Enhanced Energy Storage Properties of La-Doped Sr0.6Ba0.4Nb2O6 Relaxor Ferroelectric Ceramics Prepared by Spark Plasma Sintering

Abstract

:1. Introduction

2. Experimental Procedures

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- He, J.; Liu, X.; Zhao, Y.; Du, H.; Zhang, T.; Shi, J. Dielectric Stability and Energy-Storage Performance of BNT-Based Relaxor Ferroelectrics through Nb5+ and Its Excess Modification. ACS Appl. Electron. Mater. 2022, 4, 735–743. [Google Scholar] [CrossRef]

- Kang, R.; Wang, Z.; Lou, X.; Liu, W.; Shi, P.; Zhu, X.; Guo, X.; Li, S.; Sun, H.; Zhang, L.; et al. Energy storage performance of Bi0.5Na0.5TiO3-based relaxor ferroelectric ceramics with superior temperature stability under low electric fields. Chem. Eng. J. 2021, 410, 128376. [Google Scholar] [CrossRef]

- Zhou, W.; Li, T.; Yuan, M.; Li, B.; Zhong, S.; Li, Z.; Liu, X.; Zhou, J.; Wang, Y.; Cai, H.; et al. Decoupling of inter-particle polarization and intra-particle polarization in core-shell structured nanocomposites towards improved dielectric performance. Energy Storage Mater. 2021, 42, 1–11. [Google Scholar] [CrossRef]

- Shi, J.; Liu, X.; Zhu, F.; Tian, W.; Xia, Y.; Li, T.; Rao, R.; Zhang, T.; Liu, L. Oxygen vacancy migration and its lattice structural origin in A-site non-stoichiometric bismuth sodium titanate perovskites. J. Mater. 2022, 8, 719–729. [Google Scholar] [CrossRef]

- Wang, G.; Lu, Z.; Li, Y.; Li, L.; Ji, H.; Feteira, A.; Zhou, D.; Wang, D.; Zhang, S.; Reaney, I.M. Electroceramics for High-Energy Density Capacitors: Current Status and Future Perspectives. Chem. Rev. 2021, 121, 6124–6172. [Google Scholar] [CrossRef]

- Li, D.; Zeng, X.; Li, Z.; Shen, Z.Y.; Hao, H.; Luo, W.; Wang, X.; Song, F.; Wang, Z.; Li, Y. Progress and perspectives in dielectric energy storage ceramics. J. Adv. Ceram. 2021, 10, 675–703. [Google Scholar] [CrossRef]

- Yang, Z.; Du, H.; Jin, L.; Poelman, D. High-performance lead-free bulk ceramics for electrical energy storage applications: Design strategies and challenges. J. Mater. Chem. A 2021, 9, 18026–18085. [Google Scholar] [CrossRef]

- Bhaumik, I.; Ganesamoorthy, S.; Bhatt, R.; Subramanian, N.; Karnal, A.K.; Gupta, P.K.; Takekawa, S.; Kitamura, K. Influence of cerium doping on the dielectric relaxation of Sr0.75Ba0.25Nb2O6 single crystal grown by the double crucible Stepanov technique. J. Alloys Compd. 2015, 621, 26–29. [Google Scholar] [CrossRef]

- Said, M.; Velayutham, T.S.; Gan, W.C.; Abd Majid, W.H. The structural and electrical properties of SrxBa(1−x)Nb2O6 (SBN) ceramic with varied composition. Ceram. Int. 2015, 41, 7119–7124. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, J.; Zhang, L.; Shi, X.; Liu, S.; Zhang, D. Relaxor transition and properties of Mn-doped SrxBa1−xNb2O6 ferroelectric ceramics. Ceram. Int. 2016, 42, 16697–16702. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, J.; Zhang, L.; Liu, S.; Zhang, D.; Wang, X. Large activation energy in aged Mn-doped Sr0.4Ba0.6Nb2O6 ferroelectric ceramics. RSC Adv. 2017, 7, 26894–26902. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Zhang, L.; Kang, R.; Yang, W.; He, L.; Mao, P.; Lou, X.; Zhang, L.; Wang, J. (Bi0.5Na0.5)TiO3-based relaxor ferroelectrics with enhanced energy-storage density and efficiency under low/moderate-fields via average ionic polarizability design. Chem. Eng. J. 2022, 431, 133716. [Google Scholar] [CrossRef]

- Ma, W.; Fan, P.; Salamon, D.; Kongparakul, S.; Samart, C.; Zhang, T.; Zhang, G.; Jiang, S.; Chang, J.J.; Zhang, H. Fine-grained BNT-based lead-free composite ceramics with high energy-storage density. Ceram. Int. 2019, 45, 19895–19901. [Google Scholar] [CrossRef]

