Ultrashort Pulsed Laser Drilling of Printed Circuit Board Materials

Abstract

:1. Introduction

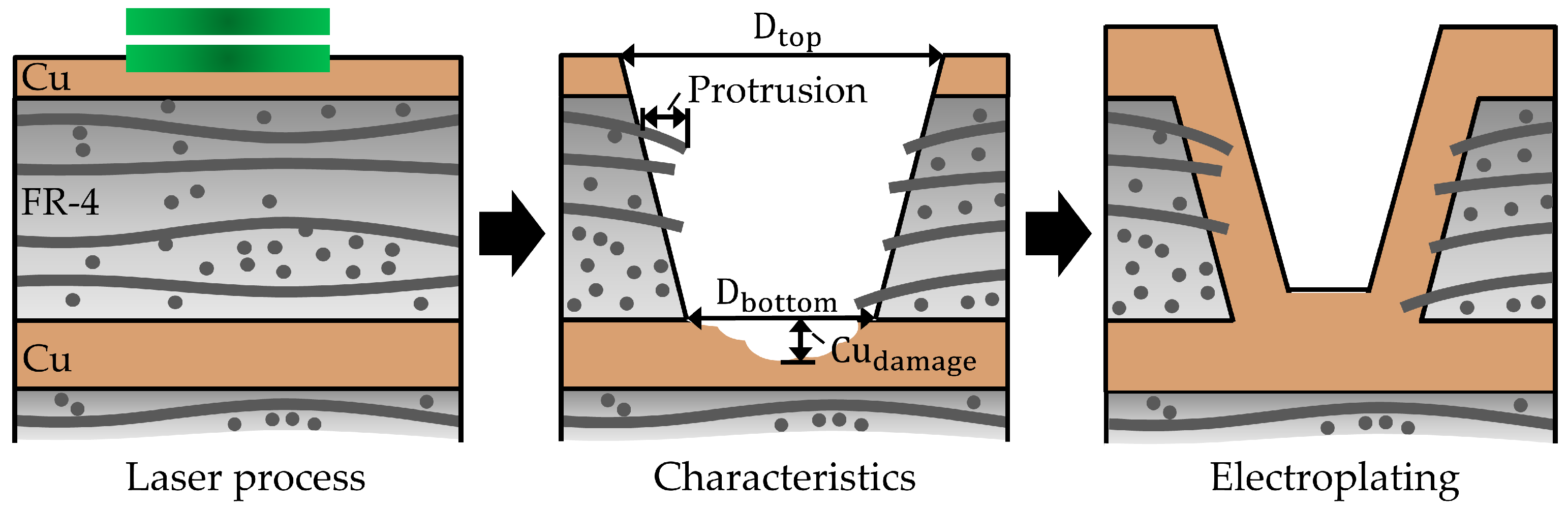

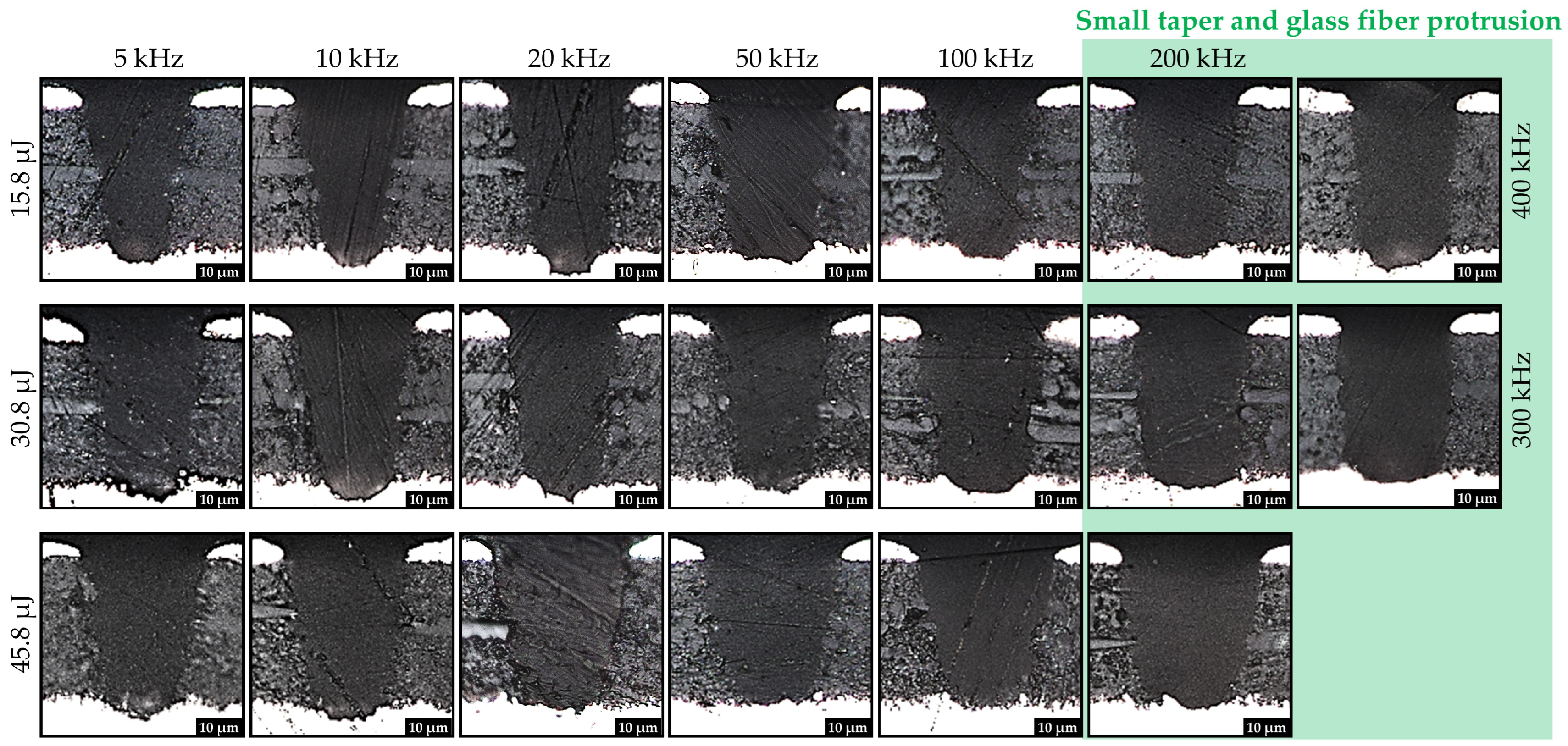

- Small glass fiber protrusions;

- Small taper;

- Minimal damage of the inner copper layers;

- Small variation of the microvia diameters.

