Effect of TiO2 Nanoparticles on the Fresh Performance of 3D-Printed Cementitious Materials

Abstract

:1. Introduction

2. Materials and Methods

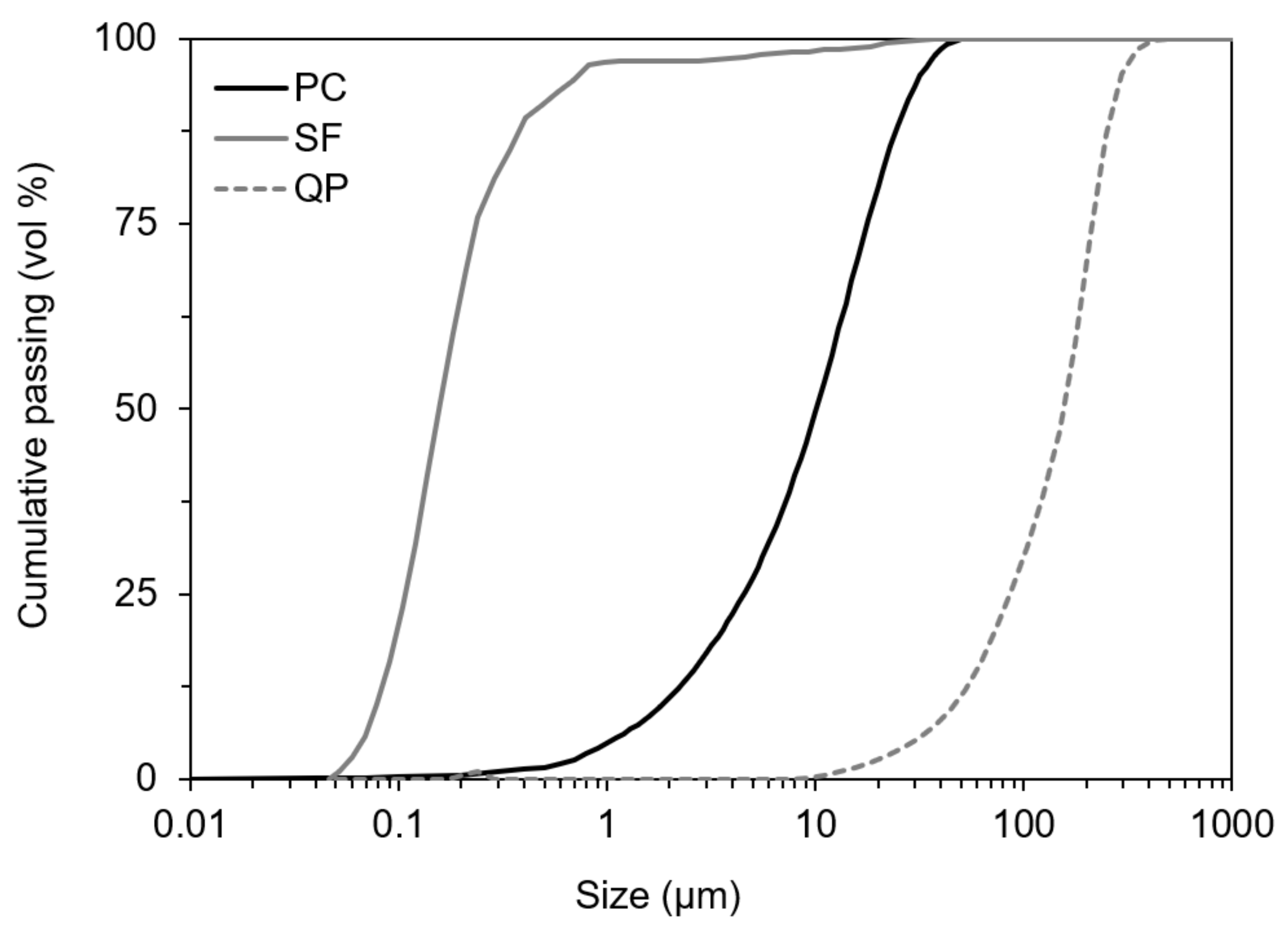

2.1. Materials

2.2. Mix Proportions and Sample Preparation

