Microstructural Evolution, Tensile Failure, Fatigue Behavior and Wear Properties of Al2O3 Reinforced Al2014 Alloy T6 Heat Treated Metal Composites

Abstract

:1. Introduction

2. Preparation of the Al2014-Al2O3 MMCs and Experimentation Details

2.1. Details of Matrix and Microparticulate Reinforcement Materials

2.2. Preparation of the Al2014-Al2O3 MMCs

2.3. Experimental Details

3. Results and Discussions

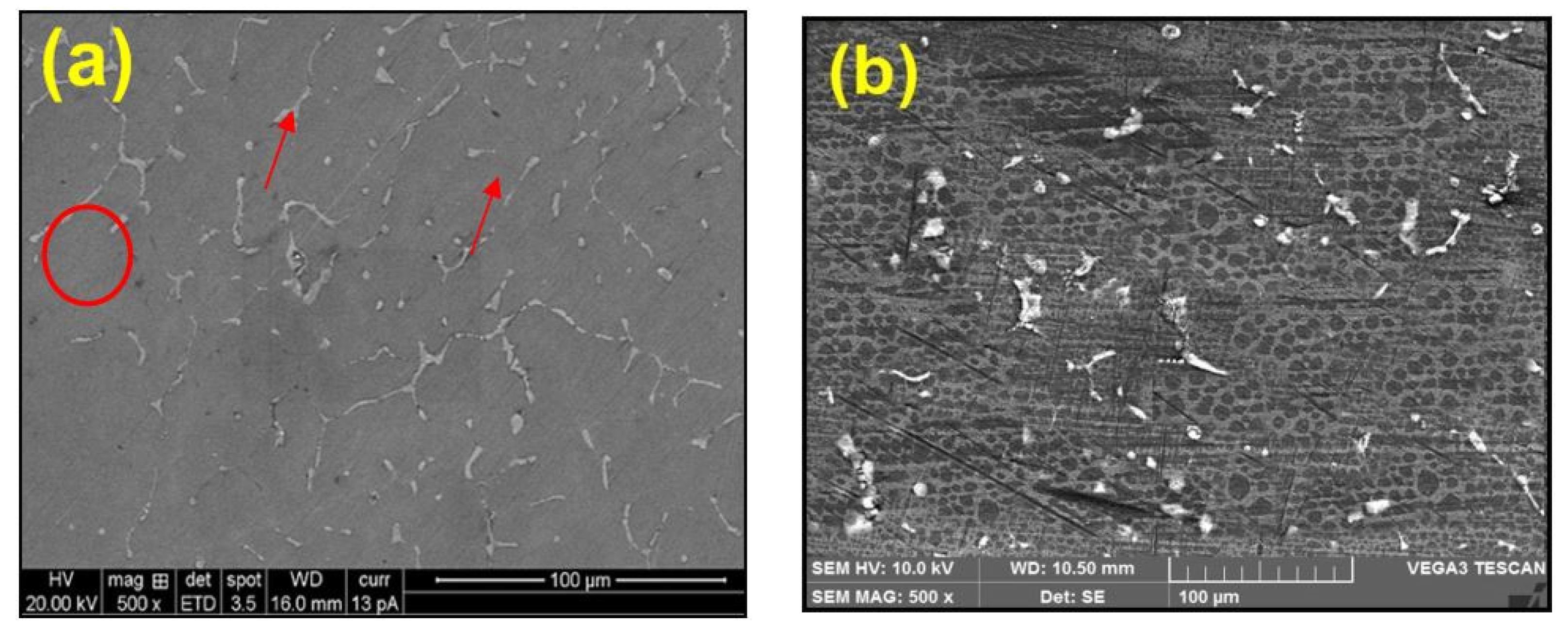

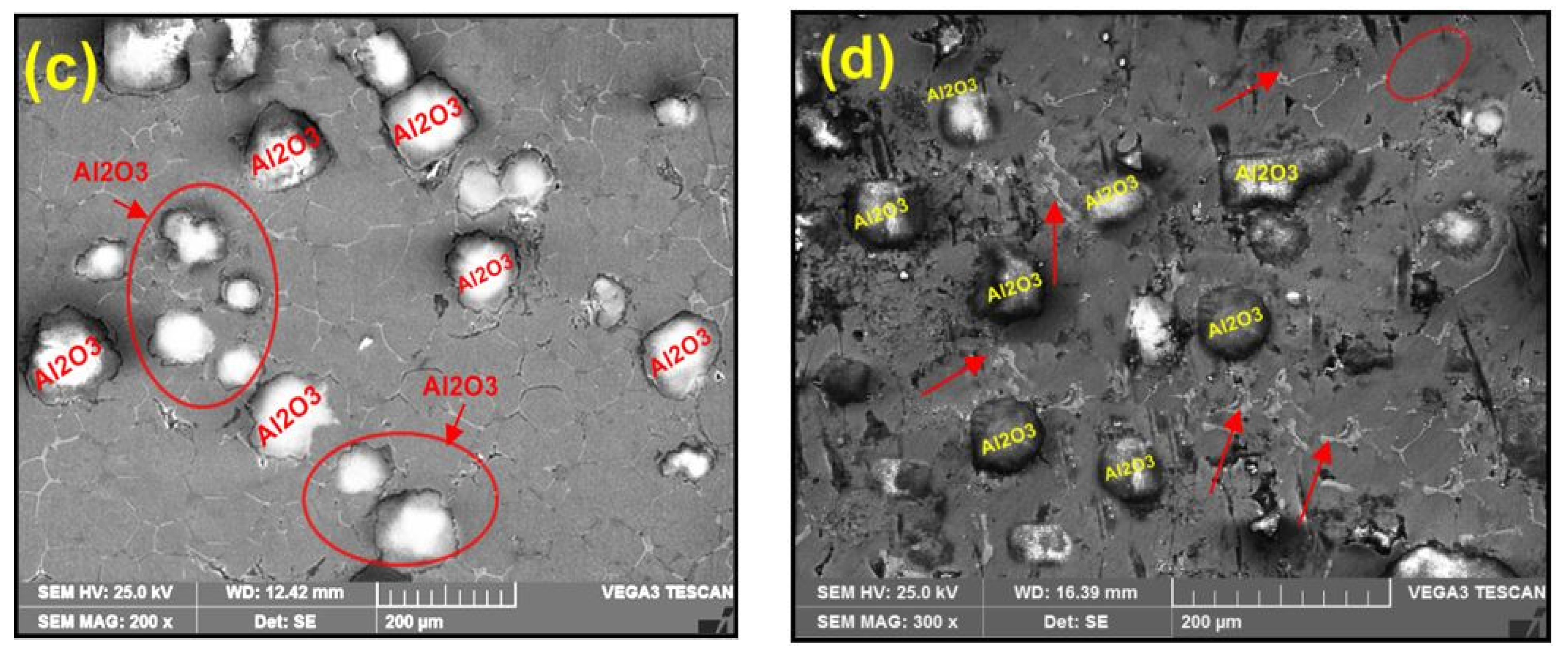

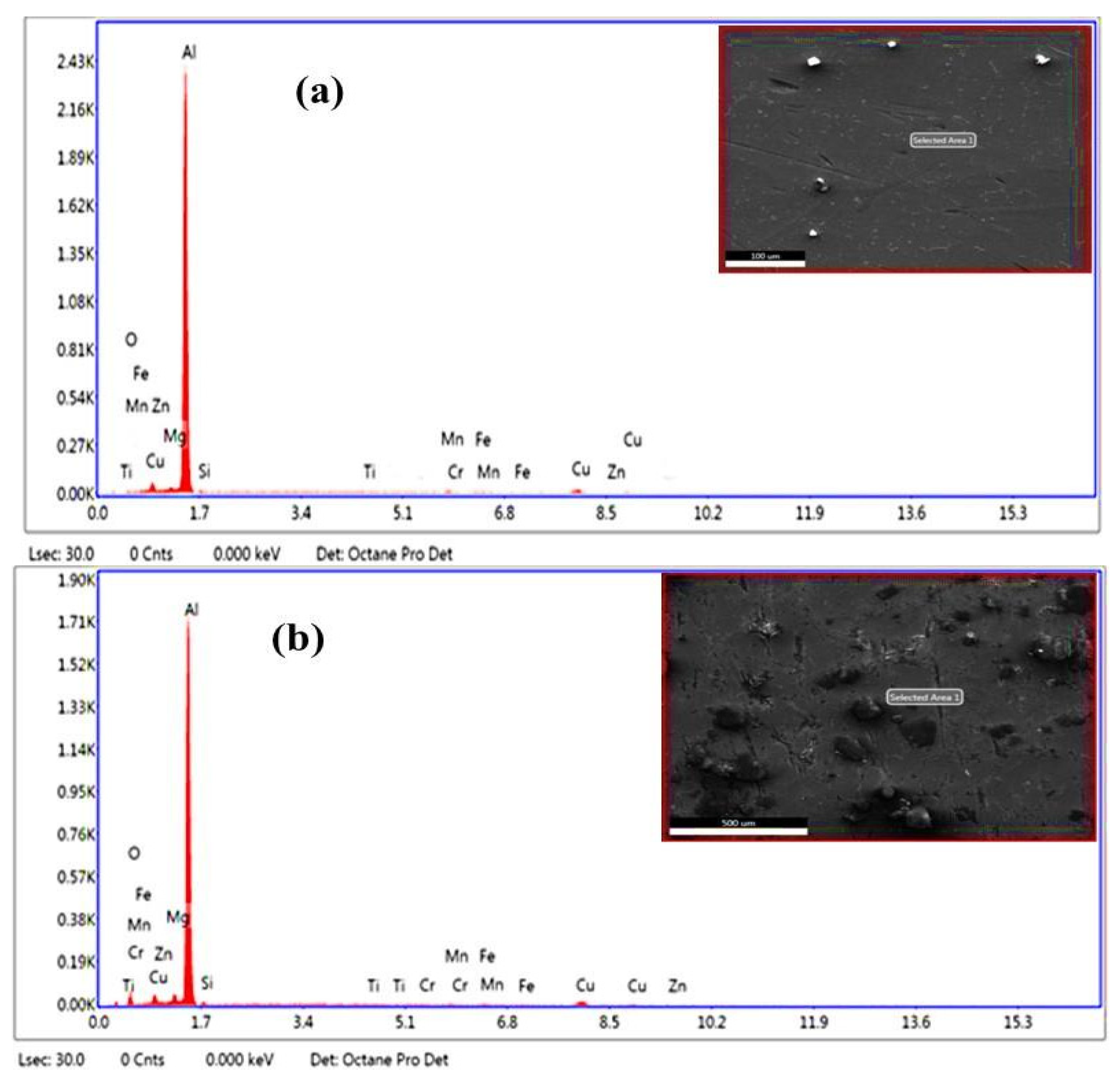

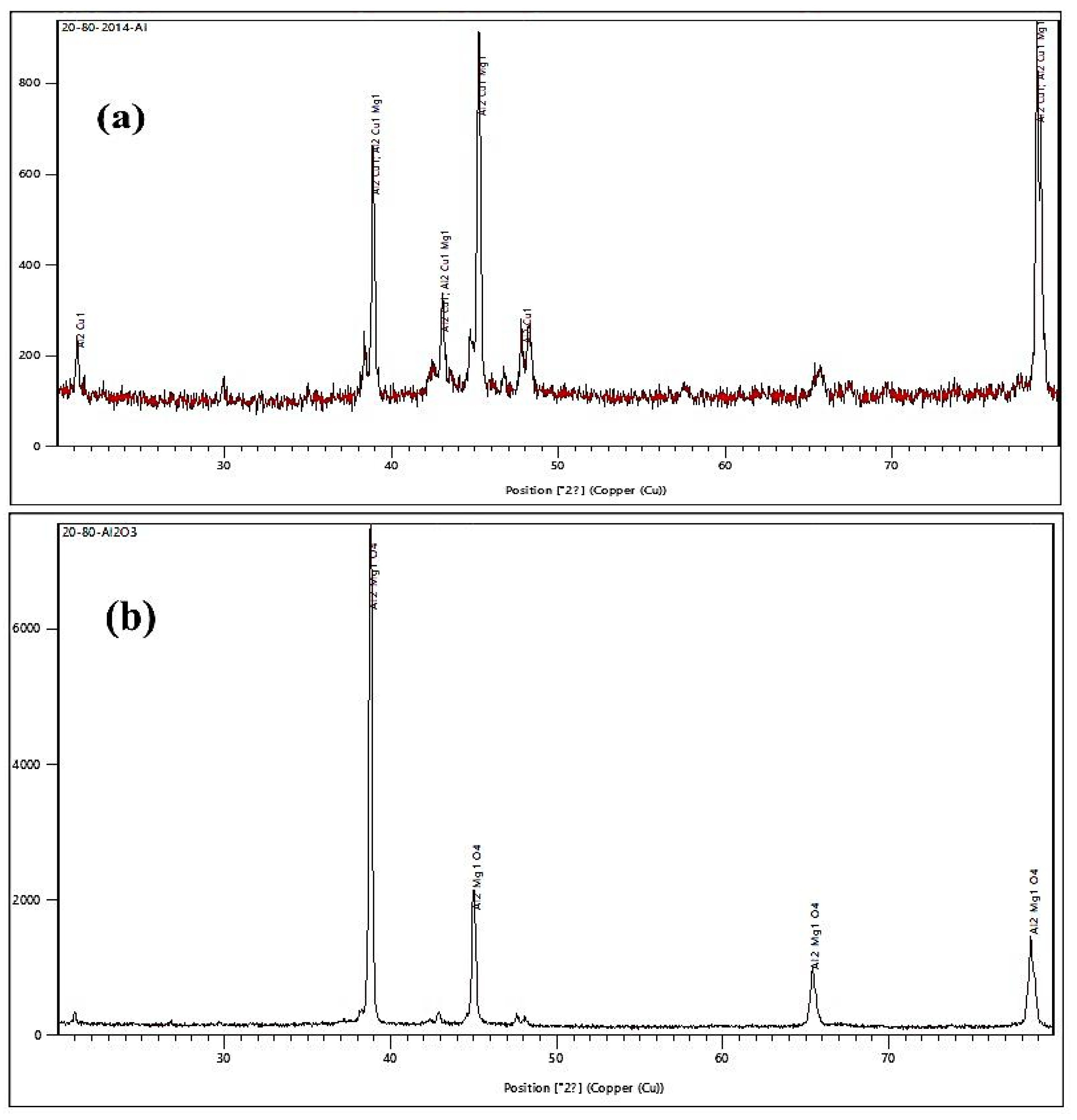

3.1. Microstructural Studies

3.2. Hardness Measurements

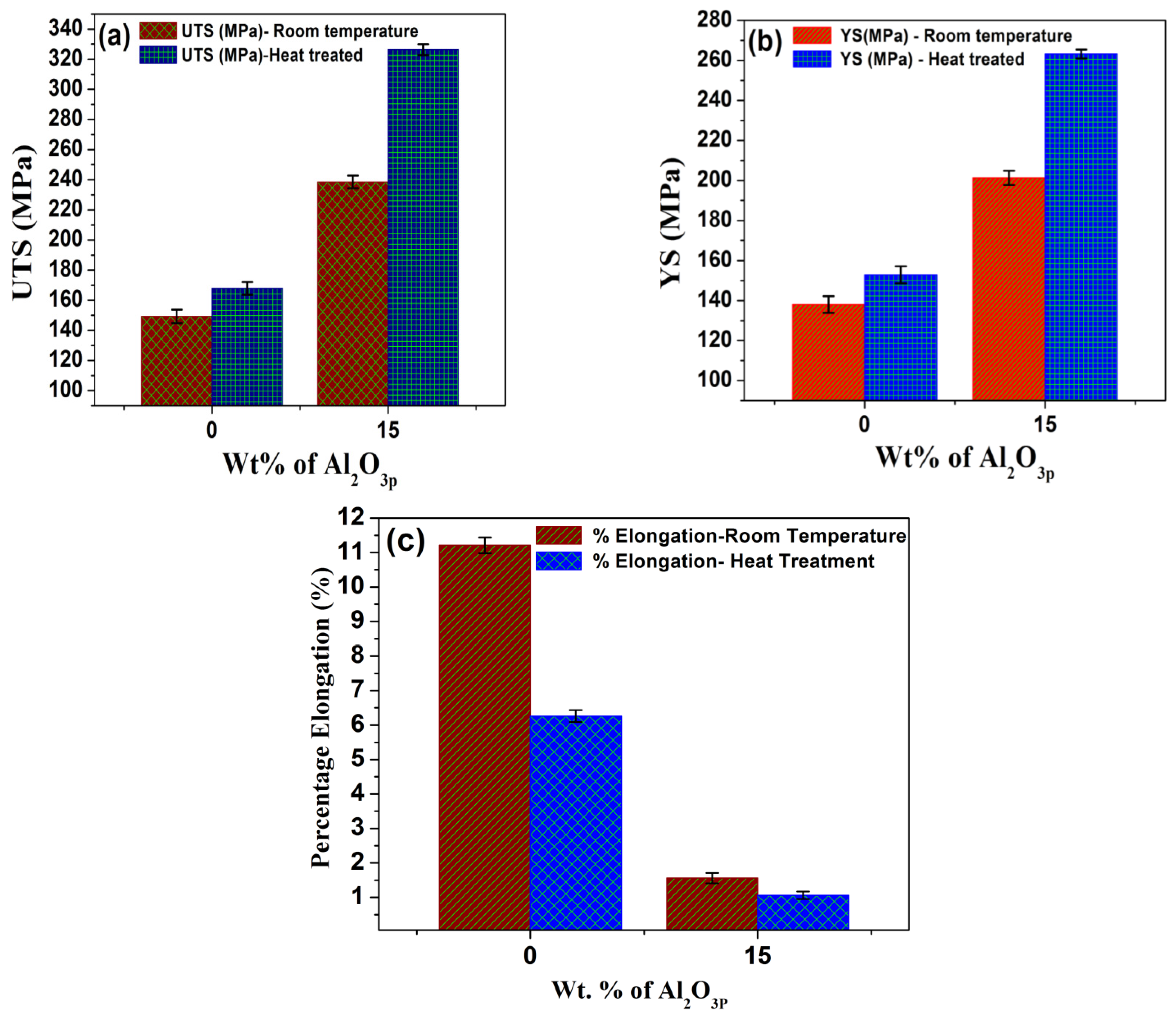

