Dual-Scale Porosity Alumina Structures Using Ceramic/Camphene Suspensions Containing Polymer Microspheres

Abstract

:1. Introduction

2. Materials and Methods

2.1. Starting Materials

2.2. Freeze Casting of Alumina Suspensions

2.3. Porous Structure and Microstructure Evaluations

2.4. Compressive Strength Tests

3. Results and Discussion

3.1. Effect of PMMA Addition on Pore Structure and Microstructure of Green Objects

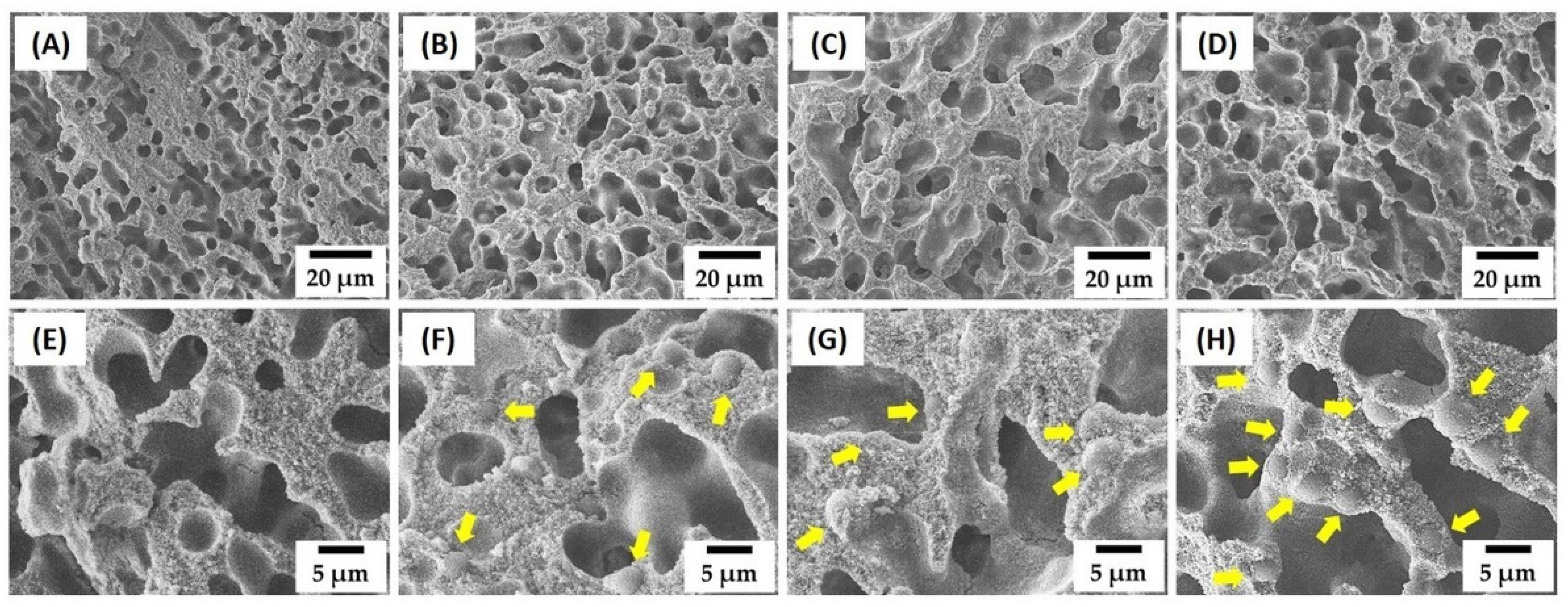

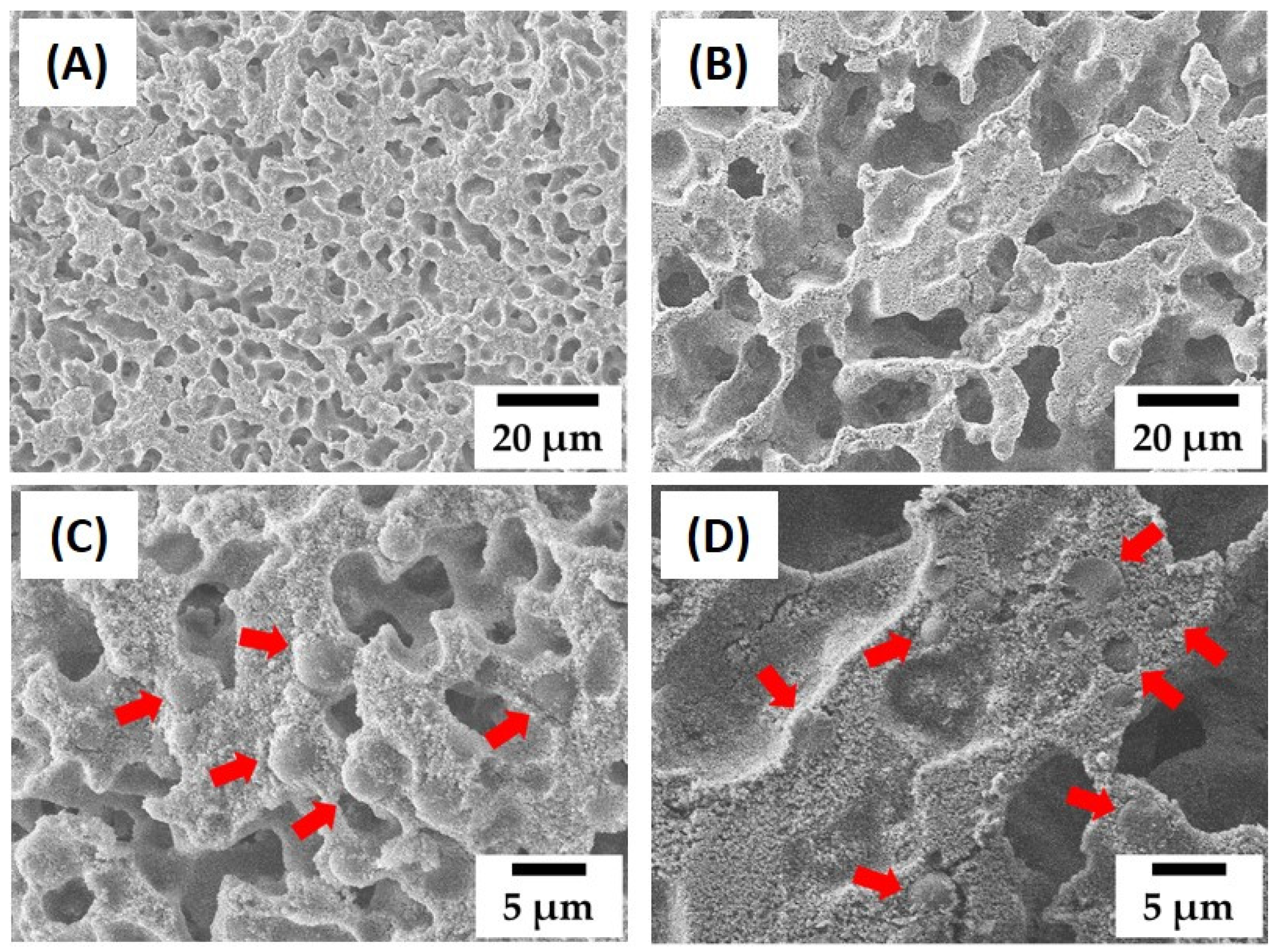

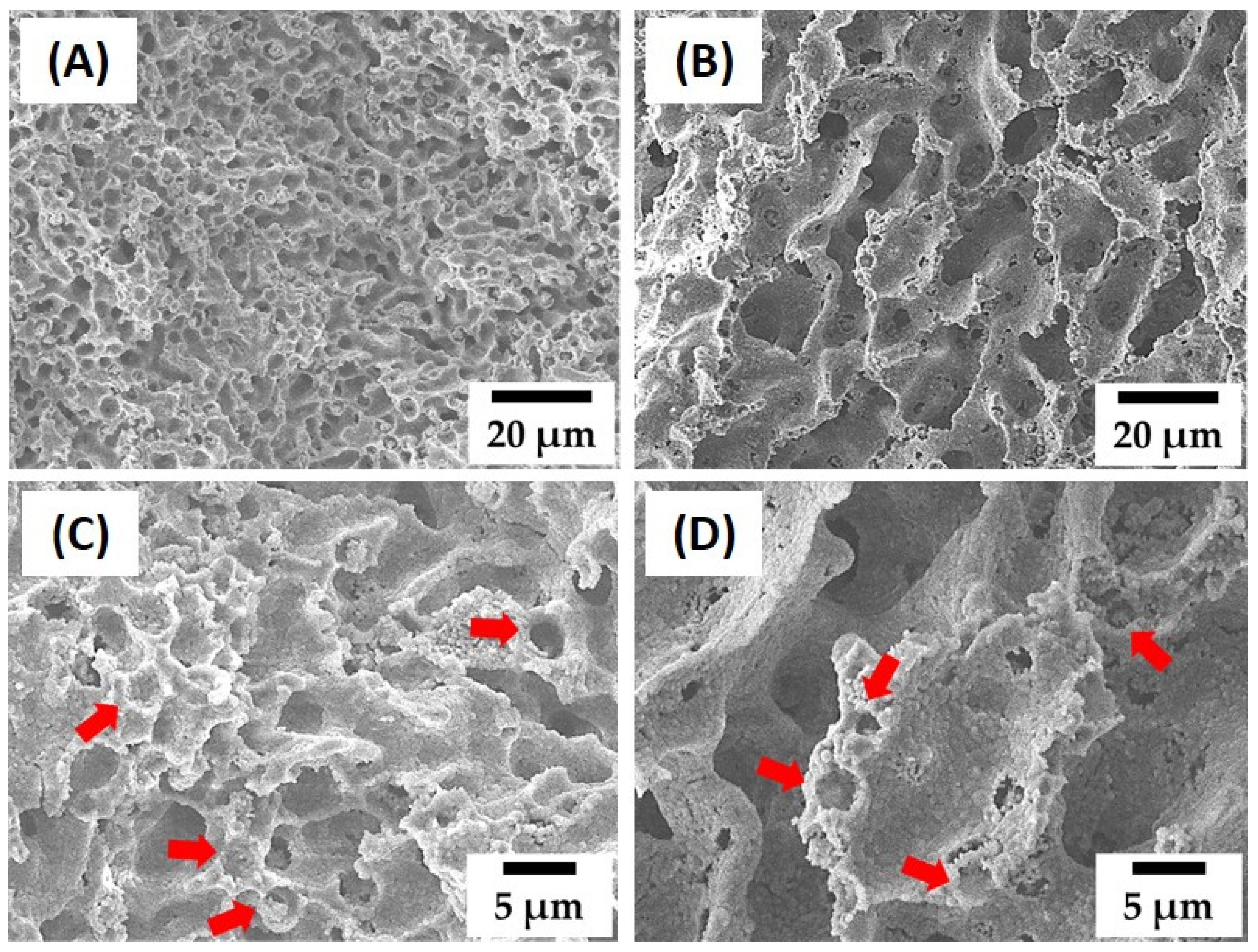

3.2. Dual-Scale Pore Structures of Sintered Objects

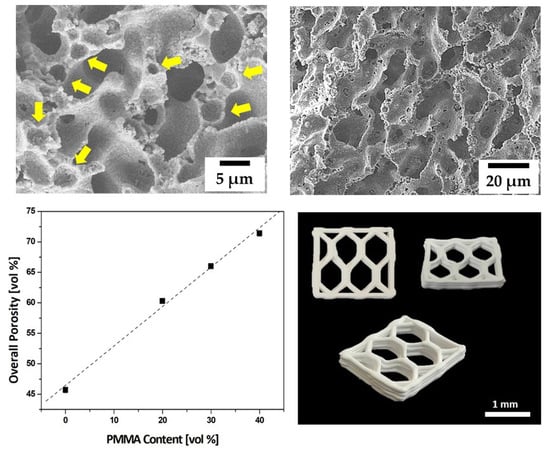

3.3. Total Porosities of Dual-Scale Porosity Structures

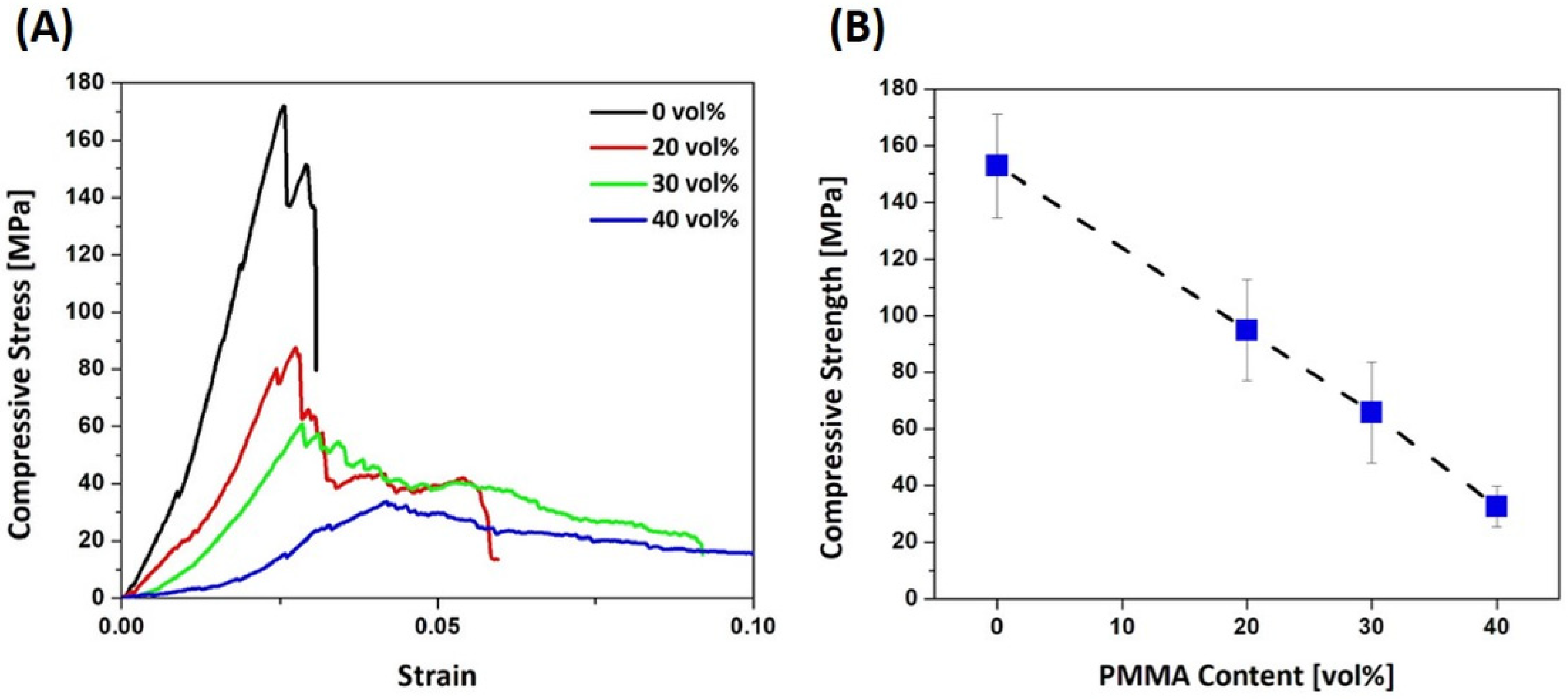

