Portland and Belite Cement Hydration Acceleration by C-S-H Seeds with Variable w/c Ratios

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Pastes and Mortars Fabrications

2.3. Analytical Techniques

2.3.1. Mortar Consistency Measurement

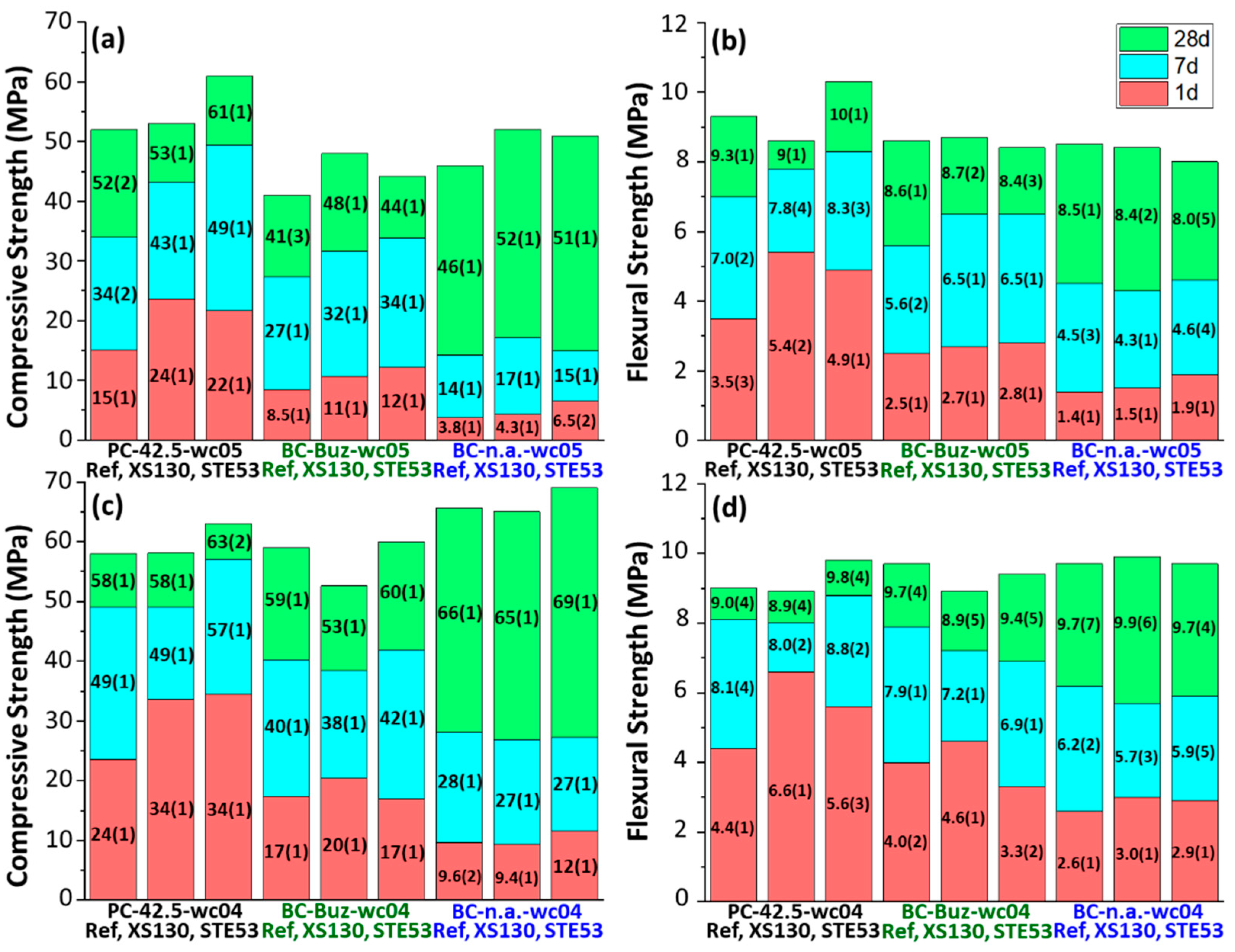

2.3.2. Compressive and Flexural Strengths

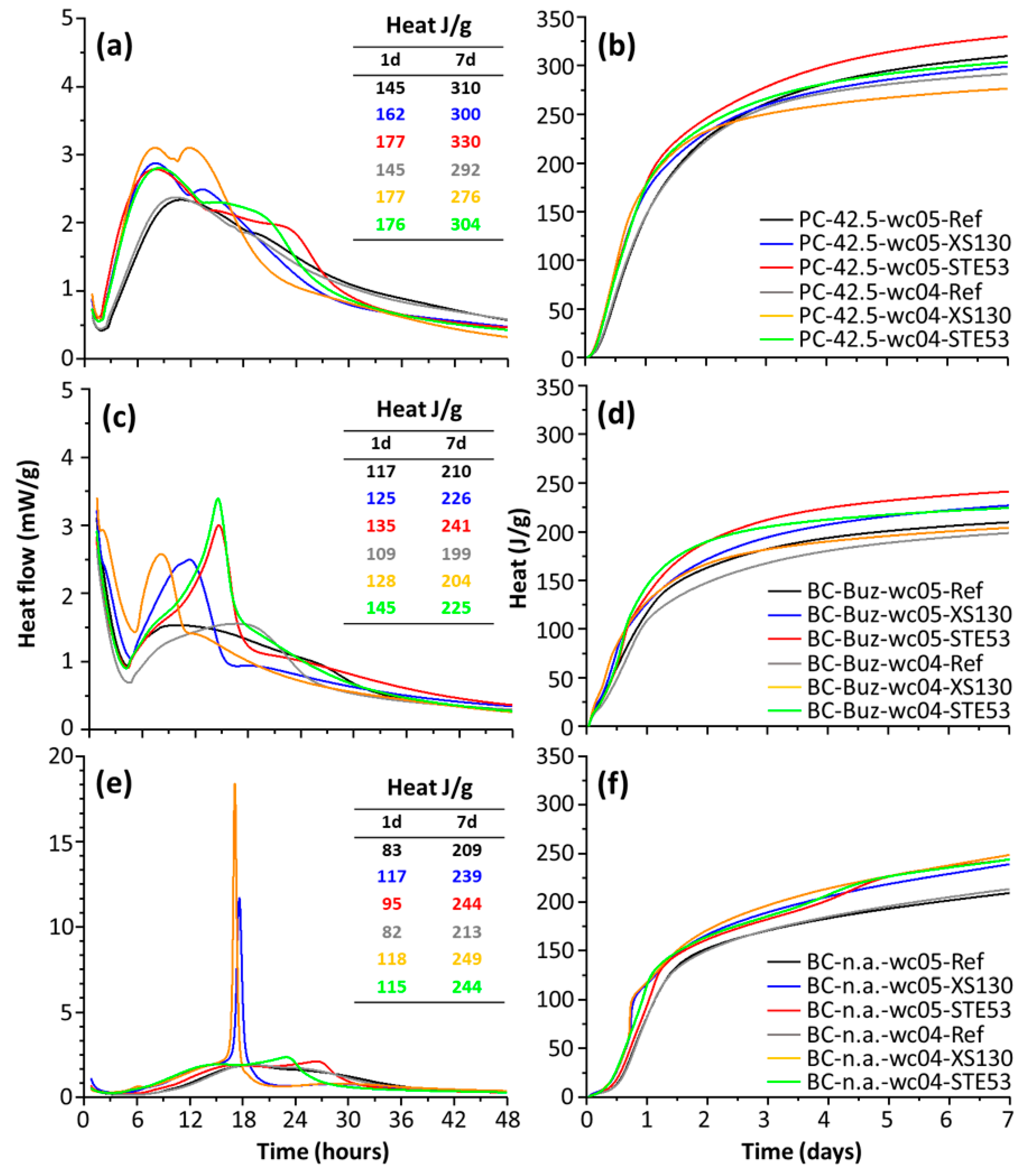

2.3.3. Isothermal Calorimetry

2.3.4. Thermal Analysis (TA)

2.3.5. Laboratory X-ray Powder Diffraction (LXRPD)

2.3.6. Calculated Phase and Water Contents Based on Chemical Reactions

2.3.7. Mercury Intrusion Porosimetry (MIP)

3. Results and Discussion

3.1. Mechanical Strengths

3.2. Calorimetric Study

3.3. Thermal Analysis Characterization

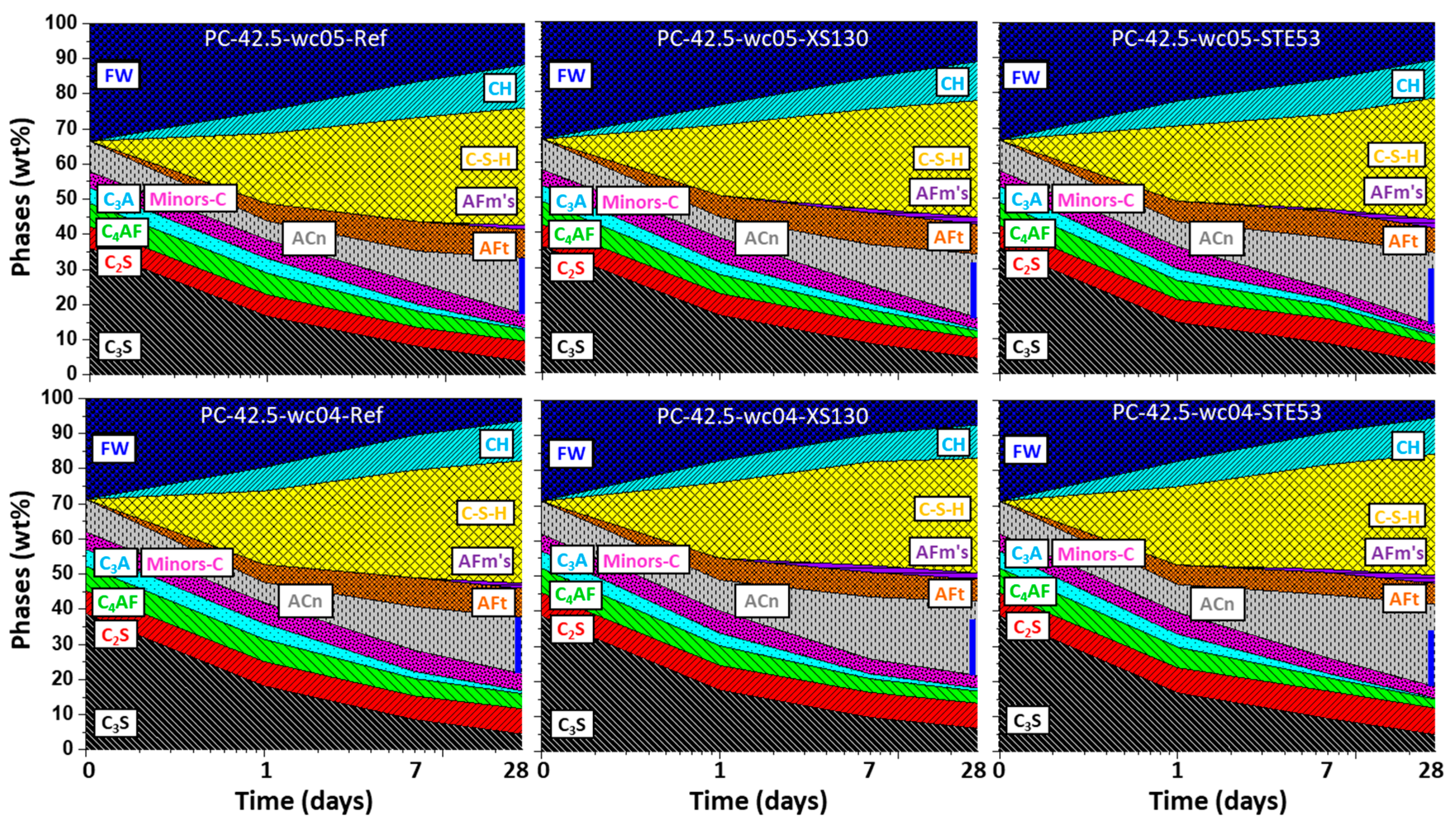

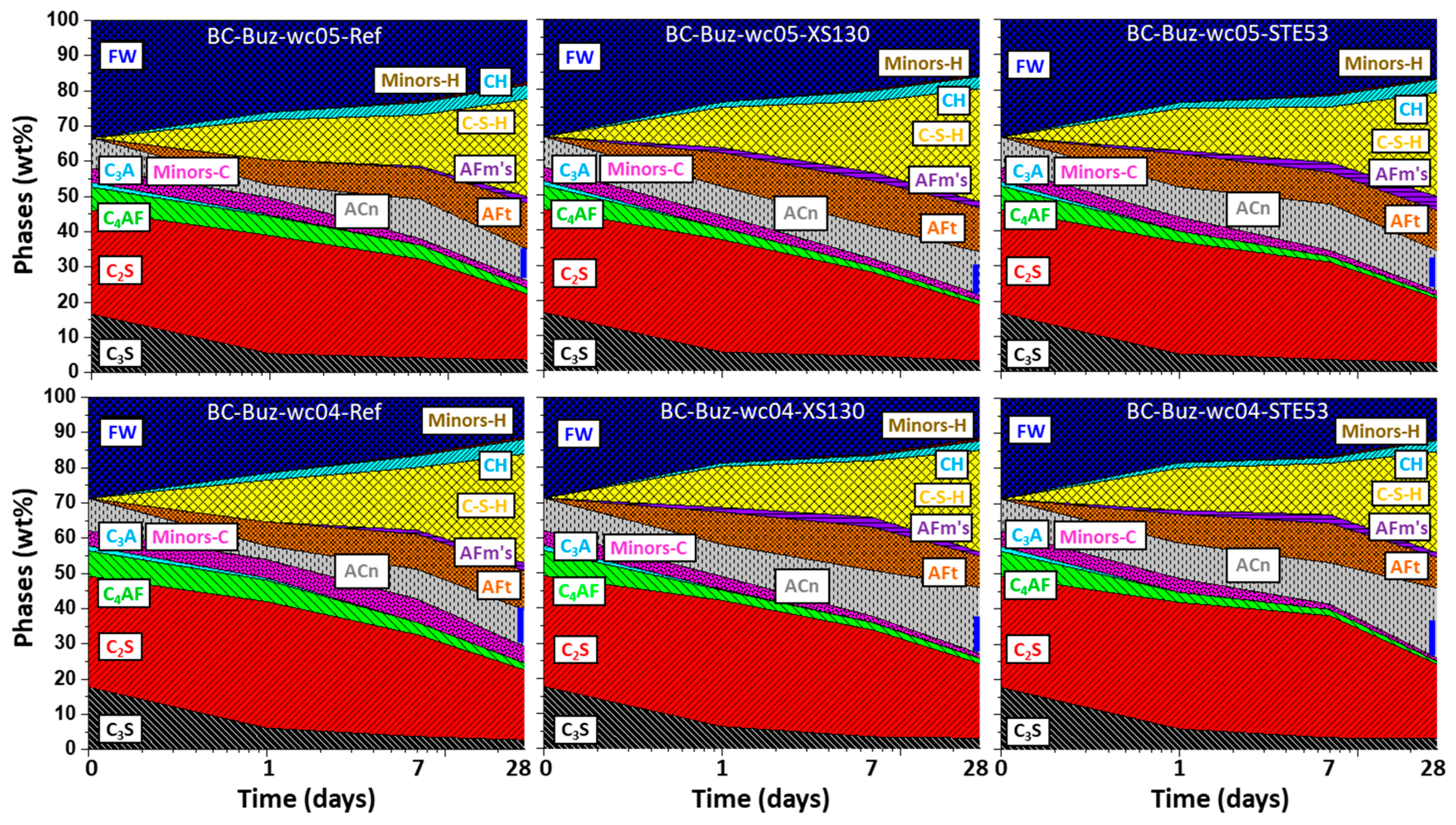

3.4. Rietveld Quantitative Phase Analyses

3.4.1. Dissolution of the Clinker Phases

- Alite/C3S. For PC-42.5 and the two studied w/c ratios, the DoH of the alite was approximately 55, 75, and 90% at 1, 7, and 28 days, respectively. This is fully in line with the known