Influence of Different Welding Parameters on the Morphology, Microstructure, and Mechanical Properties of 780 Duplex-Phase Steel Laser Lap Welded Joint

Abstract

:1. Introduction

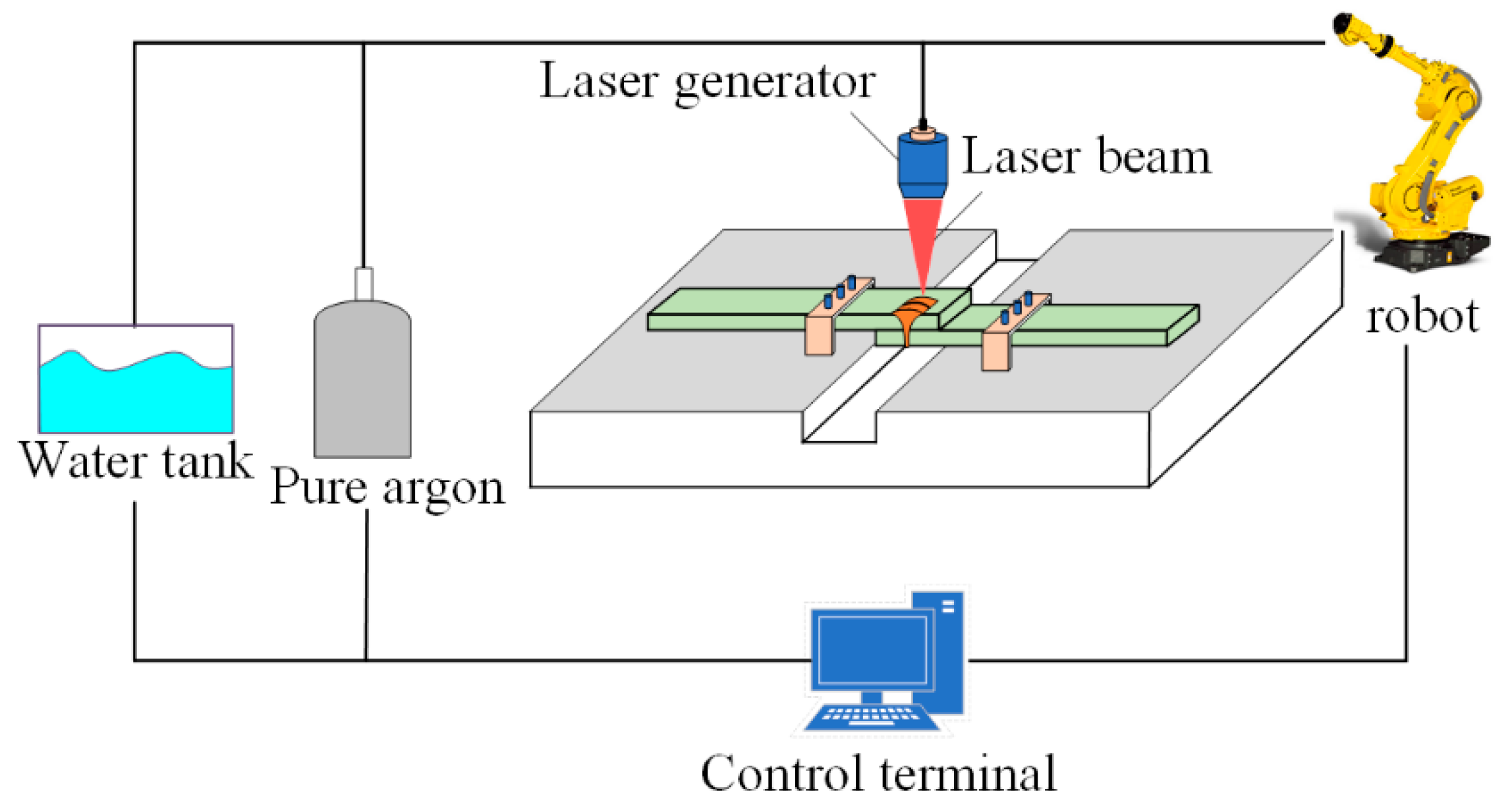

2. Materials and Methods

2.1. Materials and Welding Procedure

2.2. Experimental Procedure

3. Results and Discussion

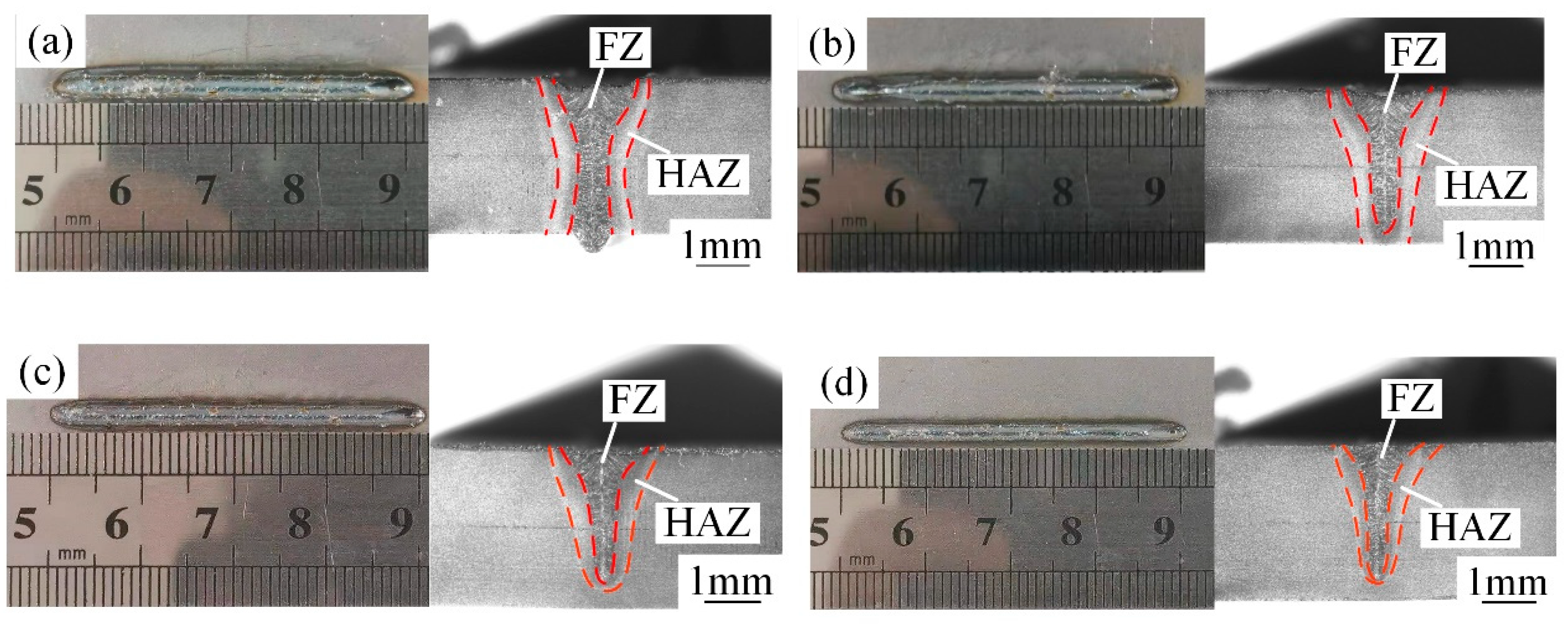

3.1. The Influence of Welding Process on the Morphology of Weld

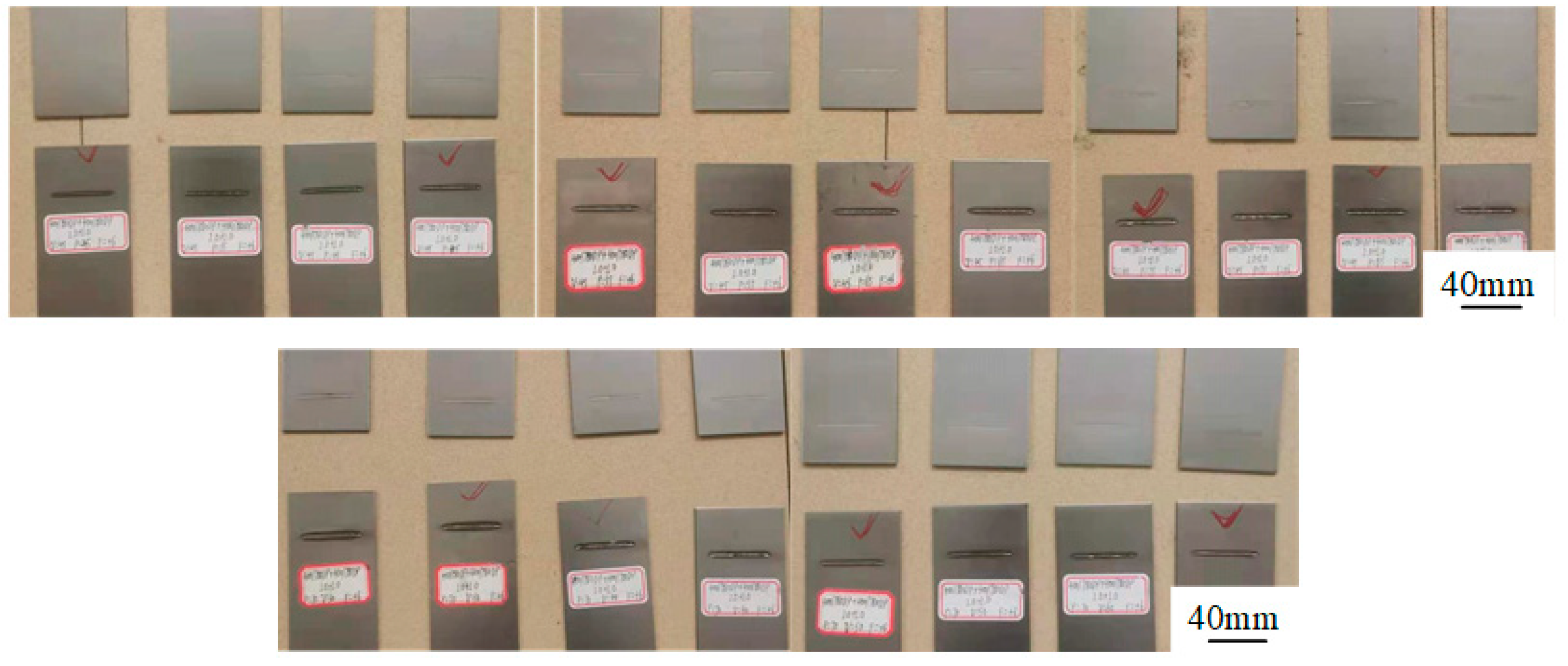

3.1.1. The Influence of Welding Speeds on the Morphology of Weld

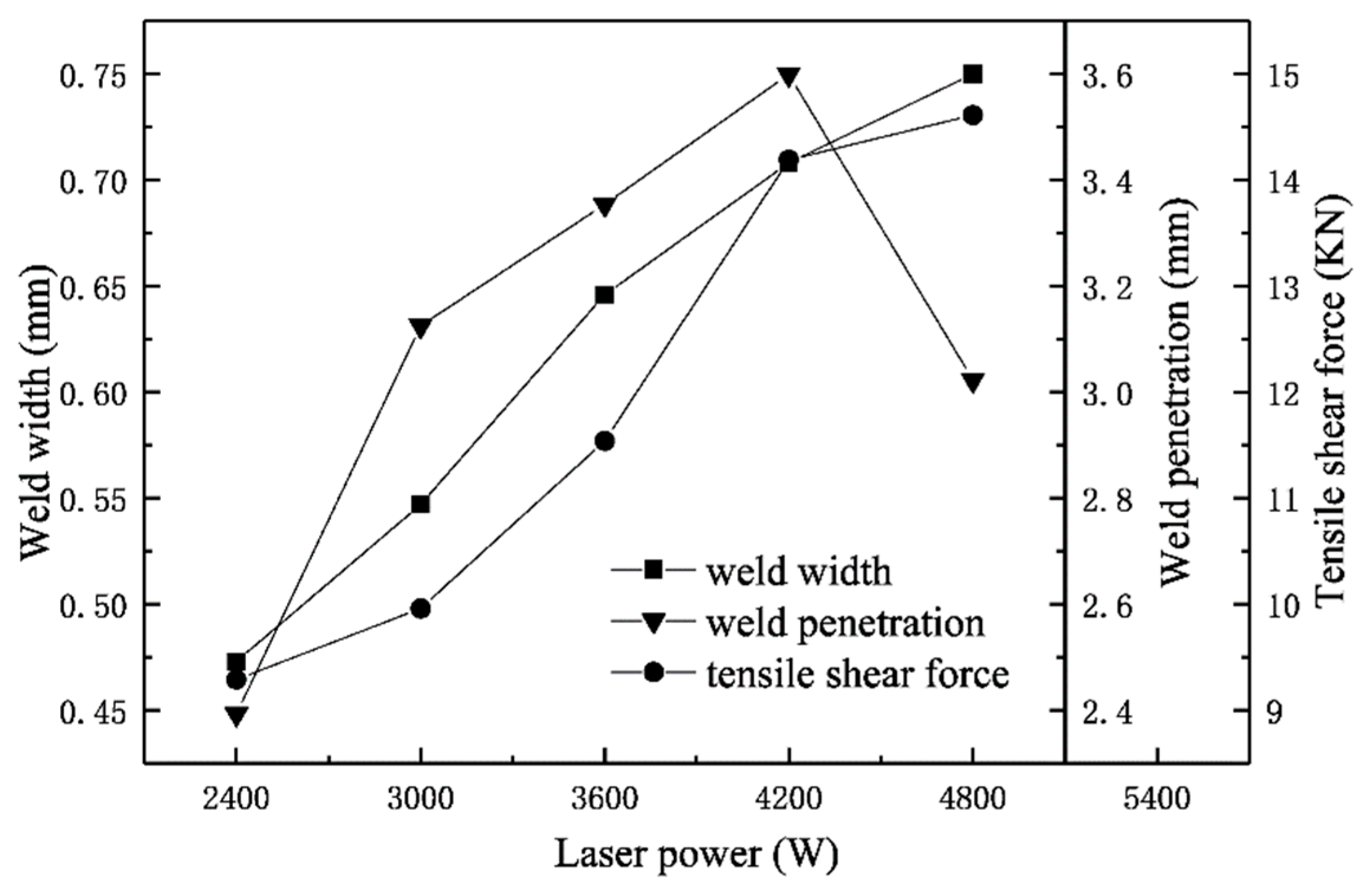

3.1.2. The Influence of Laser Power on the Morphology of Weld

