2014, 15, 3164–3185. [Google Scholar] [CrossRef]

- He, S.; Zhang, Y.; Gao, J.; Nag, A.; Rahaman, A. Integration of Different Graphene Nanostructures with PDMS to Form Wearable Sensors. Nanomaterials 2022, 12, 950. [Google Scholar] [CrossRef] [PubMed]

- Nag, A.; Simorangkir, R.B.; Valentin, E.; Björninen, T.; Ukkonen, L.; Hashmi, R.M.; Mukhopadhyay, S.C. A transparent strain sensor based on PDMS-embedded conductive fabric for wearable sensing applications. IEEE Access 2018, 6, 71020–71027. [Google Scholar] [CrossRef]

- Nag, A.; Mukhopadhyay, S.C.; Kosel, J. Tactile sensing from laser-ablated metallized PET films. IEEE Sens. J. 2016, 17, 7–13. [Google Scholar] [CrossRef]

- Li, S.; Lin, P.; Zhao, L.; Wang, C.; Liu, D.; Liu, F.; Sun, P.; Liang, X.; Liu, F.; Yan, X. The room temperature gas sensor based on Polyaniline@ flower-like WO3 nanocomposites and flexible PET substrate for NH3 detection. Sens. Actuators B Chem. 2018, 259, 505–513. [Google Scholar] [CrossRef]

- Han, T.; Nag, A.; Afsarimanesh, N.; Akhter, F.; Liu, H.; Sapra, S.; Mukhopadhyay, S.; Xu, Y. Gold/Polyimide-Based Resistive Strain Sensors. Electronics 2019, 8, 565. [Google Scholar] [CrossRef] [Green Version]

- Nag, A.; Mukhopadhyay, S.C.; Kosel, J. Sensing system for salinity testing using laser-induced graphene sensors. Sens. Actuators A Phys. 2017, 264, 107–116. [Google Scholar] [CrossRef] [Green Version]

- Kumar, V.; Matai, I.; Kumar, A.; Sachdev, A. GNP-CeO2-polyaniline hybrid hydrogel for electrochemical detection of peroxynitrite anion and its integration in a microfluidic platform. Microchim. Acta 2021, 188, 436. [Google Scholar] [CrossRef]

- Kulkarni, S.; Navale, Y.; Navale, S.; Stadler, F.; Ramgir, N.; Patil, V. Hybrid polyaniline-WO3 flexible sensor: A room temperature competence towards NH3 gas. Sens. Actuators B Chem. 2019, 288, 279–288. [Google Scholar] [CrossRef]

- Deng, L.; Yuan, J.; Huang, H.; Xie, S.; Xu, J.; Yue, R. Fabrication of hierarchical Ru/PEDOT: PSS/Ti3C2Tx nanocomposites as electrochemical sensing platforms for highly sensitive Sudan I detection in food. Food Chem. 2022, 372, 131212. [Google Scholar] [CrossRef]

- Wang, Y.-F.; Sekine, T.; Takeda, Y.; Yokosawa, K.; Matsui, H.; Kumaki, D.; Shiba, T.; Nishikawa, T.; Tokito, S. Fully printed PEDOT: PSS-based temperature sensor with high humidity stability for wireless healthcare monitoring. Sci. Rep. 2020, 10, 2467. [Google Scholar] [CrossRef] [Green Version]

- Nag, A.; Alahi, M.; Eshrat, E.; Mukhopadhyay, S.C.; Liu, Z. Multi-walled carbon nanotubes-based sensors for strain sensing applications. Sensors 2021, 21, 1261. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Zhao, X.; Li, P.; Huang, Y.; Wang, J.; Zhang, J. Highly sensitive Fe3O4 nanobeads/graphene-based molecularly imprinted electrochemical sensor for 17β-estradiol in water. Anal. Chim. Acta 2015, 884, 106–113. [Google Scholar] [CrossRef] [PubMed]

- Phan, T.T.V.; Huynh, T.-C.; Manivasagan, P.; Mondal, S.; Oh, J. An up-to-date review on biomedical applications of palladium nanoparticles. Nanomaterials 2020, 10, 66. [Google Scholar] [CrossRef] [Green Version]

