Finite Element Analysis of the Mechanical Properties of Axially Compressed Square High-Strength Concrete-Filled Steel Tube Stub Columns Based on a Constitutive Model for High-Strength Materials

Abstract

:1. Introduction

2. Introduction to the Constitutive Relation of the Materials

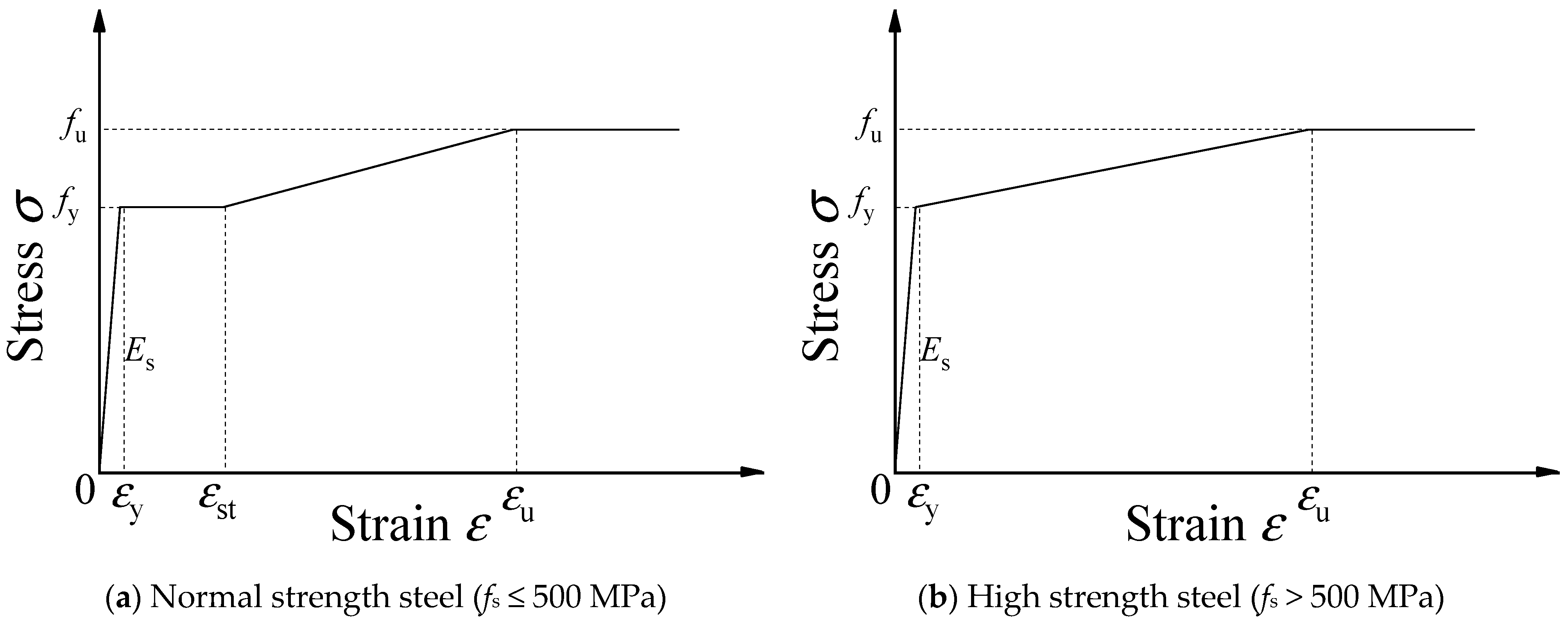

2.1. Stress–Strain Relation for Steel

