Contact-Free Support Structures for the Direct Metal Laser Melting Process

Abstract

:1. Introduction

2. Materials and Methods

3. Results

4. Conclusions

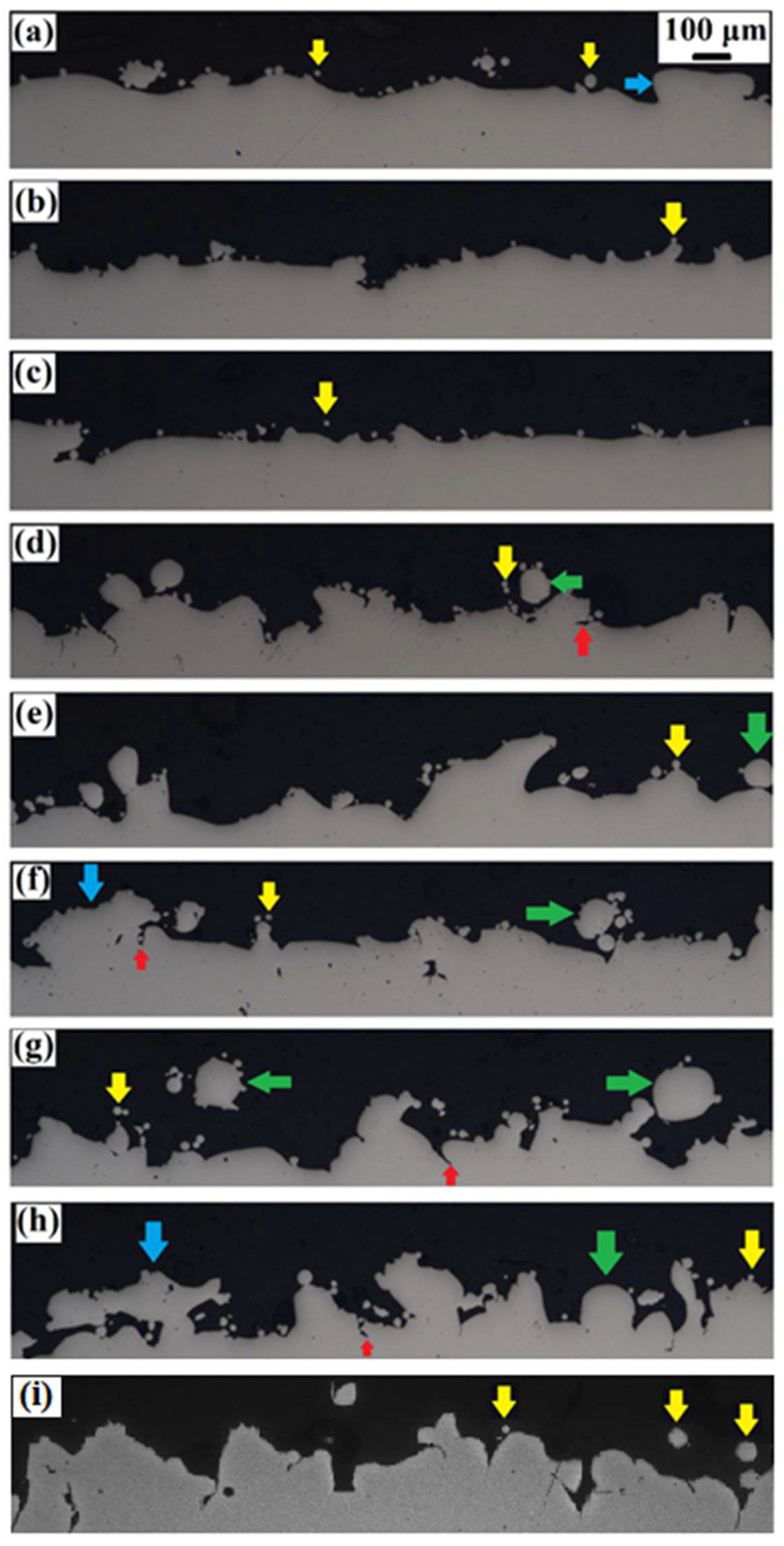

- The gap distance for contact-free support structures is a very critical factor and needs to be optimized. The fusion of the contact-free supports and overhang surfaces mainly occurs at lower gap distances, namely 100, 125, and 150 µm which are 2, 2.5, and 3 folds of the selected layer thickness. The fusion is mainly due to the melt pool depth exceeding 2–3 layer thicknesses. At the lowest oblique angle of 15°, all the produced specimens exhibited either fusion with the contact-free support or a very poor surface quality impossible to measure.

