Development of a Formability Prediction Model for Aluminium Sandwich Panels with Polymer Core

Abstract

:1. Introduction

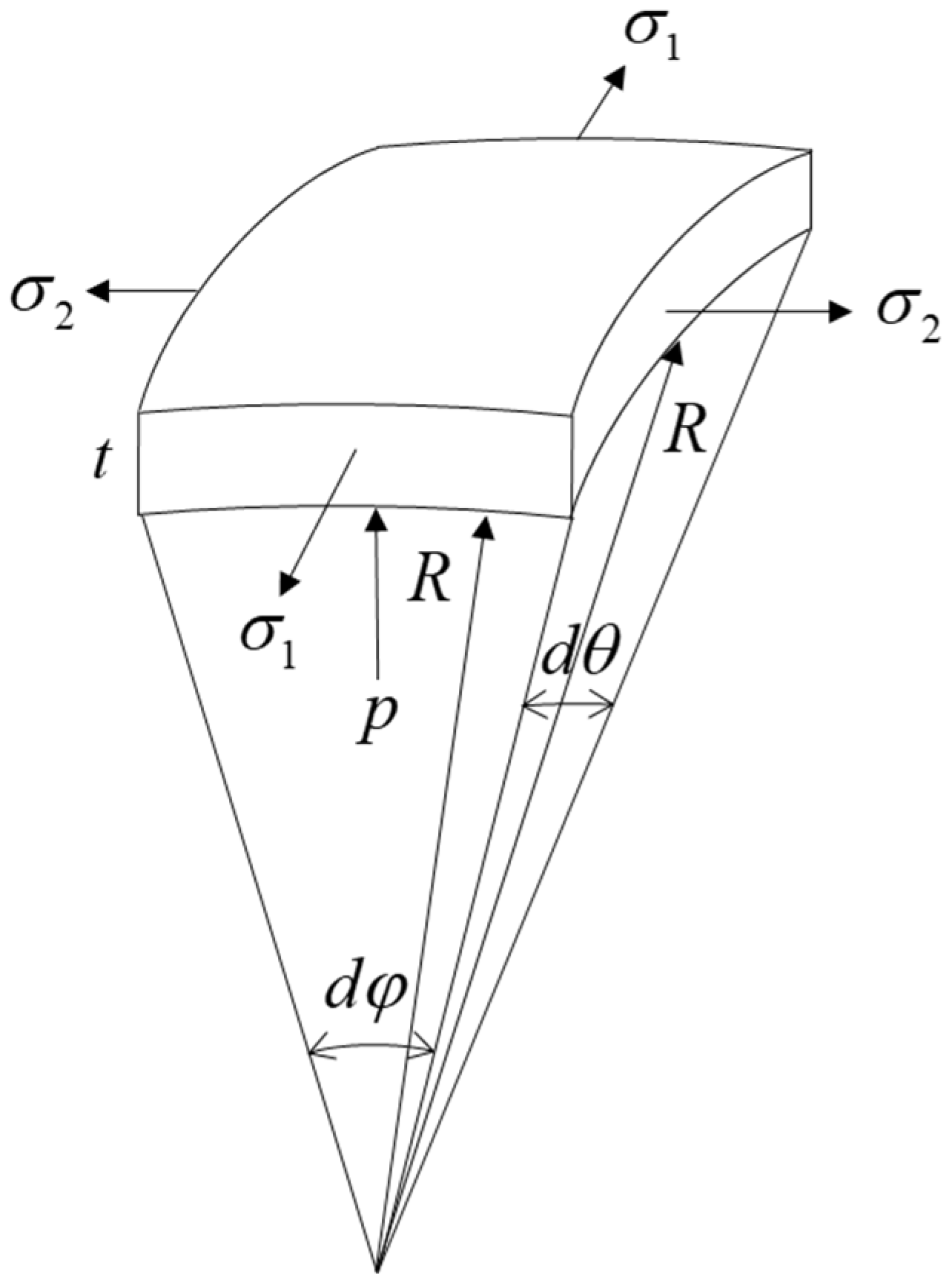

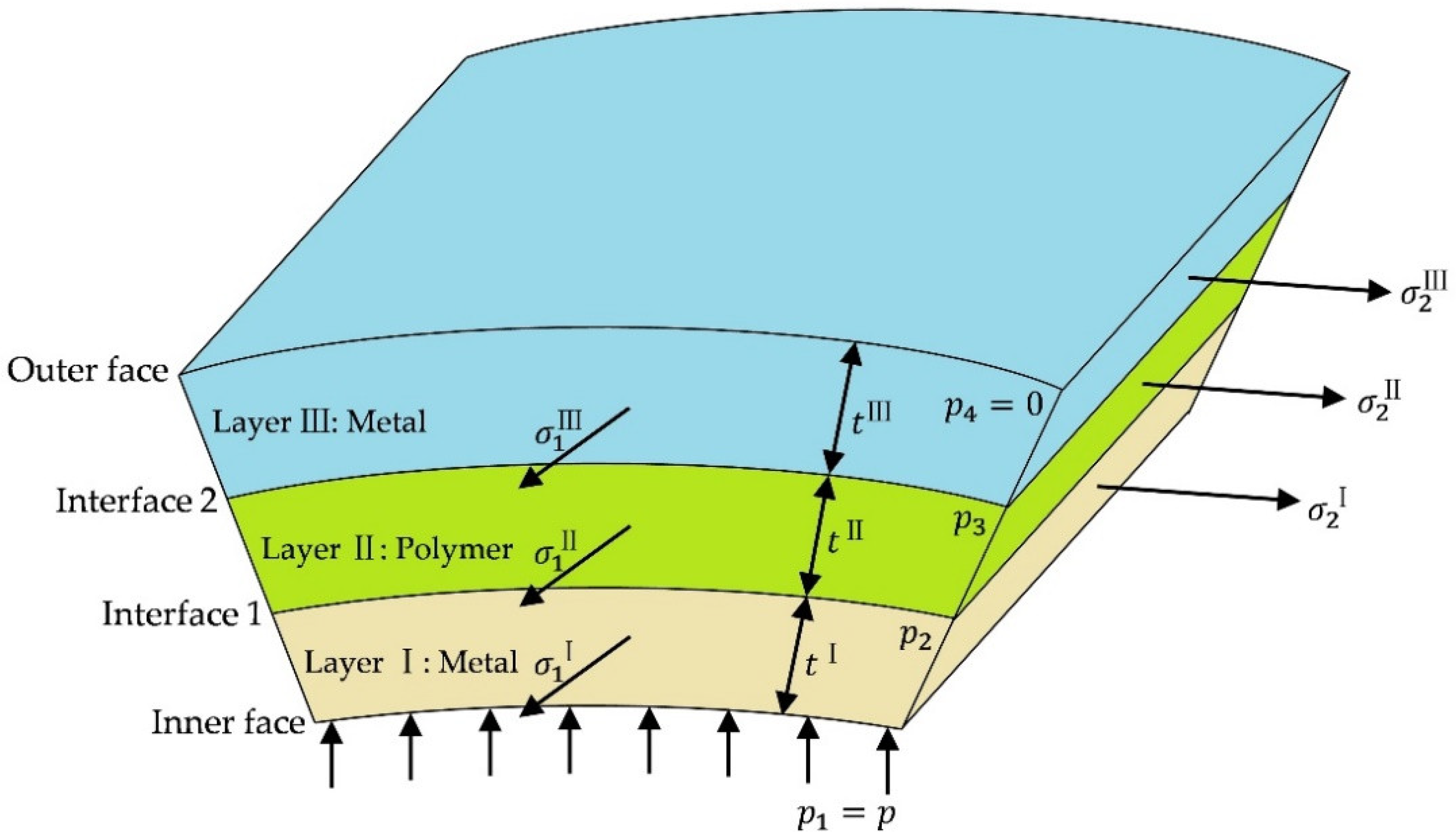

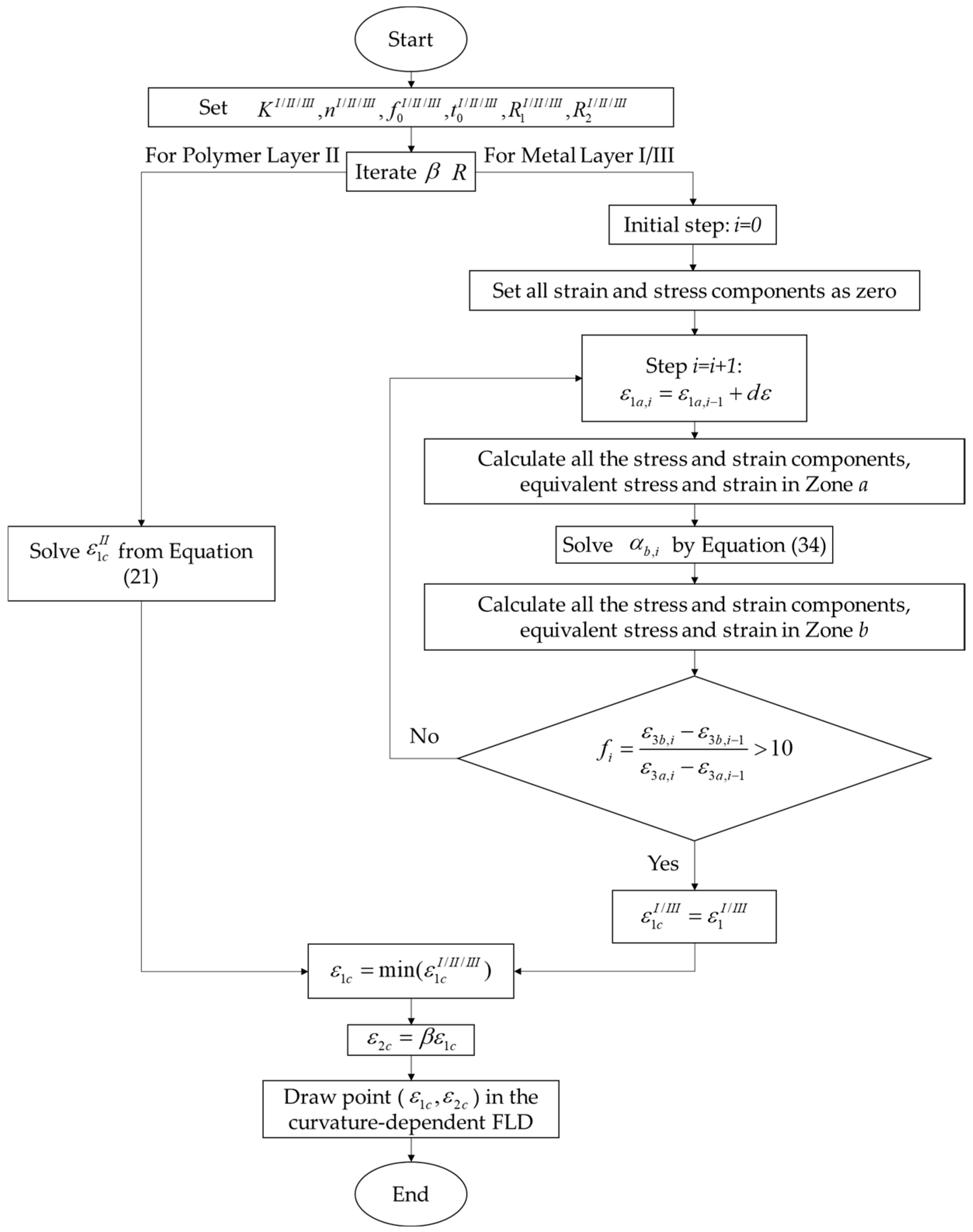

2. The Mechanics-Based Analysis of the Nakajima Test with Sandwich Panels

2.1. Principles of Plastic Deformation