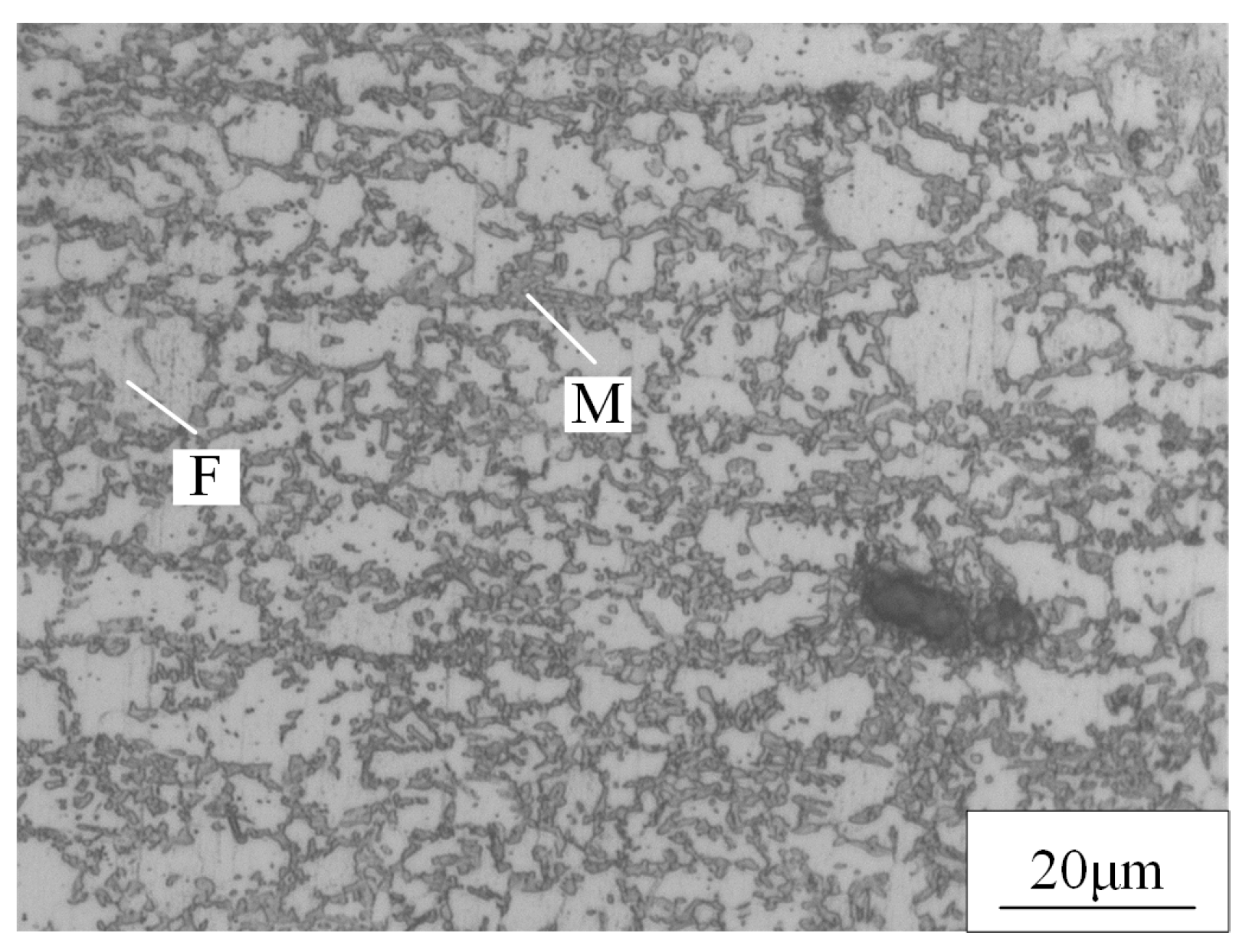

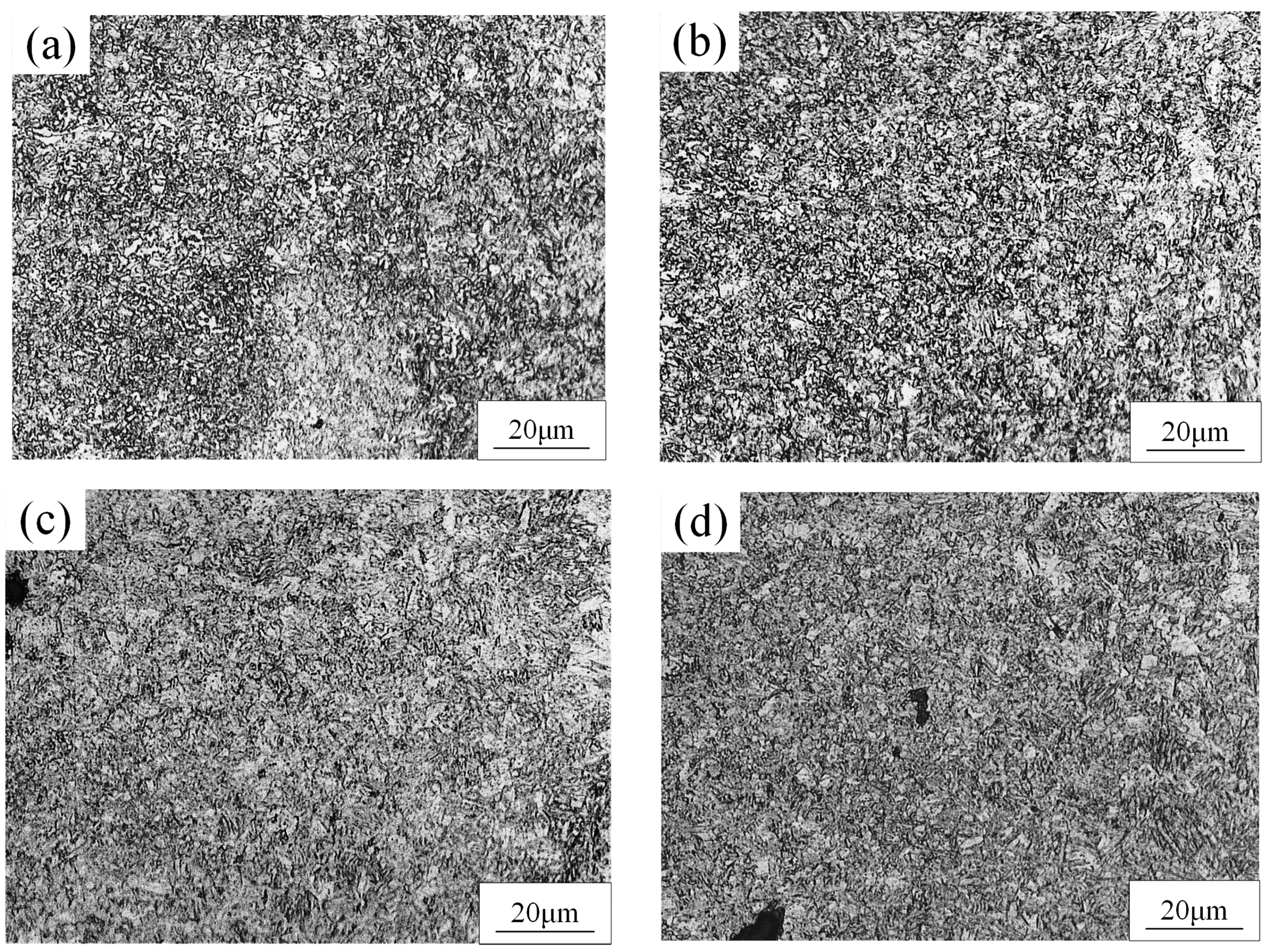

3.2. The Influence of Welding Process on the Microstructure of WJs

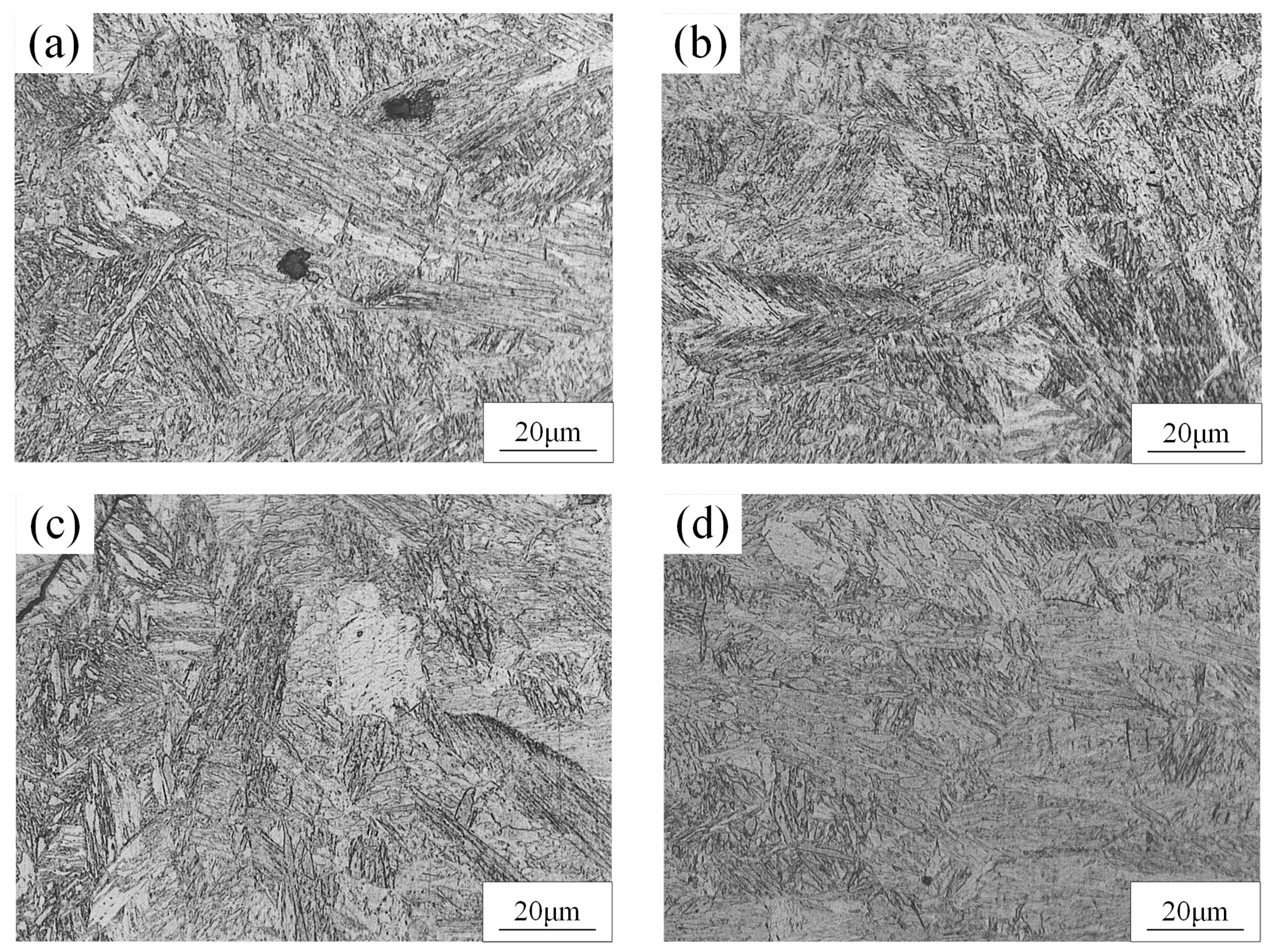

3.2.1. The Influence of Welding Speeds on the Microstructure of WJs

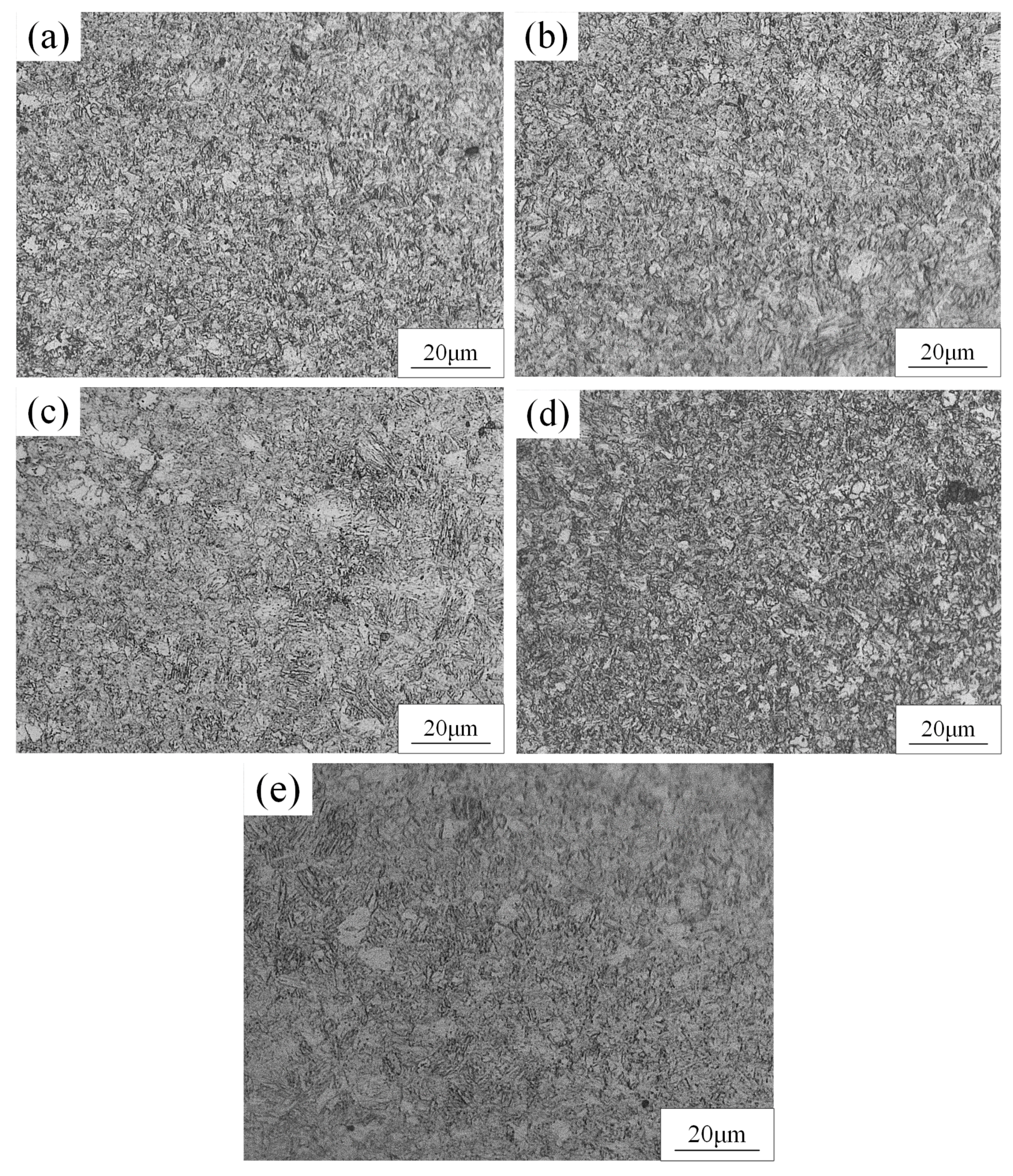

3.2.2. The Influence of Laser Power on the Microstructure of WJs

3.3. The Influence of Welding-Process Parameters on the Strength of Weld

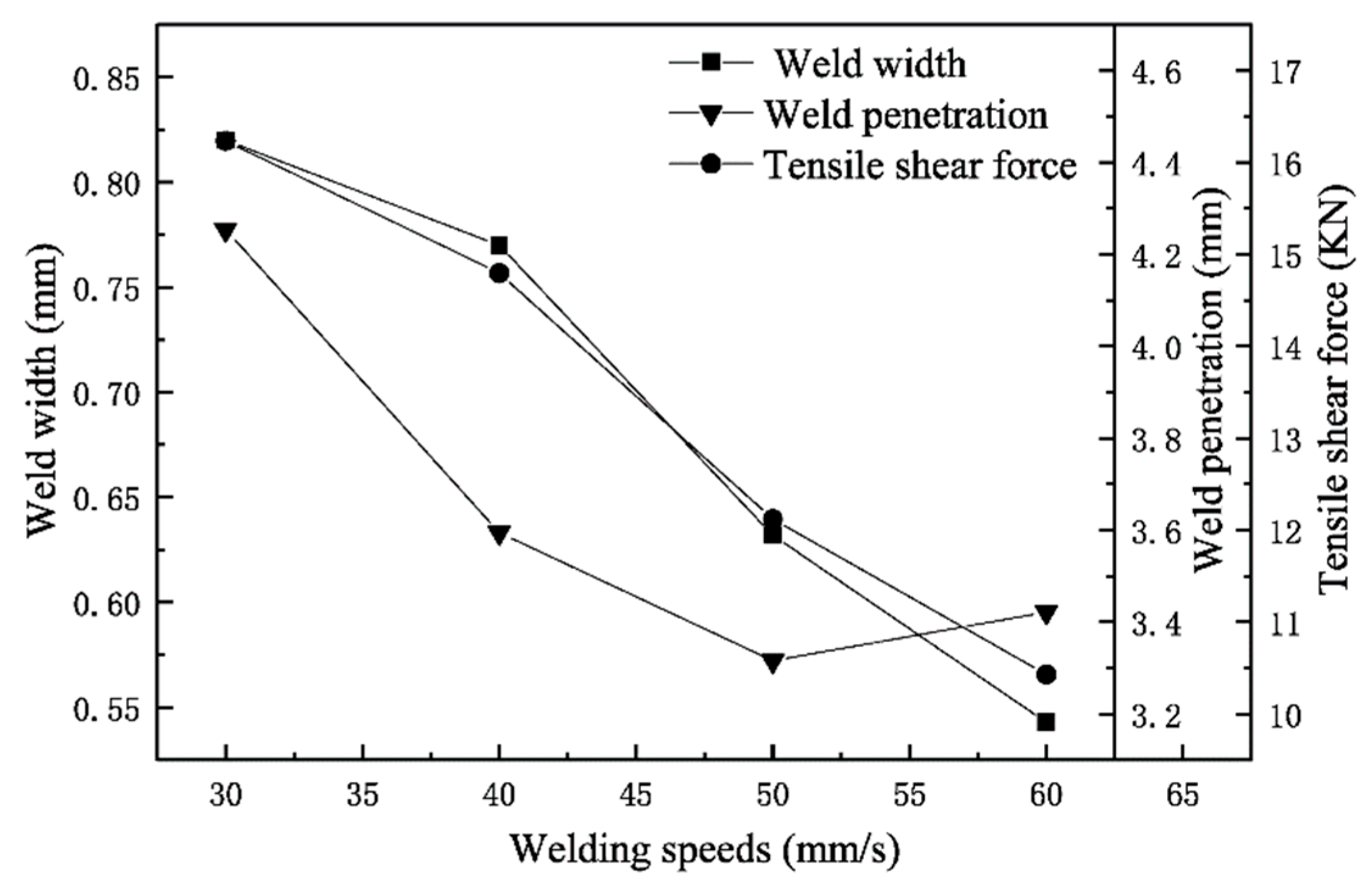

3.3.1. The Influence of Welding Speeds on the Tensile-Shear Forces of Weld

3.3.2. The Effect of Laser Power on the Tensile-Shear Forces of Weld

