Improvement in Durability and Mechanical Performance of Concrete Exposed to Aggressive Environments by Using Polymer

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Mix Proportion

2.2.2. Preparation of Samples

2.2.3. Workability

2.2.4. Mechanical Strength

2.2.5. Durability Issues and External Attacks

2.2.6. Scanning Electron Microscopic (SEM) Studies

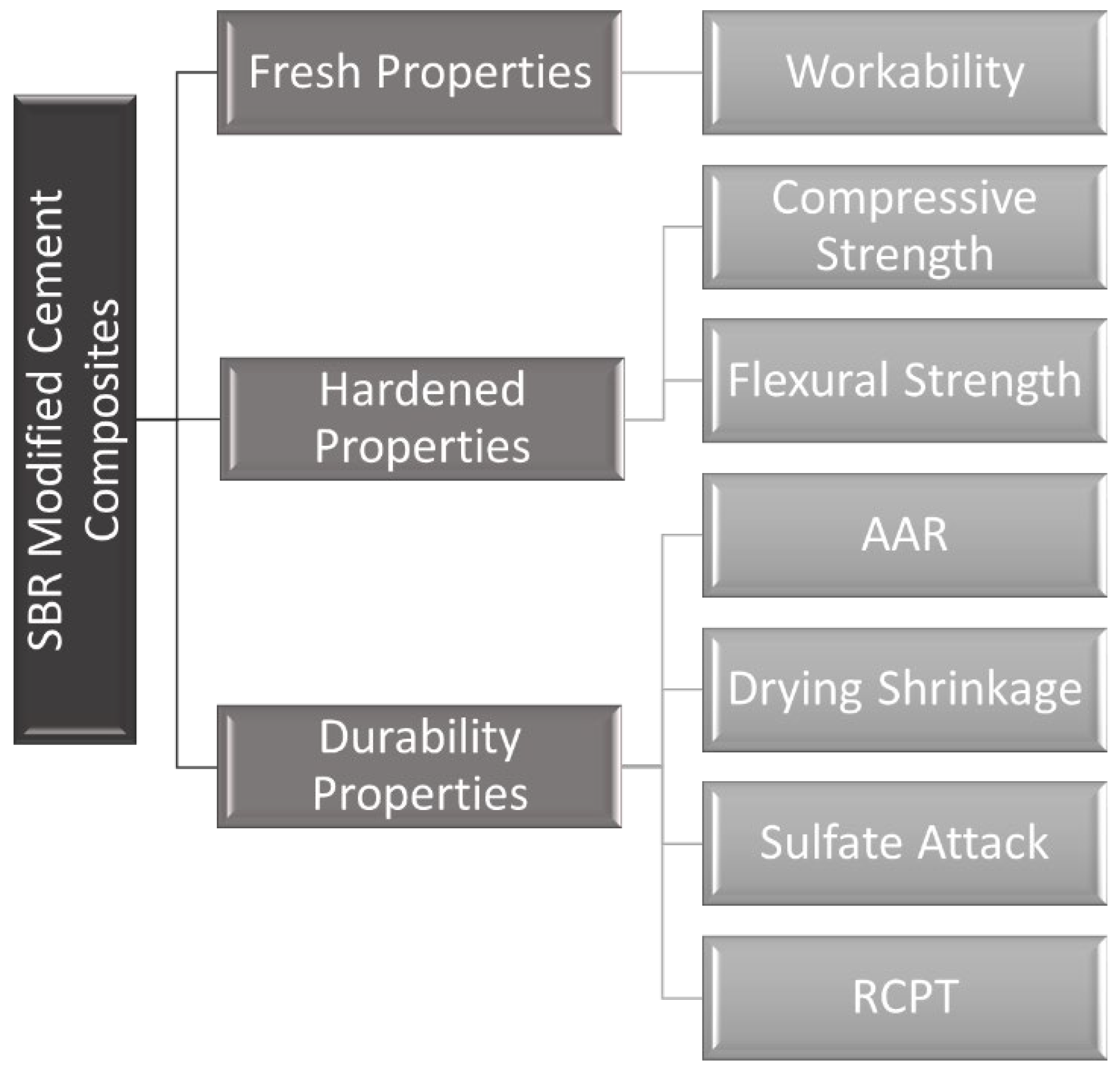

3. Results and Discussions

