Experimental Study of Emulative Precast Concrete Beam-to-Column Connections Locally Reinforced by U-Shaped UHPC Shells

Abstract

:1. Introduction

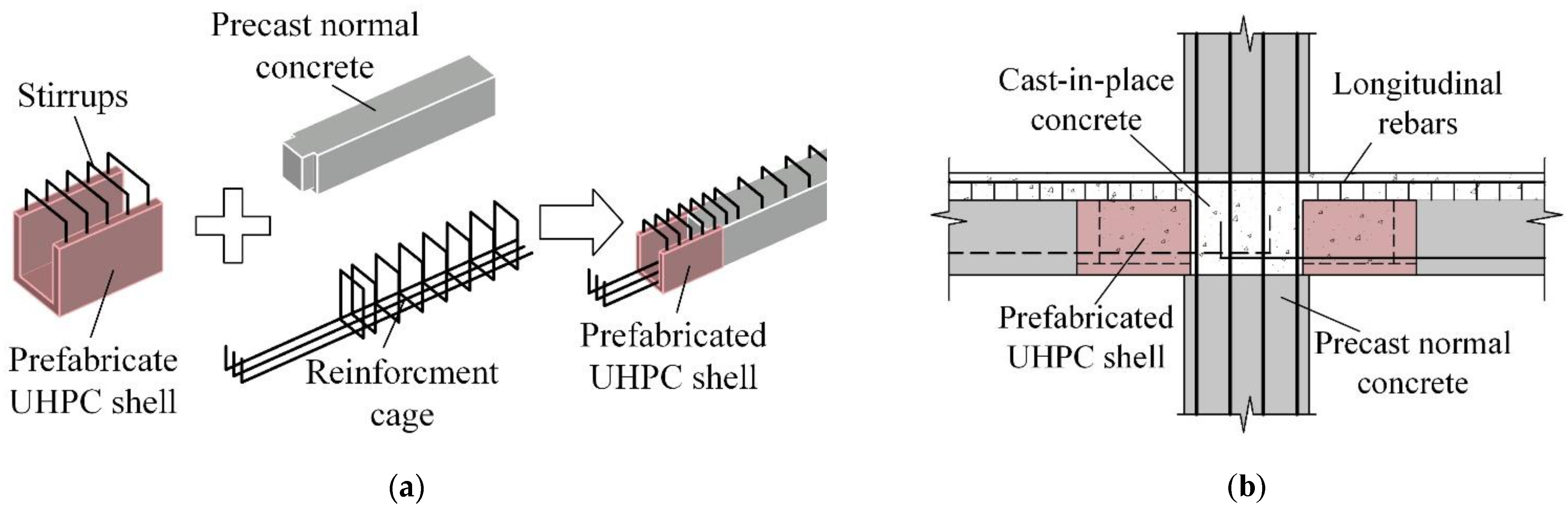

2. Structural Details of the Innovative Connection