behaviour of PC hydration [56,57]. This study cannot conclusively prove that the reaction rate of crystalline alite in PC-42.5 is increased by C-S-H gel nanoparticle seeding at the studied hydration times, i.e., 1 day or later. For BC-Buz, with both w/c ratios, the alite reaction degree is approximately 65, 80, and 85% at 1, 7, and 28 days. Again, the alite DoH is not significantly accelerated by these admixtures. The slightly higher reaction degree at the very early ages, when compared to PC-42.5, is likely related to the lower amount of C3S, which results in higher water-to-alite mass ratio(s). For BC-n.a., the alite DoH was approximately 60, 85, and 90% at 1, 7, and 28 days, respectively. In agreement with the previous observations, C-S-H seeding does not seem to accelerate alite hydration. Finally, these results, for the studied PC and hydrating times, do not support the widely known picture that C-S-H seeding accelerates alite hydration. Faster alite hydration at the very early ages, i.e., earlier than 24 h, cannot be ruled out with the experimental data reported here.

- Belite/C2S. As can be seen in Table 1 for PC-42.5, the belite did not significantly react in the first week. This is again in line with the known features of ordinary PC hydration [56]. This is not the case for the BC-Buz pastes. For w/c = 0.50, the belite reacted about 5% at 7 days and, even more importantly, about 35% at 28 days. For w/c = 0.40, the belite hydrated about 10 and 40% at 7 and 28 days. This enhanced DoH of belite is due to the sulphur activation in the clinkering stage, which can be mapped out by a larger belite unit cell volume [58,59,60]. The scattering of the results did not allow a firm conclusion on any significant acceleration of belite phase hydration by XS130 or STE53. For the non-activated belite cement, the belite did not react at 7 days in any studied paste. Without admixtures, the DoH of belite for both w/c ratios was approximately 20% at 28 days. The admixtures seem to moderately accelerate belite hydration at 28 days, XS130 to 40% and STE53 to 30%. However, this isolated result needs additional confirmation.