3.4. Tensile-Shear Estimation Model Using Regression Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ma, J. Experimental and Numerical Studies on the Issues in Laser Welding of Galvanized High-Strength Dual-Phase Steels in a Zero-Gap Lap Joint Configuration. Ph.D. Thesis, Southern Methodist University, Dallas, TX, USA, 2013. [Google Scholar]

- Zhang, X.H.; Mao, W.; Zhu, G.H.; Zhang, X.G. Research and development and production of cold rolled ultra-high strength dual-phase steel for automobile purpose. Wuhan Iron Steel Corp. Technol. 2008, 3, 57–61. [Google Scholar]

- Tian, Z.Q.; Tang, D.; Jiang, H.T.; Ma, X.L.; Xu, H.X. Research and production status of dual phase steels for automobiles. Mater. Mech. Eng. 2009, 33, 1–5. [Google Scholar]

- Dong, D.Y.; Liu, Y.; Wang, L.; Liu, C.S. Dynamic tensile characteristics of dp600 steel sheets for automotive applications. Adv. Mater. Res. 2012, 509, 40–45. [Google Scholar] [CrossRef]

- Wang, X.H.; Gu, X.Y.; Sun, D.Q. Research on interface characteristic of laser welding joints of steel/aluminum dissimilar materials. J. Mech. Eng. 2017, 53, 26–33. [Google Scholar] [CrossRef]

- Ghandi, A.; Shamanian, M.; Salmani, M.R.; Kangazian, J. Improvement of the microstructural features and mechanical properties of advanced high-strength steel DP590 welds. Int. J. Miner. Metall. Mater. 2021, 28, 1022–1029. [Google Scholar] [CrossRef]

