Effect of Curing Temperature on High-Strength Metakaolin-Based Geopolymer Composite (HMGC) with Quartz Powder and Steel Fibers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mix Ratio and Preparation of HMGC

2.2.1. Mix Ratio Design

2.2.2. Preparation of HMGC

2.3. Experiment Method

2.3.1. Determination of HMGC Setting Time

2.3.2. The Mechanical Properties of HMGC

2.3.3. Phase Analysis—X-ray Diffraction Test (XRD)

2.3.4. Morphology Analysis—Scanning Electron Microscope Experiment

2.3.5. Structural Gene Analysis—Infrared Spectroscopy (FTIR)

2.3.6. Pore Structure Analysis—Mercury Intrusion Porosimetry (MIP)

3. Results

3.1. Optimization of Quartz Powder Content

3.2. Optimization of Steel Fiber Content

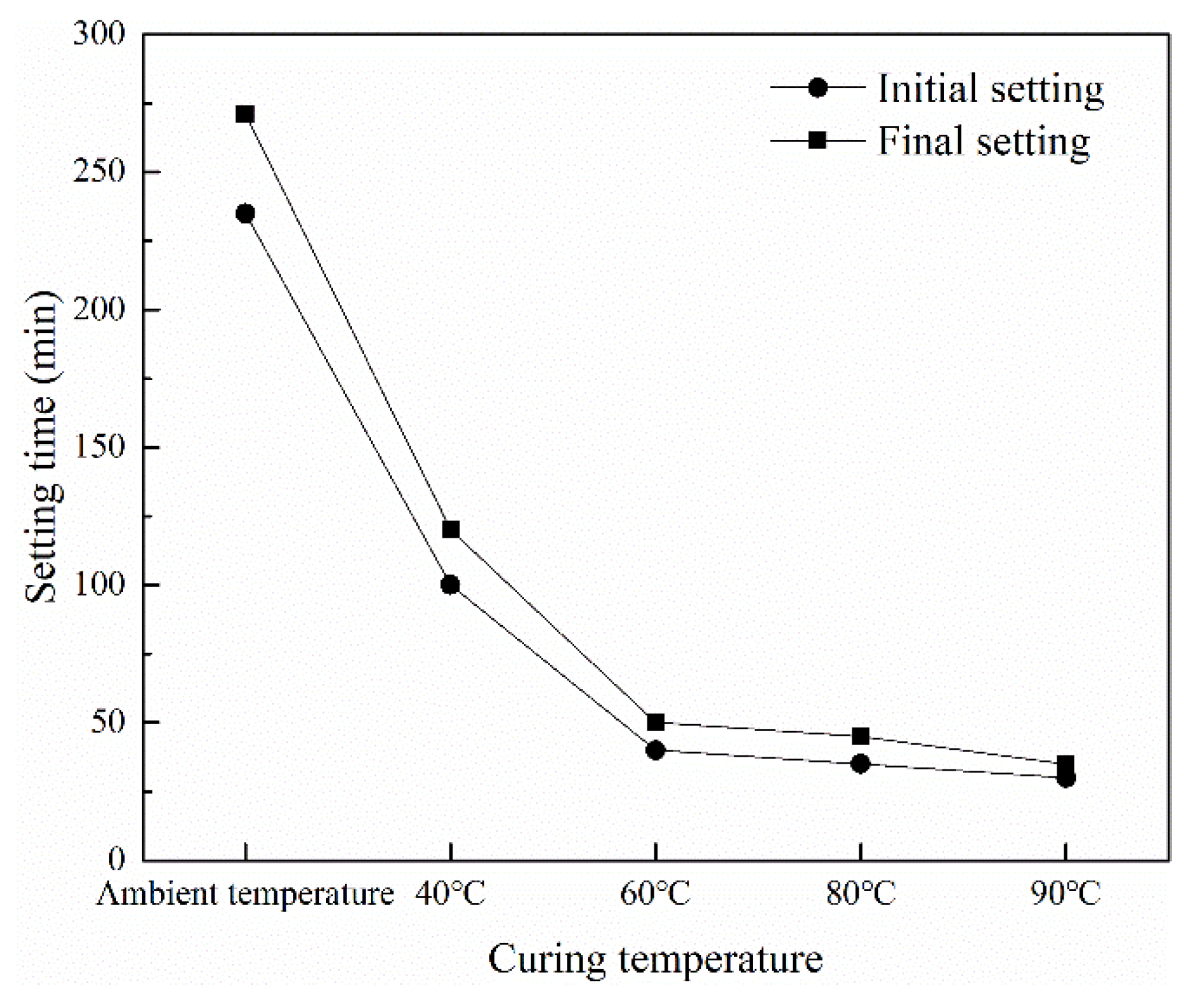

3.3. Setting Time of HMGC

3.4. Compressive Strength of HMGC

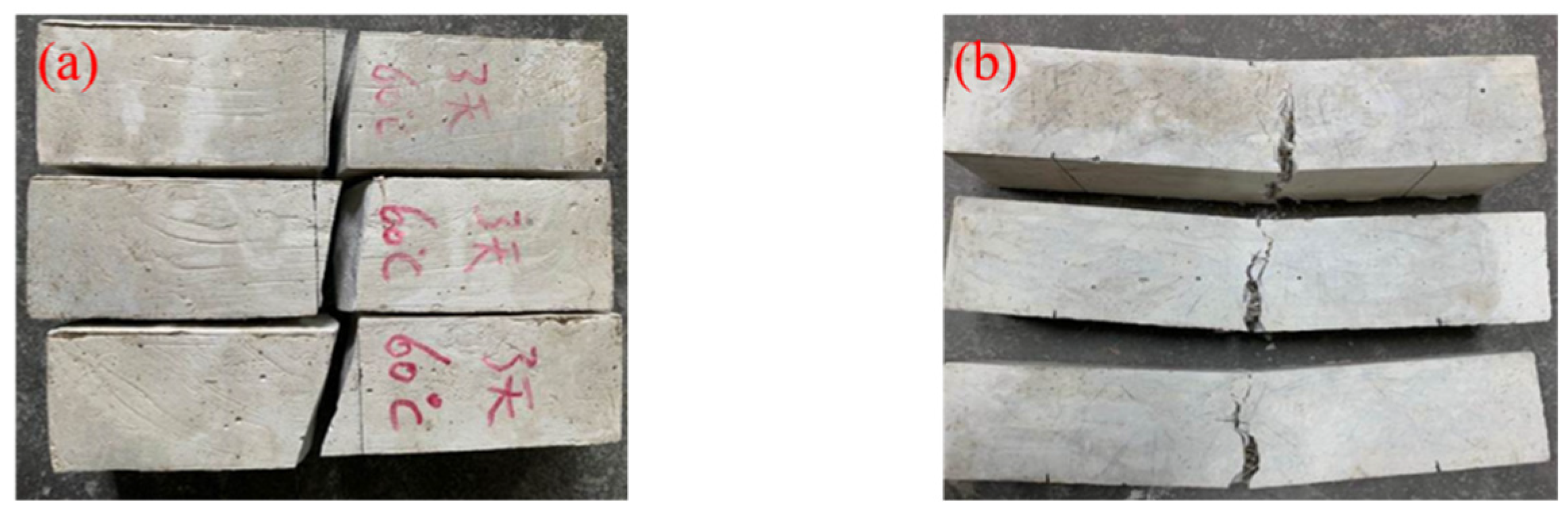

3.5. Flexural Strength Analysis of HMGC

3.6. Micromorphology-SEM Analysis of HMGC

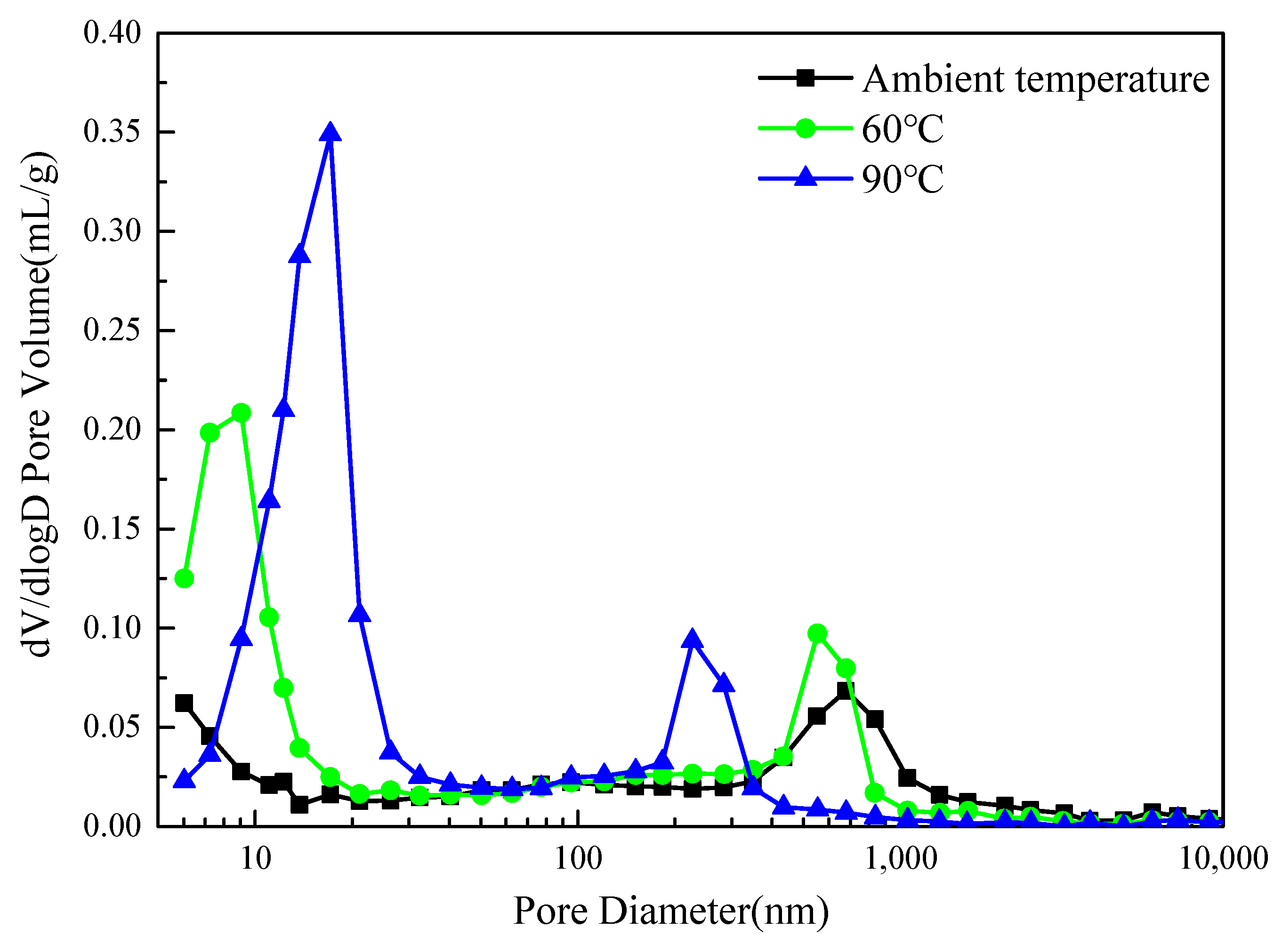

3.7. Pore Structure Analysis of HMGC

3.8. Phase Analysis of HMGC

3.9. FTIR Results Analysis of HMGC

4. Conclusions

- (1)

- The optimized quartz powder/metakaolin ratio is 1.5 and steel fibers content is 1.5 vol.%, according to the mechanical performance of the HMGC.

- (2)

- The curing temperature has little effect on the crystalline product and chemical structures of the HMGC. The effect of curing temperature on strength is majorly due to microstructure changes.

- (3)

- Heat curing at an appropriate temperature (such as 60 °C) can significantly speed up the process of geopolymerization and enhance the pore-filling effect of the gel. This leads to a high mechanical strength of the HMGC. However, long-term heat curing under too-high temperature (such as 90 °C, 7 days) would coarsen the pores and cause micro-defects in the gel phase of the HMGC due to chemical shrinkage, thus reducing the mechanical performance of the HMGC.