2.3. Testing Methods

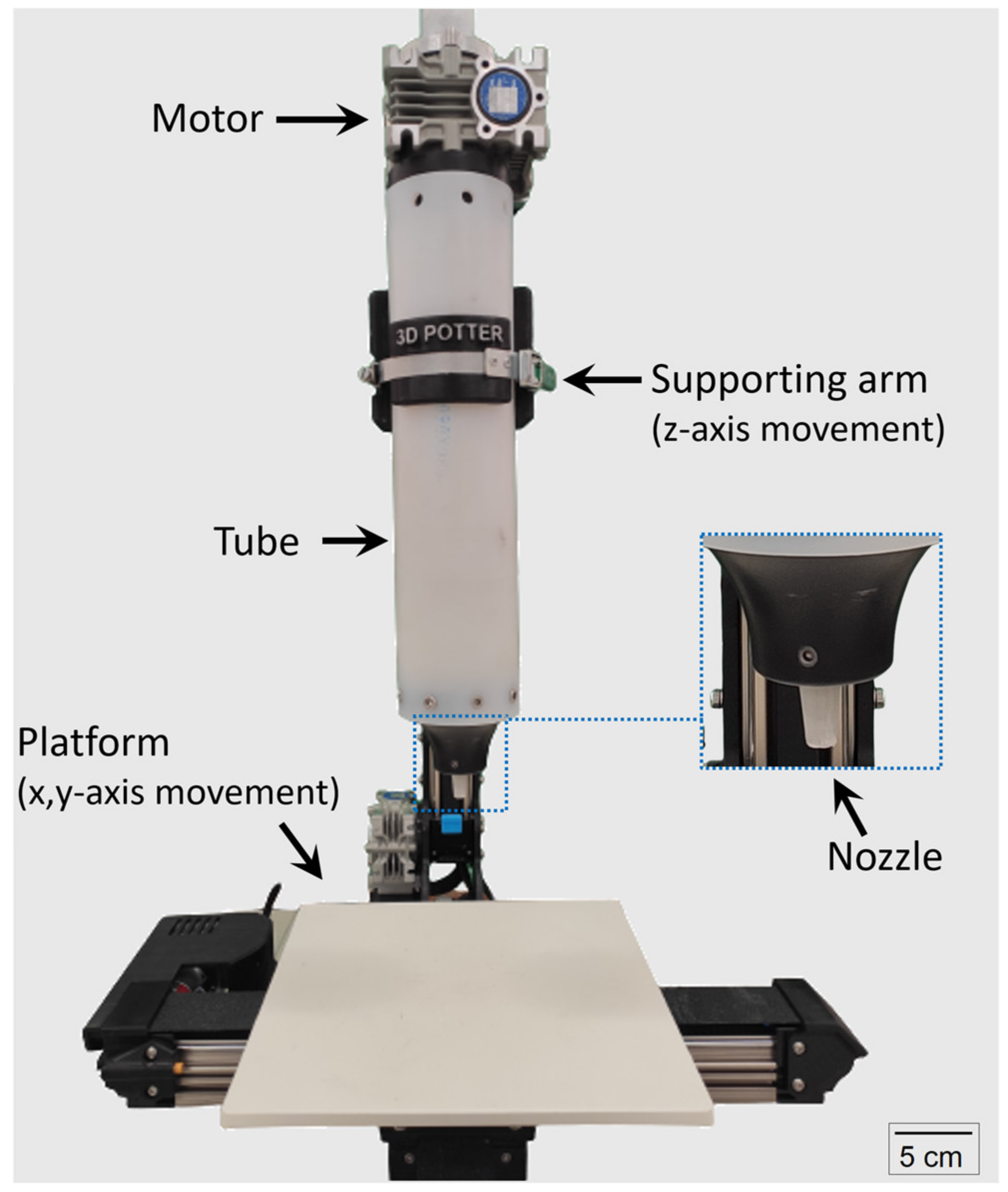

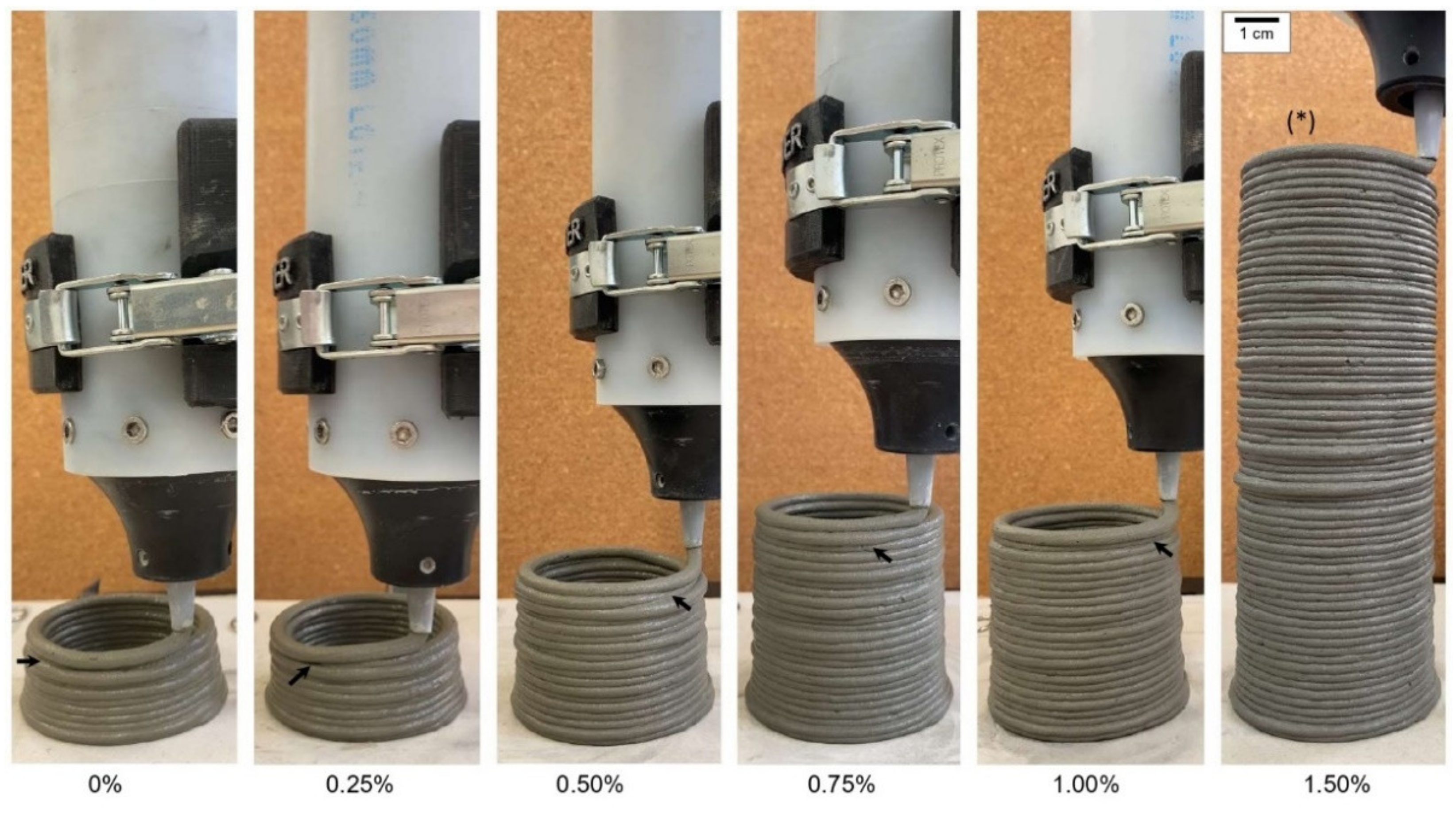

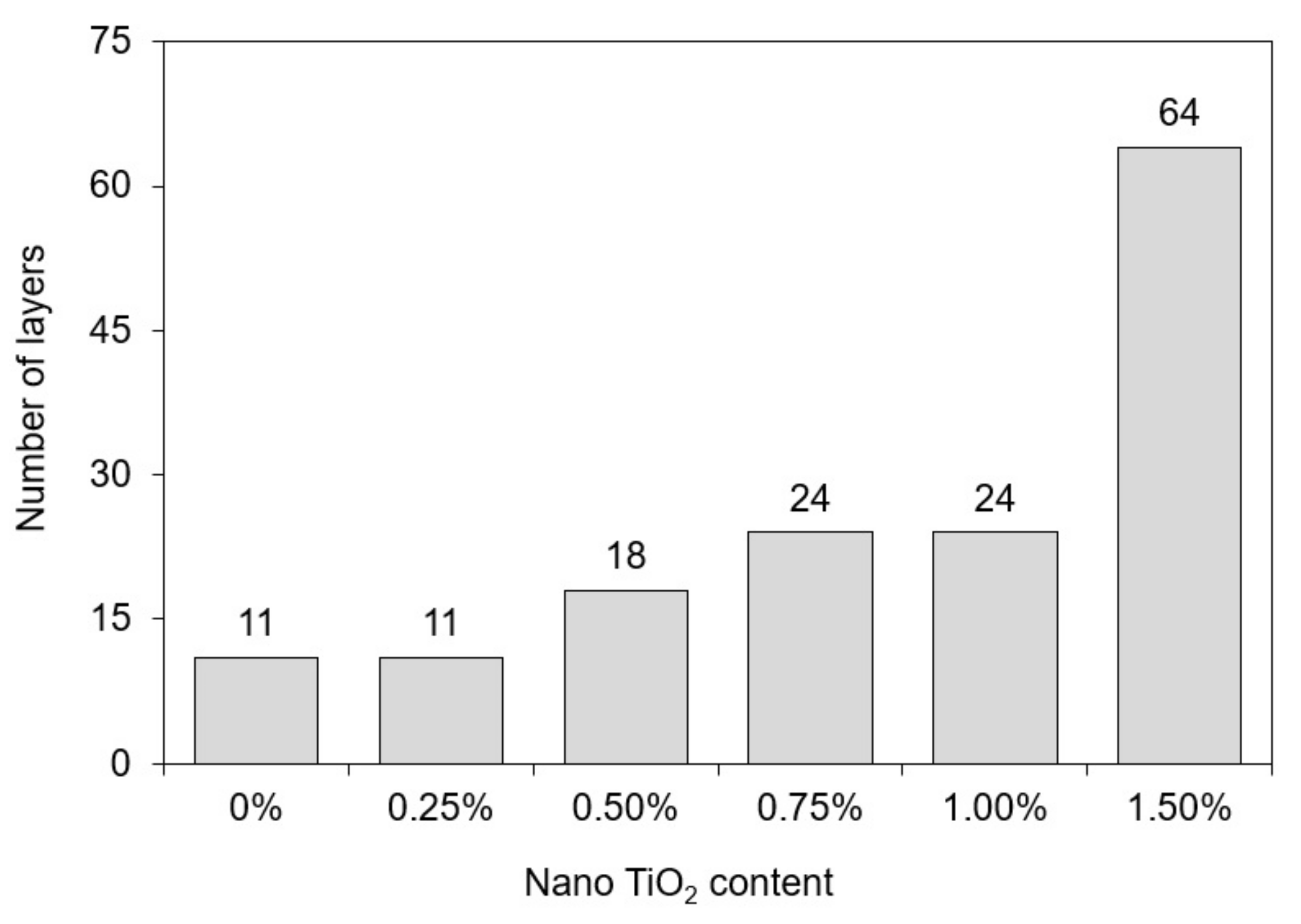

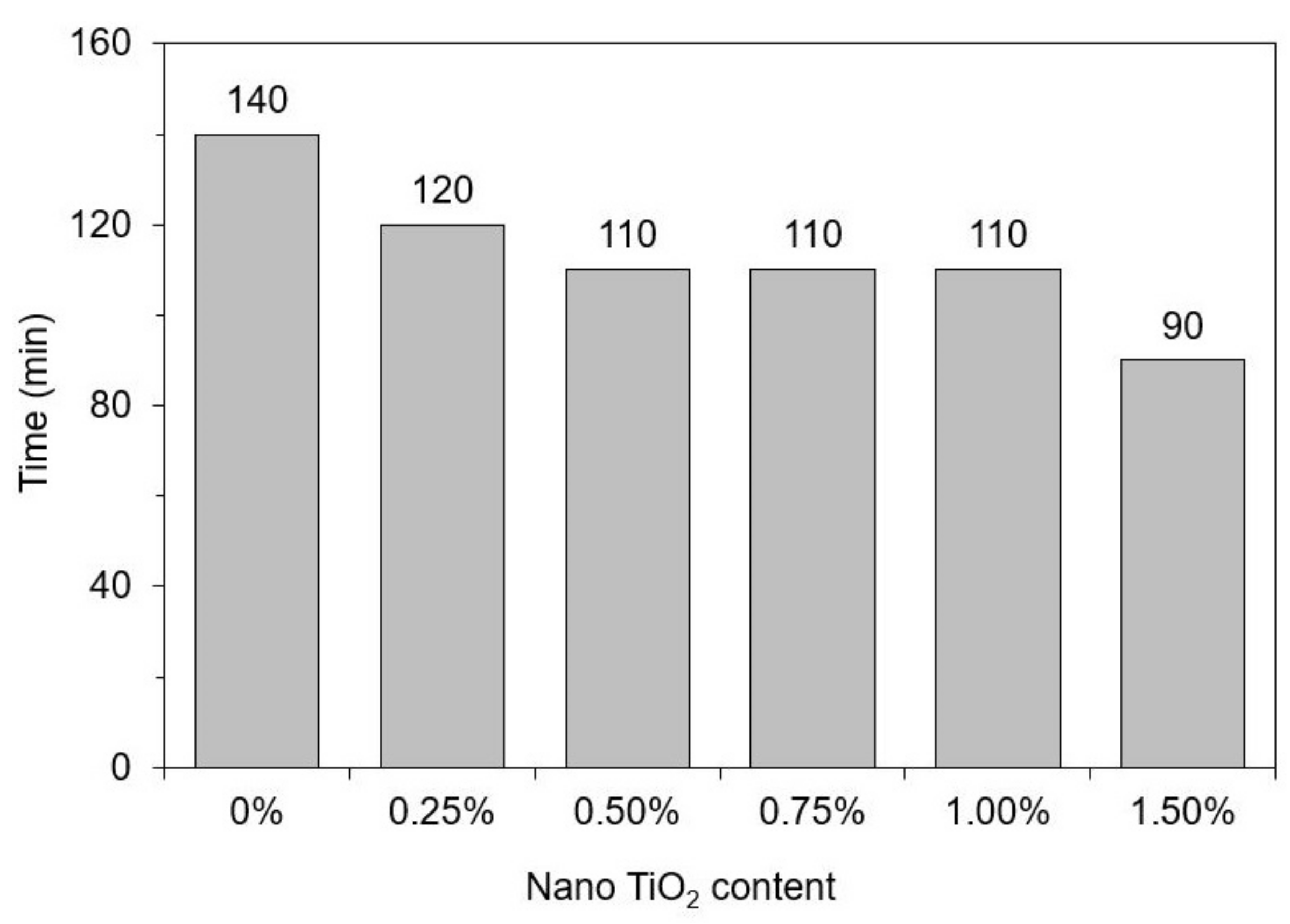

2.3.1. 3D Printing—Printability and Buildability

2.3.2. Fresh-State Tests

- (i)

- a constant shear rate of 0.01 s−1 was kept for 60 s to determine the static yield stress;

- (ii)

- the sample was sheared for 60 s at 100 s−1;

- (iii)

- the shear rate was decreased from 100 to 0 s−1 during 90 s to determine the flow curve.