- Tetracalcium alumino-ferrite/C4AF. For PC-42.5 and the two studied w/c ratios, the reaction degree of C4AF was approximately 10, 30, and 40% at 1, 7, and 28 days, respectively. The admixtures very significantly accelerated its hydration. For w/c = 0.50, both admixtures yielded a C4AF DoH of 20, 45, and 65%. For w/c = 0.40, the corresponding values were 20, 45, and 60%. Therefore, the acceleration of C4AF hydration by the employed admixtures is firmly established. On the other hand, C4AF reacts faster in BC-Buz. For the reference pastes, i.e., without admixtures, the DoH was 20, 40, and 75% (w/c = 0.50) and 15, 50, and 75% (w/c = 0.40) with hydrating time. In agreement with the results for PC-42.5, both admixtures accelerated C4AF hydration, the DoH being 55, 75, and 85% (w/c = 0.50) and 60, 75, and 85% (w/c = 0.40). Concerning the unseeded BC-n.a. pastes, the reaction degree of C4AF was approximately 15, 35, and 40% at 1, 7, and 28 days, respectively. Again, the admixtures strongly accelerated C4AF hydration as its degree of hydration increased to 25, 45, and 70% at the studied ages.

- Tricalcium aluminate/C3A. For PC-42.5 and both w/c ratios, the DoH of C3A was 7, 60, and 85% at 1, 7, and 28 days, respectively. The studied admixtures significantly accelerated C3A hydration. With some scattering in the results, the DoH of the studied pastes increased to 25, 65, and 90%. For BC-Buz, C3A had fully dissolved at 7 days. However, the hydration acceleration at 1 day was noteworthy. Finally, BC-n.a. did not contain C3A; hence, the role of the admixtures cannot be discussed.