2.2. Uniaxial Stress–Strain Curve of the Core Concrete

3. Finite Element Theoretical Analysis

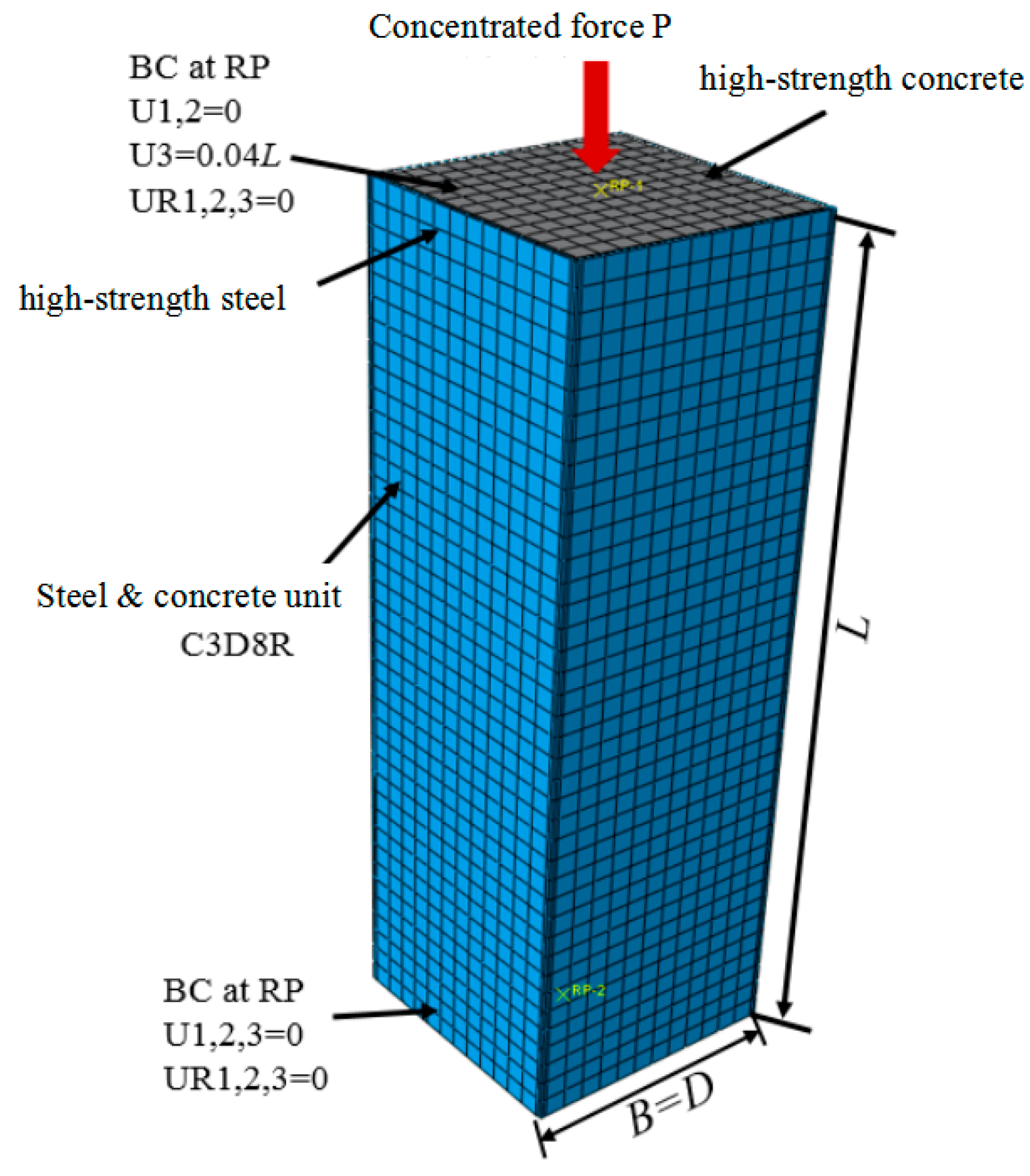

3.1. Element Type and Meshing

3.2. Material Constitutive Model

3.3. Interface Simulation

3.4. Boundary Conditions and Loading Methods

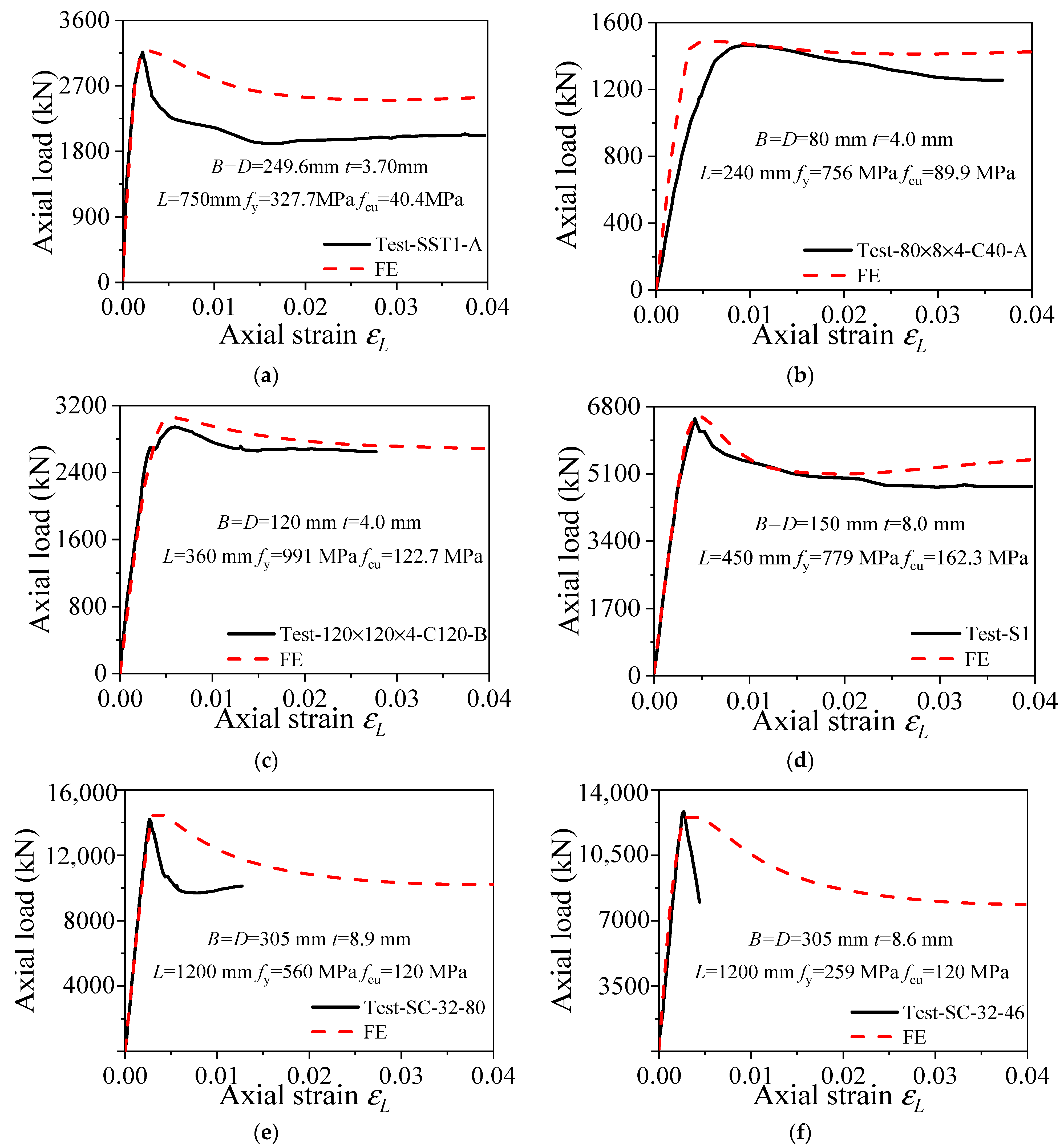

3.5. Model Validation

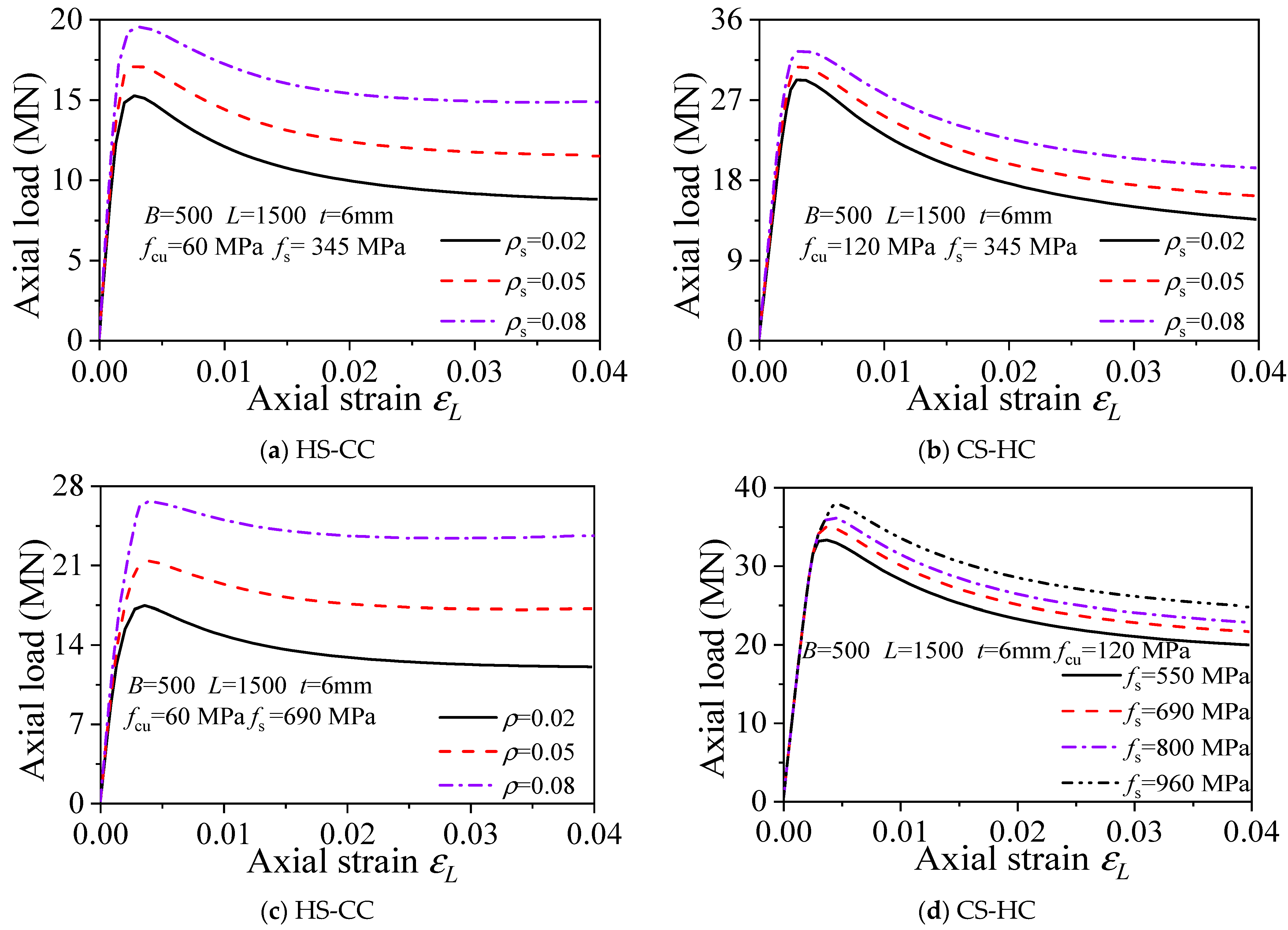

