Experimental Study on the Flexural Properties of Concrete Beams Reinforced with Hybrid Steel/Fiber-Belt-Bars

Abstract

:1. Introduction

2. Materials and Methods

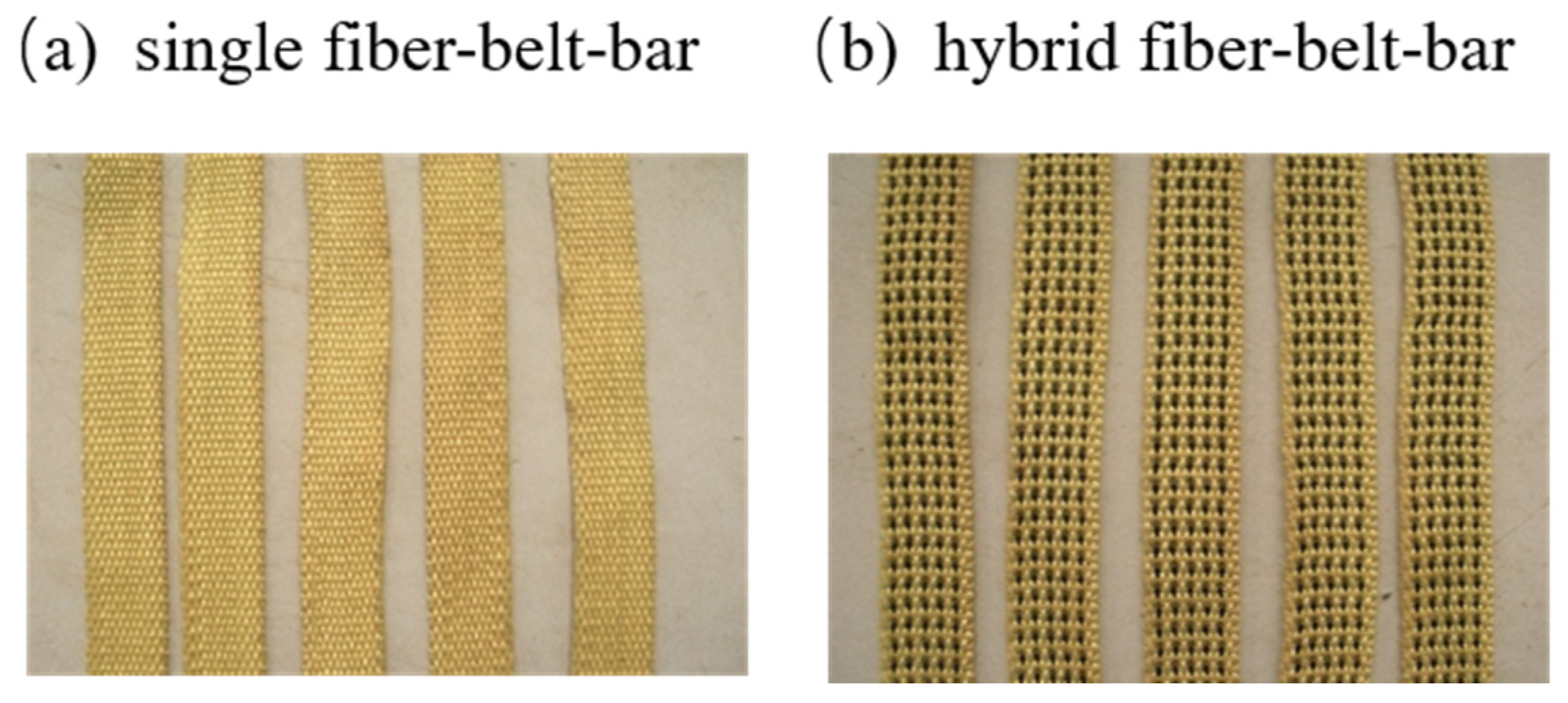

2.1. Materials

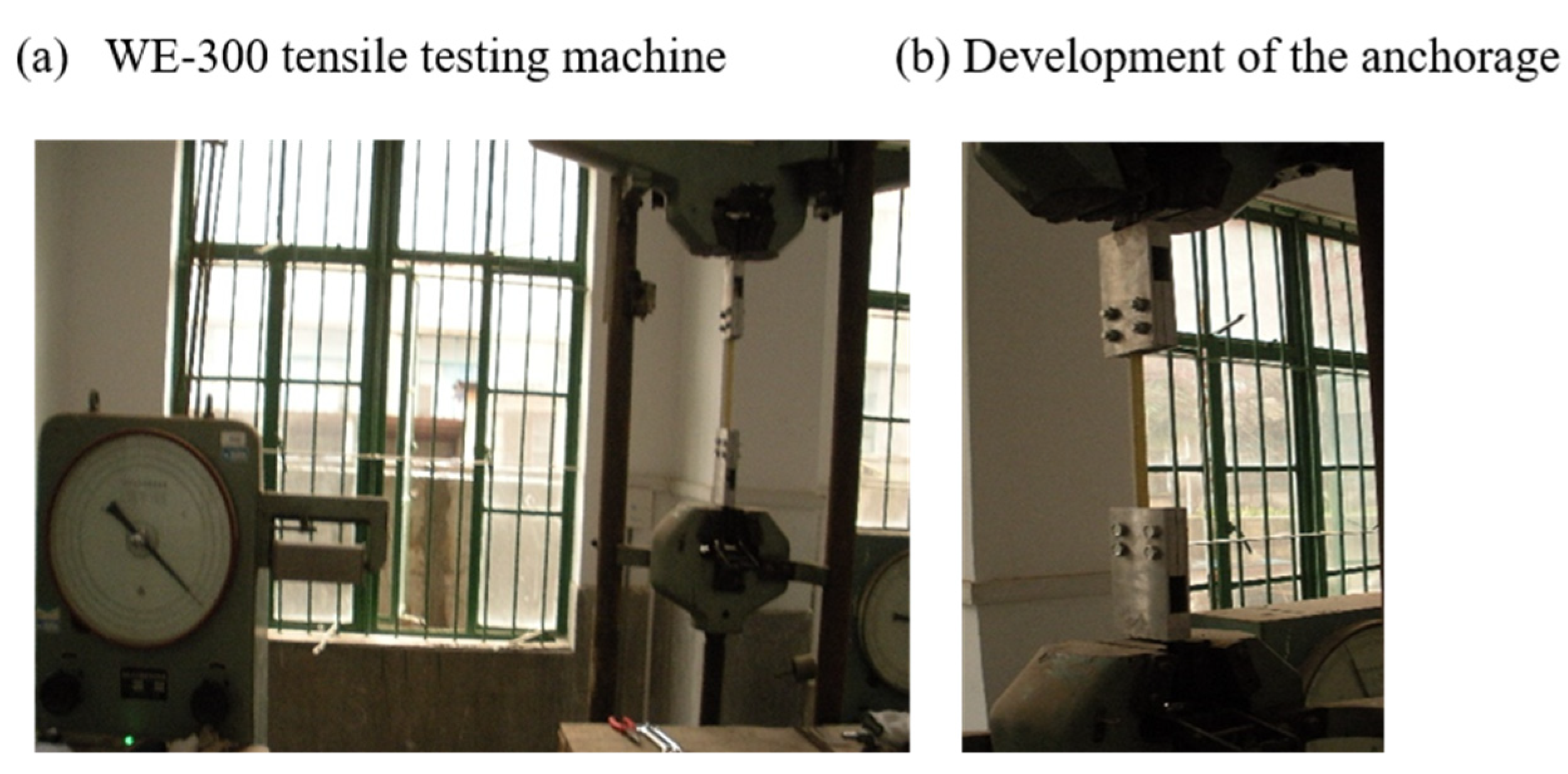

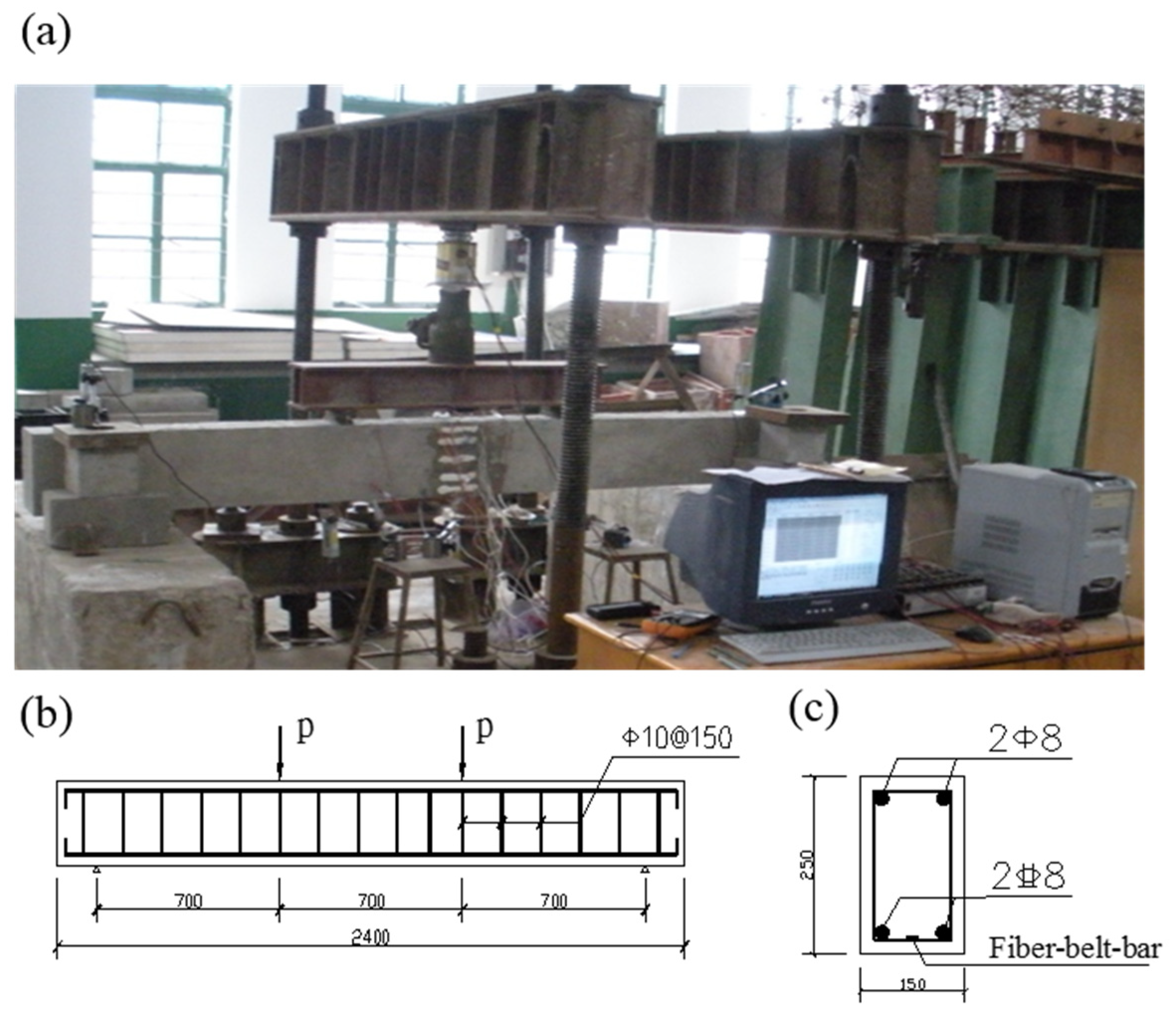

2.2. Experimental Methods

3. Result and Discussion