3. Experimental Investigation

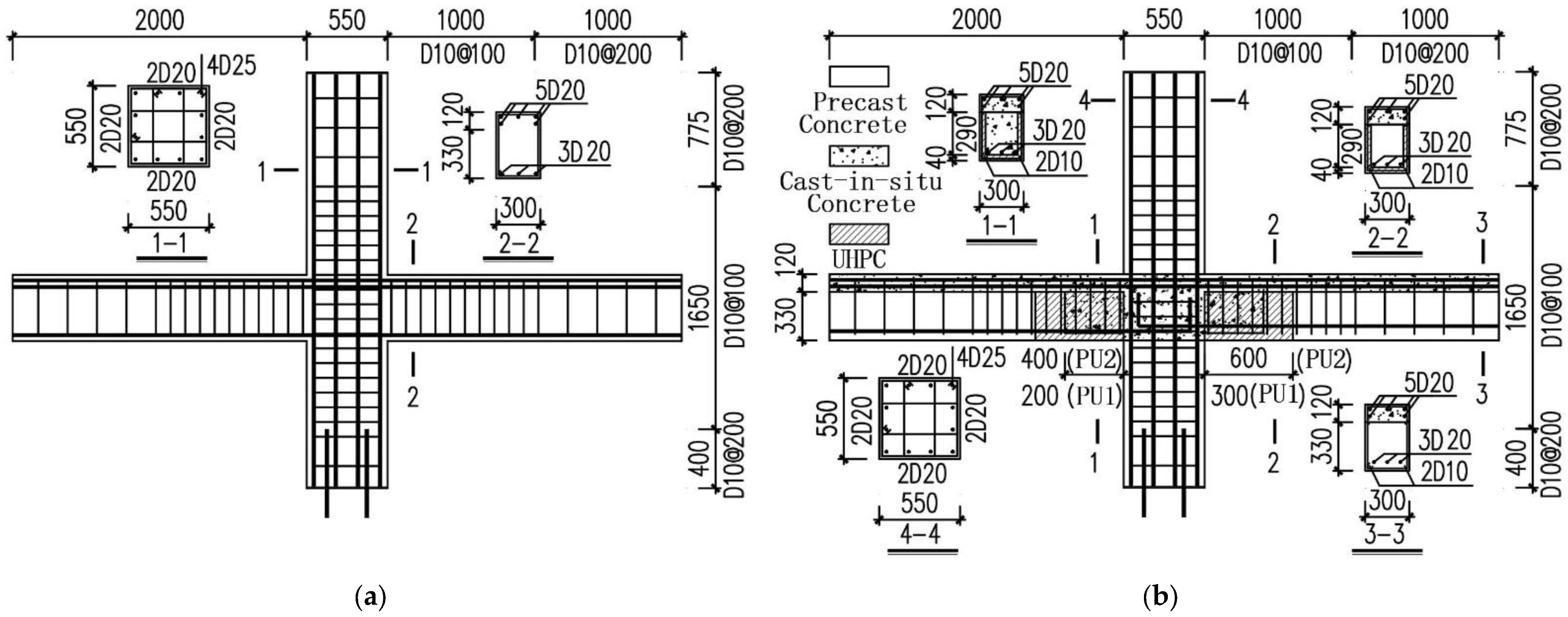

3.1. Specimen Description

3.2. Material Properties

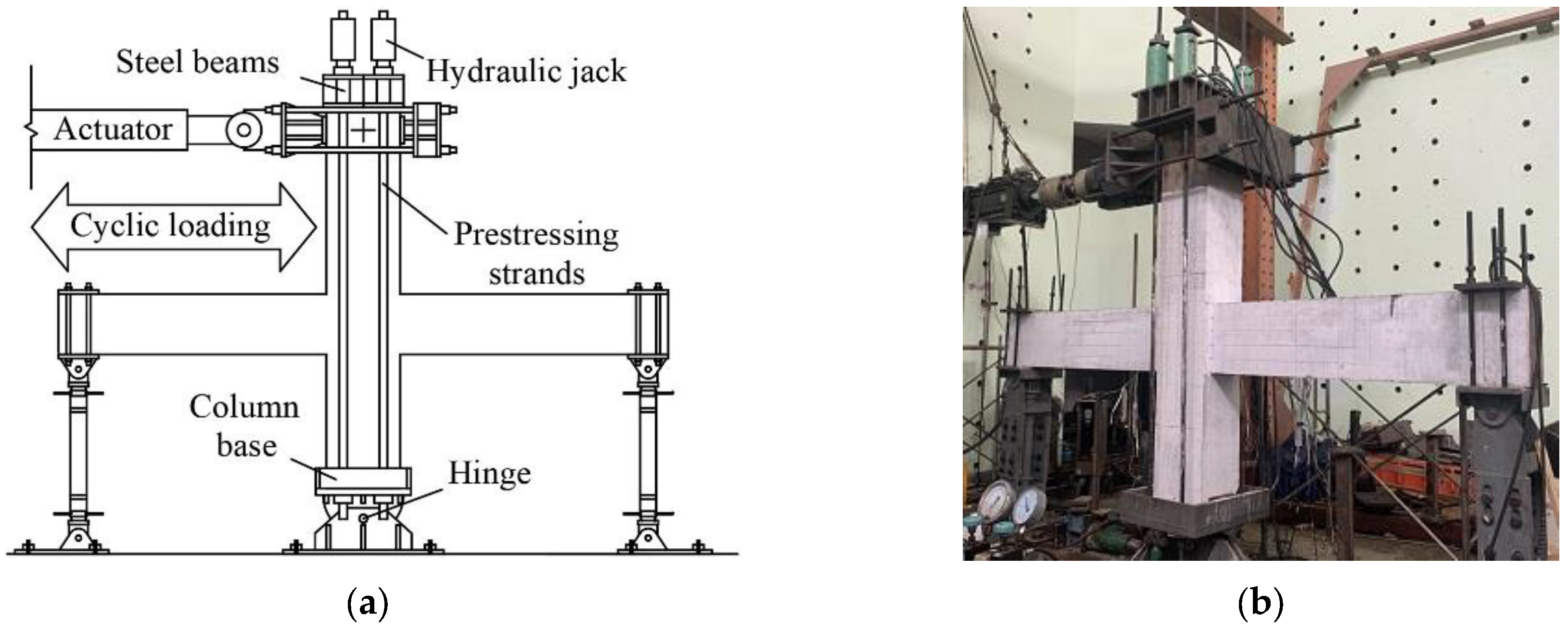

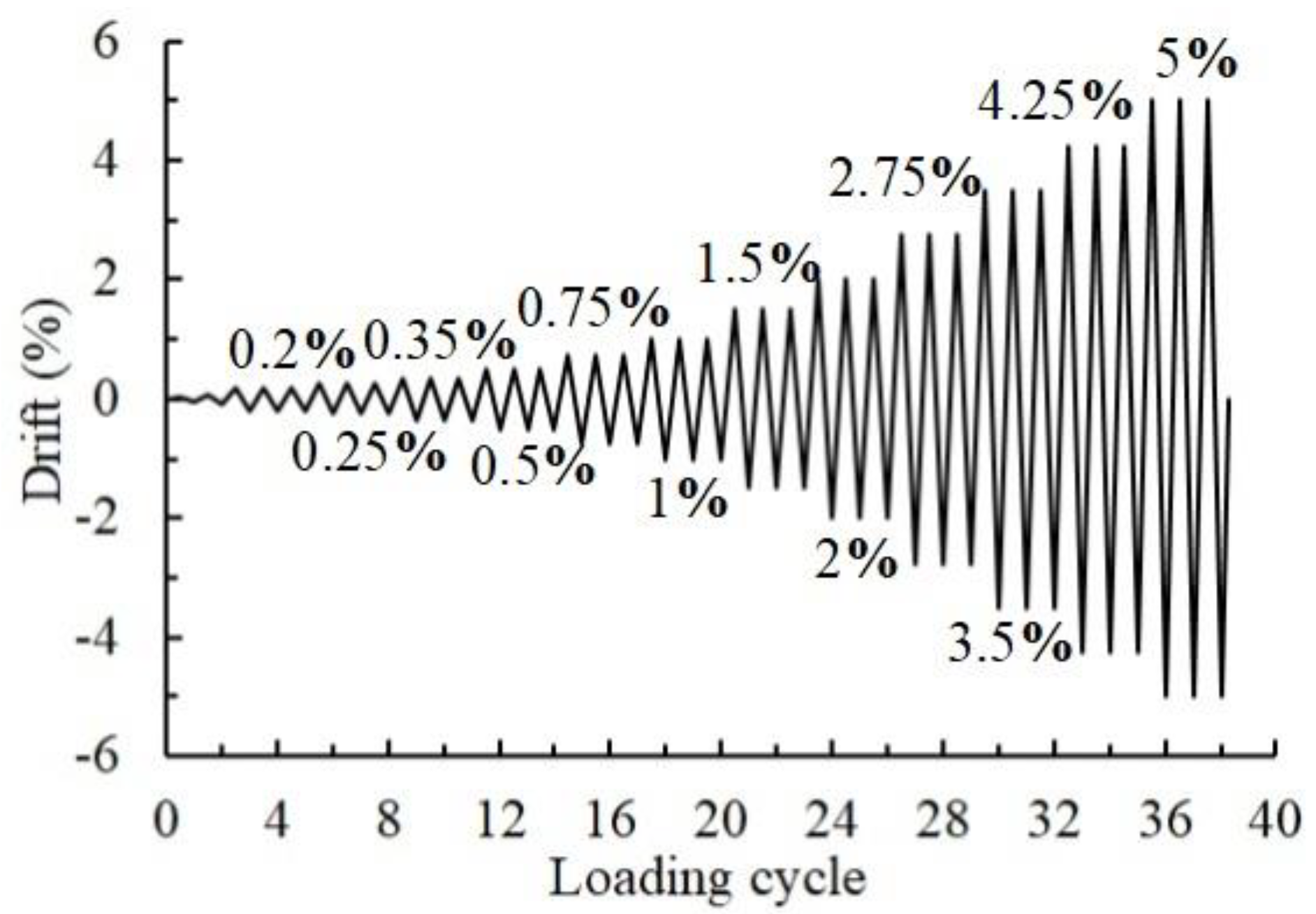

