A New Creep–Fatigue Interaction Model for Predicting Deformation of Coarse-Grained Soil

Abstract

:1. Introduction

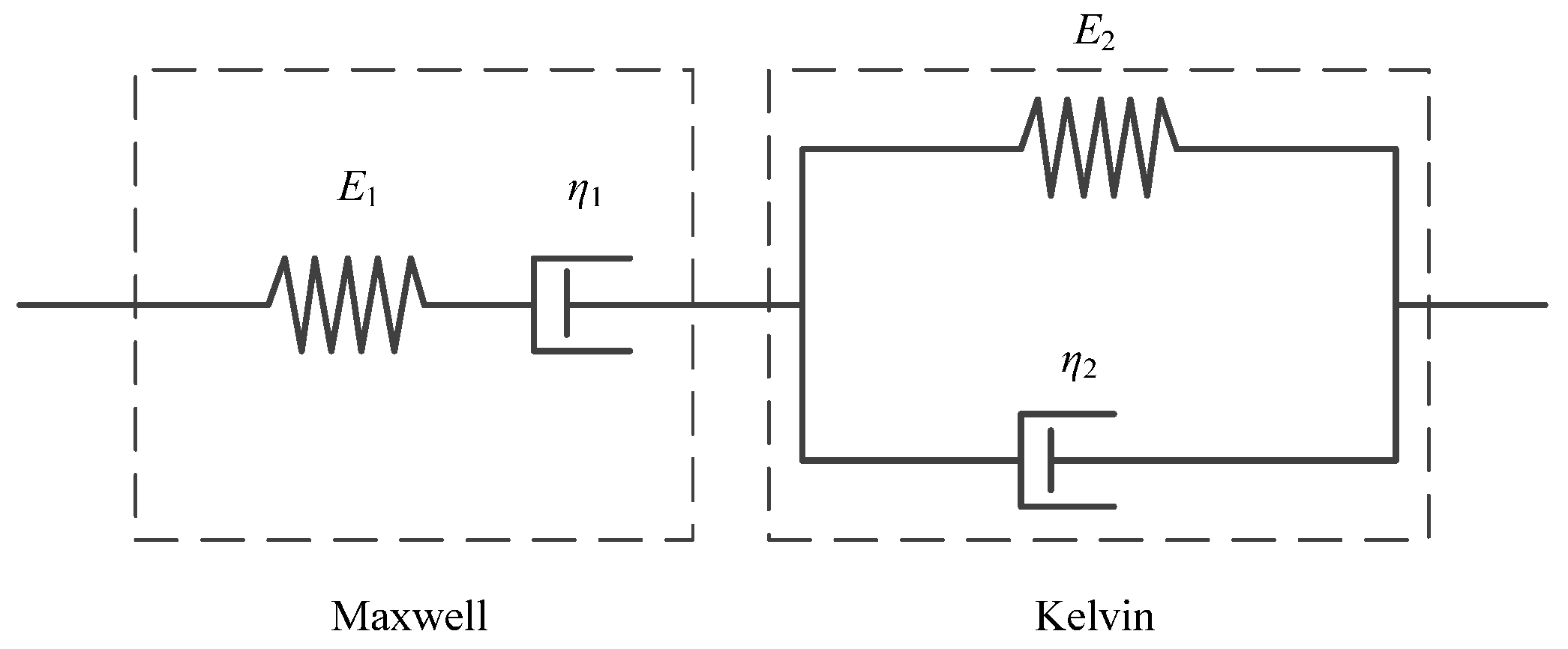

2. Establishment of New Creep–Fatigue Interaction Model