3.6. Parameter Analysis

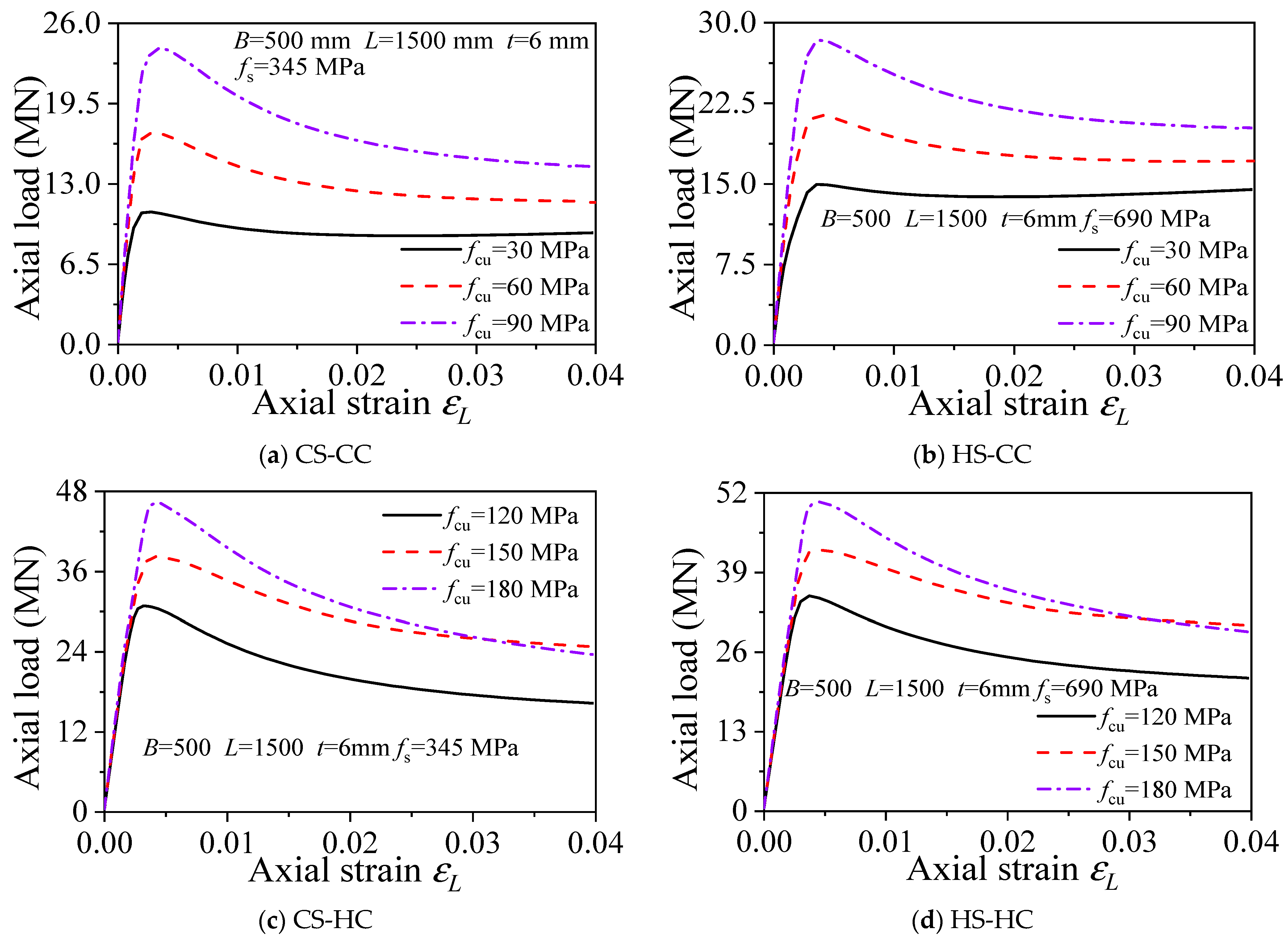

3.6.1. Concrete Strength fcu

3.6.2. Steel Yield Strength fs

3.6.3. Width-to-Thickness Ratio (B/t)

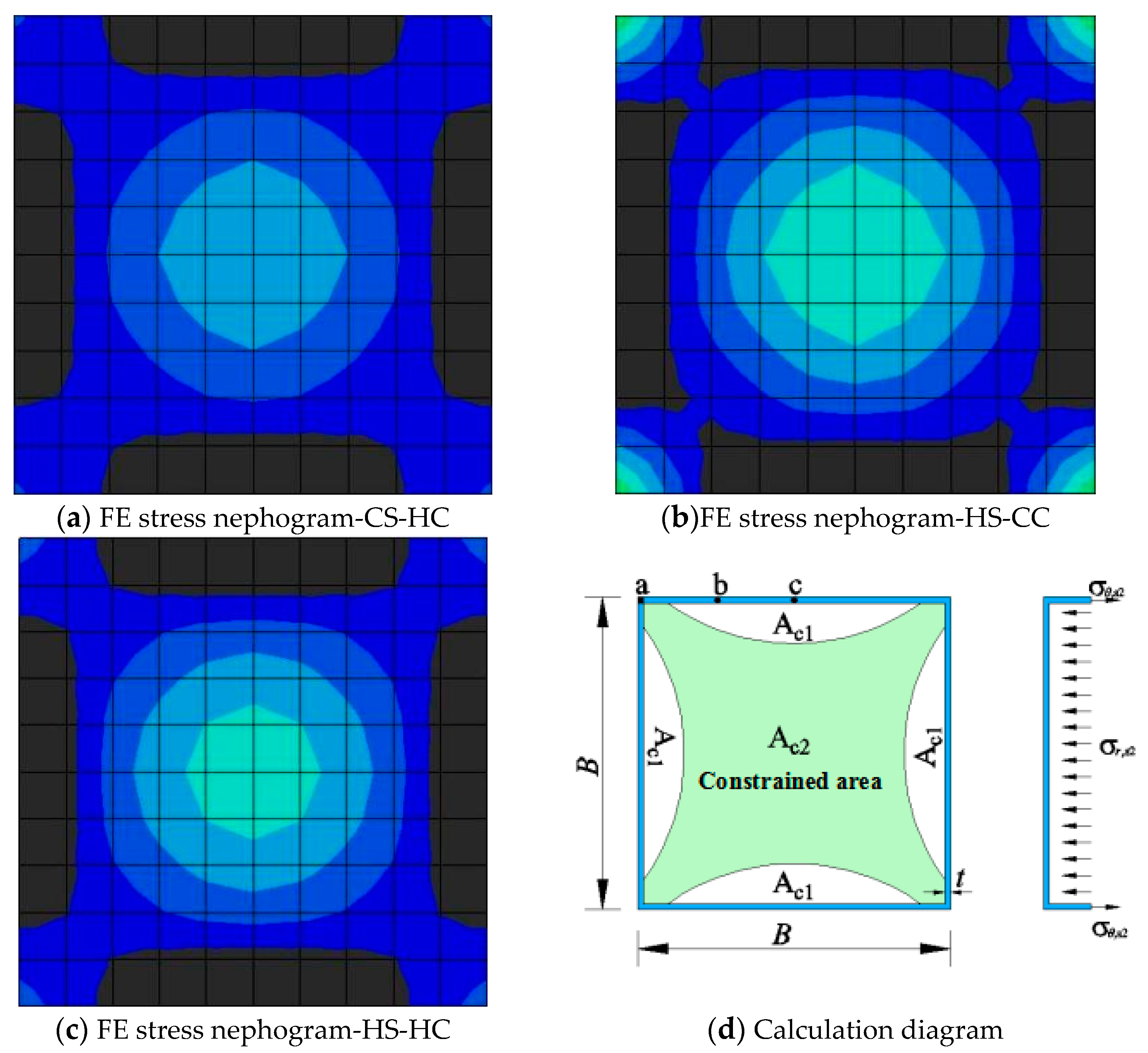

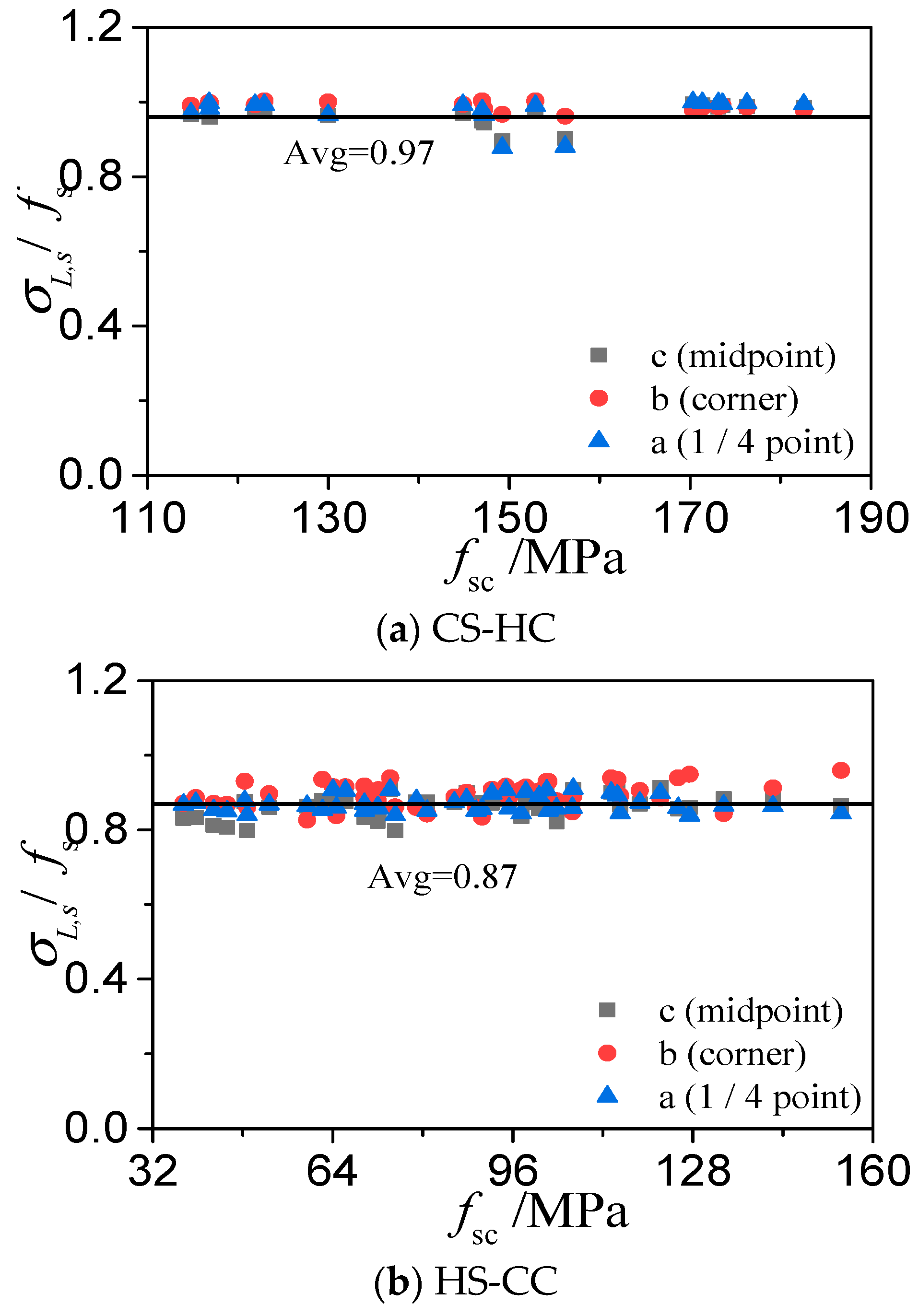

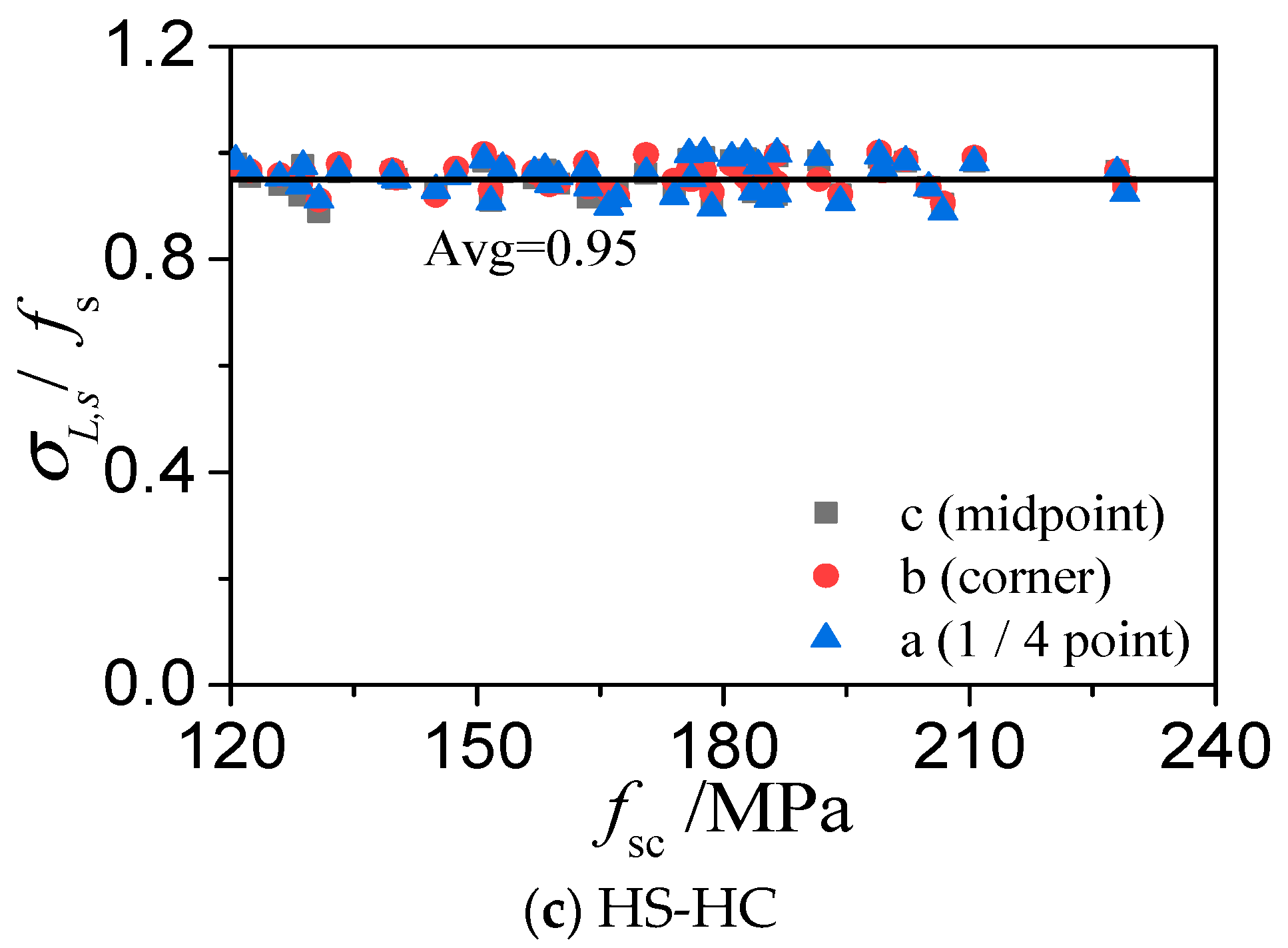

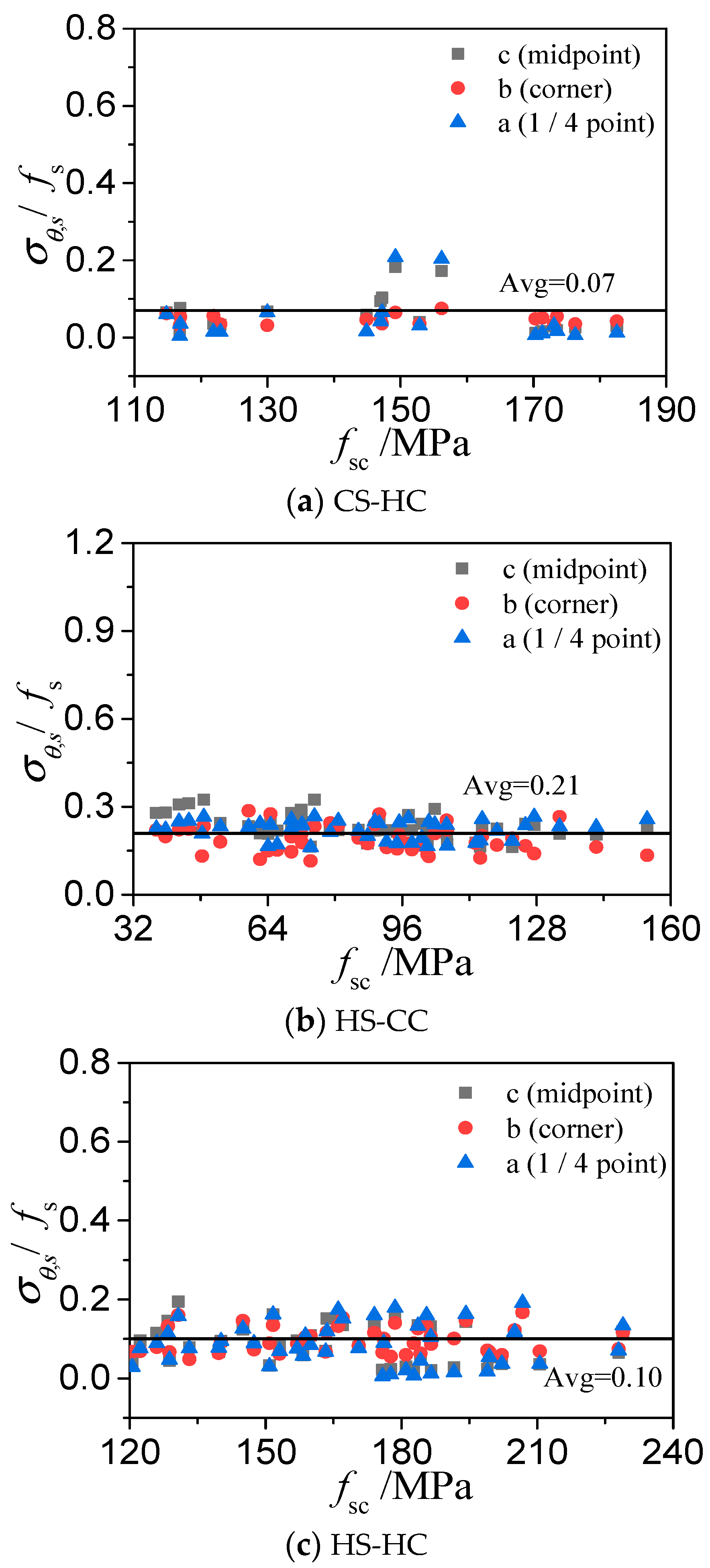

3.7. Analysis of the Confinement Effect

