Size Effect of Hydrated Lime on the Mechanical Performance of Asphalt Concrete

Abstract

:1. Introduction

2. Materials

2.1. Raw Materials

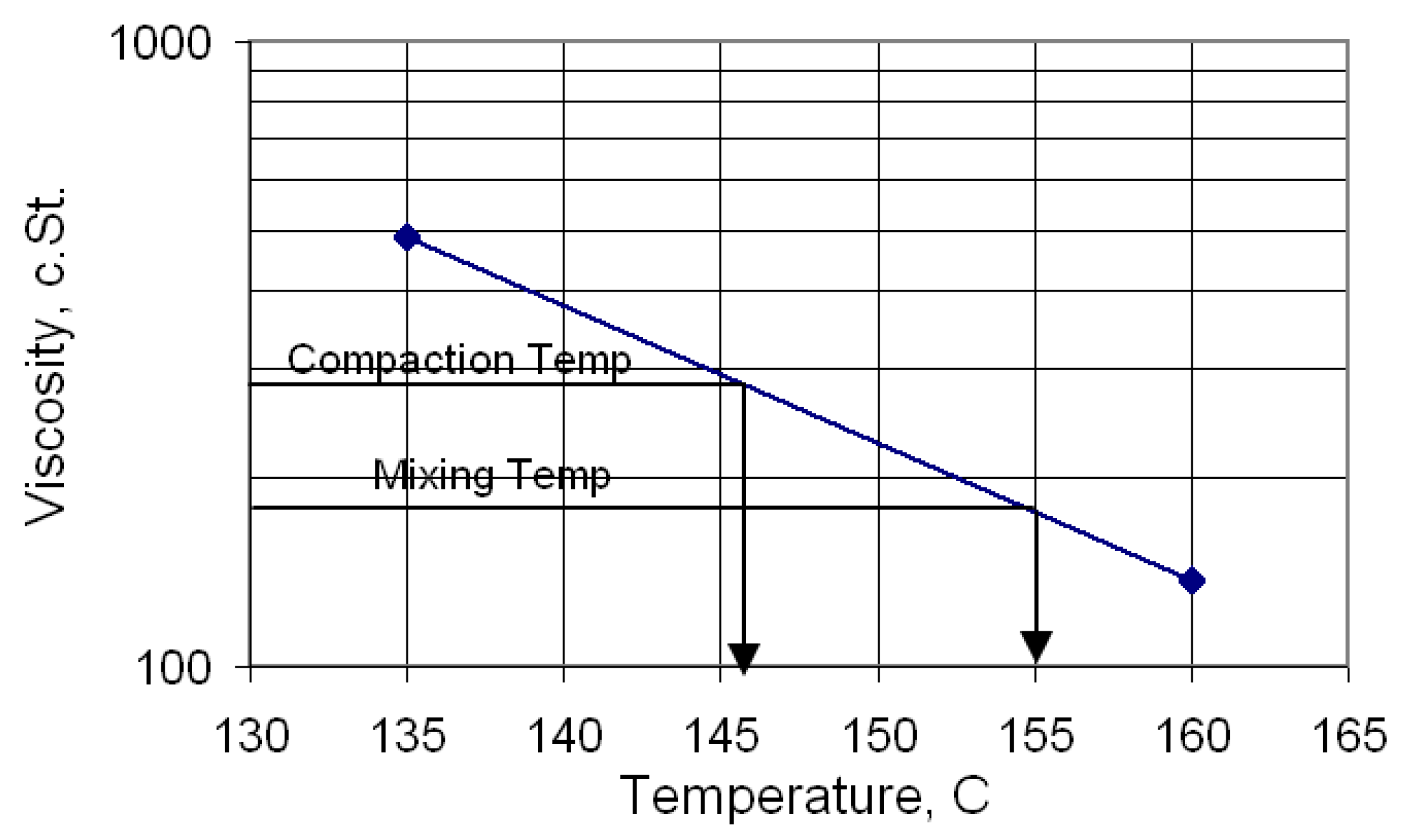

2.1.1. Asphalt Cement

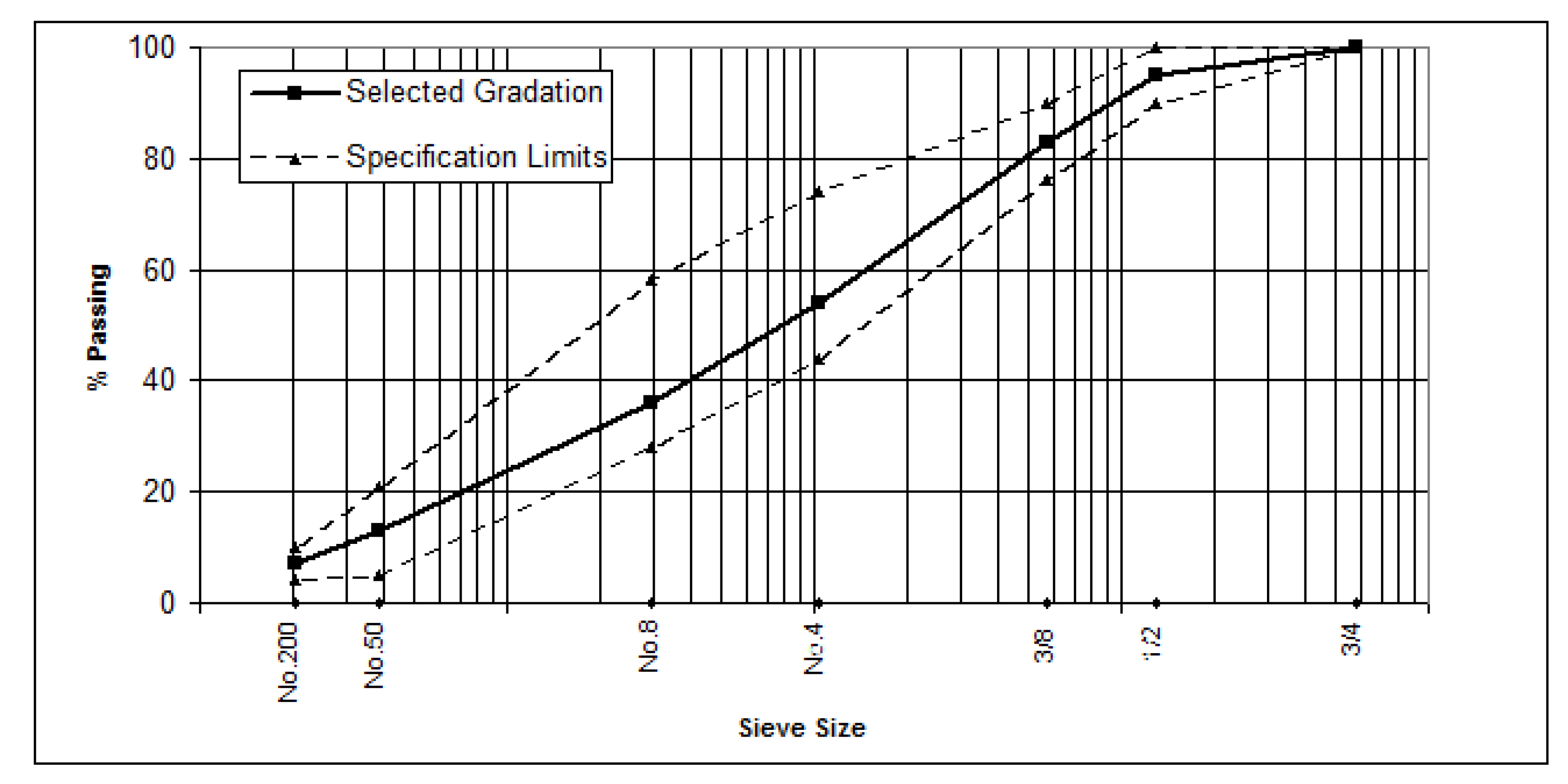

2.1.2. Aggregate

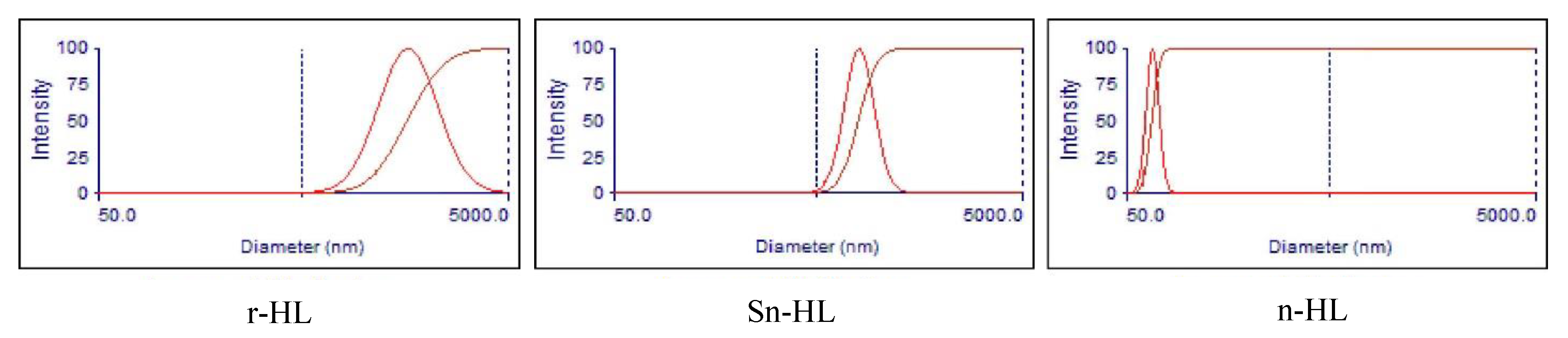

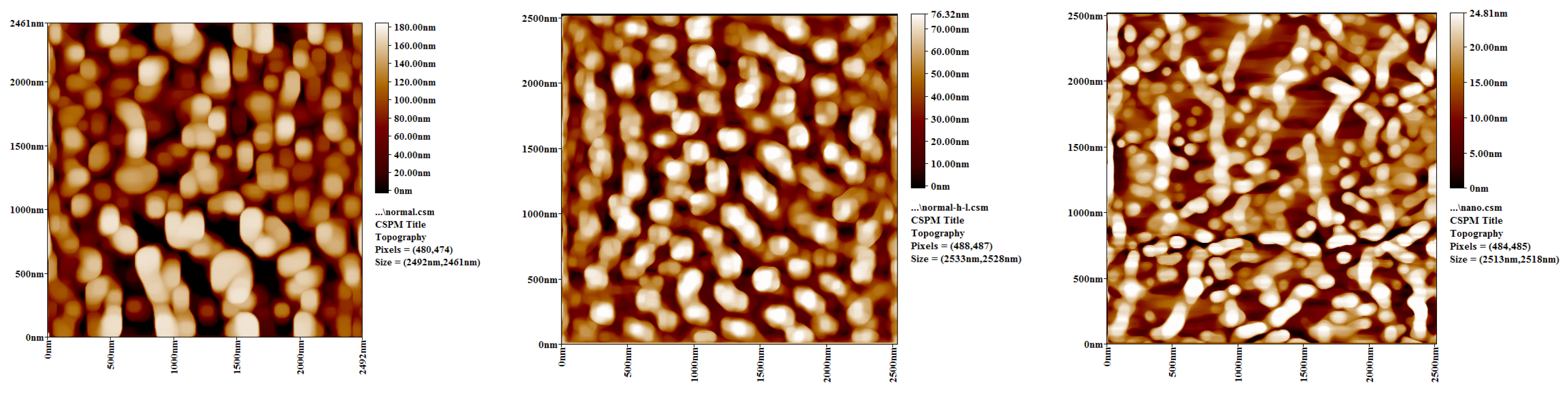

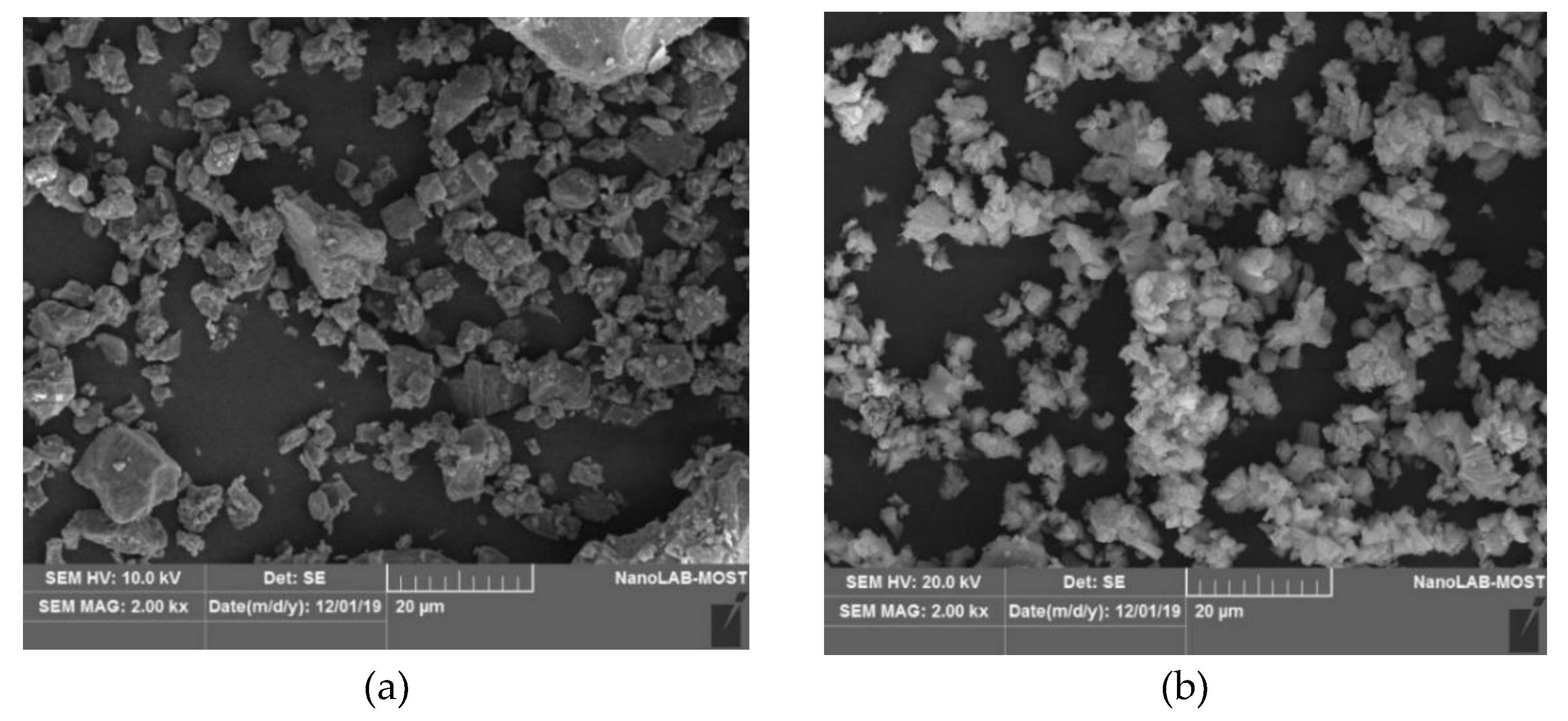

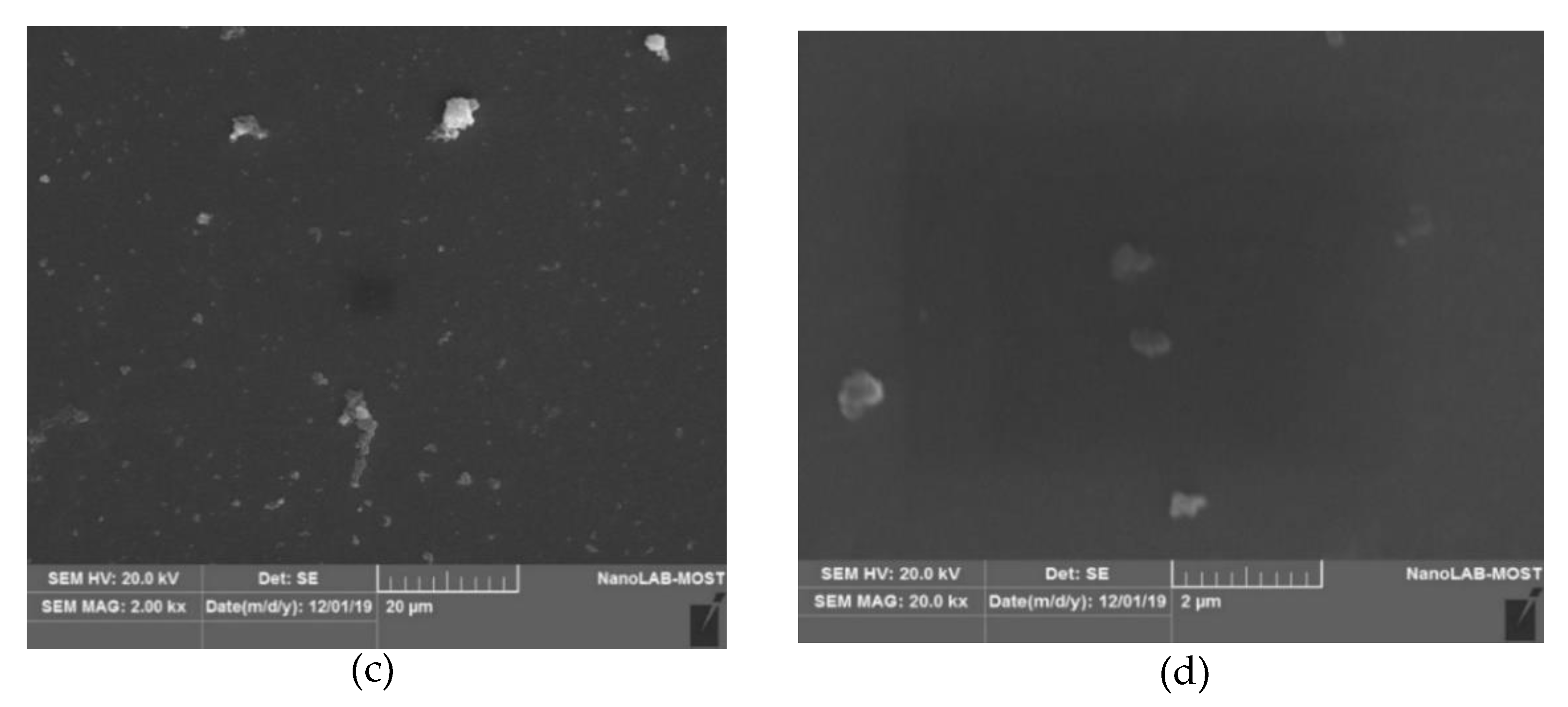

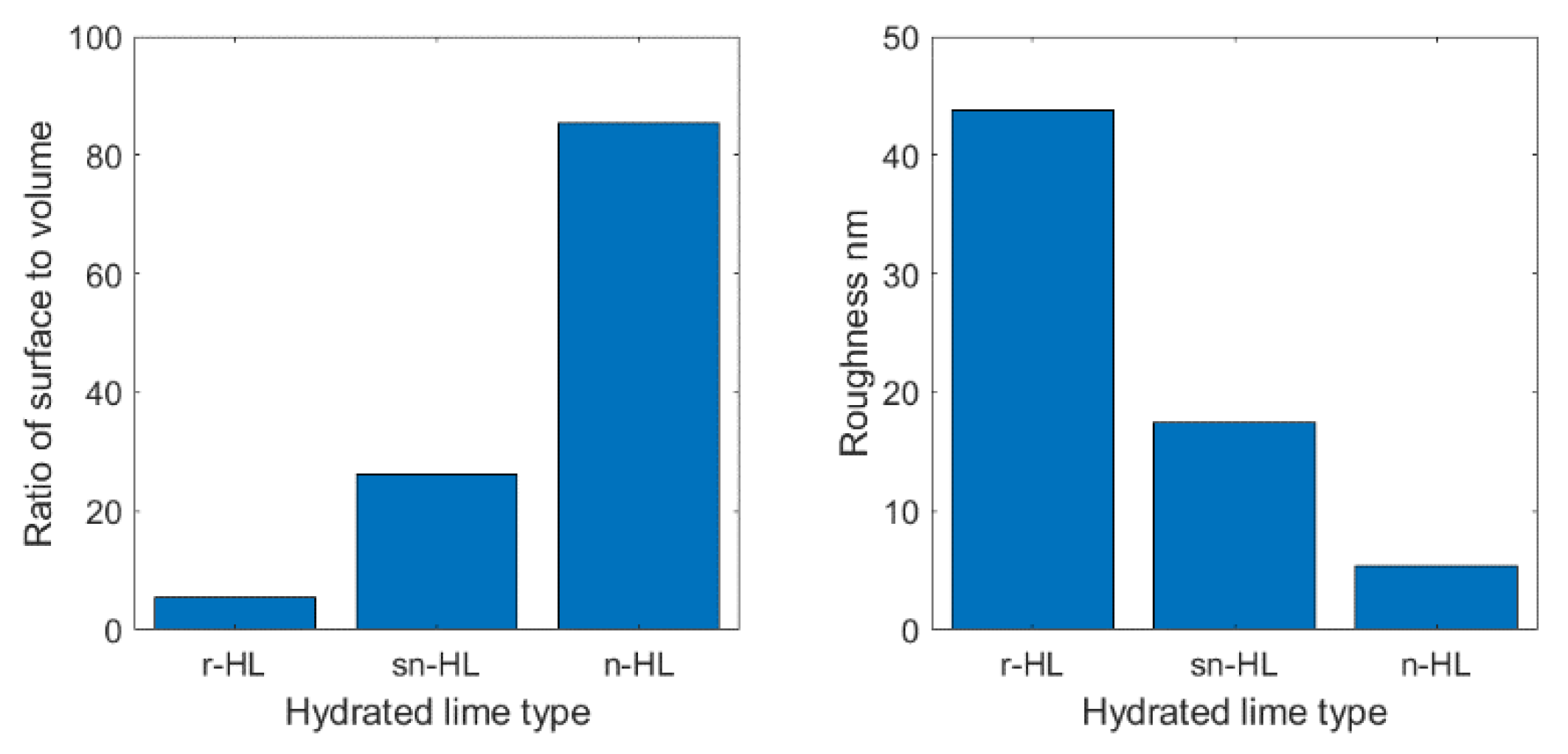

2.1.3. Filler

2.2. HL Addition

3. Experimental Tests

3.1. Marshall Properties

3.2. Indirect Splitting Tensile Strength

3.3. Uniaxial Compressive Deformation and Resilient Modulus

4. Results and Discussion

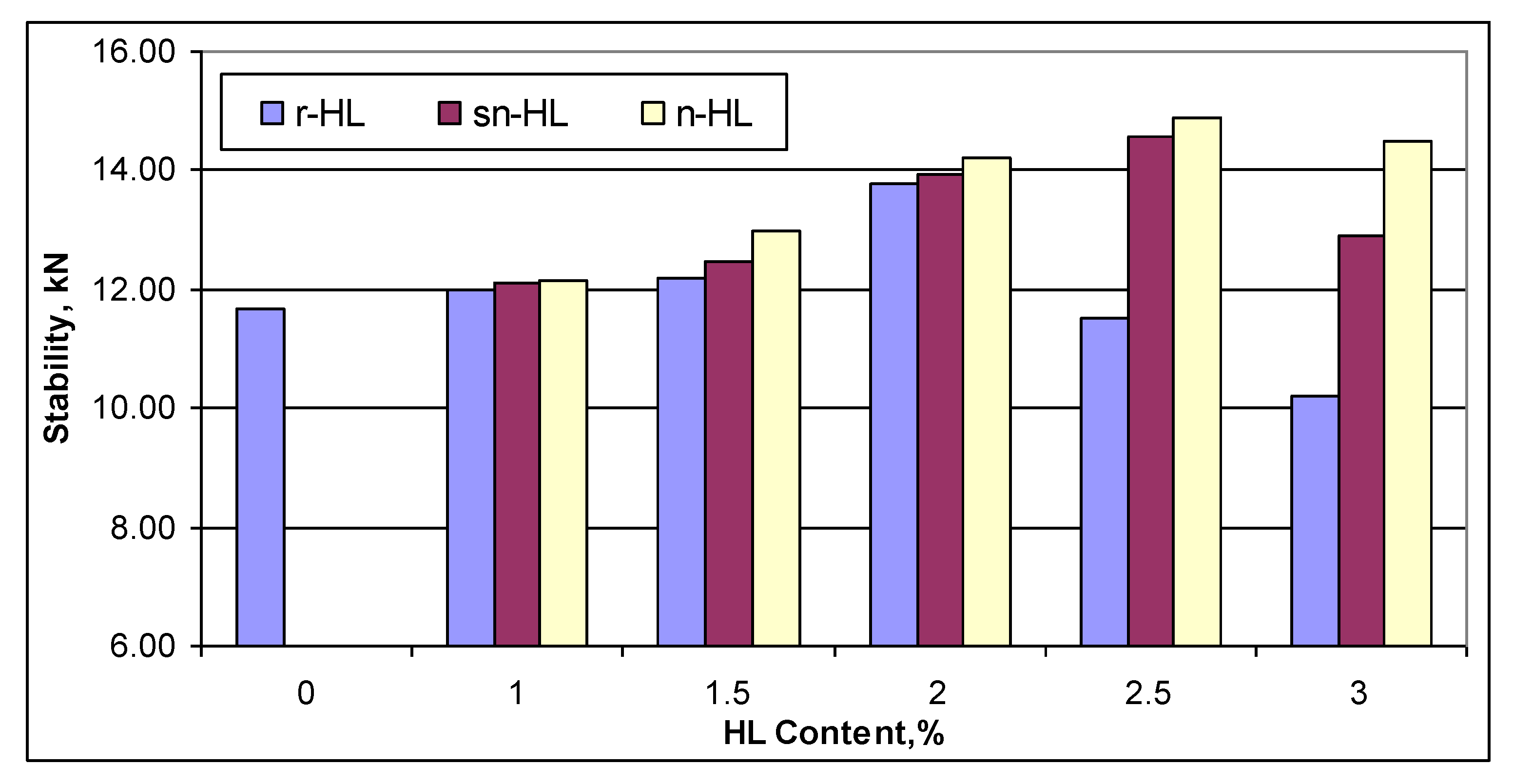