2.1. Definition of the New Creep–Fatigue Interaction Factor

2.2. Determination of Creep–Fatigue Interaction Factor

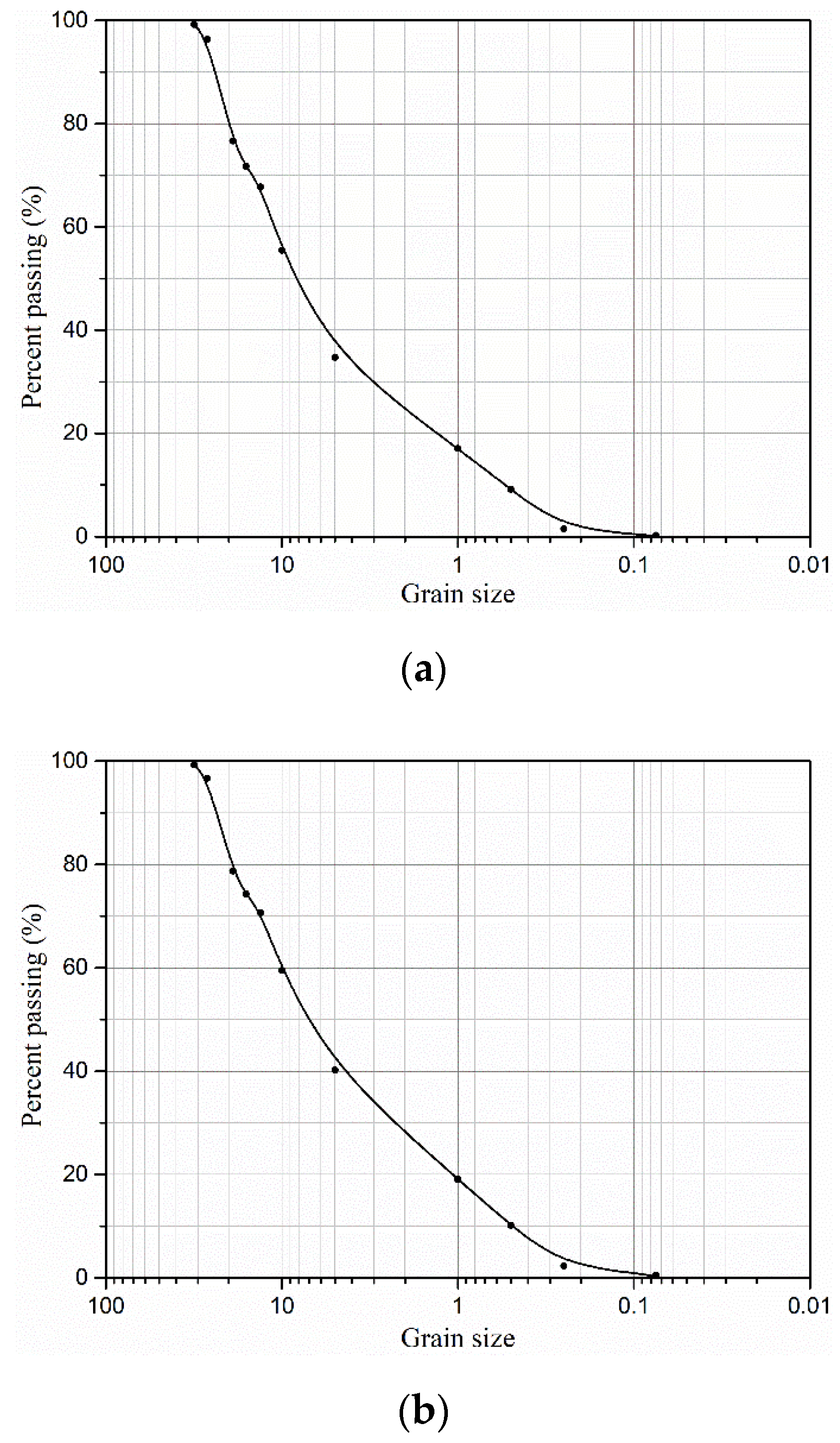

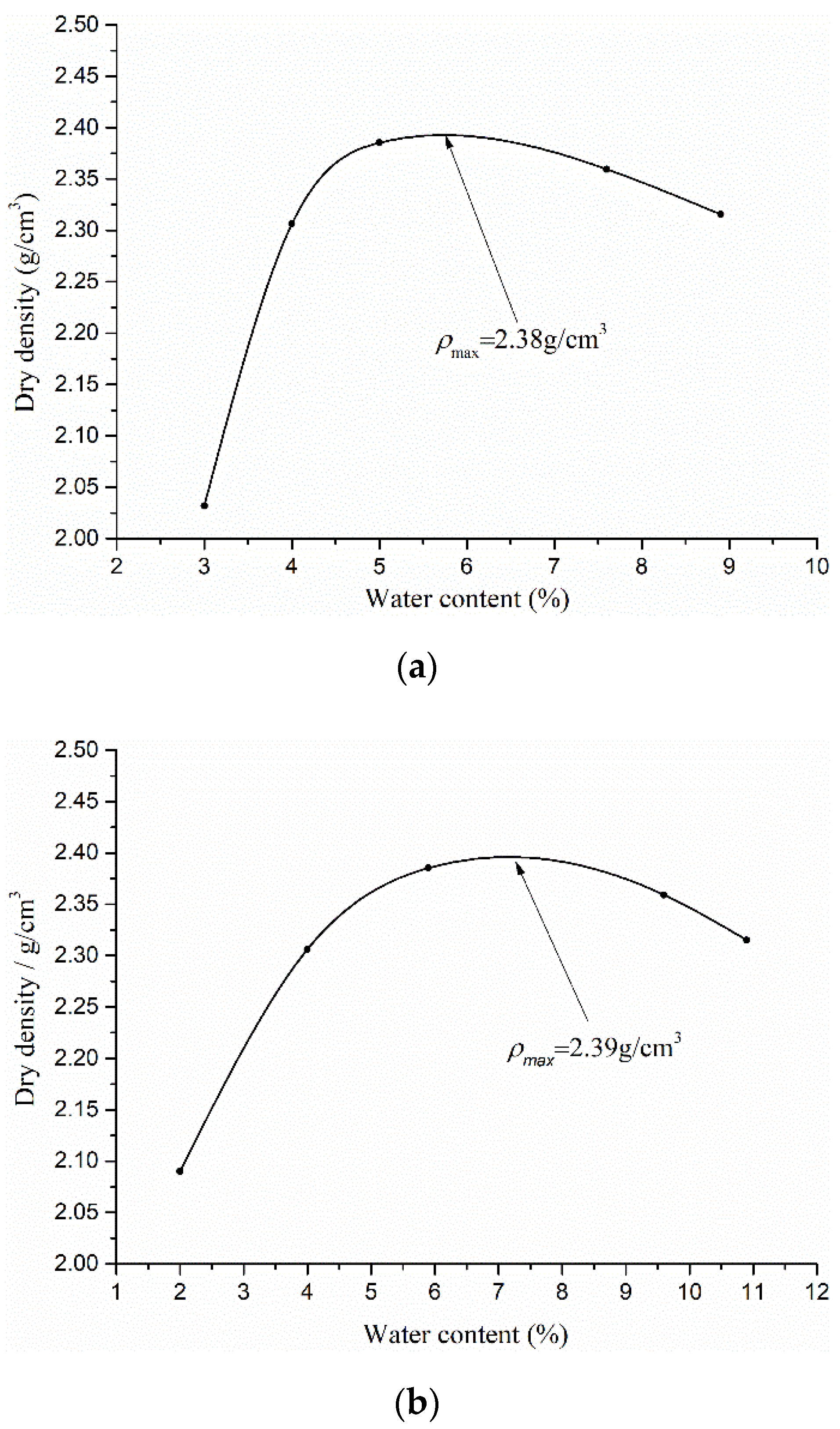