- Suzuki, K.; Nakagawa, R.; Zhang, Q.; Miura, H. Development of highly sensitive strain sensor using area-arrayed graphene nanoribbons. Nanomaterials 2021, 11, 1701. [Google Scholar] [CrossRef] [PubMed]

- Mousavi, S.M.; Hashemi, S.A.; Gholami, A.; Mazraedoost, S.; Chiang, W.-H.; Arjmand, O.; Omidifar, N.; Babapoor, A. Precise blood glucose sensing by nitrogen-doped graphene quantum dots for tight control of diabetes. J. Sens. 2021, 2021, 5580203. [Google Scholar] [CrossRef]

- Niazvand, F.; Wagh, P.R.; Khazraei, E.; Dastjerdi, M.B.; Patil, C.; Najar, I.A. Application of carbon allotropes composites for targeted cancer therapy drugs: A review. J. Compos. Compd. 2021, 3, 140–151. [Google Scholar] [CrossRef]

- Nasir, S.; Hussein, M.Z.; Zainal, Z.; Yusof, N.A. Carbon-based nanomaterials/allotropes: A glimpse of their synthesis, properties and some applications. Materials 2018, 11, 295. [Google Scholar] [CrossRef] [Green Version]

- Sáenz-Trevizo, A.; Hodge, A. Nanomaterials by design: A review of nanoscale metallic multilayers. Nanotechnology 2020, 31, 292002. [Google Scholar] [CrossRef]

- Ovid’Ko, I.; Valiev, R.; Zhu, Y. Review on superior strength and enhanced ductility of metallic nanomaterials. Prog. Mater. Sci. 2018, 94, 462–540. [Google Scholar] [CrossRef]

- Gao, J.; He, S.; Nag, A.; Wong, J.W.C. A Review of the Use of Carbon Nanotubes and Graphene-Based Sensors for the Detection of Aflatoxin M1 Compounds in Milk. Sensors 2021, 21, 3602. [Google Scholar] [CrossRef] [PubMed]

- Han, T.; Nag, A.; Mukhopadhyay, S.C.; Xu, Y. Carbon nanotubes and its gas-sensing applications: A review. Sens. Actuators A Phys. 2019, 291, 107–143. [Google Scholar] [CrossRef]

- Han, T.; Nag, A.; Simorangkir, R.B.; Afsarimanesh, N.; Liu, H.; Mukhopadhyay, S.C.; Xu, Y.; Zhadobov, M.; Sauleau, R. Multifunctional flexible sensor based on laser-induced graphene. Sensors 2019, 19, 3477. [Google Scholar] [CrossRef] [Green Version]

- Nag, A.; Mitra, A.; Mukhopadhyay, S.C. Graphene and its sensor-based applications: A review. Sens. Actuators A Phys. 2018, 270, 177–194. [Google Scholar] [CrossRef]

- Nag, A.; Feng, S.; Mukhopadhyay, S.; Kosel, J.; Inglis, D. 3D printed mould-based graphite/PDMS sensor for low-force applications. Sens. Actuators A Phys. 2018, 280, 525–534. [Google Scholar] [CrossRef]

- Nag, A.; Afasrimanesh, N.; Feng, S.; Mukhopadhyay, S.C. Strain induced graphite/PDMS sensors for biomedical applications. Sens. Actuators A Phys. 2018, 271, 257–269. [Google Scholar] [CrossRef]

- Chen, M.; Hu, X.; Li, K.; Sun, J.; Liu, Z.; An, B.; Zhou, X.; Liu, Z. Self-assembly of dendritic-lamellar mxene/carbon nanotube conductive films for wearable tactile sensors and artificial skin. Carbon 2020, 164, 111–120. [Google Scholar] [CrossRef]

- Xu, M.; Gao, Y.; Yu, G.; Lu, C.; Tan, J.; Xuan, F. Flexible pressure sensor using carbon nanotube-wrapped polydimethylsiloxane microspheres for tactile sensing. Sens. Actuators A Phys. 2018, 284, 260–265. [Google Scholar] [CrossRef]

- Sia, S.K.; Whitesides, G.M. Microfluidic devices fabricated in poly (dimethylsiloxane) for biological studies. Electrophoresis 2003, 24, 3563–3576. [Google Scholar] [CrossRef]