2.2. Strain and Stress Analysis of Sandwich Panels

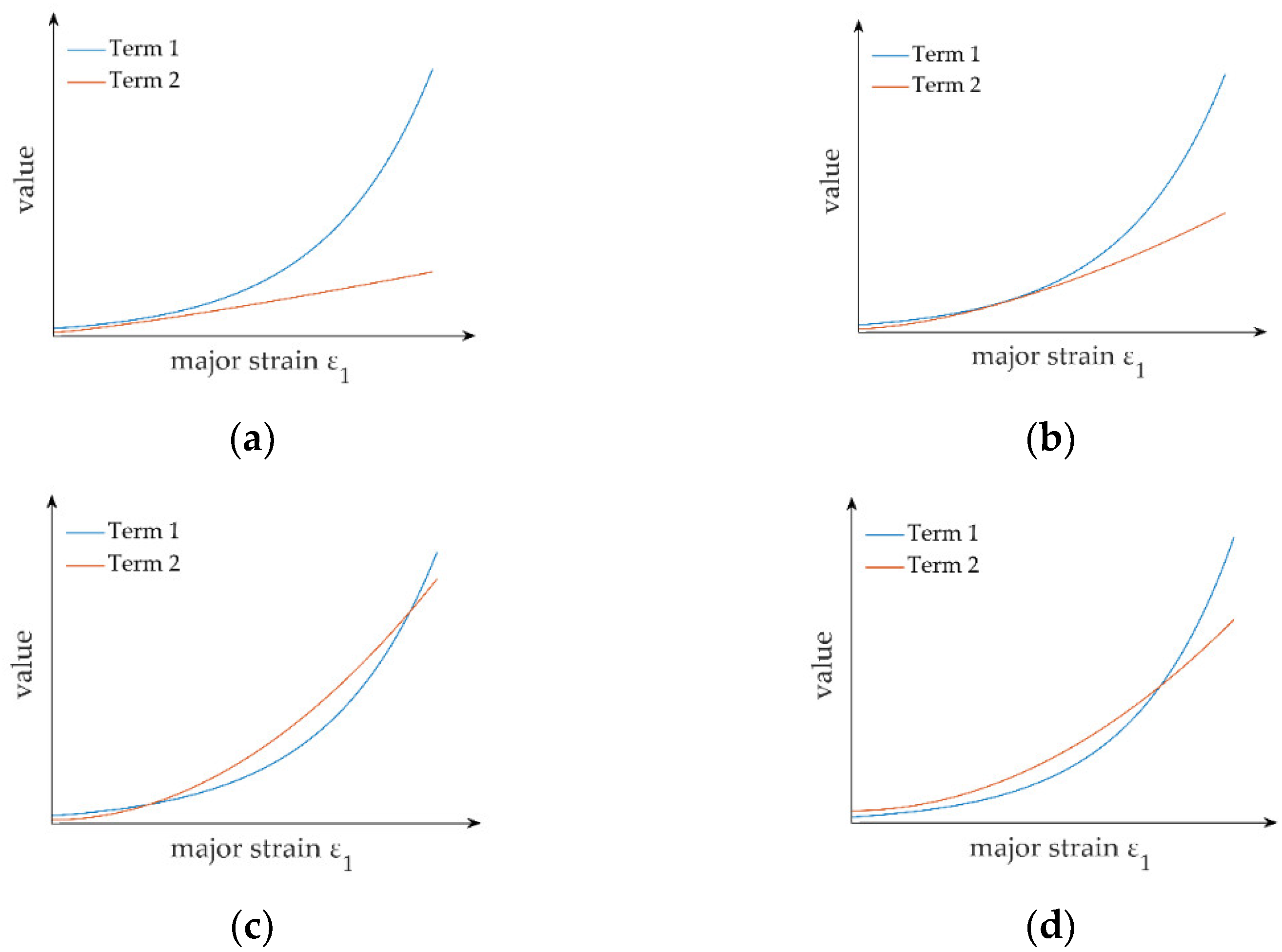

2.3. Failure Criteria of Polymer Layer

- (a)

- If Term 1 was always larger than Term 2, no solution existed, suggesting that the sandwich panel would not fail as the failure criteria of the polymer layer was not met;

- (b)

- If Term 1 was larger than Term 2 when and the two terms became equal at a given point, where the derivative of each was equal, a unique solution existed;

- (c)

- If Term 1 was larger than Term 2 when and it became smaller at a given point, where the derivative of each was equal, two solutions existed, of which the smaller one was true as the failure occurred and the increase in terminated;

- (d)

- If Term 1 was smaller than Term 2 when , a unique solution existed.