- (4)

- The curing temperature should be carefully controlled to produce a HMGC with better performance in applications.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sathonsaowophak, A.; Chindaprasirt, P. Workability and strength of lignite bottom ash geopolymer mortar. J. Hazard. Mater. 2009, 168, 44–50. [Google Scholar] [CrossRef] [PubMed]

- Chindaprasirt, T. Workability and strength of coarse high calcium fly ash geopolymer. Cem. Concr. Compos. 2007, 29, 224–229. [Google Scholar] [CrossRef]

- Guo, X. Compressive strength and microstructural characteristics of class C fly ash geopolymer. Cem. Concr. Compos. 2010, 32, 142–147. [Google Scholar] [CrossRef]

- Zivica, V.; Palou, T. High strength metahalloysite based geopolymer. Compos. Part B Eng. 2014, 57, 155–165. [Google Scholar] [CrossRef]

- Bagheri, A.; Nazari, A. Compressive strength of high strength class C fly ash-based geopolymers with reactive granulated blast furnace slag aggregates designed by Taguchi method. Mater. Des. 2014, 54, 483–490. [Google Scholar] [CrossRef]

- Vafaei, M.; Allahverdi, A. High strength geopolymer binder based on waste-glass powder. Adv. Powder Technol. 2017, 28, 215–222. [Google Scholar] [CrossRef]

- Duan, P.; Yan, C. Compressive strength and microstructure of fly ash based geopolymer blended with silica fume under thermal cycle. Cem. Concr. Compos. 2017, 78, 108–119. [Google Scholar] [CrossRef]

- Dun-Xing, L.I.; Chen, X.P.; Zhang, Y.; Xie, X.M. Effect of Slag Content on Properties and Structures of Metakaolin-based Geopolymer. Contemp. Chem. Ind. 2017, 11, 2181–2184. (In Chinese) [Google Scholar]

- Khan, M.Z.N.; Shaikh, F.U.N. Synthesis of high strength ambient cured geopolymer composite by using low calcium fly ash. Constr. Build. Mater. 2016, 125, 809–820. [Google Scholar] [CrossRef]

- Atis, C.D.; Görür, E.B. Very high strength (120 MPa) class F fly ash geopolymer mortar activated at different NaOH amount heat curing temperature and heat curing duration. Constr. Build. Mater. 2015, 96, 673–678. [Google Scholar] [CrossRef]

- Xie, S. Preparation of Functional Gradient Porous Bioactive Geopolymer Composites. Master’s Thesis, Wuhan Institute of Technology, Wuhan, China, 2016. (In Chinese). [Google Scholar]

- Abbas, S.; Soliman, A.M.; Nehdi, M.L. Exploring mechanical and durability properties of ultra-high performance concrete incorporating various steel fiber lengths and dosages. Constr. Build. Mater. 2015, 75, 429–441. [Google Scholar] [CrossRef]

- Prem, P.R.; Ramachandra Murthy, A.; Bharatkumar, B.H. Influence of curing regime and steel fibres on the mechanical properties of UHPC. Mag. Concr. Res. 2015, 67, 988–1002. [Google Scholar] [CrossRef]

- Wang, R.; Gao, X. Relationship between flowability, entrapped air content and strength of UHPC mixtures containing different dosage of steel fiber. Appl. Sci. 2016, 6, 216. [Google Scholar] [CrossRef] [Green Version]

- Hung, C.C.; Lee, H.S.; Chan, S.N. Tension-stiffening effect in steel-reinforced UHPC composites: Constitutive model and effects of steel fibers, loading patterns, and rebar sizes. Compos. Part B Eng. 2019, 158, 269–278. [Google Scholar] [CrossRef]

- He, B.; Zhu, X.; Ren, Q.; Jiang, Z. Effects of fibers on flexural strength of ultra-high-performance concrete subjected to cryogenic attack. Constr. Build. Mater. 2020, 265, 120323. [Google Scholar] [CrossRef]

- Tadepalli, P.R.; Mo, Y.L.; Hsu, T.T.C. Mechanical properties of steel fibre concrete. Mag. Concr. Res. 2013, 65, 462–474. [Google Scholar] [CrossRef]

- Kang, S.H.; Jeong, Y.; Tan, K.H.; Moon, J. The use of limestone to replace physical filler of quartz powder in UHPFRC. Cem. Concr. Compos. 2018, 94, 238–247. [Google Scholar] [CrossRef]

- Kathirvel, P.; Sreekumaran, S. Sustainable development of ultra high performance concrete using geopolymer technology. J. Build. Eng. 2021, 39, 102267. [Google Scholar] [CrossRef]