3.3. Ultimate Tensile Strength (UTS), Yield Strength (YS), and Percentage Elongation

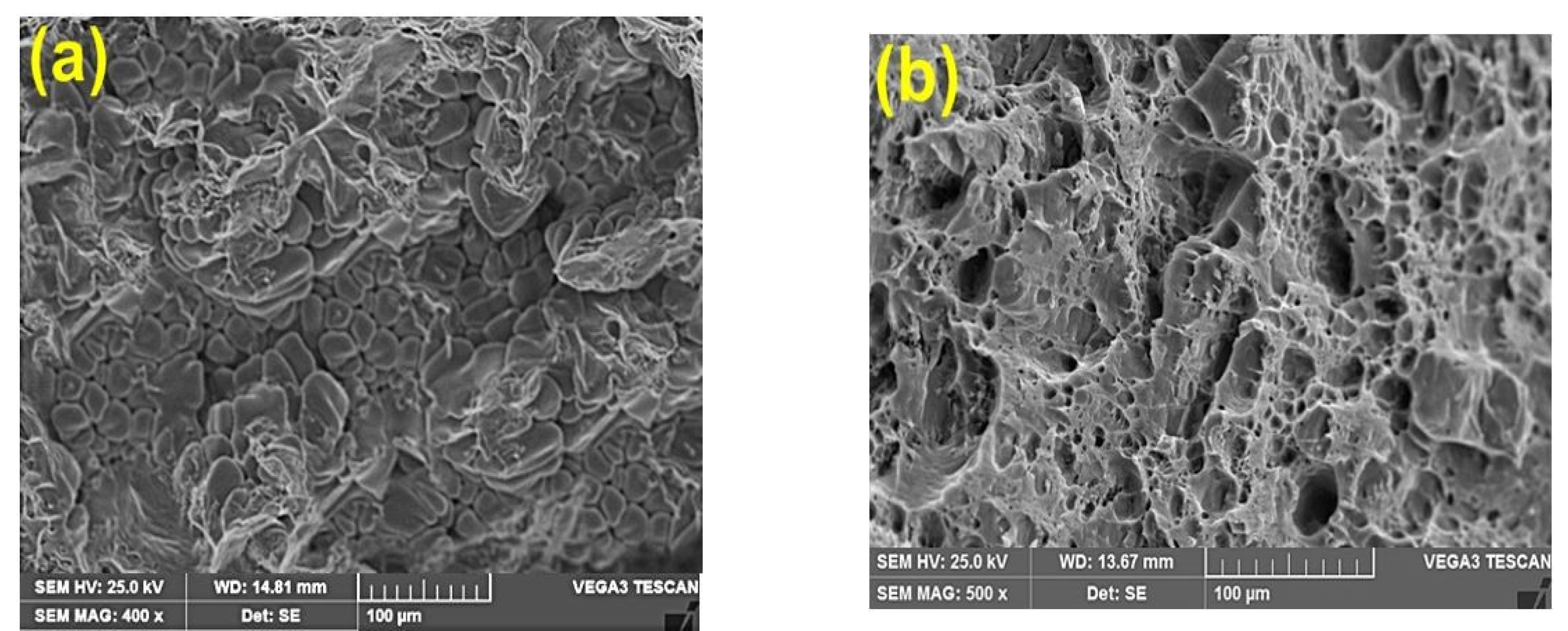

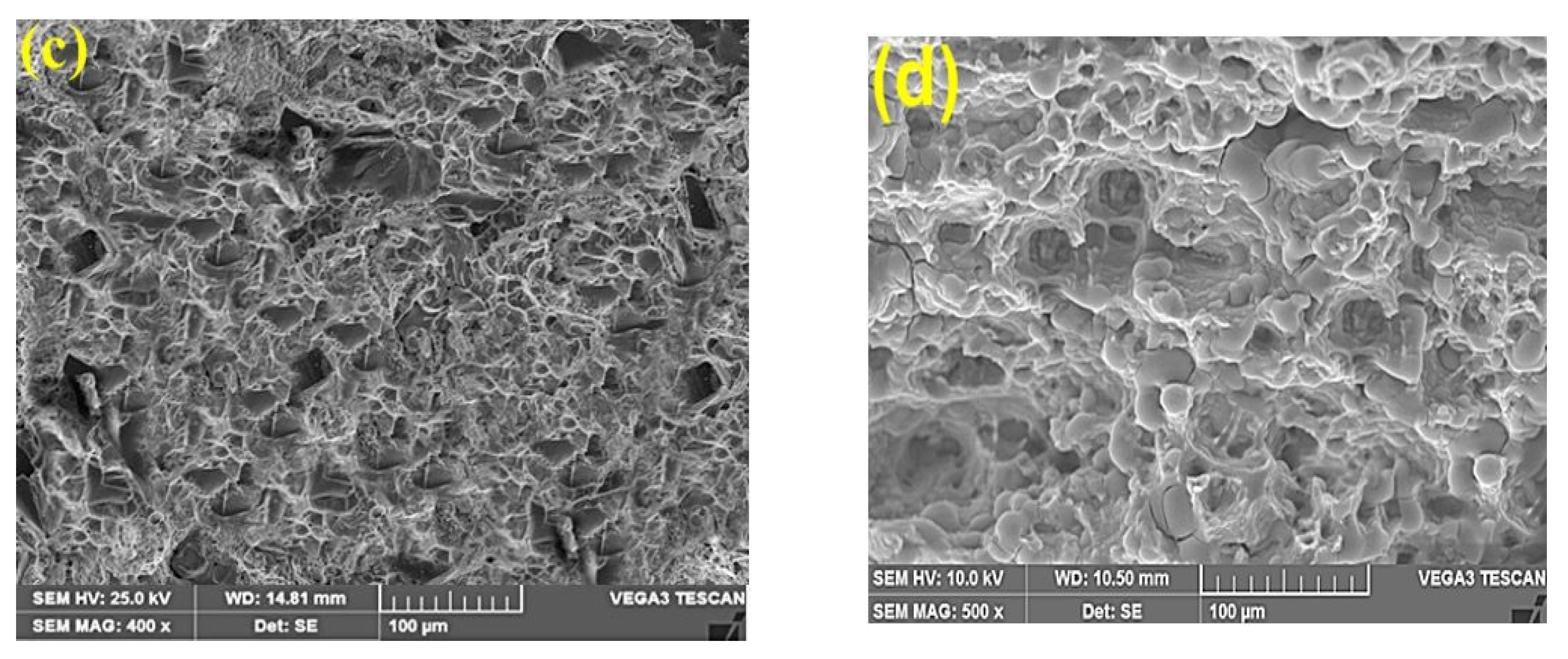

3.4. Tensile Fracture Behaviour

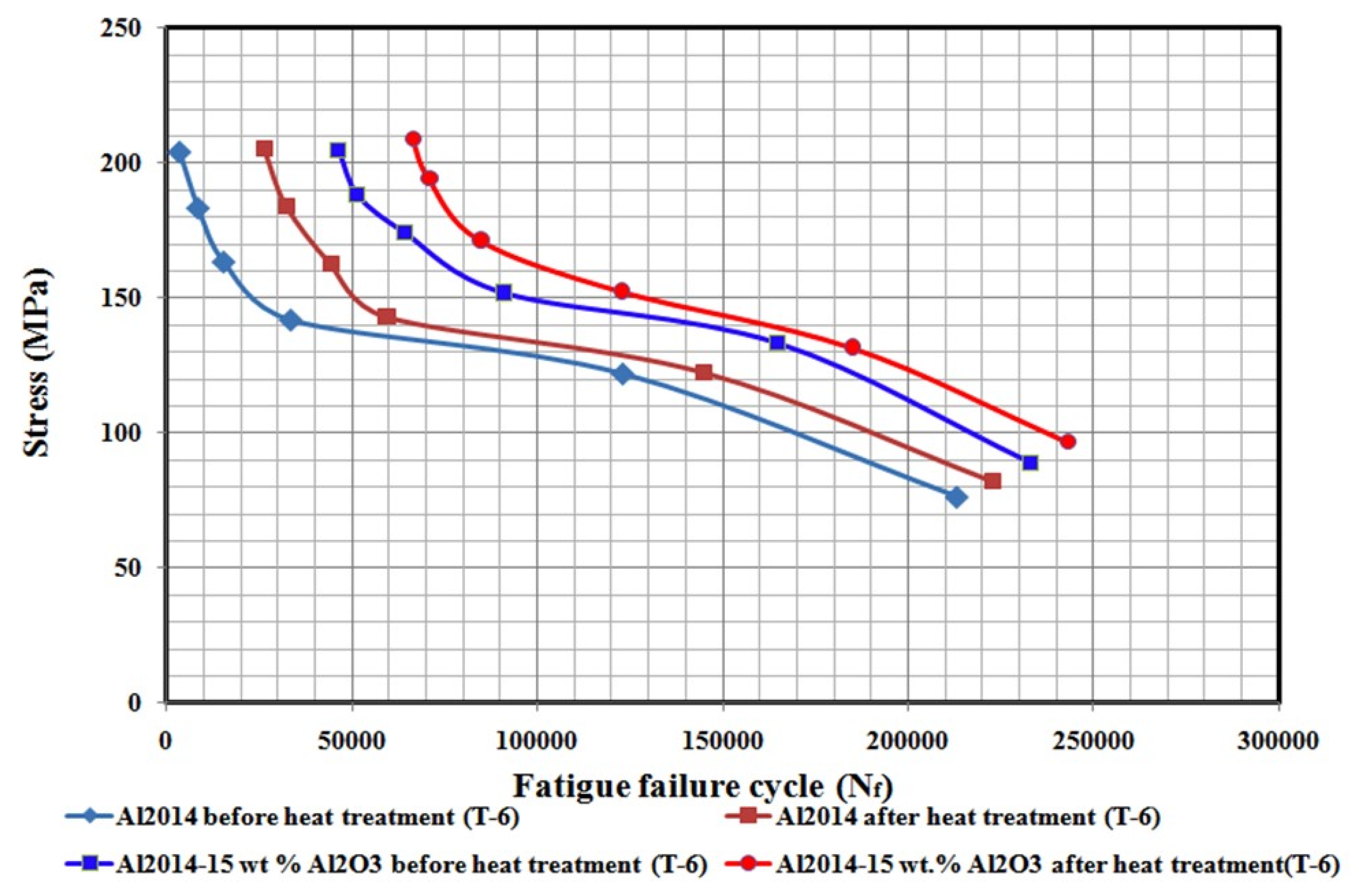

3.5. Fatigue Test

3.6. Wear Studies

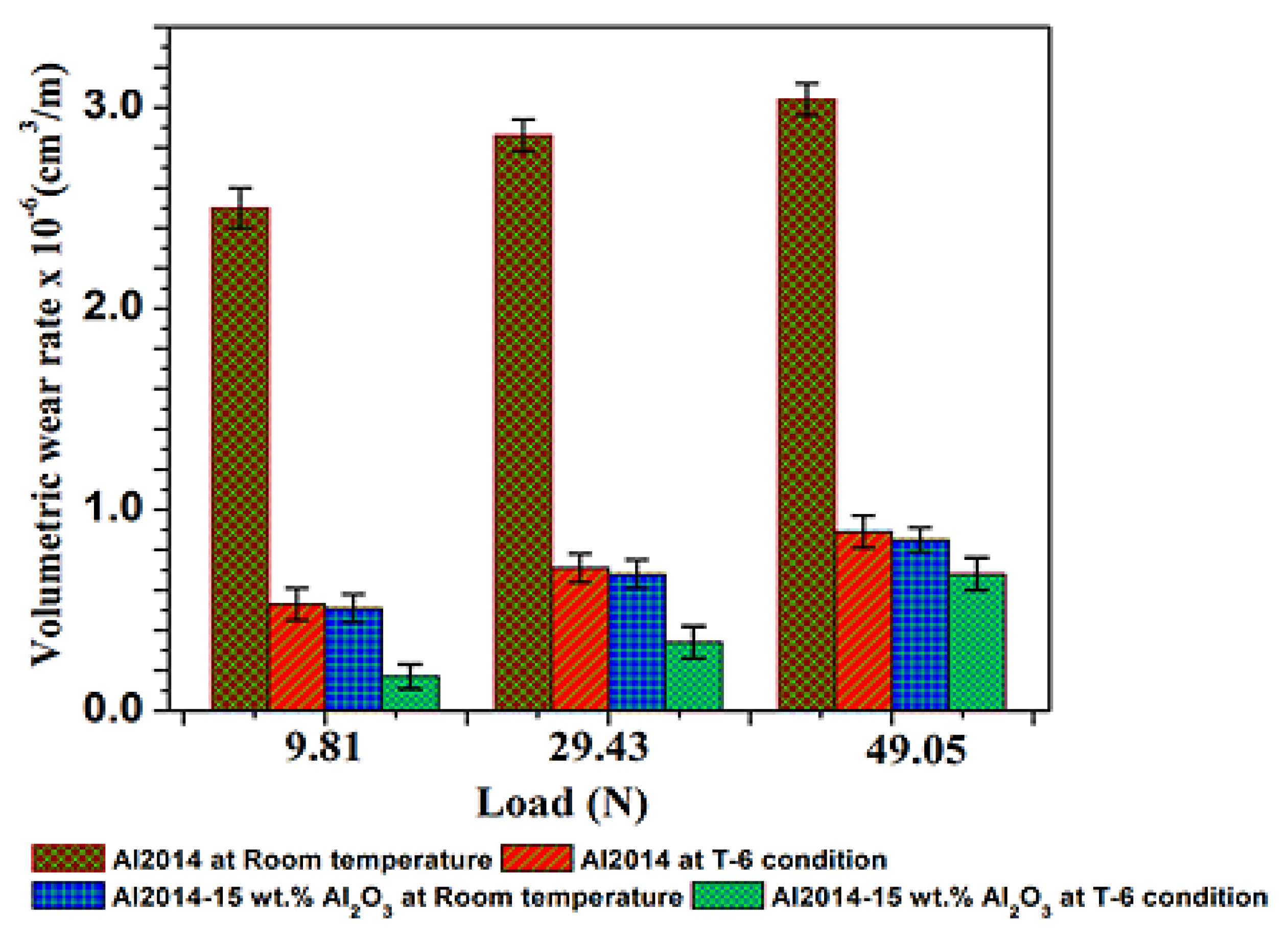

3.6.1. Impact of Variable Loads