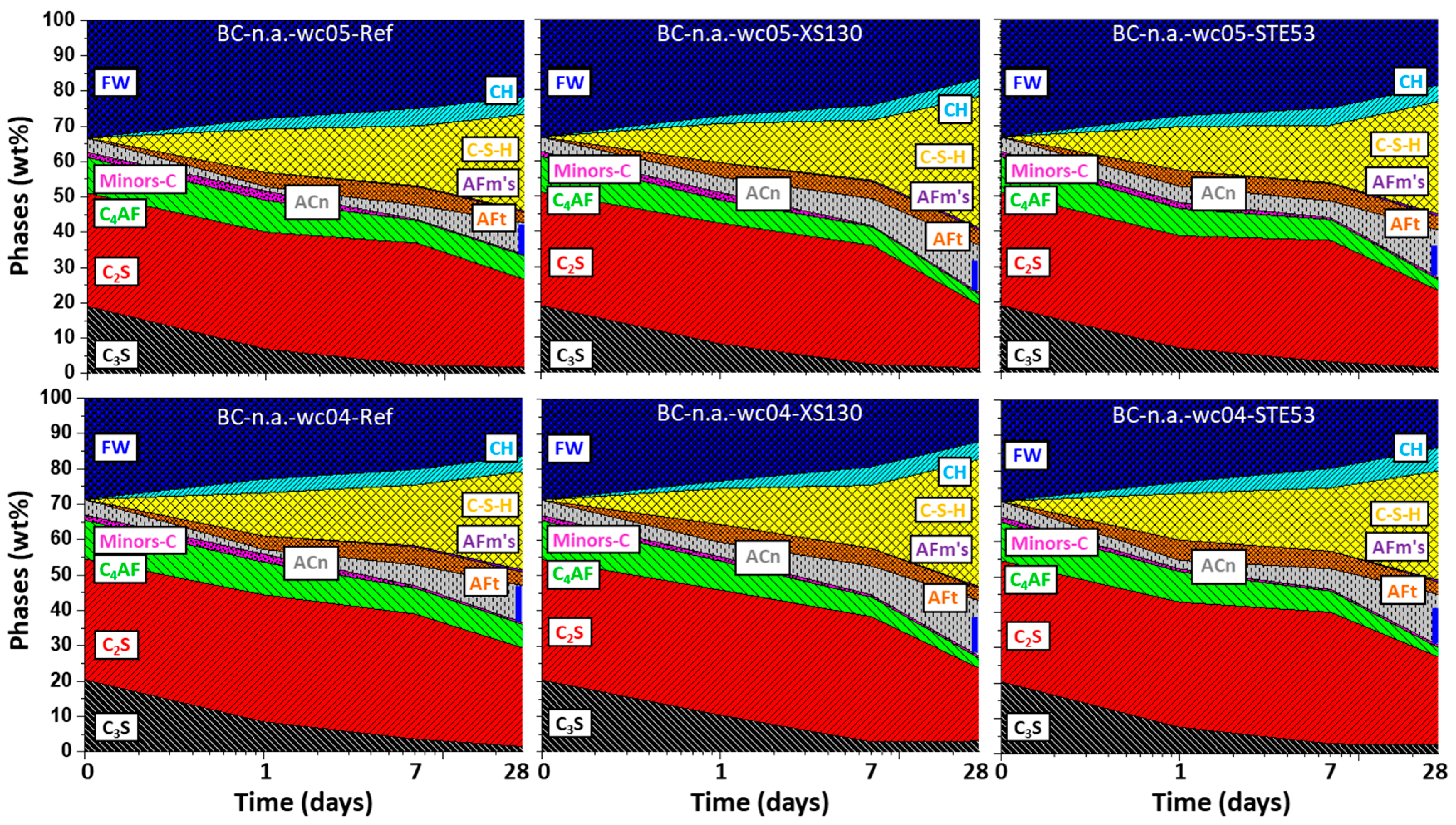

3.4.2. Precipitation of Hydrated Phases

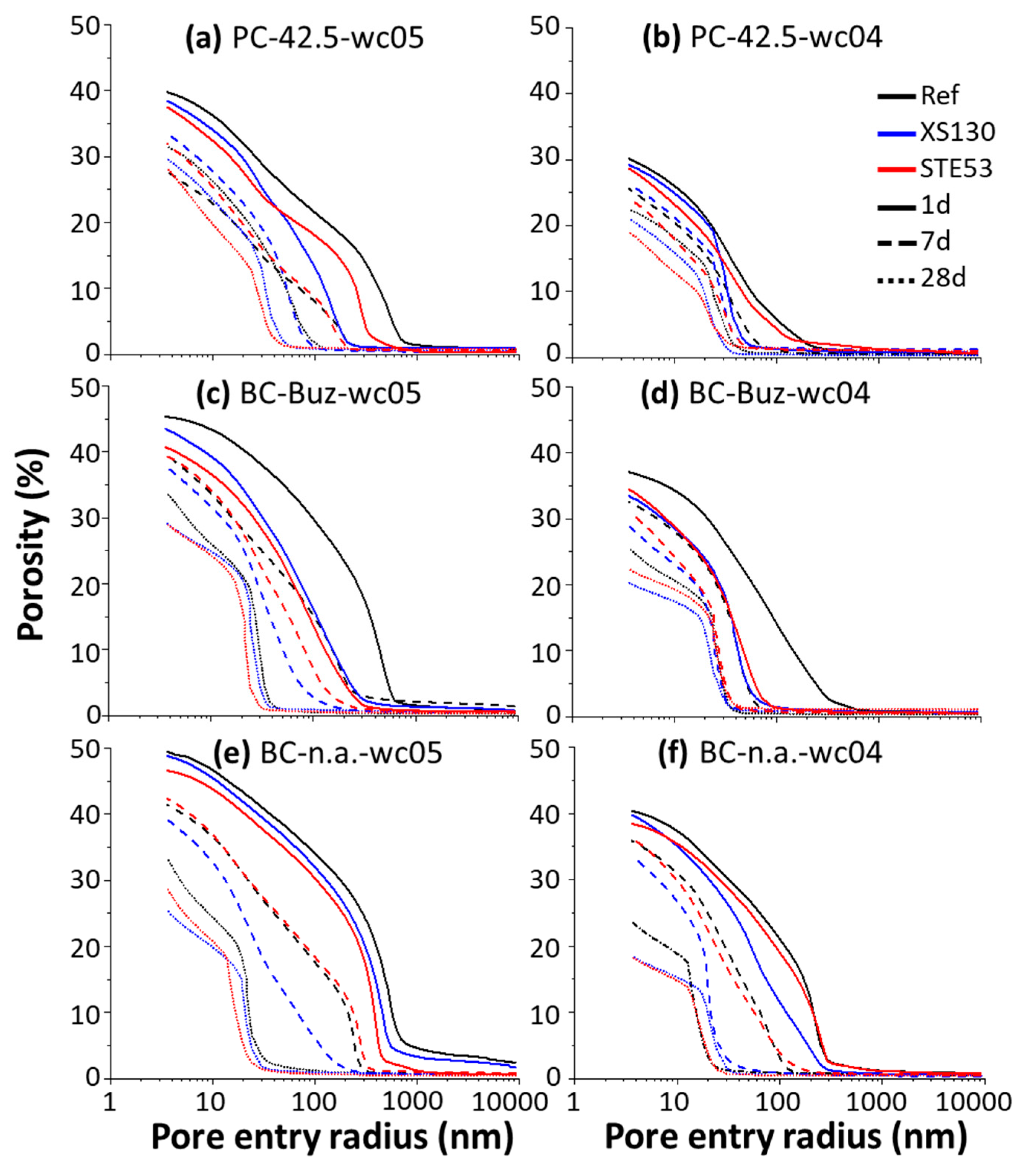

3.5. Mercury Intrusion Porosimetry Study

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- UN Environment; Scrivener, K.L.; John, V.M.; Gartner, E. Eco-efficient cements: Potential, economically viable solutions for a low-CO2, cement-based materials industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar] [CrossRef]

- Juenger, M.C.G.; Siddique, R. Recent advances in understanding the role of supplementary cementitious materials in concrete. Cem. Concr. Res. 2015, 78, 71–80. [Google Scholar] [CrossRef]

- Juenger, M.C.G.; Snellings, R.; Bernal, S.A. Supplementary cementitious materials: New sources, characterization, and performance insights. Cem. Concr. Res. 2019, 122, 257–273. [Google Scholar] [CrossRef]

- Cuesta, A.; Ayuela, A.; Aranda, M.A.G. Belite cements and their activation. Cem. Concr. Res. 2021, 140, 106319. [Google Scholar] [CrossRef]

- Flatt, R.J.; Roussel, N.; Cheeseman, C.R. Concrete: An eco material that needs to be improved. J. Eur. Ceram. Soc. 2012, 32, 2787–2798. [Google Scholar] [CrossRef]

- Boscaro, F.; Palacios, M.; Flatt, R.J. Formulation of low clinker blended cements and concrete with enhanced fresh and hardened properties. Cem. Concr. Res. 2021, 150, 106605. [Google Scholar] [CrossRef]

- Habert, G.; Miller, S.A.; John, V.M.; Provis, J.L.; Favier, A.; Horvath, A.; Scrivener, K.L. Environmental impacts and decarbonization strategies in the cement and concrete industries. Nat. Rev. Earth Environ. 2020, 1, 559–573. [Google Scholar] [CrossRef]

- Sharma, M.; Bishnoi, S.; Martirena, F.; Scrivener, K. Limestone calcined clay cement and concrete: A state-of-the-art review. Cem. Concr. Res. 2021, 149, 106564. [Google Scholar] [CrossRef]

- Aiticin, P.C. Accelerators. In Science and Technology of Concrete Admixtures; Aiticin, P.C., Flatt, R.J., Eds.; Elsevier: Amsterdam, The Netherlands, 2016; pp. 405–413. ISBN 9780081006962. [Google Scholar]

- Amran, M.; Fediuk, R.; Murali, G.; Avudaiappan, S.; Ozbakkaloglu, T.; Vatin, N.; Karelina, M.; Klyuev, S.; Gholampour, A. Fly Ash-Based Eco-Efficient Concretes: A Comprehensive Review of the Short-Term Properties. Materials 2021, 14, 4264. [Google Scholar] [CrossRef]

- Volodchenko, A.A.; Lesovik, V.S.; Cherepanova, I.A.; Volodchenko, A.N.; Zagorodnjuk, L.H.; Elistratkin, M.Y. Peculiarities of non-autoclaved lime wall materials production using clays. IOP Conf. Ser. Mater. Sci. Eng. 2018, 327, 022021. [Google Scholar] [CrossRef]

- Ganjian, E.; Ehsani, A.; Mason, T.J.; Tyrer, M. Application of power ultrasound to cementitious materials: Advances, issues and perspectives. Mater. Des. 2018, 160, 503–513. [Google Scholar] [CrossRef]

- Ehsani, A.; Ganjian, E.; Mason, T.J.; Tyrer, M.; Bateman, M. Insights into the positive effects of power ultrasound on the pore solution of Portland cement pastes. Cem. Concr. Compos. 2022, 125, 104302. [Google Scholar] [CrossRef]