3.1. Workability of Concrete

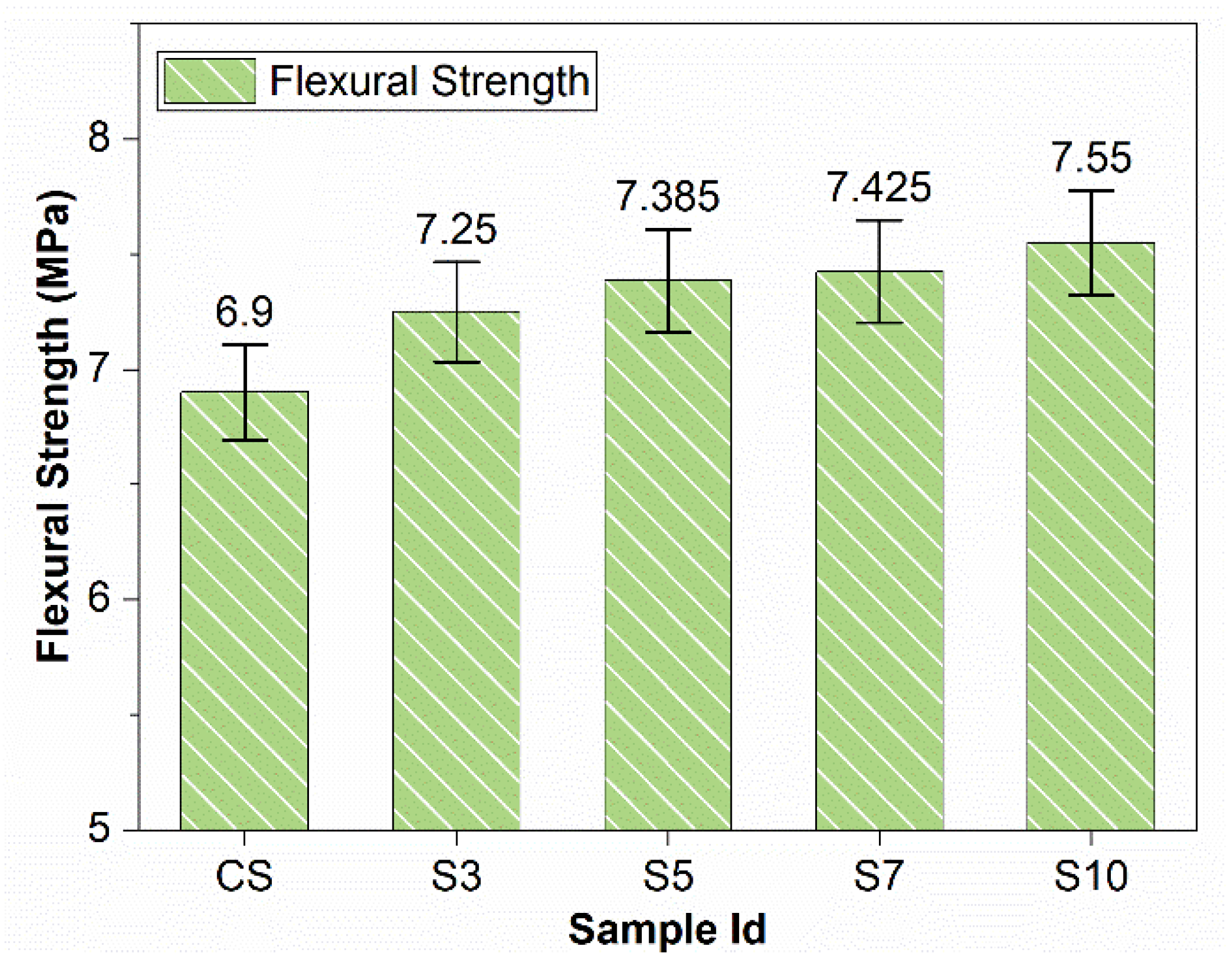

3.2. Mechanical Properties

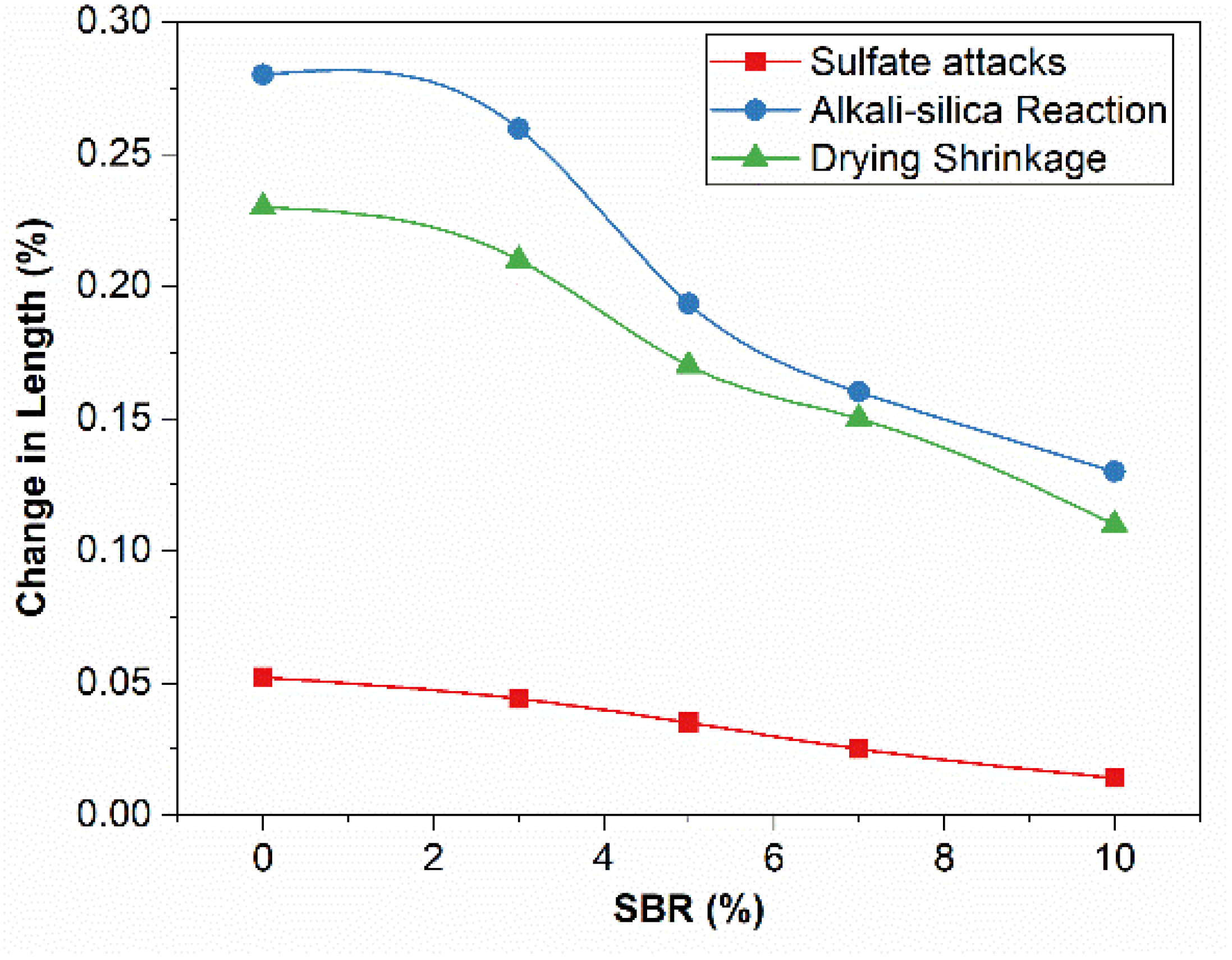

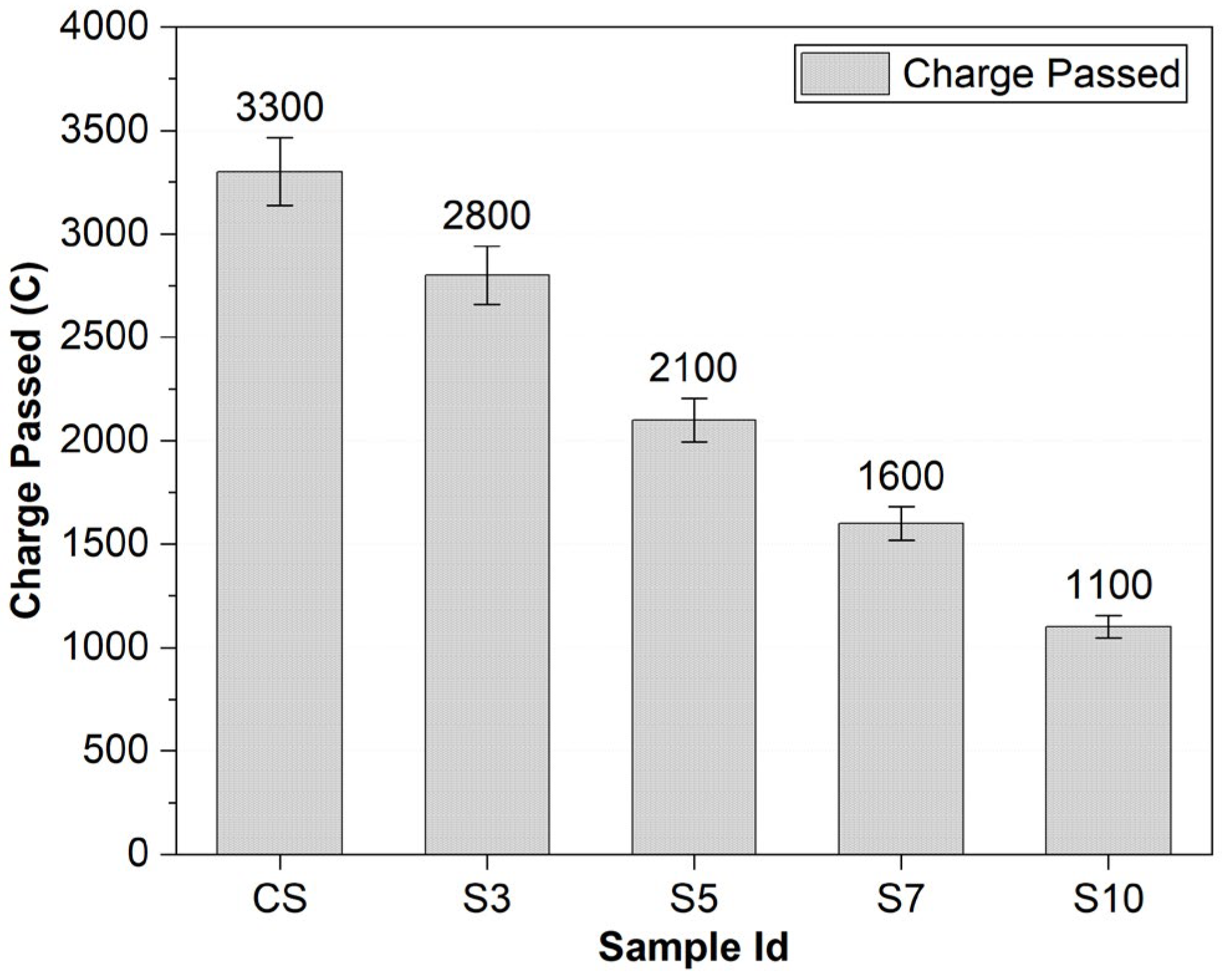

3.3. Permeability and Durability