- Luo, C.; Wei, Y.; Feng, Q.; Wang, M.; Luo, N.; Yuan, C.; Zhou, C.; Fujita, T.; Xu, J. Significantly enhanced energy-storage properties of Bi0.47Na0.47Ba0.06TiO3-CaHfO3 ceramics by introducing Sr0.7Bi0.2TiO3 for pulse capacitor application. Chem. Eng. J. 2022, 429, 132165. [Google Scholar] [CrossRef]

- Shi, P.; Zhu, X.; Lou, X.; Yang, B.; Liu, Q.; Kong, C.; Yang, S.; He, L.; Kang, R.; Zhao, J. Tailoring ferroelectric polarization and relaxation of BNT-based lead-free relaxors for superior energy storage properties. Chem. Eng. J. 2022, 428, 132612. [Google Scholar] [CrossRef]

- Song, J.; Han, L.; Liu, T.; Feng, Q.; Luo, Z.; Lu, A. Microstructures and energy storage properties of BSN ceramics with crystallizable glass addition. J. Mater. Sci-Mater Electron. 2018, 29, 5934–5943. [Google Scholar] [CrossRef]

- Xiu, S.; Xiao, S.; Xue, S.; Shen, B.; Zhai, J. Crystallization kinetics behaviour and dielectric properties of strontium barium niobate-based glass–ceramics. J. Mater. Sci.-Mater. Electron. 2016, 27, 5324–5330. [Google Scholar] [CrossRef]

- Zhao, P.; Chen, L.; Li, L.; Wang, X. Ultrahigh energy density with excellent thermal stability in lead-free multilayer ceramic capacitors via composite strategy design. J. Mater. Chem. A 2021, 9, 25914–25921. [Google Scholar] [CrossRef]

- Huang, Y.H.; Wu, Y.J.; Liu, B.; Yang, T.N.; Wang, J.J.; Li, J.; Chen, L.Q.; Chen, X.M. From core–shell Ba0.4Sr0.6TiO3@SiO2 particles to dense ceramics with high energy storage performance by spark plasma sintering. J. Mater. Chem. A 2018, 6, 4477–4484. [Google Scholar] [CrossRef]

- Zhai, Y.; Xie, X.; Zhou, R.; Li, X.; Liu, X.; Liu, S. High performance room temperature ferroelectric barium strontium titanate ceramics by spark-plasma-sintering ultrafine nanocrystals. Ceram. Int. 2019, 45, 15526–15531. [Google Scholar] [CrossRef]

- Ochoa, D.A.; Suñol, F.; Rubio-Marcos, F.; García, J.E. Enhancement of piezoelectric properties stability of submicron-structured piezoceramics obtained by spark plasma sintering. J. Eur. Ceram. Soc. 2018, 38, 4659–4663. [Google Scholar] [CrossRef]

- Tokita, M. Progress of Spark Plasma Sintering (SPS) Method, Systems, Ceramics Applications and Industrialization. Ceramics 2021, 4, 160–198. [Google Scholar] [CrossRef]

- Luan, W.L.; Gao, L.; Guo, J.K. Size effect on dielectric properties of fine-grained BaTiO3 ceramics. Ceram. Int. 1999, 25, 727–729. [Google Scholar] [CrossRef]

- Hanani, Z.; Mezzane, D.; Amjoud, M.; Fourcade, S.; Razumnaya, A.G.; Luk’yanchuk, I.A.; Goune, M. Enhancement of dielectric properties of lead-free BCZT ferroelectric ceramics by grain size engineering. Superlattices Microst. 2019, 127, 109–117. [Google Scholar] [CrossRef] [Green Version]

- Tan, Y.Q.; Zhang, J.L.; Wu, Y.Q.; Wang, C.L.; Koval, V.; Shi, B.G.; Ye, H.T.; McKinnon, R.; Viola, G.; Yan, H.X. Unfolding grain size effects in barium titanate ferroelectric ceramics. Sci. Rep. 2015, 5, 9953. [Google Scholar] [CrossRef] [Green Version]

- Shi, J.; Zhao, Y.; He, J.; Li, T.; Zhu, F.; Tian, W.; Liu, X. Deferred Polarization Saturation Boosting Superior Energy-Storage Efficiency and Density Simultaneously under Moderate Electric Field in Relaxor Ferroelectrics. ACS Appl. Energ. Mater. 2022, 5, 3436–3446. [Google Scholar] [CrossRef]