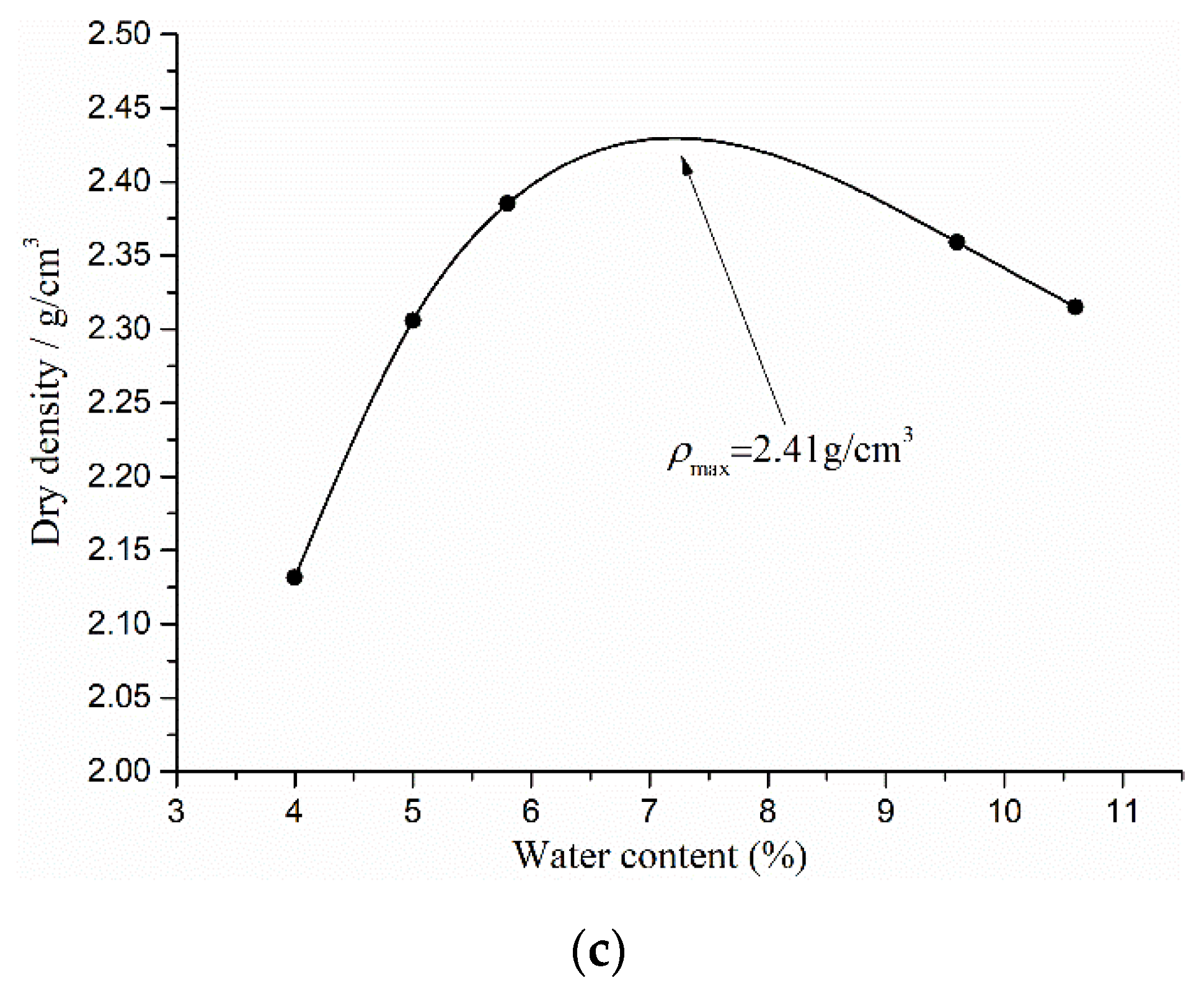

2.2.1. Scheme of Triaxial Creep and Fatigue Tests

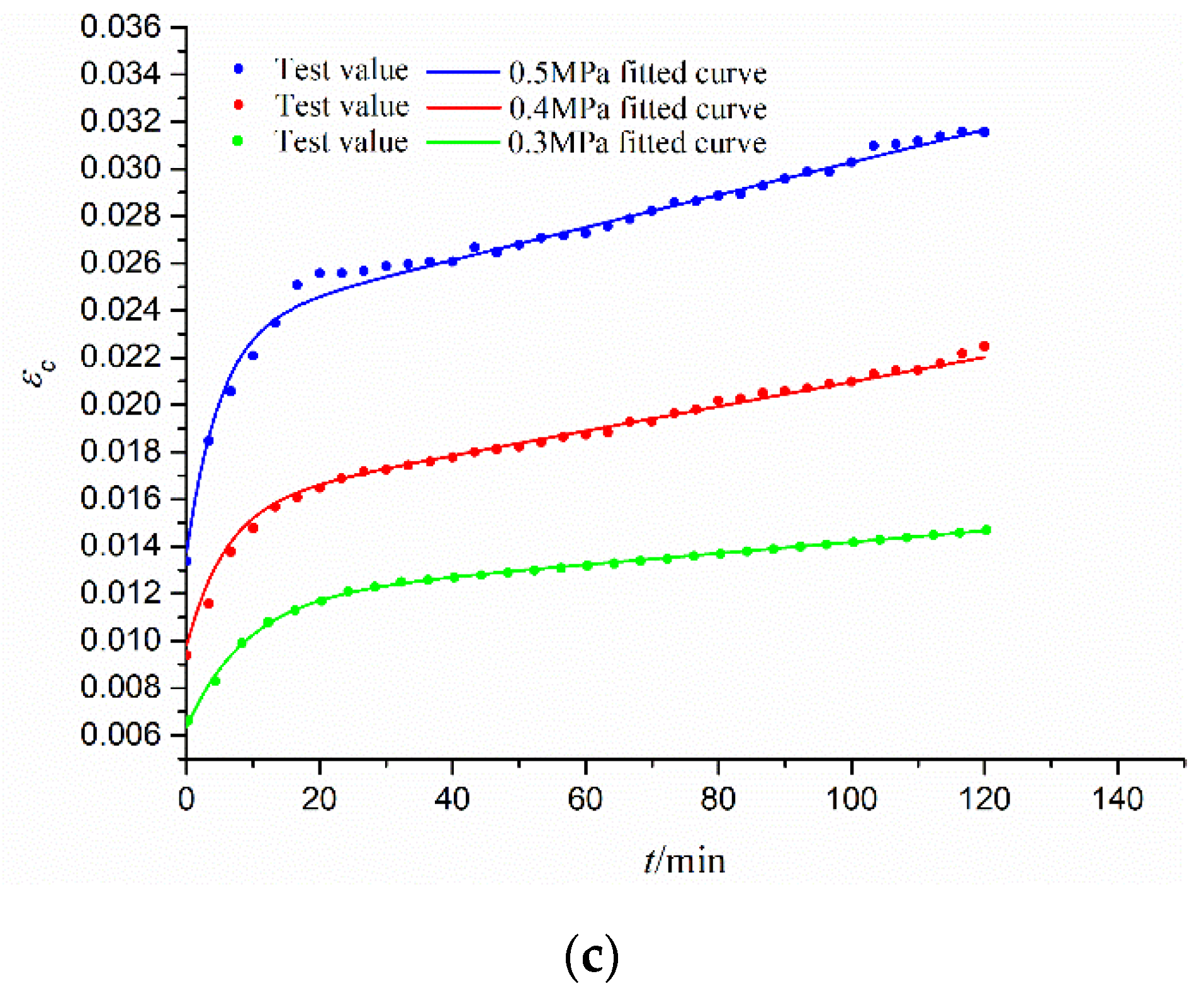

2.2.2. Triaxial Creep Test and Analyses

- (1)

- Creep parameters under different stress