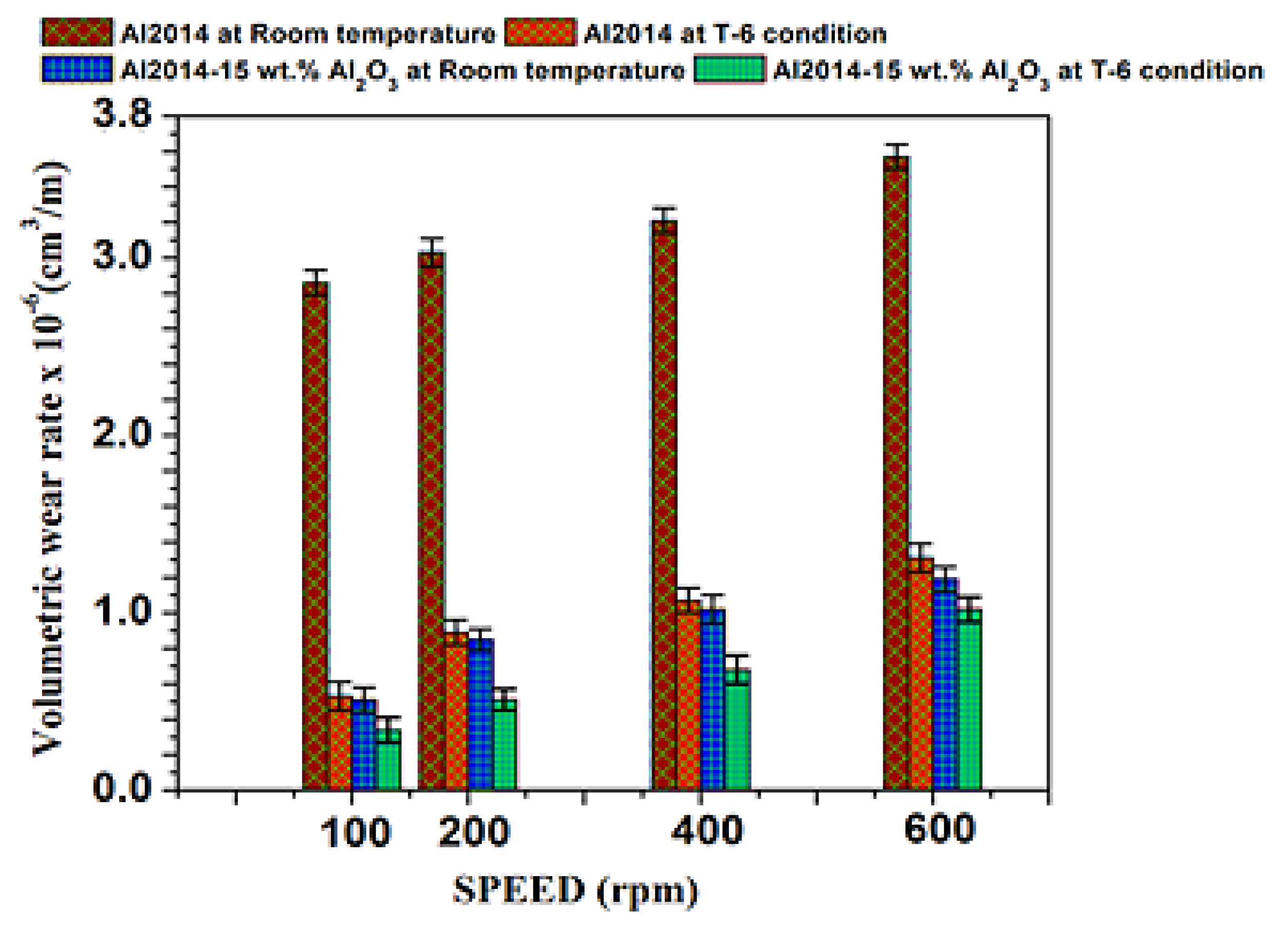

3.6.2. Impact of Variable Speed

3.6.3. Impact of Variable Sliding Distance

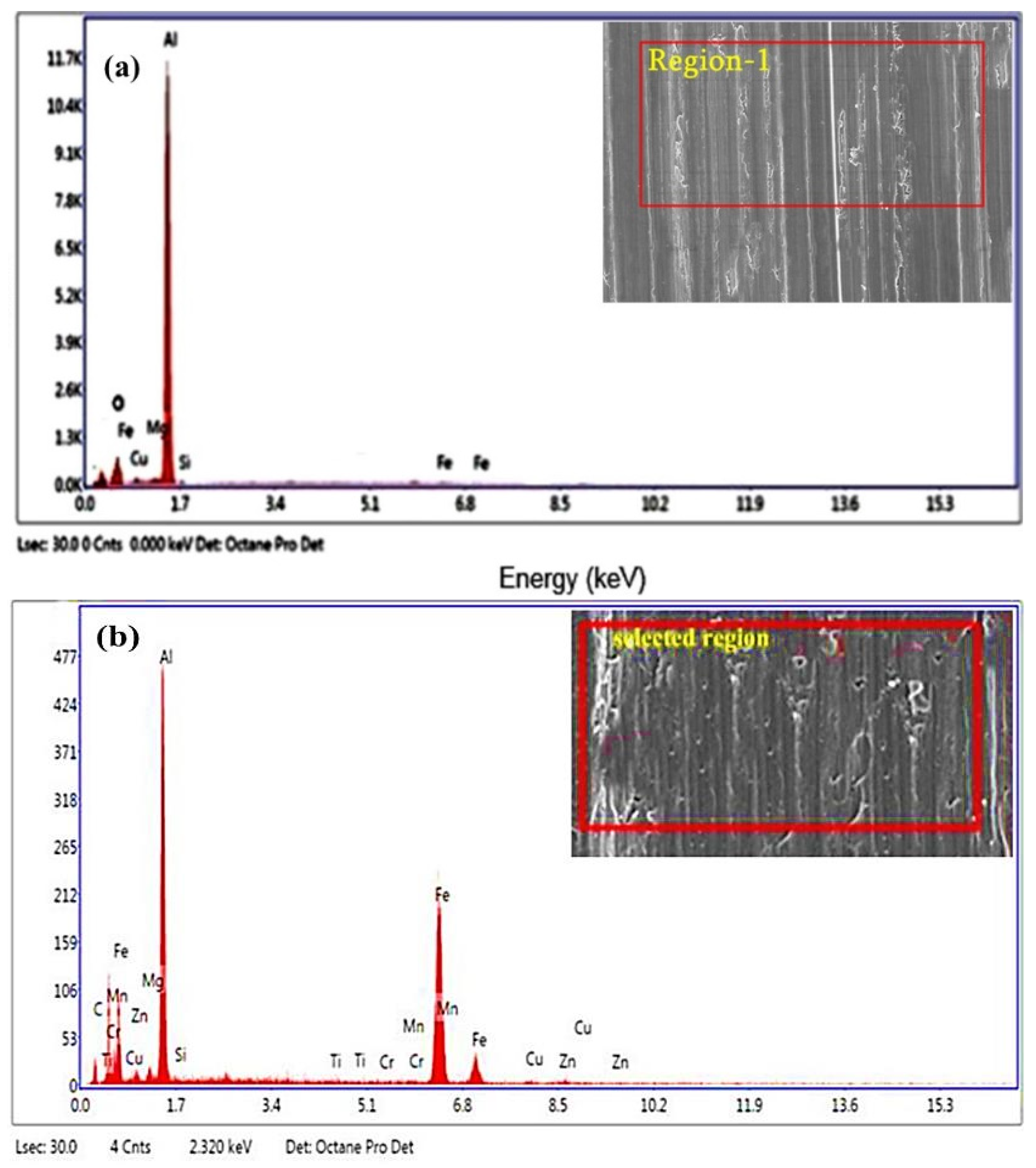

3.7. Morphological Worn Surface and Wear Debris Characteristics

4. Conclusions

- The SEM microphotographs of the Al2014 and Al2014-15 wt.% Al2O3 composites were successfully produced by the stir casting method with the two-step addition of Al2O3, which leads to the uniform dissemination of Al2O3 in the Al2014 matrix alloy.

- The microstructure of the heat-treated Al2014-15 wt.% Al2O3 composite is fragmented and thinner than the heat-treated Al2014 matrix alloy at 175 °C after aging for 10 h at a temperature of 175 °C, with Al2Cu precipitation.