2. Materials and Methods

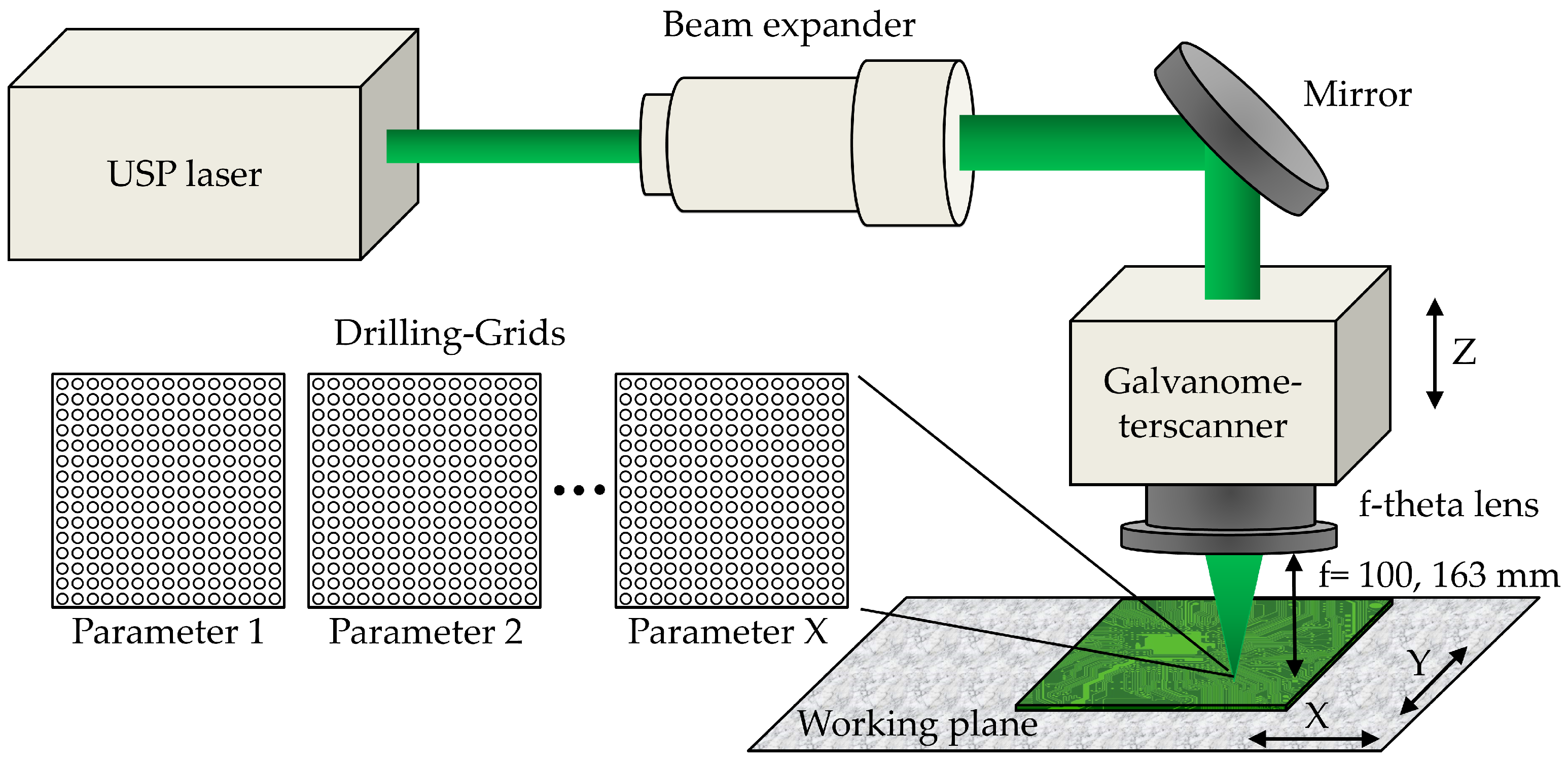

2.1. Experimental Setup

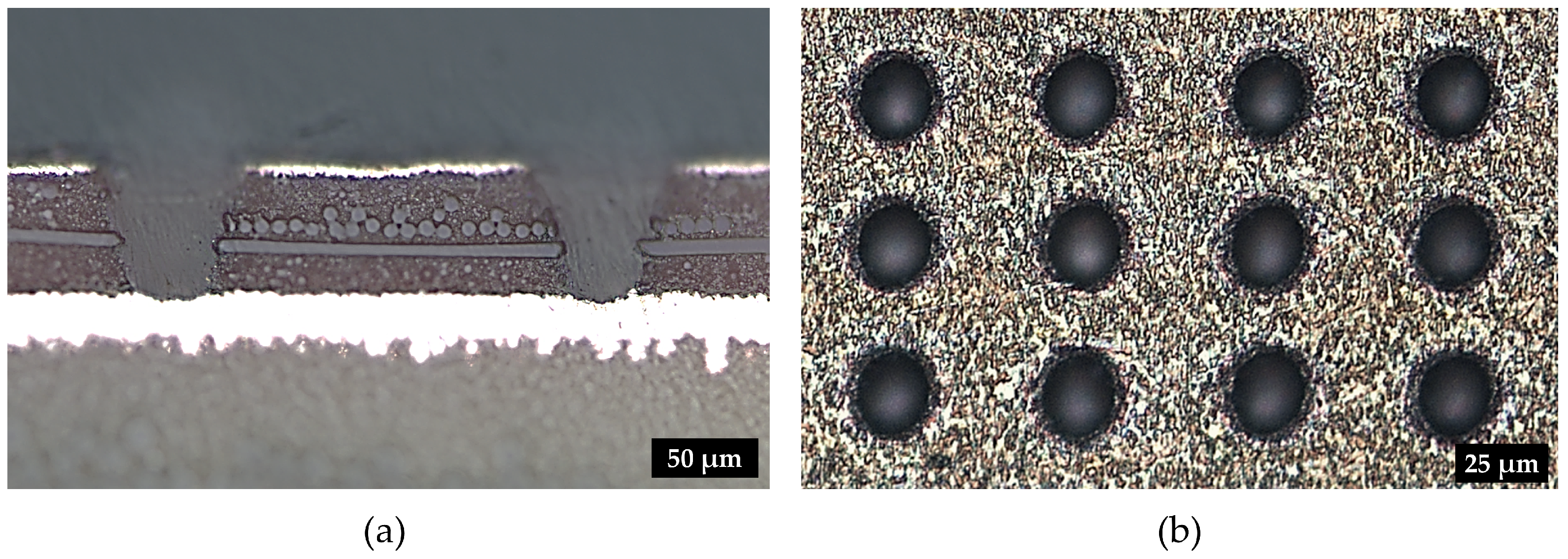

2.2. Microvia Characterization

2.3. Materialographic Preparation and PCB Material

3. Results and Discussion

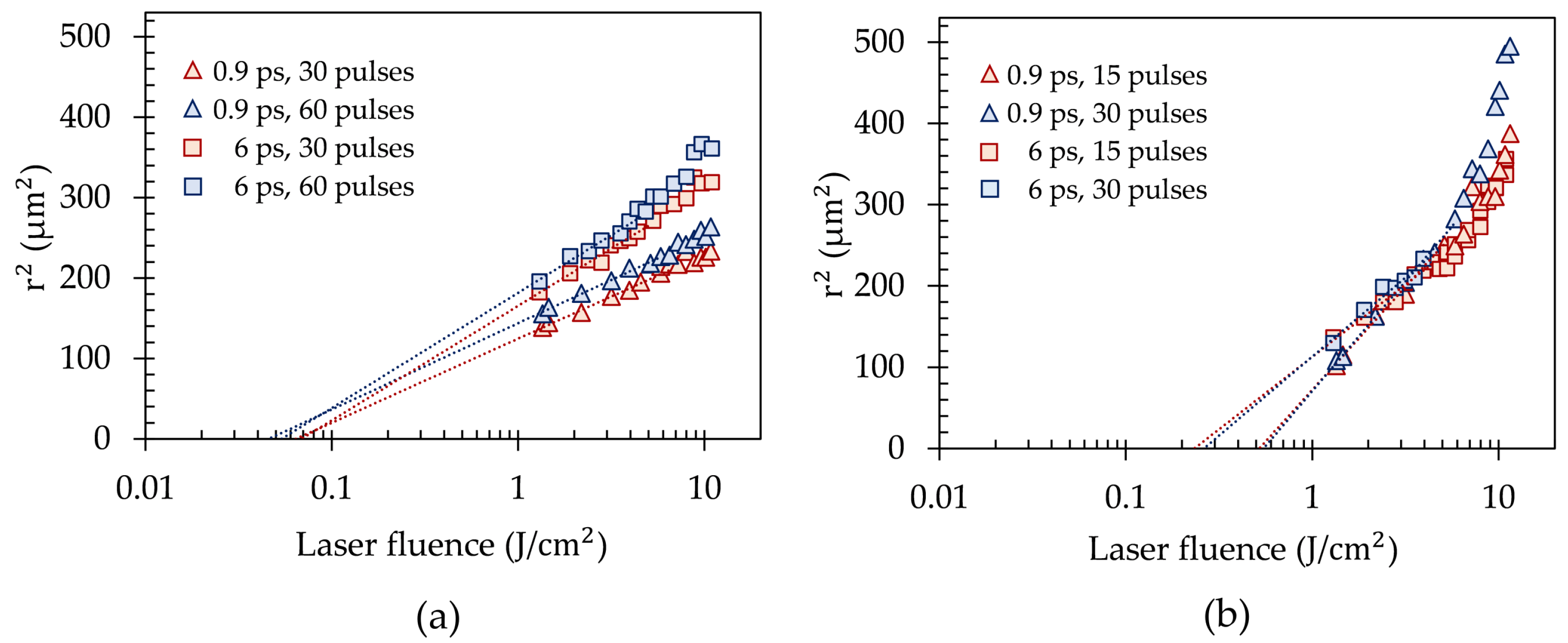

3.1. Ablation Thresholds

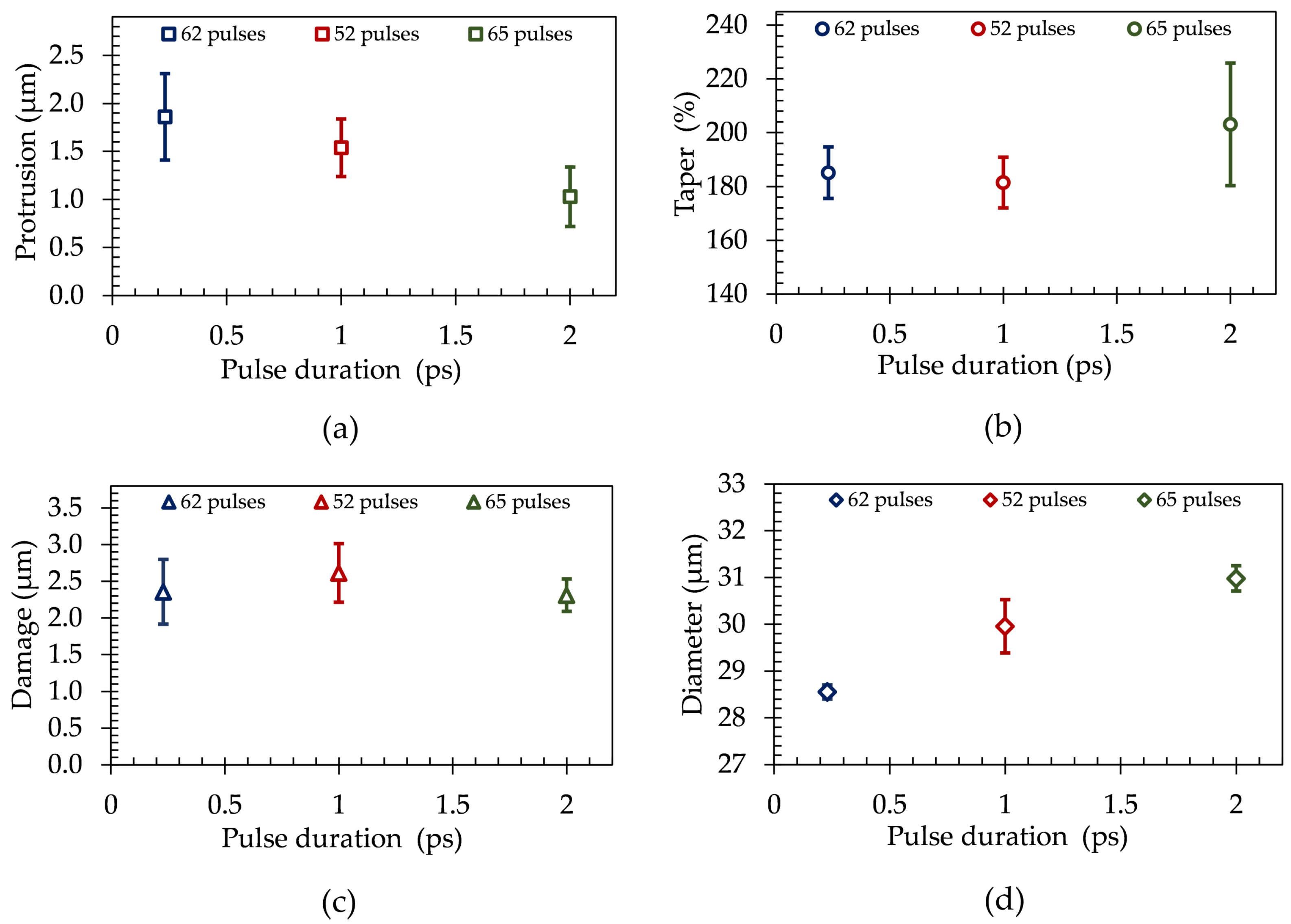

3.2. Influence of the Laser Pulse Duration

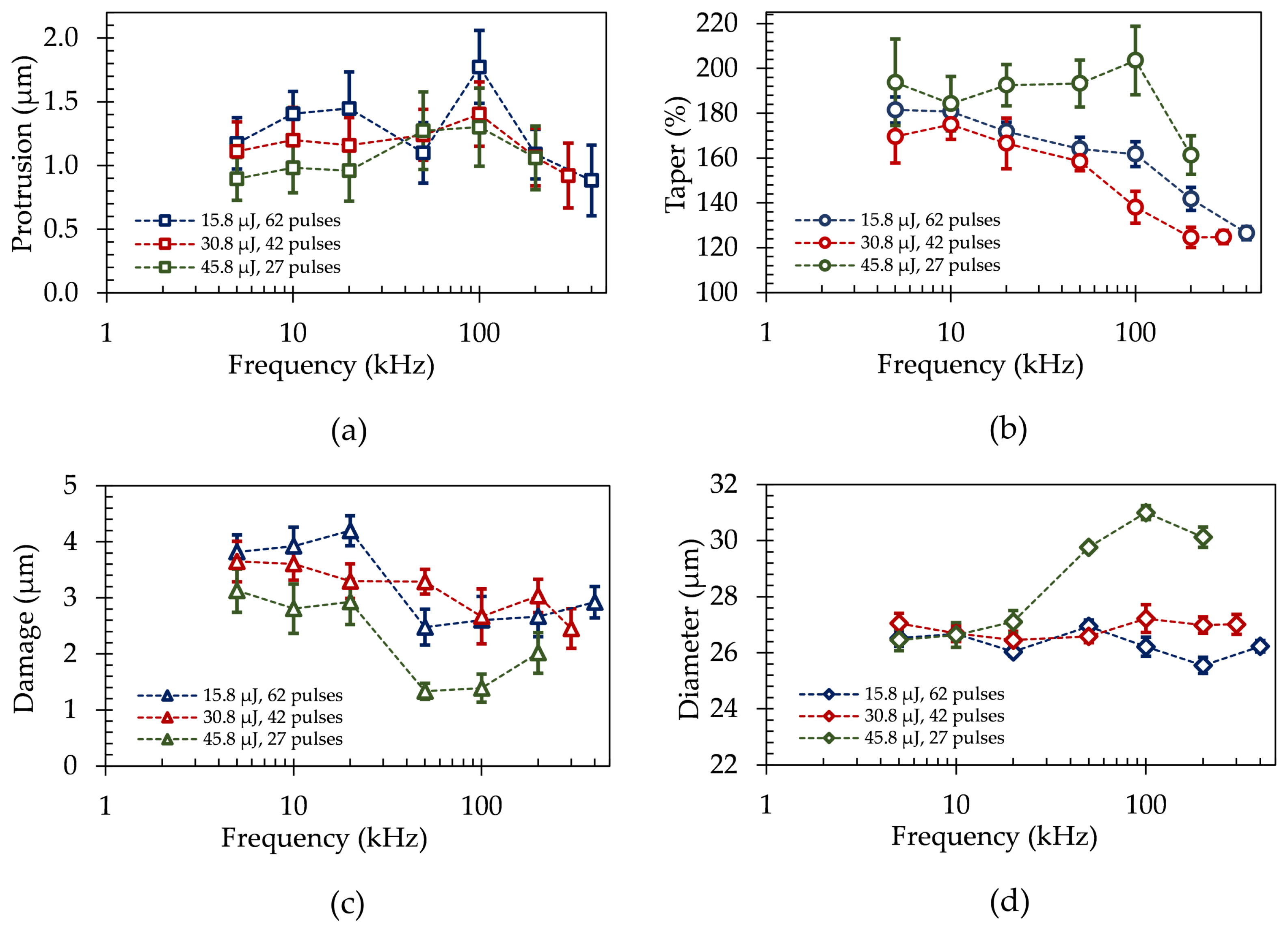

3.3. Influence of the Laser Pulse Energy and Repetition Rate

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hasan, M.; Zhao, J.; Jiang, Z. A review of modern advancements in micro drilling techniques. J. Manuf. Process. 2017, 29, 343–375. [Google Scholar] [CrossRef] [Green Version]