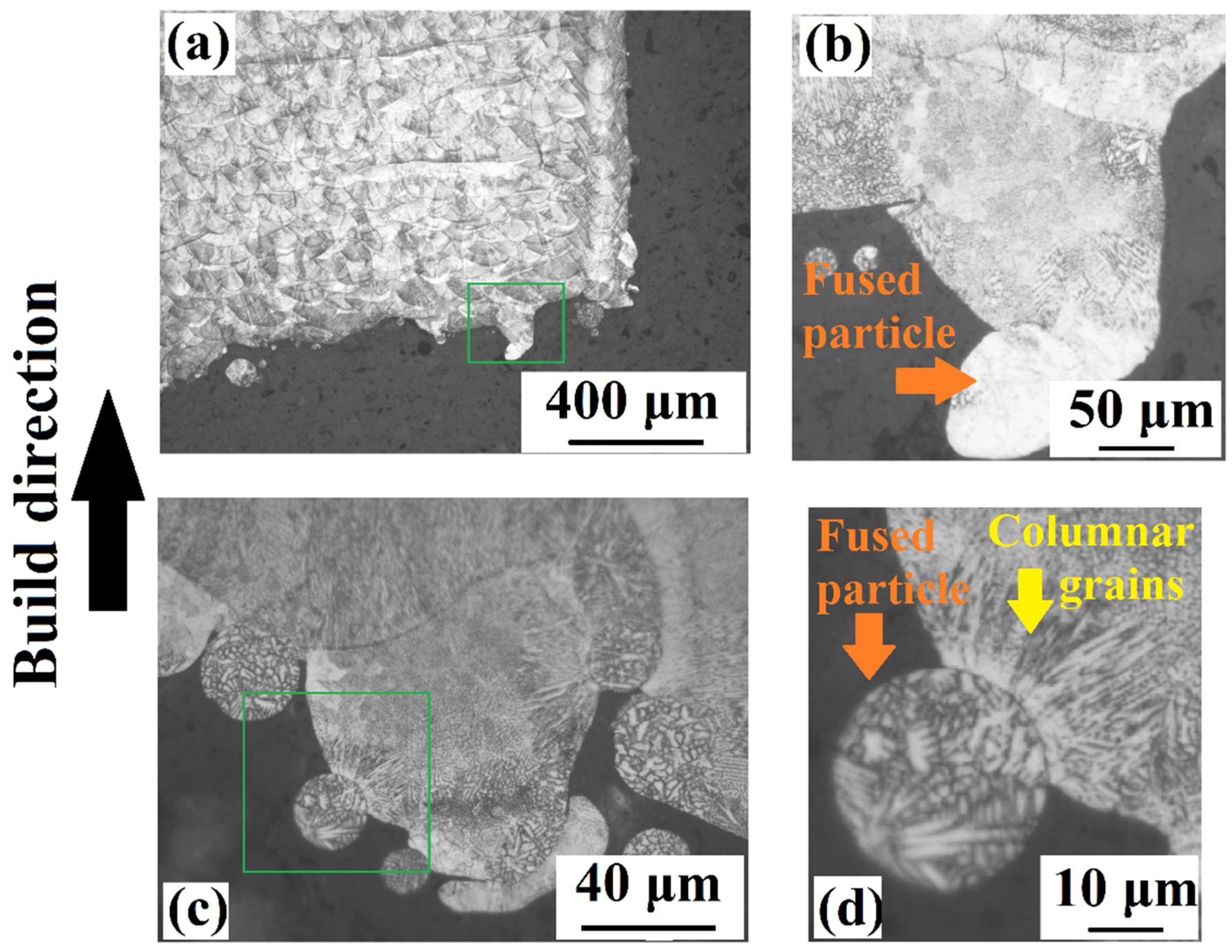

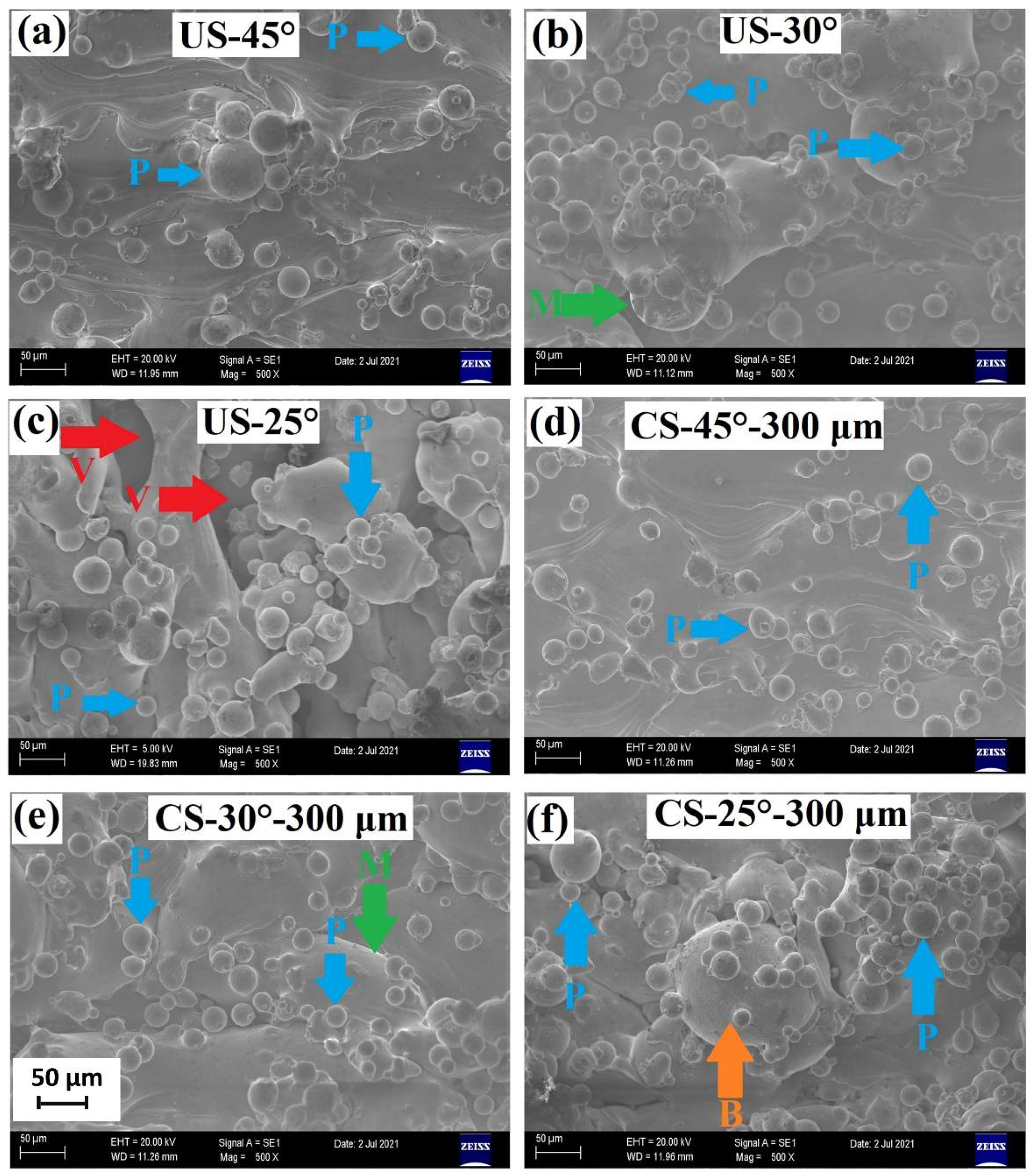

- The OM and SEM micrographs showed that protrusion of the melt pool into the powder bed results in direct contact of the melt pool with the support surfaces and/or acting of particles in the powder bed as bridges connecting the melt pool and support structure at lower gap distances.