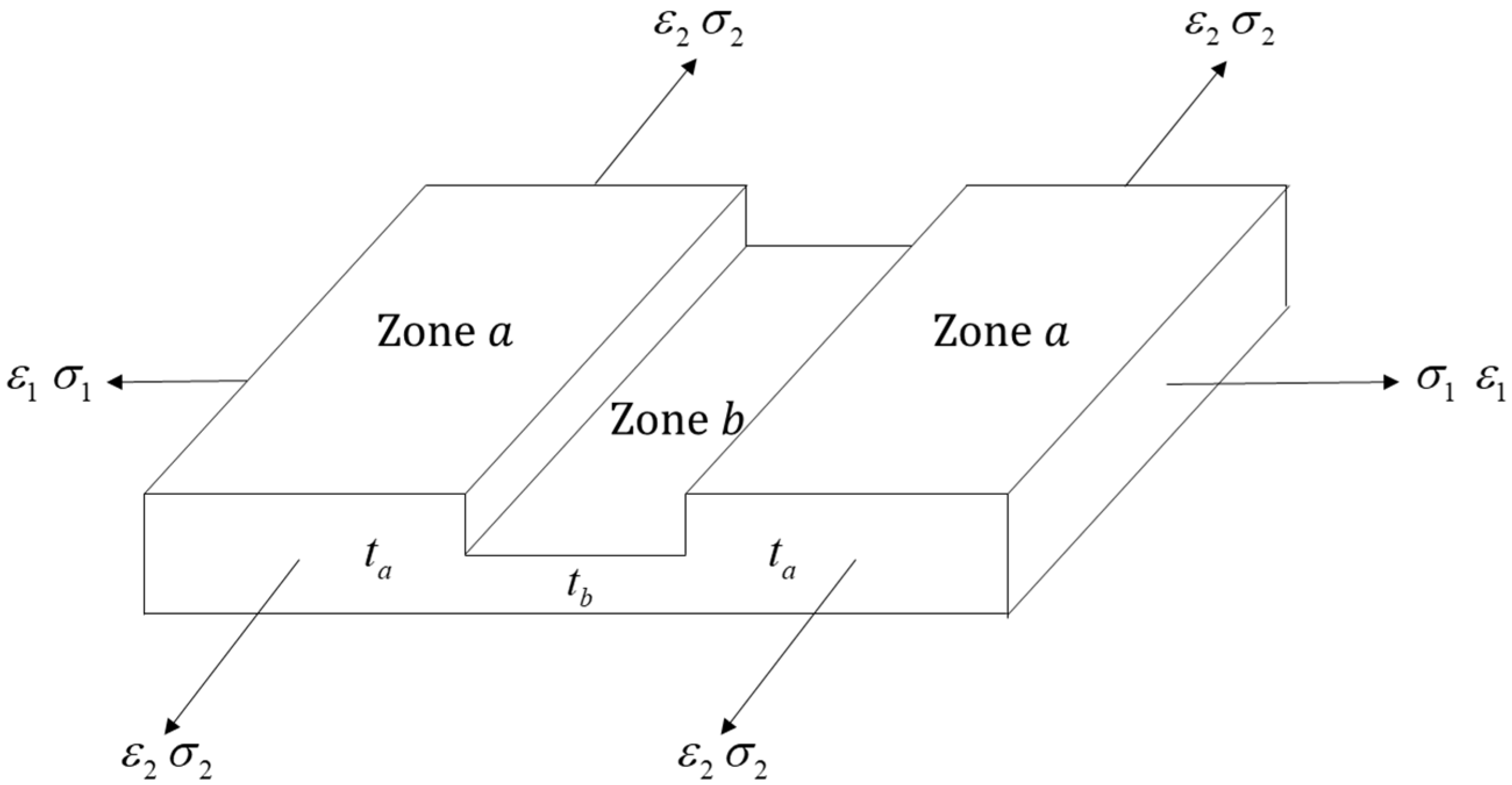

2.4. Failure Criteria of Metal Layers

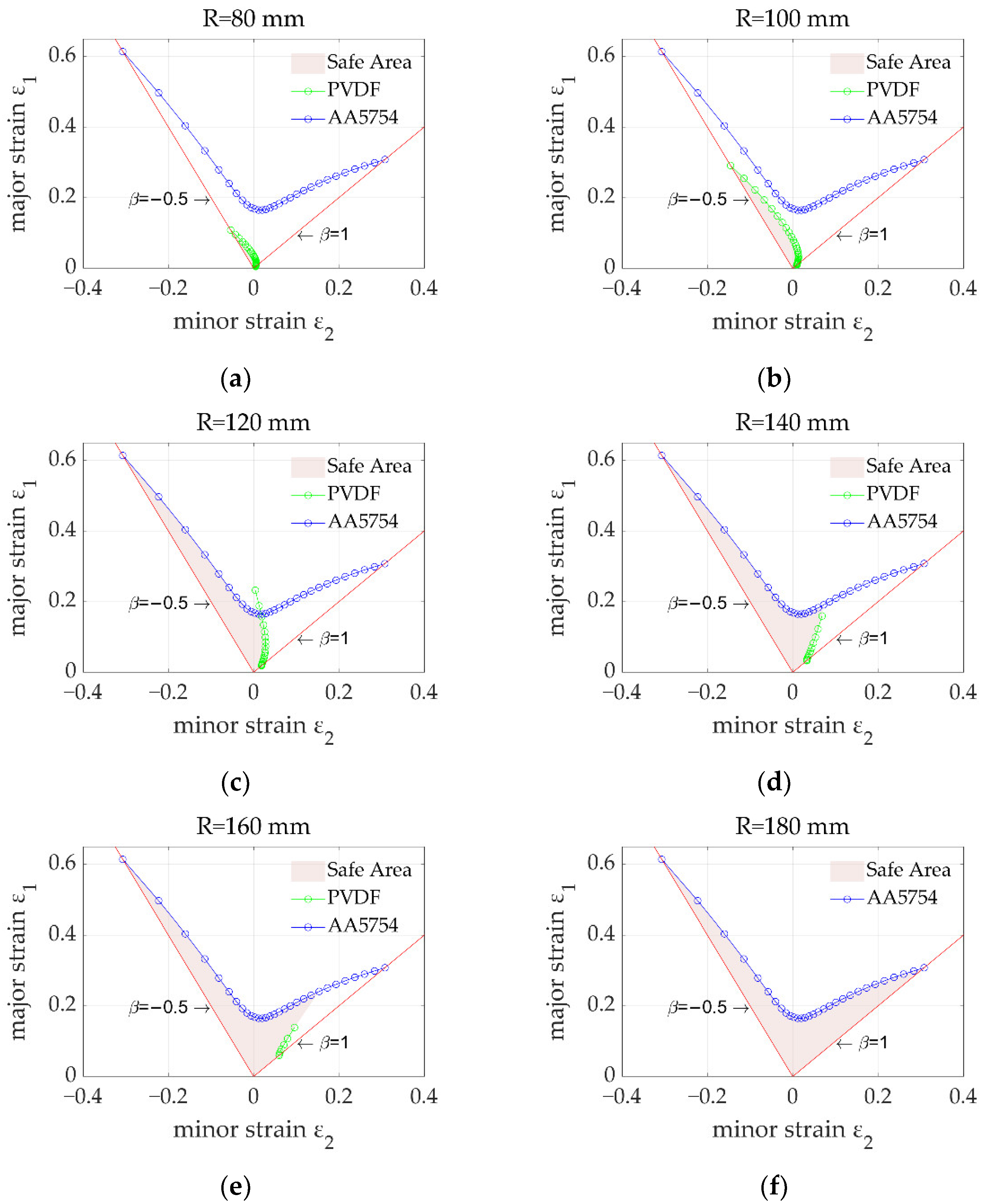

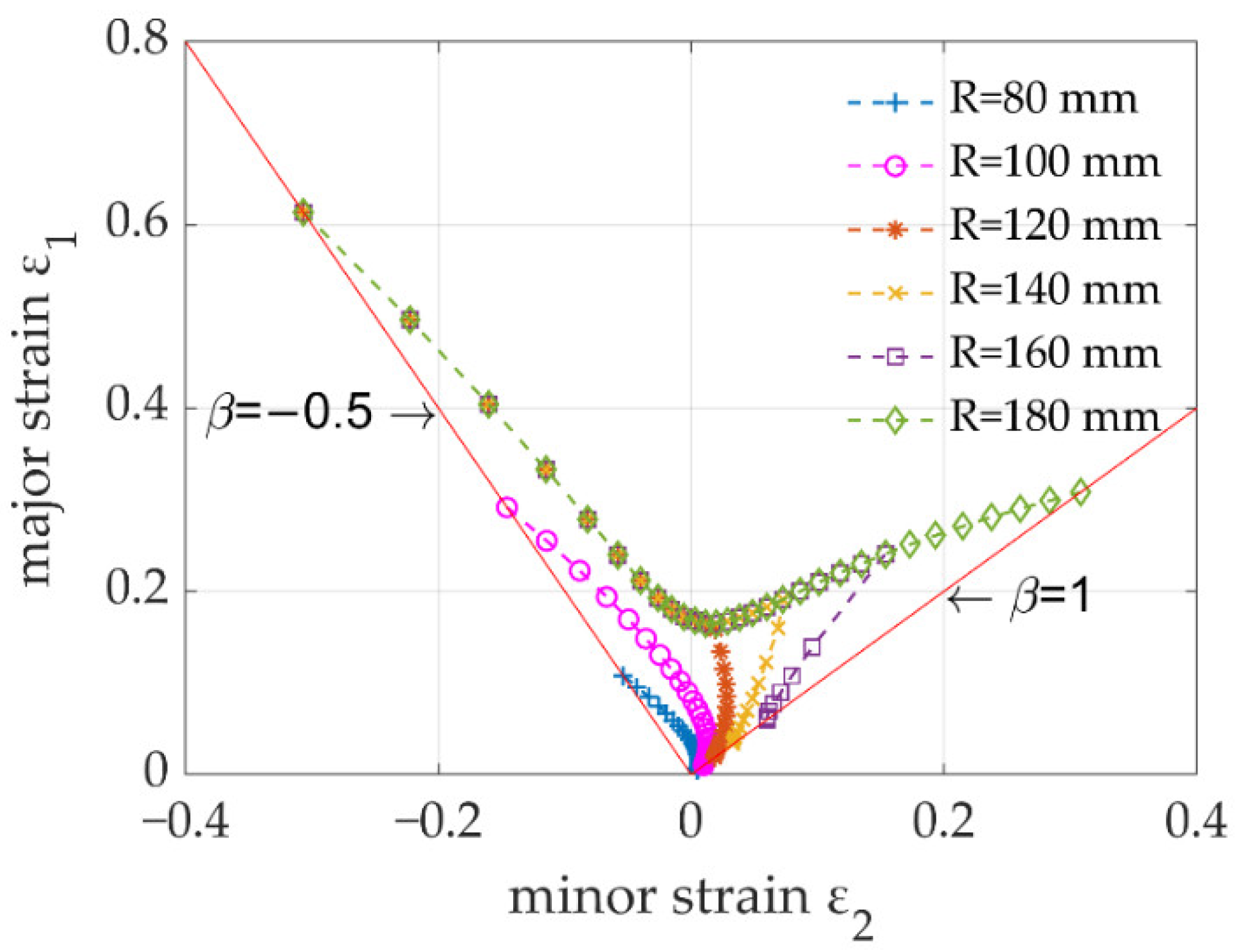

3. Case Study

4. Conclusions

- The failure of the polymer layer was curvature-radius dependent. At a small radius, the polymer layer readily failed, while at a large radius, the sandwich panel would be more formable. This feature contributed to the curvature-radius-dependent FLD of the sandwich panel.

- Under the same punch radius/curvature, the polymer layer always failed rapidly at a larger strain ratio. The worst case was the equi-biaxial ( = 1) loading path.

- The developed FLD model overcame the limitation of traditional FLD models and was capable of predicting the formability of sandwich panels made from composite materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Keeler, S.P.; Backofen, W.A. Plastic instability and fracture in sheets stretched over rigid punches. ASM Trans. 1963, 56, 25–48. [Google Scholar]

- Goodwin, G.M. Application of strain analysis to sheet metal forming problems in the press shop. SAE Tech. Pap. 1968, 77, 680093. [Google Scholar] [CrossRef]

- ISO 12004-2; Metallic Materials—Determination of Forming-Limit Curves for Sheet and Strip—Part 2: Determination of Forming-Limit Curves in the Laboratory. ISO: Geneva, Switzerland, 2021.