- Nag, A.; Alahi, M.E.E.; Mukhopadhyay, S.C. Recent progress in the fabrication of graphene fibers and their composites for applications of monitoring human activities. Appl. Mater. Today 2021, 22, 100953. [Google Scholar] [CrossRef]

- Das, P.P.; Chaudhary, V. Application of Graphene-Based Biopolymer Nanocomposites for Automotive and Electronic Based Components. In Graphene Based Biopolymer Nanocomposites; Springer: Berlin/Heidelberg, Germany, 2021; pp. 311–323. [Google Scholar]

- Yu, H.; Guo, W.; Lu, X.; Xu, H.; Yang, Q.; Tan, J.; Zhang, W. Reduced graphene oxide nanocomposite based electrochemical biosensors for monitoring foodborne pathogenic bacteria: A review. Food Control 2021, 127, 108117. [Google Scholar] [CrossRef]

- Nuthalapati, S.; Shirhatti, V.; Kedambaimoole, V.; Takao, H.; Nayak, M.; Rajanna, K. Highly sensitive flexible strain and temperature sensors using solution processed graphene palladium nanocomposite. Sens. Actuators A Phys. 2022, 334, 113314. [Google Scholar] [CrossRef]

- Nuthalapati, S.; Kedambaimoole, V.; Shirhatti, V.; Kumar, S.; Takao, H.; Nayak, M.; Rajanna, K. Flexible strain sensor with high sensitivity, fast response, and good sensing range for wearable applications. Nanotechnology 2021, 32, 505506. [Google Scholar] [CrossRef]

- Nuthalapati, S.; Shirhatti, V.; Kedambaimoole, V.; Neella, N.; Nayak, M.; Rajanna, K.; Takao, H. Highly sensitive, scalable reduced graphene oxide with palladium nano-composite as strain sensor. Nanotechnology 2019, 31, 035501. [Google Scholar] [CrossRef]

- Daikh, S.; Zeggai, F.; Bellil, A.; Benyoucef, A. Chemical polymerization, characterization and electrochemical studies of PANI/ZnO doped with hydrochloric acid and/or zinc chloride: Differences between the synthesized nanocomposites. J. Phys. Chem. Solids 2018, 121, 78–84. [Google Scholar] [CrossRef]

- Dong, L.; Gao, S.; Peng, H.; Chen, C.; Wang, J.; Yan, W.; Jung, J.C.-Y.; Zhang, J. Boosting high-rate-partial-state-of-charge performance of lead-acid batteries by incorporating trace amount of sodium dodecyl sulfate modified multiwalled carbon nanotubes into negative active materials. J. Energy Storage 2021, 44, 103402. [Google Scholar] [CrossRef]

- Goh, S.X.L.; Goh, E.X.Y.; Lee, H.K. Sodium dodecyl sulfate-multi-walled carbon nanotubes-coated-membrane solid phase extraction of glucocorticoids in aqueous matrices. Talanta 2021, 221, 121624. [Google Scholar] [CrossRef]

- Duan, W.H.; Wang, Q.; Collins, F. Dispersion of carbon nanotubes with SDS surfactants: A study from a binding energy perspective. Chem. Sci. 2011, 2, 1407–1413. [Google Scholar] [CrossRef]

- Cheng, H.K.F.; Pan, Y.; Sahoo, N.G.; Chong, K.; Li, L.; Hwa Chan, S.; Zhao, J. Improvement in properties of multiwalled carbon nanotube/polypropylene nanocomposites through homogeneous dispersion with the aid of surfactants. J. Appl. Polym. Sci. 2012, 124, 1117–1127. [Google Scholar] [CrossRef]

- Rejisha, C.; Soundararajan, S.; Sivapatham, N.; Palanivelu, K. Effect of MWCNT on thermal, mechanical, and morphological properties of polybutylene terephthalate/polycarbonate blends. J. Polym. 2014, 2014, 157137. [Google Scholar] [CrossRef]

- Sulym, I.; Zdarta, J.; Ciesielczyk, F.; Sternik, D.; Derylo-Marczewska, A.; Jesionowski, T. Pristine and poly (Dimethylsiloxane) modified multi-walled carbon nanotubes as supports for lipase immobilization. Materials 2021, 14, 2874. [Google Scholar] [CrossRef] [PubMed]