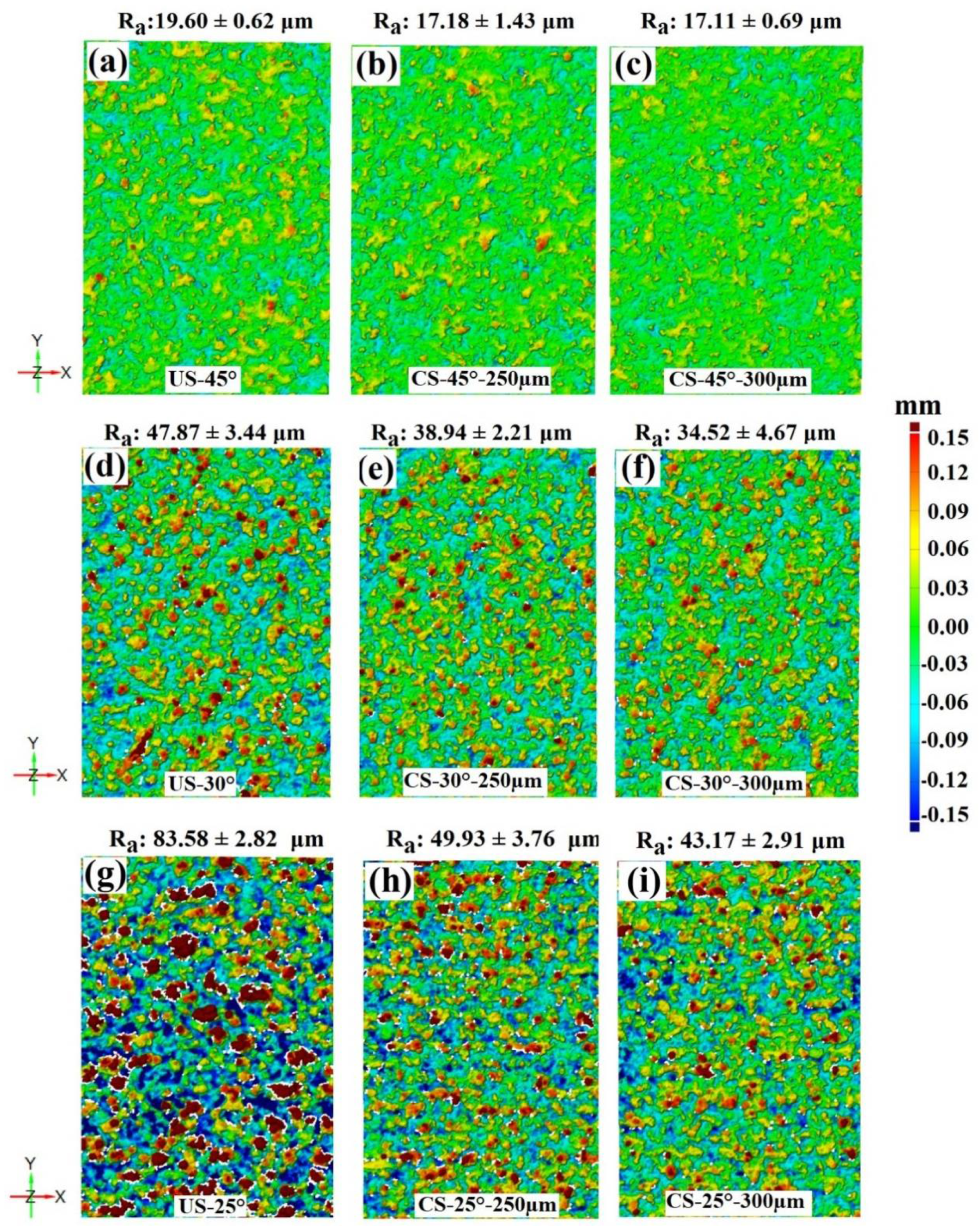

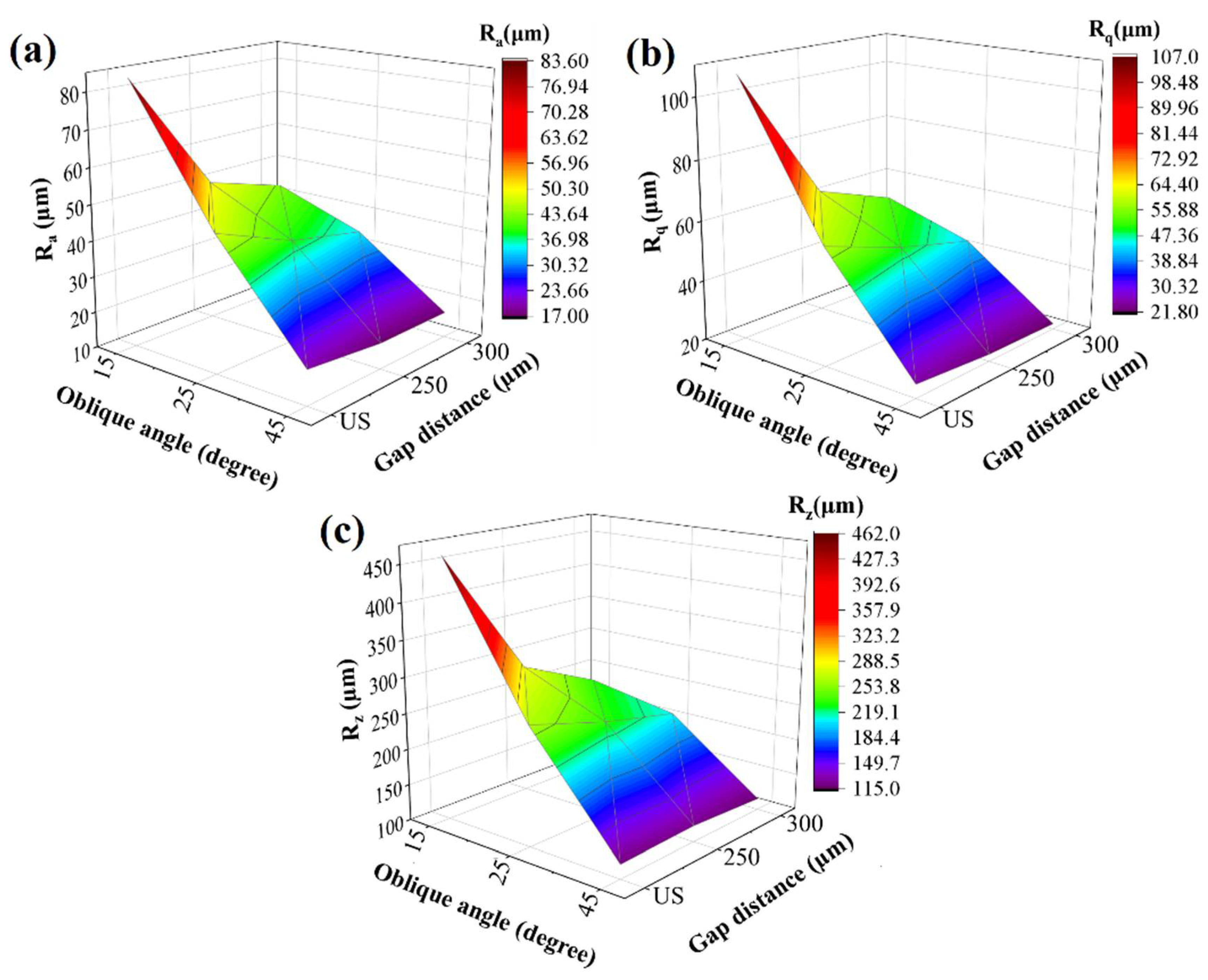

- The surface roughness values (Ra, Rq, and Rz) of the CS-25°-250 µm, CS-25°-300 µm, CS-30°-250 µm, and CS-30°-300 µm significantly decrease compared to their unsupported counterparts. Thus, the decrement rate in surface roughness parameters is more remarkable at higher gap distances. Ra, Rq, and Rz decrease by around 2 times in CS-25°-300 µm compared to those of unsupported cases.