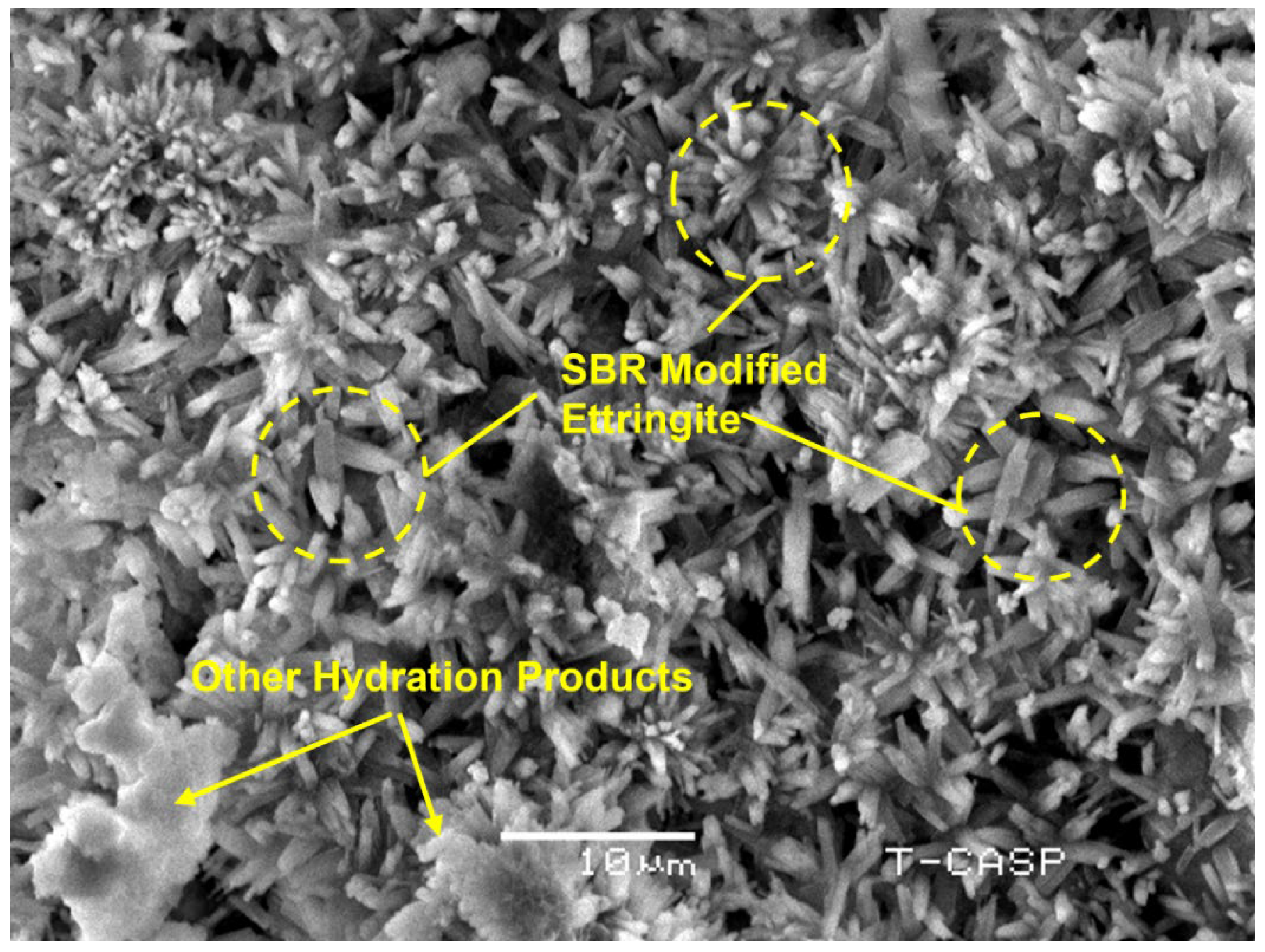

3.4. Scanning Electron Microscopic (SEM) Studies

4. Conclusions

- The workability of concrete increases with the increase in the percentage of SBR powder. SBR (10%) increased slump value by 90%.

