The Characteristics of Time-Dependent Changes of Coefficient of Permeability for Superabsorbent Polymer-Soil Mixtures

Abstract

:1. Introduction

2. Materials and Methods

- -

- Two types of soils collected in the field—Coarse sand and Loamy sand;

- -

- Two types of commercially available superabsorbents- cross-linked copolymer of acrylamide and potassium acrylate: Aquasorb 3005 KS and Aquasorb 3005 KM (hereafter referred to as KS and KM, respectively), obtained from SNF FLOERGER, Andrézieux, France;

- -

- Substance that will infiltrate through the samples—deionized (DI) water.

- -

- SAP-soil mixture in the air-dry state was prepared at a predefined proportion (0.3%, 0.5%, or 1.0% of SAP addition by mass);

- -

- A mixture was placed in a stainless-steel cylinder (volume V = 760.0 cm3, height L = 8.0 cm, diameter D = 11.0 cm) having a porous base with a rapid filtering grade mesh;

- -

- A Cylinder containing the SAP-soil mixture was placed on a vibration plate in order to achieve the desired sample dry bulk density (ρd = 1.65 g/cm3);

- -

- A filtration mesh and porous circular pad was placed on top of the SAP-soil mixture.

- -

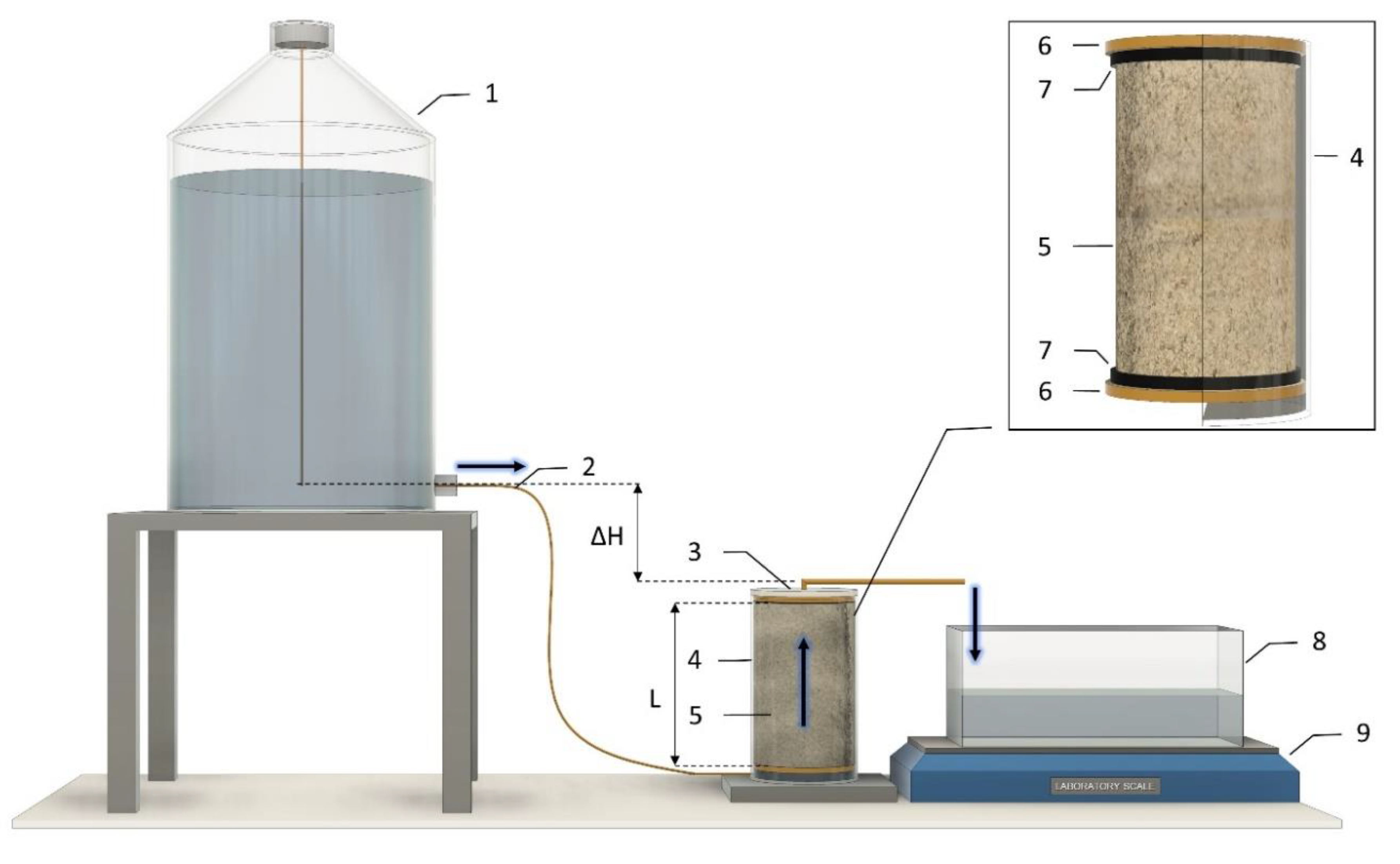

- The laboratory equipment (Figure 1) was arranged in the following order: Mariotte’s bottle filled with water placed at height H1, connected with the cylinder containing the SAP-soil mixture of a defined height L, covered with a lid with a water outlet tube (D = 0.4 cm, L = 15 cm) at the defined height H2, leading to the container placed on the weighing scale machine.