3.3. Test Setup and Loading Protocol

4. Results and Discussions

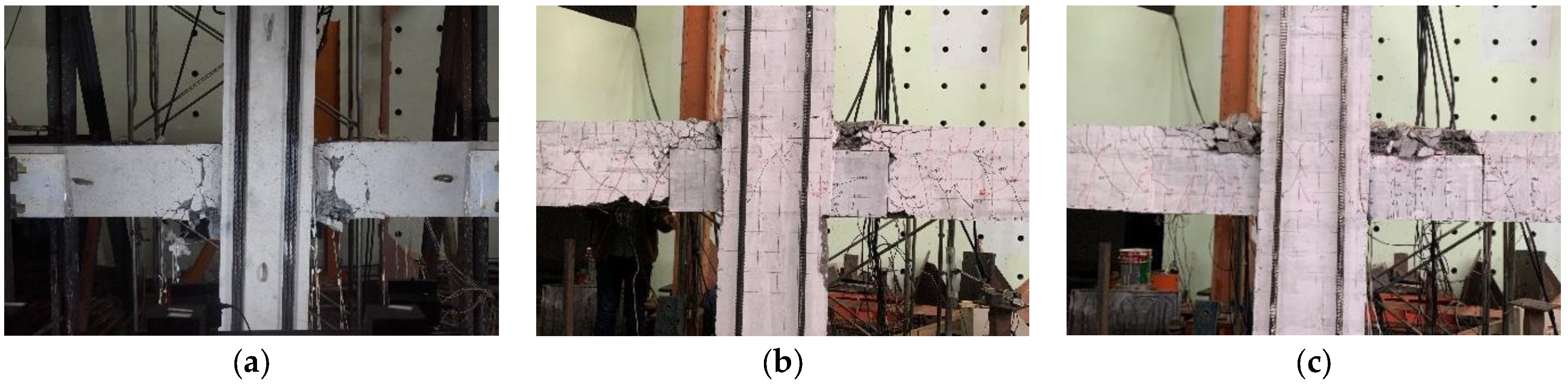

4.1. Damage and Failure Modes

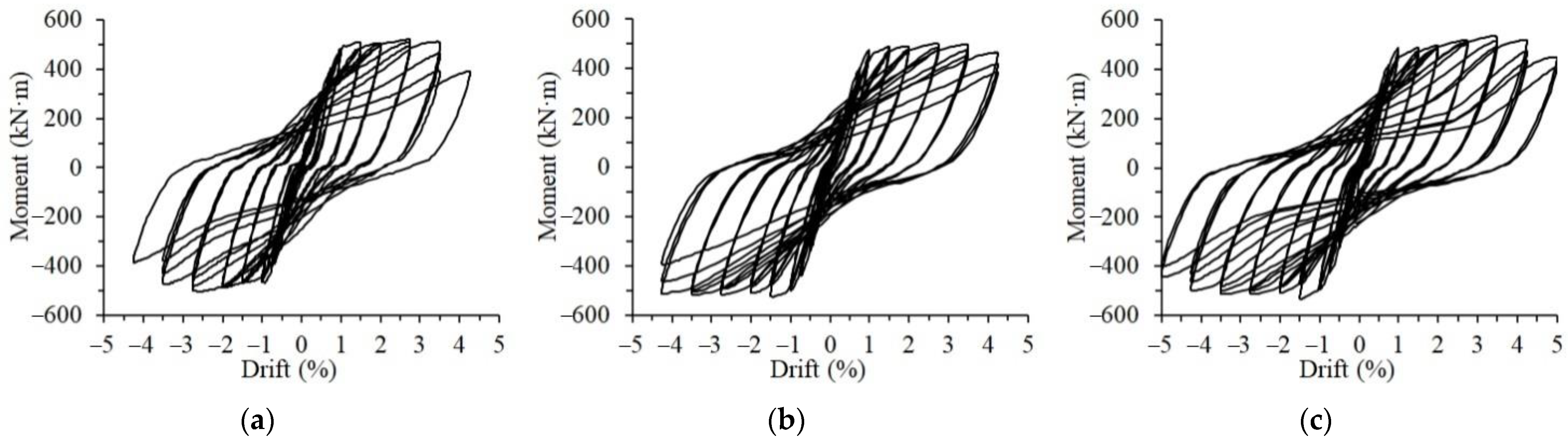

4.2. Hysteresis and Skeleton Curves