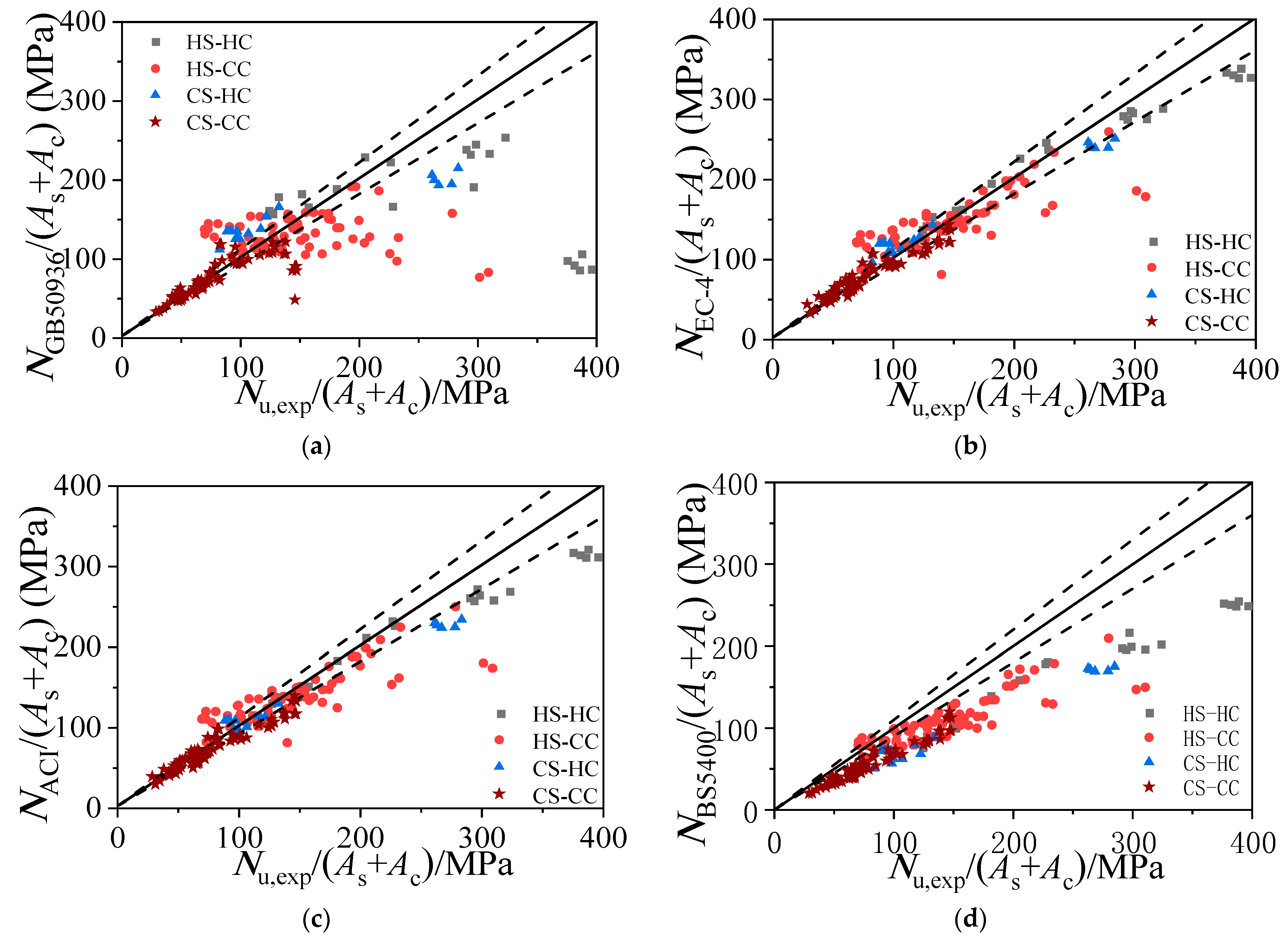

4. Calculation Formula for Bearing Capacity

4.1. Model Simplification and Formula Establishment

4.2. Formula Verification

5. Conclusions

- (1)

- A refined 3D finite element model consisting of 181 sets of axially compressed square HSCFST members is established using the unified constitutive relation of steel and concrete.

