The Effect of Periodic Loading of Glued Laminated Beams on Their Static Bending Strength

Abstract

:1. Introduction

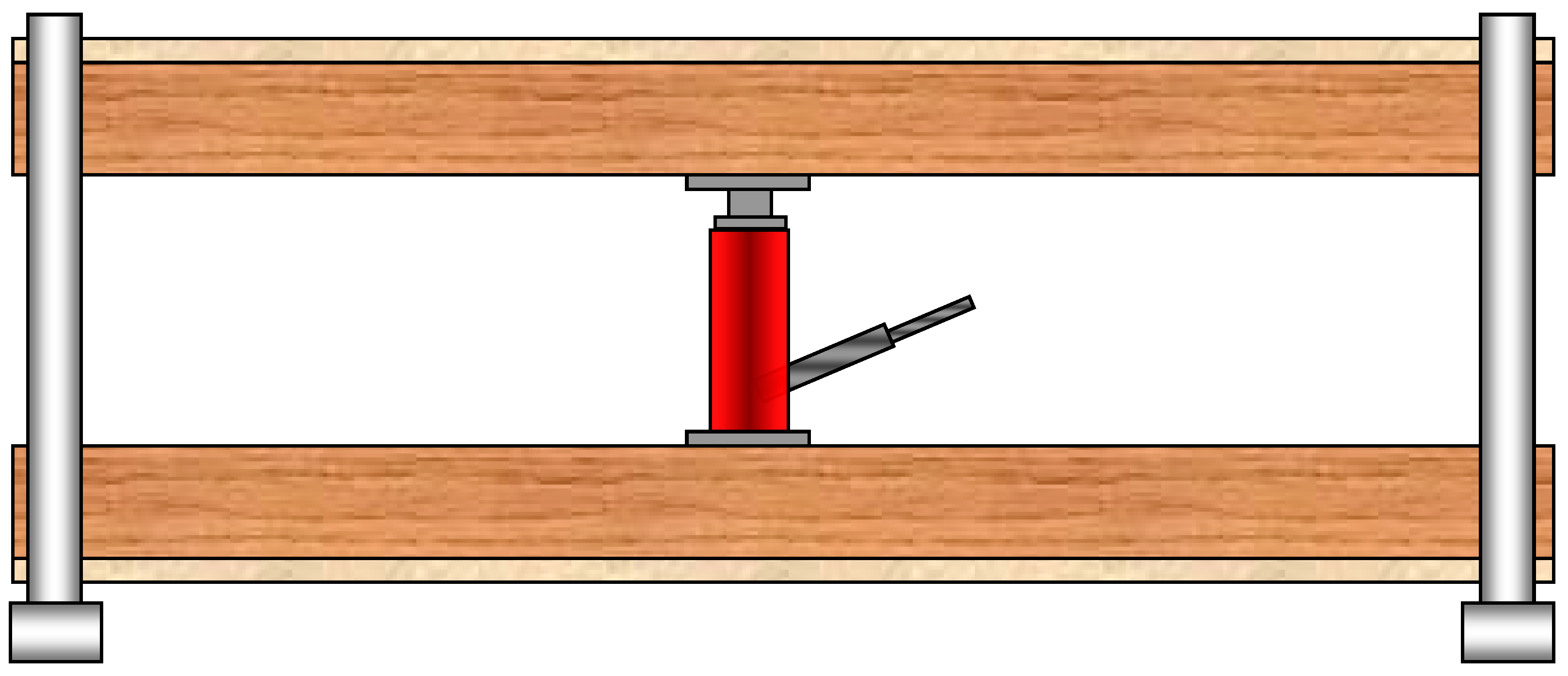

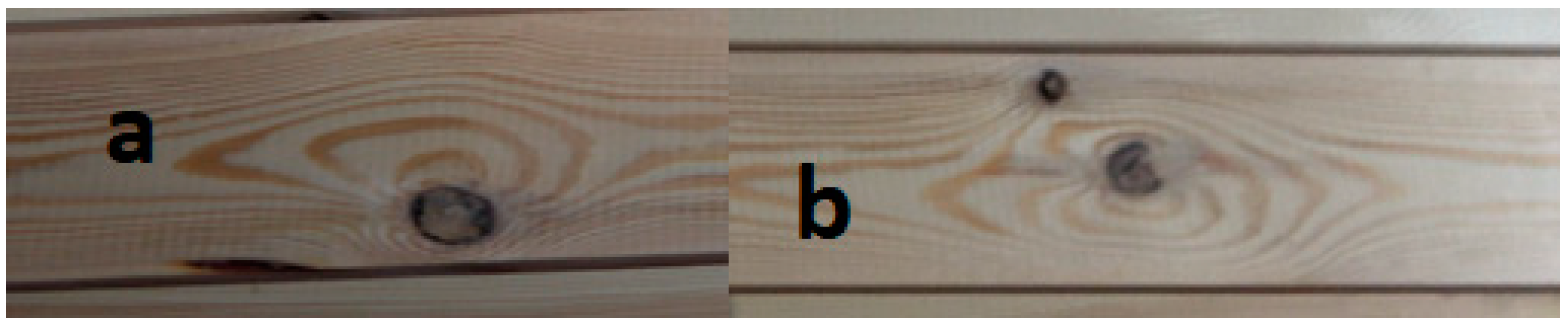