- Blank, T. Functional Layers in Printed Circuit Board Development of Intelligent Micro Vibration Sensors in Multidimensional Printed Circuit Board Technology. Ph.D. Thesis, Karlsruher Institut für Technologie, Karlsruhe, Germany, 2013. (Engl. Translation). [Google Scholar]

- Liu, F.; Zhang, R.; Khurana, G.; DeProspo, B.H.; Nair, C.; Tummala, R.R.; Swaminathan, M. Smaller microvias for packaging interconnects by picosecond UV laser with a nanometer metal barrier layer: A feasibility study. IEEE Trans. Compon. Packag. 2020, 10, 1411–1418. [Google Scholar] [CrossRef]

- Suzuki, Y.; Snyder, E.; Ji, C.; Walther, S.; Gupta, A.; Gottschalk, C.; Sundaram, V.; Tummala, R.R. Microvia formation in 5-µm-thick dry-film dielectric by ozone etch processes. IEEE Trans. Compon. Packag. 2017, 7, 2073–2078. [Google Scholar]

- Matsumoto, H.; Unrath, M.; Zhang, H.; Hainsey, B. Laser direct ablation for patterning printed wiring boards using ultrafast lasers and high speed beam delivery architectures. J. Laser Micro Nanoeng. 2013, 8, 315–320. [Google Scholar] [CrossRef]

- Sanapala, R.; Sood, B.; Das, D.; Pecht, M. Effect of lead-free soldering on key material properties of FR-4 printed circuit board laminates. IEEE Trans. Compon. Packag. 2009, 32, 272–280. [Google Scholar] [CrossRef]

- Lei, W.; Davignon, J. Solid state UV laser technology for electronic packaging applications. Lasers Manuf. Mater. Process. 2005, 5629, 314–326. [Google Scholar]

- Lee, D. Picosecond IR pulsed laser drilling of copper-coated glass/epoxy composite. IEEE Trans. Compon. Packag. 2017, 7, 2066–2072. [Google Scholar] [CrossRef]

- Yang, C.; Hu, H.; Zhang, H. Modeling AOD-driven laser microvia drilling with machine learning approaches. J. Manuf. Process. 2018, 34, 555–565. [Google Scholar] [CrossRef]

- Ning, Y.; Azarian, M.H.; Pecht, M. Effects of voiding on thermomechanical reliability of copper-filled microvias: Modeling and simulation. IEEE Trans. Device Mater. Reliab. 2015, 15, 500–510. [Google Scholar] [CrossRef]

- Ning, Y.; Azarian, M.H.; Pecht, M. Influence of plating quality on reliability of microvias. In Proceedings of the IPC APEX EXPO Conference, San Diego, CA, USA, 24–26 February 2015. [Google Scholar]