4.3. Performance of Strength and Deformability

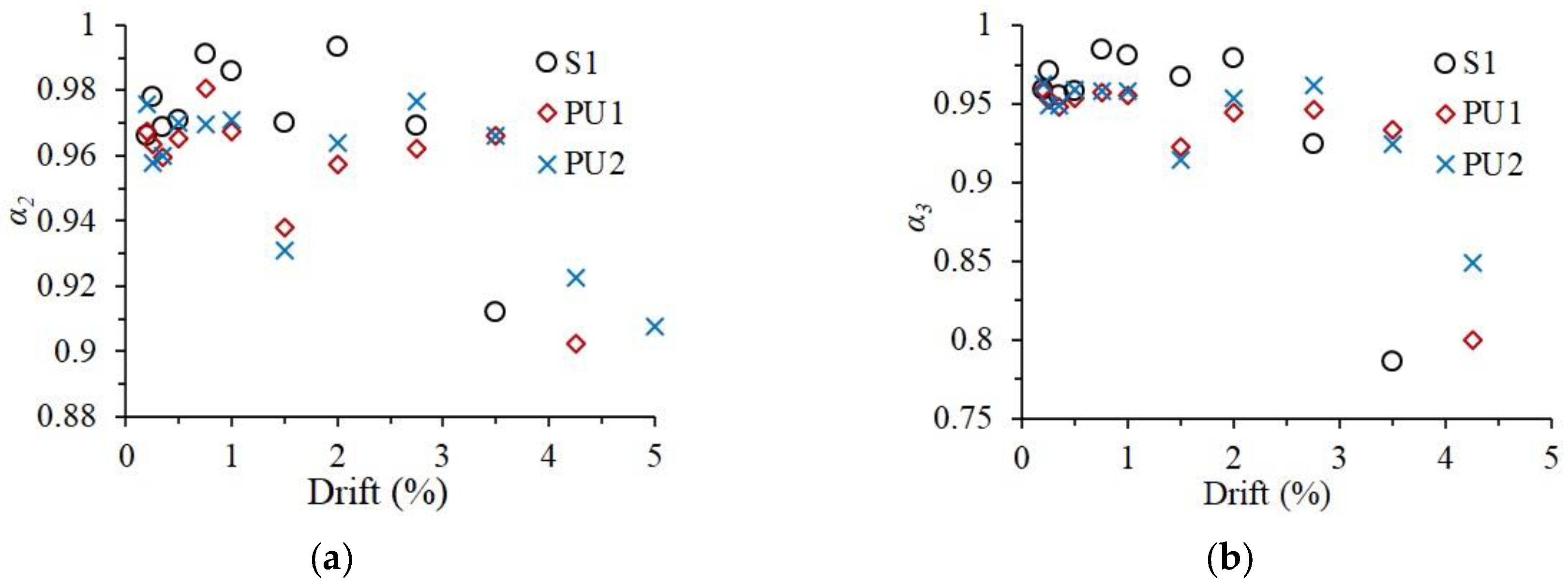

4.4. Performance Degradation

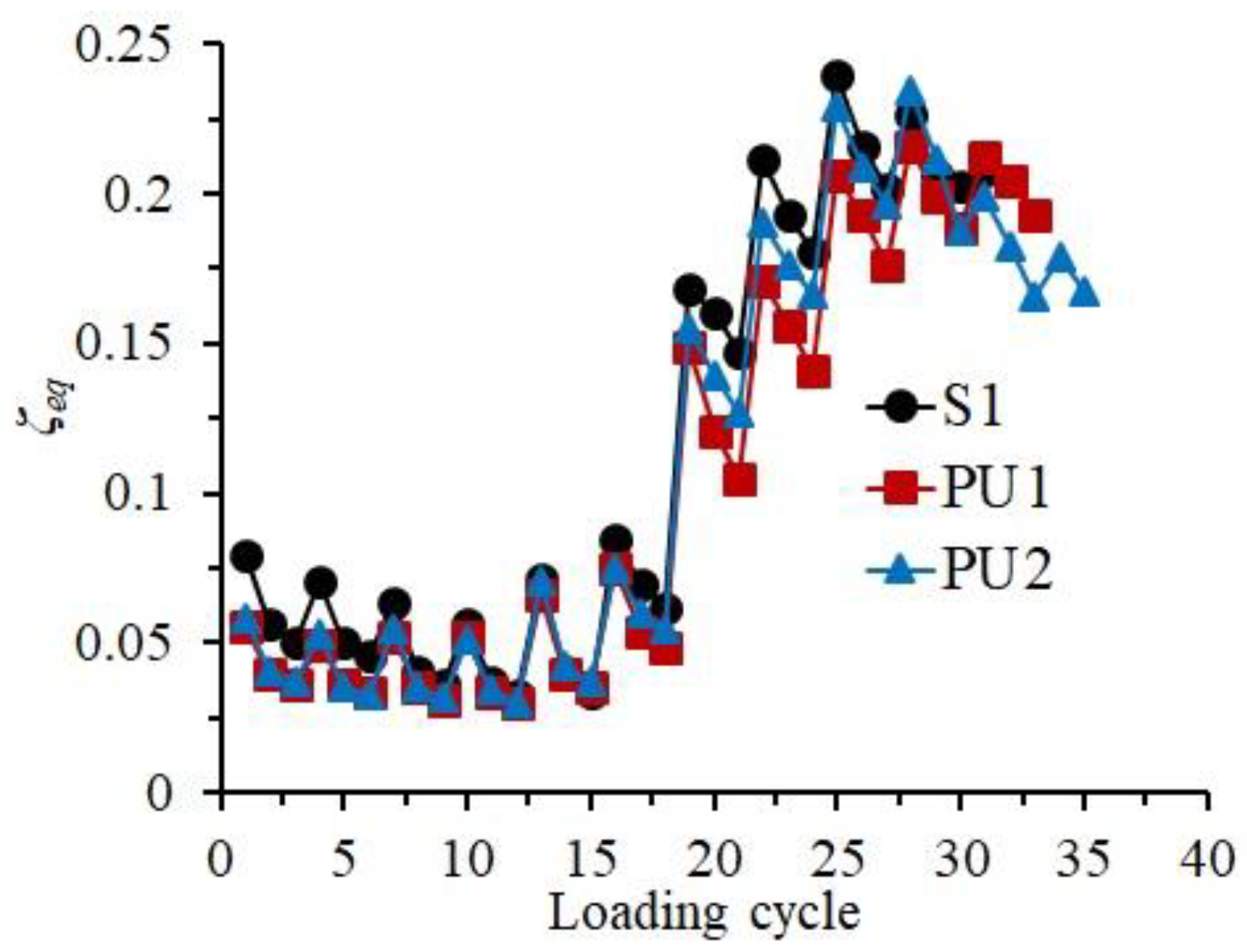

4.5. Capacity of Energy Dissipation

4.6. Length of Plastic Hinges

5. Conclusions

- (1)

- The precast concrete beam–column connections, locally reinforced by U-shaped UHPC shells, exhibited good seismic performance with comparable hysteresis behaviors that were close to the ones of the monolithic reference specimen.