2. Materials and Methods

- -

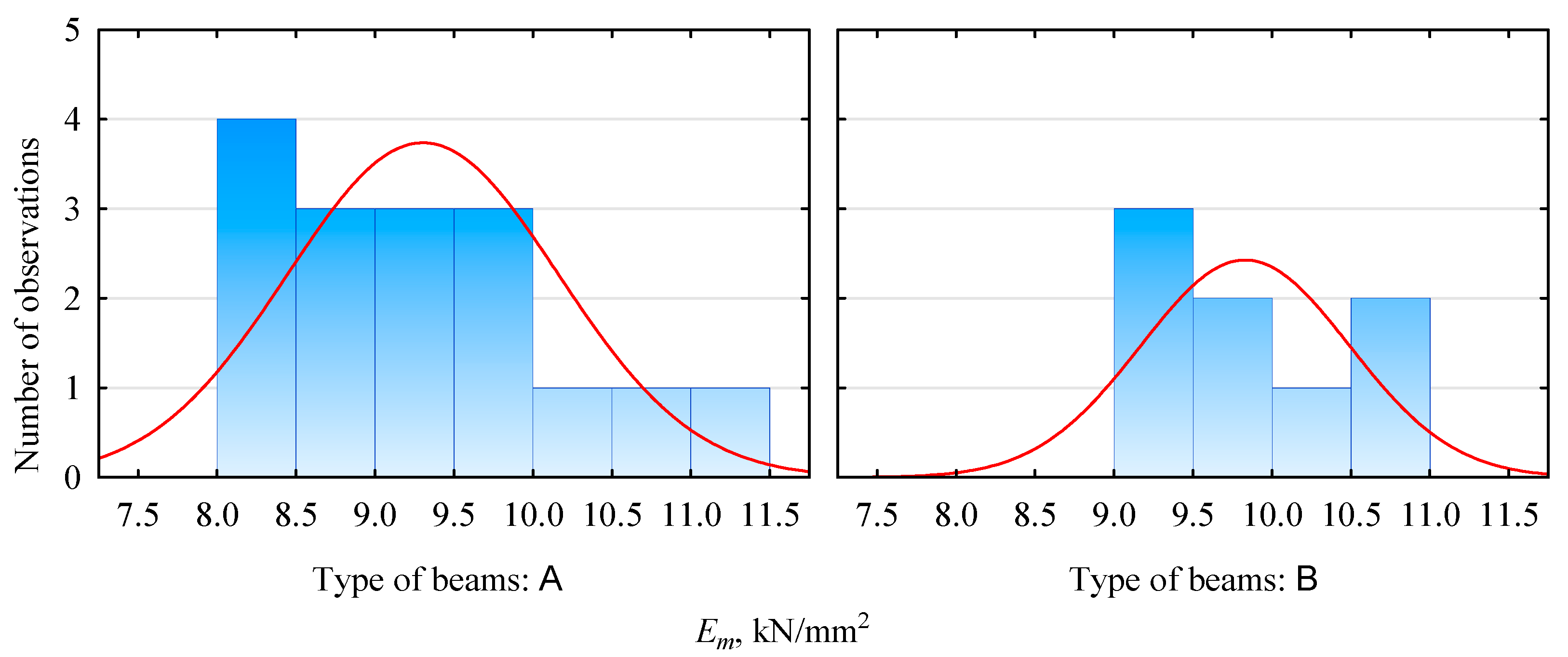

- A—beams with a plywood face not subjected to the long-term loading process;

- -

- B—beams with a plywood face in the long-term loading process;