- Watanabe, A.O.; Ito, H.; Markondeya, R.P.; Tummala, R.R.; Swaminathan, M. Low-loss impedance-matched sub-25- µm vias in 3-D millimeter-wave packages. IEEE Trans. Compon. Packag. 2011, 10, 870–877. [Google Scholar]

- Müller, D.; Brune, J.; Pätzel, R. Structuring redistribution layers down to 2 micron line spacing with laser direct ablation. In Proceedings of the China Semiconductor Technology International Conference, Shanghai, China, 11–12 March 2018; pp. 1–3. [Google Scholar]

- Hollman, R.; Dimov, O.; Malik, S.; Hichri, H.; Arendt, M. Ultra fine RDL structure fabrication using alternative patterning and bottum-up plating processes. In Proceedings of the Electronic Components and Technology Conference, San Diego, CA, USA, 29 May–1 June 2018; pp. 58–63. [Google Scholar]

- Yamanaka, K.; Kobayashi, K.; Hayashi, K.; Fukui, M. Materials, processes, and performance of high-wiring density buildup substrate with ultralow-coefficient of thermal expansion. IEEE Trans. Compon. Packag. 2009, 33, 453–461. [Google Scholar] [CrossRef]

- Stafford, S. Printed circuit board processing with UV lasers. Ind.-Lasers 2014, 29, 2. [Google Scholar]

- Liu, F.; Khurana, G.; Zhang, R.; Watanabe, A.O.; DeProspo, B.H.; Nair, C.; Tummala, R.R. Innovative sub-5-μm microvias by picosecond UV laser for post-moore packaging interconnects. IEEE Trans. Compon. Packag. 2019, 9, 2016–2023. [Google Scholar]

- Patel, R.; Bovatsek, J.; Chui, H. Nano to pico to femto: Pulse widths for optimal laser micromachining outcomes. Ind. Laser Solut. Manuf. 2017, 32, 21–24. [Google Scholar]

- Ostendorf, A.; Kamlage, G.; Klug, U.; Korte, F.; Chichkov, B.N. Femtosecond versus picosecond laser ablation. In Proceedings of the Photon Processing in Microelectronics and Photonics IV, San Diego, CA, USA, 12 April 2005; The International Society for Optics and Photonics: Bellingham, WA, USA, 2005; Volume 5713, pp. 1–8. [Google Scholar]

- Zhao, W.; Wang, L. Microdrilling of through-holes in flexible printed circuits using picosecond ultrashort pulse laser. Polymers 2018, 10, 1390. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lutz, C.; Roth, G.-L.; Rung, S.; Esen, C.; Hellmann, R. Efficient ultrashort pulsed laser processing by dynamic spatial light modulator beam shaping for industrial use. J. Laser Micro Nanoeng. 2016, 21. [Google Scholar] [CrossRef]

- Schwarz, S.; Rung, S.; Esen, C.; Hellmann, R. Enhanced ablation efficiency using GHz bursts in micromachining fused silica. Opt. Lett. 2021, 46, 282–285. [Google Scholar] [CrossRef] [PubMed]

- Hohlfeld, J.; Wellershoff, S.S.; Güdde, J.; Conrad, U.; Jähnke, V.; Matthias, E. Electron and lattice dynamics following optical excitation of metals. Chem. Phys. 2000, 251, 237–258. [Google Scholar] [CrossRef]

- Wellershoff, S.S.; Hohlfeld, J.; Güdde, J.; Matthias, E. The role of electron-phonon coupling in femtosecond laser damage of metals. Appl. Phys. A 1999, 69, 99–107. [Google Scholar]

- Ancona, A.; Döring, S.; Jauregui, C.; Röser, F.; Limpert, J.; Nolte, S.; Tünnermann, A. Femtosecond and picosecond laser drilling of metals at high repetition rates and average powers. Opt. Lett. 2009, 34, 3304–3306. [Google Scholar] [CrossRef]

- Liu, X.; Du, D.; Mourou, G. Laser ablation and micromachining with ultrashort laser pulses. IEEE J. Quantum Electron. 1997, 33, 1706–1716. [Google Scholar] [CrossRef]

- Chichkov, B.N.; Momma, C.; Nolte, S.; von Alvensleben, F.; Tünnermann, A. Femtosecond, picosecond and nanosecond laser ablation of solids. Appl. Phys. A 1996, 63, 109–115. [Google Scholar] [CrossRef]

- Roth, G.-L.; Rung, S.; Hellmann, R. Ultrashort pulse laser micro-welding of cyclo-olefin copolymers. Opt. Lasers Eng. 2017, 93, 178–181. [Google Scholar] [CrossRef]

- Sima, F.; Sugioka, K.; Vázquez, R.M.; Osellame, R.; Kelemen, L.; Ormos, P. Three-dimensional femtosecond laser processing for lab-on-a-chip applications. Nanophotonics 2018, 7, 613–634. [Google Scholar] [CrossRef]

- Sugioka, K.; Cheng, Y. Ultrafast lasers-reliable tools for advanced materials processing. Light Sci. Appl. 2014, 3, e149. [Google Scholar] [CrossRef]

- Negel, J.-P.; Voss, A.; Ahmed, M.A.; Bauer, D.; Sutter, D.; Killi, A.; Graf, T. 1.1 kW average output power from a thin-disk multipass amplifier for ultrashort laser pulses. Opt. Lett. 2013, 38, 5442–5445. [Google Scholar] [CrossRef]