- (2)

- Unified creep parameters for different creep stresses and gradations

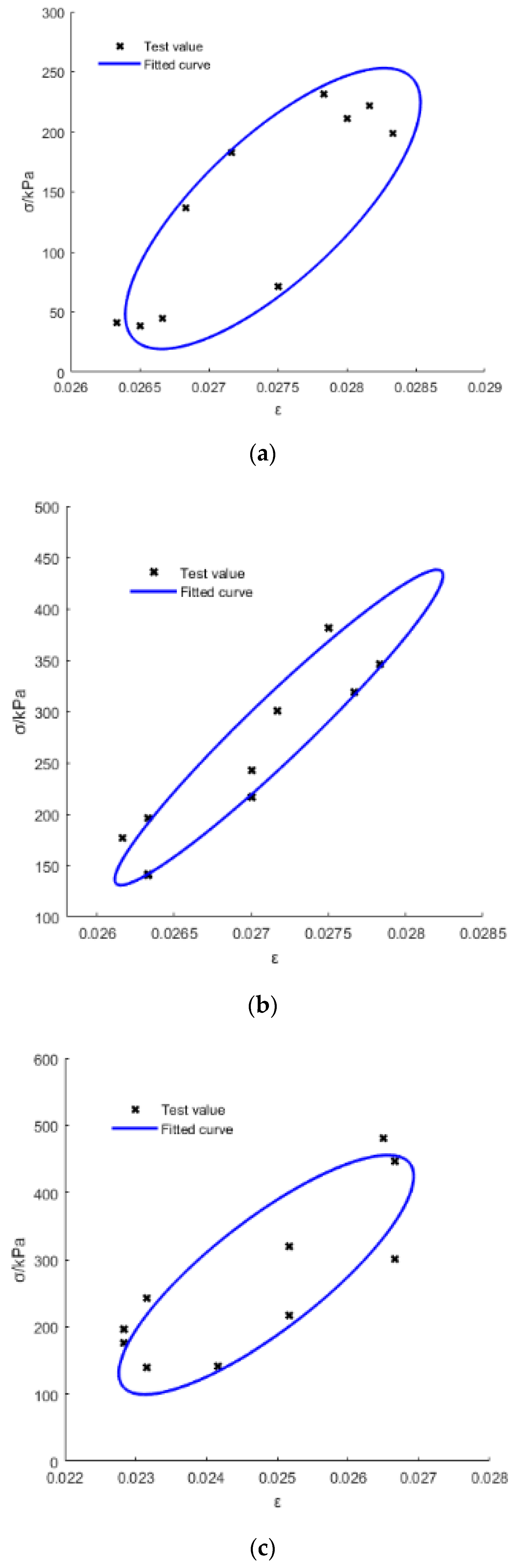

2.2.3. Triaxial Fatigue Test and Analyze

- (1)

- Fatigue compliance formulae

- (2)