- (2)

- A total of 126 groups of examples were constructed to analyze the effects of the diameter-to-thickness ratio, concrete strength fcu, and steel strength fs on the bearing capacity and confinement effect of the members. Increasing the steel yield strength and reducing the concrete strength will weaken the confinement efficiency of the steel tube to the concrete. Among the four types of CFSTs, CS-CC has the strongest confinement effect, while CS-HC has the weakest confinement effect. Compared with concrete strength and the steel yield strength, the width-to-thickness ratio has a greater impact on the initial stiffness of the members. The greater the width-to-thickness ratio of a member is, the greater the initial stiffness of the member.

- (3)

- Based on the equilibrium condition, a practical formula considering the confinement coefficient for the ultimate bearing capacity of square CFST stub columns under axial loading with different material matches was proposed. The proposed formula shows a better calculation accuracy and clearer physical meaning of HSCFST compared with major code formulae.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Specimen Number | Literature | D × t × L/mm | fcu/MPa | fy/MPa | Nu,e/kN | Nu,FE/kN | Nu,Eq/kN | Nu,e/Nu,FE | Nu,e/Nu,Eq |

|---|---|---|---|---|---|---|---|---|---|

| NS1 | [35] | 186×3×558 | 40 | 300 | 1555 | 1628 | 1694 | 0.96 | 0.92 |

| NS7 | 246×3×738 | 47.5 | 300 | 3095 | 2918 | 3005 | 1.06 | 1.03 | |

| NS13 | 306×3×918 | 47.5 | 281 | 4003 | 4179 | 4281 | 0.96 | 0.93 | |

| NS16 | 306×3×918 | 58.75 | 281 | 4658 | 4985 | 5087 | 0.93 | 0.92 | |

| S2 | [36] | 127×4.34×609.6 | 32.5 | 357 | 1095 | 1144 | 1220 | 0.96 | 0.90 |

| S3 | 127×4.55×609.6 | 29.75 | 322 | 1113 | 1189 | 1152 | 0.94 | 0.97 | |

| S4 | 127×5.67×609.6 | 29.75 | 312 | 1202 | 1225 | 1310 | 0.98 | 0.92 | |

| C10K6-1-6-1 | [37] | 150×4.5×1855 | 80.00 | 379.8 | 1895 | 1758 | 1841 | 1.08 | 1.03 |

| C10K6-1-6-2 | 150×4.5×1855 | 80.00 | 379.8 | 1889 | 1758 | 1841 | 1.07 | 1.03 | |

| C10K6-1-6-3 | 150×4.5×1855 | 80.00 | 379.8 | 1886 | 1758 | 1841 | 1.07 | 1.02 | |

| C10K6-1-6-4 | 150×4.5×1855 | 80.00 | 379.8 | 1892 | 1758 | 1841 | 1.08 | 1.03 | |

| C10K6-1-6-5 | 150×4.5×1855 | 80.00 | 379.8 | 1862 | 1758 | 1841 | 1.06 | 1.01 | |

| C10K6-1-6-6 | 150×4.5×1855 | 80.00 | 379.8 | 1890 | 1758 | 1841 | 1.07 | 1.03 | |

| C12K6-1-6-1 | 150×4.5×1855 | 94.00 | 379.8 | 2066.1 | 1935 | 1984 | 1.07 | 1.04 | |

| C12K6-1-6-2 | 150×4.5×1855 | 94.00 | 379.8 | 2196.4 | 2017 | 2017 | 1.09 | 1.09 | |

| C12K6-1-6-3 | 150×4.5×1855 | 94.00 | 379.8 | 2096.1 | 1935 | 2182 | 1.08 | 0.96 | |

| C12K6-1-6-4 | 150×4.5×1855 | 94.00 | 379.8 | 2090.1 | 1935 | 2100 | 1.08 | 1.00 | |

| C12K6-1-6-5 | 150×4.5×1855 | 94.00 | 379.8 | 2006.7 | 1935 | 1853 | 1.04 | 1.08 | |

| C12K6-1-6-6 | 150×4.5×1855 | 94.00 | 379.8 | 2083.5 | 1935 | 1935 | 1.08 | 1.08 | |

| HSS1 | [38] | 110×5×330 | 35 | 750 | 1836 | 1819 | 2024 | 1.01 | 0.91 |

| HSS2 | 110×5×330 | 35 | 750 | 1832 | 1866 | 2024 | 0.98 | 0.91 | |

| HSS8 | 160×5×480 | 37.5 | 750 | 2868 | 2918 | 3127 | 0.98 | 0.92 | |

| HSS9 | 160×5×480 | 37.5 | 750 | 2922 | 2964 | 3220 | 0.99 | 0.91 | |

| CSC40SD8 | [39] | 150×8.275×453 | 43.2 | 488.38 | 3500 | 3326 | 3188 | 1.05 | 1.10 |

| CSC50SD9 | 150×8.275×451 | 55.3 | 488.38 | 3575 | 3518 | 3381 | 1.02 | 1.06 | |

| CR4-A-8 | [40] | 148×4.38×444 | 87 | 262 | 2108 | 2145 | 2211 | 0.98 | 0.95 |

| CR4-A-2 | 148×4.38×444 | 35.4 | 262 | 1153 | 1135 | 1201 | 1.02 | 0.96 | |

| CR4-A-4-1 | 148×4.38×444 | 50.5 | 262 | 1414 | 1435 | 1501 | 0.99 | 0.94 | |

| CR4-A-4-2 | 148×4.38×444 | 50.5 | 262 | 1402 | 1435 | 1501 | 0.98 | 0.93 | |

| CR4-A-4-3 | 210×5.48×630 | 46 | 294 | 3183 | 2830 | 2961 | 1.10 | 1.07 | |

| CR4-C-4-3 | 210×4.5×630 | 46 | 277 | 2713 | 2534 | 2637 | 1.07 | 1.03 | |

| CR4-C-8 | 215×4.38×645 | 90.3 | 262 | 3837 | 4028 | 4221 | 0.92 | 0.91 | |

| CR4-D-4-1 | 323×4.38×645 | 51.375 | 262 | 4950 | 5311 | 5457 | 0.93 | 0.91 | |

| CR6-A-2 | 144×6.36×432 | 31.75 | 618 | 2572 | 2615 | 2831 | 0.98 | 0.91 | |

| CR6-A-4-1 | 144×6.36×432 | 50.625 | 618 | 2808 | 2866 | 3082 | 0.98 | 0.91 | |

| CR6-A-4-2 | 144×6.36×432 | 50.625 | 618 | 2765 | 2655 | 2871 | 1.04 | 0.96 | |

| CR6-A-8 | 144×6.36×432 | 87 | 618 | 3399 | 3125 | 3342 | 1.09 | 1.02 | |