- The OM and SEM micrographs also showed that the surface texture is determined by several factors such as attached particles, inverted mushroom-like features, balling phenomena, undercuts, bumpiness of the melt pool, etc.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, S.; Shin, Y.C. Additive manufacturing of Ti6Al4V alloy: A review. Mater. Des. 2018, 164, 107552. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Kniepkamp, M.; Fischer, J.; Abele, E. Dimensional accuracy of small parts manufactured by micro selective laser melting. In Proceeding of the 2016 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 8–10 August 2013. [Google Scholar]

- Sing, S.L.; Wiria, F.E.; Yeong, W.Y. Selective laser melting of lattice structures: A statistical approach to manufacturability and mechanical behavior. Robot. Comput. Manuf. 2018, 49, 170–180. [Google Scholar] [CrossRef]

- Yildirim, U.; Abanteriba, S. Manufacture, Qualification and Approval of New Aviation Turbine Fuels and Additives. Procedia Eng. 2012, 49, 310–315. [Google Scholar] [CrossRef] [Green Version]

- Gisario, A.; Kazarian, M.; Martina, F.; Mehrpouya, M. Metal additive manufacturing in the commercial aviation industry: A review. J. Manuf. Syst. 2019, 53, 124–149. [Google Scholar] [CrossRef]

- Najmon, J.C.; Raeisi, S.; Tovar, A. Review of additive manufacturing technologies and applications in the aerospace industry. Addit. Manuf. Aerosp. Ind. 2019, 7–31. [Google Scholar] [CrossRef]

- Chua, C.K.; Leong, K.F. 3D Printing and Additive Manufacturing: Principles and Applications, 4th ed.; World Scientific: Singapore, 2014; p. 518. [Google Scholar]

- Gockel, J.; Sheridan, L.; Koerper, B.; Whip, B. The influence of additive manufacturing processing parameters on surface roughness and fatigue life. Int. J. Fatigue 2019, 124, 380–388. [Google Scholar] [CrossRef]

- Vayssette, B.; Saintier, N.; Brugger, C.; EL May, M.; Pessard, E. Numerical modelling of surface roughness effect on the fatigue behavior of Ti-6Al-4V obtained by additive manufacturing. Int. J. Fatigue 2019, 123, 180–195. [Google Scholar] [CrossRef] [Green Version]

- Krol, M.; Tomasz, T. Surface Quality Research for Selective Laser Melting of Ti-6Al-4V Alloy. Arch. Metall. Mater. 2016, 61, 945–950. [Google Scholar] [CrossRef]

- Nakatani, M.; Masuo, H.; Tanaka, Y.; Murakami, Y. Effect of Surface Roughness on Fatigue Strength of Ti-6Al-4V Alloy Manufactured by Additive Manufacturing. Procedia Struct. Integr. 2019, 19, 294–301. [Google Scholar] [CrossRef]

- Pintado, C.N.; Vázquez, J.; Domínguez, J.; Periñán, A.; García, M.H.; Lasagni, F.; Bernarding, S.; Slawik, S.; Mücklich, F.; Boby, F.; et al. Effect of surface treatment on the fatigue strength of additive manufactured Ti6Al4V alloy. Frat. Integrita Strutt. 2020, 14, 337–344. [Google Scholar] [CrossRef]

- Yuri, T.; Ono, Y.; Ogata, T. Effects of surface roughness and notch on fatigue properties for Ti–5Al–2.5Sn ELI alloy at cryogenic temperatures. Sci. Technol. Adv. Mater. 2003, 4, 291–299. [Google Scholar] [CrossRef]

- Chan, K.S.; Peralta-Duran, A. A Methodology for Predicting Surface Crack Nucleation in Additively Manufactured Metallic Components. Met. Mater. Trans. A Phys. Metall. Mater. Sci. 2019, 50, 4378–4387. [Google Scholar] [CrossRef]

- Soro, N.; Saintier, N.; Attar, H.; Dargusch, M.S. Surface and morphological modification of selectively laser melted titanium lattices using a chemical post treatment. Surf. Coat. Technol. 2020, 393, 125794. [Google Scholar] [CrossRef]

- Bezuidenhout, M.; Ter Haar, G.; Becker, T.; Rudolph, S.; Damm, O.; Sacks, N. The effect of HF-HNO3 chemical polishing on the surface roughness and fatigue life of laser powder bed fusion produced Ti6Al4V. Mater. Today Commun. 2020, 25, 101396. [Google Scholar] [CrossRef]

- Benoist, V.; Arnaud, L.; Baili, M. A new method of design for additive manufacturing including machining constraints. Int. J. Adv. Manuf. Technol. 2020, 111, 25–36. [Google Scholar] [CrossRef]

- Careri, F.; Imbrogno, S.; Umbrello, D.; Attallah, M.M.; Outeiro, J.; Batista, A.C. Machining and heat treatment as post-processing strategies for Ni-superalloys structures fabricated using direct energy deposition. J. Manuf. Process. 2021, 61, 236–244. [Google Scholar] [CrossRef]