- Experimental determination of fatigue compliance

2.2.4. Determination of Creep–Fatigue Interaction Parameters

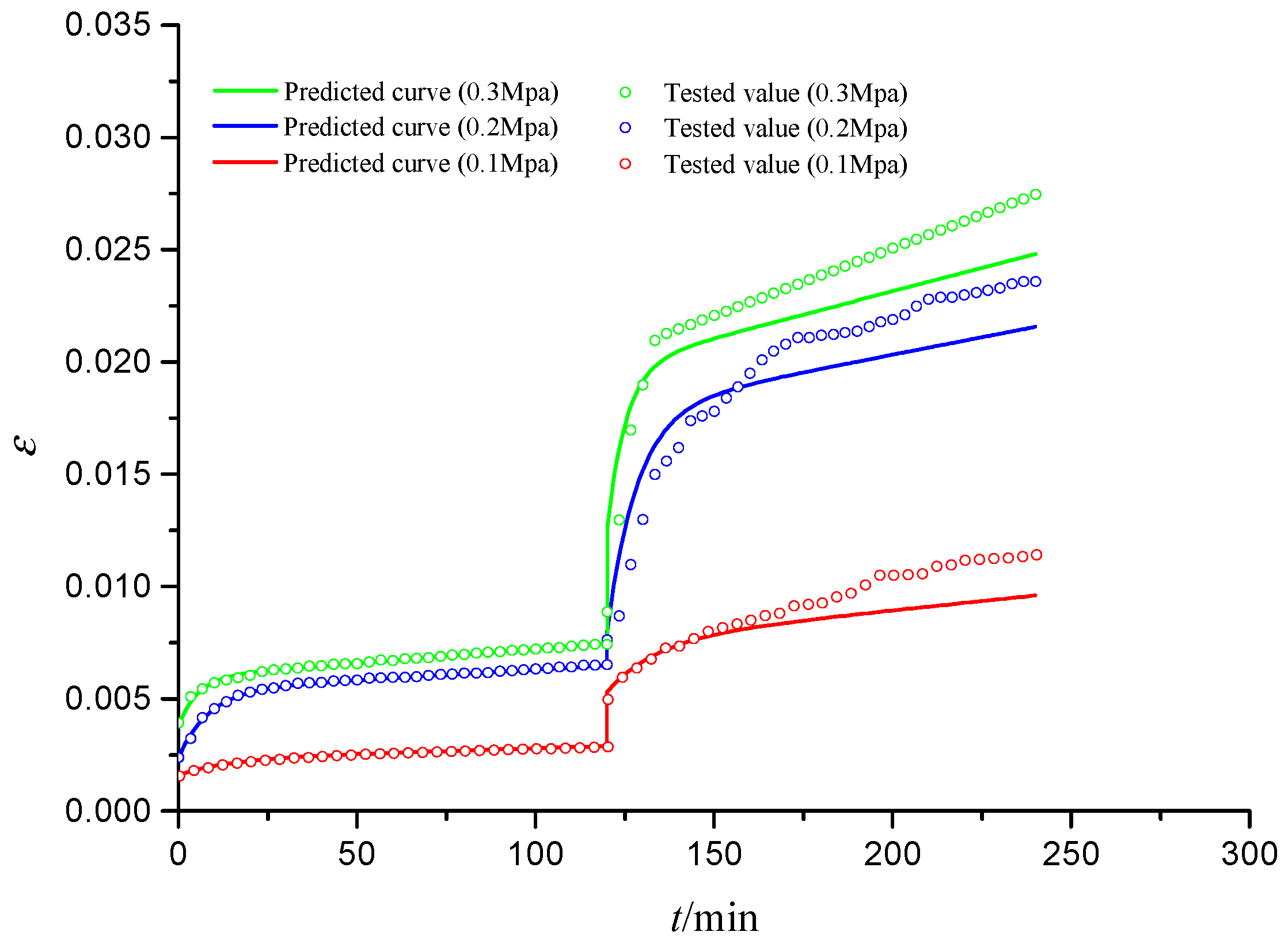

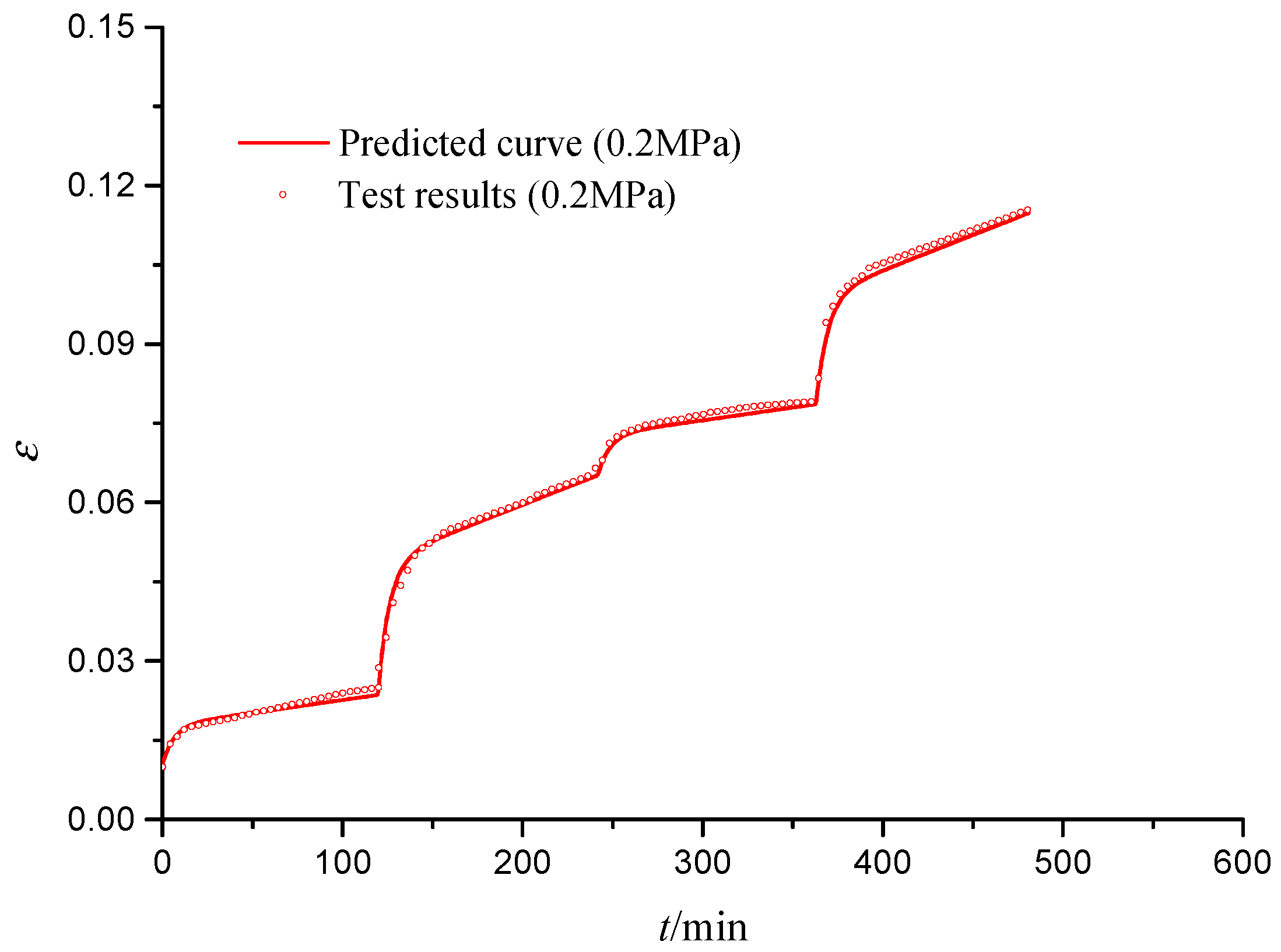

3. Test Verification of the Creep–Fatigue Interaction Model

3.1. Prediction Method and Test Scheme

3.2. Results and Analysis

3.2.1. Triaxial Creep–Fatigue Interaction Deformation

3.2.2. Triaxial Fatigue–Creep Interaction Deformation

3.2.3. Triaxial Creep–Fatigue Multi-Interaction Deformation

4. Conclusions

- (1)

- New transformation parameters (k and g) are proposed to establish a new creep–fatigue interaction model based on both the rheologic mechanics and the interactive relationship between creep and fatigue complex compliance, in order to predict the creep–fatigue interaction deformation of CGS.