- The SEM, XRD and EDAX studies confirm the presence of Al2Cu1, Al2Cu1Mg1 Al2Mg1O4 secondary intermetallic phases and reinforced Al2O3 particles in the heat-treated Al2014-15 wt.% Al2O3 composite and Al2014 matrix alloy, respectively.

- The microhardness of the heat-treated Al2014 matrix alloy and Al2014-15 wt.% Al2O3 composite is further enhanced by 10.36% and 32.71%, as contrasted to the untreated Al2014 matrix alloy and untreated Al2014-15 wt.% Al2O3 composite, respectively.

- An improvement in UTS of about 167.90 MPa and 326.39 MPa is observed in the heat-treated base alloy and Al2014-15 wt.% Al2O3 composite, respectively, as contrasted to the base alloy and Al2014-15 wt.% Al2O3 composite before heat treatment and an improvement in the YS of about 152.89 MPa and 263.23 MPa is observed in the heat-treated base alloy and Al2014-15 wt.% Al2O3 composite, respectively, as contrasted to the base alloy and Al2014-15 wt.% Al2O3 composite before heat treatment.

- Heat-treated Al2014-15 wt.% Al2O3 composites have shown lower ductility of about 1.06%, compared to untreated Al2014-15 wt.% Al2O3composites of about 1.56% and 6.26% in heat-treated Al2014 matrix alloys, as contrasted to unreinforced Al2014 matrix alloys of about 11.21% before heat treatment, respectively.

- The examined fractured surfaces of the heat-treated composite sample Al2014-15 wt.% Al2O3 show dimples that are comparatively smaller in size with rough structures when viewed on a microscopic scale, as compared to the Al2014-15 wt.% Al2O3 composite without heat treatment. Microscopic voids intermingled with tear ridges surrounding the reinforcement and pockets of shallow dimples are also observed. This describes the ductile nature of material systems studied, due to the heat treatment effect when compared with the composite produced without heat treatment.

- The fatigue strength of the composite increases after the addition of Al2O3 particles in Al2014 matrix alloys for both heat-treated and untreated conditions. The heat-treated Al2014-15 wt.% Al2O3 composite showed a noticeable improvement in fatigue strength, as contrasted to the untreated Al2014-15 wt.% Al2O3 compositeand Al2014 alloy.

- The wear rate of the heat-treated Al2014-15 wt.% of Al2O3 MMCis lower when contrasted to the untreated Al2014-15 wt.% of Al2O3 MMC, in addition to the untreated Al2014 matrix alloy, in all tested conditions, i.e., by varying the sliding speed, distance and applied load.

- The worn surface of the heat-treated Al2014-15 wt.% Al2O3 composites shows that the dominant wear mechanism is slightly plowing and contributes to improving the resistivity of delamination of the composite, as contrasted to the untreated Al2014-15 wt.% Al2O3 composite.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xu, J.; Liu, W. Wear characteristic of in situ synthetic TiB2 particulate-reinforced Al matrix composite formed by laser cladding. Wear 2006, 260, 486–492. [Google Scholar] [CrossRef]

- Davis, J.R. Aluminium and aluminium alloys. In ASM Specialty Handbook; ASM International: Russell, OH, USA, 1993. [Google Scholar]

- Sunday, O.; Fayomi, I.; Patricia, A.; Popoola, I.; Udoye, N.E. Effect of Alloying Element on the Integrity and Functionality of Aluminium-Based Alloy. In Aluminium Alloys-Recent Trends in Processing, Characterization, Mechanical Behavior and Applications; IntechOpen: London, UK, 2017; pp. 243–261. [Google Scholar] [CrossRef] [Green Version]

- Valsange, M.; Kulkarni, S.G.; Sonawane, S.A. Stir casting used in the manufacturing of aluminium matrix composite. Int. J. Res. Technol. Stud. 2014, 1. [Google Scholar]

- Bharath, V.; Nagaral, M.; Auradi, V.; Kori, S. Preparation of 6061Al-Al2O3 MMCs by stir casting and evaluation of mechanical and wear properties. Procedia Mater. Sci. 2014, 6, 1658–1677. [Google Scholar] [CrossRef] [Green Version]

- Alpas, A.T.; Embury, J.D. Sliding and abrasive wear behavior of an aluminium (2014)–SiC particle reinforced composite. Scr. Metall. Mater. 1990, 24, 931–935. [Google Scholar] [CrossRef]

- Kumar, G.B.V.; Rao, C.S.P.; Selvaraj, N. Studies on mechanical and dry sliding wear of A16061-SiC Composites. J. Compos. Part B Eng. 2012, 43, 1185–1191. [Google Scholar] [CrossRef]

- Roy, M.; Venkataraman, B.; Prasad, V.V.B.; Mahajan, Y.R.; Sundararajan, G. The effect of participate reinforcement on the sliding wear behavior of aluminum matrix composites. Metall. Mater. Trans. A 1992, 23, 2833–2847. [Google Scholar] [CrossRef]

- Zhang, Z.F.; Zhang, L.C.; Mai, Y.W. Wear of ceramic particle-reinforced metal–matrix composites Part-I wear mechanisms. J. Mater. Sci. 1995, 30, 1961–1966. [Google Scholar] [CrossRef]

- Khatris, S.; Koczak, M. Formation of TiC in in-situ processed composites via solid–gas, solid–liquid and liquid–gas reaction in molten Al–Ti. Mater. Sci. Eng. A 1993, 162, 153–162. [Google Scholar] [CrossRef]

- Das, S.; Prasad, S.V. Microstructure and wear of cast (Al–Si Alloy)–graphite composites. Wear 1989, 133, 173–187. [Google Scholar] [CrossRef]

- Ramesh, C.S. Engineering Materials; Spectrum Publishers: Bangalore, India, 1995; p. 65. [Google Scholar]

- Ceschini, L.; Minak, G.; Morri, A. Tensile and Fatigue properties of the AA6061/20 vol.% Al2O3 and AA7005/10 vol.% A12O3p Composites. Compos. Sci. Technol. 2006, 66, 333–342. [Google Scholar] [CrossRef]

- Doel, T.J.A.; Bowen, P. Tensile Properties of Particulate Reinforced Metal Matrix Composites. Compos. Part A 1996, 27, 655–665. [Google Scholar] [CrossRef]

- Hong, S.J.; Kim, H.M.; Huh, D.; Suryanarayana, C.; Chun, B.S. Effects of Clustering on the Mechanical Properties of SiC Particulate–Reinforced Aluminum Alloy 2024 Metal Matrix Composites. Mater. Sci. Eng. A 2003, 347, 198–204. [Google Scholar] [CrossRef]

- Al-Qutub, A.M.; Allam, I.M.; Qureshi, T.W. Wear Properties of 10% Sub-Micron A12O3/6061 Aluminum Alloy Composite. Int. J. Appl. Mech. Eng. 2002, 7, 329–334. [Google Scholar]

- Kouzeli, M.; Dunand, D.C. Effect of Reinforcement Connectivity on the Elasto-Plastic Behavior of Aluminum Composites Containing Sub-Micron Alumina Particles. Acta Mater. 2003, 51, 6105–6121. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Wu, G.; Sun, D.; Qin, C.; Tian, Y. Micro-Yield Property of Sub-Micron A12O3 Particle Reinforced 2024 Aluminum Matrix Composite. Mater. Lett. 2004, 58, 333–336. [Google Scholar] [CrossRef]

- Ray, S. Synthesis of cast metal matrix particulate composites. J. Mater. Sci. 1993, 28, 5397–5413. [Google Scholar] [CrossRef]

- Prabhavalkar, Y.; Chapgaon, A.N. Effect of volume fraction of Al2O3 on tensile strength of aluminium 6061 by varying stir casting furnace parameters: A review. Int. Res. J. Eng. Technol. 2017, 4, 1351–1355. [Google Scholar]

- Mazahery, A.; OstadShabani, M. Microstructural and abrasive wear properties of SiC reinforced aluminium based composite produced by compocasting. Trans. Nonferrous Met. Soc. China 2013, 23, 1905–1914. [Google Scholar] [CrossRef]

- Bharath, V.; Auradi, V.; Nagaral, M.; Boppana, S.B. Experimental Investigations on Mechanical and Wear Behaviour of 2014Al–Al2O3 Composites. J. Bio-Tribo-Corros. 2020, 6, 45. [Google Scholar] [CrossRef]