- The compressive strength of SBR-powder-modified concrete increases with increases in SBR percentage. SBR (10%) increased compressive strength by 23%. Moreover, flexural strengths of SBR-modified concrete increase slightly (9.4% for SBR10%) with an increase in the percentage of SBR.

- SBR powder reduces chloride permeability and provides protection against corrosion caused by chloride ingress. SBR (10%) decreased the charge passed and hence chloride permeability by one-third as compared to the control sample.

- SBR provides excellent volume stability by giving outstanding performance against dying shrinkage and expansions due to alkali-silica reactions and sulfate attacks. SBR (10%) reduced expansion in mortar bars due to sulfate attacks and ASR by 73% and 57%, respectively, and reduced shrinkage due to ASR by 52%.

- By increasing SBR powder from 5% to 10%, the durability issues are abated noticeably. The interrelation is developed for permeability and durability issues for SBR-modified concrete.

- Hence, it is inferred that concrete durability issues are substantially reduced by replacing cement with ultrafine SBR powder from 5 to 10% (especially at 10%). A highly sustainable and better-performance concrete is produced that is particularly suitable for harsh environments.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Makul, N. Modern sustainable cement and concrete composites: Review of current status, challenges and guidelines. Sustain. Mater. Technol. 2020, 25, e00155. [Google Scholar] [CrossRef]

- Haque, M.I.; Khan, R.I.; Ashraf, W.; Pendse, H. Production of sustainable, low-permeable and self-sensing cementitious composites using biochar. Sustain. Mater. Technol. 2021, 28, e00279. [Google Scholar] [CrossRef]

- Zhao, Z.; Qu, X.; Li, J. Application of polymer modified cementitious coatings (PCCs) for impermeability enhancement of concrete. Constr. Build. Mater. 2020, 249, 118769. [Google Scholar] [CrossRef]

- Hatungimana, D.; Taşköprü, C.; İçhedef, M.; Saç, M.M.; Yazıcı, Ş. Compressive strength, water absorption, water sorptivity and surface radon exhalation rate of silica fume and fly ash based mortar. J. Build. Eng. 2019, 23, 369–376. [Google Scholar] [CrossRef]

- Liu, B.; Luo, G.; Xie, Y. Effect of curing conditions on the permeability of concrete with high volume mineral admixtures. Construct. Build. Mater. 2018, 167, 359–371. [Google Scholar] [CrossRef]

- Liu, B.; Shi, J.; Sun, M.; He, Z.; Xu, H.; Tan, J. Mechanical and permeability properties of polymer-modified concrete using hydrophobic agent. J. Build. Eng. 2020, 31, 101337. [Google Scholar] [CrossRef]

- Durga, C.S.S.; Ruben, N. Assessment of various self healing materials to enhance the durability of concrete structures. Ann. Chim. Sci. Mater. 2019, 43, 75–79. [Google Scholar] [CrossRef] [Green Version]

- Tang, S.W.; Yao, Y.; Andrade, C.; Li, Z.J. Recent durability studies on concrete structure. Cem. Concr. Res. 2015, 78, 143–154. [Google Scholar] [CrossRef]

- Li, K.; Zhang, D.; Li, Q.; Fan, Z. durability for concrete structures in marine environments of HZM project: Design, assessment and beyond. Cem. Concr. Res. 2019, 115, 545–558. [Google Scholar]

- Al Menhosh, A.; Wang, Y.; Augusthus-Nelson, L. Long term durability properties of concrete modified with metakaolin and polymer admixture. Constr. Build. Mater. 2018, 172, 41–51. [Google Scholar] [CrossRef]

- Ferdous, W.; Manalo, A.; Wong, H.S.; Abousnina, R.; Al Ajarmeh, O.S.; Zhuge, Y.; Schubel, P. Optimal design for epoxy polymer concrete based on mechanical properties and durability aspects. Constr. Build. Mater. 2020, 232, 117229. [Google Scholar] [CrossRef]

- Yi, H.; Oh, K.; Kou, R.; Qiao, Y. Sand-filler structural material with a low content of polyethylene binder. Sustain. Mater. Technol. 2020, 25, e00194. [Google Scholar] [CrossRef]