3.4. Compressive Strengths of Dual-Scale Porosity Structures

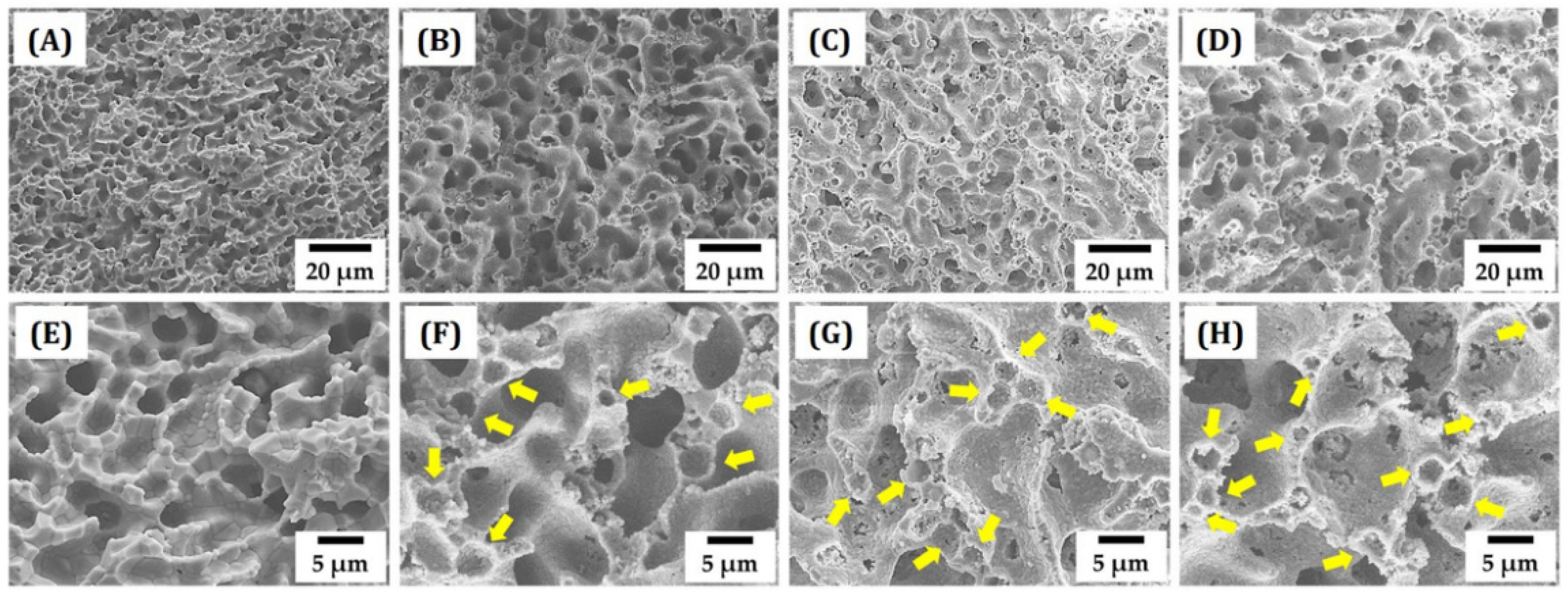

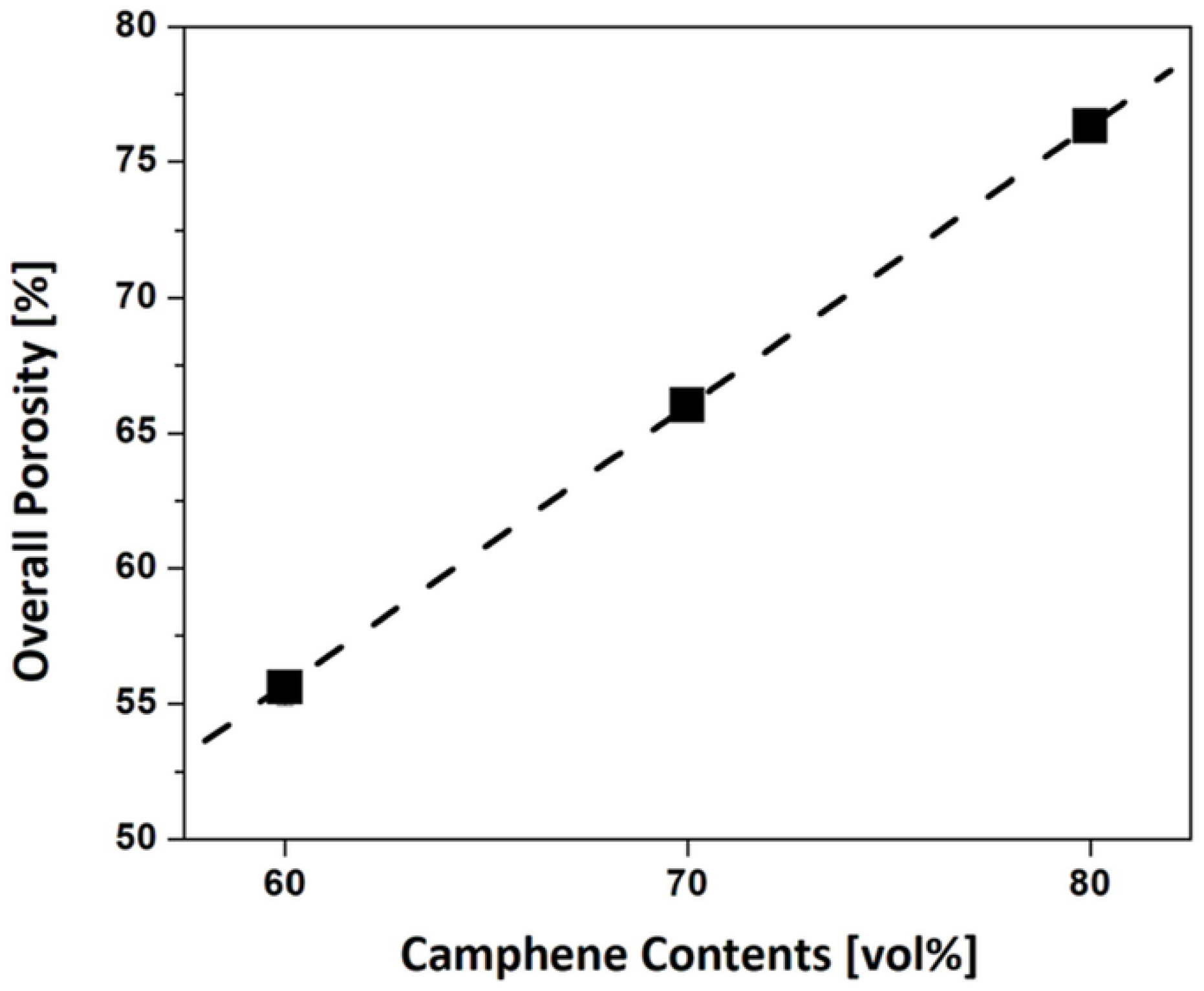

3.5. Control over Dual-Scale Pore Structures by Camphene Content

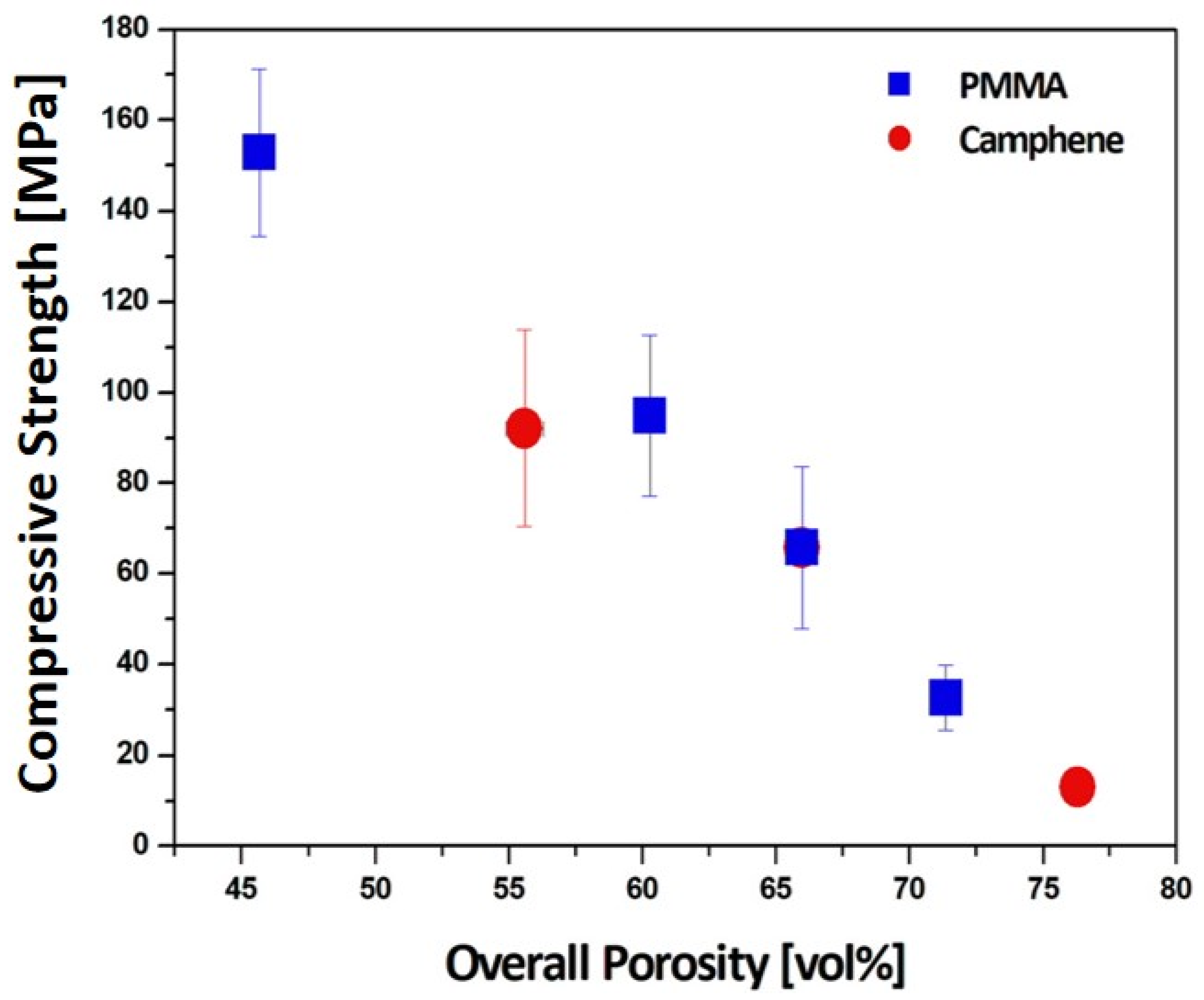

3.6. Overall Relationship between Total Porosity and Compressive Strength

3.7. Feasibility as Feedstock for 3D Printing of Multi-Scale Porosity Structures

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Islam, T.; Felfel, R.M.; Neel, E.A.A.; Grant, D.M.; Ahmed, I.; Hossain, K.M.Z. Bioactive calcium phosphate–based glasses and ceramics and their biomedical applications: A review. J. Tissue Eng. 2017, 8, 1–16. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hing, K.A. Bioceramic Bone Graft Substitutes: Influence of Porosity and Chemistry. Int. J. Appl. Ceram. Technol. 2005, 2, 184–199. [Google Scholar] [CrossRef]

- Jeong, J.; Kim, J.H.; Shim, J.H.; Hwang, N.S.; Heo, C.Y. Bioactive calcium phosphate materials and applications in bone regeneration. Biomater. Res. 2019, 23, 9. [Google Scholar] [CrossRef] [Green Version]