3.1. Experimental Study on the Mechanical Properties

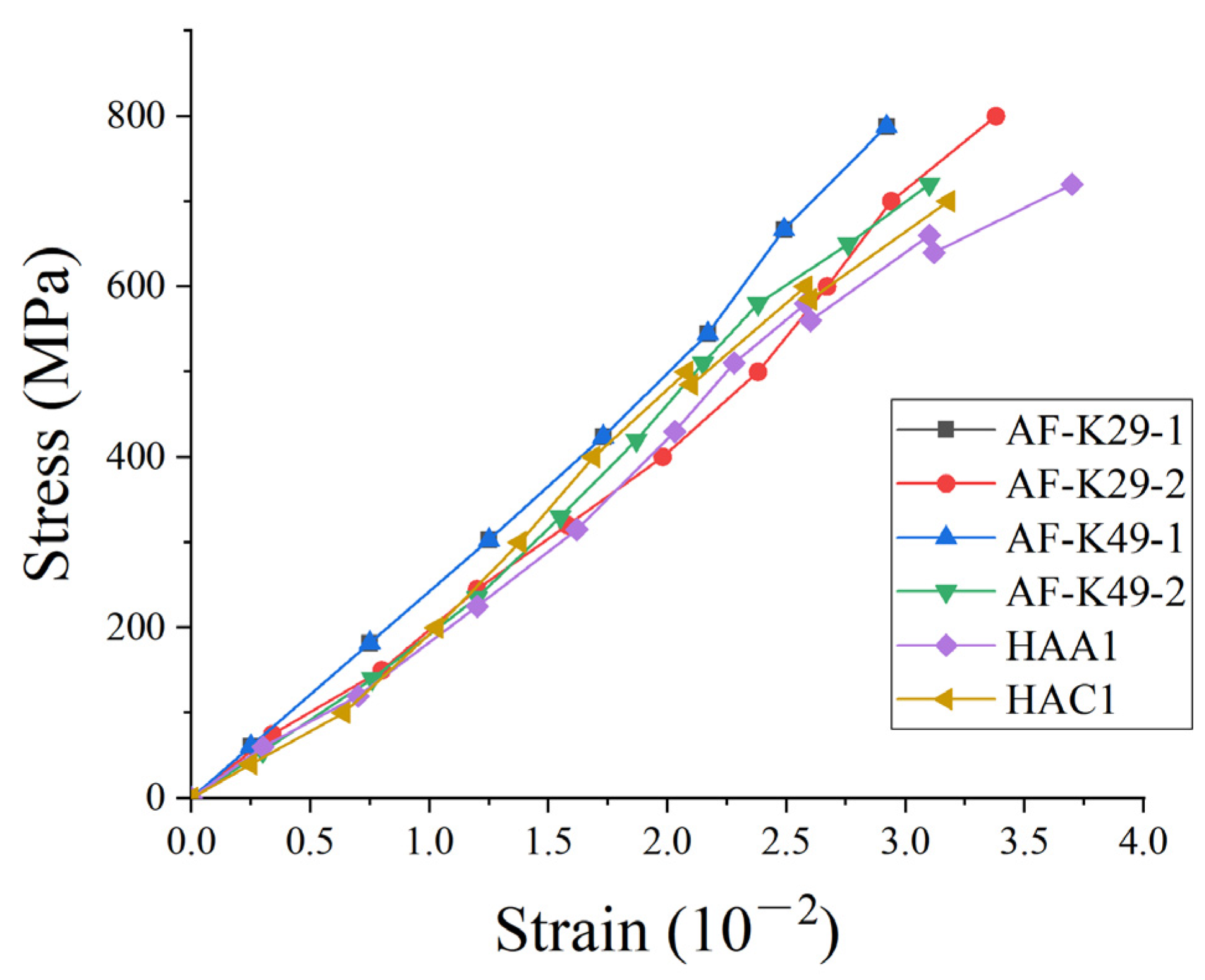

3.1.1. Analysis of the Mechanical Properties of Single Fiber Belt

3.1.2. Analysis of Mechanical Properties of Hybrid Fiber-Belt-Bars

3.2. Flexural Test on Normal Section of Fiber Reinforced Concrete Beam

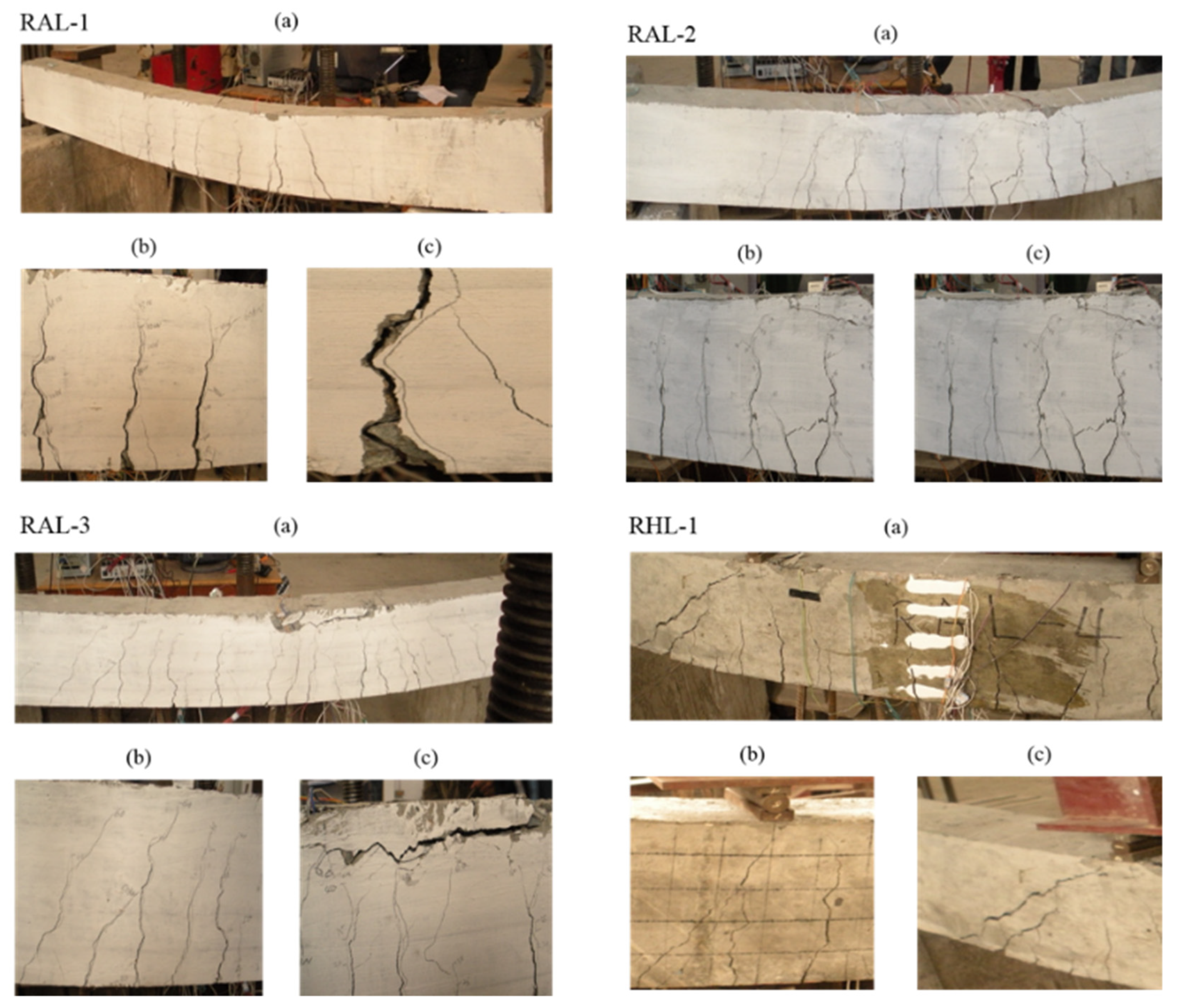