- Bentz, D.P.; Zunino, F.; Lootens, D. Chemical vs. Physical Acceleration of Cement Hydration. Concr. Int. 2016, 38, 37–44. [Google Scholar] [PubMed]

- Bost, P.; Regnier, M.; Horgnies, M. Comparison of the accelerating effect of various additions on the early hydration of Portland cement. Constr. Build. Mater. 2016, 113, 290–296. [Google Scholar] [CrossRef]

- Gonzalez-Panicello, L.; Garcia-Lodeiro, I.; Puertas, F.; Palacios, M. Influence of Accelerating Admixtures on the Reactivity of Synthetic Aluminosilicate Glasses. Materials 2022, 15, 818. [Google Scholar] [CrossRef]

- Wang, Y.; Shi, C.; Ma, Y.; Xiao, Y.; Liu, Y. Accelerators for shotcrete—Chemical composition and their effects on hydration, microstructure and properties of cement-based materials. Constr. Build. Mater. 2021, 281, 122557. [Google Scholar] [CrossRef]

- Dorn, T.; Blask, O.; Stephan, D. Acceleration of cement hydration—A review of the working mechanisms, effects on setting time, and compressive strength development of accelerating admixtures. Constr. Build. Mater. 2022, 323, 126554. [Google Scholar] [CrossRef]

- Plank, J.; Ilg, M. The Role of Chemical Admixtures in the Formulation of Modern Advanced Concrete. In Proceedings of the 3rd International Conference on the Application of Superabsorbent Polymers (SAP) and Other New Admixtures Towards Smart Concrete, Skukuza, South Africa, 25–26 November 2019; Boshoff, W., Ed.; RILEM Bookseries. Springer: Cham, Switzerland, 2019; Volume 24, pp. 143–157. [Google Scholar] [CrossRef]

- Xu, Z.; Li, W.; Sun, J.; Hu, Y.; Xu, K.; Ma, S.; Shen, X. Research on cement hydration and hardening with different alkanolamines. Constr. Build. Mater. 2017, 141, 296–306. [Google Scholar] [CrossRef]

- Thomas, J.J.; Jennings, H.M.; Chen, J.J. Influence of Nucleation Seeding on the Hydration Mechanisms of Tricalcium Silicate and Cement. J. Phys. Chem. C 2009, 113, 4327–4334. [Google Scholar] [CrossRef] [Green Version]

- Alizadeh, R.; Raki, L.; Makar, J.M.; Beaudoin, J.J.; Moudrakovski, I. Hydration of tricalcium silicate in the presence of synthetic calcium-silicate-hydrate. J. Mater. Chem. 2009, 19, 7937–7946. [Google Scholar] [CrossRef] [Green Version]

- Dal Sasso, G.; Dalconi, M.C.; Ferrari, G.; Pedersen, J.S.; Tamburini, S.; Bertolotti, F.; Guagliardi, A.; Bruno, M.; Valentini, L.; Artioli, G. An Atomistic Model Describing the Structure and Morphology of Cu-Doped C-S-H Hardening Accelerator Nanoparticles. Nanomaterials 2022, 12, 342. [Google Scholar] [CrossRef] [PubMed]

- He, J.; Long, G.; Ma, K.; Xie, Y.; Cheng, Z. Improvement of the Hydration of a Fly Ash-Cement System by the Synergic Action of Triethanolamine and C-S-H Seeding. ACS Sustain. Chem. Eng. 2021, 9, 2804–2815. [Google Scholar] [CrossRef]

- John, E.; Matschei, T.; Stephan, D. Nucleation seeding with calcium silicate hydrate—A review. Cem. Concr. Res. 2018, 113, 74–85. [Google Scholar] [CrossRef]

- Artioli, G.; Ferrari, G.; Dalconi, M.C.; Valentini, L. Nanoseeds as modifiers of the cement hydration kinetics. In Smart Nanoconcretes and Cement-Based Materials: Properties, Modelling and Applications; Shahir Liew, M., Nguyen-Tri, P., Nguyen, T.A., Kakooei, S., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 257–269. [Google Scholar]

- Nicoleau, L. The acceleration of cement hydration by seeding: Influence of the cement mineralogy. ZKG Int. 2013, 51, 40–49. [Google Scholar]

- Li, H.; Xue, Z.; Liang, G.; Wu, K.; Dong, B.; Wang, W. Effect of C-S-Hs-PCE and sodium sulfate on the hydration kinetics and mechanical properties of cement paste. Constr. Build. Mater. 2021, 266, 121096. [Google Scholar] [CrossRef]

- Pedrosa, H.C.; Reales, O.M.; Reis, V.D.; das Dores Paiva, M.; Fairbairn, E.M.R. Hydration of Portland cement accelerated by C-S-H seeds at different temperatures. Cem. Concr. Res. 2020, 129, 105978. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Z.; Yao, Y.; Tang, R.; Li, S.; Liu, X.; Sun, D. The effect and mechanism of C-S-H -PCE nanocomposites on the early strength of mortar under different water-to-cement ratio. J. Build. Eng. 2021, 44, 103360. [Google Scholar] [CrossRef]

- Boháč, M.; Staněk, T.; Zezulová, A.; Rybová, A.; Kubátová, D.; Novotný, R. Early Hydration of Activated Belite-Rich Cement. Adv. Mater. Res. 2019, 1151, 23–27. [Google Scholar] [CrossRef]

- Kanchanason, V.; Plank, J. Effectiveness of a calcium silicate hydrate—Polycarboxylate ether (C-S-H–PCE) nanocomposite on early strength development of fly ash cement. Constr. Build. Mater. 2018, 169, 20–27. [Google Scholar] [CrossRef]

- Szostak, B.; Golewski, G.L. Effect of Nano Admixture of CSH on Selected Strength Parameters of Concrete Including Fly Ash. IOP Conf. Ser. Mater. Sci. Eng. 2018, 416, 012105. [Google Scholar] [CrossRef]

- Zou, F.; Hu, C.; Wang, F.; Ruan, Y.; Hu, S. Enhancement of early-age strength of the high content fly ash blended cement paste by sodium sulfate and C-S-H seeds towards a greener binder. J. Clean. Prod. 2020, 244, 118566. [Google Scholar] [CrossRef]