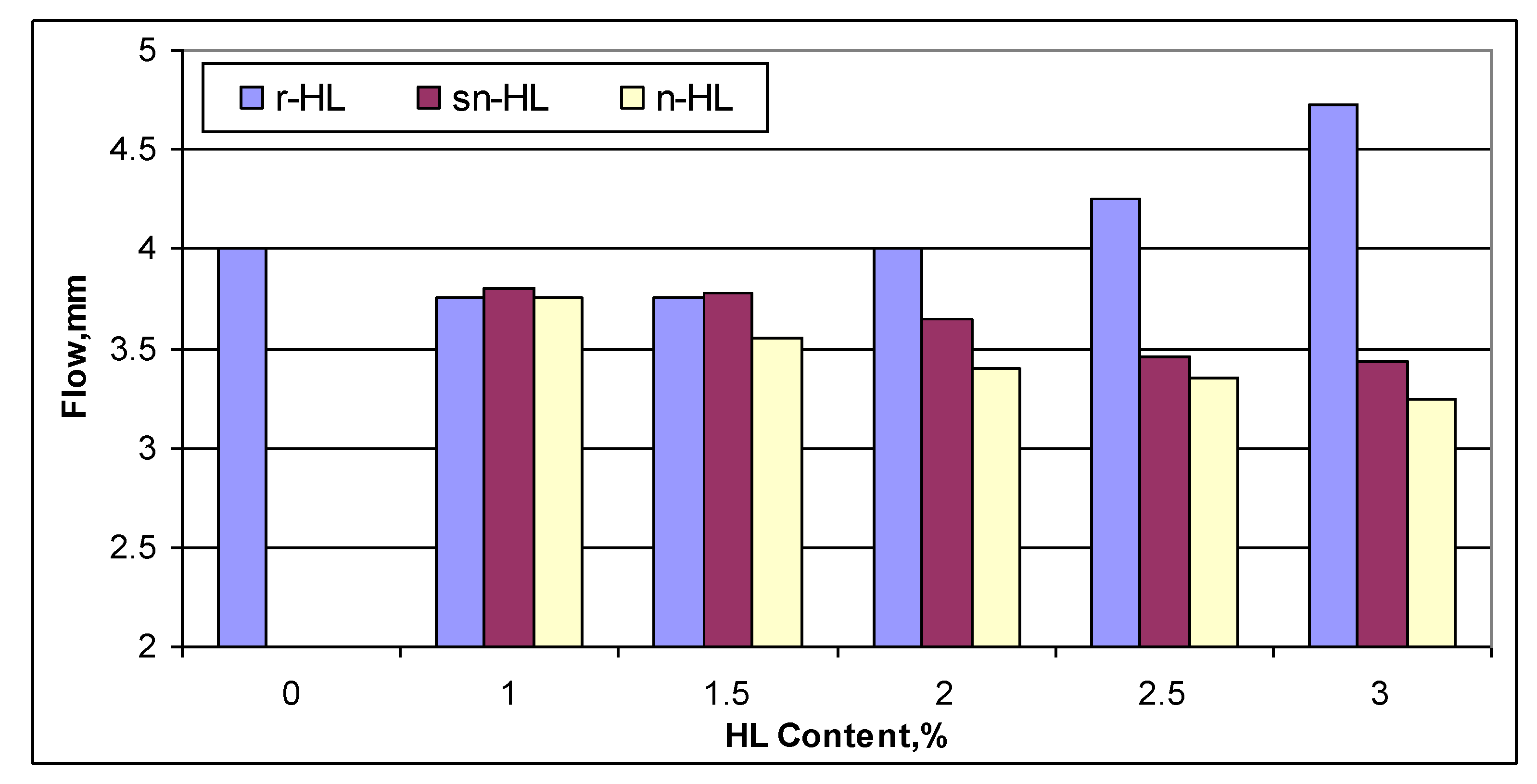

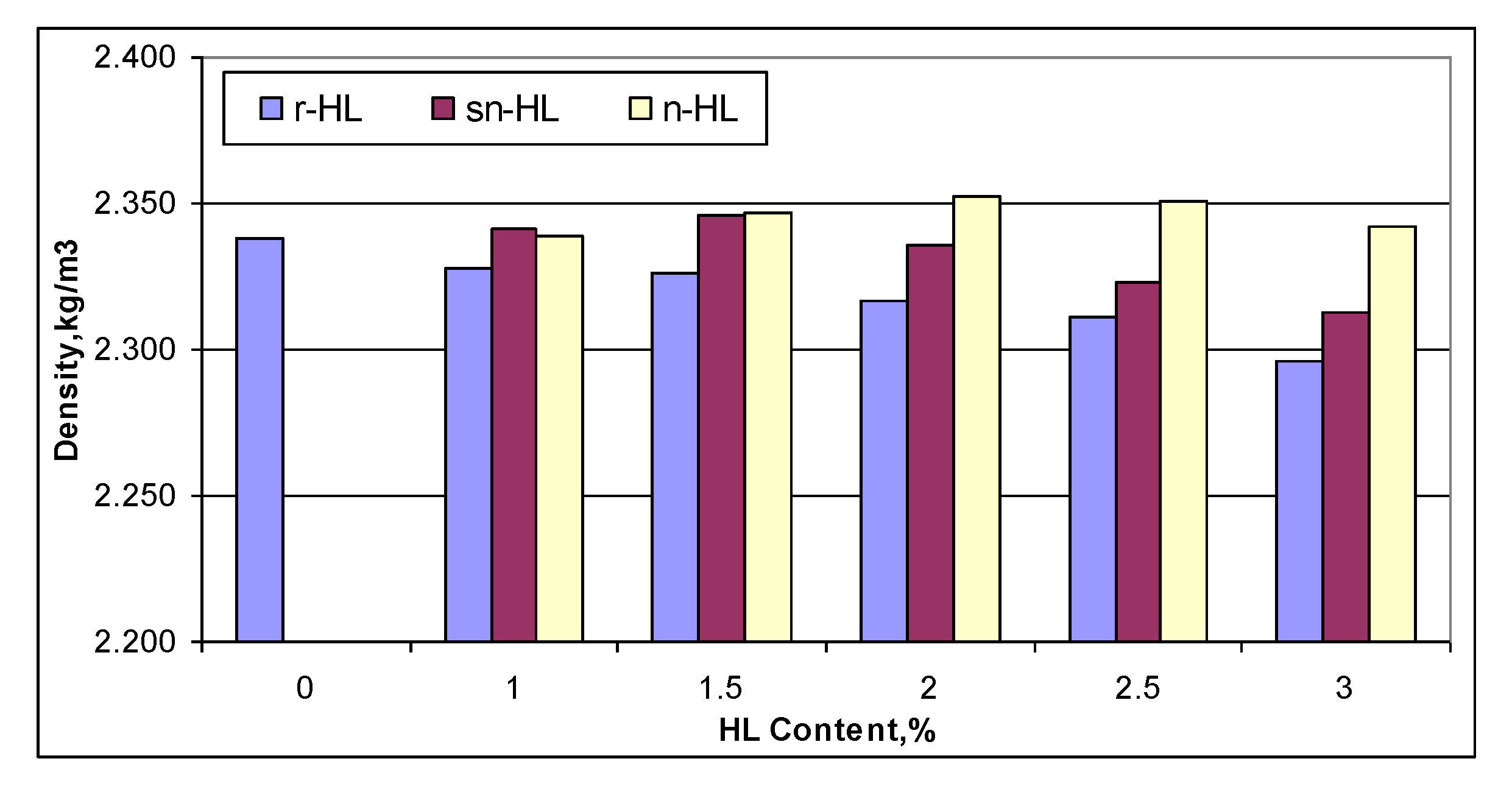

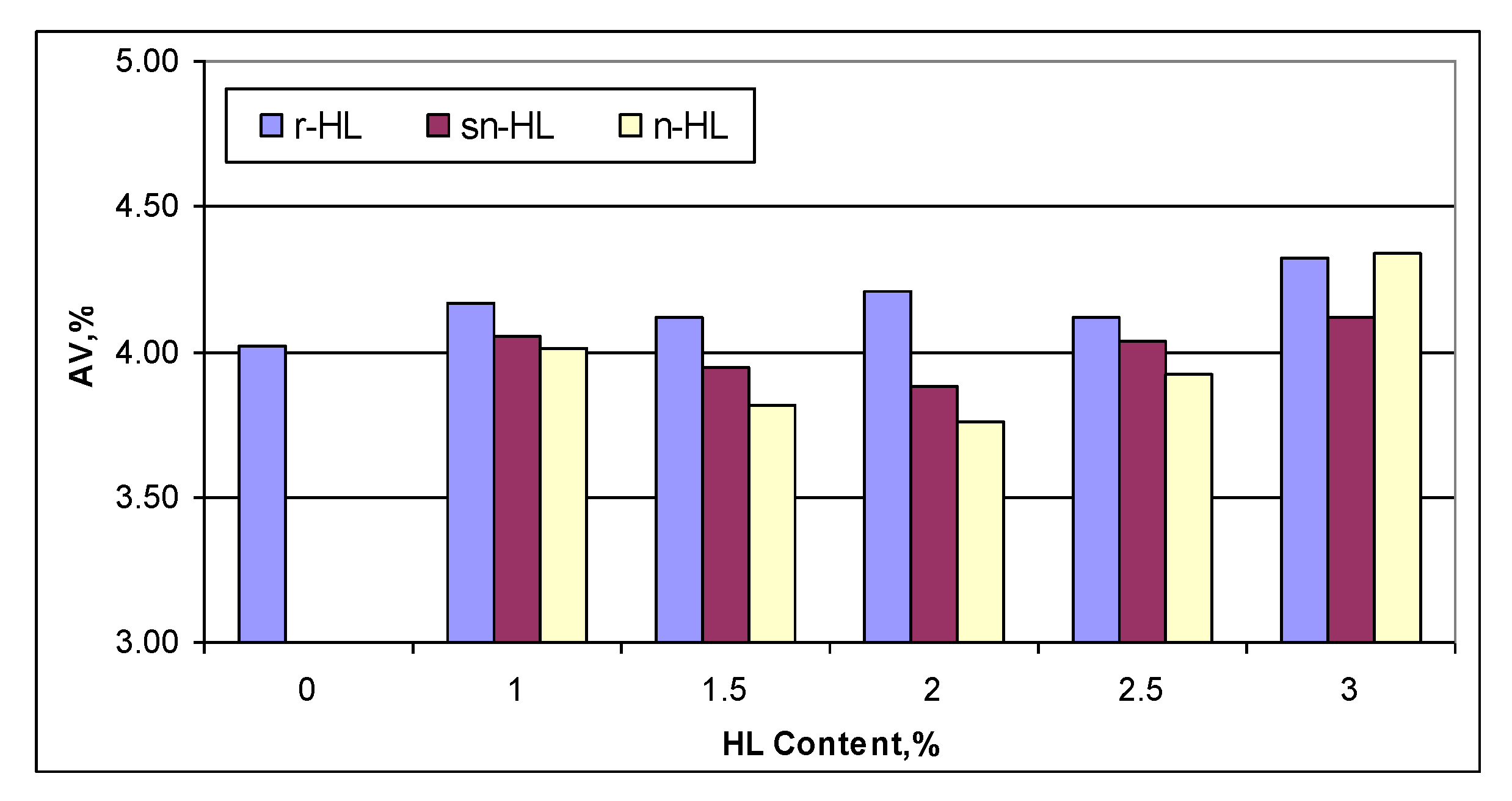

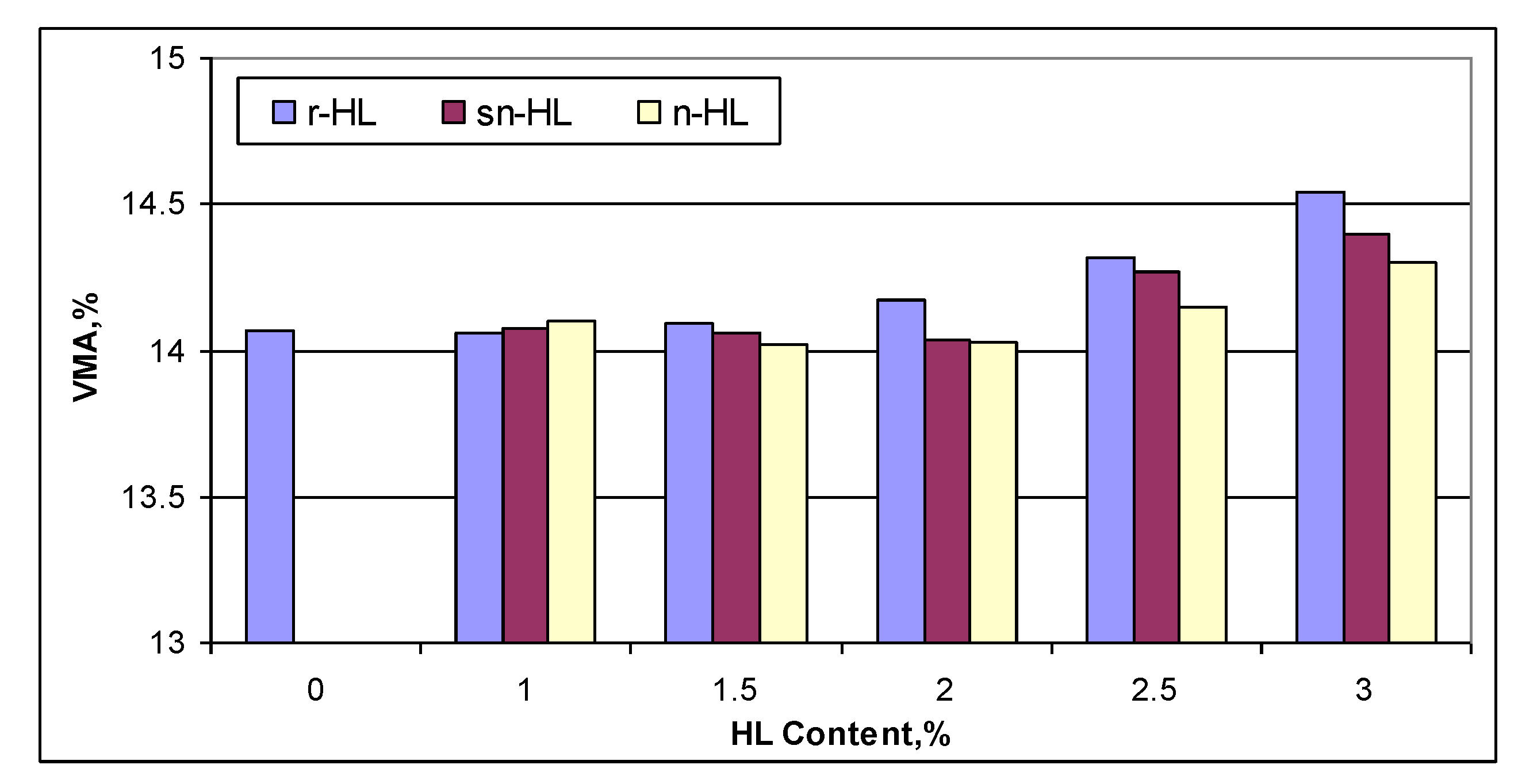

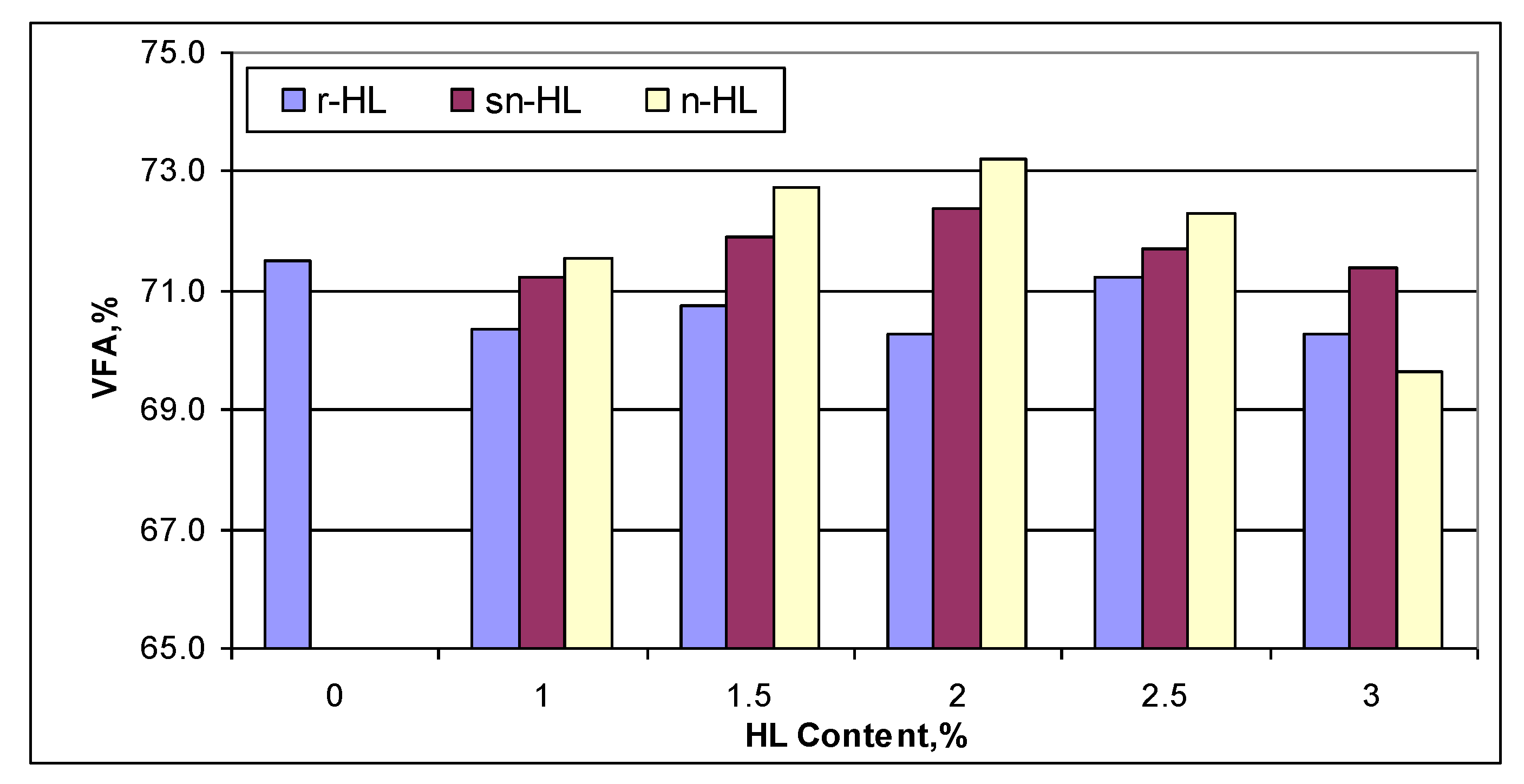

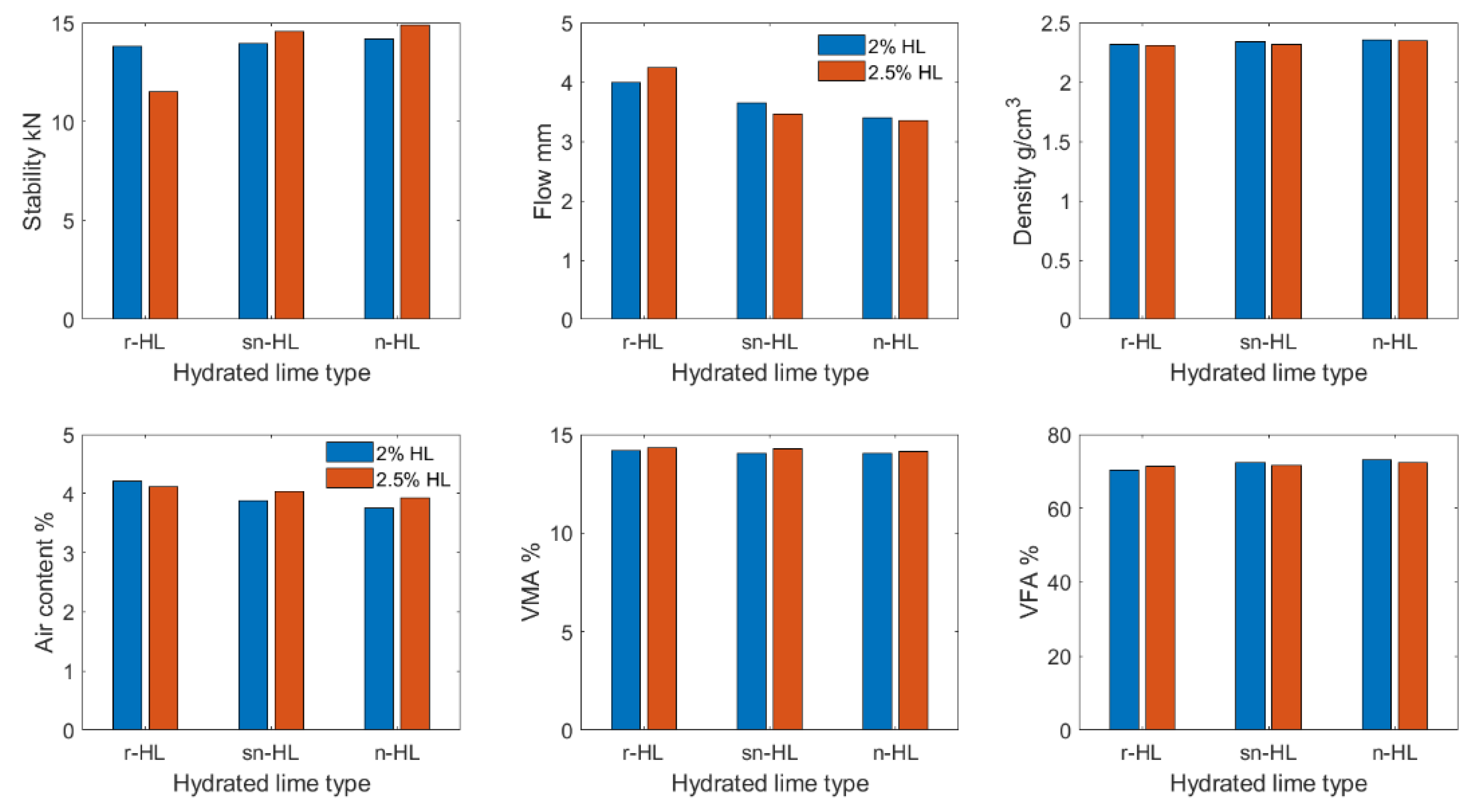

4.1. The HL Size Effect on Marshall Properties

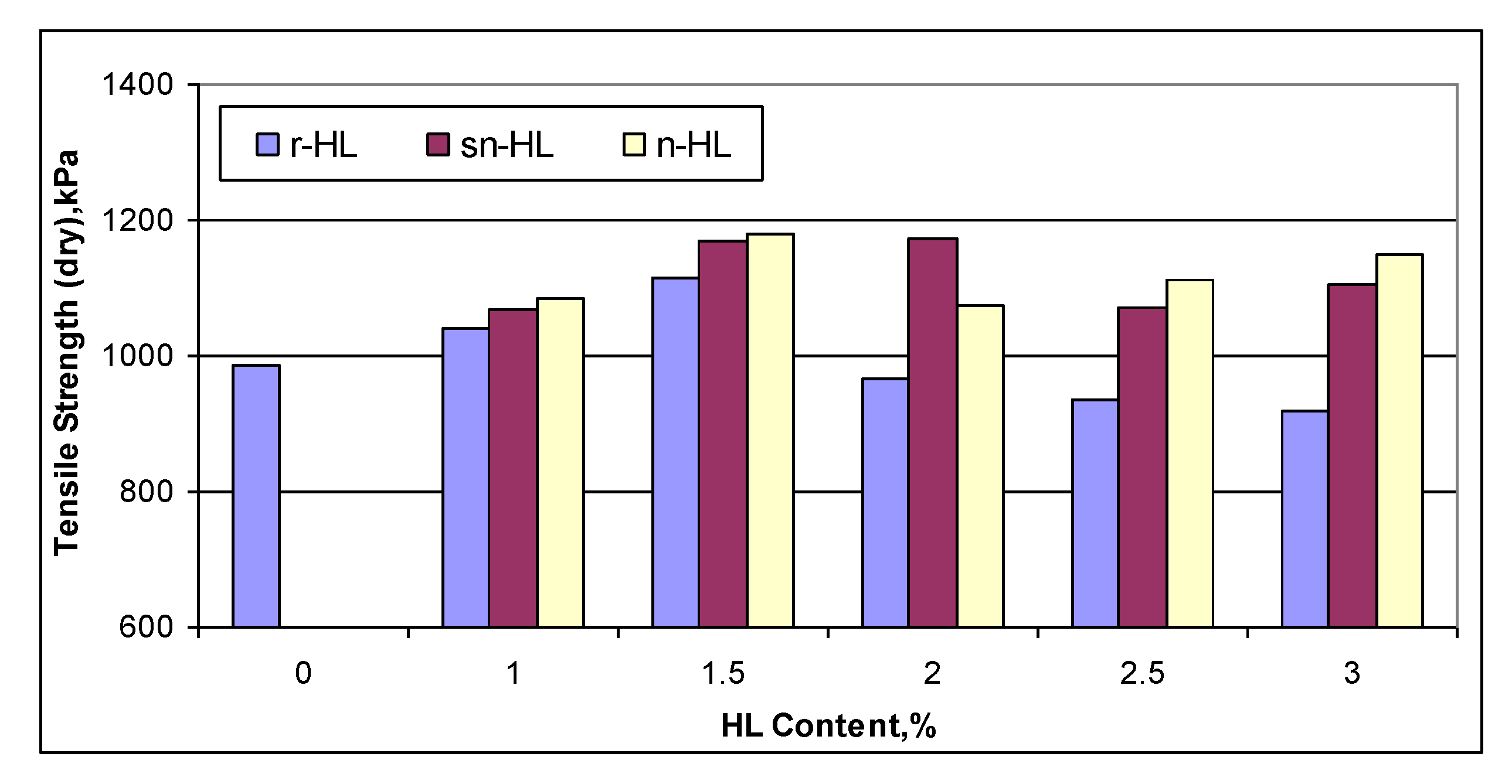

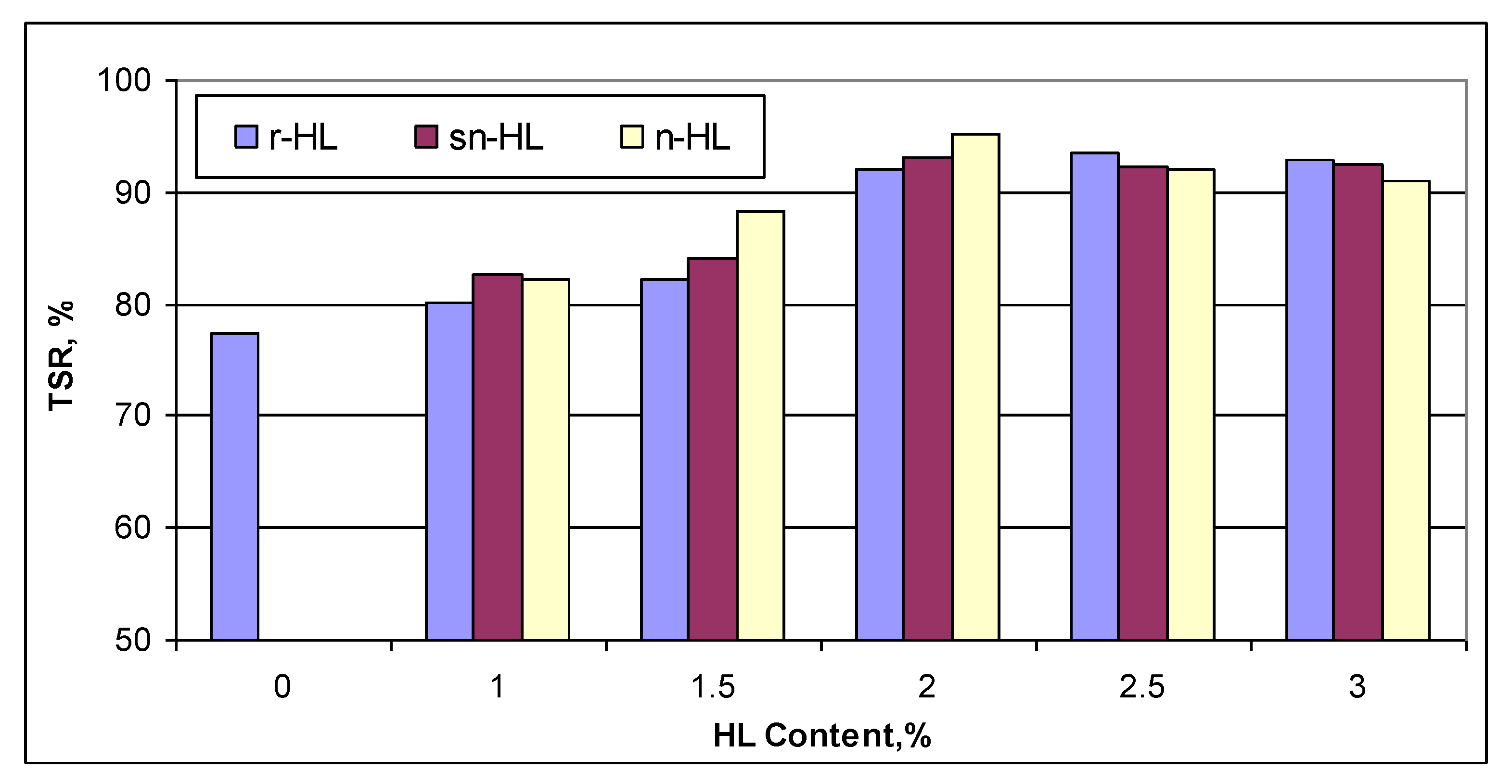

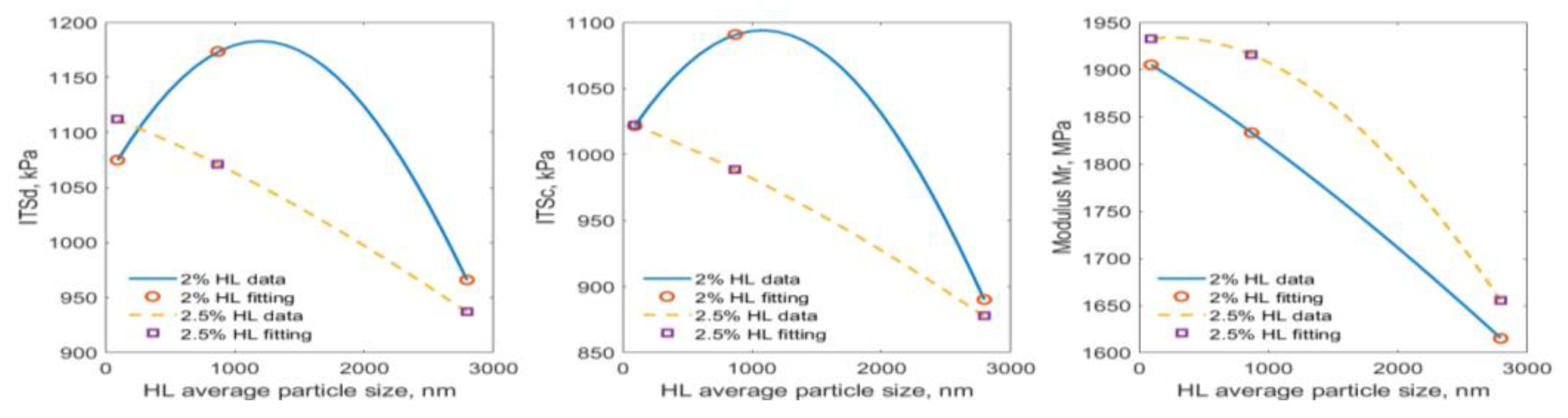

4.2. The HL Size Effect on Tensile Strength and Moisture Susceptibility

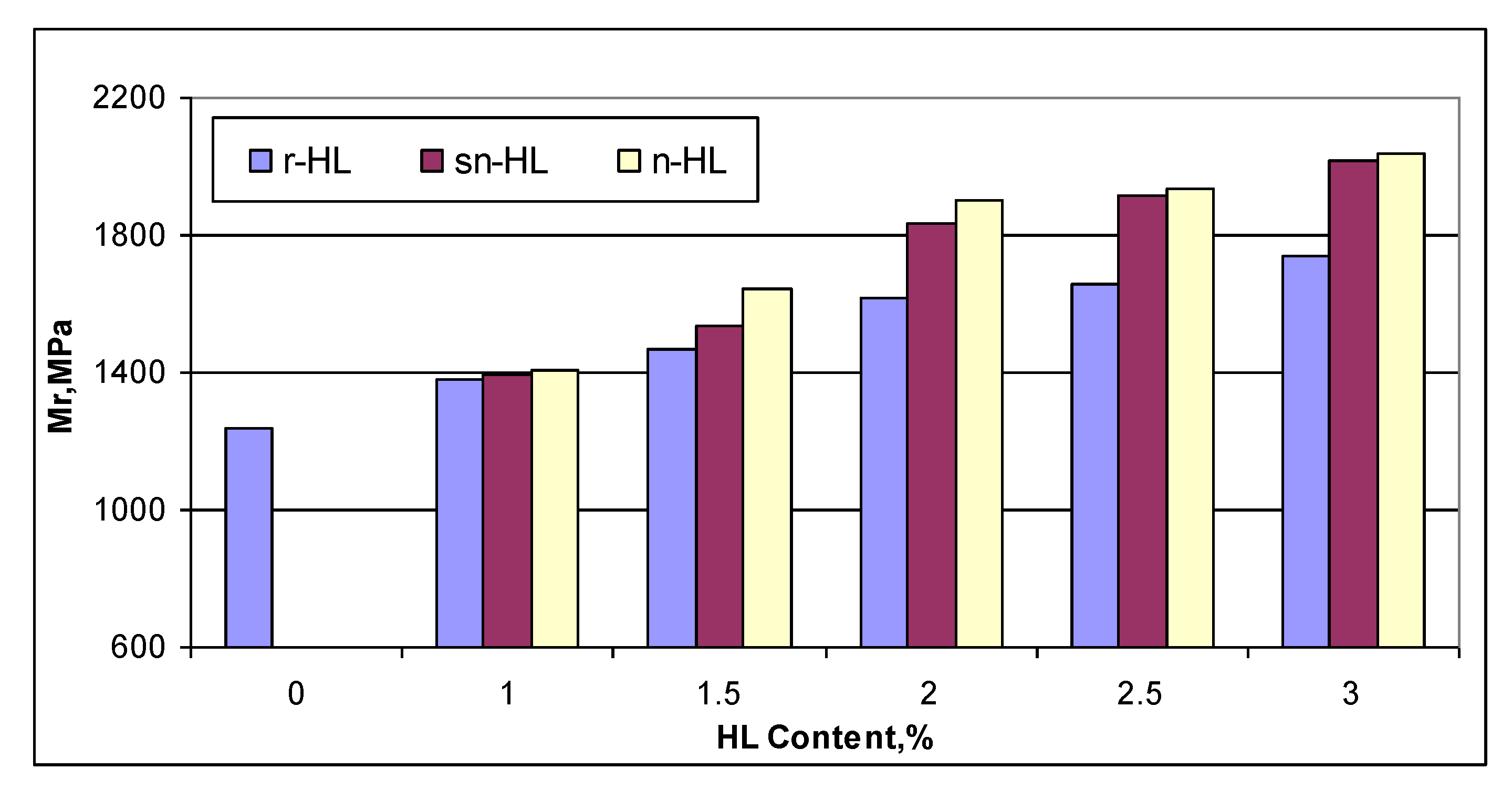

4.3. The HL Size Effect on Resilient Modulus (Mr)

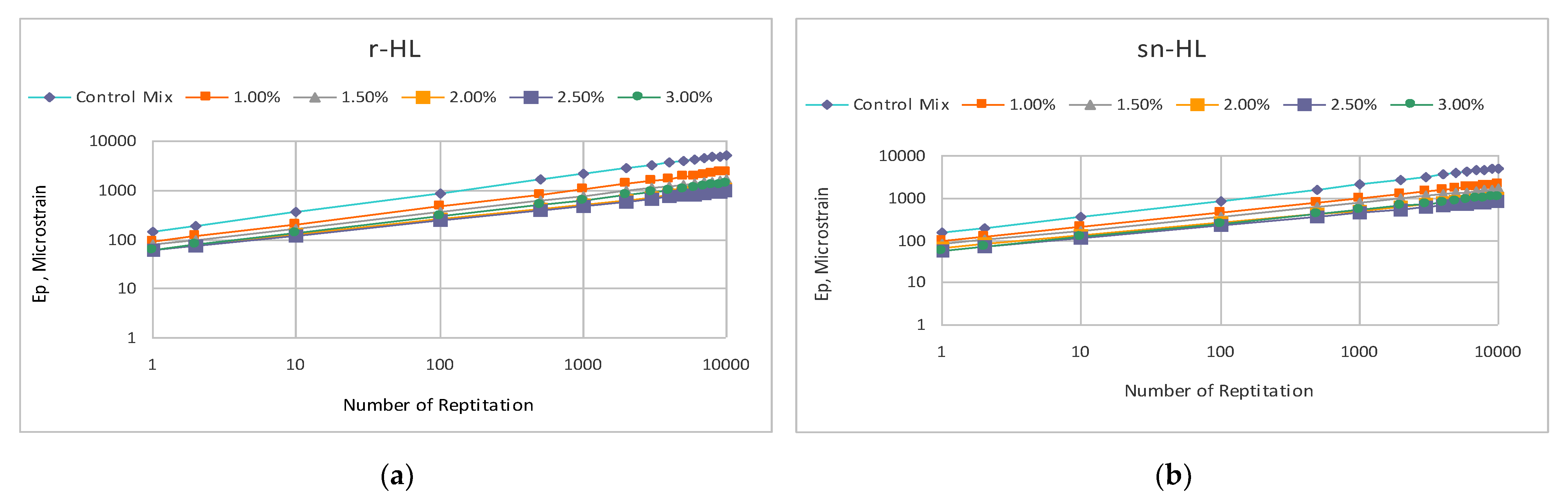

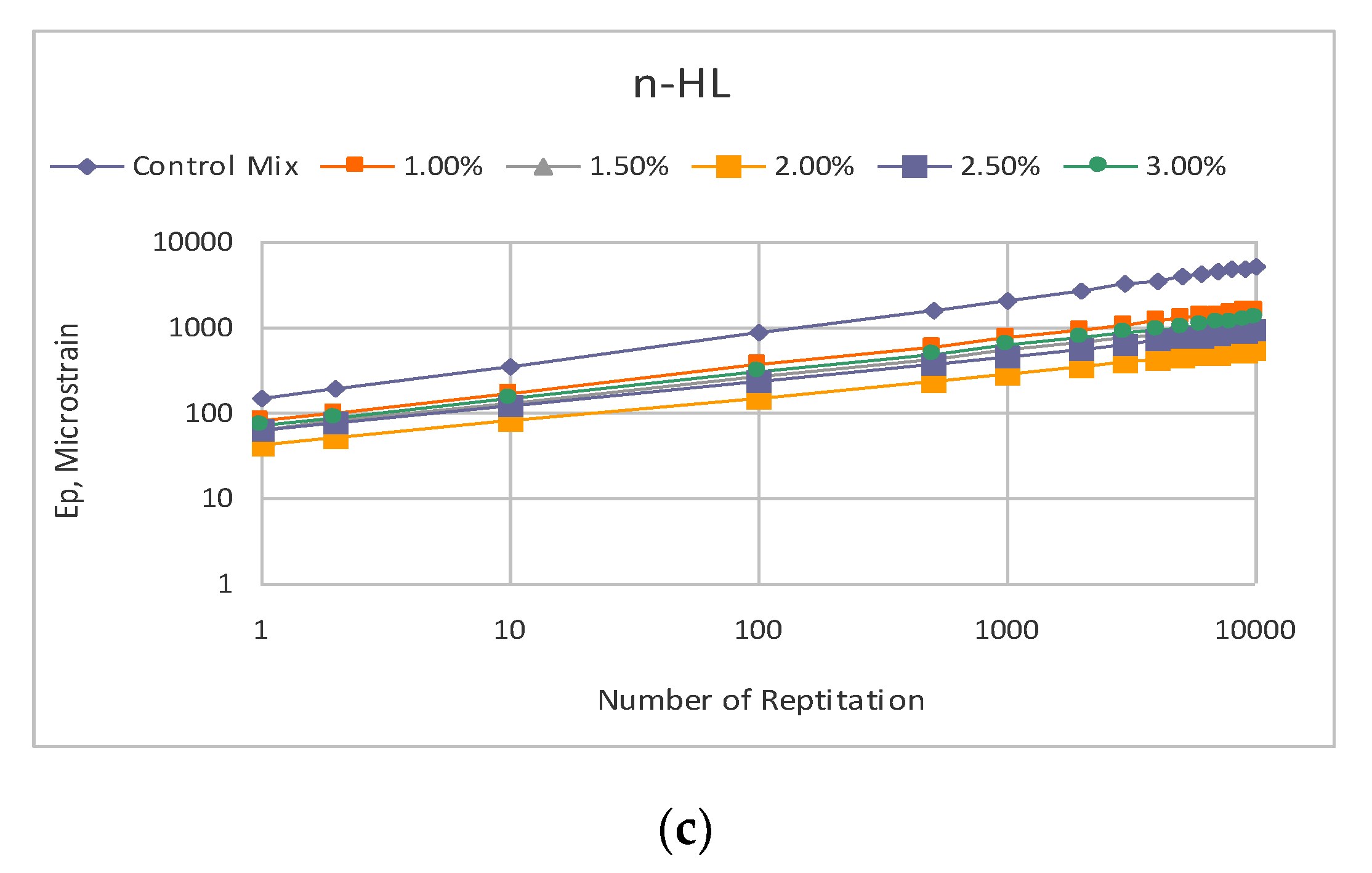

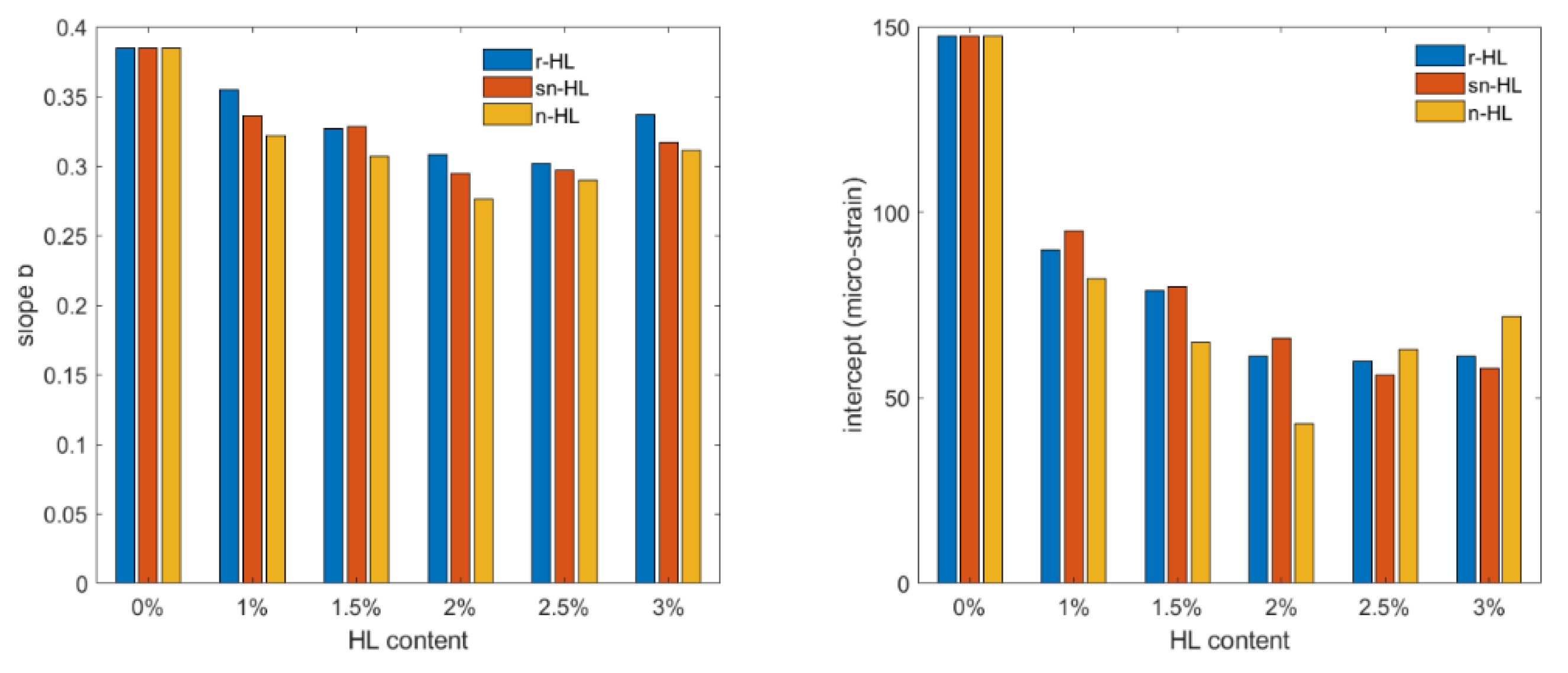