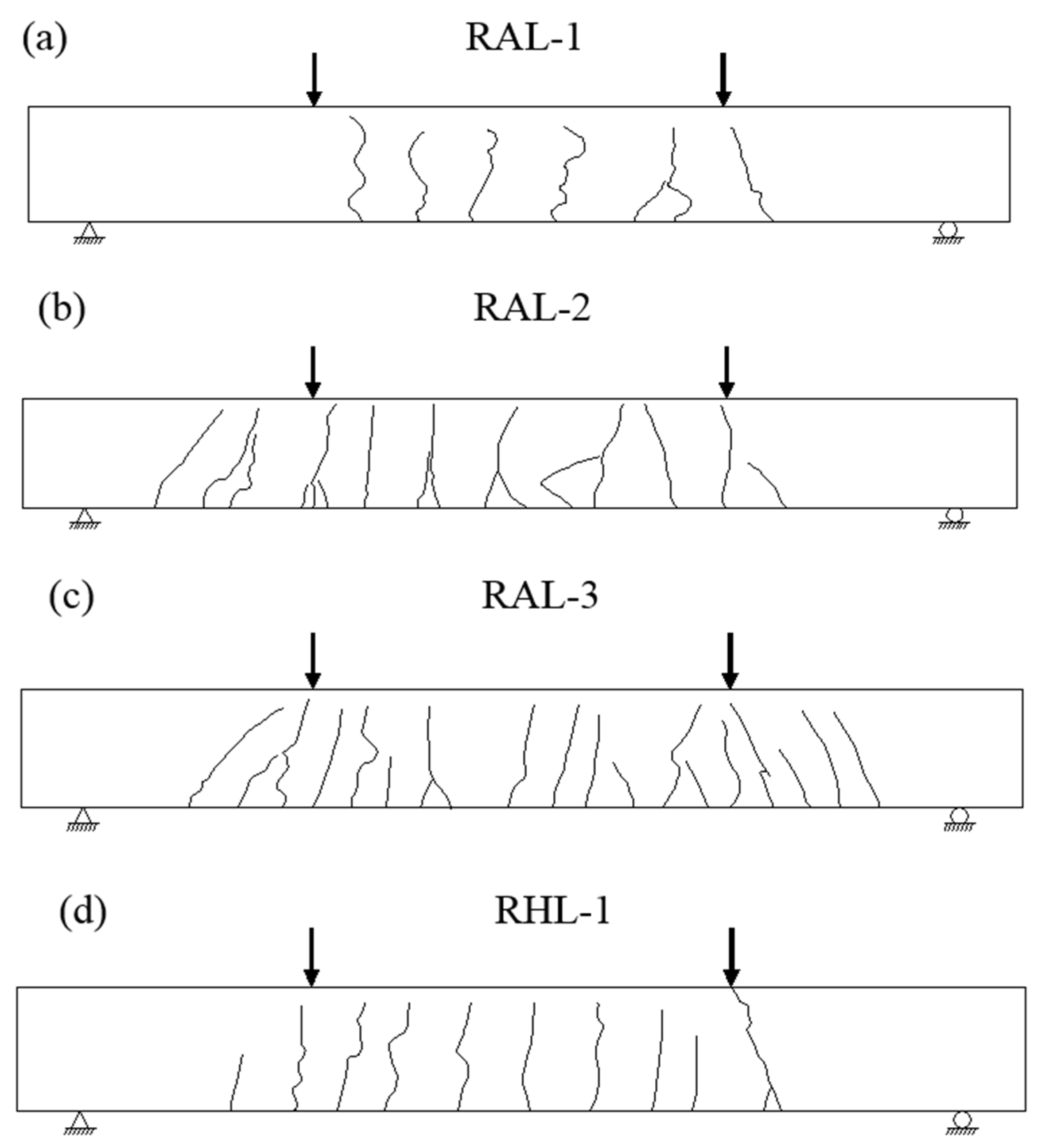

3.2.1. Characteristics of Cracking Load and Crack Distribution

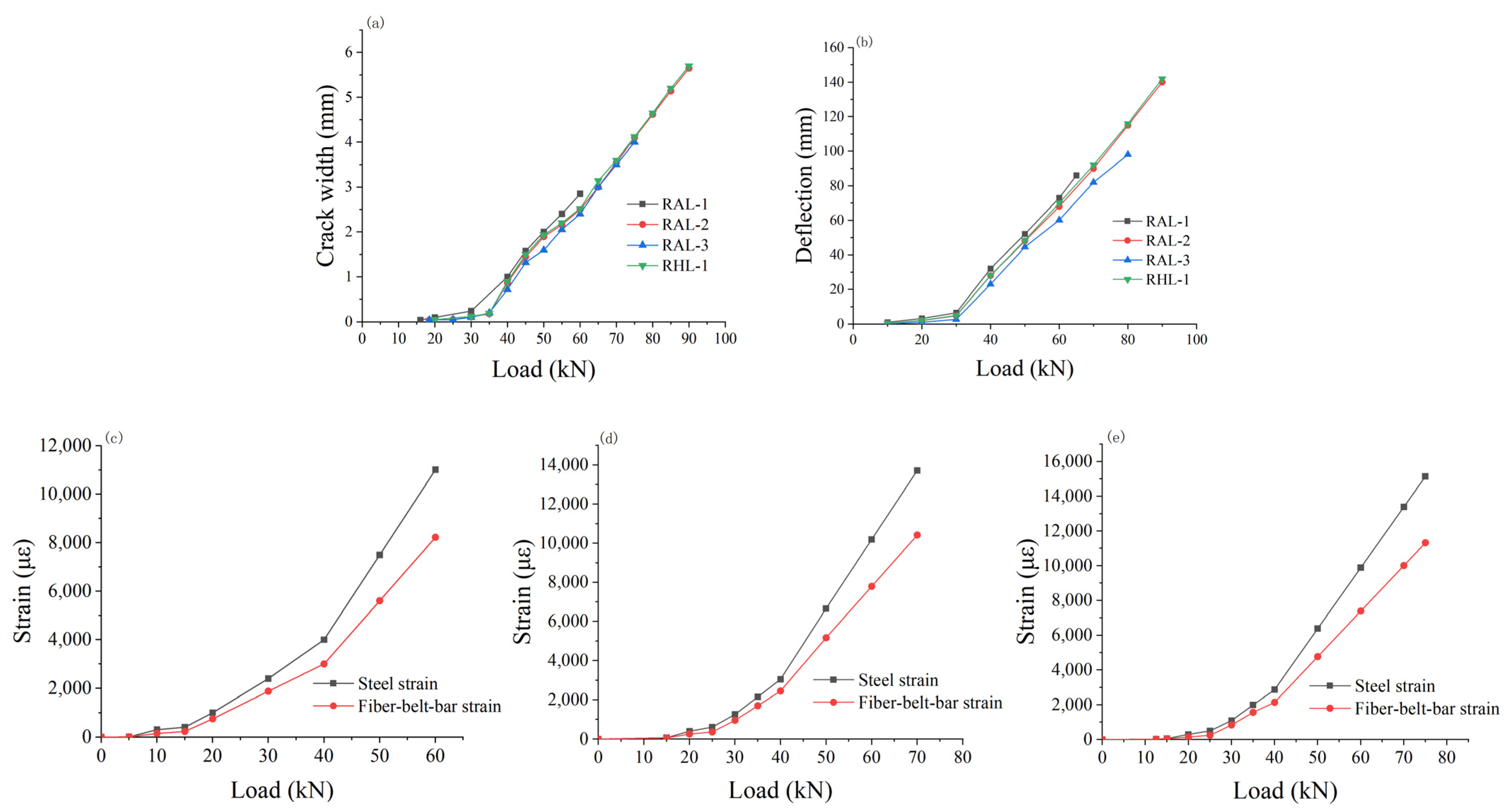

3.2.2. Strain Changes of Tensile Bars

3.2.3. Load-Deflection Curve

3.3. Improved Calculation of Crack Width and Deflection of Fiber Reinforced Concrete Beams

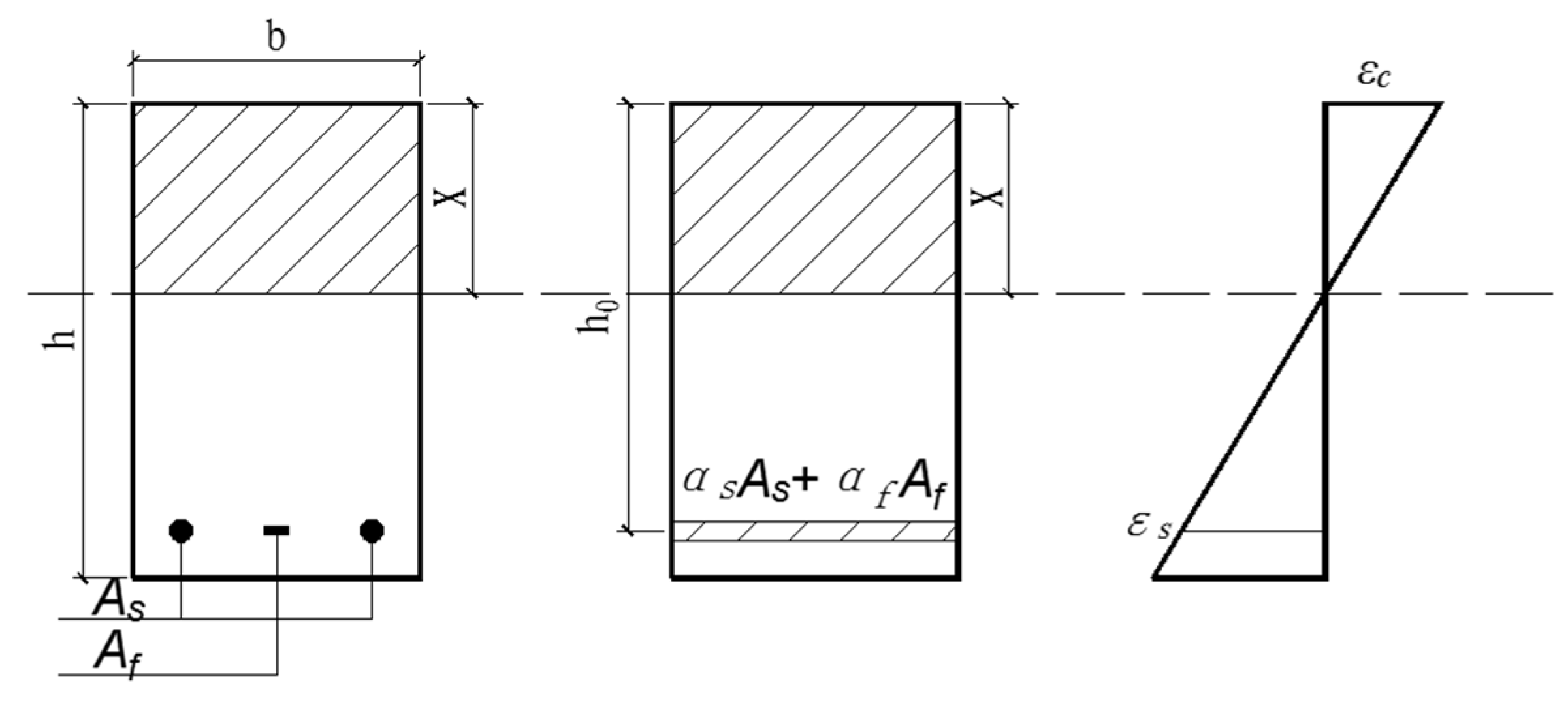

3.3.1. Derivation of Calculation Formula for Crack Width

3.3.2. Calculation of Deflection of Flexural Component under Short-Term Load

4. Conclusions

- The tensile strength of the fiber-belt-bars was lower than that of the fiber filament. The tensile strength of the fiber was generally about 30% of the tensile strength of the fiber filament. The tensile failure of a single fiber-belt-bar was a fracture failure, and the stress–strain curve changed linearly before failure. However, the stress–strain relationship of hybrid fiber-belt-bars had strain mutation, and the stress–strain relationship showed a broken line change.

- The coefficient in the formula for calculating the maximum crack width of reinforced concrete beams proposed in ACI standard was adjusted appropriately so that the formula can meet the requirements of the maximum crack width of concrete beams with fiber bars. By comparing the theoretical calculation value of the formula with the measured value of the test, the crack calculation formula proposed in this paper can predict the maximum crack width of the beam under various loads.