2.1. Coefficient of Permeability Measurement Procedure

2.2. Physical Characteristics of SAP and Soil Grains

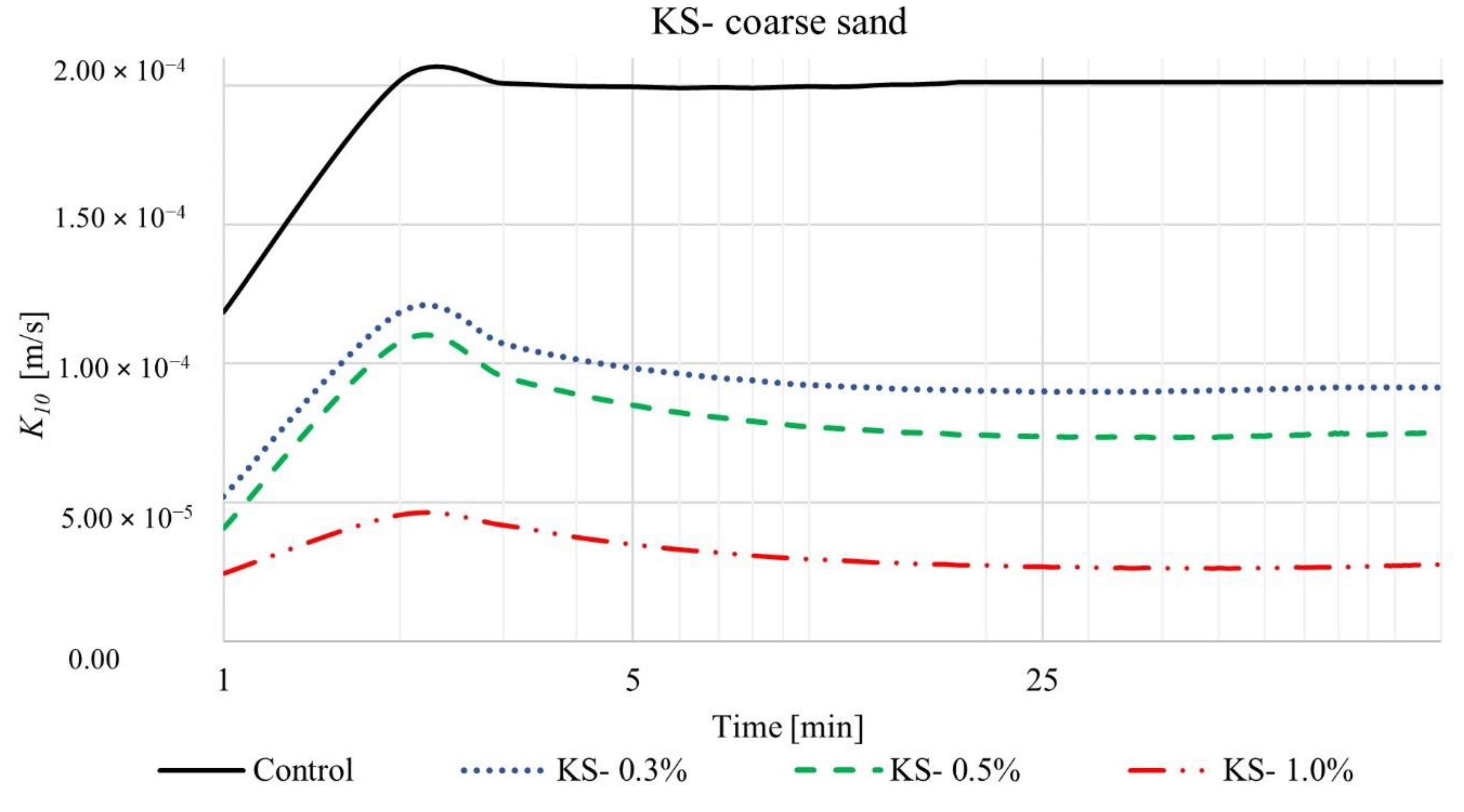

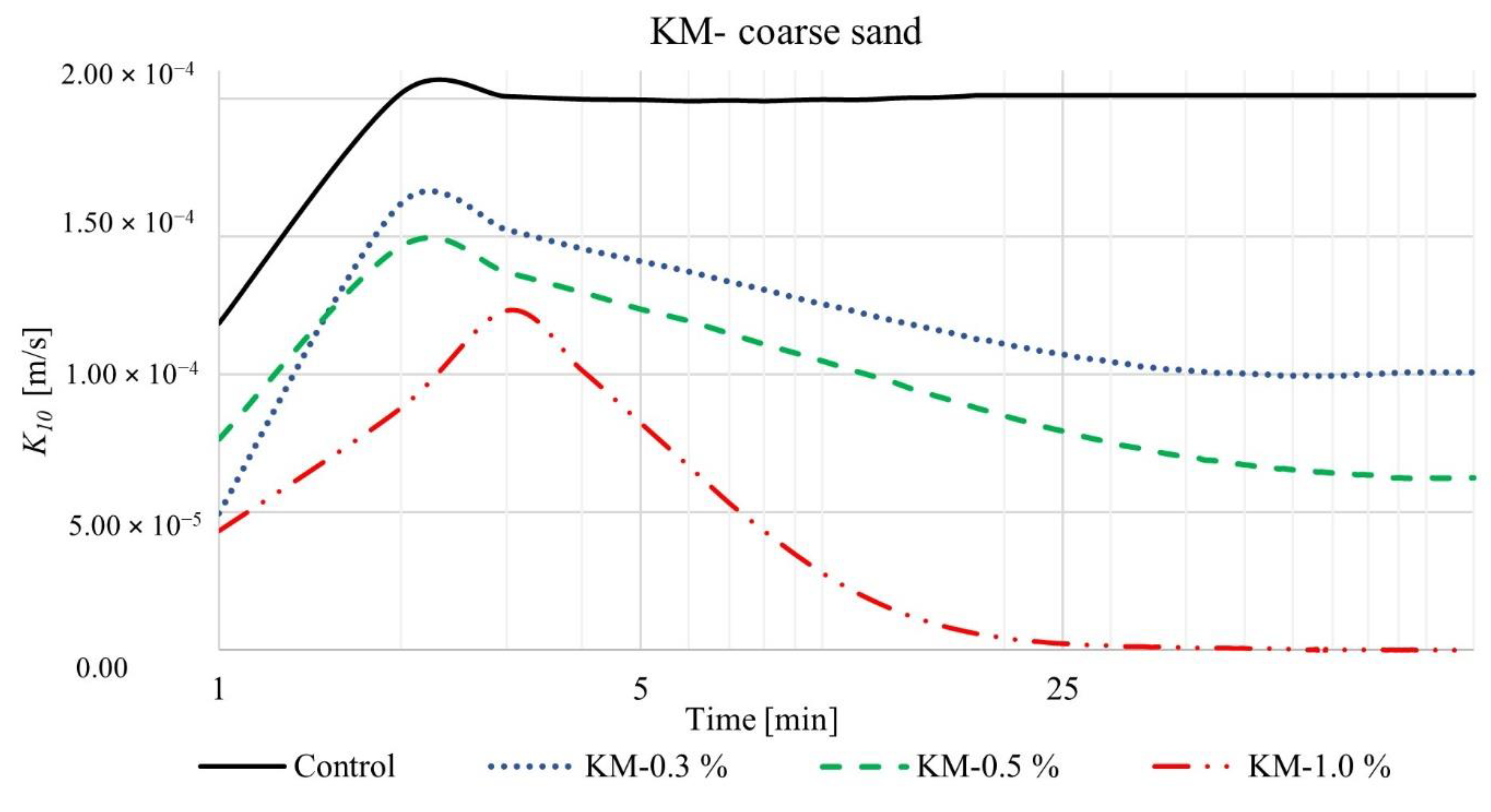

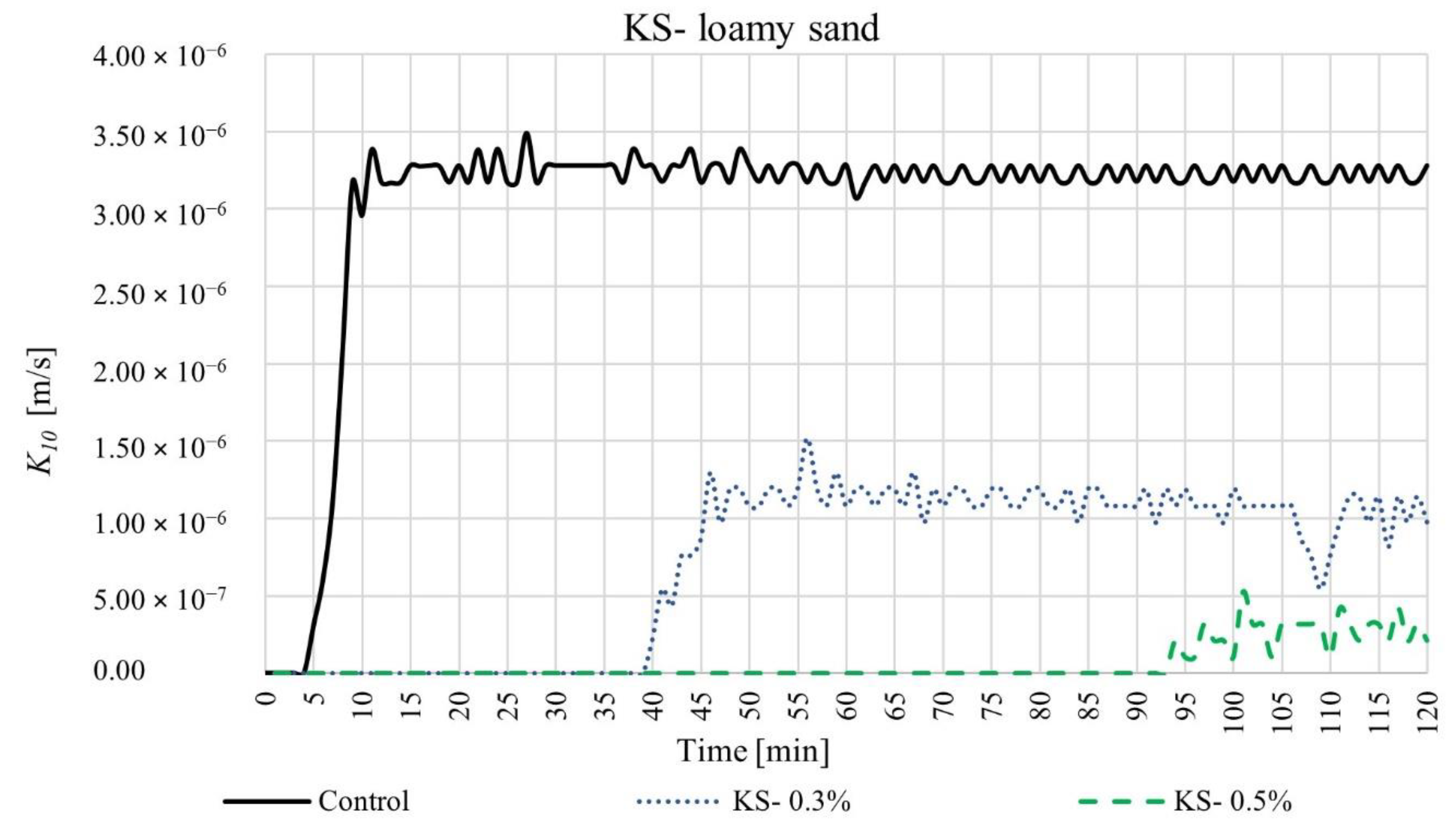

3. Results of Coefficient of Permeability Measurements

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Braun, O.; Coquery, C.; Kieffer, J.; Blondel, F.; Favero, C.; Besset, C.; Mesnager, J.; Voelker, F.; Delorme, C.; Matioszek, D. Spotlight on the Life Cycle of Acrylamide-Based Polymers Supporting Reductions in Environmental Footprint: Review and Recent Advances. Molecules 2021, 27, 42. [Google Scholar] [CrossRef]

- Berninger, T.; Dietz, N.; González López, Ó. Water-soluble Polymers in Agriculture: Xanthan Gum as Eco-friendly Alternative to Synthetics. Microb. Biotechnol. 2021, 14, 1881–1896. [Google Scholar] [CrossRef]