- -

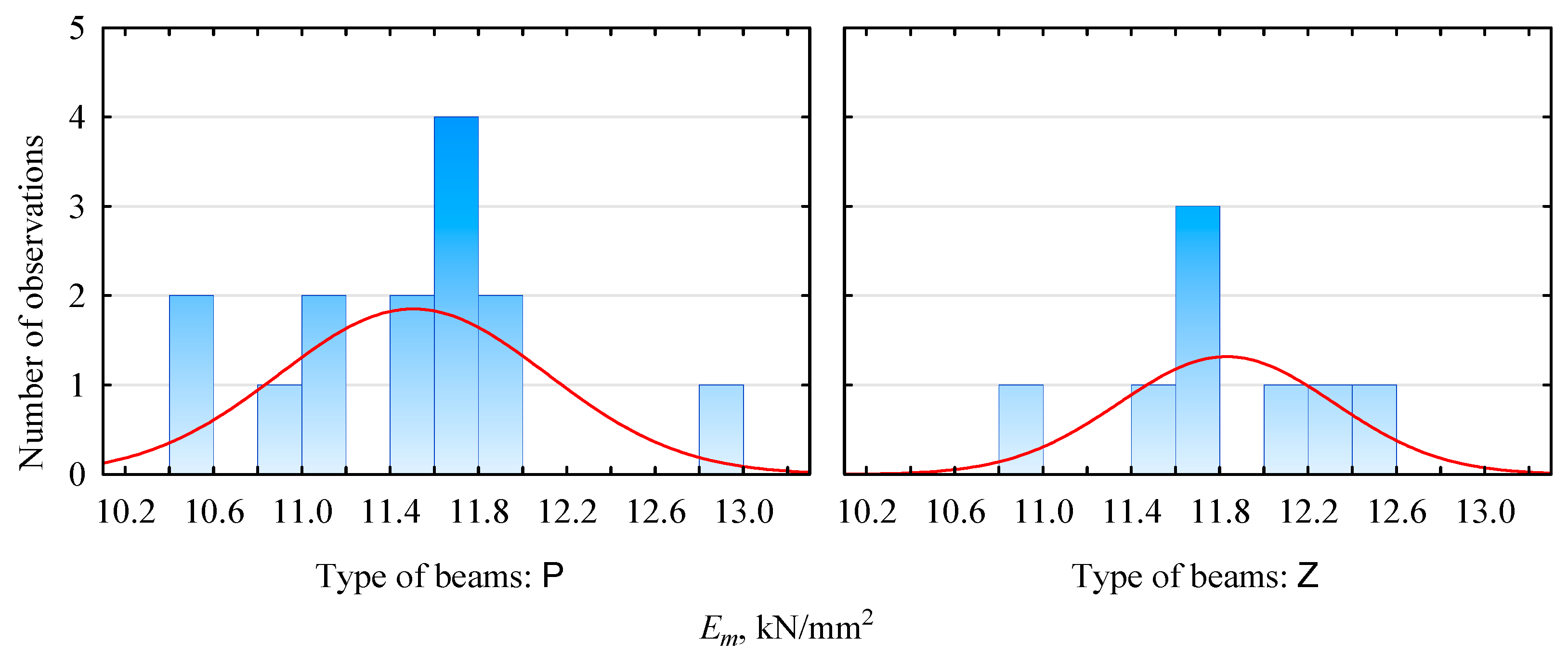

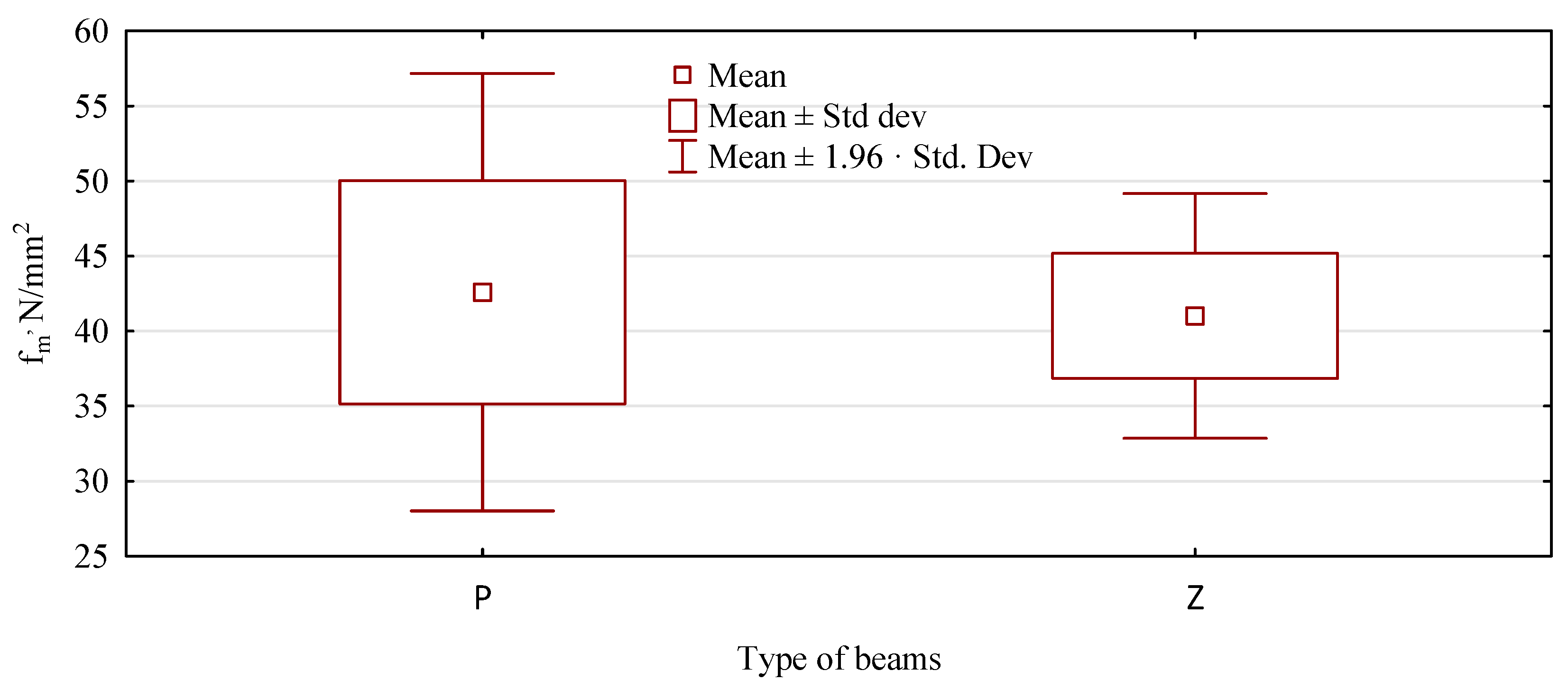

- P—beams with the face of visually graded lumber not subjected to long-term loading;

- -

- Z—beams with the face of visually graded lumber subjected to long-term loading.