- Wang, X.P.; Zhang, Y.Q.; Ju, J.B.; Zhang, J.Q.; Yang, J.W. Characteristics of welding crack defects and failure mode in resistance spot welding of DP780 steel. J. Iron Steel Res. Int. 2016, 23, 1104–1110. [Google Scholar] [CrossRef]

- Zhang, X.Q.; Chen, G.L.; Zhang, Y.S. Characteristics of electrode wear in resistance spot welding dual-phase steels. Mater. Des. 2008, 29, 279–283. [Google Scholar] [CrossRef]

- Yang, H.G.; Zhang, Y.S.; Lai, X.M.; Chen, G. An experimental investigation on critical specimen sizes of high strength steels DP600 in resistance spot welding. Mater. Des. 2008, 29, 1679–1684. [Google Scholar] [CrossRef]

- Lee, J.H.; Park, S.H.; Kwon, H.S.; Kim, G.S.; Lee, C.S. Laser, tungsten inert gas, and metal active gas welding of DP780 steel: Comparison of hardness, tensile properties and fatigue resistance. Mater. Des. 2014, 64, 559–565. [Google Scholar] [CrossRef]

- Mei, L.F.; Yi, J.M.; Yan, D.B.; Liu, J.; Chen, G. Comparative study on CO2 laser overlap welding and resistance spot welding for galvanized steel. Mater. Des. 2012, 40, 433–442. [Google Scholar] [CrossRef]

- Elmesalamy, A.; Francis, J.A.; Li, L. A comparison of residual stresses in multi pass narrow gap laser welds and gas-tungsten arc welds in AISI 316L stainless steel. Int. J. Press. Vessel. Pip. 2014, 113, 49–59. [Google Scholar] [CrossRef]

- Schlather, A.; Theurer, F.; Oefele, F.; Zaeh, M.F. Process forces during remote laser beam welding and resistance spot welding—A comparative study. Procedia CIRP 2018, 74, 669–673. [Google Scholar] [CrossRef]

- Bhanu, V.; Fydrych, D.; Gupta, A.; Pandey, C. Study on microstructure and mechanical properties of laser welded dissimilar joint of P91 steel and INCOLOY 800HT nickel alloy. Materials 2021, 14, 5876. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Yang, L.; Sun, M.; Liu, T.; Li, H. Effect of energy input on the microstructure and properties of butt joints in DP1000 steel laser welding. Mater. Des. 2016, 90, 642–649. [Google Scholar] [CrossRef]