- Kang, G.-Z.; Yand, C.; Zhang, J.-X. Tensile properties of randomly oriented short δ-Al2O3 fiber reinforced Aluminum alloy composites—Microstructure characteristics, fracture mechanisms and strength prediction. Compos. Part A 2002, 33, 647–656. [Google Scholar] [CrossRef]

- Kouzeli, M.; Mortensen, A. Size dependent strengthening in particle reinforced Aluminium. Acta Mater. 2002, 50, 39–51. [Google Scholar] [CrossRef] [Green Version]

- Ma, Z.Y.; Tjong, S.C.; Wang, Z.G. Cyclic and static creep behavior of Al-Cu alloy composite reinforced with in-situ Al2O3 and TiB2 particulates. Mater. Sci. Eng. A 1999, 264, 177–187. [Google Scholar] [CrossRef]

- Perng, C.-C.; Hwang, J.-R.; Dooong, J.-L. Elevated-temperature, low-cycle fatigue behavior of Al2O3p/6061-T6 Aluminum matrix composites. Compos. Sci. Technol. 1993, 49, 225–236. [Google Scholar] [CrossRef]

- Hochreiter, E.; Panzenbock, M.; Jeglitsch, F. Fatigue properties of particle reinforced metal matrix composites. Int. J. Fatigue 1993, 15, 493–499. [Google Scholar] [CrossRef]

- Senthilkumar, R.; Arunkumar, N.; ManzoorHussian, M.A. Comparative study on low cycle fatigue behaviour of nano and micro Al2O3 reinforced AA2014 particulate hybrid composites. Res. Phys. 2015, 5, 273–280. [Google Scholar]

- Hoskins, F.M.; Aillo, P.O.; Woderlin, F.F.; Mehrabian, R. Composites of Aluminium alloys: Fabrication and wear behaviour. J. Mater. Sci. 1982, 17, 477–498. [Google Scholar] [CrossRef]

- Dhadsanadhep, C.; Luangvaranunt, T.; Umeda, J. Fabrication of Al/Al2O3 Composite by Powder Metallurgy Method from Aluminum and Rice Husk Ash. J. Met. Mater. Miner. 2008, 18, 4. [Google Scholar]

- Seleznew, M.L.; Argon, A.S.; Seleznev, I.L.; Cornie, J.A.; Mason, R.P. Effect of Composition Particle Size and Heat Treatment on Mechanical Properties of Al-4.5 wt% Cu, Based, Alumina Particulates Reinforced Composites. In Proceedings of the SAE International Congress, Detroit, MI, USA, 23–26 February 1998. [Google Scholar]

- Salama, E. Aging Behavior of Spray Cast AL-Zn-Mg–Cu Alloy. Turk. J. Eng. Environ. Sci. 2001, 25, 681–686. [Google Scholar]

- Daoud, A.; Abou El-Khair, M.T.; Abdul Azin, A.N. Effect of Al2O3 Particles Microstructure and Sliding Wear of 7075 Al-Alloy Manufactured by Squeeze Casting Method. J. Mater. Eng. Perform. 2004, 13, 135–143. [Google Scholar] [CrossRef]

- Bharath, V.; Ajawan, S.S.; Nagaral, M.; Auradi, V.; Kori, S.A. Characterization and mechanical properties of aluminium alloy reinforced with Al2O3 composite produced by two-stage stir casting route. J. Inst. Eng. India Ser. C 2018, 100, 277–282. [Google Scholar] [CrossRef]

- Sudarshan, M.; Surappa, K. Dry sliding wear of fly ash particle reinforced A356 Al composites. Wear 2008, 265, 349–360. [Google Scholar] [CrossRef]

- Rajkumar, K.; Kundu, K.; Aravindan, S.; Kulkarni, M.S. Accelerated wear testing for evaluating the life characteristics of copper-graphite tribological composites. Mater. Des. 2011, 32, 3029–3035. [Google Scholar] [CrossRef]

- Jahanmir, S.; Suh, N.P. Mechanics of subsurface void nucleation in delamination wear. Wear 1977, 44, 17–38. [Google Scholar] [CrossRef]

- Dutta, I.; Allen, S.M.; Hafley, J.L. Effect of Reinforcement on the Aging Response of Cast 6061 Al–Al2O3 Particulate Composites. Metall. Trans. A 1991, 22, 2553–2563. [Google Scholar] [CrossRef]

- Song, Y.; Baker, T.N. Accelerated Aging Process in Ceramic Reinforced AA6061 Composites. Mater. Sci. Technol. 1994, 10, 406–413. [Google Scholar] [CrossRef]

- Mahmoud, T.S.; Gaafer, A.M.; Abdel-Aziz, M. Mechanical Properties and Aging Behaviour of Al2O3 Reinforced Aluminum Composites Prepared by Rheocasting Technique. In Proceedings of the 9th International Mining, Petroleum, and Metallurgical Engineering Conference, Cairo, Egypt, 21–24 February 2004; pp. 1–10. [Google Scholar]

- Cottu, J.P.; Couderc, J.J.; Viguier, B.; Bernard, L. Influence of SiC reinforcement on precipitation and hardening of a metal matrix composite. J. Mater. Sci. 1992, 27, 3068–3074. [Google Scholar] [CrossRef]

- Yamanoğlu, R.; Karakulak, E.; Zeren, A.; Zeren, M. Effect of heat treatment on the tribological properties of Al–Cu–Mg/nano SiC composites. Mater. Des. 2013, 49, 820–825. [Google Scholar] [CrossRef]

- Myriounis, D.; Hasan, S.; Matikas, T. Heat treatment and interface effects on the mechanical behavior of SiC-particle reinforced aluminium matrix composites. J. ASTM Int. 2008, 5, 1–10. [Google Scholar]

- Odabasi, D.; Su, S. A comparison of the reciprocating and continuous two-body abrasive wear behavior of solution-treated and age-hardened 2014 Al alloy. Wear 1997, 208, 25. [Google Scholar] [CrossRef]

- Ibrahim, I.A.; Mohammed, F.A.; Lavernia, E.J. Particulate Reinforced Metal Matrix Composites a Overview. J. Mater. Sci. 1991, 26, 1137–1155. [Google Scholar] [CrossRef]

- AnanthaPadmanabham, K.C.; Mruthunjaya, M. Microstructure Studies and Mechanical Characterisation of T6 Heat Treated Aluminium and Copper Based Alloy Reinforced with Zircon and Graphite Composite. J. Eng. Sci. Technol. 2019, 14, 2063–2073. [Google Scholar]

- Hu, Y.; Wu, T.; Guo, Y.; Wang, W.; Song, M.; Qian, L.; Zhao, H.; Wang, M. Effects of T6 Treatment, Tensile Temperature, and Mass Fraction of SiC on the Mechanical Properties of SiCp/6061Al Composites. Materials 2019, 12, 1602. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hussein, S.G.; Al-Shammari, M.; Takhakh, A.M.; Al-Waily, M. Effect of Heat Treatment on Mechanical and Vibration Properties for 6061 and 2024 Aluminum Alloys. J. Mech. Eng. Res. Dev. 2020, 43, 48–66. [Google Scholar]

- Chawla, N.; Habel, U.; Shen, Y.L.; Andres, C.; Jones, J.W.; Allison, J.E. The effect of matrix microstructure on the tensile and fatigue behavior of SiC particle-reinforced 2080Al matrix composites. Metall. Mater. Trans. A 2000, 31, 531–539. [Google Scholar] [CrossRef]

- Rohatgi, P.K.; Alaraj, S.; Thakkar, R.B.; Daoud, A. Variation in fatigue properties of cast A359-SiC composites under total strain-controlled conditions: Effects of porosity and inclusions. Compos. Part A 2007, 38, 1829–1841. [Google Scholar] [CrossRef]

- Murphy, A.M.; Clyne, T.W. The effect of initial porosity and particle clustering on the tensile failure of cast particulate MMCs. In Proceedings of the ICCM-10, Whistler, BC, Canada, 14–18 August 1995; p. 295. [Google Scholar]

- Bonnen, J.J.; Allison, J.E.; Jones, J.W. Fatigue behavior of a 2xxx series aluminum alloy reinforced with 15 vol% SiCp. Metall. Mater. Trans. A 1991, 22, 1007–1019. [Google Scholar] [CrossRef]