- Louf, J.-F.; Lu, N.B.; O’Connell, M.G.; Cho, H.J.; Datta, S.S. Under Pressure: Hydrogel Swelling in a Granular Medium. Sci. Adv. 2021, 7, eabd2711. [Google Scholar] [CrossRef]

- Said, M.; Atassi, Y.; Tally, M.; Khatib, H. Environmentally Friendly Chitosan-g-Poly(Acrylic Acid-Co-Acrylamide)/Ground Basalt Superabsorbent Composite for Agricultural Applications. J. Polym. Environ. 2018, 26, 3937–3948. [Google Scholar] [CrossRef]

- Wei, J.; Yang, H.; Cao, H.; Tan, T. Using Polyaspartic Acid Hydro-Gel as Water Retaining Agent and Its Effect on Plants under Drought Stress. Saudi J. Biol. Sci. 2016, 23, 654–659. [Google Scholar] [CrossRef] [Green Version]

- Assouline, S. What Can We Learn from the Water Retention Characteristic of a Soil Regarding Its Hydrological and Agricultural Functions? Review and Analysis of Actual Knowledge. Water Resour. Res. 2021, 57, e2021WR031026. [Google Scholar] [CrossRef]

- Li, W.; Wainwright, H.M.; Yan, Q.; Zhou, H.; Dafflon, B.; Wu, Y.; Versteeg, R.; Tartakovsky, D.M. Estimation of Evapotranspiration Rates and Root Water Uptake Profiles from Soil Moisture Sensor Array Data. Water Resour. Res. 2021, 57, e2021WR030747. [Google Scholar] [CrossRef]

- Abedi-Koupai, J.; Sohrab, F.; Swarbrick, G. Evaluation of Hydrogel Application on Soil Water Retention Characteristics. J. Plant Nutr. 2008, 31, 317–331. [Google Scholar] [CrossRef]

- Hemvichian, K.; Chanthawong, A.; Suwanmala, P. Synthesis and Characterization of Superabsorbent Polymer Prepared by Radiation-Induced Graft Copolymerization of Acrylamide onto Carboxymethyl Cellulose for Controlled Release of Agrochemicals. Radiat. Phys. Chem. 2014, 103, 167–171. [Google Scholar] [CrossRef]

- Nascimento, C.D.V.; Mota, J.C.A.; Nascimento, Í.V.; da Silva Albuquerque, G.H.; Simmons, R.W.; dos Santos Dias, C.T.; Costa, M.C.G. Temperature Limitations in the Use of Hydrogels on Leptosols in a Semi-Arid Region of Brazil. Geoderma Reg. 2021, 26, e00407. [Google Scholar] [CrossRef]

- Davis, C.R.; Kelly, S.L.; Erk, K.A. Comparing Laser Diffraction and Optical Microscopy for Characterizing Superabsorbent Polymer Particle Morphology, Size, and Swelling Capacity. J. Appl. Polym. Sci. 2018, 135, 46055. [Google Scholar] [CrossRef]

- Snoeck, D.; Pel, L.; De Belie, N. The Water Kinetics of Superabsorbent Polymers during Cement Hydration and Internal Curing Visualized and Studied by NMR. Sci. Rep. 2017, 7, 9514. [Google Scholar] [CrossRef]

- Guilherme, M.R.; Aouada, F.A.; Fajardo, A.R.; Martins, A.F.; Paulino, A.T.; Davi, M.F.T.; Rubira, A.F.; Muniz, E.C. Superabsorbent Hydrogels Based on Polysaccharides for Application in Agriculture as Soil Conditioner and Nutrient Carrier: A Review. Eur. Polym. J. 2015, 72, 365–385. [Google Scholar] [CrossRef] [Green Version]

- Laftah, W.A.; Hashim, S.; Ibrahim, A.N. Polymer Hydrogels: A Review. Polym. Plast. Technol. Eng. 2011, 50, 1475–1486. [Google Scholar] [CrossRef]

- Li, H.; Sui, L.; Niu, Y. Preparation and Properties of a Double-Coated Slow-Release Urea Fertilizer with Poly(Propylene Carbonate), a Sodium Polyacrylate Hydroscopicity Resin and Sodium Alginate. ChemistrySelect 2018, 3, 7643–7647. [Google Scholar] [CrossRef]

- Tubert, E.; Vitali, V.A.; Alvarez, M.S.; Tubert, F.A.; Baroli, I.; Amodeo, G. Synthesis and Evaluation of a Superabsorbent-Fertilizer Composite for Maximizing the Nutrient and Water Use Efficiency in Forestry Plantations. J. Environ. Manag. 2018, 210, 239–254. [Google Scholar] [CrossRef]