2.3.3. Cement Hydration

3. Results and Discussion

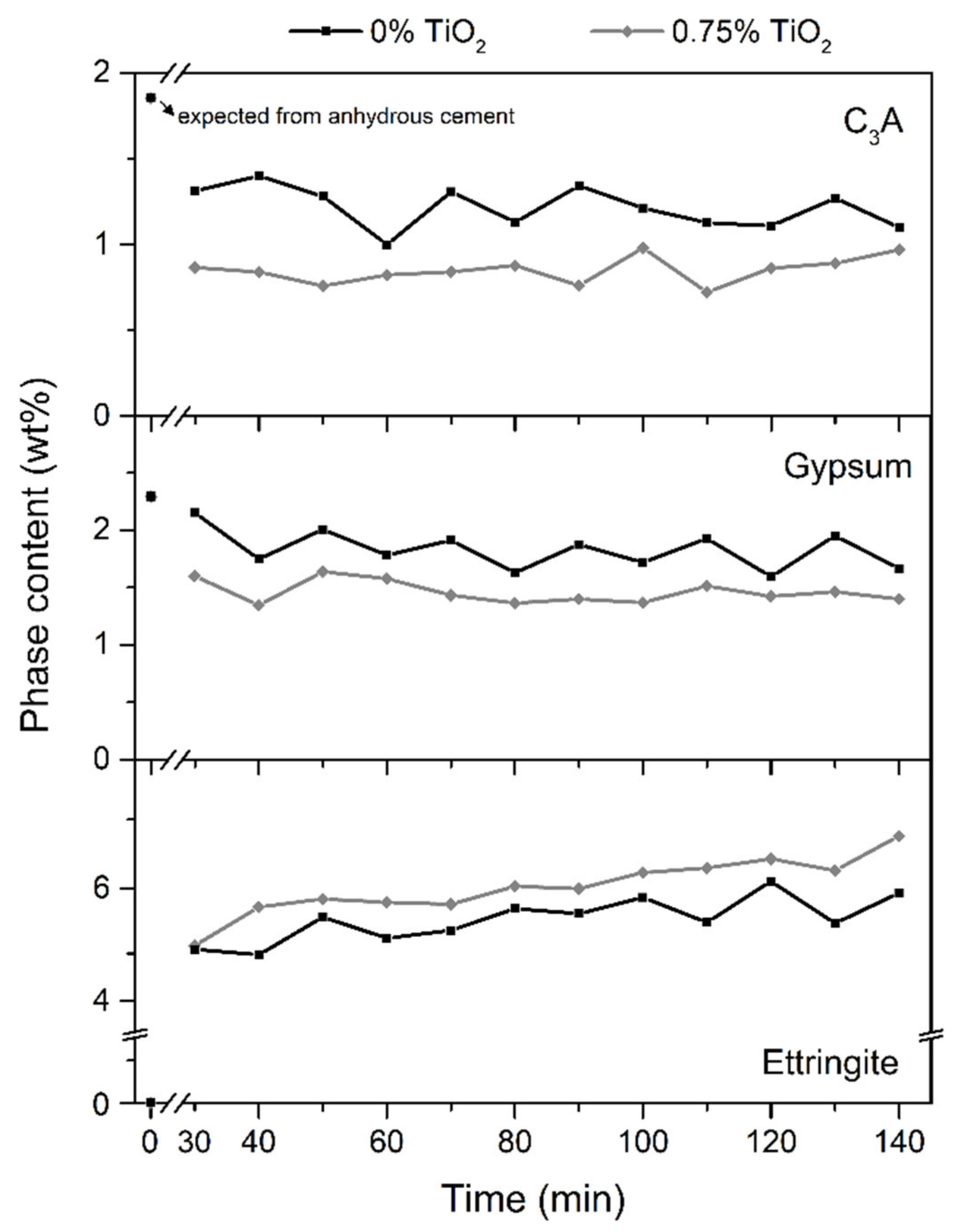

3.1. Cement Hydration

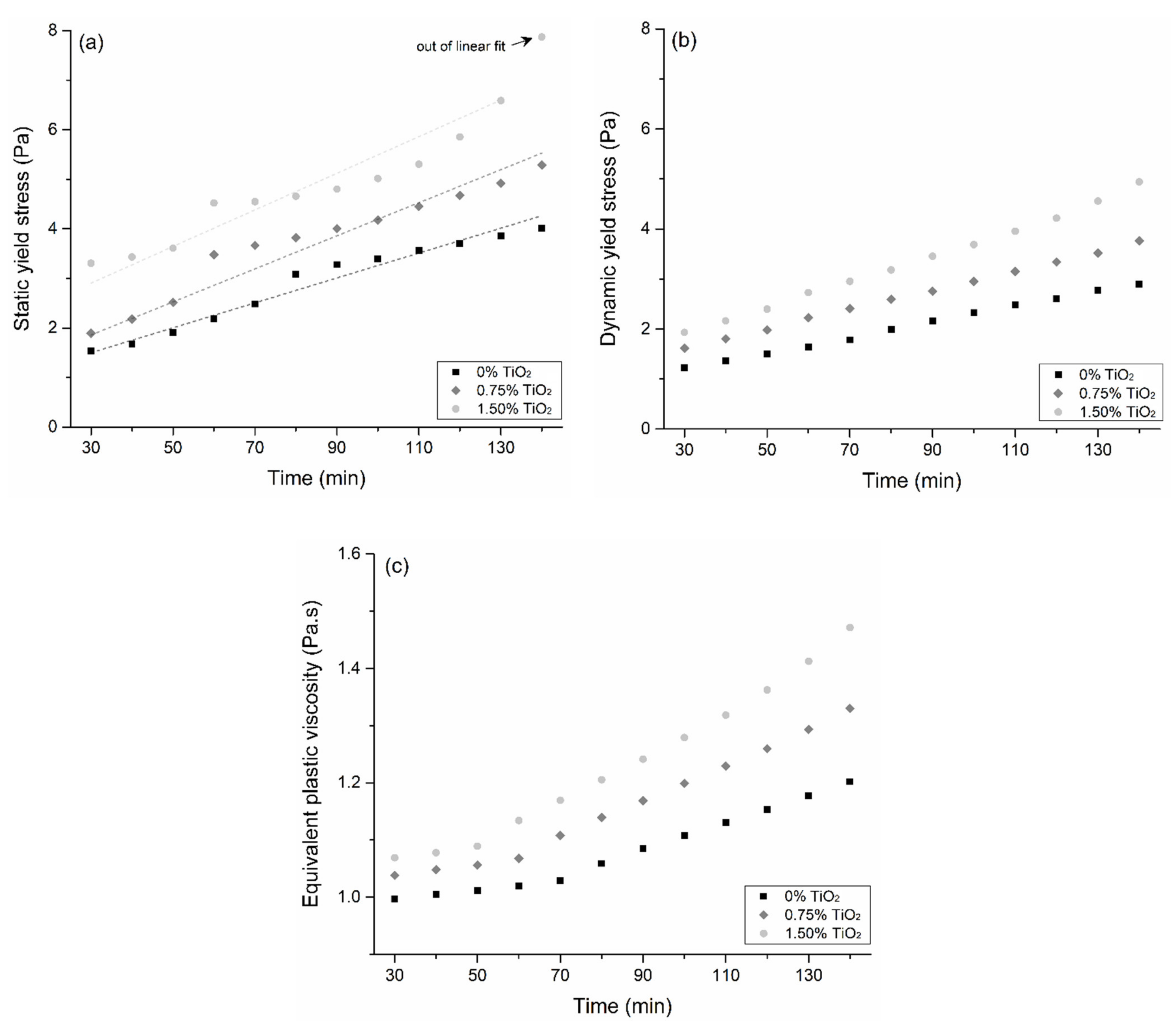

3.2. Rheological Characterization

3.3. 3D Printing Tests

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Phase | ICSD Code | Content (wt.%) |