4.4. The HL Size Effect on Permanent Deformation

5. Conclusions

- The surface to volume ratio of the hydrated lime particles increases from regular size to the nano level, and, conversely, their roughness decreases.

- A positive correlation exists between several asphalt concrete mechanical properties and the fineness of hydrated lime particles.

- Using sub-nano-hydrated lime and nano-hydrated lime generates an optimum improvement on the Marshall properties and volumetric properties of the modified asphalt concrete at a content in 2~2.5%.

- The resilient modulus increases with HL addition, and decrease of the HL particle size. Up to 2% HL, the improvement rate are +250, +218.5 and +118 mPa for each 0.5 percent addition of n-HL, sn-HL and r-HL, respectively.

- When subjected to a repetitive loading, nano-hydrated lime asphalt concrete demonstrates the best rutting resistance performance with an optimum content at 2%. The sub-nano-hydrated lime mix shows a much higher deformation starting from initial load up to 10,000 repetitions, and its optimum content is 2.5%.

- The sub-nano-hydrated lime mix shows the best improvement in moisture susceptibility at 2% content, but this is marginal compared to nano-hydrated lime concrete. So overall, 2~2.5% replacement of the conventional mineral filler using nano-hydrated lime is proposed to be the optimum mix for the surface wearing course, from this study.