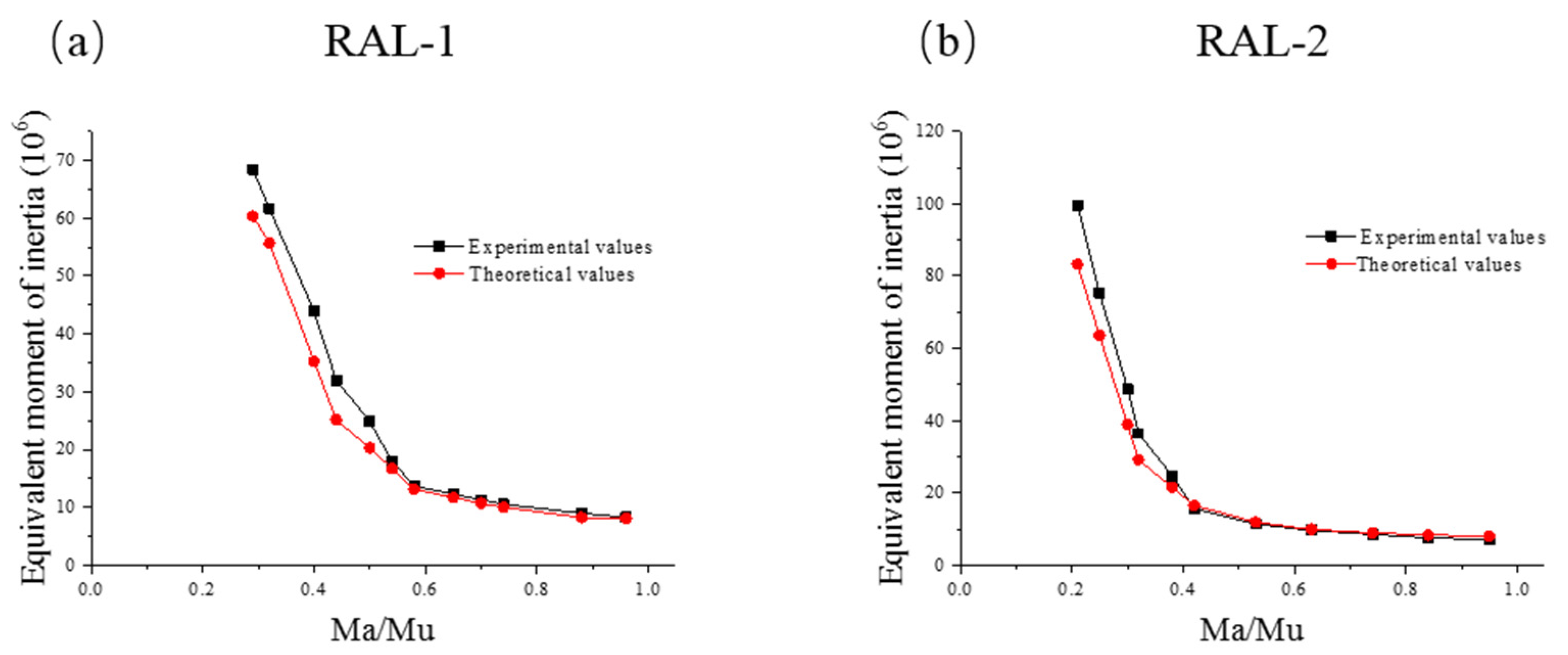

- The effective moment of inertia Ie in the ACI standard was modified by introducing the coefficients α and β. The coefficient α was derived from the test beam, and the coefficient β was derived from the elastic modulus and relative bond coefficient of the fiber-belt-bar. Through data comparison, we concluded that the deflection calculation formula proposed in this paper can better predict the deflection size of the beam. According to the bending characteristics of fiber-reinforced concrete beams under a normal service load, the maximum crack width or deflection limit may be reached before the test beams reached the ultimate state of bearing capacity. Therefore, the beam may be controlled by the limit state of normal service or the limit state of the bearing capacity with a different reinforcement ratio, section size and coefficient Kf.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Touileb, K.; Hedhibi, A.C.; Djoudjou, R.; Ouis, A.; Bensalama, A.; Ibrahim, A.; Abdo, H.S.; Ahmed, M.M.Z. Mechanical, Microstructure, and Corrosion Characterization of Dissimilar Austenitic 316L and Duplex 2205 Stainless-Steel ATIG Welded Joints. Materials 2022, 15, 2470. [Google Scholar] [CrossRef] [PubMed]

- Saura, P.; Zornoza, E.; Andrade, C.; Ferrandiz-Mas, V.; Garces, P. Composition of Corroded Reinforcing Steel Surface in Solutions Simulating the Electrolytic Environments in the Micropores of Concrete in the Propagation Period. Materials 2022, 15, 2216. [Google Scholar] [CrossRef] [PubMed]

- Rehman, F.U.; Cashell, K.A.; Anguilano, L. Experimental Study of the Post-Fire Mechanical and Material Response of Cold-Worked Austenitic Stainless Steel Reinforcing Bar. Materials 2022, 15, 1564. [Google Scholar] [CrossRef] [PubMed]

- Kioumarsi, M.; Benenato, A.; Ferracuti, B.; Imperatore, S. Residual flexural capacity of corroded prestressed reinforced concrete beams. Materials 2021, 11, 442. [Google Scholar] [CrossRef]

- Bonopera, M.; Chang, K.C. Novel method for identifying residual prestress force in simply supported concrete girder-bridges. Adv. Struct. Eng. 2021, 24, 3238–3251. [Google Scholar] [CrossRef]

- Protchenko, K. Residual Fire Resistance Testing of Basalt- and Hybrid-FRP Reinforced Concrete Beams. Materials 2022, 15, 1509. [Google Scholar] [CrossRef]

- Tang, L. Maintenance and Inspection of Fiber-Reinforced Polymer (FRP) Bridges: A Review of Methods. Materials 2021, 14, 7826. [Google Scholar] [CrossRef]

- El-Nemr, A.; Ahmed, E.A.; Benmokrane, B. Flexural Behavior and serviceability of normal- and high-Strength concrete beams reinforced with glass fiber-reinforced polymer bars. ACI Struct. J. 2013, 110, 1077–1087. [Google Scholar]

- Saleem, S.; Pimanmas, A.; Qureshi, M.I.; Rattanapitikon, W. Axial Behavior of PET FRP-Confined Reinforced Concrete. J. Compos. Constr. 2021, 25, 04020079. [Google Scholar] [CrossRef]

- Saleem, S.; Hussain, Q.; Pimanmas, A. Compressive Behavior of PET FRP-Confined Circular, Square, and Rectangular Concrete Columns. J. Compos. Constr. 2017, 21, 04016097. [Google Scholar] [CrossRef]

- Ye, Y.-Y.; Smith, S.T.; Zeng, J.-J.; Zhuge, Y.; Quach, W.-M. Novel ultra-high-performance concrete composite plates reinforced with FRP grid: Development and mechanical behaviour. Compos. Struct. 2021, 269, 114033. [Google Scholar] [CrossRef]

- Badawi, M.; Soudki, K. Flexural strengthening of RC beams with prestressed NSM CFRP rods—Experimental and analytical investigation. Constr. Build. Mater. 2009, 23, 3292–3300. [Google Scholar] [CrossRef]

- Chan, T.K.; Niall, M.A. Strengthening of one-way slabs using carbon fibre plates: The effect of preload. Civ. Eng. Res. 2001, 14, 1–4. [Google Scholar]

- Triantafillou, T.C.; Plevris, N. Strengthening of RC beams with epoxy-bonded fibre-composite materials. Mater. Struct. 1992, 25, 201–211. [Google Scholar] [CrossRef]

- Foraboschi, P. Predictive multiscale model of delayed debonding for concrete members with adhesively bonded external reinforcement. Compos. Mech. Comput. Appl. 2012, 3, 307–329. [Google Scholar] [CrossRef]

- Aiello, M.A.; Ombres, L. Structural Performances of Concrete Beams with Hybrid (Fiber-Reinforced Polymer-Steel) Reinforcements. J. Compos. Constr. 2002, 6, 133–140. [Google Scholar] [CrossRef]

- Leung, H.Y.; Balendran, R.V. Flexural behaviour of concrete beams internally reinforced with GFRP rods and steel rebars. Struct. Surv. 2003, 21, 146–157. [Google Scholar] [CrossRef]

- Tang, W.C.; Balendran, R.V.; Nadeem, A.; Leung, H.Y. Flexural strengthening of reinforced lightweight polystyrene aggregate concrete beams with near-surface mounted GFRP bars. Build. Environ. 2006, 41, 1381–1393. [Google Scholar] [CrossRef]