- Russbueldt, P.; Mans, T.; Weitenberg, J.; Hoffmann, H.D.; Poprawe, R. Compact diode-pumped 1.1 kW Yb: YAG Innoslab femtosecond amplifier. Opt. Lett. 2010, 35, 4169–4171. [Google Scholar] [CrossRef] [PubMed]

- Finger, J.T. Pulse to Pulse Interactions during Ultrashort Pulse Laser Ablation with High Repetition Rates. Ph.D. Thesis, RWTH Aachen University, Aachen, Germany, 2017. (Engl. Translation). [Google Scholar]

- Neuenschwander, B.; Jaeggi, B.; Schmidt, M.; Hennig, G. Surface structuring with ultra-short laser pulses: Basics, limitations and needs for high throughput. Phys. Procedia 2014, 56, 1047–1058. [Google Scholar] [CrossRef] [Green Version]

- Römer, G.R.B.E.; Bechtold, P. Electro-optic and acousto-optic laser beam scanners. Phys. Procedia 2014, 56, 29–39. [Google Scholar] [CrossRef] [Green Version]

- Ancona, A.; Röser, F.; Rademaker, K.; Limpert, J.; Nolte, S.; Tünnermann, A. High speed laser drilling of metals using a high repetition rate, high average power ultrafast fiber CPA system. Opt. Express 2008, 16, 8958–8968. [Google Scholar] [CrossRef]

- Breitling, D.; Ruf, A.; Dausinger, F. Fundamental aspects in machining of metals with short and ultrashort laser pulses. In Proceedings of the Photon Processing in Microelectronics and Photonics III, San Jose, CA, USA, 26–29 January 2004; The International Society for Optics and Photonics: Bellingham, WA, USA, 2004; Volume 5339, pp. 49–63. [Google Scholar]

- Finger, J.; Weinand, M.; Wortmann, D. Investigations on processing of carbon fiber reinforced plastics using ultrashort pulsed laser radiation with high average power. In Proceedings of the ICALEO, Miami, FL, USA, 6–10 October 2013. [Google Scholar]

- Föhl, C. Application of Ultrashort Pulsed Laser Radiation for Precision Drilling of Metals. Ph.D. Thesis, Universität Stuttgart, Stuttgart, Germany, 2011. (Engl. Translation). [Google Scholar]

- Hertweck, S.M. Temporal Pulse Shaping in Laser Micromaterial Processing: Basic Investigations and Applications. Ph.D. Thesis, Friedrich-Alexander-Universität Erlangen-Nürnberg, Erlangen, Germany, 2017. (Engl. Translation). [Google Scholar]

- Hördemann, C. Particle-Free Ablation of Layer Systems for Solid-State Batteries by Means of Ultrashort Pulsed Laser Processing. Ph.D. Thesis, RWTH Aachen University, Aachen, Germany, 2018. (Engl. Translation). [Google Scholar]

- Finger, J.; Reininghaus, M. Effect of pulse to pulse interactions on ultrashort pulse laser drilling of steel with repetition rates up to 10 MHz. Opt. Express 2014, 22, 18790–18799. [Google Scholar] [CrossRef] [PubMed]

- Kononenko, T.V.; Freitag, C.; Sovyk, D.N.; Lukhter, A.B.; Skvortsov, K.V.; Konov, V.I. Influence of pulse repetition rate on percussion drilling of Ti-based alloy by picosecond laser pulses. Opt. Lasers Eng. 2018, 103, 65–70. [Google Scholar] [CrossRef]

- Gruner, A.; Naumann, L.; Schille, J.; Löschner, U. High pulse repetition frequency micro hole drilling of silicon using ultrashort pulse laser radiation. J. Laser Micro Nanoeng. 2019, 14, 190–197. [Google Scholar]

- Döring, S.; Ullsperger, T.; Heisler, F.; Richter, S.; Tünnermann, A.; Nolte, S. Hole formation process in ultrashort pulse laser percussion drilling. Phys. Procedia 2013, 41, 431–440. [Google Scholar] [CrossRef]

- Karimelahi, S.; Abolghasemi, L.; Herman, P.R. Rapid micromachining of high aspect ratio holes in fused silica glass by high repetition rate picosecond laser. Appl. Phys. A 2014, 114, 91–111. [Google Scholar] [CrossRef]

- Holden, H. 35 years of HDI fabrication processes and obstacles for implementation. The PCB Magazine, November 2017; pp. 12–24. [Google Scholar]

- Liu, J.M. Simple technique for measurements of pulsed Gaussian-beam spot sizes. Opt. Lett. 1982, 7, 196–198. [Google Scholar] [CrossRef]

- Zhou, B.; Kar, A.; Soileau, M.J.; Yu, X. Invariance of the r2-ln (F) relationship and attainable precision in ultrafast laser ablation experiments. Opt. Express 2021, 29, 5635–5643. [Google Scholar] [CrossRef]

- Mannion, P.; Magee, J.; Coyne, E.; O’Connor, G.M. Ablation thresholds in ultrafast laser micromachining of common metals in air. In Proceedings of the Opto-Ireland 2002: Optics and Photonics Technologies and Applications, Galway, Ireland, 5–6 September 2003; The International Society for Optics and Photonics: Bellingham, WA, USA, 2003; Volume 4876, pp. 470–478. [Google Scholar]

- Furusawa, K.; Takahashi, K.; Kumagai, H.; Midorikawa, K.; Obara, M. Ablation characteristics of Au, Ag, and Cu metals using a femtosecond Ti: Sapphire laser. Appl. Phys. A 1999, 69, 359–366. [Google Scholar] [CrossRef]