- Chafik, G.; Indranil, B.; Julien, G.; Mutlu, O.; Franz, E.W. 3D-printed HA-based scaffolds for bone regeneration: Microporosity, osteoconduction and osteoclastic resorption. Materials 2022, 15, 1433. [Google Scholar]

- Shafiquzzaman, M.; Al-Mahmud, A.; AlSaleem, S.S.; Haider, H. Application of a Low Cost Ceramic Filter for Recycling Sand Filter Backwash Water. Water 2018, 10, 150. [Google Scholar] [CrossRef] [Green Version]

- Shivaraju, H.P.; Egumbo, H.; Madhusudan, P.; Kumar, K.M.A.; Midhun, G. Preparation of affordable and multifunctional clay-based ceramic filter matrix for treatment of drinking water. Environ. Technol. 2018, 40, 1633–1643. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Ren, B.; Chen, Y.; Lu, Y.; Zhang, S.; Rong, Y.; Yang, J. Novel design of alumina foams with three-dimensional reticular architecture for effective high-temperature particulate matter capture. J. Am. Ceram. Soc. 2019, 102, 5576–5586. [Google Scholar] [CrossRef]

- Rajpoot, S.; Malik, R.; Kim, Y.-W. Effects of polysiloxane on thermal conductivity and compressive strength of porous silica ceramics. Ceram. Int. 2019, 45, 21270–21277. [Google Scholar] [CrossRef]

- Kultayeva, S.; Ha, J.-H.; Malik, R.; Kim, Y.-W.; Kim, K.J. Effects of porosity on electrical and thermal conductivities of porous SiC ceramics. J. Eur. Ceram. Soc. 2020, 40, 996–1004. [Google Scholar] [CrossRef]

- Lu, X.; Taiwo, O.O.; Bertei, A.; Li, T.; Li, K.; Brett, D.J.L.; Shearing, P.R. Multi-length scale tomography for the determination and optimization of the effective microstructural properties in novel hierarchical solid oxide fuel cell anodes. J. Power Sources 2017, 367, 177–186. [Google Scholar] [CrossRef]

- Du, Y.; Hedayat, N.; Panthi, D.; Ilkhani, H.; Emley, B.J.; Woodson, T. Freeze-casting for the fabrication of solid oxide fuel cells: A review. Materialia 2018, 1, 198–210. [Google Scholar] [CrossRef]

- Hu, X.; Li, X.; Yan, K.; Qi, X.; Chen, W.; Wu, D. Fabrication of porous PZT ceramics using micro-stereolithography technology. Ceram. Int. 2021, 47, 32376–32381. [Google Scholar] [CrossRef]

- Studart, A.R.; Gonzenbach, U.T.; Tervoort, E.; Gauckler, L.J. Processing Routes to Macroporous Ceramics: A Review. J. Am. Ceram. Soc. 2006, 89, 1771–1789. [Google Scholar] [CrossRef]

- Minas, C.; Carnelli, D.; Tervoort, E.; Studart, A.R. 3D Printing of Emulsions and Foams into Hierarchical Porous Ceramics. Adv. Mater. 2016, 28, 9993–9999. [Google Scholar] [CrossRef]

- Muth, J.T.; Dixon, P.G.; Woish, L.; Gibson, L.J.; Lewis, J.A. Architected cellular ceramics with tailored stiffness via direct foam writing. Proc. Natl. Acad. Sci. USA 2017, 114, 1832–1837. [Google Scholar] [CrossRef] [Green Version]

- Maurath, J.; Willenbacher, N. 3D printing of open-porous cellular ceramics with high specific strength. J. Eur. Ceram. Soc. 2017, 37, 4833–4842. [Google Scholar] [CrossRef]

- Alison, L.; Menasce, S.; Bouville, F.; Tervoort, E.; Mattich, I.; Ofner, A.; Studart, A.R. 3D printing of sacrificial templates into hierarchical porous materials. Sci. Rep. 2019, 9, 409. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.; Miao, Y.; Liang, H.; Diao, J.; Hao, L.; Shi, Z.; Zhao, N.; Wang, Y. 3D-printed bioactive ceramic scaffolds with biomimetic micro/nano-HAp surfaces mediated cell fate and promoted bone augmentation of the bone–implant interface in vivo. Bioact. Mater. 2022, 12, 120–132. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, H.; Xiong, Y.; Dong, L.; Li, X. Development of hierarchical porous bioceramic scaffolds with controlled micro/nano surface topography for accelerating bone regeneration. Mater. Sci. Eng. C 2021, 130, 112437. [Google Scholar] [CrossRef]

- Maurice, N.C.; Guang, R.; Kieran, Y.; Pina, S.; Rui, L.; Reis, J.; Oliveira, M. Scaffold fabrication technologies and structure/function properties in bone tissue engineering. Adv. Funct. Mater. 2021, 31, 2010609. [Google Scholar]

- Liu, R.; Xu, T.; Wang, C.-A. A review of fabrication strategies and applications of porous ceramics prepared by freeze-casting method. Ceram. Int. 2016, 42, 2907–2925. [Google Scholar] [CrossRef]

- Shao, G.; Hanaor, D.A.H.; Shen, X.; Gurlo, A. Freeze Casting: From Low-Dimensional Building Blocks to Aligned Porous Structures—A Review of Novel Materials, Methods, and Applications. Adv. Mater. 2020, 31, 1907176. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Algharaibeh, S.; Ireland, A.J.; Su, B. Bi-directional freeze casting of porous alumina ceramics: A study of the effects of different processing parameters on microstructure. J. Eur. Ceram. Soc. 2019, 39, 514–521. [Google Scholar] [CrossRef] [Green Version]