- Szewrański, S.; Chruściński, J.; Kazak, J.; Świąder, M.; Tokarczyk-Dorociak, K.; Żmuda, R. Pluvial Flood Risk Assessment Tool (PFRA) for Rainwater Management and Adaptation to Climate Change in Newly Urbanised Areas. Water 2018, 10, 386. [Google Scholar] [CrossRef] [Green Version]

- Bandak, S.; Naeini, S.A.R.M.; Zeinali, E.; Bandak, I. Effects of Superabsorbent Polymer A200 on Soil Characteristics and Rainfed Winter Wheat Growth (Triticum Aestivum L.). Arab. J. Geosci. 2021, 14, 712. [Google Scholar] [CrossRef]

- Garbowski, M.; Brown, C.S.; Johnston, D.B. Soil Amendment Interacts with Invasive Grass and Drought to Uniquely Influence Aboveground versus Belowground Biomass in Aridland Restoration. Restor. Ecol. 2020, 28, A13–A23. [Google Scholar] [CrossRef] [Green Version]

- Michalik, R.; Wandzik, I. A Mini-Review on Chitosan-Based Hydrogels with Potential for Sustainable Agricultural Applications. Polymers 2020, 12, 2425. [Google Scholar] [CrossRef]

- Saha, A.; Sekharan, S.; Manna, U. Superabsorbent Hydrogel (SAH) as a Soil Amendment for Drought Management: A Review. Soil Tillage Res. 2020, 204, 104736. [Google Scholar] [CrossRef]

- Dharumarajan, S.; Hegde, R.; Lalitha, M.; Kalaiselvi, B.; Singh, S.K. Pedotransfer Functions for Predicting Soil Hydraulic Properties in Semi-Arid Regions of Karnataka Plateau, India. Curr. Sci. 2019, 116, 1237. [Google Scholar] [CrossRef]

- Souza, A.J.J.; Guimarães, R.J.; Dominghetti, A.W.; Scalco, M.S.; Rezende, T.T. Water-Retaining Polymer and Seedling Type When Planting Irrigated Coffee. Rev. Cienc. Agron. 2016, 47, 334–343. [Google Scholar] [CrossRef] [Green Version]

- Banedjschafie, S.; Durner, W. Water Retention Properties of a Sandy Soil with Superabsorbent Polymers as Affected by Aging and Water Quality. J. Plant Nutr. Soil Sci. 2015, 178, 798–806. [Google Scholar] [CrossRef]

- Wu, H.; Li, Z.; Song, W.; Bai, S. Effects of Superabsorbent Polymers on Moisture Migration and Accumulation Behaviors in Soil. J. Clean. Prod. 2021, 279, 123841. [Google Scholar] [CrossRef]

- Mohawesh, O.; Durner, W. Effects of Bentonite, Hydrogel and Biochar Amendments on Soil Hydraulic Properties from Saturation to Oven Dryness. Pedosphere 2019, 29, 598–607. [Google Scholar] [CrossRef]

- Misiewicz, J.; Lejcuś, K.; Dąbrowska, J.; Marczak, D. The Characteristics of Absorbency Under Load (AUL) for Superabsorbent and Soil Mixtures. Sci. Rep. 2019, 9, 18098. [Google Scholar] [CrossRef] [Green Version]

- Misiewicz, J.; Głogowski, A.; Lejcuś, K.; Marczak, D. The Characteristics of Swelling Pressure for Superabsorbent Polymer and Soil Mixtures. Materials 2020, 13, 5071. [Google Scholar] [CrossRef]

- Thombare, N.; Mishra, S.; Siddiqui, M.Z.; Jha, U.; Singh, D.; Mahajan, G.R. Design and Development of Guar Gum Based Novel, Superabsorbent and Moisture Retaining Hydrogels for Agricultural Applications. Carbohydr. Polym. 2018, 185, 169–178. [Google Scholar] [CrossRef]

- Akhter, J.; Mahmood, K.; Malik, K.A.; Mardan, A.; Ahmad, M.; Iqbal, M.M. Effects of Hydrogel Amendment on Water Storage of Sandy Loam and Loam Soils and Seedling Growth of Barley, Wheat and Chickpea. Plant Soil Environ. 2011, 50, 463–469. [Google Scholar] [CrossRef] [Green Version]

- Essawy, H.A.; Ghazy, M.B.M.; El-Hai, F.A.; Mohamed, M.F. Superabsorbent Hydrogels via Graft Polymerization of Acrylic Acid from Chitosan-Cellulose Hybrid and Their Potential in Controlled Release of Soil Nutrients. Int. J. Biol. Macromol. 2016, 89, 144–151. [Google Scholar] [CrossRef] [PubMed]