- Zou, F.; Shen, K.; Hu, C.; Wang, F.; Yang, L.; Hu, S. Effect of Sodium Sulfate and C-S-H Seeds on the Reaction of Fly Ash with Different Amorphous Alumina Contents. ACS Sustain. Chem. Eng. 2020, 8, 1659–1670. [Google Scholar] [CrossRef]

- Szostak, B.; Golewski, G.L. Improvement of Strength Parameters of Cement Matrix with the Addition of Siliceous Fly Ash by Using Nanometric C-S-H Seeds. Energies 2020, 13, 6734. [Google Scholar] [CrossRef]

- Theobald, M.; Plank, J. C-S-H –Polycondensate nanocomposites as effective seeding materials for Portland composite cements. Cem. Concr. Compos. 2022, 125, 104278. [Google Scholar] [CrossRef]

- Zhao, D.; Khoshnazar, R. Hydration and microstructural development of calcined clay cement paste in the presence of calcium-silicate-hydrate (C-S-H) seed. Cem. Concr. Compos. 2021, 122, 104162. [Google Scholar] [CrossRef]

- Ouellet-Plamondon, C.; Scherb, S.; Köberl, M.; Thienel, K.C. Acceleration of cement blended with calcined clays. Constr. Build. Mater. 2020, 245, 118439. [Google Scholar] [CrossRef]

- Alzaza, A.; Ohenoja, K.; Langås, I.; Arntsen, B.; Poikelispää, M.; Illikainen, M. Low-temperature (−10 °C) curing of Portland cement paste—Synergetic effects of chloride-free antifreeze admixture, C-S-H seeds, and room-temperature pre-curing. Cem. Concr. Compos. 2022, 125, 104319. [Google Scholar] [CrossRef]

- Xu, Y.; He, T.; Ma, X.; Yang, R. The research on mechanism of C-S-H nanocrystal improving early properties of shotcrete at low temperature by thermodynamic modelling. Constr. Build. Mater. 2022, 325, 126738. [Google Scholar] [CrossRef]

- Artioli, G.; Valentini, L.; Dalconi, M.C.; Parisatto, M.; Voltolini, M.; Russo, V.; Ferrari, G. Imaging of nano-seeded nucleation in cement pastes by X-ray diffraction tomography. Int. J. Mater. Res. 2014, 105, 628–631. [Google Scholar] [CrossRef]

- Valentini, L.; Ferrari, G.; Russo, V.; Štefančič, M.; Serjun, V.Z.; Artioli, G. Use of nanocomposites as permeability reducing admixtures. J. Am. Ceram. Soc. 2018, 101, 4275–4284. [Google Scholar] [CrossRef] [Green Version]

- Morales-Cantero, A.; Cuesta, A.; De la Torre, A.G.; Santacruz, I.; Mazanec, O.; Borralleras, P.; Weldert, K.S.; Gastaldi, D.; Canonico, F.; Aranda, M.A.G. C-S-H seeding activation of Portland and Belite Cements: An enlightening in situ synchrotron powder diffraction study. Cem. Concr. Res. 2022; submitted. [Google Scholar]

- De la Torre, A.G.; Bruque, S.; Aranda, M.A.G. Rietveld quantitative amorphous content analysis. J. Appl. Crystallogr. 2001, 34, 196–202. [Google Scholar] [CrossRef]

- Shirani, S.; Cuesta, A.; Morales-Cantero, A.; De la Torre, A.G.; Olbinado, M.P.; Aranda, M.A.G. Influence of curing temperature on belite cement hydration: A comparative study with Portland cement. Cem. Concr. Res. 2021, 147, 106499. [Google Scholar] [CrossRef]

- Larson, A.C.; Von Dreele, R.B. General structure analysis system (GSAS). Los Alamos Natl. Lab. Rep. LAUR 2004, 748, 86–748. [Google Scholar]

- Cuesta, A.; Zea-Garcia, J.D.; Londono-Zuluaga, D.; De la Torre, A.G.; Santacruz, I.; Vallcorba, O.; Dapiaggi, M.; Sanfélix, S.G.; Aranda, M.A.G. Multiscale understanding of tricalcium silicate hydration reactions. Sci. Rep. 2018, 8, 8544. [Google Scholar] [CrossRef] [Green Version]

- Scrivener, K.L.; Snellings, R.; Lothenbach, B. A Practical Guide to Microstructural Analysis of Cementitious Materials; CRC Press: Boca Raton, FL, USA, 2016; ISBN 9781498738675. [Google Scholar]

- Scrivener, K.L.; Ouzia, A.; Juilland, P.; Kunhi Mohamed, A. Advances in understanding cement hydration mechanisms. Cem. Concr. Res. 2019, 124, 105823. [Google Scholar] [CrossRef]

- Nicoleau, L.; Schreiner, E.; Nonat, A. Ion-specific effects influencing the dissolution of tricalcium silicate. Cem. Concr. Res. 2014, 59, 118–138. [Google Scholar] [CrossRef]

- Pustovgar, E.; Mishra, R.K.; Palacios, M.; d’Espinose de Lacaillerie, J.-B.; Matschei, T.; Andreev, A.S.; Heinz, H.; Verel, R.; Flatt, R.J. Influence of aluminates on the hydration kinetics of tricalcium silicate. Cem. Concr. Res. 2017, 100, 245–262. [Google Scholar] [CrossRef]

- Wagner, D.; Bellmann, F.; Neubauer, J. Influence of aluminium on the hydration of triclinic C3S with addition of KOH solution. Cem. Concr. Res. 2020, 137, 106198. [Google Scholar] [CrossRef]

- Huang, L.; Yang, Z. Hydration kinetics of tricalcium silicate with the presence of portlandite and calcium silicate hydrate. Thermochim. Acta 2019, 681, 178398. [Google Scholar] [CrossRef]

- Aranda, M.A.G.; De la Torre, A.G.; Leon-Reina, L. Rietveld Quantitative Phase Analysis of OPC Clinkers, Cements and Hydration Products. Rev. Mineral. Geochem. 2012, 74, 169–209. [Google Scholar] [CrossRef] [Green Version]

- Taylor, H.F.W. (Ed.) Cement Chemistry; Thomas Telford Publishing: London, UK, 1997; 480p, ISBN 0 7277 2592 0. [Google Scholar]

- Scrivener, K.L.; Nonat, A. Hydration of cementitious materials, present and future. Cem. Concr. Res. 2011, 41, 651–665. [Google Scholar] [CrossRef]