| CR6-C-2 | 211×6.36×633 | 31.75 | 618 | 3920 | 5342 | 5663 | 1.08 | 1.02 | |

| CR6-D-4-1 | 319×6.36×957 | 51.375 | 618 | 7780 | 7138 | 7630 | 1.09 | 1.02 | |

| CR6-D-4-2 | 318×6.36×954 | 51.375 | 618 | 7473 | 7108 | 7598 | 1.05 | 0.98 | |

| CR6-D-8 | 319×6.36×957 | 95.1 | 618 | 10,357 | 10,568 | 11,060 | 0.98 | 0.94 | |

| CR8-A-2 | 120×6.47×360 | 31.75 | 835 | 2819 | 2794 | 3039 | 1.01 | 0.93 | |

| CR8-A-4-1 | 120×6.47×360 | 50.625 | 835 | 2957 | 2971 | 3216 | 1.00 | 0.92 | |

| CR8-A-4-2 | 120×6.47×360 | 50.625 | 835 | 2961 | 2971 | 3216 | 1.00 | 0.92 | |

| CR8-A-8 | 119×6.47×357 | 87 | 835 | 3318 | 3100 | 3343 | 1.07 | 0.99 | |

| CR8-C-2 | 175×6.47×525 | 31.75 | 835 | 4210 | 4343 | 4707 | 0.97 | 0.89 | |

| CR8-C-4-2 | 175×6.47×525 | 50.625 | 835 | 4542 | 4733 | 5097 | 0.96 | 0.89 | |

| CR8-C-8 | 175×6.47×525 | 87 | 835 | 5366 | 5121 | 5485 | 1.05 | 0.98 | |

| CR8-D-2 | 265×6.47×795 | 31.75 | 835 | 6546 | 6691 | 7249 | 0.98 | 0.90 | |

| CR8-D-4-1 | 264×6.47×792 | 51.375 | 835 | 7117 | 7286 | 7841 | 0.98 | 0.91 | |

| CR8-D-4-2 | 265×6.47×795 | 51.375 | 835 | 7172 | 7303 | 7860 | 0.98 | 0.91 | |

| CR8-D-8 | 265×6.47×795 | 90.3 | 835 | 8990 | 8613 | 9171 | 1.04 | 0.98 | |

| CR4-A-9 | 211×5.48×633 | 101.1 | 294 | 4773 | 4552 | 4950 | 0.99 | 0.96 | |

| CR4-C-9 | 211×4.5×633 | 101.1 | 277 | 4371 | 4282 | 4694 | 1.02 | 0.93 | |

| CR6-A-9 | 211×8.83×633 | 113.875 | 536 | 7008 | 7079 | 7008 | 0.99 | 0.95 | |

| CR6-C-9 | 204×5.95×612 | 101.1 | 540 | 5303 | 5766 | 5403 | 0.92 | 0.90 | |

| CR8-A-4-3 | 180×9.45×540 | 48.875 | 825 | 6803 | 6640 | 6587 | 1.02 | 1.03 | |

| CR8-A-9 | 180×9.45×540 | 101.1 | 825 | 7402 | 6786 | 7402 | 1.09 | 0.93 | |

| CR8-C-9 | 180×6.6×540 | 101.1 | 824 | 5873 | 5446 | 5873 | 1.08 | 0.91 | |

| R7-1 | [41] | 106×4×320 | 99 | 495 | 1749 | 1658 | 1739 | 1.05 | 1.01 |

| R7-2 | 106×4×320 | 99 | 495 | 1824 | 1658 | 1739 | 1.10 | 1.05 | |

| R10-1 | 140×4×420 | 99 | 495 | 2752 | 2604 | 2712 | 1.06 | 1.01 | |

| R10-2 | 140×4×420 | 99 | 495 | 2828 | 2604 | 2712 | 1.09 | 1.04 | |

| R1-1 | 120×4×360 | 70 | 495 | 1701 | 1669 | 1760 | 1.02 | 0.97 | |

| R1-2 | 120×4×360 | 70 | 495 | 1657 | 1669 | 1760 | 0.99 | 0.94 | |

| R4-1 | 130×4×390 | 70 | 495 | 2020 | 1884 | 1984 | 1.07 | 1.02 | |

| R4-2 | 130×4×390 | 70 | 495 | 2018 | 1884 | 1984 | 1.07 | 1.02 | |

| R7-1 | 106×4×318 | 99 | 495 | 1749 | 1658 | 1739 | 1.05 | 1.01 | |

| R7-2 | 106×4×318 | 99 | 495 | 1824 | 1658 | 1739 | 1.10 | 1.05 | |

| R10-1 | 140×4×420 | 99 | 495 | 2752 | 2604 | 2712 | 1.06 | 1.01 | |

| R10-2 | 140×4×420 | 99 | 495 | 2828 | 2604 | 2712 | 1.09 | 1.04 | |

| A1 | [42] | 120×5.8×360 | 93 | 300 | 1697 | 1566 | 1773 | 1.08 | 0.96 |

| A2 | 120×5.8×360 | 116 | 300 | 1919 | 1840 | 2078 | 1.04 | 0.92 | |

| A3-1 | 200×5.8×600 | 93 | 300 | 3996 | 3892 | 4243 | 1.03 | 0.94 | |

| A3-2 | 200×5.8×600 | 93 | 300 | 3862 | 3892 | 4162 | 0.99 | 0.93 | |

| A9-1 | 120×4×360 | 65 | 495 | 1739 | 1609 | 1701 | 1.08 | 1.02 | |

| A9-2 | 120×4×360 | 65 | 495 | 1718 | 1609 | 1701 | 1.07 | 1.01 | |

| A12-1 | 130×4×390 | 65 | 495 | 1963 | 1814 | 1914 | 1.08 | 1.03 | |

| A12-2 | 130×4×390 | 65 | 495 | 1988 | 1814 | 1914 | 1.10 | 1.04 | |

| HSSC1 | [43] | 110×5×330 | 64.50 | 701 | 2203.00 | 2048 | 2195 | 1.08 | 1.00 |

| HSSC2 | 110×5×330 | 64.50 | 701 | 2234.00 | 2048 | 2195 | 1.09 | 1.02 | |

| HSSC3 | 140×5×420 | 64.50 | 701 | 2942.00 | 2842 | 3031 | 1.04 | 0.97 | |

| HSSC4 | 140×5×420 | 64.50 | 701 | 2840.00 | 2842 | 3031 | 1.00 | 0.94 | |

| 80 × 80 × 4-C120-A | 80×4×240 | 122.70 | 756 | 1504.00 | 1896 | 1898 | 1.00 | 1.00 | |

| 80 × 80 × 4-C80-B | 80×4×240 | 89.90 | 1022 | 1791 | 1687 | 1811 | 1.06 | 0.99 | |

| 80 × 80 × 4-C120-B | 80×4×240 | 122.70 | 1022 | 1898 | 1896 | 1898 | 1.00 | 1.00 | |

| 100 × 100 × 4-C40-B | 100×4×299.5 | 44.90 | 980 | 2009 | 1852 | 2003 | 1.08 | 1.00 | |

| 100 × 100 × 4-C80-B | 100×4×299.5 | 89.90 | 980 | 2177 | 2210 | 2360 | 0.99 | 0.92 | |

| 100 × 100 × 4-C120-B | 100×4×299.5 | 122.70 | 980 | 2266 | 2431 | 2266 | 0.93 | 0.89 | |

| 120 × 120 × 4-C40-B | 120×4×360 | 44.90 | 991 | 2557 | 2338 | 2522 | 1.09 | 1.01 | |

| 120 × 120 × 4-C80-B | 120×4×359 | 89.90 | 991 | 2853 | 2868 | 3052 | 0.99 | 0.93 | |

| 120 × 120 × 4-C80-B-r | 120×4×359 | 89.90 | 991 | 2798 | 2868 | 3052 | 0.98 | 0.92 | |