- Wang, X.; Li, S.; Fu, Y.; Gao, H. Finishing of additively manufactured metal parts by abrasive flow machining. In Proceeding of the 2016 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 8–10 August 2013. [Google Scholar]

- Mohammadian, N.; Turenne, S.; Brailovski, V. Surface finish control of additively-manufactured Inconel 625 components using combined chemical-abrasive flow polishing. J. Mater. Process. Technol. 2018, 252, 728–738. [Google Scholar] [CrossRef]

- Nagalingam, A.P.; Yeo, S. Surface finishing of additively manufactured Inconel 625 complex internal channels: A case study using a multi-jet hydrodynamic approach. Addit. Manuf. 2020, 36, 101428. [Google Scholar] [CrossRef]

- Fox, J.C.; Moylan, S.P.; Lane, B.M. Effect of Process Parameters on the Surface Roughness of Overhanging Structures in Laser Powder Bed Fusion Additive Manufacturing. Procedia CIRP 2016, 45, 131–134. [Google Scholar] [CrossRef] [Green Version]

- Charles, A.; Elkaseer, A.; Thijs, L.; Hagenmeyer, V.; Scholz, S. Effect of Process Parameters on the Generated Surface Roughness of Down-Facing Surfaces in Selective Laser Melting. Appl. Sci. 2019, 9, 1256. [Google Scholar] [CrossRef] [Green Version]

- Tian, Y.; Tomus, D.; Rometsch, P.; Wu, X. Influences of processing parameters on surface roughness of Hastelloy X produced by selective laser melting. Addit. Manuf. 2017, 13, 103–112. [Google Scholar] [CrossRef]

- Karimi, P.; Schnur, C.; Sadeghi, E.; Andersson, J. Contour design to improve topographical and microstructural characteristics of Alloy 718 manufactured by electron beam-powder bed fusion technique. Addit. Manuf. 2020, 32, 101014. [Google Scholar] [CrossRef]

- Whip, B.; Sheridan, L.; Gockel, J. The effect of primary processing parameters on surface roughness in laser powder bed additive manufacturing. Int. J. Adv. Manuf. Technol. 2019, 103, 4411–4422. [Google Scholar] [CrossRef]

- Strano, G.; Hao, L.; Everson, R.M.; Evans, K.E. Surface roughness analysis, modelling and prediction in selective laser melting. J. Mater. Process. Technol. 2013, 213, 589–597. [Google Scholar] [CrossRef]

- Li, L.; Li, J.-Q.; Fan, T.-H. Phase-field modeling of wetting and balling dynamics in powder bed fusion process. Phys. Fluids 2021, 33, 042116. [Google Scholar] [CrossRef]

- Piscopo, G.; Salmi, A.; Atzeni, E. On the quality of unsupported overhangs produced by laser powder bed fusion. Int. J. Manuf. Res. 2019, 14, 198. [Google Scholar] [CrossRef] [Green Version]

- Witkin, D.B.; Patel, D.N.; Helvajian, H.; Steffeney, L.; Diaz, A. Surface Treatment of Powder-Bed Fusion Additive Manufactured Metals for Improved Fatigue Life. J. Mater. Eng. Perform. 2019, 28, 681–692. [Google Scholar] [CrossRef]

- Oter, Z.C.; Coskun, M.; Akca, Y.; Surmen, O.; Yilmaz, M.S.; Ozer, G.; Tarakçi, G.; Khan, H.; Koc, E. Support optimization for overhanging parts in direct metal laser sintering. Optik 2019, 181, 575–581. [Google Scholar] [CrossRef]

- Gan, M.X.; Wong, C. Practical support structures for selective laser melting. J. Mater. Process. Technol. 2016, 238, 474–484. [Google Scholar] [CrossRef]

- Cloots, M.; Spierings, A.B.; Wegener, K. Assessing new support minimizing strategies for the additive manufacturing technology SLM. In Proceeding of the 2013 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 12–14 August 2013. [Google Scholar]

- Hussein, A.; Hao, L.; Yan, C.; Everson, R.; Young, P. Advanced lattice support structures for metal additive manufacturing. J. Mater. Process. Technol. 2013, 213, 1019–1026. [Google Scholar] [CrossRef]

- Han, Q.; Gu, H.; Soe, S.; Setchi, R.; Lacan, F.; Hill, J. Manufacturability of AlSi10Mg overhang structures fabricated by laser powder bed fusion. Mater. Des. 2018, 160, 1080–1095. [Google Scholar] [CrossRef]

- Strano, G.; Hao, L.; Everson, R.M.; Evans, K.E. A new approach to the design and optimisation of support structures in additive manufacturing. Int. J. Adv. Manuf. Technol. 2013, 66, 1247–1254. [Google Scholar] [CrossRef]

- Langelaar, M. Combined optimization of part topology, support structure layout and build orientation for additive manufacturing. Struct. Multidiscip. Optim. 2018, 57, 1985–2004. [Google Scholar] [CrossRef] [Green Version]