- BSI 12004-2; Metallic Materials—Determination of Forming-Limit Curves for Sheet and Strip. Determination of Forming-Limit Curves in the Laboratory. BSI: London, UK, 2021.

- Swift, H.W. Plastic instability under plane stress. J. Mech. Phys. Solids. 1952, 1, 1–18. [Google Scholar] [CrossRef]

- Hill, R. A theory of the yielding and plastic flow of anisotropic metals. Proc. R. Soc. Lond. A 1948, 193, 281–297. [Google Scholar] [CrossRef]

- Stören, S.; Rice, J.R. Localized necking in thin sheets. J. Mech. Phys. Solids. 1975, 23, 421–441. [Google Scholar] [CrossRef]

- Marciniak, Z.; Kuczyński, K. Limit strains in the processes of stretch-forming sheet metal. Int. J. Mech. Sci. 1967, 9, 609–620. [Google Scholar] [CrossRef]

- Gao, H.; El Fakir, O.; Wang, L.; Politis, D.J.; Li, Z. Forming limit prediction for hot stamping processes featuring non-isothermal and complex loading conditions. Int. J. Mech. Sci. 2017, 131, 792–810. [Google Scholar] [CrossRef]

- Zhu, M.; Lim, Y.C.; Liu, X.; Cai, Z.; Dhawan, S.; Gao, H.; Politis, D.J. Numerical forming limit prediction for the optimisation of initial blank shape in hot stamping of AA7075. Int. J. Light. Mater. Manuf. 2021, 4, 269–280. [Google Scholar] [CrossRef]

- Butcher, C.; Khameneh, F.; Abedini, A.; Connolly, D.; Kurukuri, S. On the experimental characterization of sheet metal formability and the consistent calibration of the MK model for biaxial stretching in plane stress. J. Mater. Process. Tech. 2021, 287, 116887. [Google Scholar] [CrossRef]

- Eyckens, P.; Van Bael, A.; Van Houtte, P. An extended Marciniak–Kuczynski model for anisotropic sheet subjected to monotonic strain paths with through-thickness shear. Int. J. Plast. 2011, 27, 1577–1597. [Google Scholar] [CrossRef]

- Jeong, Y.; Jeon, B.; Tome, C.N. Finite element analysis using an incremental elasto-visco-plastic self-consistent polycrystal model: FE simulations on Zr and low-carbon steel subjected to bending, stress-relaxation, and unloading. Int. J. Plast. 2021, 147, 103110. [Google Scholar] [CrossRef]

- Yu, K.; Li, Q.; Wu, Y.; Guo, M.; Li, D.; Liu, C.; Zhuang, L.; Wu, P. An improved Marciniak-Kuczynski approach for predicting sheet metal formability. Int. J. Mech. Sci. 2022, 221, 107200. [Google Scholar] [CrossRef]

- Allwood, J.M.; Shouler, D.R. Generalised forming limit diagrams showing increased forming limits with non-planar stress states. Int. J. Plast. 2009, 25, 1207–1230. [Google Scholar] [CrossRef]

- Wang, C.; Wang, H.; Chen, G.; Zhu, Q.; Zhang, P.; Fu, M.W. Experiment and modeling based studies of the mesoscaled deformation and forming limit of Cu/Ni clad foils using a newly developed damage model. Int. J. Plast. 2022, 149, 103173. [Google Scholar] [CrossRef]

- Joudi, A.; Svedung, H.; Rönnelid, M. Energy efficient surfaces on building sandwich panels-A dynamic simulation model. Energy Build. 2011, 43, 2462–2467. [Google Scholar] [CrossRef]

- Silva, T.; Correia, L.; Dehshirizadeh, M.; Sena-Cruz, J. Flexural creep response of hybrid GFRP-FRC sandwich panels. Materials 2022, 15, 2536. [Google Scholar] [CrossRef]

- Sun, Y.; Li, C.; You, J.; Bu, C.; Yu, L.; Yan, Z.; Liu, X.; Zhang, Y.; Chen, X. An Investigation of the properties of expanded polystyrene concrete with fibers based on an orthogonal experimental design. Materials 2022, 15, 1228. [Google Scholar] [CrossRef]

- Eschen, H.; Harnisch, M.; Schüppstuhl, T. Flexible and automated production of sandwich panels for aircraft interior. Procedia Manuf. 2018, 18, 35–42. [Google Scholar] [CrossRef]