- Hou, Z.; Ye, F.; Liu, Q.; Liu, L.; Jiang, H.; Zhang, S. Pore architectures and mechanical properties of porous α-SiAlON ceramics fabricated via unidirectional freeze casting based on camphene-templating. Materials 2019, 12, 687. [Google Scholar] [CrossRef] [Green Version]

- Wang, N.; Liu, Y.; Zhang, Y.; Du, Y.; Zhang, J. Control of pore structure during freeze casting of porous SiC ceramics by different freezing modes. Ceram. Int. 2019, 45, 11558–11563. [Google Scholar] [CrossRef]

- Lloreda-Jurado, P.J.; Pérez-Soriano, E.M.; Paúl, A.; Herguido, J.; Peña, J.A.; Sepúlveda, R. Doped iron oxide scaffolds with gradient porosity fabricated by freeze casting: Pore morphology prediction and processing parameters. Mater. Sci. Technol. 2020, 36, 1227–1237. [Google Scholar] [CrossRef]

- Qi, Y.; Jiang, K.; Zhou, C.; Han, W.; Du, Z. Preparation and properties of high-porosity ZrB2-SiC ceramics by water-based freeze casting. J. Eur. Ceram. Soc. 2020, 41, 2239–2246. [Google Scholar] [CrossRef]

- Arai, N.; Faber, K.T. Hierarchical porous ceramics via two-stage freeze casting of preceramic polymers. Scr. Mater. 2019, 162, 72–76. [Google Scholar] [CrossRef]

- Mukkavilli, R.S.; Papakollu, K.; Kumar, R. Microstructural transitions in camphene-based freeze casted ceria: Effect of primary building blocks. Adv. Appl. Ceram. 2021, 120, 248–253. [Google Scholar] [CrossRef]

- Zhang, X.; Yuan, J.; Ding, Y.; Liu, B.; Zhang, S.; Yang, J. Directly growing nanowire-assembled nanofibrous ceramic foams with multi-lamellar structure via freeze-casting process. J. Eur. Ceram. Soc. 2021, 41, 1041–1047. [Google Scholar] [CrossRef]

- Zhang, X.-Y.; Ding, Y.-J.; Wu, J.-M.; Liu, B.; Zhang, B.-L.; Zhang, S.-G. SiC–Si3N4 composite with multi-laminate nanowires originated from oriented porous structure by freeze-casting. Ceram. Int. 2020, 46, 26238–26243. [Google Scholar] [CrossRef]

- Scotti, K.L.; Dunand, D.C. Freeze casting—A review of processing, microstructure and properties via the open data repository, FreezeCasting.net. Prog. Mater. Sci. 2018, 94, 243–305. [Google Scholar] [CrossRef] [Green Version]

- Yoon, B.-H.; Koh, Y.-H.; Park, C.-S.; Kim, H.-E. Generation of Large Pore Channels for Bone Tissue Engineering Using Camphene-Based Freeze Casting. J. Am. Ceram. Soc. 2007, 90, 1744–1752. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Zhu, W.; Guan, K.; Peng, C.; Wu, J. Freeze-casting of alumina ultra-filtration membranes with good performance for anionic dye separation. Ceram. Int. 2018, 44, 11901–11904. [Google Scholar] [CrossRef]

- Lee, J.-B.; Maeng, W.-Y.; Koh, Y.-H.; Kim, H.-E. Novel additive manufacturing of photocurable ceramic slurry containing freezing vehicle as porogen for hierarchical porous structure. Ceram. Int. 2019, 45, 21321–21327. [Google Scholar] [CrossRef]

- Maeng, W.-Y.; Jeon, J.-W.; Lee, J.-B.; Lee, H.; Koh, Y.-H.; Kim, H.-E. Photocurable ceramic/monomer feedstocks containing terpene crystals as sublimable porogen for UV curing-assisted 3D plotting. J. Eur. Ceram. Soc. 2020, 40, 3469–3477. [Google Scholar] [CrossRef]

- Jeon, J.W.; Maeng, W.Y.; Lee, H.; Koh, Y.H.; Kim, H.E. UV curing-assisted 3D plotting of core-shelled feedrod for macroporous hydroxyapatite scaffolds comprised of microporous hollow filaments. J. Eur. Ceram. Soc. 2021, 41, 6729–6737. [Google Scholar] [CrossRef]

- Hao, B.L.; Lang, Y.; Bian, D.Q.; Wang, C.A. Preparation of near net size porous alumina-calcium aluminate ceramics by gelcasting-pore-forming agent processs. J. Am. Ceram. Soc. 2020, 103, 4602–4610. [Google Scholar] [CrossRef]

- Zhang, M.; Li, X.; Zhang, M.; Xiu, Z.; Li, J.-G.; Li, J.; Xie, M.; Chen, J.; Sun, X. High-strength macro-porous alumina ceramics with regularly arranged pores produced by gel-casting and sacrificial template methods. J. Mater. Sci. 2019, 54, 10119–10129. [Google Scholar] [CrossRef]

- Hooshmand, S.; Nordin, J.; Akhtar, F. Porous alumina ceramics by gel casting: Effect of type of sacrificial template on the properties. Int. J. Ceram. Eng. Sci. 2019, 1, 77–84. [Google Scholar] [CrossRef] [Green Version]

- Parkhomchuk, E.; Fedotov, K.; Semeykina, V.; Lysikov, A. Polystyrene microsphere-template method for textural design of alumina—An effective catalyst support for macromolecule conversion. Catal. Today 2020, 353, 180–186. [Google Scholar] [CrossRef]