- Calignano, F. Design optimization of supports for overhanging structures in aluminum and titanium alloys by selective laser melting. Mater. Des. 2014, 64, 203–213. [Google Scholar] [CrossRef]

- Krol, T.A.; Zach, F.; Seidel, C. Optimization of supports in metal-based additive manufacturing by means of finite element models. In Proceeding of the 2012 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 6–8 August 2012. [Google Scholar]

- Jhabvala, J.; Boillat, E.; André, C.; Glardon, R. An innovative method to build support structures with a pulsed laser in the selective laser melting process. Int. J. Adv. Manuf. Technol. 2012, 59, 137–142. [Google Scholar] [CrossRef] [Green Version]

- Cooper, K.; Steele, P.; Bo, C.; Chou, K. Contact-Free Support Structures for Part Overhangs in Powder-Bed Metal Additive Manufacturing. Inventions 2018, 3, 2. [Google Scholar] [CrossRef] [Green Version]

- Xiang, Z.; Wang, L.; Yang, C.; Yin, M.; Yin, G. Analysis of the quality of slope surface in selective laser melting process by simulation and experiments. Optik 2019, 176, 68–77. [Google Scholar] [CrossRef]

- Paggi, U.; Ranjan, R.; Thijs, L.; Ayas, C.; Langelaar, M.; van Keulen, F.; van Hooreweder, B. New support structures for reduced overheating on downfacing regions of direct metal printed parts. In Proceeding of the 2019 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 12–14 August 2019. [Google Scholar]

- ASM International Handbook Committee. Nickel, Cobalt and Their Alloys. In ASM Handbook; Materials Park; ASM International: Geauga, OH, USA, 2000. [Google Scholar]

- Betteridge, W. Cobalt and Its Alloys; Halsted Press: New York, NY, USA, 1982. [Google Scholar]

- Tan, X.; Wang, P.; Kok, Y.; Toh, W.; Sun, Z.; Nai, S.; Descoins, M.; Mangelinck, D.; Liu, E.; Tor, S.B. Carbide precipitation characteristics in additive manufacturing of Co-Cr-Mo alloy via selective electron beam melting. Scr. Mater. 2017, 143, 117–121. [Google Scholar] [CrossRef]

- Manivasagam, G.; Dhinasekaran, D.; Rajamanickam, A. Biomedical Implants: Corrosion and Its Prevention—A Review. Recent Pat. Corros. Sci. 2010, 2, 40–54. [Google Scholar] [CrossRef] [Green Version]

- Song, C.; Yang, Y.; Wang, Y.; Wang, D.; Yu, J. Research on rapid manufacturing of CoCrMo alloy femoral component based on selective laser melting. Int. J. Adv. Manuf. Technol. 2014, 75, 445–453. [Google Scholar] [CrossRef]

- Sun, J.; Zhang, F.-Q. The Application of Rapid Prototyping in Prosthodontics. J. Prosthodont. 2012, 21, 641–644. [Google Scholar] [CrossRef] [PubMed]

- Torabi, K.; Farjood, E.; Hamedani, S. Rapid Prototyping Technologies and their Applications in Prosthodontics, a Review of Literature. J. Dent. 2015, 16, 1–9. [Google Scholar]

- Ozeren, E.; Altan, M. Effect of structural hybrid design on mechanical and biological properties of CoCr scaffolds fabricated by selective laser melting. Rapid Prototyp. J. 2019, 26, 615–624. [Google Scholar] [CrossRef]

- Wang, X.; Chou, K. Effect of support structures on Ti-6Al-4V overhang parts fabricated by powder bed fusion electron beam additive manufacturing. J. Mater. Process. Technol. 2018, 257, 65–78. [Google Scholar] [CrossRef]

- Qi, M.; Huang, S.; Ma, Y.; Youssef, S.S.; Zhang, R.; Qiu, J.; Lei, J.; Yang, R. Columnar to equiaxed transition during β heat treatment in a near β alloy by laser additive manufacture. J. Mater. Res. Technol. 2021, 13, 1159–1168. [Google Scholar] [CrossRef]

- Newton, L.; Senin, N.; Gomez, C.; Danzl, R.; Helmli, F.; Blunt, L.; Leach, R. Areal topography measurement of metal additive surfaces using focus variation microscopy. Addit. Manuf. 2018, 25, 365–389. [Google Scholar] [CrossRef]

- Boutaous, M.; Liu, X.; Siginer, D.A.; Xin, S. Balling phenomenon in metallic laser based 3D printing process. Int. J. Therm. Sci. 2021, 167, 107011. [Google Scholar] [CrossRef]