- A Gaussian characterization model well represents the HL size effect on asphalt concrete major mechanical properties. The model can be used in practice for pavement material and structural design for to optimize the targeted applications and cost.

6. Recommendations for Future Research

- The content and size effect of HL on the fatigue mode of failure for asphalt concrete;

- Life cycle cost analysis of the hot mix asphalt wearing course considering the content and size effect of HL.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Preti, F.; Accardo, C.; Gouveia, B.C.; Romeo, E.; Tebaldi, G. Influence of high-surface-area hydrated lime on cracking performance of open-graded asphalt mixtures. Road Mat. Pavement Des. 2021, 22, 2654–2660. [Google Scholar] [CrossRef]

- Lesueur, D.; Petit, J.; Ritter, H.J. The mechanisms of hydrated lime modification of asphalt mixtures: A state-of-the-art review. Road Mat. Pavement Des. 2013, 14, 1–16. [Google Scholar] [CrossRef]

- Sebaaly, P.E.; Little, D.N.; Epps, J.A. The Benefits of Hydrated Lime in Hot Mix Asphalt; Report Prepared for the National Lime Association, National Lime Associate: Arlington, VA, USA, 2006. [Google Scholar]

- Iwanski, M.M. Effect of Hydrated Lime on Indirect Tensile Stiffness Modulus of Asphalt Concrete Produced in Half-Warm Mix Technology. Materials 2020, 13, 4731. [Google Scholar] [CrossRef] [PubMed]

- Kakade, V.B.; Reddy, M.A.; Reddy, K.S. Rutting performance of hydrated lime modified bituminous mixes. Constr. Build. Mater. 2018, 186, 1–10. [Google Scholar] [CrossRef]

- Şengül, C.E.; Ayyildiz, D.; Iskender, E.; Aksoy, A. The Effect of Hydrated Lime Mixing Forms and Ratios on Performance in Asphalt Pavements. Tek. Dergi 2022, 33. [Google Scholar] [CrossRef]

- Al-Tameemi, A.F.; Wang, Y.; Albayati, A. Experimental study of the performance related properties of asphalt concrete modified with hydrated lime. J. Mater. Civ. Eng. 2016, 28, 04015185. [Google Scholar] [CrossRef]

- Al-Tameemi, A.F.; Wang, Y.; Albayati, A.; Haynes, J. Moisture Susceptibility and Fatigue Performance of Hydrated Lime–Modified Asphalt Concrete: Experiment and Design Application Case Study. J. Mater. Civ. Eng. 2019, 31, 04019019. [Google Scholar] [CrossRef] [Green Version]