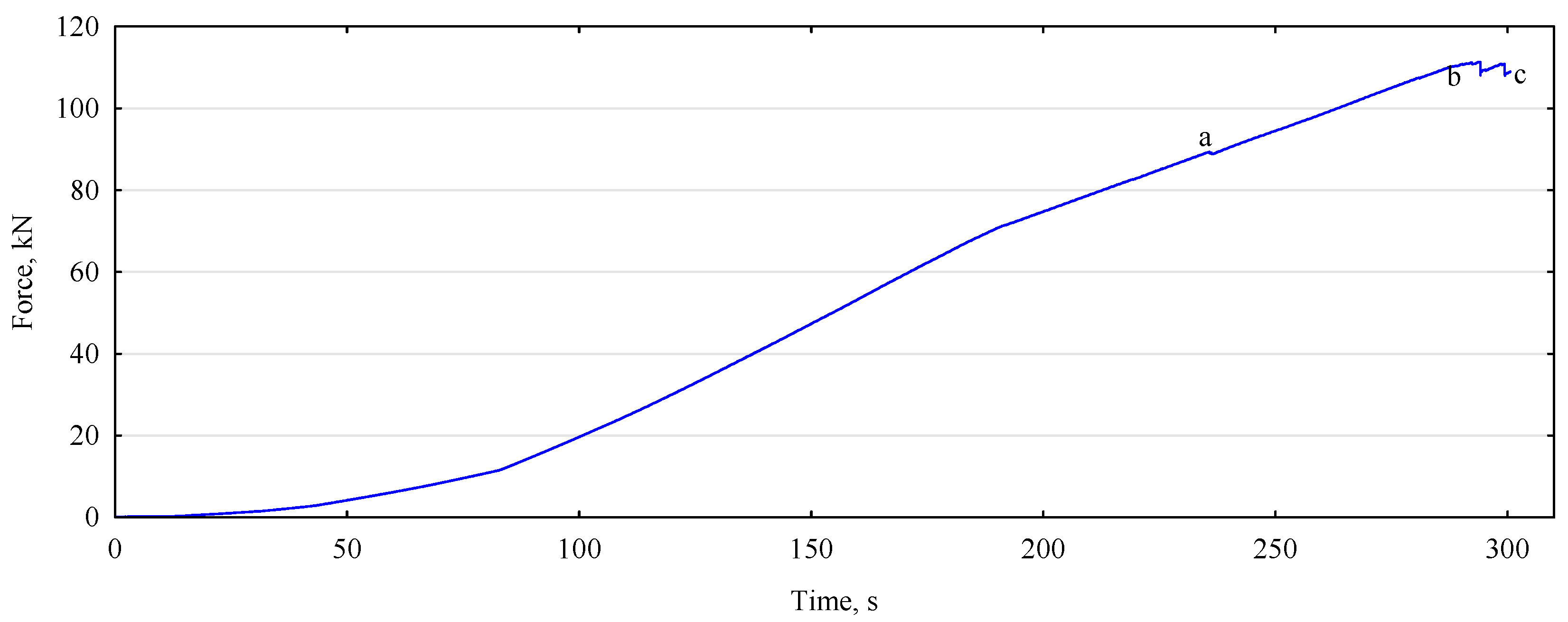

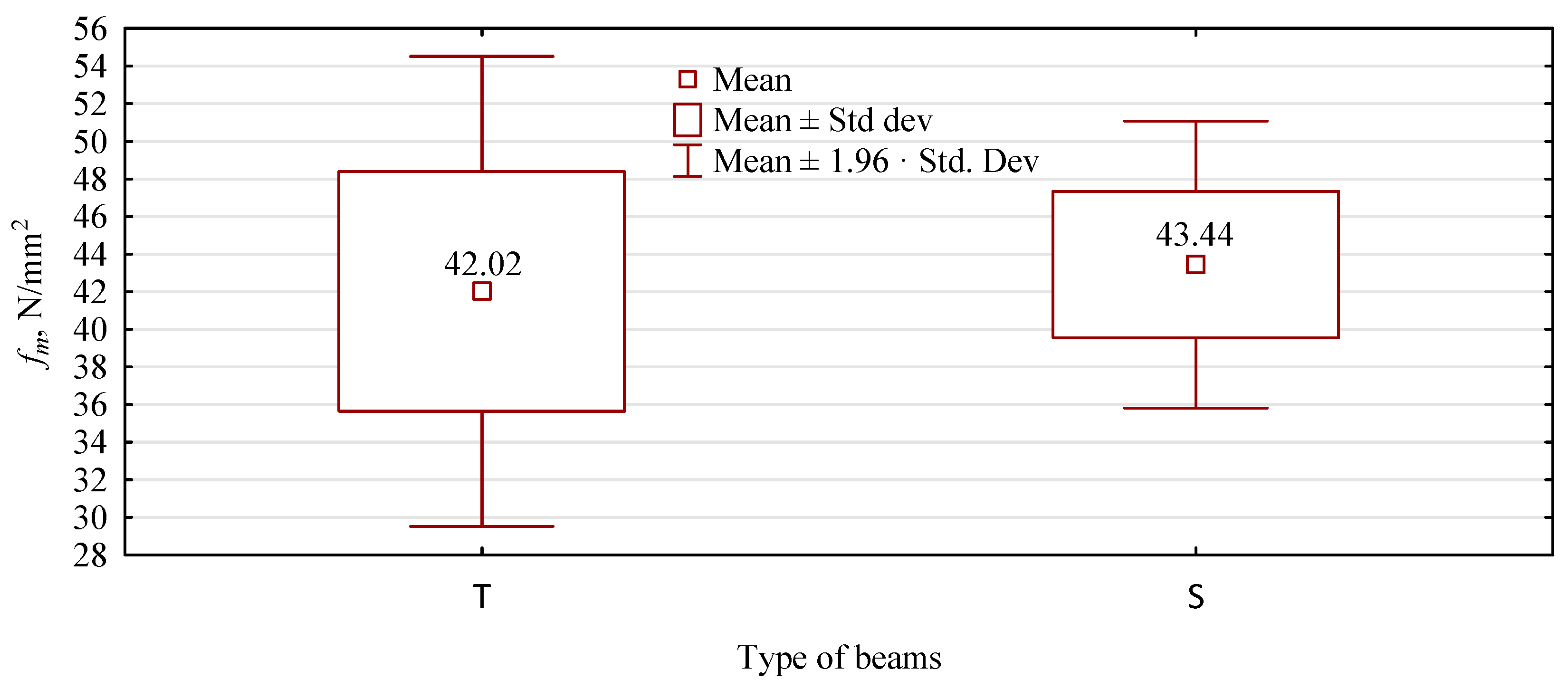

3. Results and Discussion

4. Conclusions

- -

- Beams manufactured with a plywood face have a narrower confidence interval than beams manufactured with pine lumber alone;

- -

- One year of loading in the range of about 45% of the load capacity of the beams did not significantly affect their bending strength or modulus of elasticity;

- -

- The lack of significant changes in the quality of the beams analyzed may be due to the too-short testing period resulting from the duration of the project’s research phase or the level of stress exerted being too low. It seems that the designed structures are rarely loaded continuously with a load of more than 50% of the ad hoc strength. However, the presented results and applied load will be used as an indication for further studies regarding the effect of changing conditions. Taking into account the high impact of humidity which we expect, this study will allow one to compare the results more clearly;

- -

- The presented results could be a valuable reference for designing the next studies. They will help to assume the minimum value of the load.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rowell, R.M.; Caldeira, F.; Rowell, J.K. Sustainable Development in the Forest Products Industry; University Fernando Pessoa: Porto, Portugal, 2010; ISBN 989-643-052-7. [Google Scholar]

- Adams, W.M. The Future of Sustainability: Re-Thinking Environment and Development in the Twenty-First Century; Report IUCN; IUCN: Zurich, Switzerland, 2006. [Google Scholar]

- Kolb, J. Systems in Timber Engineering: Loadbearing Structures and Component Layers; Walter de Gruyter: Berlin, Deutschland, 2008; ISBN 3-7643-8690-8. [Google Scholar]