- Bozeya, A.; Makableh, Y.F.; Abu-Zurayk, R.; Khalaf, A.; Al Bawab, A. Thermal and Structural Properties of High Density Polyethylene/Carbon Nanotube Nanocomposites: A Comparison Study. Chemosensors 2021, 9, 136. [Google Scholar] [CrossRef]

- Kanagaraj, S.; Varanda, F.R.; Zhil’tsova, T.V.; Oliveira, M.S.; Simões, J.A. Mechanical properties of high density polyethylene/carbon nanotube composites. Compos. Sci. Technol. 2007, 67, 3071–3077. [Google Scholar] [CrossRef]

- Shi, Y.; Ren, L.; Li, D.; Gao, H.; Yang, B. Optimization conditions for single-walled carbon nanotubes dispersion. J. Surf. Eng. Mater. Adv. Technol. 2013, 3, 27316. [Google Scholar] [CrossRef] [Green Version]

- Johnston, I.; McCluskey, D.; Tan, C.; Tracey, M. Mechanical characterization of bulk Sylgard 184 for microfluidics and microengineering. J. Micromech. Microeng. 2014, 24, 035017. [Google Scholar] [CrossRef]

- Pan, S.; Wang, T.; Jin, K.; Cai, X. Understanding and designing metal matrix nanocomposites with high electrical conductivity: A review. J. Mater. Sci. 2022, 57, 6487–6523. [Google Scholar] [CrossRef]

- Şenocak, A.; Tümay, S.O.; Ömeroğlu, İ.; Şanko, V. Crosslinker polycarbazole supported magnetite MOF@ CNT hybrid material for synergetic and selective voltammetric determination of adenine and guanine. J. Electroanal. Chem. 2022, 905, 115963. [Google Scholar] [CrossRef]

- Chronopoulos, D.D.; Saini, H.; Tantis, I.; Zbořil, R.; Jayaramulu, K.; Otyepka, M. Carbon Nanotube Based Metal–Organic Framework Hybrids From Fundamentals Toward Applications. Small 2022, 18, 2104628. [Google Scholar] [CrossRef]

- Wang, Q.; Liu, J.; Ran, X.; Zhang, D.; Shen, G.; Miao, M. High-performance flexible self-powered strain sensor based on carbon nanotube/ZnSe/CoSe2 nanocomposite film electrodes. Nano Res. 2022, 15, 170–178. [Google Scholar] [CrossRef]

| Carbon Nanotubes (wt. %) | Sodium Dodecyl Sulfonate (wt. %) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 0.3 | 0.1 | 0.15 | 0.2 | 0.25 | 0.3 | 0.4 | 0.45 | 0.5 | 0.55 |

| 0.6 | 0.1 | 0.15 | 0.2 | 0.25 | 0.3 | 0.4 | 0.45 | 0.5 | 0.55 |

| 0.9 | 0.1 | 0.15 | 0.2 | 0.25 | 0.3 | 0.4 | 0.45 | 0.5 | 0.55 |

| 1.2 | 0.1 | 0.15 | 0.2 | 0.25 | 0.3 | 0.4 | 0.45 | 0.5 | 0.55 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nag, A.; Afsarimanesh, N.; Nuthalapati, S.; Altinsoy, M.E. Novel Surfactant-Induced MWCNTs/PDMS-Based Nanocomposites for Tactile Sensing Applications. Materials 2022, 15, 4504. https://doi.org/10.3390/ma15134504

Nag A, Afsarimanesh N, Nuthalapati S, Altinsoy ME. Novel Surfactant-Induced MWCNTs/PDMS-Based Nanocomposites for Tactile Sensing Applications. Materials. 2022; 15(13):4504. https://doi.org/10.3390/ma15134504

Chicago/Turabian StyleNag, Anindya, Nasrin Afsarimanesh, Suresh Nuthalapati, and Mehmet Ercan Altinsoy. 2022. "Novel Surfactant-Induced MWCNTs/PDMS-Based Nanocomposites for Tactile Sensing Applications" Materials 15, no. 13: 4504. https://doi.org/10.3390/ma15134504

APA StyleNag, A., Afsarimanesh, N., Nuthalapati, S., & Altinsoy, M. E. (2022). Novel Surfactant-Induced MWCNTs/PDMS-Based Nanocomposites for Tactile Sensing Applications. Materials, 15(13), 4504. https://doi.org/10.3390/ma15134504