- (2)

- The failure mode of the beam sideway mechanism was achieved by the novel connections; thus, the principle of a “strong column–weak beam” could be used to design the proposed connection.

- (3)

- In comparison with the monolithic reference specimen, the prefabricated UHPC shells could reduce the damage in the concrete near the lower parts of the beam ends. They could also enhance the seismic behaviors of the precast concrete specimens under large loading drifts and maintained better capacity of load-bearing and energy dissipation when the precast specimens approached failure.

- (4)

- The longer precast UHPC shell was more conducive to reducing the concrete damage of the precast specimens and improving the strength, ultimate deformation capacity, and capacity of energy dissipation. The precast specimen with 600-mm long UHPC shells can achieve a ductility of 4.87 and 4.0% higher strength than the monolithic reference specimen.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wu, G.; Feng, D.C.; Xu, Z.; Miu, C.W. Research developments in pecast concrete structural systems. J. Civ. Eng. Manag. 2021, 38, 41–51. [Google Scholar]

- Bagheri, M.; Chahkandi, A.; Jahangir, H. Seismic reliability analysis of RC frames rehabilitated by glass fiber-reinforced polymers. Int. J. Civ. Eng. 2019, 17, 1785–1797. [Google Scholar] [CrossRef]

- Ghosh, S.K.; Nakaki, S.D.; Krishnan, K. Precast Structures in Regions of High Seismicity: 1997 UBC Design Provisions. PCI J. 1997, 42, 76–93. [Google Scholar] [CrossRef]

- Ameli, M.J.; Pantelides, C.P. Seismic Analysis of Precast Concrete Bridge Columns Connected with Grouted Splice Sleeve Connectors. J. Struct. Eng. 2017, 143, 04016176. [Google Scholar] [CrossRef]

- Liu, L.; Huang, X.K.; Tian, C.Y.; Yin, X.W.; Li, R.; Li, G.Q. Experimental study on seismic performance of precast RC frame joints with HRB500 high strength rebars of large diameter and spacing. J. Build. Eng. 2016, 37, 247–254. [Google Scholar]

- Zhao, Y.; Li, R.; Wang, X.F.; Han, C. Experimental research on seismic behaviors of precast concrete columns with large-diameter and high-yield strength reinforcements rplicing by grout-filled coupling sleeves. J. China Civ. Eng. J. 2017, 50, 27–35. [Google Scholar]

- Zhu, Z.F.; Guo, Z.X. Experimental research on the seismic performance of new hybrid precast concrete shear walls under various axial compression ratios. J. Eng. Plast. Appl. 2016, 33, 143–149. [Google Scholar]

- Guan, D.; Jiang, C.; Guo, Z.; Ge, H. Development and Seismic Behavior of Precast Concrete Beam-to-Column Connections. J. Earthq. Eng. 2018, 22, 234–256. [Google Scholar] [CrossRef]

- Guan, D.; Chen, Z.; Liu, J.; Lin, Z.; Guo, Z. Seismic performance of precast concrete columns with prefabricated UHPC jackets in plastic hinge zone. J. Eng. Struct. 2021, 245, 112776. [Google Scholar] [CrossRef]

- Liu, J.B.; Chen, Y.G.; Guo, Z.X.; Yuan, F. Seismic Behavior of Precast Shear Wall with Rectangular Spiral Stirrups-Constraint Grouted Corrugated Pipe Connection. J. S. China Univ. Technol. Nat. Sci. Ed. 2014, 42, 92–98. [Google Scholar]

- Guan, D.; Guo, Z.; Jiang, C.; Yang, S.; Yang, H. Experimental Evaluation of Precast Concrete Beam-Column Connections with High-strength Steel Rebars. J. KSCE J. Civ. Eng. 2019, 23, 238–250. [Google Scholar] [CrossRef]

- Marvila, M.T.; Azevedo, A.; Monteiro, S.; Matos, P.; Vieira, C. Materials for production of high and ultra-high performance concrete: Review and perspective of possible novel materials. Materials 2021, 14, 4304. [Google Scholar] [CrossRef] [PubMed]

- Yan, P.; Chen, B.; Afgan, S.; Aminul Haque, M.; Wu, M.; Han, J. Experimental Research on Ductility Enhancement of Ultra-High Performance Concrete Incorporation with Basalt Fibre, Polypropylene Fibre and Glass Fibre. Constr. Build. Mater. 2021, 279, 122489. [Google Scholar] [CrossRef]

- ASTM C1856/C1856M-17; Standard Practice for Fabricating and Testing Specimens of Ultra-High Performance Concrete. ASTM International: West Conshohocken, PA, USA, 2017.