- Asif, M. Sustainability of Timber, Wood and Bamboo in Construction. In Sustainability of Construction Materials; Elsevier: Amsterdam, The Netherlands, 2009; pp. 31–54. [Google Scholar]

- Dodoo, A.; Gustavsson, L.; Sathre, R. Carbon Implications of End-of-Life Management of Building Materials. Resour. Conserv. Recycl. 2009, 53, 276–286. [Google Scholar] [CrossRef]

- Wherry, G.; Buehlmann, U. Product Life Cycle of the Manufactured Home Industry. BioResources 2014, 9, 6652–6668. [Google Scholar] [CrossRef] [Green Version]

- Kirkham, W.J.; Gupta, R.; Miller, T.H. State of the Art: Seismic Behavior of Wood-Frame Residential Structures. J. Struct. Eng. 2014, 140, 04013097. [Google Scholar] [CrossRef] [Green Version]

- De Araujo, V.A.; Cortez-Barbosa, J.; Gava, M.; Garcia, J.N.; de Souza, A.J.D.; Savi, A.F.; Morales, E.A.M.; Molina, J.C.; Vasconcelos, J.S.; Christoforo, A.L. Classification of Wooden Housing Building Systems. BioResources 2016, 11, 7889–7901. [Google Scholar] [CrossRef] [Green Version]

- EN 14080; Timber Structures—Glued Laminated Timber and Glued Solid Timber—Requirements. European Standard: Brussels, Belgium, 2013.

- Sterr, R. Untersuchungen Zur Dauerfestigkeit von Schichtholzbalken: Investigations on the Fatique Resistance of Laminated Wood Beams, Technische Hochschule München. Holz Als Roh Werkst. 1963, 21, 47–61. [Google Scholar] [CrossRef]

- Gerhards, C.C. Effect of Earlywood and Latewood on Stress-Wave Measurements Parallel to the Grain. Wood Sci. 1978, 11, 69–72. [Google Scholar]

- Krzosek, S. Strength Trading of Polish Pine Structural Sawn Timber. In Rozprawy Naukowe i Monografie; Szkola Glowna Gospodarstwa Wiejskiego: Warszawa, Polska, 2009. [Google Scholar]

- Falk, R.H.; Colling, F. Laminating Effects in Glued-Laminated Timber Beams. J. Struct. Eng. 1995, 121, 1857–1863. [Google Scholar] [CrossRef]

- Yang, H.; Liu, W. Study on Flexural Behavior of FRP Reinforced Glulam Beams. J. Build. Struct. 2007, 28, 64–71. [Google Scholar]

- Komariah, R.N.; Hadi, Y.S.; Massijaya, M.Y.; Suryana, J. Physical-Mechanical Properties of Glued Laminated Timber Made from Tropical Small-Diameter Logs Grown in Indonesia. J. Korean Wood Sci. Technol. 2015, 43, 156–167. [Google Scholar] [CrossRef] [Green Version]

- Yanagawa, Y.; Masuda, K. Evaluation of Bonding Durability for Wood Preservative Treated Glulam by Accelerated Aging Test and Outdoor Exposure Test I. Bonding Durability Evaluated by Accelerated Aging Test. Mokuzai Gakkaishi 2011, 57, 211–222. [Google Scholar] [CrossRef] [Green Version]

- Yanagawa, Y.; Masuda, K. Evaluation of Bonding Durability for Wood Preservative Treated Glulam by Accelerated Aging Test and Outdoor Exposure Test II Bonding Durability Evaluated by Outdoor Exposure Test and Correlation to Accelerated Aging Test. Mokuzai Gakkaishi 2011, 57, 265–275. [Google Scholar] [CrossRef] [Green Version]

- Mirski, R.; Dziurka, D.; Chuda-Kowalska, M.; Kawalerczyk, J.; Kuliński, M.; Łabęda, K. The Usefulness of Pine Timber (Pinus Sylvestris L.) for the Production of Structural Elements. Part II: Strength Properties of Glued Laminated Timber. Materials 2020, 13, 4029. [Google Scholar] [CrossRef]

- Serrano, E. Glued-in Rods for Timber Structures—A 3D Model and Finite Element Parameter Studies. Int. J. Adhes. Adhes. 2001, 21, 115–127. [Google Scholar] [CrossRef]

- Kägi, A.; Niemz, P.; Mandallaz, D. Einfluss Der Holzfeuchte Und Ausgewählter Technologischer Parameter Auf Die Verklebung Mit 1K-PUR Klebstoffen Unter Extremen Klimatischen Bedingungen. Holz Als Roh Werkst. 2006, 64, 261–268. [Google Scholar] [CrossRef] [Green Version]