|---|---|---|

| C3S-M3 | 94742 | 33.62 |

| C3S-M1 | * | 13.13 |

| C2S-α’H | 81097 | 0.22 |

| β-C2S | 81096 | 8.34 |

| C3A-cubic | 1841 | 2.50 |

| C3A-orthorhombic | 1880 | 0.34 |

| C4AF | 9197 | 6.45 |

| Aphthitalite | 26014 | 0.45 |

| Langbeinite | 40989 | 0.31 |

| Syngenite | 157072 | 1.79 |

| Periclase | 9863 | 0.84 |

| Portlandite | 15471 | 1.46 |

| Lime | 75786 | 0.77 |

| Gypsum | 151692 | 3.09 |

| Bassanite | 69060 | 0.33 |

| Calcite | 73446 | 4.93 |

| Dolomite | 10404 | 0.56 |

| Quartz | 174 | 0.28 |

| Ettringite | 155395 | - |

| ACn ** | - | 20.60 |

| Rwp (%) | - | 5.14 |

References

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D printing of ceramics: A review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Souza, M.T.; Ferreira, I.M.; Guzi de Moraes, E.; Senff, L.; Novaes de Oliveira, A.P. 3D printed concrete for large-scale buildings: An overview of rheology, printing parameters, chemical admixtures, reinforcements, and economic and environmental prospects. J. Build. Eng. 2020, 32, 101833. [Google Scholar] [CrossRef]

- De Schutter, G.; Lesage, K.; Mechtcherine, V.; Nerella, V.N.; Habert, G.; Agusti-Juan, I. Vision of 3D printing with concrete—Technical, economic and environmental potentials. Cem. Concr. Res. 2018, 112, 25–36. [Google Scholar] [CrossRef]

- Souza, M.T.; Simão, L.; Guzi de Moraes, E.; Senff, L.; de Castro Pessôa, J.R.; Ribeiro, M.J.; Novaes de Oliveira, A.P. Role of temperature in 3D printed geopolymers: Evaluating rheology and buildability. Mater. Lett. 2021, 293, 129680. [Google Scholar] [CrossRef]

- Weng, Y.; Ruan, S.; Li, M.; Mo, L.; Unluer, C.; Tan, M.J.; Qian, S. Feasibility study on sustainable magnesium potassium phosphate cement paste for 3D printing. Constr. Build. Mater. 2019, 221, 595–603. [Google Scholar] [CrossRef]

- Volpe, S.; Petrella, A.; Sangiorgio, V.; Notarnicola, M.; Fiorito, F. Preparation and characterization of novel environmentally sustainable mortars based on magnesium potassium phosphate cement for additive manufacturing. AIMS Mater. Sci. 2021, 8, 640–658. [Google Scholar] [CrossRef]

- Jiao, D.; Shi, C.; Yuan, Q.; An, X.; Liu, Y.; Li, H. Effect of constituents on rheological properties of fresh concrete-A review. Cem. Concr. Compos. 2017, 83, 146–159. [Google Scholar] [CrossRef]

- Zhang, C.; Nerella, V.N.; Krishna, A.; Wang, S.; Zhang, Y.; Mechtcherine, V.; Banthia, N. Mix design concepts for 3D printable concrete: A review. Cem. Concr. Compos. 2021, 122, 104155. [Google Scholar] [CrossRef]

- Wangler, T.; Flatt, R.J.; Roussel, N.; Perrot, A.; Sonebi, M.; Wolfs, R.; Bos, F.; Lowke, D.; Freund, N.; Stephan, D.; et al. Digital Fabrication with Cement-Based Materials; Roussel, N., Lowke, D., Eds.; Springer International Publishing: Cham, Switzerland, 2022. [Google Scholar]

- Bica, B.O.; de Melo, J.V.S. Concrete blocks nano-modified with zinc oxide (ZnO) for photocatalytic paving: Performance comparison with titanium dioxide (TiO2). Constr. Build. Mater. 2020, 252, 119120. [Google Scholar] [CrossRef]

- Staub de Melo, J.V.; Trichês, G. Study of the influence of nano-TiO2 on the properties of Portland cement concrete for application on road surfaces. Road Mater. Pavement Des. 2018, 19, 1011–1026. [Google Scholar] [CrossRef]

- Casagrande, C.A.; Repette, W.L.; Hotza, D. Effect of environmental conditions on degradation of NOx gases by photocatalytic nanotitania-based cement mortars after long-term hydration. J. Clean. Prod. 2020, 274, 123067. [Google Scholar] [CrossRef]

- Reches, Y. Nanoparticles as concrete additives: Review and perspectives. Constr. Build. Mater. 2018, 175, 483–495. [Google Scholar] [CrossRef]

- Silvestro, L.; Gleize, P.J.P. Effect of carbon nanotubes on compressive, flexural and tensile strengths of Portland cement-based materials: A systematic literature review. Constr. Build. Mater. 2020, 264, 120237. [Google Scholar] [CrossRef]

- Marchon, D.; Kawashima, S.; Bessaies-Bey, H.; Mantellato, S.; Ng, S. Hydration and rheology control of concrete for digital fabrication: Potential admixtures and cement chemistry. Cem. Concr. Res. 2018, 112, 96–110. [Google Scholar] [CrossRef]

- Mendoza Reales, O.A.; Duda, P.; Silva, E.C.C.M.; Paiva, M.D.M.; Filho, R.D.T. Nanosilica particles as structural buildup agents for 3D printing with Portland cement pastes. Constr. Build. Mater. 2019, 219, 91–100. [Google Scholar] [CrossRef]

- Douba, A.E.; Ma, S.; Kawashima, S. Rheology of fresh cement pastes modified with nanoclay-coated cements. Cem. Concr. Compos. 2022, 125, 104301. [Google Scholar] [CrossRef]

- Kruger, J.; Zeranka, S.; van Zijl, G. An ab initio approach for thixotropy characterisation of (nanoparticle-infused) 3D printable concrete. Constr. Build. Mater. 2019, 224, 372–386. [Google Scholar] [CrossRef]

- Sanjayan, J.G.; Jayathilakage, R.; Rajeev, P. Vibration induced active rheology control for 3D concrete printing. Cem. Concr. Res. 2021, 140, 106293. [Google Scholar] [CrossRef]

- Senff, L.; Labrincha, J.A.; Ferreira, V.M.; Hotza, D.; Repette, W.L. Effect of nano-silica on rheology and fresh properties of cement pastes and mortars. Constr. Build. Mater. 2009, 23, 2487–2491. [Google Scholar] [CrossRef]