- Liu, J.; Chen, Z.; Guan, D.; Lin, Z.; Guo, Z. Experimental study on interfacial shear behaviour between ultra-high performance concrete and normal strength concrete in precast composite members. J. Constr. Build. Mater. 2020, 261, 120008. [Google Scholar] [CrossRef]

- Abusafaqa, F.R.; Samaaneh, M.A.; Dwaikat, M.B. Improving ductility behavior of sway-special exterior beam-column joint using ultra-high performance fiber-reinforced concrete. Structures 2022, 36, 979–996. [Google Scholar] [CrossRef]

- Guan, D.; Xu, R.; Yang, S.; Chen, Z.; Guo, Z. Development and seismic behavior of a novel UHPC-shell strengthened prefabricated concrete column. J. Build. Eng. 2022, 46, 103672. [Google Scholar] [CrossRef]

- Maya, L.F.; Zanuy, C.; Albajar, L.; Lopez, C.; Portabella, J. Experimental assessment of connections for precast concrete frames using ultra high performance fibre reinforced concrete. J. Constr. Build. Mater. 2013, 48, 173–186. [Google Scholar] [CrossRef]

- Xue, W.; Hu, X.; Song, J. Experimental study on seismic behavior of precast concrete beam-column joints using UHPC-based connections. J. Struct. 2021, 34, 4867–4881. [Google Scholar] [CrossRef]

- Zhang, Z.-Y.; Ding, R.; Nie, X.; Fan, J.-S. Seismic performance of a novel interior precast concrete beam- column joint using ultra-high performance concrete. J. Eng. Struct. 2020, 222, 111145. [Google Scholar] [CrossRef]

- Ma, Y.Q.; Long, L.B.; Zhen, Q.Z. Innovative study on new type connection of prefabricated joints and structure system based on UHPC. J. Build. Mater. 2016, 38, 1724–1725. [Google Scholar]

- Ma, F.; Deng, M.; Ma, Y.; Lü, H.; Yang, Y.; Sun, H. Experimental study on interior precast concrete beam–Column connections with lap-spliced steel bars in field-cast RPC. J. Eng. Struct. 2021, 228, 111481. [Google Scholar] [CrossRef]

- Lin, Y.; Chen, Z.; Guan, D.; Guo, Z. Experimental study on interior precast concrete beam-column connections with UHPC core shells. Structures 2021, 32, 1103–1114. [Google Scholar] [CrossRef]

- GB50010-2010 [2010]; Code for Design of Concrete Structures. The Standardization Administration of the People’s Republic of China: Beijing, China, 2010.

- Han, F.Y.; Liu, J.Z.; Liu, J.P.; Ma, B.; Sha, J.; Wang, X. Study on anchorage behavior of steel bar in ultra-high performance concrete. J. Mater. Rep. 2019, 33.z1, 244–248. [Google Scholar]

- GB/T 31387-2015; Reactive Powder Concrete. The Standardization Administration of the People’s Republic of China: Beijing, China, 2015.

- Rokugo, K. Recommendations for design and construction of High Performance Fiber Reinforced Cement Composites with multiple fine cracks (HPFRCC). J. Concr. J. 2007, 45, 3–9. [Google Scholar] [CrossRef] [Green Version]

- ACI-374.1-05, ACI Committee 374; Acceptance Criteria for Moment Frames Based on Structural Testing and Commentary. American Concrete Institute: Farmington Hills, MI, USA, 2005.

- ASCE/SEI 41-06; A New Seismic Rehabilitation Standard. American Society of Civil Engineers: Reston, VA, USA, 2017.

- Ho, C. Inelastic Design of Reinforced Concrete Beams and Limited Ductilehigh-Strength Concrete Columns; The University of Hong Kong: Hong Kong, China, 2003. [Google Scholar]

- Ning, C.-L.; Li, B. Probabilistic Approach for Estimating Plastic Hinge Length of Reinforced Concrete Columns. J. Struct. Eng. U. S. 2016, 142, 04015164. [Google Scholar] [CrossRef]

- Elmenshawi, A.; Brown, T.; El-Metwally, S. Plastic Hinge Length Considering Shear Reversal in Reinforced Concrete Elements. J. Earthq. Eng. 2012, 16, 188–210. [Google Scholar] [CrossRef]

| Reactive Powder | River Sand a | Water | Steel Fibre b | Admixture c |

|---|---|---|---|---|

| 1170 | 930 | 182 | 160 | 22 |

| Specimen | Cubic Compressive Strength (MPa) | Tensile Strength (MPa) |

|---|---|---|

| UHPC | 103.7 | 7.82 |

| Concrete of precast elements | 40.7 | - |

| Cast-in-place concrete | 41.3 | - |

| Reinforcing Rebars | Diameter (mm) | Yield Strength (MPa) | Ultimate Strength (MPa) |

|---|---|---|---|

| Longitudinal rebars | 20 | 413 | 580 |

| 25 | 439 | 598 | |

| Stirrups | 8 | 613 | 710 |

| 10 | 542 | 635 |

| Specimen | Direction | Yield Strength (kN·m) | Maximum Strength (kN·m) | Ratio of Maximum Strength to Yield Strength | Average |