- Salimi, H.; Pourjavadi, A.; Seidi, F.; Jahromi, P.E.; Soleyman, R. New Smart Carrageenan-Based Superabsorbent Hydrogel Hybrid: Investigation of Swelling Rate and Environmental Responsiveness. J. Appl. Polym. Sci. 2010, 117, 3228–3238. [Google Scholar] [CrossRef]

- Lejcuś, K.; Śpitalniak, M.; Dabrowska, J. Swelling Behaviour of Superabsorbent Polymers for Soil Amendment under Different Loads. Polymers 2018, 10, 271. [Google Scholar] [CrossRef]

- Saha, A.; Rattan, B.; Sekharan, S.; Manna, U. Quantifying the Interactive Effect of Water Absorbing Polymer (WAP)-Soil Texture on Plant Available Water Content and Irrigation Frequency. Geoderma 2020, 368, 114310. [Google Scholar] [CrossRef]

- Bryk, M. Resolving Compactness Index of Pores and Solid Phase Elements in Sandy and Silt Loamy Soils. Geoderma 2018, 318, 109–122. [Google Scholar] [CrossRef]

- Sauerwein, M.; Steeb, H. A Modified Effective Stress Principle for Chemical Active Multiphase Materials with Internal Mass Exchange. Geomech. Energy Environ. 2018, 15, 19–34. [Google Scholar] [CrossRef]

- Fennell, E.; Huyghe, J.M. Chemically Responsive Hydrogel Deformation Mechanics: A Review. Molecules 2019, 24, 3521. [Google Scholar] [CrossRef] [Green Version]

- Albalasmeh, A.A.; Hamdan, E.H.; Gharaibeh, M.A.; Hanandeh, A. El Improving Aggregate Stability and Hydraulic Properties of Sandy Loam Soil by Applying Polyacrylamide Polymer. Soil Tillage Res. 2021, 206, 104821. [Google Scholar] [CrossRef]

- Sperry, J.S.; Hacke, U.G. Desert Shrub Water Relations with Respect to Soil Characteristics and Plant Functional Type. Funct. Ecol. 2002, 16, 367–378. [Google Scholar] [CrossRef] [Green Version]

- Li, K.; Yang, H.; Han, X.; Xue, L.; Lv, Y.; Li, J.; Fu, Z.; Li, C.; Shen, W.; Guo, H.; et al. Fractal Features of Soil Particle Size Distributions and Their Potential as an Indicator of Robinia Pseudoacacia Invasion1. Sci. Rep. 2018, 8, 7075. [Google Scholar] [CrossRef]

- Zhao, W.; Cao, T.; Dou, P.; Sheng, J.; Luo, M. Effect of Various Concentrations of Superabsorbent Polymers on Soil Particle-Size Distribution and Evaporation with Sand Mulching. Sci. Rep. 2019, 9, 3511. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Han, Y.; Wang, Q.; Xia, W.; Liu, J.; Wang, J.; Chen, Y.; Shen, J. Experimental Study on the Hydraulic Conductivity of Unsaturated Dispersive Soil with Different Salinities Subjected to Freeze-Thaw. J. Hydrol. 2020, 583, 124297. [Google Scholar] [CrossRef]

- Ning, S.; Jumai, H.; Wang, Q.; Zhou, B.; Su, L.; Shan, Y.; Zhang, J. Comparison of the Effects of Polyacrylamide and Sodium Carboxymethylcellulose Application on Soil Water Infiltration in Sandy Loam Soils. Adv. Polym. Technol. 2019, 2019, 6869454. [Google Scholar] [CrossRef]

- Adamonytė, I.; Grybauskienė, V.; Vyčienė, G. The influence of biological additives on the moisture retention of soil. In Proceedings of the International Scientific Conference “RURAL DEVELOPMENT 2017”; Aleksandras Stulginskis University: Kaunas, Lithuania, 2017; Volume 3230, pp. 839–843. [Google Scholar]

- Ma, T.; Yao, C.; Dong, Y.; Yi, P.; Wei, C. Physicochemical Approach to Evaluating the Swelling Pressure of Expansive Soils. Appl. Clay Sci. 2019, 172, 85–95. [Google Scholar] [CrossRef]

- Carman, P.C. Fluid Flow through Granular Beds. Chem. Eng. Res. Des. 1997, 75, S32–S48. [Google Scholar] [CrossRef]

- Verneuil, E.; Durian, D.J. Permeability of Mixed Soft and Hard Granular Material: Hydrogels as Drainage Modifiers. Eur. Phys. J. E 2011, 34, 65. [Google Scholar] [CrossRef]

- Snd Floerger Aquasorb: Water Retainers for Soils and Substrates. Available online: https://snf.com.au/downloads/Aquasorb_E.pdf (accessed on 15 May 2022).