| 120 × 120 × 4-C120-B | 120×4×360 | 122.70 | 991 | 2950 | 3089 | 2950 | 0.95 | 0.88 | |

| SC-32-80 | [30] | 305×8.9×1200 | 120.00 | 560 | 14,116 | 14,401 | 14,116 | 0.98 | 0.93 |

| SC-48-80 | 305×6.1×1200 | 120.00 | 660 | 12,307 | 12,749 | 12,307 | 0.97 | 0.86 | |

| SC-32-46 | 305×8.6×1200 | 120.00 | 259 | 11,390 | 10,942 | 11,999 | 1.04 | 0.95 | |

| SC-48-46 | 305×5.8×1200 | 120.00 | 471 | 11,568 | 11,138 | 11,568 | 1.04 | 0.91 | |

| S1 | [44] | 150×8×450 | 162.30 | 779 | 6536 | 6510 | 6536 | 1.00 | 0.99 |

| S2 | 150×8×450 | 167.20 | 779 | 6715 | 6358 | 6715 | 1.06 | 1.00 | |

| S3 | 150×8×450 | 157.00 | 779 | 6616 | 6867 | 6616 | 0.96 | 1.02 | |

| S4 | 150×8×450 | 174.10 | 779 | 7276 | 7557 | 7276 | 0.96 | 1.06 | |

| S5 | 150×8×450 | 158.00 | 779 | 6974 | 6532 | 6974 | 1.07 | 1.07 | |

| S6 | 150×12×450 | 162.30 | 756 | 8585 | 7765 | 8585 | 1.10 | 1.08 | |

| S7 | 150×12×450 | 167.20 | 756 | 8452 | 7850 | 8452 | 1.08 | 1.06 | |

| S8 | 150×12×450 | 157.00 | 756 | 8687 | 7674 | 8687 | 1.03 | 1.10 | |

| S9 | 150×12×450 | 174.10 | 756 | 8730 | 8723 | 8730 | 1.00 | 1.07 | |

| S10 | 150×12×450 | 158.00 | 756 | 8912 | 8135 | 8912 | 1.10 | 1.00 | |

| S11 | 150×12.5×450 | 162.30 | 446 | 5953 | 6355 | 6049 | 0.94 | 0.98 | |

| S12 | 150×12.5×450 | 167.20 | 446 | 5911 | 6439 | 5703 | 0.92 | 1.04 | |

| S13 | 150×12.5×450 | 157.00 | 446 | 6039 | 6265 | 6572 | 0.96 | 0.92 | |

| S14 | 150×12.5×450 | 174.10 | 446 | 6409 | 6557 | 6557 | 0.98 | 0.98 | |

| S15 | 150×12.5×450 | 158.00 | 446 | 6285 | 6282 | 5976 | 1.00 | 1.05 | |

| C1-1 | [45] | 100.3×4.18×300 | 80.80 | 550 | 1490 | 1464 | 1552 | 1.02 | 0.96 |

| C1-2 | 101.5×4.18×300 | 80.80 | 550 | 1535 | 1504 | 1593 | 1.02 | 0.96 | |

| C2-1 | 101.2×4.18×300 | 92.10 | 550 | 1740 | 1601 | 1691 | 1.09 | 1.03 | |

| C2-2 | 100.7×4.18×300 | 92.10 | 550 | 1775 | 1587 | 1676 | 1.12 | 1.06 | |

| C3 | 182.8×4.18×540 | 80.80 | 550 | 3590 | 3727 | 3890 | 0.96 | 0.92 | |

| C4 | 181.8×4.18×540 | 92.10 | 550 | 4210 | 4028 | 4191 | 1.05 | 1.00 | |

| C5-1 | 120.7×4.18×360 | 80.80 | 550 | 1450 | 1462 | 1550 | 0.99 | 0.94 | |

| C5-2 | 119.3×4.18×360 | 80.80 | 550 | 1425 | 1454 | 1543 | 0.98 | 0.92 | |

| C6-1 | 119.6×4.18×360 | 92.10 | 550 | 1560 | 1546 | 1635 | 1.01 | 0.95 | |

| C6-2 | 120.5×4.18×360 | 92.10 | 550 | 1700 | 1556 | 1645 | 1.09 | 1.03 | |

| C7-1 | 179.7×4.18×540 | 80.80 | 550 | 2530 | 2703 | 2838 | 0.94 | 0.89 | |

| C8-1 | 180.4×4.18×540 | 92.10 | 550 | 2970 | 2897 | 3031 | 1.03 | 0.98 | |

| C9-2 | 160.7×4.18×480 | 80.80 | 550 | 1820 | 1852 | 1959 | 0.98 | 0.93 | |

| C10-1 | 160.1×4.18×480 | 92.10 | 550 | 1880 | 1976 | 2083 | 0.95 | 0.90 | |

| C10-2 | 160.6×4.18×480 | 92.10 | 550 | 2100 | 1966 | 2073 | 1.07 | 1.01 | |

| C12-1 | 199.2×4.18×600 | 92.10 | 550 | 2900 | 2801 | 2936 | 1.04 | 0.99 | |

| C12-2 | 199.8×4.18×600 | 92.10 | 550 | 2800 | 2759 | 2893 | 1.01 | 0.97 |

References

- Han, L.H.; Li, W.; Bjorhovde, R. Developments and advanced applications of concrete-filled steel tubular (CFST) structures: Members. J. Constr. Steel Res. 2014, 100, 211–228. [Google Scholar] [CrossRef]

- Ralston, M.; Korman, R. Composite System Stiffened with 19000-psiMix. Eng. News Rec. 1989, 222, 44–53. [Google Scholar]

- Abed, F.; Alhamaydeh, M.; Abdalla, S. Experimental and numerical investigations of the compressive behavior of concrete filled steel tubes (CFSTs). J. Constr. Steel Res. 2013, 80, 429–439. [Google Scholar] [CrossRef]

- Uy, B. Local and post-local buckling of concrete filled steel welded box columns. J. Constr. Steel Res. 2018, 47, 47–72. [Google Scholar] [CrossRef]

- Bradford, M.A.; Loh, H.Y.; Uy, B. Slenderness limits for filled circular steel tubes. J. Constr. Steel Res. 2002, 58, 243–252. [Google Scholar] [CrossRef]

- Yu, Z.; Ding, F.; Cai, C.S. Experimental behavior of circular concrete-filled steel tube stub columns. J. Constr. Steel Res. 2007, 63, 165–174. [Google Scholar] [CrossRef]

- Aboutaha, R.; Machado, R. Seismic resistance of steel-tubed high-strength reinforced-concrete columns. J. Struct. Eng. 1999, 125, 485–494. [Google Scholar] [CrossRef]

- Han, L.H.; Huo, J.S.; Yang, Y.F. Concrete-filled HSS columns after exposure to the Iso-834 standard fire. Adv. Steel Constr. 2002, 2, 1127–1134. [Google Scholar]

- Chen, M.; Lin, B.; Huang, H. Research on the Bearing Capacity of Corroded Circular Concrete Filled Steel Tubular Short Columns. Prog. Steel Build. Struct. 2018, 20, 73–81. [Google Scholar]

- Zhong, S.T. Comparison of behaviors and economics for concrete-filled steel tube with circular and square cross-sections. NCREE 2003, 20, 199–206. [Google Scholar]

- Ding, F.X.; Lu, D.R.; Bai, Y.; Zhou, Q.S.; Ni, M.; Yu, Z.W.; Jiang, G.S. Comparative study of square stirrup-confined concrete-filled steel tubular stub columns under axial loading. Thin-Walled Struct. 2016, 98, 443–453. [Google Scholar] [CrossRef]

- Patel, V.I.; Hassanein, M.F.; Thai, H.T.; Abadi, H.A.; Elchalakani, M.; Bai, Y. Ultra-high strength circular short CFST columns: Axisymmetric analysis, behaviour and design. Eng. Struct. 2019, 179, 268–283. [Google Scholar] [CrossRef]

- Ekmekyapar, T.; AL-Eliwi, B.J.M. Experimental behaviour of circular concrete filled steel tube columns and design specifications. Thin-Walled Struct. 2016, 105, 220–230. [Google Scholar] [CrossRef]

- Sojobi, A.O.; Aladegboye, O.J.; Awolusi, T.F. Green interlocking paving units. Constr. Build. Mater. 2018, 173, 600–614. [Google Scholar] [CrossRef]

- Tys, A.; Kai, X.B. Performance of axially-loaded concrete-filled steel tubular circular columns using ultra-high strength concrete. Structures 2020, 24, 163–176. [Google Scholar]

- Jin, L.; Fan, L.; Li, D.; Du, X. Size effect of square concrete-filled steel tubular columns subjected to lateral shear and axial compression: Modelling and formulation. Thin-Walled Struct. 2020, 157, 107158. [Google Scholar] [CrossRef]

- Yin, F.; Zhang, J.; Xu, P. Summary of Research on Concrete Filled Steel Tubular (CFST) Columns. Adv. Mater. Res. 2012, 594–597, 891–895. [Google Scholar] [CrossRef]

- Yan, Y.; Xu, L.; Li, B.; Chi, Y.; Yu, M.; Zhou, K.; Song, Y. Axial behavior of ultra-high performance concrete (UHPC) filled stocky steel tubes with square sections. J. Constr. Steel Res. 2019, 158, 417–428. [Google Scholar] [CrossRef]

- Lai, Z.; Varma, A.H. High-strength rectangular CFT members: Database, modeling, and design of short columns. J. Struct. Eng. 2018, 144, 04018036. [Google Scholar] [CrossRef]

- Cai, Y.; Su, M.; Chen, X.; Young, B. High strength steel square and rectangular tubular stub columns infilled with concrete. J. Constr. Steel Res. 2021, 179, 106536. [Google Scholar] [CrossRef]

- Ding, F.; Cao, Z.; Lyu, F.; Huang, S.; Hu, M.; Lin, Q. Practical design equations of the axial compressive capacity of circular CFST stub columns based on finite element model analysis incorporating constitutive models for high-strength materials. Case Stud. Constr. Mater. 2022, 16, e01115. [Google Scholar] [CrossRef]

- Ding, F.; Wu, X.; Xiang, P.; Yu, Z. New Damage Ratio Strength Criterion for Concrete and Lightweight Aggregate Concrete. ACI Struct. J. 2021, 118, 165–178. [Google Scholar]

- Hassanein, M.F. Numerical modelling of concrete-filled lean duplex slender stainless steel tubular stub columns. J. Constr. Steel Res. 2010, 66, 1057–1068. [Google Scholar] [CrossRef]

- Lu, D.R.; Wang, W.J.; Ding, F.; Liu, X.M.; Fang, C.J. The impact of stirrups on the composite action of concrete-filled steel tubular stub columns under axial loading. Structures 2021, 30, 786–802. [Google Scholar] [CrossRef]

- Ding, F.; Wang, W.; Lu, D.; Liu, X. Study on the behavior of concrete-filled square double-skin steel tubular stub columns under axial loading. Structures 2020, 23, 665–676. [Google Scholar] [CrossRef]

- Xu, Y. Confinement effect and efficiency of concentrically loaded RACFCST stub columns. Materials 2021, 15, 154. [Google Scholar]

- Ding, F.; Zhu, J.; Cheng, S.; Liu, X. Comparative study of stirrup-confined circular concrete-filled steel tubular stub columns under axial loading. Thin-Walled Struct. 2018, 123, 294–304. [Google Scholar] [CrossRef] [Green Version]

- Xiong, M.X.; Xiong, D.X.; Liew, J. Axial performance of short concrete filled steel tubes with high- and ultra-high- strength materials. Eng. Struct. 2017, 136, 494–510. [Google Scholar] [CrossRef]

- Varma, A.H.; Sause, R.; Ricles, J.M.; Li, Q. Development and validation of fiber model for high-strength square concrete-filled steel tube beam-columns. ACI Struct. J. 2005, 102, 73–84. [Google Scholar]

- Sojobi, A.O.; Liew, K.M. Flexural behaviour and efficiency of CFRP-laminate reinforced recycled concrete beams: Optimization using linear weighted sum method. Compos. Struct. 2021, 260, 113259. [Google Scholar] [CrossRef]

- BS EN 1994-1-1:2004 Eurocode 4; Design of Composite Steel and Concrete Structures General Rules and Rules for Buildings. British Standards Institution: London, UK, 2004; pp. 1–121.

- BS 5400-5:2005; Steel, Concrete and Composite Bridges. Part 5: Code of Practice for Design of Composite Bridges. British Standards Institution: London, UK, 2005; pp. 1–48.

- GB 50936-2014; Technical Code for Concrete Filled Steel Tubular Structures. China Architecture & Building Press: Beijng, China, 2014; pp. 1–184.