- Okada, T.; Kobori, H.; Kojima, Y.; Suzuki, S.; Nishikido, K.; Hirose, A.; Takahashi, K. Evaluating the Durability of Structural Glulam Bonded with Aqueous Polymer-Isocyanate Adhesive by Two Kinds of Accelerated Aging Treatments. Eur. J. Wood Wood Prod. 2020, 78, 113–122. [Google Scholar] [CrossRef]

- Teder, M.; Wang, X. Nondestructive Evaluation of a 75-Year Old Glulam Arch. In Proceedings of the 18th International Nondestructive Testing and Evaluation of Wood Symposium, Madison, WI, USA, 24–27 September 2013; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2013; pp. 624–632. [Google Scholar]

- Sernek, M.; Boonstra, M.; Pizzi, A.; Despres, A.; Gérardin, P. Bonding Performance of Heat Treated Wood with Structural Adhesives. Holz Als Roh Werkst. 2008, 66, 173–180. [Google Scholar] [CrossRef]

- Krueger, G.P.; Eddy, F.M., Jr. Ultimate-Strength Design of Reinforced Timber: Moment Rotation Characteristics. Wood Sci. Technol. 1974, 6, 330–344. [Google Scholar]

- Borri, A.; Corradi, M. Strengthening of Timber Beams with High Strength Steel Cords. Compos. Part B Eng. 2011, 42, 1480–1491. [Google Scholar] [CrossRef]

- Jasieńko, J.; Nowak, T.P. Solid Timber Beams Strengthened with Steel Plates–Experimental Studies. Constr. Build. Mater. 2014, 63, 81–88. [Google Scholar] [CrossRef]

- Mirski, R.; Dziurka, D.; Chuda-Kowalska, M.; Wieruszewski, M.; Kawalerczyk, J.; Trociński, A. The Usefulness of Pine Timber (Pinus Sylvestris L.) for the Production of Structural Elements. Part I: Evaluation of the Quality of the Pine Timber in the Bending Test. Materials 2020, 13, 3957. [Google Scholar] [CrossRef]

- Guan, Z.W.; Rodd, P.D.; Pope, D.J. Study of Glulam Beams Pre-Stressed with Pultruded GRP. Comput. Struct. 2005, 83, 2476–2487. [Google Scholar] [CrossRef]

- Kim, Y.J.; Harries, K.A. Modeling of Timber Beams Strengthened with Various CFRP Composites. Eng. Struct. 2010, 32, 3225–3234. [Google Scholar] [CrossRef]

- Schober, K.-U.; Rautenstrauch, K. Post-Strengthening of Timber Structures with CFRP’s. Mater. Struct. 2007, 40, 27–35. [Google Scholar] [CrossRef]

- Raftery, G.M.; Harte, A.M. Low-Grade Glued Laminated Timber Reinforced with FRP Plate. Compos. Part B Eng. 2011, 42, 724–735. [Google Scholar] [CrossRef]

- Vanerek, J.; Benesova, A.; Rovnanik, P.; Drochytka, R. Evaluation of FRP/Wood Adhesively Bonded Epoxy Joints on Environmental Exposures. J. Adhes. Sci. Technol. 2014, 28, 1405–1417. [Google Scholar] [CrossRef]

- Zhang, J.; Hu, X.; Sun, Q.; Zhang, Y.; Zhu, W.; Li, L. Experimental Study on Seismic Performance of Glulam-Concrete Composite Beam-to-Column Joints. Compos. Struct. 2020, 236, 111864. [Google Scholar] [CrossRef]

- Richart, F.E.; Williams, C.B. Tests of Composite Timber and Concrete Beams; University of Illinois at Urbana Champaign, College of Engineering: Urbana, IL, USA, 1943. [Google Scholar]

- Ceccotti, A. Composite Concrete-timber Structures. Prog. Struct. Eng. Mater. 2002, 4, 264–275. [Google Scholar] [CrossRef]

- Miotto, J.L.; Dias, A.A. Glulam-Concrete Composites: Experimental Investigation into the Connection System. Mater. Res. 2011, 14, 53–59. [Google Scholar] [CrossRef] [Green Version]

- Dziurka, D.; Kuliński, M.; Trociński, A.; Mirski, R. Possibility to Use Short Sawn Timber in the Production of Glued Laminated Beams. Materials 2022, 15, 2992. [Google Scholar] [CrossRef]

- Mirski, R.; Kuliński, M.; Dziurka, D.; Thomas, M.; Antonowicz, R. Strength Properties of Structural Glulam Elements from Pine (Pinus Sylvestris L.) Timber Reinforced in the Tensile Zone with Steel and Basalt Rods. Materials 2021, 14, 2574. [Google Scholar] [CrossRef]

- Mirski, R.; Dziurka, D.; Kuliński, M.; Trociński, A.; Kawalerczyk, J.; Antonowicz, R. Strength Properties of Structural Glulam Manufactured from Pine (Pinus Sylvestris L.) Side Boards. Materials 2021, 14, 7312. [Google Scholar] [CrossRef] [PubMed]