- Yang, L.; Kong, X.; Li, F.; Hao, H.; Cheng, Z.; Liu, H.; Li, J.F.; Zhang, S. Perovskite lead-free dielectrics for energy storage applications. Prog. Mater. Sci. 2019, 102, 72–108. [Google Scholar] [CrossRef]

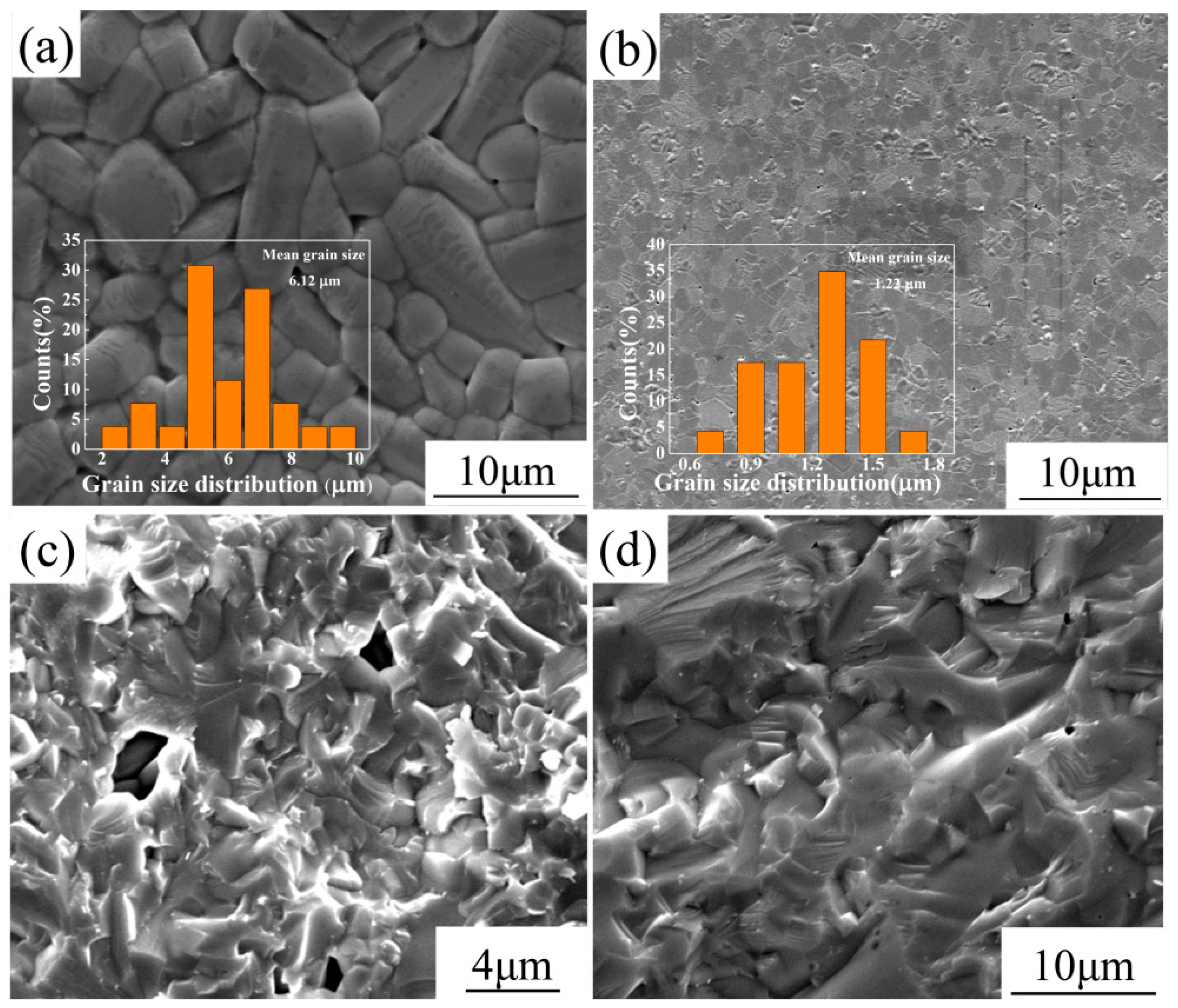

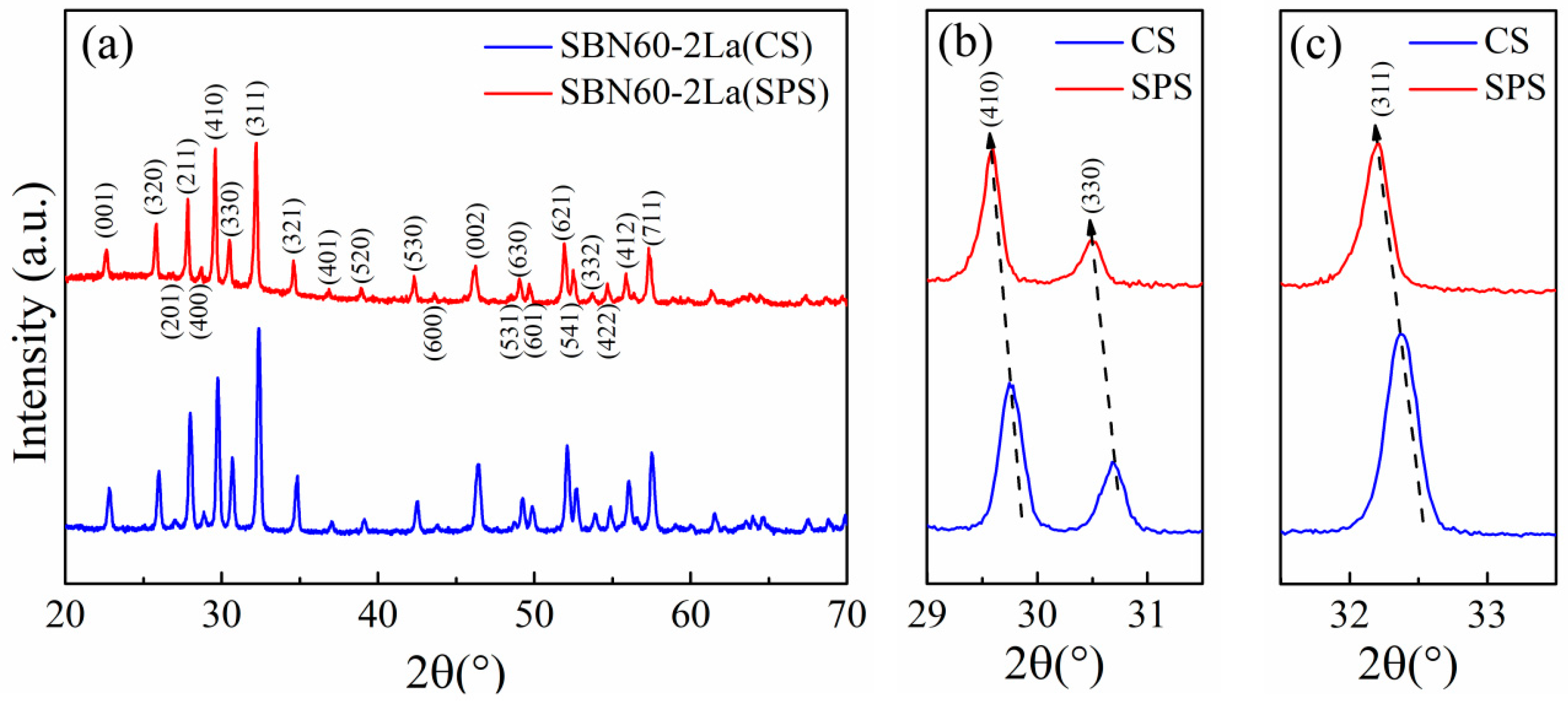

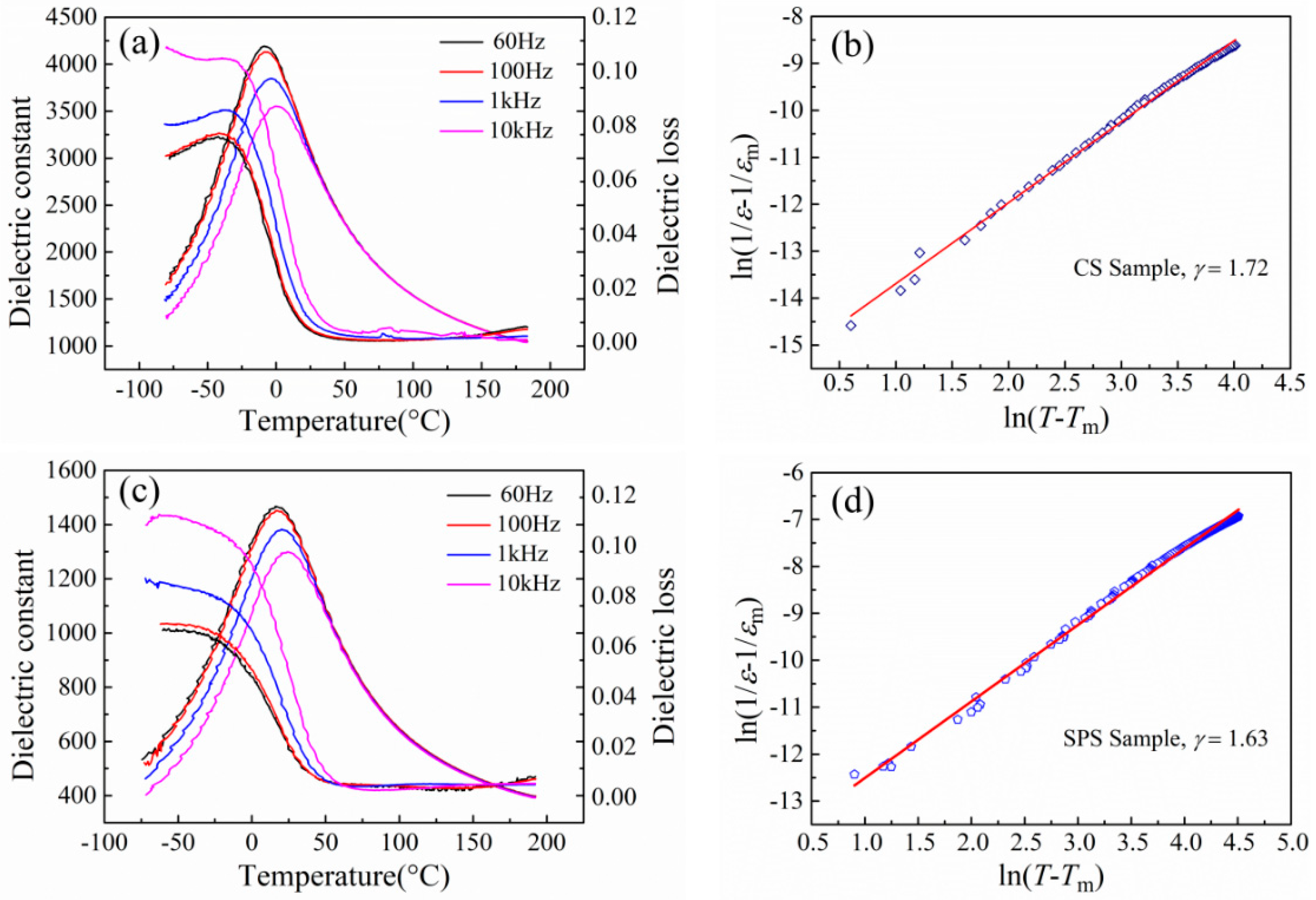

| Ceramics | Relative Density | Mean Grain Size (μm) | Tm/1 kHz (°C) | γ/1 kHz | Wtotal (J·cm−3) | Wrec (J·cm−3) | η |

|---|---|---|---|---|---|---|---|

| CS Sample | 95.3% | 6.12 | −3 | 1.72 | 0.086 | 0.076 | 89.0% |