- Rashad, A.M.; Hassan, A.A.; Zeedan, S.R. An investigation on alkali-activated Egyptian metakaolin pastes blended with quartz powder subjected to elevated temperatures. Appl. Clay Sci. 2016, 132, 366–376. [Google Scholar] [CrossRef]

- Kaplan, G.A.Z.; Bayrak, B.; Alcan, H.G.; Elebi, O.; Aydn, A.C. Effect of quartz powder on mid-strength fly ash geopolymers at short curing time and low curing temperature. Constr. Build. Mater. 2022, 329, 127153. [Google Scholar] [CrossRef]

- Bing-Hui, M.; Zhu, H.; Xue-Min, C.; He, Y.; Si-Yu, G. Effect of curing temperature on geopolymerization of metakaolin-based geopolymers. Appl. Clay Sci. 2014, 99, 144–148. [Google Scholar]

- Sukmak, P.; Horpibulsuk, S.; Shen, S.L.; Chindaprasirt, P.; Suksiripattanapong, C. Factors influencing strength development in clay–fly ash geopolymer. Constr. Build. Mater. 2013, 47, 1125–1136. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P.K. Use of OPC to improve setting and early strength properties of low calcium fly ash geopolymer concrete cured at room temperature. Cem. Concr. Compos. 2015, 55, 205–214. [Google Scholar] [CrossRef]

- Chen, S.; Wu, C.; Yan, D. Binder-scale creep behavior of metakaolin-based geopolymer. Cem. Concr. Res. 2019, 124, 105810. [Google Scholar] [CrossRef]

- GB T1346-2011; Test Methods for Water Requirements of Normal Consistency, Setting Time and Soundness of Portland Cement. CNS: Beijing, China, 2011. (In Chinese)

- Chinese National Standard GB/T 17671-1999; Method of Testing Cements—Determination of Strength. CNS: Beijing, China, 1999. (In Chinese)

- Nath, P.; Sarker, P.K. Effect of GGBFS on setting, workability and early strength properties of fly ash geopolymer concrete cured in ambient condition. Constr. Build. Mater. 2014, 66, 163–171. [Google Scholar] [CrossRef] [Green Version]

- Bakharev, T.; Sanjayan, J.G.; Cheng, Y.-B. Effect of elevated temperature curing on properties of alkali-activated slag concrete. Cem. Concr. Res. 1999, 29, 1619–1625. [Google Scholar] [CrossRef]

- Muñiz-Villarreala, M.S.; Manzano-Ramíreza, A.; Sampieri-Bulbarelaa, S.; RamónGasca-Tiradoa, J.; Reyes-Araizaa, J.L.; Rubio-Ávalosa, J.C.; Pérez-Buenob, J.J.; Apatigac, L.M.; Zaldivar-Cadenad, A.; Amigó-Borrás, V. The effect of temperature on the geopolymerization process of a metakaolin-based geopolymer. Mater. Lett. 2011, 65, 995–998. [Google Scholar] [CrossRef]

- Aamer, B.; Paulo, H. Flexural behavior of geopolymer composites reinforced with steel and polypropylene macro fibers. Cem. Concr. Compos. 2017, 80, 31–40. [Google Scholar]

- Asrani, N.P.; Murali, G.; Parthiban, K.; Surya, K.; Prakash, A.; Rathika, K. A feasibility of enhancing the impact resistance of hybrid fibrous geopolymer composites: Experiments and modelling. Constr. Build. Mater. 2019, 203, 56–68. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, S.; Zuo, Y.; Chen, W.; Ye, G. Chemical deformation of metakaolin based geopolymer. Cem. Concr. Res. 2019, 120, 108–118. [Google Scholar] [CrossRef]

- Chen, S.; Wang, K.; Wei, E.; Muhamm, Y.; Yi, M.; Wei, Y.; Fujita, T. Preparation of Al2O3-2SiO2/geopolymer powder by hydrolytic sol-gel method and its activity characterization and research on the reaction mechanism. Powder Technol. 2022, 397, 117026. [Google Scholar] [CrossRef]

- Palomo, A.; Blanco-Varela, M.T.; Granizo, M.L.; Puertas, F.; Grutzeck, M.W. Chemical stability of cementitious materials based on metakaolin. Cem. Concr. Res. 1999, 29, 997–1004. [Google Scholar] [CrossRef]