- American Concrete Institute. Commentary on Building Code Requirements for Structural Concrete (ACI 318R-14); ACI: Detroit, MI, USA, 2011; pp. 1–524. [Google Scholar]

- Uy, B. Axial compressive strenth of short steel and composite columns fabricated with high strength steel plate. Steel Compos. Struct. 2001, 1, 171–185. [Google Scholar] [CrossRef]

- Schneider, S.P. Axially loaded concrete-filled steel tubes. J. Struct. Eng. 1999, 124, 1125–1138. [Google Scholar] [CrossRef]

- Lue, D.M.; Liu, J.; Yen, T. Experimental study on rectangular CFT columns with high-strength concrete. J. Constr. Steel Res. 2007, 63, 37–44. [Google Scholar] [CrossRef]

- Uy, B. Strength of short concrete filled high strength steel box columns. J. Constr. Steel Res. 2001, 57, 113–134. [Google Scholar] [CrossRef]

- Du, Y.; Chen, Z.; Liewc, J.Y.R.; Xiong, M. Rectangular concrete-filled steel tubular beam-columns using high-strength steel: Experiments and design. J. Constr. Steel Res. 2017, 131, 1–18. [Google Scholar] [CrossRef]

- Sakino, K.; Nakahara, H.; Morino, S. Behavior of Centrally Loaded Concrete-Filled Steel-Tube Short Columns. J. Struct. Eng. 2004, 130, 180–188. [Google Scholar] [CrossRef]

- Liu, D. Tests on high-strength rectangular concrete-filled steel hollow section stub columns. J. Constr. Steel Res. 2005, 61, 902–911. [Google Scholar] [CrossRef]

- Liu, D.; Gho, W.M. Axial load behaviour of high-strength rectangular concrete-filled steel tubular stub columns. Thin-Walled Struct. 2005, 43, 1131–1142. [Google Scholar] [CrossRef]

- Aslani, F.; Uy, B.; Tao, Z.; Mashiri, F. Behaviour and design of composite columns incorporating compact high-strength steel plates. J. Constr. Steel Res. 2015, 107, 94–110. [Google Scholar] [CrossRef]

- Xiong, M.; Xiong, D.; RichardLiew, J.Y. Behaviour of steel tubular members infilled with ultra high strength concrete. J. Constr. Steel Res. 2017, 138, 168–183. [Google Scholar] [CrossRef]

- Liu, D.; Gho, W.M.; Yuan, J. Ultimate capacity of high-strength rectangular concrete-filled steel hollow section stub columns. J. Constr. Steel Res. 2003, 59, 1499–1515. [Google Scholar] [CrossRef]

| Types | fs | fc | L | B | D | t | D/t | L/D |

|---|---|---|---|---|---|---|---|---|

| CS-CC | 235 | 30 | 1500 | 500 | 500 | 3 | 167 | 500 |

| CS-CC | 60 | 500 | 500 | 6 | 83 | |||

| CS-CC | 90 | 500 | 500 | 10 | 50 | |||

| CS-HC | 120 | 500 | 500 | 3 | 167 | |||

| CS-HC | 150 | 500 | 500 | 6 | 83 | |||

| CS-HC | 180 | 500 | 500 | 10 | 50 | |||

| CS-CC | 345 | 30 | 1500 | 500 | 500 | 3 | 167 | 500 |

| CS-CC | 60 | 500 | 500 | 6 | 83 | |||

| CS-CC | 90 | 500 | 500 | 10 | 50 | |||

| CS-HC | 120 | 500 | 500 | 3 | 167 | |||

| CS-HC | 150 | 500 | 500 | 6 | 83 | |||

| CS-HC | 180 | 500 | 500 | 10 | 50 | |||

| CS-CC | 460 | 30 | 1500 | 500 | 500 | 3 | 167 | 500 |

| CS-CC | 60 | 500 | 500 | 6 | 83 | |||

| CS-CC | 90 | 500 | 500 | 10 | 50 | |||

| CS-HC | 120 | 500 | 500 | 3 | 167 | |||

| CS-HC | 150 | 500 | 500 | 6 | 83 | |||

| CS-HC | 180 | 500 | 500 | 10 | 50 | |||

| HS-CC | 550 | 30 | 1500 | 500 | 500 | 3 | 167 | 500 |

| HS-CC | 60 | 500 | 500 | 6 | 83 | |||

| HS-CC | 90 | 500 | 500 | 10 | 50 | |||

| HS-HC | 120 | 500 | 500 | 3 | 167 | |||

| HS-HC | 150 | 500 | 500 | 6 | 83 | |||

| HS-HC | 180 | 500 | 500 | 10 | 50 | |||

| HS-CC | 690 | 30 | 1500 | 500 | 500 | 3 | 167 | 500 |

| HS-CC | 60 | 500 | 500 | 6 | 83 | |||

| HS-CC | 90 | 500 | 500 | 10 | 50 | |||

| HS-HC | 120 | 500 | 500 | 3 | 167 | |||

| HS-HC | 150 | 500 | 500 | 6 | 83 | |||

| HS-HC | 180 | 500 | 500 | 10 | 50 | |||

| HS-CC | 800 | 30 | 1500 | 500 | 500 | 3 | 167 | 500 |

| HS-CC | 60 | 500 | 500 | 6 | 83 | |||

| HS-CC | 90 | 500 | 500 | 10 | 50 | |||

| HS-HC | 120 | 500 | 500 | 3 | 167 | |||

| HS-HC | 150 | 500 | 500 | 6 | 83 | |||

| HS-HC | 180 | 500 | 500 | 10 | 50 | |||

| HS-CC | 960 | 30 | 1500 | 500 | 500 | 3 | 167 | 500 |

| HS-CC | 60 | 500 | 500 | 6 | 83 | |||

| HS-CC | 90 | 500 | 500 | 10 | 50 | |||

| HS-HC | 120 | 500 | 500 | 3 | 167 | |||

| HS-HC | 150 | 500 | 500 | 6 | 83 | |||

| HS-HC | 180 | 500 | 500 | 10 | 50 |

| Match Type | Formula | α | β | K | Quantity | Equation (16) | FE | ||

|---|---|---|---|---|---|---|---|---|---|

| Average | Dispersion | Average | Dispersion | ||||||

| CS-CC | Nu = fcAc + KfsAs | 0.96 | 0.19 | 1.20 | 74 | 1.02 | 0.083 | 1.08 | 0.043 |

| HS-CC | 0.87 | 0.21 | 1.14 | 68 | 0.96 | 0.083 | 0.98 | 0.062 | |

| HS-HC | 0.95 | 0.10 | 1.07 | 20 | 1.03 | 0.080 | 1.02 | 0.061 | |

| CS-HC | 0.97 | 0.07 | 1.06 | 19 | 1.00 | 0.091 | 0.99 | 0.058 | |

| total | 1.00 | 0.065 | 1.02 | 0.038 | |||||

| Reference | Formulas | Average Values (Nu,exp/Nu,ref) | Dispersion Coefficient (Nu,exp/Nu,ref) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| CS- CC | HS- CC | CS- HC | HS- HC | Total | CS- CC | HS- CC | CS- HC | HS- HC | Total | ||

| GB50936 (2014) | 1.06 | 1.17 | 0.91 | 1.84 | 1.17 | 0.300 | 0.473 | 0.296 | 0.733 | 0.552 | |

| EC4 (2004) | 0.99 | 1.00 | 0.93 | 1.03 | 0.99 | 0.131 | 0.125 | 0.139 | 0.104 | 0.172 | |

| BS 5400 (1979) | 1.43 | 1.32 | 1.51 | 1.10 | 1.39 | 0.076 | 0.176 | 0.111 | 0.111 | 0.142 | |

| ACI-318 (2011) | 1.07 | 1.07 | 1.03 | 1.10 | 1.07 | 0.124 | 0.201 | 0.127 | 0.092 | 0.160 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, B.; Ding, F.; Lu, D.; Lyu, F.; Huang, S.; Cao, Z.; Wang, H. Finite Element Analysis of the Mechanical Properties of Axially Compressed Square High-Strength Concrete-Filled Steel Tube Stub Columns Based on a Constitutive Model for High-Strength Materials. Materials 2022, 15, 4313. https://doi.org/10.3390/ma15124313

Li B, Ding F, Lu D, Lyu F, Huang S, Cao Z, Wang H. Finite Element Analysis of the Mechanical Properties of Axially Compressed Square High-Strength Concrete-Filled Steel Tube Stub Columns Based on a Constitutive Model for High-Strength Materials. Materials. 2022; 15(12):4313. https://doi.org/10.3390/ma15124313

Chicago/Turabian StyleLi, Biao, Faxing Ding, Deren Lu, Fei Lyu, Shijian Huang, Zheya Cao, and Haibo Wang. 2022. "Finite Element Analysis of the Mechanical Properties of Axially Compressed Square High-Strength Concrete-Filled Steel Tube Stub Columns Based on a Constitutive Model for High-Strength Materials" Materials 15, no. 12: 4313. https://doi.org/10.3390/ma15124313

APA StyleLi, B., Ding, F., Lu, D., Lyu, F., Huang, S., Cao, Z., & Wang, H. (2022). Finite Element Analysis of the Mechanical Properties of Axially Compressed Square High-Strength Concrete-Filled Steel Tube Stub Columns Based on a Constitutive Model for High-Strength Materials. Materials, 15(12), 4313. https://doi.org/10.3390/ma15124313