- Lee, Y.-H.; Lee, J.-W.; Yang, S.-Y.; Lee, H.; Koh, Y.-H.; Kim, H.-E. Dual-scale porous biphasic calcium phosphate gyroid scaffolds using ceramic suspensions containing polymer microsphere porogen for digital light processing. Ceram. Int. 2021, 47, 11285–11293. [Google Scholar] [CrossRef]

- Koh, Y.-H.; Lee, E.-J.; Yoon, B.-H.; Song, J.-H.; Kim, H.-E.; Kim, H.-W. Effect of Polystyrene Addition on Freeze Casting of Ceramic/Camphene Slurry for Ultra-High Porosity Ceramics with Aligned Pore Channels. J. Am. Ceram. Soc. 2006, 89, 3646–3653. [Google Scholar] [CrossRef]

- Moon, Y.-W.; Shin, K.-H.; Koh, Y.-H.; Jung, H.-D.; Kim, H.-E. Three-dimensional Ceramic/Camphene-based Coextrusion for Unidirectionally Macrochanneled Alumina Ceramics with Controlled Porous Walls. J. Am. Ceram. Soc. 2014, 97, 32–34. [Google Scholar] [CrossRef]

- Yoon, B.-H.; Choi, W.-Y.; Kim, H.-E.; Kim, J.-H.; Koh, Y.-H. Aligned porous alumina ceramics with high compressive strengths for bone tissue engineering. Scr. Mater. 2008, 58, 537–540. [Google Scholar] [CrossRef]

- Nelson, I.; Nalew, S.E. Intrinsic and extrinsic control of freeze casting. J. Mater. Res. Technol. 2019, 8, 2372–2385. [Google Scholar] [CrossRef]

- Seuba, J.; Deville, S.; Guizard, C.; Stevenson, A.J. Mechanical properties and failure behavior of unidirectional porous ceramics. Sci. Rep. 2016, 6, 24326. [Google Scholar] [CrossRef] [Green Version]

- Deville, S. Freeze-Casting of Porous Biomaterials: Structure, Properties and Opportunities. Materials 2010, 3, 1913–1927. [Google Scholar] [CrossRef]

- Choe, G.-B.; Kim, G.-N.; Lee, H.; Koh, Y.-H.; Kim, H.-E. Novel camphene/photopolymer solution as pore-forming agent for photocuring-assisted additive manufacturing of porous ceramics. J. Eur. Ceram. Soc. 2021, 41, 655–662. [Google Scholar] [CrossRef]

- Meille, S.; Lombardi, M.; Chevalier, J.; Montanaro, L. Mechanical properties of porous ceramics in compression: On the transition between elastic, brittle, and cellular behavior. J. Eur. Ceram. Soc. 2012, 32, 3959–3967. [Google Scholar] [CrossRef]

- Moon, Y.W.; Choi, I.J.; Koh, Y.H.; Kim, H.E. Macroporous alumina scaffolds consisting of highly microporous hollow filaments using three-dimensional ceramic/camphene-based co-extrusion. J. Eur. Ceram. Soc. 2015, 35, 4623–4627. [Google Scholar] [CrossRef]

| Component | Material (Supplier) |

|---|---|

| Ceramic Powder | Alumina (Kojundo Chemical Co., Ltd., Sakado, Japan) |

| Freezing Vehicle | Camphene (Sigma-Aldrich, St. Louis, MO, USA) |

| Porogen | Poly(methyl methacrylate) (PMMA) (Sunjin Beauty Science, Ansan-si, Korea) |

| Dispersant | Hypermer KD-4 (UniQema, Everburg, Belgium) |

| Camphene [vol%] | PMMA [vol%] | Alumina [vol%] | KD4 [vol%] | |

|---|---|---|---|---|

| PMMA Contents | 70.00 | 0.00 | 27.57 | 2.43 |

| 70.00 | 6.00 | 21.91 | 2.09 | |

| 70.00 | 9.00 | 19.08 | 1.92 | |

| 70.00 | 12.00 | 16.25 | 1.75 | |

| Camphene Contents | 60.00 | 12.00 | 25.44 | 2.56 |

| 80.00 | 6.00 | 12.72 | 1.28 |

| PMMA Content [vol%] | 0 | 20 | 30 | 40 |

|---|---|---|---|---|

| Sintering shrinkage [%] | 17.8 ± 0.4 | 16.2 ± 0.7 | 15.3 ± 0.7 | 15.6 ± 1.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, H.; Jeon, J.-W.; Koh, Y.-H.; Kim, H.-E. Dual-Scale Porosity Alumina Structures Using Ceramic/Camphene Suspensions Containing Polymer Microspheres. Materials 2022, 15, 3875. https://doi.org/10.3390/ma15113875

Lee H, Jeon J-W, Koh Y-H, Kim H-E. Dual-Scale Porosity Alumina Structures Using Ceramic/Camphene Suspensions Containing Polymer Microspheres. Materials. 2022; 15(11):3875. https://doi.org/10.3390/ma15113875

Chicago/Turabian StyleLee, Hyun, Jong-Won Jeon, Young-Hag Koh, and Hyoun-Ee Kim. 2022. "Dual-Scale Porosity Alumina Structures Using Ceramic/Camphene Suspensions Containing Polymer Microspheres" Materials 15, no. 11: 3875. https://doi.org/10.3390/ma15113875

APA StyleLee, H., Jeon, J.-W., Koh, Y.-H., & Kim, H.-E. (2022). Dual-Scale Porosity Alumina Structures Using Ceramic/Camphene Suspensions Containing Polymer Microspheres. Materials, 15(11), 3875. https://doi.org/10.3390/ma15113875