- Mignon, A.; Snoeck, D.; Dubruel, P.; Van Vlierberghe, S.; De Belie, N. Crack mitigation in concrete: Superabsorbent polymers as key to success? Materials 2017, 10, 237. [Google Scholar] [CrossRef] [Green Version]

- Khattab, M.M.; Tobeia, S.B.; Lafta, M.J. The effects of different polymer materials on concrete properties containing superabsorbent polymers (SAP)-experimental study. In IOP Conference Series: Materials Science and Engineering, Proceedings of the 4th International Conference on Buildings, Construction and Environmental Engineering, Istanbul, Turkey, 7–9 October 2019; IOP Publishing: Bristol, UK, 2019; p. 737. [Google Scholar]

- Sokołowska, J.J. Long-term compressive strength of polymer concrete-like composites with various fillers. Materials 2020, 13, 1207. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Łagoda, G.; Gajda, T. Change of Mechanical Properties of Repair Mortars after Frost Resistance Rests. Materials 2021, 14, 3199. [Google Scholar] [CrossRef] [PubMed]

- Pilla, S.D. Slip and Fall Prevention: A Practical Handbook; CRC: Boca Raton, FL, USA, 2004; p. 82. ISBN 978-0-203-49672-5. [Google Scholar]

- Sadrmomtazi, A.; Khoshkbijari, R.K. Determination and prediction of bonding strength of polymer modified concrete (PMC) as the repair overlay on the conventional concrete substrate. KSCE J. Civ. Eng. 2019, 23, 1141–1149. [Google Scholar] [CrossRef]

- Kumar, M.S.A. Experimental Investigation of Styrene Butadiene Rubber in Plain Concrete. Forefr. J. Eng. Technol. 2020, 2, 19–32. [Google Scholar]

- Benali, Y.; Ghomari, F. Mechanical behavior and durability of latex modified mortars. J. Build. Mater. Struct. 2018, 5, 110–126. [Google Scholar] [CrossRef]

- Kim, K.K.; Yeon, J.; Lee, H.J.; Yeon, K.S. Strength development characteristics of SBR-modified cementitious mixtures for 3-demensional concrete printing. Sustainability 2019, 11, 4164. [Google Scholar] [CrossRef] [Green Version]

- Kim, K.K.; Yeon, J.; Lee, H.J.; Yeon, K.S. Dimensional stability of SBR-modified cementitious mixtures for use in 3D additive construction. Appl. Sci. 2019, 9, 3386. [Google Scholar] [CrossRef] [Green Version]

- Łukowski, P.; Dębska, D. Effect of polymer addition on performance of Portland cement mortar exposed to sulphate attack. Materials 2019, 13, 71. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tarannum, N.; Pooja, K.M.; Khan, R. Preparation and applications of hydrophobic multicomponent based redispersible polymer powder: A review. Constr. Build. Mater. 2020, 247, 118579. [Google Scholar] [CrossRef]

- Idrees, M.; Saeed, F.; Amin, A.; Hussain, T. Improvement in compressive strength of Styrene-Butadiene-Rubber (SBR) modified mortars by using powder form and nanoparticles. J. Build. Eng. 2021, 44, 102651. [Google Scholar] [CrossRef]

- C109/C109M−16; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars. American Society for Testing and Materials: West Conshohocken, PA, USA, 2013.

- C78/C78-18; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). American Society for Testing and Materials: West Conshohocken, PA, USA, 2009.

- C1437–15; Standard Test Method for Slump of Hydraulic Cement Concrete. American Society for Testing and Materials: West Conshohocken, PA, USA, 2015.

- Idrees, M.; Hussain, A.T.; Saeed, F.; Hussain, T. Effectiveness of metakaolin and hybrid polymers incorporated mortar for the compressive strength and acid resistance of industrial and wastewater infrastructure. Environ. Prog. Sustain. Energy 2021, 40, e13534. [Google Scholar] [CrossRef]

- Kapeluszna, K.; Kotwica, L.; Pichór, W.; Wczelik, W.N. Cement-based composites with waste expanded perlite—Structure, mechanical properties and durability in chloride and sulphate environments. Sustain. Mater. Technol. 2020, 24, e00160. [Google Scholar] [CrossRef]

- C1202–19; Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration. American Society for Testing and Materials: West Conshohocken, PA, USA, 2019.

- C1260–14; Standard Test Method for Potential Alkali Reactivity of Aggregates (Mortar-Bar Method). American Society for Testing and Materials: West Conshohocken, PA, USA, 2007.

- C490/C490M-17; Standard Practice for Use of Apparatus for the Determination of Length Change of Hardened Cement Paste, Mortar, and Concrete Length. American Society for Testing and Materials: West Conshohocken, PA, USA, 2017.

- C596–18; Standard Test Method for Drying Shrinkage of Mortar Containing Hydraulic Cement. American Society for Testing and Materials: West Conshohocken, PA, USA, 2018.