- Chung, Y.; Shrestha, R.; Lee, S.; Kim, W. Binarization mechanism evaluation for water ingress detectability in honeycomb sandwich structure using lock-in thermography. Materials 2022, 15, 2333. [Google Scholar] [CrossRef]

- Lee, H.; Park, H. Study on structural design and manufacturing of sandwich composite floor for automotive structure. Materials 2021, 14, 1732. [Google Scholar] [CrossRef]

- Kee Paik, J.; Thayamballi, A.K.; Sung Kim, G. The strength characteristics of aluminum honeycomb sandwich panels. Thin Walled Struct. 1999, 35, 205–231. [Google Scholar] [CrossRef]

- Maneengam, A.; Siddique, M.J.; Selvaraj, R.; Kakaravada, I.; Arumugam, A.B.; Singh, L.K.; Kumar, N. Influence of multi-walled carbon nanotubes reinforced honeycomb core on vibration and damping responses of carbon fiber composite sandwich shell structures. Polym. Compos. 2022, 43, 2073–2088. [Google Scholar] [CrossRef]

- Kassa, M.K.; Selvaraj, R.; Wube, H.D.; Arumugam, A.B. Investigation of the bending response of carbon nanotubes reinforced laminated tapered spherical composite panels with the influence of waviness, interphase and agglomeration. Mech. Based Des. Struct. Mach. 2021, 1–23. [Google Scholar] [CrossRef]

- Liu, J.; Liu, W.; Xue, W. Forming limit diagram prediction of AA5052/polyethylene/AA5052 sandwich sheets. Mater. Design 2013, 46, 112–120. [Google Scholar] [CrossRef]

- Reggente, M.; Harhash, M.; Kriegel, S.; He, W.; Masson, P.; Faerber, J.; Pourroy, G.; Palkowski, H.; Carrado, A. Resin-free three-layered Ti/PMMA/Ti sandwich materials: Adhesion and formability study. Compos. Struct. 2019, 218, 107–119. [Google Scholar] [CrossRef]

- Khardin, M.; Harhash, M.; Chernikov, D.; Glushchenkov, V.; Palkowski, H. Preliminary studies on electromagnetic forming of aluminum/polymer/aluminum sandwich sheets. Compos. Struct. 2020, 252, 112729. [Google Scholar] [CrossRef]

- Zhang, J.; Yanagimoto, J. Density-based topology optimization integrated with genetic algorithm for optimizing formability and bending stiffness of 3D printed CFRP core sandwich sheets. Compos. B. Eng. 2021, 225, 109428. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, Q.; Cai, Z. Prediction and prevention of fracture defect in plastic forming for aluminum foam sandwich panel. J. Mater. Res. Technol. 2021, 15, 1145–1154. [Google Scholar] [CrossRef]

- Logan, R.W.; Hosford, W.F. Upper-bound anisotropic yield locus calculations assuming <111>-pencil glide. Int. J. Mech. Sci. 1980, 22, 419–430. [Google Scholar] [CrossRef]

- Iadicola, M.A.; Foecke, T.; Banovic, S.W. Experimental observations of evolving yield loci in biaxially strained AA5754-O. Int. J. Plast. 2008, 24, 2084–2101. [Google Scholar] [CrossRef]

- Hosford, W.F. Mechanical Behavior of Materials, 2nd ed.; Cambridge University Press: Cambridge, UK, 2010; p. 85. [Google Scholar]

| Material | K [MPa] | n | l | |||

|---|---|---|---|---|---|---|

| AA5754 | 0.73 | 0.69 | 0 | 474 | 0.317 | 8 |

| PVDF | 1 | 1 | 0 | 6.51 | 0.465 | 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Di, B.; Yu, X.; Liu, H.; Dhawan, S.; Politis, D.J.; Kopec, M.; Wang, L. Development of a Formability Prediction Model for Aluminium Sandwich Panels with Polymer Core. Materials 2022, 15, 4140. https://doi.org/10.3390/ma15124140

Liu X, Di B, Yu X, Liu H, Dhawan S, Politis DJ, Kopec M, Wang L. Development of a Formability Prediction Model for Aluminium Sandwich Panels with Polymer Core. Materials. 2022; 15(12):4140. https://doi.org/10.3390/ma15124140

Chicago/Turabian StyleLiu, Xiaochuan, Bozhou Di, Xiangnan Yu, Heli Liu, Saksham Dhawan, Denis J. Politis, Mateusz Kopec, and Liliang Wang. 2022. "Development of a Formability Prediction Model for Aluminium Sandwich Panels with Polymer Core" Materials 15, no. 12: 4140. https://doi.org/10.3390/ma15124140

APA StyleLiu, X., Di, B., Yu, X., Liu, H., Dhawan, S., Politis, D. J., Kopec, M., & Wang, L. (2022). Development of a Formability Prediction Model for Aluminium Sandwich Panels with Polymer Core. Materials, 15(12), 4140. https://doi.org/10.3390/ma15124140