- Soltani, N.; Nodooshan, H.R.J.; Bahrami, A.; Pech-Canul, M.I.; Liu, W.; Wu, G. Effect of hot extrusion on wear properties of Al–15 wt.% Mg2Si in situ metal matrix composites. Mater. Des. 2014, 53, 774–781. [Google Scholar] [CrossRef]

- Deaquino-Lara, R.; Soltani, N.; Bahrami, A.; Gutiérrez-Castañeda, E.; García-Sánchez, E.; Hernandez-Rodríguez, M.A.L. Tribological characterization of Al7075–graphite composites fabricated by mechanical alloying and hot extrusion. Mater. Des. 2015, 67, 224–231. [Google Scholar] [CrossRef]

- Avinash, L.; Ramprabhu, T.; Bontha, S. The Effect on the drysliding wear behavior of gravity cast A357 reinforced with dual size silicon carbide particles. Appl. Mech. Mater. 2016, 829, 83–89. [Google Scholar] [CrossRef]

- Lakshmikanthan, A.; Bontha, S.; Krishna, M.; Koppad, P.G.; Ramprabhu, T. Microstructure, mechanical and wear properties of the A357 composites reinforced with dual sized SiC particles. J. Alloys Compd. 2019, 786, 570–580. [Google Scholar] [CrossRef]

- Prabhu, T.R. Effect of bimodal size particles reinforcement on the wear, friction and mechanical properties of brake composites. Tribol.–Mater. Surf. Interfaces 2016, 10, 163–171. [Google Scholar] [CrossRef]

- Rajeev, V.; Dwivedi, D.; Jain, S. Effect of load and reciprocating velocity on the transition from mild to severe wear behavior of Al–Si–SiCp composites in reciprocating conditions. Mater. Des. 2010, 31, 4951–4959. [Google Scholar] [CrossRef]

- Gomezde Salazar, J.M.; Barrena, M.I. Influence of heat treatments on the wear behaviour of an AA6092/SiC25p composite. Wear 2004, 256, 286–293. [Google Scholar] [CrossRef]

- Levy, G.; Lingford, R.G.; Mitchell, L.A. Wear behaviour and mechanical properties: The similarity of seemingly unrelated approaches. Wear 1972, 21, 167–177. [Google Scholar] [CrossRef]

- Kumar, S.; Pandey, O.P. Role of fine size zircon sand ceramic particle on controlling the cell morphology of aluminum composite foams. J. Manuf. Process 2015, 20, 172–180. [Google Scholar] [CrossRef]

| Chemical Compositions | Si | Cu | Mn | Fe | Cr | Zn | Mg | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| Al2014 | 0.7 | 4.5 | 0.83 | 0.2 | 0.01 | 0.19 | 0.63 | 0.06 | Bal |

| Material | Density (g/cc) | Elastic Modulus (Gpa) | Poisson’s Ratio | Hardness (HB500) | Tensile Strength (T)/Compressive Strength (C) (Mpa) |

|---|---|---|---|---|---|

| Al2014 | 2.8 | 72 | 2.7 | 130 BHN | 410 (T) |

| Al2O3 | 3.69 | 300 | 0.21 | 1175 | 2100(C) |

| Elements | Al2014 (T6 Condition) | 15 wt.% Alumina (T6 Condition) |

|---|---|---|

| O | 0.24 | 20.27 |

| Mg | 0.87 | 2.16 |

| Si | 0.92 | 1.08 |

| Fe | 0.45 | 0.52 |

| Cu | 3.37 | 4.31 |

| Ti | 0.38 | 0.34 |

| Cr | 0.39 | 0.47 |

| Zn | 0.30 | 0.51 |

| Mn | 0.71 | 0.47 |

| Al | 92.37 | 69.87 |

| Compositions of Composite Samples | Condition | Speed (rpm) | Sliding Distance (m) | Variable Load (N) | ||

|---|---|---|---|---|---|---|

| 9.81 | 29.43 | 49.05 | ||||

| Volumetric Wear Rate ∗ 10−6 (cm3/m) | ||||||

| Al2014 | RT | 400 | 2000 | 2.50 ± 0.10 | 2.86 ± 0.08 | 3.04 ± 0.08 |

| Al2014 | T6 | 400 | 2000 | 0.53 ± 0.08 | 0.71 ± 0.07 | 0.89 ± 0.08 |

| Al2014-15 wt.% Al2O3 | RT | 400 | 2000 | 0.51 ± 0.07 | 0.68 ± 0.07 | 0.85 ± 0.06 |

| Al2014-15 wt.% Al2O3 | T6 | 400 | 2000 | 0.17 ± 0.06 | 0.34 ± 0.08 | 0.68 ± 0.08 |

| Compositions of Composite Samples | Condition | Load (N) | Sliding Distance (m) | Variable Speed (rpm) | |

|---|---|---|---|---|---|

| 100 | 200 | ||||

| Volumetric Wear Rate ∗ 10−6 (cm3/m) | |||||

| Al2014 | RT | 49.05 | 2000 | 2.86 ± 0.07 | 3.03 ± 0.08 |

| Al2014 | T-6 | 49.05 | 2000 | 0.53 ± 0.08 | 0.89 ± 0.07 |

| Al2014-15 wt.% Al2O3 | 0.85 ± 0.06 | ||||

| RT | 49.05 | 2000 | 0.51 ± 0.07 | ||

| Al2014-15 wt.% Al2O3 | 0.51 ± 0.06 | ||||

| T-6 | 49.05 | 2000 | 0.34 ± 0.07 | ||

| Composition sof Composite Samples | Condition | Load (N) | Speed (rpm) | Variable Sliding Distance (rpm) | |||

|---|---|---|---|---|---|---|---|

| 500 | 1000 | 1500 | 2000 | ||||

| Volumetric Wear Rate ∗ 10−6 (cm3/m) | |||||||

| Al2014 | RT | 49.05 | 400 | 10.72 ± 0.17 | 5.36 ± 0.15 | 3.57 ± 0.14 | 2.68 ± 0.15 |

| Al2014 | T-6 | 49.05 | 400 | 4.28 ± 0.14 | 2.14 ± 0.17 | 1.42 ± 0.12 | 1.07 ± 0.13 |

| Al2014-15 wt.% Al2O3 | RT | 49.05 | 400 | 2.72 ± 0.07 | 1.36 ± 0.07 | 0.91 ± 0.08 | 0.68 ± 0.07 |

| Al2014-15 wt.% Al2O3 | T-6 | 49.05 | 400 | 2.04 ± 0.07 | 1.02 ± 0.08 | 0.68 ± 0.07 | 0.51 ± 0.07 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bharath, V.; Auradi, V.; Kumar, G.B.V.; Nagaral, M.; Chavali, M.; Helal, M.; Sami, R.; Aljuraide, N.; Hu, J.W.; Galal, A.M. Microstructural Evolution, Tensile Failure, Fatigue Behavior and Wear Properties of Al2O3 Reinforced Al2014 Alloy T6 Heat Treated Metal Composites. Materials 2022, 15, 4244. https://doi.org/10.3390/ma15124244

Bharath V, Auradi V, Kumar GBV, Nagaral M, Chavali M, Helal M, Sami R, Aljuraide N, Hu JW, Galal AM. Microstructural Evolution, Tensile Failure, Fatigue Behavior and Wear Properties of Al2O3 Reinforced Al2014 Alloy T6 Heat Treated Metal Composites. Materials. 2022; 15(12):4244. https://doi.org/10.3390/ma15124244

Chicago/Turabian StyleBharath, V., V. Auradi, G. B. Veeresh Kumar, Madeva Nagaral, Murthy Chavali, Mahmoud Helal, Rokayya Sami, NI Aljuraide, Jong Wan Hu, and Ahmed M. Galal. 2022. "Microstructural Evolution, Tensile Failure, Fatigue Behavior and Wear Properties of Al2O3 Reinforced Al2014 Alloy T6 Heat Treated Metal Composites" Materials 15, no. 12: 4244. https://doi.org/10.3390/ma15124244

APA StyleBharath, V., Auradi, V., Kumar, G. B. V., Nagaral, M., Chavali, M., Helal, M., Sami, R., Aljuraide, N., Hu, J. W., & Galal, A. M. (2022). Microstructural Evolution, Tensile Failure, Fatigue Behavior and Wear Properties of Al2O3 Reinforced Al2014 Alloy T6 Heat Treated Metal Composites. Materials, 15(12), 4244. https://doi.org/10.3390/ma15124244