- Qin, R.; Zhou, A.; Lau, D. Effect of reinforcement ratio on the flexural performance of hybrid FRP reinforced concrete beams. Compos. Part B Eng. 2017, 108, 200–209. [Google Scholar] [CrossRef]

- Pang, L.; Qu, W.; Zhu, P.; Xu, J. Design Propositions for Hybrid FRP-Steel Reinforced Concrete Beams. J. Compos. Constr. 2016, 20, 04015086. [Google Scholar] [CrossRef]

- Qu, W.J.; Zhang, X.L.; Huang, H.Q. Flexural behavior of concrete beams reinforced with hybrid (GFRP and steel) bars. J. Compos. Constr. 2009, 13, 350–359. [Google Scholar] [CrossRef]

- Farmington, H. Building Code Requirements for Structural Concrete; ACI 318-19; American Concrete Institute: Michigan, MI, USA, 2019. [Google Scholar]

- Qu, W.J.; Zhang, J.; Huang, H.Q. Flexural Test and Crack and Deflection Algorithm of Reinforced GFRP Reinforced Concrete Beams. Build. Struct. 2006, 36, 38–41. [Google Scholar]

| Sample Code | Materials | Representation Area (mm2) | Actual Cross-Sectional Area (mm2) |

|---|---|---|---|

| AF-K29-1 | AFRP (Kevlar29) | 12 × 3 | 16.5 |

| AF-K29-2 | AFRP (Kevlar29) | 20 × 3 | 25 |

| AF-K49-1 | AFRP (Kevlar49) | 12 × 3 | 16.5 |

| AF-K49-2 | AFRP (Kevlar49) | 20 × 3 | 25 |

| HAA1 | 80% K29 + 10% K49 + 10% T300 | 20 × 3 | 25 |

| HAC1 | 80% K29 + 20% T300 | 20 × 3 | 25 |

| Sample Code | Fiber Types | Number of Fiber-Belt-Bar (Root) | ρf (%) | As (mm2) | ρs (%) | Kf |

|---|---|---|---|---|---|---|

| RAL-1 | AF-K49-2 | 1 | 0.18 | 100.48 | 0.3 | 0.37 |

| RAL-2 | AF-K49-2 | 3 | 0.54 | 100.48 | 0.3 | 0.64 |

| RAL-3 | AF-K49-2 | 4 | 0.73 | 100.48 | 0.3 | 0.72 |

| RHL-1 | HAC1 | 3 | 0.54 | 100.48 | 0.3 | 0.64 |

| Materials | Concrete | AF-K49-2 | HAC1 | ||||

|---|---|---|---|---|---|---|---|

| Performance Indictors | The Compressive Strength fcu (MPa) | Tensile Modulus Eaf (GPa) | Tensile Strength ffu (MPa) | Elongation εafu | Tensile Modulus Eaf (GPa) | Tensile Strength ffu (MPa) | Elongation εafu |

| Average values | 48 | 24 | 946 | 0.039 | 21 | 783 | 0.037 |

| Standard values | 43 | — | 922 | — | — | 760 | — |

| Sample Code | AF-K29-1 | AF-K29-2 | AF-K49-1 | AF-K49-2 | HAA1 | HAC1 |

|---|---|---|---|---|---|---|

| Effective cross section (mm2) | 16.5 | 25 | 16.5 | 25 | 25 | 25 |

| Average values (MPa) | 873 | 874 | 921 | 946 | 845 | 783 |

| Standard values (MPa) | 829 | 828 | 871 | 922 | 824 | 760 |

| standard deviation σ | 27 | 28 | 31 | 24 | 13 | 14 |

| Modulus of elasticity (GPa) | 26 | 22 | 26 | 24 | 20 | 21 |

| Elongation (%) | 3.36 | 3.97 | 3.54 | 3.94 | 5.35 | 5.50 |

| Sample Code | Cracking Load (kN) | Ultimate Load (kN) | Damage |

|---|---|---|---|

| RAL-1 | 13.5 | 68 | Tensile failure of fiber-belt-bar |

| RAL-2 | 15.5 | 95 | Concrete crushing |

| RAL-3 | 16 | 80 | Concrete crushing |

| RHL-1 | 15 | 95 | Shear failure of fiber-belt-bar |

| Sample Code | Mean Crack Width | |||||

|---|---|---|---|---|---|---|

| 20 kN | 40 kN | 60 kN | ||||

| Width (mm) | Width (mm) | Width (mm) | ||||

| RAL-1 | 0.49 | 0.18 | 0.37 | 0.16 | 1.00 | 2.85 |

| RAL-2 | 0.85 | 0.54 | 0.64 | 0.06 | 0.77 | 2.5 |

| RAL-3 | 1.03 | 0.72 | 0.72 | 0.05 | 0.72 | 2.4 |

| RHL-1 | 0.85 | 0.54 | 0.64 | 0.06 | 0.79 | 2.52 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, W.; Liu, H.; Dong, Y. Experimental Study on the Flexural Properties of Concrete Beams Reinforced with Hybrid Steel/Fiber-Belt-Bars. Materials 2022, 15, 3505. https://doi.org/10.3390/ma15103505

Gu W, Liu H, Dong Y. Experimental Study on the Flexural Properties of Concrete Beams Reinforced with Hybrid Steel/Fiber-Belt-Bars. Materials. 2022; 15(10):3505. https://doi.org/10.3390/ma15103505

Chicago/Turabian StyleGu, Wenhu, Hengrui Liu, and Yun Dong. 2022. "Experimental Study on the Flexural Properties of Concrete Beams Reinforced with Hybrid Steel/Fiber-Belt-Bars" Materials 15, no. 10: 3505. https://doi.org/10.3390/ma15103505

APA StyleGu, W., Liu, H., & Dong, Y. (2022). Experimental Study on the Flexural Properties of Concrete Beams Reinforced with Hybrid Steel/Fiber-Belt-Bars. Materials, 15(10), 3505. https://doi.org/10.3390/ma15103505