- (2)

- The creep–fatigue interaction factor k is almost unchanged with the frequency (f) and changed non-monotonic with the pebble content (γ). The creep–fatigue interaction factor g is increased with both f and γ. The creep strain and fatigue strain of the creep–fatigue and fatigue–creep interaction are increased with the increase in average stress (σa)

- (3)

- For the different interaction orders (creep–fatigue interaction or fatigue–creep interaction), the fatigue deformation is always larger than the creep deformation under the same stress level because of the dynamic effect.

- (4)

- For the creep–fatigue multi-interaction, the second creep and fatigue deformation is always smaller than the first creep and fatigue deformation because of the compaction effect.

- (5)

- The new creep–fatigue interaction model is proved valid by the good agreement between the predicted results and test results of the triaxial creep–fatigue interaction. It can be further developed for predicting the creep–fatigue interaction of multi-layered coarse-grained soil.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- GB/T 50145—2007; Standard for Engineering Classification of Soil. Planning Press: Beijing, China, 2008.

- Medley, E. The Engineering Characterization of Mélanges and Similar Block-In-Matrix Rocks (Bimrocks). Ph.D. Thesis, University of California, Los Angeles, CA, USA, 1994. [Google Scholar]

- Guo, G.Q. Engineering Characteristics and Application of Coarse-Grained Soil; The Yellow River Water Conservancy Press: Zhengzhou, China, 1998. [Google Scholar]

- Long, X.; Cen, G.; Cai, L.; Chen, Y. Model experiment of uneven frost heave of airport pavement structure on coarse-grained soils foundation. Constr. Build. Mater. 2018, 188, 372–380. [Google Scholar] [CrossRef]

- Su, Y.; Cui, Y.-J.; Dupla, J.-C.; Canou, J.; Qi, S. A fatigue model for track-bed materials with consideration of the effect of coarse grain content. Transp. Geotech. 2020, 23, 100353. [Google Scholar] [CrossRef]

- Cai, Y.; Chen, Y.; Cao, Z.; Sun, H.; Guo, L. Dynamic responses of a saturated poroelastic half-space generated by a moving truck on the uneven pavement. Soil Dyn. Earthq. Eng. 2015, 69, 172–181. [Google Scholar] [CrossRef]

- Manoukas, G.; Athanatopoulou, A.; Avramidis, I. Multimode pushover analysis for asymmetric buildings under biaxial seismic excitation based on a new concept of the equivalent single degree of freedom system. Soil Dyn. Earthq. Eng. 2012, 38, 88–96. [Google Scholar] [CrossRef]

- Hou, F.; Lai, Y.; Liu, E.; Luo, H.; Liu, X. A creep constitutive model for frozen soils with different contents of coarse grains. Cold Reg. Sci. Technol. 2018, 145, 119–126. [Google Scholar] [CrossRef]

- Larue, G.S.; Watling, C.N.; Black, A.; Wood, J.M. Improving the safety of distracted pedestrians with in-ground flashing lights. A railway crossing field study. J. Saf. Res. 2021, 77, 170–181. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, X.; Wang, H.; Jiang, B. Laboratory testing and analysis of dynamic and static resilient modulus of subgrade soil under various influencing factors. Constr. Build. Mater. 2019, 195, 178–186. [Google Scholar] [CrossRef]

- Liu, H.; Yang, X.; Jiang, L.; Lv, S.; Huang, T.; Yang, Y. Fatigue-creep damage interaction model of asphalt mixture under the semi-sine cycle loading. Constr. Build. Mater. 2020, 251, 119070. [Google Scholar] [CrossRef]

- Wang, J.; Li, J.; Shi, Z. Deformation damage and acoustic emission characteristics of red sandstone under fatigue–creep interaction. Theor. Appl. Fract. Mech. 2022, 117, 103192. [Google Scholar] [CrossRef]

- Ma, L.; Wang, Y.; Wang, M.; Xue, B.; Duan, L. Mechanical properties of rock salt under combined creep and fatigue. Int. J. Rock Mech. Min. Sci. 2021, 141, 104654. [Google Scholar] [CrossRef]

- Dong, N.; Wang, D.; Zhang, S.; Chen, Z.; Liang, H.; Ni, F.; Yu, J.; Yu, H. Exploring creep and recovery behavior of hot mix asphalt field cores with multi-sequenced repeated load test. Constr. Build. Mater. 2021, 279, 122435. [Google Scholar] [CrossRef]

- Golub, V.P. Procedure for the calculation of cyclic creep and longevity from static loading data. Int. Appl. Mech. 1984, 20, 363–368. [Google Scholar] [CrossRef]

- Li, Y.; Sun, H.; He, X.; Tan, Y. Fatigue damage and creep characteristics of cement emulsified asphalt composite binder. Constr. Build. Mater. 2020, 234, 117416. [Google Scholar] [CrossRef]

- Li, Q.; Liu, M.; Lu, Z.; Deng, X. Creep Model of High-Strength High-Performance Concrete Under Cyclic Loading. J. Wuhan Univ. Technol. Sci. Ed. 2019, 34, 622–629. [Google Scholar] [CrossRef]

- Al-Mistarehi, B.W.; Khadaywi, T.S.; Hussein, A.K. Investigating the effects on creep and fatigue behavior of asphalt mixtures with recycled materials as fillers. J. King Saud Univ.-Eng. Sci. 2021, 33, 355–363. [Google Scholar] [CrossRef]

- Tarefder, R.; Faisal, H.; Barlas, G. Freeze-thaw effects on fatigue LIFE of hot mix asphalt and creep stiffness of asphalt binder. Cold Reg. Sci. Technol. 2018, 153, 197–204. [Google Scholar] [CrossRef]