- Morsli, K.; De la Torre, A.G.; Zahir, M.; Aranda, M.A.G. Mineralogical phase analysis of alkali and sulfate bearing belite rich laboratory clinkers. Cem. Concr. Res. 2007, 37, 639–646. [Google Scholar] [CrossRef]

- Morsli, K.; De la Torre, A.G.; Stöber, S.; Cuberos, A.J.M.; Zahir, M.; Aranda, M.A.G. Quantitative phase analysis of laboratory-active belite clinkers by synchrotron powder diffraction. J. Am. Ceram. Soc. 2007, 90, 3205–3212. [Google Scholar] [CrossRef]

- Yamashita, M.; Tanaka, H.; Sakai, E.; Tsuchiya, K. Mineralogical study of high SO3 clinker produced using waste gypsum board in a cement kiln. Constr. Build. Mater. 2019, 217, 507–517. [Google Scholar] [CrossRef]

- Westphal, T.; Füllmann, T.; Pöllmann, H. Rietveld quantification of amorphous portions with an internal standard—Mathematical consequences of the experimental approach. Powder Diffr. 2009, 24, 239–243. [Google Scholar] [CrossRef]

- Snellings, R.; Bazzoni, A.; Scrivener, K.L. The existence of amorphous phase in Portland cements: Physical factors affecting Rietveld quantitative phase analysis. Cem. Concr. Res. 2014, 59, 139–146. [Google Scholar] [CrossRef]

- Li, J.; Cheng, G.; Huang, S.; Lian, P. Effect of ZnO on the whiteness of white Portland cement clinker. Cem. Concr. Res. 2021, 143, 106372. [Google Scholar] [CrossRef]

| Sample | DoH C3S (%) | DoH C2S (%) | DoH C4AF (%) | DoH C3A (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 d | 7 d | 28 d | 1 d | 7 d | 28 d | 1 d | 7 d | 28 d | 1 d | 7 d | 28 d | |

| PC-42.5-wc05-Ref | 54 | 78 | 89 | 2 | 6 | 6 | 8 | 30 | 50 | 7 | 56 | 89 |

| PC-42.5-wc05-XS130 | 55 | 77 | 88 | - | 3 | 8 | 18 | 45 | 68 | 22 | 60 | 87 |

| PC-42.5-wc05-STE53 | 59 | 76 | 93 | - | - | 6 | 18 | 42 | 65 | 27 | 64 | 89 |

| PC-42.5-wc04-Ref | 53 | 78 | 88 | - | - | - | 9 | 29 | 39 | 6 | 58 | 83 |

| PC-42.5-wc04-XS130 | 55 | 75 | 83 | - | - | - | 20 | 44 | 50 | 25 | 71 | 83 |

| PC-42.5-wc04-STE53 | 57 | 75 | 87 | - | - | - | 16 | 46 | 63 | 23 | 75 | 94 |

| BC-Buz-wc05-Ref | 67 | 75 | 78 | - | 5 | 36 | 18 | 40 | 75 | 69 | 100 | 100 |

| BC-Buz-wc05-XS130 | 68 | 75 | 83 | - | 19 | 46 | 51 | 75 | 84 | 100 | 100 | 100 |

| BC-Buz-wc05-STE53 | 70 | 80 | 84 | - | 6 | 38 | 54 | 76 | 87 | 100 | 100 | 100 |

| BC-Buz-wc04-Ref | 66 | 79 | 85 | - | 8 | 37 | 15 | 51 | 74 | 57 | 100 | 100 |

| BC-Buz-wc04-XS130 | 64 | 81 | 83 | - | 3 | 33 | 60 | 71 | 79 | 79 | 100 | 100 |

| BC-Buz-wc04-STE53 | 67 | 81 | 82 | - | - | 33 | 60 | 75 | 89 | 100 | 100 | 100 |

| BC-n.a.-wc05-Ref | 64 | 87 | 91 | - | - | 22 | 11 | 37 | 34 | - | - | - |

| BC-n.a.-wc05-XS130 | 57 | 88 | 94 | - | - | 44 | 36 | 48 | 71 | - | - | - |

| BC-n.a.-wc05-STE53 | 64 | 84 | 93 | - | - | 32 | 24 | 42 | 69 | - | - | - |

| BC-n.a.-wc04-Ref | 59 | 82 | 93 | - | - | 18 | 17 | 33 | 39 | - | - | - |

| BC-n.a.-wc04-XS130 | 49 | 86 | 85 | - | - | 40 | 25 | 49 | 73 | - | - | - |

| BC-n.a.-wc04-STE53 | 63 | 86 | 88 | - | - | 27 | 21 | 45 | 76 | - | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morales-Cantero, A.; Cuesta, A.; De la Torre, A.G.; Mazanec, O.; Borralleras, P.; Weldert, K.S.; Gastaldi, D.; Canonico, F.; Aranda, M.A.G. Portland and Belite Cement Hydration Acceleration by C-S-H Seeds with Variable w/c Ratios. Materials 2022, 15, 3553. https://doi.org/10.3390/ma15103553

Morales-Cantero A, Cuesta A, De la Torre AG, Mazanec O, Borralleras P, Weldert KS, Gastaldi D, Canonico F, Aranda MAG. Portland and Belite Cement Hydration Acceleration by C-S-H Seeds with Variable w/c Ratios. Materials. 2022; 15(10):3553. https://doi.org/10.3390/ma15103553

Chicago/Turabian StyleMorales-Cantero, Alejandro, Ana Cuesta, Angeles G. De la Torre, Oliver Mazanec, Pere Borralleras, Kai S. Weldert, Daniela Gastaldi, Fulvio Canonico, and Miguel A. G. Aranda. 2022. "Portland and Belite Cement Hydration Acceleration by C-S-H Seeds with Variable w/c Ratios" Materials 15, no. 10: 3553. https://doi.org/10.3390/ma15103553

APA StyleMorales-Cantero, A., Cuesta, A., De la Torre, A. G., Mazanec, O., Borralleras, P., Weldert, K. S., Gastaldi, D., Canonico, F., & Aranda, M. A. G. (2022). Portland and Belite Cement Hydration Acceleration by C-S-H Seeds with Variable w/c Ratios. Materials, 15(10), 3553. https://doi.org/10.3390/ma15103553