- Nath, S.K.; Kumar, S. Influence of iron making slags on strength and microstructure of fly ash geopolymer. Constr. Build. Mater. 2013, 38, 924–930. [Google Scholar] [CrossRef]

- Lee, W.K.W.; van Deventer, J.S.J. Use of infrared spectroscopy to study geopolymerization of heterogeneous amorphous aluminosilicates. Langmuir 2003, 19, 8726–8734. [Google Scholar] [CrossRef]

- Bernal, S.A.; Gutierreza, R.M.; Provis, J.L.; Rose, V. Effect of silicate modulus and metakaolin incorporation on the carbonation of alkali silicate-activated slags. Cem. Concr. Res. 2010, 40, 898–907. [Google Scholar] [CrossRef]

| Content | SiO2 | Al2O3 | TiO2 | Fe2O3 | Na2O | K2O | CaO | LOI |

|---|---|---|---|---|---|---|---|---|

| wt.% | 57.46 | 39.81 | 1.79 | 0.43 | 0.27 | 0.21 | 0.04 | 0.34 |

| Length (mm) | Diameter (mm) | Density (g/cm3) | Elastic Modulus (GPa) | Tensile Strength (MPa) |

|---|---|---|---|---|

| 15 | 0.2 | 7.9 | 200 | 2850 |

| Number | Quartz Powder/Metakaolin Ratio | Water Glass | NaOH | Metakaolin | Quartz Powder |

|---|---|---|---|---|---|

| 1 | 0 | 295.2 | 47.4 | 225.0 | 0 |

| 2 | 0.5 | 295.2 | 47.4 | 225.0 | 112.5 |

| 3 | 1.0 | 295.2 | 47.4 | 225.0 | 225.0 |

| 4 | 1.5 | 295.2 | 47.4 | 225.0 | 337.5 |

| 5 | 2.0 | 295.2 | 47.4 | 225.0 | 450.0 |

| Number | Fibers Volume Fraction | Water Glass | NaOH | Metakaolin | Quartz Powder | Steel Fibers |

|---|---|---|---|---|---|---|

| 1 | 0 | 590.4 | 94.9 | 450.0 | 675.0 | 0 |

| 2 | 0.5% | 590.4 | 94.9 | 450.0 | 675.0 | 30.3 |

| 3 | 1.0% | 590.4 | 94.9 | 450.0 | 675.0 | 60.7 |

| 4 | 1.5% | 590.4 | 94.9 | 450.0 | 675.0 | 91.0 |

| 5 | 2.0% | 590.4 | 94.9 | 450.0 | 675.0 | 121.3 |

| Ambient Temperature | 60 °C | 90 °C | |

|---|---|---|---|

| Porosity/% | 13.6 | 20.3 | 25.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Q.; Chen, S.; Zhang, Y.; Hu, Y.; Wang, Q.; Zhou, Q.; Yan, Y.; Liu, Y.; Yan, D. Effect of Curing Temperature on High-Strength Metakaolin-Based Geopolymer Composite (HMGC) with Quartz Powder and Steel Fibers. Materials 2022, 15, 3958. https://doi.org/10.3390/ma15113958

Li Q, Chen S, Zhang Y, Hu Y, Wang Q, Zhou Q, Yan Y, Liu Y, Yan D. Effect of Curing Temperature on High-Strength Metakaolin-Based Geopolymer Composite (HMGC) with Quartz Powder and Steel Fibers. Materials. 2022; 15(11):3958. https://doi.org/10.3390/ma15113958

Chicago/Turabian StyleLi, Qiang, Shikun Chen, Yajun Zhang, Yunjin Hu, Quanlin Wang, Quan Zhou, Yongmao Yan, Yi Liu, and Dongming Yan. 2022. "Effect of Curing Temperature on High-Strength Metakaolin-Based Geopolymer Composite (HMGC) with Quartz Powder and Steel Fibers" Materials 15, no. 11: 3958. https://doi.org/10.3390/ma15113958

APA StyleLi, Q., Chen, S., Zhang, Y., Hu, Y., Wang, Q., Zhou, Q., Yan, Y., Liu, Y., & Yan, D. (2022). Effect of Curing Temperature on High-Strength Metakaolin-Based Geopolymer Composite (HMGC) with Quartz Powder and Steel Fibers. Materials, 15(11), 3958. https://doi.org/10.3390/ma15113958