- Li, X.; Qi, C.; Zhang, P. A micro-macro confined compressive fatigue creep failure model in brittle solids. Int. J. Fatigue 2020, 130, 105278. [Google Scholar] [CrossRef]

- Kindrachuk, V.M.; Thiele, M.; Unger, J. Constitutive modeling of creep-fatigue interaction for normal strength concrete under compression. Int. J. Fatigue 2015, 78, 81–94. [Google Scholar] [CrossRef]

- Gedik, A.; Selcuk, S.; Lav, A.H. Investigation of recycled fluorescent lamps waste as mineral filler in highway construction: A case of asphaltic pavement layers. Resour. Conserv. Recycl. 2021, 168, 105290. [Google Scholar] [CrossRef]

- Alghrafy, Y.M.; Alla, E.-S.M.A.; El-Badawy, S.M. Rheological properties and aging performance of sulfur extended asphalt modified with recycled polyethylene waste. Constr. Build. Mater. 2021, 273, 121771. [Google Scholar] [CrossRef]

- Delfosse-Ribay, E.; Djeran-Maigre, I.; Cabrillac, R.; Gouvenot, D. Comparison of Creep Behaviour and Fatigue Behaviour of Grouted Sand. Soils Found. 2007, 47, 185–194. [Google Scholar] [CrossRef] [Green Version]

- Ameli, A.; Babagoli, R.; Asadi, S.; Norouzi, N. Investigation of the performance properties of asphalt binders and mixtures modified by Crumb Rubber and Gilsonite. Constr. Build. Mater. 2021, 279, 122424. [Google Scholar] [CrossRef]

- Qin, W.Z.; Wang, K.L. Research on the relationship between dynamic and static parameters of soil layer based on viscoelastic model. In Proceedings of the Fifteenth National Conference on Structural Engineering (No.Ⅱ); 2006; pp. 307–310. Available online: https://kns.cnki.net/kcms/detail/detail.aspx?FileName=LXFY200610002066&DbName=CPFD2006 (accessed on 13 April 2022).

- Yang, T.Q. Theory of Viscoelasticity; Huazhong University of Technology Press: Wuhan, China, 1992. [Google Scholar]

- Li, H. Viscoelastic Mechanical Response Analysis of Asphalt Mixture and Asphalt Pavement under Dynamic and Static Loads; Jilin University: Changchun, China, 2021. [Google Scholar]

| No. | Pebble (γ) | Sand | Clay |

|---|---|---|---|

| S1 | 1 | 1 | 0.30 |

| S2 | 1 | 1 | 0.75 |

| S3 | 1 | 1 | 1.33 |

| No. | Creep | Fatigue | ||||

|---|---|---|---|---|---|---|

| σc/MPa | Holding Time t/min | Peak Stress σf/MPa | Frequency f/Hz | Cycle Number num/N | Average Stress σa/MPa | |

| S1/S2/S3 | 0.3 | 120 | 0.4 | 1 | 7200 | 0.1 |

| 2 | 14,400 | |||||

| 3 | 21,600 | |||||

| 0.4 | 0.6 | 1 | 7200 | 0.2 | ||

| 2 | 14,400 | |||||

| 3 | 21,600 | |||||

| 0.5 | 0.8 | 1 | 7200 | 0.3 | ||

| 2 | 14,400 | |||||

| 3 | 21,600 | |||||

| No. | σc − σ3/MPa | E1/MPa | E2/MPa | η1/MPa·min | η2/MPa·min | R2 |

|---|---|---|---|---|---|---|

| S1 | 0.1 | 62.51 | 142.95 | 19,958.67 | 1974.63 | 0.997 |

| 0.2 | 83.33 | 66.67 | 21,276.59 | 555.56 | 0.998 | |

| 0.3 | 78.13 | 138.88 | 23,809.52 | 730.99 | 0.996 | |

| S2 | 0.1 | 29.36 | 61.22 | 7544.07 | 312.03 | 0.998 |

| 0.2 | 36.49 | 55.56 | 7407.40 | 229.56 | 0.996 | |

| 0.3 | 41.67 | 50.00 | 6578.94 | 257.73 | 0.996 | |

| S3 | 0.1 | 15.74 | 18.33 | 4196.82 | 163.64 | 0.998 |

| 0.2 | 20.28 | 33.67 | 3846.15 | 199.23 | 0.997 | |

| 0.3 | 21.73 | 31.25 | 4347.82 | 157.82 | 0.995 |

| No. | S1 | S2 | S3 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| σc/MPa | 0.3 | 0.4 | 0.5 | 0.3 | 0.4 | 0.5 | 0.3 | 0.4 | 0.5 | |

| E1/ MPa | Tested value | 62.51 | 83.33 | 78.13 | 29.36 | 36.49 | 41.67 | 15.74 | 20.28 | 21.73 |

| Calculated value | 63.65 | 73.89 | 85.78 | 30.47 | 35.37 | 41.07 | 16.38 | 19.02 | 22.08 | |

| Error | 1.82% | 11.32% | 9.79% | 3.78% | 3.06% | 0.05% | 4.06% | 6.21% | 1.61% | |

| E2/ MPa | Tested value | 142.95 | 66.67 | 138.88 | 61.22 | 55.56 | 50.00 | 18.33 | 33.67 | 31.25 |

| Calculated value | 138.02 | 58.88 | 146.98 | 54.95 | 56.23 | 57.07 | 20.41 | 27.28 | 28.96 | |

| Error | 3.44% | 11.68% | 5.81% | 10.24% | 1.21% | 14.14% | 11.34% | 18.90% | 7.32% | |

| η1/ MPa·min | Tested value | 19,958.67 | 21,276.59 | 23,809.52 | 7544.07 | 7407.40 | 6578.94 | 4196.82 | 3846.15 | 4347.82 |

| Calculated value | 21,300.86 | 21,567.37 | 21,837.21 | 7057.92 | 7146.23 | 7235.64 | 4064.62 | 4115.48 | 4166.97 | |

| Error | 6.72% | 1.36% | 8.28% | 6.44% | 3.52% | 9.98% | 3.15% | 7.00% | 4.15% | |