|---|---|---|---|---|---|

| S1 | Positive | 484.5 | 520.8 | 1.08 | 1.075 |

| Negative | −467.8 | −501.9 | 1.07 | ||

| PU1 | Positive | 462.7 | 500.9 | 1.08 | 1.070 |

| Negative | −496.8 | −526.5 | 1.06 | ||

| PU2 | Positive | 485.4 | 533.5 | 1.10 | 1.085 |

| Negative | −496.2 | −530.3 | 1.07 |

| Specimen | Direction | Yield Drift | Ultimate Drift | Ductility | Average |

|---|---|---|---|---|---|

| S1 | Positive | 1.00 | 4.07 | 4.08 | 3.82 |

| Negative | −1.12 | −4.00 | 3.57 | ||

| PU1 | Positive | 1.14 | 4.23 | 3.71 | 3.95 |

| Negative | −1.00 | −4.18 | 4.18 | ||

| PU2 | Positive | 0.99 | 4.98 | 5.03 | 4.87 |

| Negative | −1.06 | −4.98 | 4.70 |

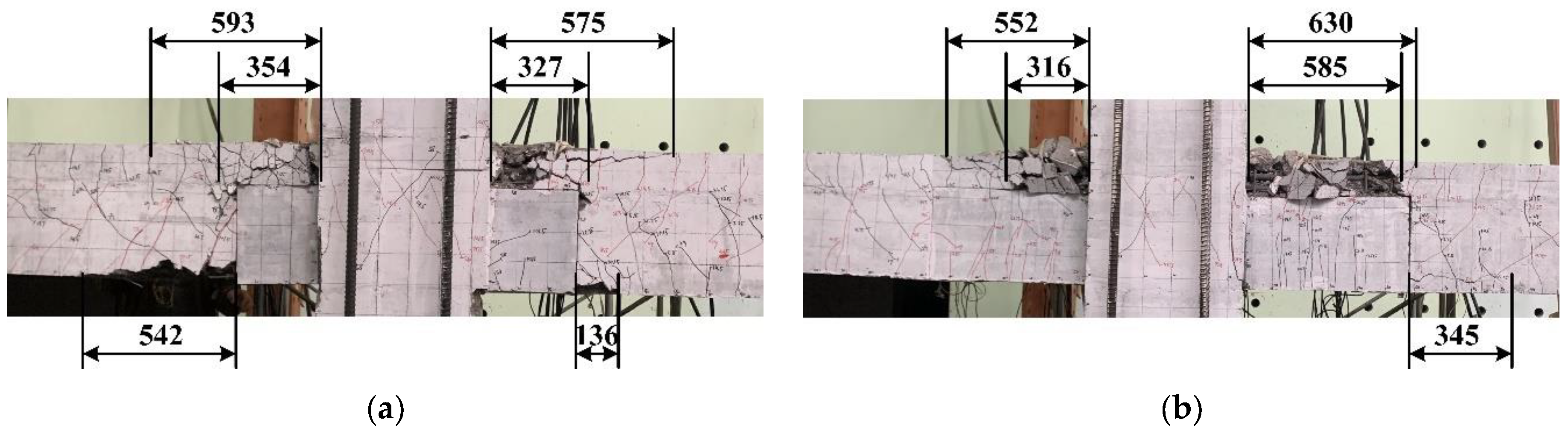

| Specimens | Left | Right | LP | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Top | Middle | Bottom | Average | Top | Middle | Bottom | Average | ||

| PU1 | 593 | 354 | 542 | 496 | 575 | 327 | 136 | 346 | 421 |

| PU2 | 552 | 316 | 0 | 289 | 630 | 585 | 345 | 520 | 405 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, L.; Tian, W.; Guan, D.; Chen, Z. Experimental Study of Emulative Precast Concrete Beam-to-Column Connections Locally Reinforced by U-Shaped UHPC Shells. Materials 2022, 15, 4066. https://doi.org/10.3390/ma15124066

Tang L, Tian W, Guan D, Chen Z. Experimental Study of Emulative Precast Concrete Beam-to-Column Connections Locally Reinforced by U-Shaped UHPC Shells. Materials. 2022; 15(12):4066. https://doi.org/10.3390/ma15124066

Chicago/Turabian StyleTang, Lei, Wenhua Tian, Dongzhi Guan, and Zixuan Chen. 2022. "Experimental Study of Emulative Precast Concrete Beam-to-Column Connections Locally Reinforced by U-Shaped UHPC Shells" Materials 15, no. 12: 4066. https://doi.org/10.3390/ma15124066

APA StyleTang, L., Tian, W., Guan, D., & Chen, Z. (2022). Experimental Study of Emulative Precast Concrete Beam-to-Column Connections Locally Reinforced by U-Shaped UHPC Shells. Materials, 15(12), 4066. https://doi.org/10.3390/ma15124066