- C1012/C1012M−18b; Standard Test Method for Length Change of Hydraulic-Cement Mortars Exposed to a Sulfate Solution. American Society for Testing and Materials: West Conshohocken, PA, USA, 2004.

- Ukrainczyk, N.; Rogina, A. Styrene–butadiene latex modified calcium aluminate cement mortar. Cem. Concr. Compos. 2013, 41, 16–23. [Google Scholar] [CrossRef]

- Barluenga, G.; Holivares, F. SBR latex modified mortar rheology and mechanical behavior. Cem. Concr. Res. 2004, 34, 527–535. [Google Scholar] [CrossRef]

- Aliabdo, A.A.E.; Abd-Elmoaty, A.E.M. Experimental Investigation on the Properties of Polymer Modified SCC. Constr. Build. Mater. 2012, 34, 584–592. [Google Scholar] [CrossRef]

- Assaad, J.J. Development and use of polymer-modified cement for adhesive and repair applications. Constr. Build. Mater. 2018, 163, 139–148. [Google Scholar] [CrossRef]

- Bhogayata, A.C.; Arora, N.K. Workability, strength, and Durability of concrete containing recycled plastic fibers and styrene-butadiene rubber latex. Constr. Build. Mater. 2018, 180, 382–395. [Google Scholar] [CrossRef]

- Panesar, D.K. Supplementary cementing materials. In Developments in the Formulation and Reinforcement of Concrete; Woodhead Publishing: Sawston, UK, 2019; pp. 55–85. [Google Scholar]

- Bai, J. Durability of sustainable construction materials. In Sustainability of Construction Materials; Woodhead Publishing: Sawston, UK, 2016; pp. 397–414. [Google Scholar]

- Wang, L.; Tsang, D.C. Carbon dioxide sequestration on composites based on waste wood. In Carbon Dioxide Sequestration in Cementitious Construction Materials; Woodhead Publishing: Sawston, UK, 2018; pp. 431–450. [Google Scholar]

- Moodi, F.; Kashi, A.; Ramezanianpour, A.A.; Pourebrahimi, M. Investigation on mechanical and durability properties of polymer and latex-modified concretes. Constr. Build. Mater. 2018, 191, 145–154. [Google Scholar] [CrossRef]

- Wang, R.; Ma, D.; Wang, P.; Wang, G. Study on waterproof mechanism of polymer modified cement mortar. Mag. Concr. Res. 2015, 67, 972–979. [Google Scholar] [CrossRef]

- Zalegowski, K.; Piotrowski, T.; Garbacz, A. Influence of polymer modification on the microstructure of shielding concrete. Materials 2020, 13, 498. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials, 4th ed.; McGraw-Hill Education: New York, NY, USA, 2014; Available online: https://www.accessengineeringlibrary.com/content/book/9780071797870 (accessed on 15 March 2022).

- Idrees, M.; Nazar, R. Effect of SBR on physical and mechanical properties of concrete. In Proceedings of the 10th International Concrete Congress, Recent Advances in Concrete Technology, Bursa, Turkey, 2–4 May 2019; pp. 164–173. [Google Scholar]

- Idrees, M. Durability Enhancing Additives and Cements. Filed Patent Pakistan-IPO Filing Date. 9 August 2021. [Google Scholar]

| Sr. | Physical Properties of Cement | Obtained Value | ||||||

| 1 | Consistency | 30 | ||||||

| 2 | Initial setting Time | 110 min | ||||||

| 3 | Final Setting Time | 180 min | ||||||

| 4 | Specific Gravity | 3.13 | ||||||

| 5 | Fineness (Blain) | 3078 cm2/gm | ||||||

| 6 | Le-Chatlier Soundness | 2.00 mm | ||||||

| Chemical Properties of Cement | Obtained Value | |||||||

| 1 | Lime Saturated Factor | 0.94 | ||||||

| 2 | Tri Calcium Aluminate | 7.52% | ||||||

| 3 | Insoluble Residue | 1.28% | ||||||

| 4 | Magnesia | 1.79% | ||||||

| 5 | Sulfuric Anhydride | 2.76% | ||||||

| 6 | Loss on Ignition | 3.24% | ||||||

| 7 | Chlorides | 0.01% | ||||||

| XRF Analysis of Cement | ||||||||

| Material | CaO | MgO | SiO2 | Al2O3 | Fe2O3 | L.O.I | K2O | Na2O |

| Cement (%) | 62.13 | 2.29 | 20.25 | 5.05 | 3.13 | 3.24 | 0.74 | 0.24 |

| Physical Properties of Aggregates | ||||||||

| Sr. | Material | Fineness Modulus | Specific Gravity | Water Absorption (Vol. %) | ||||