| η2/ MPa·min | Tested value | 1974.63 | 555.56 | 730.99 | 312.03 | 229.56 | 257.73 | 163.64 | 199.23 | 157.82 |

| Calculated value | 2092.09 | 531.02 | 630.95 | 293.26 | 251.18 | 239.88 | 158.48 | 176.42 | 165.95 | |

| Error | 5.94% | 4.41% | 13.68% | 6.01% | 9.41% | 6.92% | 3.15% | 11.44% | 5.15% | |

| No. | σa/MPa | 0.1 | 0.2 | 0.3 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| f/Hz | 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 | |

| S1 | 97.26 | 96.45 | 96.02 | 201.54 | 198.61 | 193.21 | 298.45 | 284.25 | 280.62 | |

| S2 | 187.36 | 184.56 | 183.27 | 387.58 | 385.12 | 376.31 | 572.54 | 568.14 | 557.10 | |

| S3 | 243.95 | 236.57 | 230.47 | 497.66 | 485.74 | 472.96 | 740.57 | 724.65 | 719.45 | |

| No. | γ | f/Hz | Creep | Fatigue | Matrix(M) | ||

|---|---|---|---|---|---|---|---|

| Jr(t)/Mpa−1 | Ji(t)/Mpa−1 | Jr(ω)/Mpa−1 | Ji(ω)/Mpa−1 | ||||

| S1 | 0.434 | 1 | 0.0157 | 0.000083 | 0.0531 | 0.001535 | |

| 2 | 0.0157 | 0.000041 | 0.0530 | 0.001314 | |||

| 3 | 0.0157 | 0.000027 | 0.0532 | 0.001054 | |||

| S2 | 0.363 | 1 | 0.0328 | 0.000565 | 0.1143 | 0.006992 | |

| 2 | 0.0328 | 0.000282 | 0.1145 | 0.005854 | |||

| 3 | 0.0328 | 0.000188 | 0.1142 | 0.004101 | |||

| S3 | 0.272 | 1 | 0.0611 | 0.001043 | 0.1754 | 0.013388 | |

| 2 | 0.0611 | 0.000521 | 0.1756 | 0.009633 | |||

| 3 | 0.0611 | 0.000347 | 0.1758 | 0.005702 | |||

| No. | γ | f/Hz | Creep | Fatigue | Matrix(M) | ||

|---|---|---|---|---|---|---|---|

| Jr(t)/Mpa−1 | Ji(t)/Mpa−1 | Jr(ω)/Mpa−1 | Ji(ω)/Mpa−1 | ||||

| S1 | 0.434 | 1 | 0.0135 | 0.000307 | 0.0512 | 0.002203 | |

| 2 | 0.0135 | 0.000153 | 0.0513 | 0.002015 | |||

| 3 | 0.0135 | 0.000102 | 0.0512 | 0.001674 | |||

| S2 | 0.363 | 1 | 0.0282 | 0.000655 | 0.1282 | 0.011689 | |

| 2 | 0.0282 | 0.000328 | 0.1284 | 0.010494 | |||

| 3 | 0.0282 | 0.000218 | 0.1283 | 0.008829 | |||

| S3 | 0.272 | 1 | 0.0525 | 0.000940 | 0.2155 | 0.027809 | |

| 2 | 0.0525 | 0.000471 | 0.2153 | 0.022021 | |||

| 3 | 0.0525 | 0.000313 | 0.2154 | 0.018344 | |||

| No. | γ | f/Hz | Creep | Fatigue | Matrix(M) | ||

|---|---|---|---|---|---|---|---|

| Jr(t)/Mpa−1 | Ji(t)/Mpa−1 | Jr(ω)/Mpa−1 | Ji(ω)/Mpa−1 | ||||

| S1 | 0.434 | 1 | 0.0116 | 0.000259 | 0.0857 | 0.006082 | |

| 2 | 0.0116 | 0.000129 | 0.0858 | 0.005106 | |||

| 3 | 0.0116 | 0.000086 | 0.0855 | 0.004116 | |||

| S2 | 0.363 | 1 | 0.0243 | 0.000684 | 0.1433 | 0.017303 | |

| 2 | 0.0243 | 0.000342 | 0.1435 | 0.015152 | |||

| 3 | 0.0243 | 0.000228 | 0.1436 | 0.012881 | |||

| S3 | 0.272 | 1 | 0.0453 | 0.000997 | 0.2874 | 0.037071 | |

| 2 | 0.0453 | 0.000498 | 0.2872 | 0.035391 | |||

| 3 | 0.0453 | 0.000332 | 0.2871 | 0.031228 | |||

| No. | Loading Order (C-F Interaction) | Creep | Fatigue | |||

|---|---|---|---|---|---|---|

| σc/Mpa | Holding Time (t)/min | σa/Mpa | f/Hz | Cycle Number/N | ||

| S1 | C-F | 0.1/0.2/0.3 | 120 | 0.1/0.2/0.3 | 1 | 7200 |

| S2 | F-C | 0.1/0.2/0.3 | 120 | 0.1/0.2/0.3 | 1 | 7200 |

| S3 | C-F-C-F | 0.2 | 120 | 0.2 | 1 | 14,400 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Rao, Q.; Yi, W. A New Creep–Fatigue Interaction Model for Predicting Deformation of Coarse-Grained Soil. Materials 2022, 15, 3904. https://doi.org/10.3390/ma15113904

Zhang J, Rao Q, Yi W. A New Creep–Fatigue Interaction Model for Predicting Deformation of Coarse-Grained Soil. Materials. 2022; 15(11):3904. https://doi.org/10.3390/ma15113904

Chicago/Turabian StyleZhang, Jie, Qiuhua Rao, and Wei Yi. 2022. "A New Creep–Fatigue Interaction Model for Predicting Deformation of Coarse-Grained Soil" Materials 15, no. 11: 3904. https://doi.org/10.3390/ma15113904

APA StyleZhang, J., Rao, Q., & Yi, W. (2022). A New Creep–Fatigue Interaction Model for Predicting Deformation of Coarse-Grained Soil. Materials, 15(11), 3904. https://doi.org/10.3390/ma15113904