- EN 338; Structural Timber—Strength Classes. European Committee for Standardization: Brussels, Belgium, 2016.

| Property | Layer | |||||||

|---|---|---|---|---|---|---|---|---|

| Plywood | Lumber 1 | Lumber 2 | Lumber 3 | Lumber 4 | Lumber 5 | Lumber 6 | Lumber 7 | |

| (N/mm2) | ||||||||

| fm_II | 73.8 * | 28.79 *** | 24.96 | 18.87 | 18.94 | 24.69 | 28.96 | 23.50 |

| fm_⊥ | 63.3 | - | - | - | - | - | - | - |

| EmII | 8810/8640 ** | 11,830 | 10,890 | 9110 | 9100 | 10,820 | 11,870 | 10,500 |

| Em⊥ | 7840 | - | - | - | - | - | - | - |

| Property | Layer | |||||||

|---|---|---|---|---|---|---|---|---|

| Lumber 1 | Lumber 2 | Lumber 3 | Lumber 4 | Lumber 5 | Lumber 6 | Lumber 7 | Lumber 8 | |

| (N/mm2) | ||||||||

| fm | 44.20 | 34.16 | 26.53 | 14.30 | 14.36 | 24.69 | 32.03 | 43.74 |

| Em | 15,130 | 12,730 | 11,110 | 8590 | 8770 | 10,820 | 12,440 | 14,750 |

| Mean Value kN/mm2 | Mean Value kN/mm2 | df | t | p | Standard Deviation A/P | Standard Deviation B/Z | F-Value Variances | p Variances |

|---|---|---|---|---|---|---|---|---|

| A | B | Relation A: B | ||||||

| 9.29 | 9.82 | 22 | −1.519 | 0.142996 | 0.854 | 0.657 | 1.68854 | 0.49452 |

| P | Z | Relation P: Z | ||||||

| 11.50 | 11.82 | 20 | −1.296 | 0.20960 | 0.603 | 0.484 | 1.55082 | 0.57418 |

| Mean Value | Mean Value | df | t | p | Standard Deviation | Standard Deviation | F-Value Variances | p Variances |

|---|---|---|---|---|---|---|---|---|

| N/mm2 | N/mm2 | - | - | - | N/mm2 | N/mm2 | - | - |

| A | B | Relation A: B | A | B | Relation A: B | |||

| 42.8 | 44.5 | 22 | −0.9975 | 0.3294 | 3.887 | 4.148 | 1.1385 | 0.7820 |

| P | Z | Relation P: Z | P | Z | Relation P: Z | |||

| 42.6 | 41.0 | 20 | 0.5496 | 0.5887 | 7.440 | 4.164 | 3.192 | 0.1300 |

| Mean Value | Mean Value | df | t | p | Standard Deviation | Standard Deviation | F-Value Variances | p Variances |

|---|---|---|---|---|---|---|---|---|

| % | % | - | - | - | % | % | - | - |

| A | B | Relation A: B | A | B | Relation A: B | |||

| 11.20 | 12.16 | 1.876 | 22 | 0.7394 | 1.23888 | 1.04037 | 1.41786 | 0.6634 |

| P | Z | Relation P: Z | P | Z | Relation P: Z | |||

| 10.67 | 10.80 | −0.2004 | 20 | 0.84317 | 1.5026 | 1.0922 | 1.8928 | 0.40323 |

| Levene’a F(1.df) | df Levene’a | p Levene’a |

|---|---|---|

| 6.47052625 | 45 | 0.0144725817 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dziurka, D.; Derkowski, A.; Dukarska, D.; Kawalerczyk, J.; Mirski, R. The Effect of Periodic Loading of Glued Laminated Beams on Their Static Bending Strength. Materials 2022, 15, 3928. https://doi.org/10.3390/ma15113928

Dziurka D, Derkowski A, Dukarska D, Kawalerczyk J, Mirski R. The Effect of Periodic Loading of Glued Laminated Beams on Their Static Bending Strength. Materials. 2022; 15(11):3928. https://doi.org/10.3390/ma15113928

Chicago/Turabian StyleDziurka, Dorota, Adam Derkowski, Dorota Dukarska, Jakub Kawalerczyk, and Radosław Mirski. 2022. "The Effect of Periodic Loading of Glued Laminated Beams on Their Static Bending Strength" Materials 15, no. 11: 3928. https://doi.org/10.3390/ma15113928

APA StyleDziurka, D., Derkowski, A., Dukarska, D., Kawalerczyk, J., & Mirski, R. (2022). The Effect of Periodic Loading of Glued Laminated Beams on Their Static Bending Strength. Materials, 15(11), 3928. https://doi.org/10.3390/ma15113928