| Element | Wt. % |

|---|---|

| Chromium | 27.68 |

| Molybdenum | 5.82 |

| Silicon | 0.48 |

| Iron | 0.36 |

| Manganese | 0.25 |

| Nickel | 0.23 |

| Nitrogen | 0.11 |

| Carbon | 0.10 |

| Tungsten | 0.04 |

| Oxygen | 0.02 |

| Phosphorus | <0.005 |

| Sulfur | 0.004 |

| Boron | 0.001 |

| Cobalt | Balance |

| Sample # | Support Type | Oblique Angle | Gap Distance | Sample ID |

|---|---|---|---|---|

| 1 | Unsupported | 45° | - | US-45° |

| 2 | Contactless Support | 45° | 100 µm | CS-45°-100 µm |

| 3 | Contactless Support | 45° | 125 µm | CS-45°-125 µm |

| 4 | Contactless Support | 45° | 150 µm | CS-45°-150 µm |

| 5 | Contactless Support | 45° | 250 µm | CS-45°-250 µm |

| 6 | Contactless Support | 45° | 300 µm | CS-45°-300 µm |

| 7 | Unsupported | 30° | - | US-30° |

| 8 | Contactless Support | 30° | 100 µm | CS-30°-100 µm |

| 9 | Contactless Support | 30° | 125 µm | CS-30°-125 µm |

| 10 | Contactless Support | 30° | 150 µm | CS-30°-150 µm |

| 11 | Contactless Support | 30° | 250 µm | CS-30°-250 µm |

| 12 | Contactless Support | 30° | 300 µm | CS-30°-300 µm |

| 13 | Unsupported | 15° | - | US-15° |

| 14 | Contactless Support | 15° | 100 µm | CS-15°-100 µm |

| 15 | Contactless Support | 15° | 125 µm | CS-15°-125 µm |

| 16 | Contactless Support | 15° | 150 µm | CS-15°-150 µm |

| 17 | Contactless Support | 15° | 250 µm | CS-15°-250 µm |

| 18 | Contactless Support | 15° | 300 µm | CS-15°-300 µm |

| 19 | Unsupported | 25° | - | US-25° |

| 20 | Contactless Support | 25° | 250 µm | CS-25°-250 µm |

| 21 | Contactless Support | 25° | 300 µm | CS-25°-300 µm |

| Sample ID | Support Type | Oblique Angle | Gap Distance |

|---|---|---|---|

| US-45° | 19.60 ± 0.62 | 24.49 ± 0.45 | 119.40 ± 4.04 |

| CS-45°-100 µm | Fused to the support | Fused to the support | Fused to the support |

| CS-45°-125 µm | Fused to the support | Fused to the support | Fused to the support |

| CS-45°-150 µm | 20.22 ± 0.54 | 26.69 ± 0.23 | 141.29 ± 5.22 |

| CS-45°-250 µm | 17.18 ± 1.43 | 22.35 ± 2.46 | 122.32 ± 10.23 |

| CS-45°-300 µm | 17.11 ± 0.69 | 21.81 ± 0.80 | 115.68 ± 2.94 |

| US-30° | 47.87 ± 3.44 | 58.90 ± 4.27 | 264.46 ± 24.62 |

| CS-30°-100 µm | Fused to the support | Fused to the support | Fused to the support |

| CS-30°-125 µm | Fused to the support | Fused to the support | Fused to the support |

| CS-30°-150 µm | Fused to the support | Fused to the support | Fused to the support |

| CS-30°-250 µm | 38.94 ± 2.21 | 49.77 ± 3.65 | 232.41 ± 9.40 |

| CS-30°-300 µm | 34.52 ± 4.67 | 43.25 ± 5.81 | 208.89 ± 22.50 |

| US-15° | Poor surface quality | Poor surface quality | Poor surface quality |

| CS-15°-100 µm | Fused to the support | Fused to the support | Fused to the support |

| CS-15°-125 µm | Poor surface quality | Poor surface quality | Poor surface quality |

| CS-15°-150 µm | Poor surface quality | Poor surface quality | Poor surface quality |

| CS-15°-250 µm | Poor surface quality | Poor surface quality | Poor surface quality |

| CS-15°-300 µm | Poor surface quality | Poor surface quality | Poor surface quality |

| US-25° | 83.58 ± 2.82 | 106.96 ± 5.03 | 461.50 ± 3.07 |

| CS-25°-250 µm | 49.93 ± 3.76 | 62.19 ± 4.70 | 282.50 ± 18.29 |

| CS-25°-300 µm | 43.17 ± 2.91 | 52.28 ± 3.38 | 231.52 ± 11.34 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Çelik, A.; Tekoğlu, E.; Yasa, E.; Sönmez, M.Ş. Contact-Free Support Structures for the Direct Metal Laser Melting Process. Materials 2022, 15, 3765. https://doi.org/10.3390/ma15113765

Çelik A, Tekoğlu E, Yasa E, Sönmez MŞ. Contact-Free Support Structures for the Direct Metal Laser Melting Process. Materials. 2022; 15(11):3765. https://doi.org/10.3390/ma15113765

Chicago/Turabian StyleÇelik, Alican, Emre Tekoğlu, Evren Yasa, and Mehmet Şeref Sönmez. 2022. "Contact-Free Support Structures for the Direct Metal Laser Melting Process" Materials 15, no. 11: 3765. https://doi.org/10.3390/ma15113765

APA StyleÇelik, A., Tekoğlu, E., Yasa, E., & Sönmez, M. Ş. (2022). Contact-Free Support Structures for the Direct Metal Laser Melting Process. Materials, 15(11), 3765. https://doi.org/10.3390/ma15113765