| 1 | Coarse Aggregate | 7 | 2.5 | 0.96 | ||||

| 2 | Fine Aggregate | 2.23 | 2.67 | 1.3 | ||||

| Property | Value | Unit | Method |

|---|---|---|---|

| Total Solids | 99.00 | % | ISO 1625 |

| Ash Content at 600 °C | 12.00 | % | Internal Method |

| Particle Size | 85.00 | µm | Internal Method |

| MFFT (min. film-forming temperature for re-dispersed in 50% solid concentration) | 8.00 | °C | ISO 2115 |

| Specific Gravity | 0.50 | g/cm3 | ISO 8962 |

| Sample Name | Cement (kg) | SBR Powder (g) | Sand (kg) | Aggregate (kg) | Water (mL) |

|---|---|---|---|---|---|

| CS | 4.25 | 0 | 7.22 | 10.62 | 1997 |

| S3 | 4.12 | 127.5 | 7.22 | 10.62 | 1997 |

| S5 | 4.04 | 212.5 | 7.22 | 10.62 | 1997 |

| S7 | 3.95 | 297.5 | 7.22 | 10.62 | 1997 |

| S10 | 3.83 | 425.0 | 7.22 | 10.62 | 1997 |

| Sample Name | Cement (g) | SBR Powder (g) | Aggregate (g) | Water (mL) |

|---|---|---|---|---|

| CS | 440 | 0 | 990 | 207 |

| S3 | 426 | 14 | 990 | 207 |

| S5 | 418 | 22 | 990 | 207 |

| S7 | 409 | 31 | 990 | 207 |

| S10 | 396 | 44 | 990 | 207 |

| Sample Name | Cement (g) | SBR Powder (g) | Sand (g) | Water (mL) |

|---|---|---|---|---|

| CS | 300 | 0 | 600 | 207 |

| S3 | 291 | 9 | 600 | 207 |

| S5 | 285 | 15 | 600 | 207 |

| S7 | 279 | 21 | 600 | 207 |

| S10 | 270 | 30 | 600 | 207 |

| Sample Name | Cement (g) | SBR Powder (g) | Sand (g) | Water (mL) |

|---|---|---|---|---|

| CS | 1000 | 0 | 2750 | 485 |

| S3 | 970 | 30 | 2.750 | 485 |

| S5 | 950 | 50 | 2.750 | 485 |

| S7 | 930 | 70 | 2.750 | 485 |

| S10 | 900 | 100 | 2.750 | 485 |

| Sample Name | ASR Expansion (%) | ASR Decrease (%) | Drying Shrinkage (%) | DS Percent Decrease | Sulfate Attack Expansion (%) | Decrease in Expansion (%) |

|---|---|---|---|---|---|---|

| CS | 0.28 | - | 0.218 | - | 0.52 | - |

| S3 | 0.26 | 7.14 | 0.213 | 2.29 | 0.44 | 15.4 |

| S5 | 0.19 | 32.14 | 0.147 | 32.5 | 0.35 | 32.7 |

| S7 | 0.16 | 42.8 | 0.125 | 42.6 | 0.25 | 51.9 |

| S10 | 0.12 | 57.14 | 0.103 | 52.7 | 0.14 | 73.1 |

| Concrete (ASTM C1202) | Mortar | |||

|---|---|---|---|---|

| Sample Name | Charge (Coulombs) | Decrease in Charge Passed (%) | Water Absorption (%) | Decrease (%) |

| CS | 3300 | - | 7.9 | - |

| S3 | 2899 | 12.15 | 4.1 | 49.3 |

| S5 | 2100 | 36.36 | 3.5 | 55.7 |

| S7 | 1600 | 51.51 | 3 | 62 |

| S10 | 1100 | 66.67 | 1.5 | 81 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Idrees, M.; Akbar, A.; Saeed, F.; Saleem, H.; Hussian, T.; Vatin, N.I. Improvement in Durability and Mechanical Performance of Concrete Exposed to Aggressive Environments by Using Polymer. Materials 2022, 15, 3751. https://doi.org/10.3390/ma15113751

Idrees M, Akbar A, Saeed F, Saleem H, Hussian T, Vatin NI. Improvement in Durability and Mechanical Performance of Concrete Exposed to Aggressive Environments by Using Polymer. Materials. 2022; 15(11):3751. https://doi.org/10.3390/ma15113751

Chicago/Turabian StyleIdrees, Maria, Arslan Akbar, Farhan Saeed, Huma Saleem, Tousif Hussian, and Nikolai Ivanovich Vatin. 2022. "Improvement in Durability and Mechanical Performance of Concrete Exposed to Aggressive Environments by Using Polymer" Materials 15, no. 11: 3751. https://doi.org/10.3390/ma15113751

APA StyleIdrees, M., Akbar, A., Saeed, F., Saleem, H., Hussian, T., & Vatin, N. I. (2022). Improvement in Durability and Mechanical Performance of Concrete Exposed to Aggressive Environments by Using Polymer. Materials, 15(11), 3751. https://doi.org/10.3390/ma15113751