- Grattoni, C.A.; Al-Sharji, H.H.; Yang, C.; Muggeridge, A.H.; Zimmerman, R.W. Rheology and Permeability of Crosslinked Polyacrylamide Gel. J. Colloid Interface Sci. 2001, 240, 601–607. [Google Scholar] [CrossRef]

- Weissberg, H.L. Effective Diffusion Coefficient in Porous Media. J. Appl. Phys. 1963, 34, 2636–2639. [Google Scholar] [CrossRef]

- Han, Y.; Yu, X.; Yang, P.; Li, B.; Xu, L.; Wang, C. Dynamic Study on Water Diffusivity of Soil with Super-Absorbent Polymer Application. Environ. Earth Sci. 2013, 69, 289–296. [Google Scholar] [CrossRef]

- Zhuang, W.; Li, L.; Liu, C. Effects of Sodium Polyacrylate on Water Retention and Infiltration Capacity of a Sandy Soil. Springerplus 2013, 2, S11. [Google Scholar] [CrossRef] [Green Version]

- Yang, L.; Han, Y.; Yang, P.; Wang, C.; Yang, S.; Kuang, S.; Yuan, H.; Xiao, C. Effects of Superabsorbent Polymers on Infiltration and Evaporation of Soil Moisture Under Point Source Drip Irrigation. Irrig. Drain. 2015, 64, 275–282. [Google Scholar] [CrossRef]

- Montesano, F.F.; Parente, A.; Santamaria, P.; Sannino, A.; Serio, F. Biodegradable Superabsorbent Hydrogel IncreasesWater Retention Properties of Growing Media and Plant Growth. Agric. Agric. Sci. Procedia 2015, 4, 451–458. [Google Scholar] [CrossRef] [Green Version]

- Marschalko, M.; Zięba, Z.; Niemiec, D.; Neuman, D.; Mońka, J.; Dąbrowska, J. Suitability of Engineering-Geological Environment on the Basis of Its Permeability Coefficient: Four Case Studies of Fine-Grained Soils. Materials 2021, 14, 6411. [Google Scholar] [CrossRef] [PubMed]

| Physical Properties | Soil/SAP | ||||

|---|---|---|---|---|---|

| Coarse Sand | Loamy Sand | KM | KS | ||

| Specific Weight [g/cm3] | 2.65 | 2.65 | 1.10 | 1.10 | |

| Bulk Density [g/cm3] | 1.65 | 1.65 | NA | NA | |

| Porosity [-] | 0.38 | 0.38 | NA | NA | |

| Grain Size Distribution [%] | Gravel (>2.00 mm) | 12.34 | 0 | 0 | 0 |

| Sand (0.05 mm–2.00 mm) | 87.66 | 85.01 | 100 | 98.96 | |

| Silt (0.002 mm–0.05 mm) | 0 | 14.99 | 0 | 1.04 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Misiewicz, J.; Datta, S.S.; Lejcuś, K.; Marczak, D. The Characteristics of Time-Dependent Changes of Coefficient of Permeability for Superabsorbent Polymer-Soil Mixtures. Materials 2022, 15, 4465. https://doi.org/10.3390/ma15134465

Misiewicz J, Datta SS, Lejcuś K, Marczak D. The Characteristics of Time-Dependent Changes of Coefficient of Permeability for Superabsorbent Polymer-Soil Mixtures. Materials. 2022; 15(13):4465. https://doi.org/10.3390/ma15134465

Chicago/Turabian StyleMisiewicz, Jakub, Sujit Sankar Datta, Krzysztof Lejcuś, and Daria Marczak. 2022. "The Characteristics of Time-Dependent Changes of Coefficient of Permeability for Superabsorbent Polymer-Soil Mixtures" Materials 15, no. 13: 4465. https://doi.org/10.3390/ma15134465

APA StyleMisiewicz, J., Datta, S. S., Lejcuś, K., & Marczak, D. (2022). The Characteristics of Time-Dependent Changes of Coefficient of Permeability for Superabsorbent Polymer-Soil Mixtures. Materials, 15(13), 4465. https://doi.org/10.3390/ma15134465