- Senff, L.; Hotza, D.; Repette, W.L.; Ferreira, V.M.; Labrincha, J.A. Rheological characterisation of cement pastes with nanosilica, silica fume and superplasticiser additions. Adv. Appl. Ceram. 2010, 109, 213–218. [Google Scholar] [CrossRef]

- Rodríguez, E.D.; Bernal, S.A.; Provis, J.L.; Payá, J.; Monzó, J.M.; Borrachero, M.V. Structure of Portland Cement Pastes Blended with Sonicated Silica Fume. J. Mater. Civ. Eng. 2012, 24, 1295–1304. [Google Scholar] [CrossRef]

- Yang, H.; Che, Y.; Shi, M. Influences of calcium carbonate nanoparticles on the workability and strength of 3D printing cementitious materials containing limestone powder. J. Build. Eng. 2021, 44, 102976. [Google Scholar] [CrossRef]

- Sikora, P.; Chung, S.Y.; Liard, M.; Lootens, D.; Dorn, T.; Kamm, P.H.; Stephan, D.; Abd Elrahman, M. The effects of nanosilica on the fresh and hardened properties of 3D printable mortars. Constr. Build. Mater. 2021, 281, 122574. [Google Scholar] [CrossRef]

- Senff, L.; Hotza, D.; Lucas, S.; Ferreira, V.M.; Labrincha, J.A. Effect of nano-SiO2 and nano-TiO2 addition on the rheological behavior and the hardened properties of cement mortars. Mater. Sci. Eng. A 2012, 532, 354–361. [Google Scholar] [CrossRef]

- Senff, L.; Tobaldi, D.M.; Lemes-Rachadel, P.; Labrincha, J.A.; Hotza, D. The influence of TiO2 and ZnO powder mixtures on photocatalytic activity and rheological behavior of cement pastes. Constr. Build. Mater. 2014, 65, 191–200. [Google Scholar] [CrossRef]

- Joshaghani, A.; Balapour, M.; Mashhadian, M.; Ozbakkaloglu, T. Effects of nano-TiO2, nano-Al2O3, and nano-Fe2O3 on rheology, mechanical and durability properties of self-consolidating concrete (SCC): An experimental study. Constr. Build. Mater. 2020, 245, 118444. [Google Scholar] [CrossRef]

- Jalal, M.; Fathi, M.; Farzad, M. Effects of fly ash and TiO2 nanoparticles on rheological, mechanical, microstructural and thermal properties of high strength self compacting concrete. Mech. Mater. 2013, 61, 11–27. [Google Scholar] [CrossRef]

- De Matos, P.R.; Andrade Neto, J.; Sakata, R.; Kirchheim, A.P.; Rodríguez, E.D.; Campos, C. Strategies for XRD quantitative phase analysis of blended Portland cements. Cem. Concr. Res. 2022, 131, 104571. [Google Scholar] [CrossRef]

- Ma, G.; Li, Z.; Wang, L. Printable properties of cementitious material containing copper tailings for extrusion based 3D printing. Constr. Build. Mater. 2018, 162, 613–627. [Google Scholar] [CrossRef]

- Lothenbach, B.; Le Saout, G.; Ben Haha, M.; Figi, R.; Wieland, E. Hydration of a low-alkali CEM III/B-SiO2 cement (LAC). Cem. Concr. Res. 2012, 42, 410–423. [Google Scholar] [CrossRef]

- Rahul, A.V.; Santhanam, M. Evaluating the printability of concretes containing lightweight coarse aggregates. Cem. Concr. Compos. 2020, 109, 103570. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.; Liu, G.; Yang, Y.; Wu, M.; Pang, B. Fresh properties of a novel 3D printing concrete ink. Constr. Build. Mater. 2018, 174, 263–271. [Google Scholar] [CrossRef]

- Rahul, A.V.; Santhanam, M.; Meena, H.; Ghani, Z. 3D printable concrete: Mixture design and test methods. Cem. Concr. Compos. 2019, 97, 13–23. [Google Scholar] [CrossRef]

- Yousefi, A.; Allahverdi, A.; Hejazi, P. Effective dispersion of nano-TiO2 powder for enhancement of photocatalytic properties in cement mixes. Constr. Build. Mater. 2013, 41, 224–230. [Google Scholar] [CrossRef]

- Reches, Y.; Thomson, K.; Helbing, M.; Kosson, D.S.; Sanchez, F. Agglomeration and reactivity of nanoparticles of SiO2, TiO2, Al2O3, Fe2O3, and clays in cement pastes and effects on compressive strength at ambient and elevated temperatures. Constr. Build. Mater. 2018, 167, 860–873. [Google Scholar] [CrossRef]

- Sun, J.; Xu, K.; Shi, C.; Ma, J.; Li, W.; Shen, X. Influence of core/shell TiO2@SiO2 nanoparticles on cement hydration. Constr. Build. Mater. 2017, 156, 114–122. [Google Scholar] [CrossRef]

- Meng, T.; Yu, Y.; Qian, X.; Zhan, S.; Qian, K. Effect of nano-TiO2 on the mechanical properties of cement mortar. Constr. Build. Mater. 2012, 29, 241–245. [Google Scholar] [CrossRef]

- Senff, L.; Modolo, R.C.E.; Tobaldi, D.M.; Ascenção, G.; Hotza, D.; Ferreira, V.M.; Labrincha, J.A. The influence of TiO2 nanoparticles and poliacrilonitrile fibers on the rheological behavior and hardened properties of mortars. Constr. Build. Mater. 2015, 75, 315–330. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Bos, F.P.; Perrot, A.; da Silva, W.R.L.; Nerella, V.N.; Fataei, S.; Wolfs, R.J.M.; Sonebi, M.; Roussel, N. Extrusion-based additive manufacturing with cement-based materials—Production steps, processes, and their underlying physics: A review. Cem. Concr. Res. 2020, 132, 106037. [Google Scholar] [CrossRef]

- Roussel, N. Rheological requirements for printable concretes. Cem. Concr. Res. 2018, 112, 76–85. [Google Scholar] [CrossRef]

- Suiker, A.S.J.; Wolfs, R.J.M.; Lucas, S.M.; Salet, T.A.M. Elastic buckling and plastic collapse during 3D concrete printing. Cem. Concr. Res. 2020, 135, 106016. [Google Scholar] [CrossRef]

- Carneau, P.; Mesnil, R.; Baverel, O.; Roussel, N. Layer pressing in concrete extrusion-based 3D-printing: Experiments and analysis. Cem. Concr. Res. 2022, 155, 106741. [Google Scholar] [CrossRef]

- De Matos, P.R.; Pilar, R.; Casagrande, C.A.; Gleize, P.J.P.; Pelisser, F. Comparison between methods for determining the yield stress of cement pastes. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 24. [Google Scholar] [CrossRef]