- Wang, X.N.; Sun, Q.; Zheng, Z.; Di, H.S. Microstructure and fracture behavior of laser welded joints of DP steels with different heat inputs. Mater. Sci. Eng. A 2017, 699, 18–25. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, F.; Liang, Z.; Ying, Y.; Lin, Q.; Wei, H. Correlation analysis of penetration based on keyhole and plasma plume in laser welding. J. Mater. Process. Technol. 2018, 256, 1–12. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, X.N.; Zhu, G.J.; Chen, C.; Hou, J.; Zhang, S.; Jing, H. Effect of laser welding process parameters on microstructure and mechanical properties on butt joint of new hot-rolled nano-scale precipitation-strengthened steel. Acta Metall. Sin. Engl. Lett. 2014, 27, 521–529. [Google Scholar] [CrossRef]

- Dak, G.; Sirohi, S.; Pandey, C. Study on microstructure and mechanical behavior relationship for laser-welded dissimilar joint of P92 martensitic and 304L austenitic steel. Int. J. Press. Vessel. Pip. 2022, 196, 104629. [Google Scholar] [CrossRef]

- Huang, P.F.; Xiong, W.; Tang, C.; Wang, L.P.; Lu, Z.Y. Microstructure and tensile shear property of high strength DP780 steel MAG welding lap joints. Mater. Mech. Eng. 2014, 38, 20–24. [Google Scholar]

- Yang, L.; Gao, S.; Huang, Y.; Sun, M.; Li, Y. Effect of microstructure on tensile and fatigue properties of laser-welded DP780 and DP980 high-strength steel joints. Mater. Sci. Eng. 2019, 754, 535–555. [Google Scholar] [CrossRef]

- Hao, K.; Zhang, C.; Zeng, X.; Gao, M. Effect of heat input on weld microstructure and toughness of laser-arc hybrid welding of martensitic stainless steel. J. Mater. Process. Technol. 2017, 245, 7–14. [Google Scholar] [CrossRef]

- Kim, D.Y.; Park, Y.W. Weldability evaluation and tensile strength estimation model for aluminum alloy lap joint welding using hybrid system with laser and scanner head. Trans. Nonferrous Met. Soc. China 2012, 22 (Suppl. S3), 596–604. [Google Scholar] [CrossRef]

- Wang, P.; Chen, X.; Pan, Q.; Madigan, B.; Long, J. Laser welding dissimilar materials of aluminum to steel: An overview. Int. J. Adv. Manuf. Technol. 2016, 87, 3081–3090. [Google Scholar] [CrossRef]

| Test | Defocusing Amount (mm) | Laser Power (W) | Welding Speed (mm/s) |

|---|---|---|---|

| 1 | 6 | 4200 | 30 |

| 2 | 6 | 4200 | 40 |

| 3 | 6 | 4200 | 50 |

| 4 | 6 | 4200 | 60 |

| 5 | 6 | 1800 | 40 |

| 6 | 6 | 2400 | 40 |

| 7 | 6 | 3000 | 40 |

| 8 | 6 | 3600 | 40 |

| 9 | 6 | 4800 | 40 |

| Yield Strength ReL/MPa | Tensile Strength Rm/MPa | Elongation after Breaking A(%) |

|---|---|---|

| 500~650 | ≥780 | ≥10 |

| Element | C | Si | Mn | P | S | Fe |

|---|---|---|---|---|---|---|

| Wt.% | ≤0.2 | ≤0.8 | ≤2.5 | ≤0.035 | ≤0.2 | Bal. |

| Test | Laser Power (W) | Welding Speed (mm/s) | Shear Strength (MPa) |

|---|---|---|---|

| 1 | 4200 | 30 | - |

| 2 | 4200 | 40 | 468.641 |

| 3 | 4200 | 50 | 467.737 |

| 4 | 4200 | 60 | 468.49 |

| 5 | 1800 | 40 | 479.039 |

| 6 | 2400 | 40 | 444.108 |

| 7 | 3000 | 40 | 435.513 |

| 8 | 3600 | 40 | 488.666 |

| 9 | 4800 | 40 | 474.959 |

| Fator | Regression Coefficients (bi) | |

|---|---|---|

| Laser Power | 0.003 | 0.834 |

| Welding Speed | −0.183 | −0.634 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, S.; Pang, S.; Zhang, S.; Liao, Y.; Cai, H. Influence of Different Welding Parameters on the Morphology, Microstructure, and Mechanical Properties of 780 Duplex-Phase Steel Laser Lap Welded Joint. Materials 2022, 15, 3627. https://doi.org/10.3390/ma15103627

Cui S, Pang S, Zhang S, Liao Y, Cai H. Influence of Different Welding Parameters on the Morphology, Microstructure, and Mechanical Properties of 780 Duplex-Phase Steel Laser Lap Welded Joint. Materials. 2022; 15(10):3627. https://doi.org/10.3390/ma15103627

Chicago/Turabian StyleCui, Shuwan, Shuwen Pang, Suojun Zhang, Yong Liao, and Hongfeng Cai. 2022. "Influence of Different Welding Parameters on the Morphology, Microstructure, and Mechanical Properties of 780 Duplex-Phase Steel Laser Lap Welded Joint" Materials 15, no. 10: 3627. https://doi.org/10.3390/ma15103627

APA StyleCui, S., Pang, S., Zhang, S., Liao, Y., & Cai, H. (2022). Influence of Different Welding Parameters on the Morphology, Microstructure, and Mechanical Properties of 780 Duplex-Phase Steel Laser Lap Welded Joint. Materials, 15(10), 3627. https://doi.org/10.3390/ma15103627