| SPS Sample | 98.5% | 1.22 | 20 | 1.63 | 0.130 | 0.148 | 87.8% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Liu, X.; Zhang, X.; Du, H. Enhanced Energy Storage Properties of La-Doped Sr0.6Ba0.4Nb2O6 Relaxor Ferroelectric Ceramics Prepared by Spark Plasma Sintering. Materials 2022, 15, 4360. https://doi.org/10.3390/ma15124360

Zhao Y, Liu X, Zhang X, Du H. Enhanced Energy Storage Properties of La-Doped Sr0.6Ba0.4Nb2O6 Relaxor Ferroelectric Ceramics Prepared by Spark Plasma Sintering. Materials. 2022; 15(12):4360. https://doi.org/10.3390/ma15124360

Chicago/Turabian StyleZhao, Yingying, Xiao Liu, Xiaoyu Zhang, and Huiling Du. 2022. "Enhanced Energy Storage Properties of La-Doped Sr0.6Ba0.4Nb2O6 Relaxor Ferroelectric Ceramics Prepared by Spark Plasma Sintering" Materials 15, no. 12: 4360. https://doi.org/10.3390/ma15124360

APA StyleZhao, Y., Liu, X., Zhang, X., & Du, H. (2022). Enhanced Energy Storage Properties of La-Doped Sr0.6Ba0.4Nb2O6 Relaxor Ferroelectric Ceramics Prepared by Spark Plasma Sintering. Materials, 15(12), 4360. https://doi.org/10.3390/ma15124360