- Roussel, N.; Cussigh, F. Distinct-layer casting of SCC: The mechanical consequences of thixotropy. Cem. Concr. Res. 2008, 38, 624–632. [Google Scholar] [CrossRef]

- Jansen, D.; Goetz-Neunhoeffer, F.; Stabler, C.; Neubauer, J. A remastered external standard method applied to the quantification of early OPC hydration. Cem. Concr. Res. 2011, 41, 602–608. [Google Scholar] [CrossRef]

- Jansen, D.; Stabler, C.; Goetz-Neunhoeffer, F.; Dittrich, S.; Neubauer, J. Does Ordinary Portland Cement contain amorphous phase? A quantitative study using an external standard method. Powder Diffr. 2011, 26, 31–38. [Google Scholar] [CrossRef] [Green Version]

- Naber, C.; Stegmeyer, S.; Jansen, D.; Goetz-Neunhoeffer, F.; Neubauer, J. The PONKCS method applied for time resolved XRD quantification of supplementary cementitious material reactivity in hydrating mixtures with ordinary Portland cement. Constr. Build. Mater. 2019, 214, 449–457. [Google Scholar] [CrossRef]

- Andrade Neto, J.S.; de Matos, P.R.; De la Torre, A.G.; Campos, C.E.M.; Gleize, P.J.P.; Monteiro, P.J.M.; Kirchheim, A.P. The role of sodium and sulfate sources on the rheology and hydration of C3A polymorphs. Cem. Concr. Res. 2022, 151, 106639. [Google Scholar] [CrossRef]

- De Matos, P.R.; Sakata, R.D.; Onghero, L.; Uliano, V.G.; de Brito, J.; Campos, C.E.M.; Gleize, P.J.P. Utilization of ceramic tile demolition waste as supplementary cementitious material: An early-age investigation. J. Build. Eng. 2021, 38, 102187. [Google Scholar] [CrossRef]

- Jansen, D.; Neubauer, J.; Goetz-Neunhoeffer, F.; Haerzschel, R.; Hergeth, W.D. Change in reaction kinetics of a Portland cement caused by a superplasticizer-Calculation of heat flow curves from XRD data. Cem. Concr. Res. 2012, 42, 327–332. [Google Scholar] [CrossRef]

- Berodier, E.; Scrivener, K. Understanding the filler effect on the nucleation and growth of C-S-H. J. Am. Ceram. Soc. 2014, 97, 3764–3773. [Google Scholar] [CrossRef]

- Hargis, C.W.; Kirchheim, A.P.; Monteiro, P.J.M.; Gartner, E.M. Early age hydration of calcium sulfoaluminate (synthetic ye’elimite, C 4A3) in the presence of gypsum and varying amounts of calcium hydroxide. Cem. Concr. Res. 2013, 48, 105–115. [Google Scholar] [CrossRef]

- Cyr, M.; Lawrence, P.; Ringot, E. Mineral admixtures in mortars: Quantification of the physical effects of inert materials on short-term hydration. Cem. Concr. Res. 2005, 35, 719–730. [Google Scholar] [CrossRef]

- Oey, T.; Kumar, A.; Bullard, J.W.; Neithalath, N.; Sant, G. The filler effect: The influence of filler content and surface area on cementitious reaction rates. J. Am. Ceram. Soc. 2013, 96, 1978–1990. [Google Scholar] [CrossRef]

- Bhojaraju, C.; Di Mare, M.; Ouellet-Plamondon, C.M. The impact of carbon-based nanomaterial additions on the hydration reactions and kinetics of GGBS-modified cements. Constr. Build. Mater. 2021, 303, 124366. [Google Scholar] [CrossRef]

- Wang, F.; Kong, X.; Jiang, L.; Wang, D. The acceleration mechanism of nano-C-S-H particles on OPC hydration. Constr. Build. Mater. 2020, 249, 118734. [Google Scholar] [CrossRef]

- Ivanova, I.; Ivaniuk, E.; Bisetti, S.; Nerella, V.N.; Mechtcherine, V. Comparison between methods for indirect assessment of buildability in fresh 3D printed mortar and concrete. Cem. Concr. Res. 2022, 156, 106764. [Google Scholar] [CrossRef]

- Reiter, L.; Wangler, T.; Roussel, N.; Flatt, R.J. Slow penetration for characterizing concrete for digital fabrication. Cem. Concr. Res. 2022, 157, 106802. [Google Scholar] [CrossRef]

- Roussel, N.; Ovarlez, G.; Garrault, S.; Brumaud, C. The origins of thixotropy of fresh cement pastes. Cem. Concr. Res. 2012, 42, 148–157. [Google Scholar] [CrossRef]

- Qian, Y. Effect of polycarboxylate ether (PCE) superplasticizer on thixotropic structural build-up of fresh cement pastes over time. Constr. Build. Mater. 2021, 291, 123241. [Google Scholar] [CrossRef]

- Bergold, S.T.; Goetz-Neunhoeffer, F.; Neubauer, J. Quantitative analysis of C-S-H in hydrating alite pastes by in-situ XRD. Cem. Concr. Res. 2013, 53, 119–126. [Google Scholar] [CrossRef]

- Bellmann, F.; Damidot, D.; Möser, B.; Skibsted, J. Improved evidence for the existence of an intermediate phase during hydration of tricalcium silicate. Cem. Concr. Res. 2010, 40, 875–884. [Google Scholar] [CrossRef]

- Huang, L.; Tang, L.; Gu, H.; Li, Z.; Yang, Z. New insights into the reaction of tricalcium silicate (C3S) with solutions to the end of the induction period. Cem. Concr. Res. 2022, 152, 106688. [Google Scholar] [CrossRef]

- Plank, J.; Schönlein, M.; Kanchanason, V. Study on the early crystallization of calcium silicate hydrate (C-S-H) in the presence of polycarboxylate superplasticizers. J. Organomet. Chem. 2018, 869, 227–232. [Google Scholar] [CrossRef]

- Jansen, D.; Naber, C.; Ectors, D.; Lu, Z.; Kong, X.M.; Goetz-Neunhoeffer, F.; Neubauer, J. The early hydration of OPC investigated by in-situ XRD, heat flow calorimetry, pore water analysis and 1H NMR: Learning about adsorbed ions from a complete mass balance approach. Cem. Concr. Res. 2018, 109, 230–242. [Google Scholar] [CrossRef]

- Bergold, S.T.; Jansen, D.; Dittrich, S.; Goetz-Neunhoeffer, F.; Neubauer, J. Development of C-S-H during the early hydration of alite with water at different temperatures: Direct quantification by in-situ XRD. GDCh-Monographie 2012, 45, 91–96. [Google Scholar]

- De Matos, P.R.; Prudêncio, L.R., Jr.; Pilar, R.; Gleize, P.J.P.; Pelisser, F. Use of recycled water from mixer truck wash in concrete: Effect on the hydration, fresh and hardened properties. Constr. Build. Mater. 2020, 230, 116981. [Google Scholar] [CrossRef]