- Zou, J.; Isola, M.; Roque, R.; Chun, S.; Koh, C.; Lopp, G. Effect of hydrated lime on fracture performance of asphalt mixture. Constr. Build. Mater. 2013, 44, 302–308. [Google Scholar] [CrossRef]

- Kim, S.; Shen, J.; Lee, S.; Kim, Y.; Kim, K.W. Examination of physical property degradation due to severe short-term ageing and effect of hydrated lime as antioxidant in asphalt mixture. Road Mater. Pavement Des. 2019, 20, 1638–1652. [Google Scholar] [CrossRef]

- Albayati, A.H. Mechanistic evaluation of lime-modified asphalt concrete mixtures. In RILEM International Conference on Cracking in Pavements, 7th ed.; Springer: Dordrecht, The Netherlands, 2012; pp. 921–940. [Google Scholar]

- McGennis, R.B.; Kennedy, T.W.; Machemehl, R.B. Stripping and Moisture Damage in Asphalt Mixtures; No. FHWA-TX-85-55+ 253-1 Interim Report; Transportation Research Board: Washington, DC, USA, 1984. [Google Scholar]

- Epps, J.; Berger, E.; Anagnos, J.N. Treatments in Moisture Sensitivity of Asphalt Pavements; Transportation Research Board: Washington, DC, USA, 2003. [Google Scholar]

- Taherkhani, H.; Tajdini, M. Comparing the effects of nano-silica and hydrated lime on the properties of asphalt concrete. Constr. Build. Mater. 2019, 218, 308–315. [Google Scholar] [CrossRef]

- Guo, W.; Guo, X.; Sun, M.; Dai, W. Evaluation of the durability and the property of an asphalt concrete with nano hydrophobic silane silica in spring-thawing season. Appl. Sci. 2018, 8, 1475. [Google Scholar] [CrossRef] [Green Version]

- Kavussi, A.; Barghabany, P. Investigating fatigue behavior of nanoclay and nanohydrated lime modified bitumen using LAS test. J. Mater. Civ. Eng. 2016, 28, 04015136. [Google Scholar] [CrossRef]

- Kavussi, A.; Barghabani, P. The influence of nano materials on moisture resistance of asphalt mixes. Study Civ. Eng. Archit. 2014, 3, 36–40. [Google Scholar]

- Ameri, M.; Kouchaki, S.; Roshani, H. Laboratory evaluation of the effect of nanoorganosilane anti-stripping additive on the moisture susceptibility of HMA mixtures under freeze-thaw cycles. Constr. Build. Mater. 2013, 48, 1009–1016. [Google Scholar] [CrossRef]

- Hassan, Z.; Hassan, D.; Rezvan, B.; Ali, A. Influence of bentonite additive on bitumen and asphalt mixture properties. World Acad. Sci. Eng. Technol. 2012, 6, 1534–1539. [Google Scholar]

- Razavi, S.H.; Kavussi, A. The role of nanomaterials in reducing moisture damage of asphalt mixes. Constr. Build. Mater. 2020, 239, 117827. [Google Scholar] [CrossRef]

- Al-Marafi, M.N. Effects of Hydrated Lime on Moisture Susceptibility of Asphalt Concrete. Adv. Sci. Technol. Res. J. 2021, 15, 13–17. [Google Scholar] [CrossRef]

- Behbahani, H.; Hamedi, G.H. Gilani, VNM Predictive model of modified asphalt mixtures with nano hydrated lime to increase resistance to moisture and fatigue damages by the use of deicing agents. Constr. Build. Mater. 2020, 265, 120353. [Google Scholar] [CrossRef]

- Cheng, J.; Shen, J.; Xiao, F. Moisture Susceptibility of Warm-Mix Asphalt Mixtures Containing Nanosized Hydrated Lime. J. Mater. Civ. Eng. 2011, 23, 1552–1559. [Google Scholar] [CrossRef]

- Shen, J.N.; Xie, Z.X.; Xiao, F.P.; Fan, W.Z. Evaluations of nano-sized hydrated lime on the moisture susceptibility of hot mix asphalt mixtures. Appl. Mech. Mater. 2012, 174, 82–90. [Google Scholar] [CrossRef]

- Huang, B.; Shu, X.; Dong, Q.; Shen, J. Laboratory evaluation of moisture susceptibility of hot-mix asphalt containing cementitious fillers. J. Mater. Civ. Eng. 2010, 22, 667–673. [Google Scholar] [CrossRef]

- SCRB/R9; General Specification for Roads and Bridges, Section R/9, Hot-Mix Asphalt Concrete Pavement, Revised Edition. State Corporation of Roads and Bridges, Ministry of Housing and Construction: Baghdad, Iraq, 2003.

- Ahmed, M.M. Effect of Lime on Performance Related Properties of Asphalt Concrete Mixture. Master’s Thesis, University of Baghdad, Baghdad, Iraq, 2013. [Google Scholar]

- Albayati, A.; Wang, Y.; Wang, Y.; Haynes, J. A sustainable pavement concrete using warm mix asphalt and hydrated lime treated recycled concrete aggregates. Sustain. Mater. Technol. 2018, 18, e00081. [Google Scholar] [CrossRef]

- Albayati, A.H. Permanent Deformation Prediction of Asphalt Concrete Under Repeated Loading. Master’s Thesis, University of Baghdad, Baghdad, Iraq, 2006. [Google Scholar]

- Barksdale, R.D. Laboratory evaluation of rutting in base course materials. In Proceedings of the Third International Conference on the Structural Design of Asphalt Pavements, Grosvenor House, Park Lane, London, UK, 11–15 September 1972. [Google Scholar]

- Monismith, C.L.; Ogawa, N.; Freeme, C.R. Permanent deformation characteristics of subgrade soils due to repeated loading. In Proceedings of the 54th Annual Meeting of the Transportation Research Record, Washington, DC, USA, 13–17 January 1975. [Google Scholar]

- Johansson, L.S. Bitumen Ageing and Hydrated Lime; TRITA-IP FR, Issue Number: 98-38; Kungliga Tekniska Hoegskolan, Institutionen Foer Infrastruktur Och Lanering: Stockholm, Sweden, 2000. [Google Scholar]

- Albayati, A.H. Performance evaluation of plant produced warm mix asphalt. J. Eng. 2018, 24, 145–164. [Google Scholar] [CrossRef]

- Albayati, A.H.; Mohammed, A.M. Effect of Lime Addition Methods on Performance Related Properties of Asphalt Concrete Mixture. J. Eng. 2016, 22, 1–20. [Google Scholar]

| Binder Condition | Parameters | Test Temperature °C | Measurement Data | Specification (AASHTO M320-05) |

|---|---|---|---|---|

| Original | Flash Point, °C | - | 298 | 230, min |

| Viscosity, Pa.s | 135- | 0.487 | 3, max | |

| DSR, G/sinδ at 10 rad/s, kPa | 58 | 3.3522 | 1.00, min | |

| 64 | 2.020 | |||

| 70 | 0.889 * | |||

| RTFO Aged | Mass Loss, % | - | 0.654 | 1%, max |

| DSR, G/sinδ at 10 rad/s, kPa | 58 | 4.1596 | 2.2, min | |

| 64 | 3.1483 | |||

| 70 | 1.9809 * | |||

| PAV Aged | DSR, G.sinδ at 10 rad/s, kPa | 28 | 4684 | 5000, max |

| 25 | 6477 * | |||

| BBR, Creep Stiffness, mPa | −6 | 134.0 | 300, max |

| Property | ASTM Design | Test Results | SCRB Specification |

|---|---|---|---|

| Coarse aggregate | |||

| Bulk specific gravity | C-127 | 2.646 | - |

| Apparent specific gravity | 2.656 | - | |

| Water absorption (%) | - | 0.14 | - |

| Percent wear by Los Angeles abrasion (%) | C-131 | 19.7 | 30 max |

| Soundness loss by sodium sulfate solution (%) | C-88 | 3.4 | 12 max |

| Flat and elongated (5:1) (%) | D4791 | 4 | 10 max |

| Fractured pieces (%) | D5821 | 97 | 90 min |

| Fine aggregate | |||

| Bulk specific gravity | C-128 | 2.561 | - |

| Apparent specific gravity | 2.612 | - | |

| Water absorption (%) | 0.782 | - | |

| Sand equivalent (%) | D2419 | 55 | 45 min |

| Clay lump and friable particles (%) | C-142 | 1.3 | 3 max. |

| Chemical Composition, % | ||||||

|---|---|---|---|---|---|---|

| CaO | SiO2 | Al2O3 | MgO | Fe2O3 | SO3 | L.O.I |

| 29 | 10 | 6 | 16 | 1 | 0.12 | 37 |

| Physical Properties | ||||||

| Specific Gravity | Surface Area * (m2/kg) | Passing Sieve No. 200 (0.075) % | ||||

| 2.84 | 247 | 95 | ||||

| Chemical Composition, % | ||||||

|---|---|---|---|---|---|---|

| CaO | SiO2 | Al2O3 | MgO | Fe2O3 | SO3 | L.O.I |

| 69.5 | 1.0 | - | 2.0 | - | 150 | 26 |

| HL Content, % | |||||||

|---|---|---|---|---|---|---|---|

| 0 | 1.0 | 1.5 | 2.0 | 2.5 | 3.0 | ||

| HL type | r-HL | 5130 | 2364 | 1617 | 1051 | 970 | 1364 |

| sn-HL | 2098 | 1585 | 1183 | 863 | 1075 | ||

| n-HL | 1592 | 1099 | 546 | 911 | 1263 | ||

| Mix | Property | a | b | c |

|---|---|---|---|---|

| 2% HL | ITSd | 1183 | 1195 | 3552 |

| ITSc | 1094 | 1081 | 3773 | |

| Mr | 2073 | −3664 | 1.293 × 104 | |

| 2.5% HL | ITSd | 1174 | −2518 | 1.118 × 104 |

| ITSc | 1077 | −2665 | 1.206 × 104 | |

| Mr | 1934 | 244.2 | 6462 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Albayati, A.; Wang, Y.; Haynes, J. Size Effect of Hydrated Lime on the Mechanical Performance of Asphalt Concrete. Materials 2022, 15, 3715. https://doi.org/10.3390/ma15103715

Albayati A, Wang Y, Haynes J. Size Effect of Hydrated Lime on the Mechanical Performance of Asphalt Concrete. Materials. 2022; 15(10):3715. https://doi.org/10.3390/ma15103715

Chicago/Turabian StyleAlbayati, Amjad, Yu Wang, and Jonathan Haynes. 2022. "Size Effect of Hydrated Lime on the Mechanical Performance of Asphalt Concrete" Materials 15, no. 10: 3715. https://doi.org/10.3390/ma15103715

APA StyleAlbayati, A., Wang, Y., & Haynes, J. (2022). Size Effect of Hydrated Lime on the Mechanical Performance of Asphalt Concrete. Materials, 15(10), 3715. https://doi.org/10.3390/ma15103715