- Nolte, S.; Momma, C.; Jacobs, H.; Tünnermann, A.; Chichkov, B.N.; Wellegehausen, B.; Welling, H. Ablation of metals by ultrashort laser pulses. JOSA B 1997, 14, 2716–2722. [Google Scholar] [CrossRef]

- Raciukaitis, G.; Brikas, M.; Gecys, P.; Voisiat, B.; Gedvilas, M. Use of high repetition rate and high power lasers in microfabrication: How to keep the efficiency high? J. Laser Micro Nanoeng. 2009, 4, 186–191. [Google Scholar] [CrossRef]

- Schille, J.; Schneider, L.; Lickschat, P.; Löschner, U.; Ebert, R.; Exner, H. High-pulse repetition frequency ultrashort pulse laser processing of copper. J. Laser Appl. 2015, 4, S28007. [Google Scholar] [CrossRef]

- Gamaly, E.G.; Rode, A.V.; Luther-Davies, B.; Tikhonchuk, V.T. Ablation of solids by femtosecond lasers: Ablation mechanism and ablation thresholds for metals and dielectrics. Phys. Plasmas 2002, 9, 949–957. [Google Scholar] [CrossRef]

- Hodgson, N.; Heming, S.; Steinkopff, A.; Haloui, H.; Lee, T.S. Ultrafast laser ablation at 1035 nm, 517 nm and 345 nm as a function of pulse duration and fluence. In Proceedings of the Lasers in Manufacturing Conference, Munich, Germany, 24–27 June 2019. [Google Scholar]

- Branzei, M.; Vladescu, M. Aspects on thermophisycal properties of interconnection structures for power LEDs applications. In Proceedings of the SIITME, Brasov, Romania, 22–25 October 2015. [Google Scholar]

- Caulier, O.D.; Mishchik, K.; Chimier, B.; Skupin, S.; Bourgeade, A.; Leger, C.J.; Kling, R.; Hönninger, C.; Lopez, J.; Tikhonchuk, V.; et al. Femtosecond laser pulse train interaction with dielectric materials. Appl. Phys. Lett. 2015, 107, 181110. [Google Scholar] [CrossRef]

- Wang, S.Y.; Ren, Y.; Cheng, C.W.; Chen, J.K.; Tzou, D.Y. Micromachining of copper by femtosecond laser pulses. Appl. Surf. Sci. 2013, 265, 302–308. [Google Scholar] [CrossRef]

- Yeng, Y.; Cheng, J.K.; Zhang, Y. Optical properties and thermal response of copper films induced by ultrashort-pulsed lasers. J. Appl. Phys. 2015, 110, 113102. [Google Scholar]

| Laser Sources: | Laser System 1 (Amphos 200) | Laser System 2 (Coherent Monaco) | Laser System 3 (Atarium XTR) |

|---|---|---|---|

| Technical specifications: | |||

| Wavelength (nm) | 1030/515 | 517 | 1030/515/343 |

| Laser pulse duration (ps) | 0.9–10 | 0.23–5 | <2 |

| Beam quality | <1.5 | <1.2 | <1.3 |

| Max. laser power P (W) | 200 | 30 | 15 |

| Max. laser pulse energy E (J) | 1000 | 40 | 300 |

| Max. repetition rate f (MHz) | 40 | 0.75 | 0.5 |

| Experimental data: | |||

| Raw beam diameter (mm) | 5.3 | 2.8 | 3.3 |

| Focal length of the f-theta lens (mm) | 163 | 100 | 100 |

| Laser focal diameter (m) | 30 | 28 | 26 |

| Subject of investigation: | Determination of the ablation thresholds of copper and FR-4 | Influence of different laser pulse durations on microvia quality | Influence of laser pulse energy and repetition rate on microvia quality |

| Material | Laser Pulse Duration (ps) | Number of Laser Pulses | Ablation Threshold (J/cm) |

|---|---|---|---|

| FR-4 composite material | 0.9 | 15 | 0.52 |

| 30 | 0.55 | ||

| 6 | 15 | 0.23 | |

| 30 | 0.26 | ||

| Copper | 0.9 | 30 | 0.06 |

| 60 | 0.07 | ||

| 6 | 30 | 0.05 | |

| 60 | 0.05 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Franz, D.; Häfner, T.; Kunz, T.; Roth, G.-L.; Rung, S.; Esen, C.; Hellmann, R. Ultrashort Pulsed Laser Drilling of Printed Circuit Board Materials. Materials 2022, 15, 3932. https://doi.org/10.3390/ma15113932

Franz D, Häfner T, Kunz T, Roth G-L, Rung S, Esen C, Hellmann R. Ultrashort Pulsed Laser Drilling of Printed Circuit Board Materials. Materials. 2022; 15(11):3932. https://doi.org/10.3390/ma15113932

Chicago/Turabian StyleFranz, Daniel, Tom Häfner, Tim Kunz, Gian-Luca Roth, Stefan Rung, Cemal Esen, and Ralf Hellmann. 2022. "Ultrashort Pulsed Laser Drilling of Printed Circuit Board Materials" Materials 15, no. 11: 3932. https://doi.org/10.3390/ma15113932

APA StyleFranz, D., Häfner, T., Kunz, T., Roth, G.-L., Rung, S., Esen, C., & Hellmann, R. (2022). Ultrashort Pulsed Laser Drilling of Printed Circuit Board Materials. Materials, 15(11), 3932. https://doi.org/10.3390/ma15113932