- Huang, T.; Yuan, Q.; He, F.; Xie, Y. Understanding the mechanisms behind the time-dependent viscoelasticity of fresh C3A–gypsum paste. Cem. Concr. Res. 2020, 133, 106084. [Google Scholar] [CrossRef]

- Jakob, C.; Jansen, D.; Ukrainczyk, N.; Koenders, E.; Pott, U.; Stephan, D.; Neubauer, J. Relating ettringite formation and rheological changes during the initial cement hydration: A comparative study applying XRD analysis, rheological measurements and modeling. Materials 2019, 12, 2957. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.; Kou, S.C.; Poon, C.S. Hydration and properties of nano-TiO2 blended cement composites. Cem. Concr. Compos. 2012, 34, 642–649. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, T.; Wei, J.; Yu, Q.; Ouyang, S. Evaluating the distance between particles in fresh cement paste based on the yield stress and particle size. Constr. Build. Mater. 2017, 142, 109–116. [Google Scholar] [CrossRef]

- Wong, H.H.C.; Kwan, A.K.H. Rheology of cement paste: Role of excess water to solid surface area ratio. J. Mater. Civ. Eng. 2008, 20, 189–197. [Google Scholar] [CrossRef]

- Kwan, A.K.H.; McKinley, M. Effects of limestone fines on water film thickness, paste film thickness and performance of mortar. Powder Technol. 2014, 261, 33–41. [Google Scholar] [CrossRef]

- De Azevedo, N.H.; de Matos, P.R.; Gleize, P.J.P.; Betioli, A.M. Effect of thermal treatment of SiC nanowhiskers on rheological, hydration, mechanical and microstructure properties of Portland cement pastes. Cem. Concr. Compos. 2021, 117, 103903. [Google Scholar] [CrossRef]

- Silvestro, L.; Ruviaro, A.; Lima, G.; de Matos, P.; de Azevedo, A.R.G.; Monteiro, S.N.; Gleize, P. Influence of ultrasonication of functionalized carbon nanotubes on the rheology, hydration, and compressive strength of portland cement pastes. Materials 2021, 14, 5248. [Google Scholar] [CrossRef]

- Jiang, S.; Shan, B.; Ouyang, J.; Zhang, W.; Yu, X.; Li, P.; Han, B. Rheological properties of cementitious composites with nano/fiber fillers. Constr. Build. Mater. 2018, 158, 786–800. [Google Scholar] [CrossRef]

- Mendoza Reales, O.A.; Arias Jaramillo, Y.P.; Ochoa Botero, J.C.; Delgado, C.A.; Quintero, J.H.; Toledo Filho, R.D. Influence of MWCNT/surfactant dispersions on the rheology of Portland cement pastes. Cem. Concr. Res. 2018, 107, 101–109. [Google Scholar] [CrossRef]

- Neto, J.D.S.A.; Santos, T.A.; de Andrade Pinto, S.; Dias, C.M.R.; Ribeiro, D.V. Effect of the combined use of carbon nanotubes (CNT) and metakaolin on the properties of cementitious matrices. Constr. Build. Mater. 2021, 271, 121903. [Google Scholar] [CrossRef]

- De Noirfontaine, M.N.; Courtial, M.; Dunstetter, F.; Gasecki, G.; Signes-Frehel, M. Tricalcium silicate Ca3SiO5 superstructure analysis: A route towards the structure of the M1 polymorph. Z. Krist. 2012, 227, 102–112. [Google Scholar] [CrossRef]

| Property | Portland Cement | Silica Fume | Nano-TiO2 |

|---|---|---|---|

| Chemical composition (wt.%) | |||

| SiO2 | 16.9 | 93.9 | <0.1 |

| Al2O3 | 3.6 | 0.4 | 0.4 |

| Fe2O3 | 2.6 | 0.4 | <0.1 |

| CaO | 68.4 | 0.3 | <0.1 |

| K2O | 1.1 | 0.8 | 0.2 |

| Na2O | 0.1 | 1.8 | 0.1 |

| MgO | 2.4 | 2.0 | 0.1 |

| SO3 | 4.4 | 0.1 | <0.1 |

| TiO2 | 0.3 | <0.1 | 98.5 |

| P2O5 | 0.2 | <0.1 | 0.4 |

| * L.O.I | 3.46 | - | 0.40 |

| Physical property | |||

| Density (g/cm3) | 3.08 | 2.22 | 4.23 |

| BET SSA ** (m2/g) | 2.6 | 19.3 | 70.2 |

| Mix/Material | Cement | Nano-TiO2 | Silica Fume | Quartz Powder | Water | Superplasticizer |

|---|---|---|---|---|---|---|

| 0% TiO2 | 0.9000 | 0.0000 | 0.10 | 1.00 | 0.30 | 0.018 |

| 0.25% TiO2 | 0.8975 | 0.0025 | ||||

| 0.50% TiO2 | 0.8950 | 0.0050 | ||||

| 0.75% TiO2 | 0.8925 | 0.0075 | ||||

| 1.00% TiO2 | 0.8900 | 0.0100 | ||||

| 1.50% TiO2 | 0.8850 | 0.0150 |

| Mix | (Pa) | Athix (Pa/min) | Coefficient of Determination (R2) |

|---|---|---|---|

| 0% TiO2 | 0.75 | 0.025 | 0.94 |

| 0.75% TiO2 | 0.86 | 0.033 | 0.93 |

| 1.50% TiO2 | 1.80 | 0.037 | 0.87 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Matos, P.; Zat, T.; Corazza, K.; Fensterseifer, E.; Sakata, R.; Mohamad, G.; Rodríguez, E. Effect of TiO2 Nanoparticles on the Fresh Performance of 3D-Printed Cementitious Materials. Materials 2022, 15, 3896. https://doi.org/10.3390/ma15113896

de Matos P, Zat T, Corazza K, Fensterseifer E, Sakata R, Mohamad G, Rodríguez E. Effect of TiO2 Nanoparticles on the Fresh Performance of 3D-Printed Cementitious Materials. Materials. 2022; 15(11):3896. https://doi.org/10.3390/ma15113896

Chicago/Turabian Stylede Matos, Paulo, Tuani Zat, Kiara Corazza, Emilia Fensterseifer, Rafael Sakata, Gihad Mohamad, and Erich Rodríguez. 2022. "Effect of TiO2 Nanoparticles on the Fresh Performance of 3D-Printed Cementitious Materials" Materials 15, no. 11: 3896. https://doi.org/10.3390/ma15113896

APA Stylede Matos, P., Zat, T., Corazza, K., Fensterseifer, E., Sakata, R., Mohamad, G., & Rodríguez, E. (2022). Effect of TiO2 Nanoparticles on the Fresh Performance of 3D-Printed Cementitious Materials. Materials, 15(11), 3896. https://doi.org/10.3390/ma15113896