Effect of Thermal Simulation Process on Microstructure of Seismic Steel Bars

Abstract

1. Introduction

2. Experimental Procedures

2.1. Preparation of Test Sample

2.2. Thermal Simulation Process

2.3. Experimental Methods

3. Results and Analysis

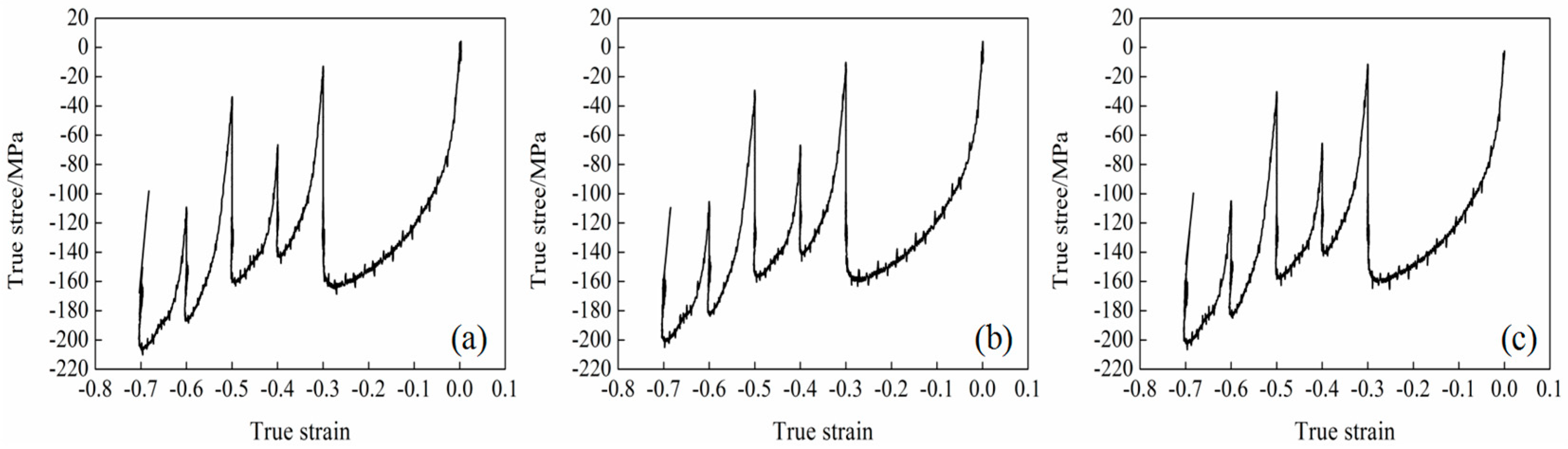

3.1. True Stress–True Strain Curve

3.2. Microstructure Analysis

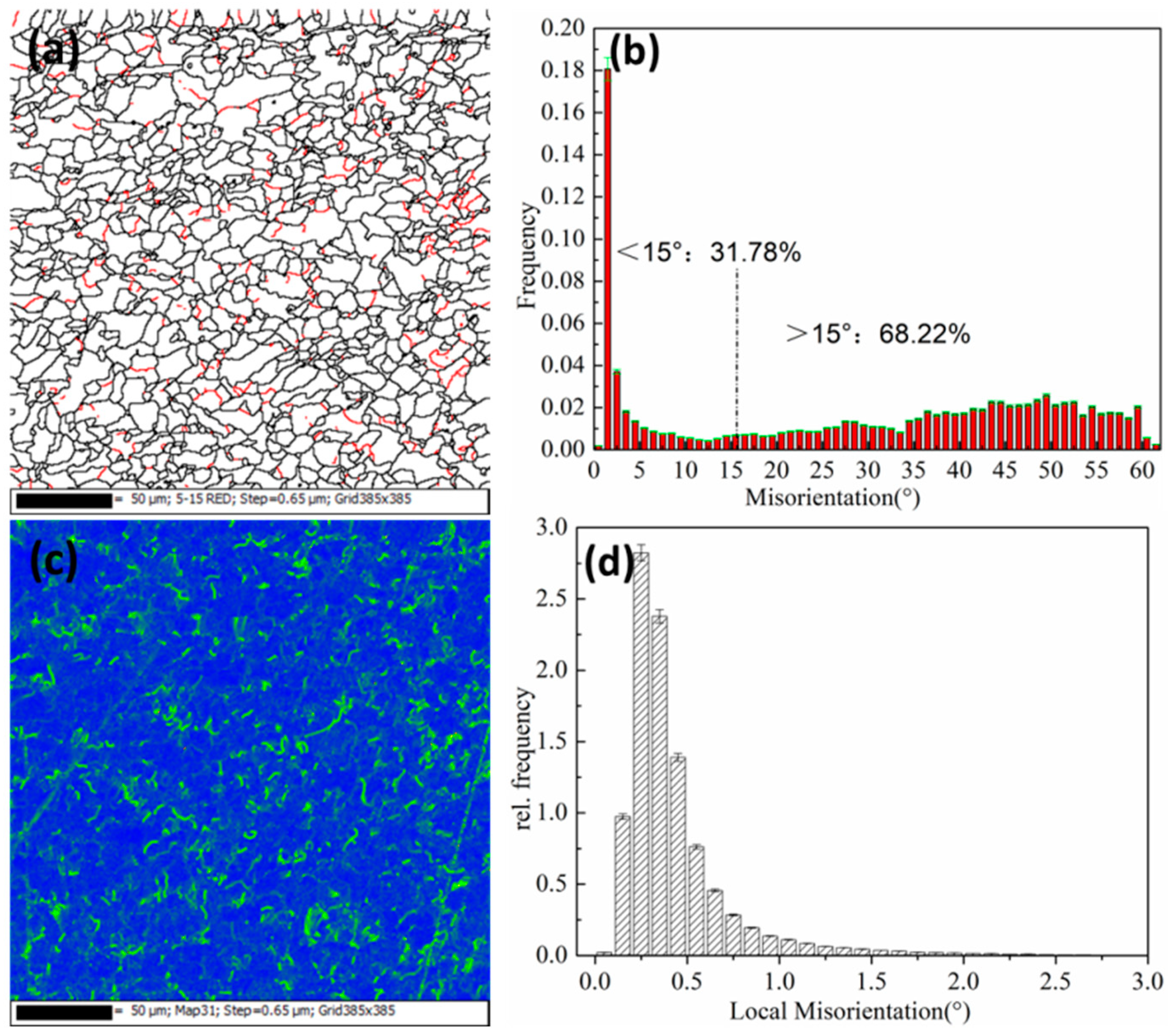

3.3. EBSD Analysis

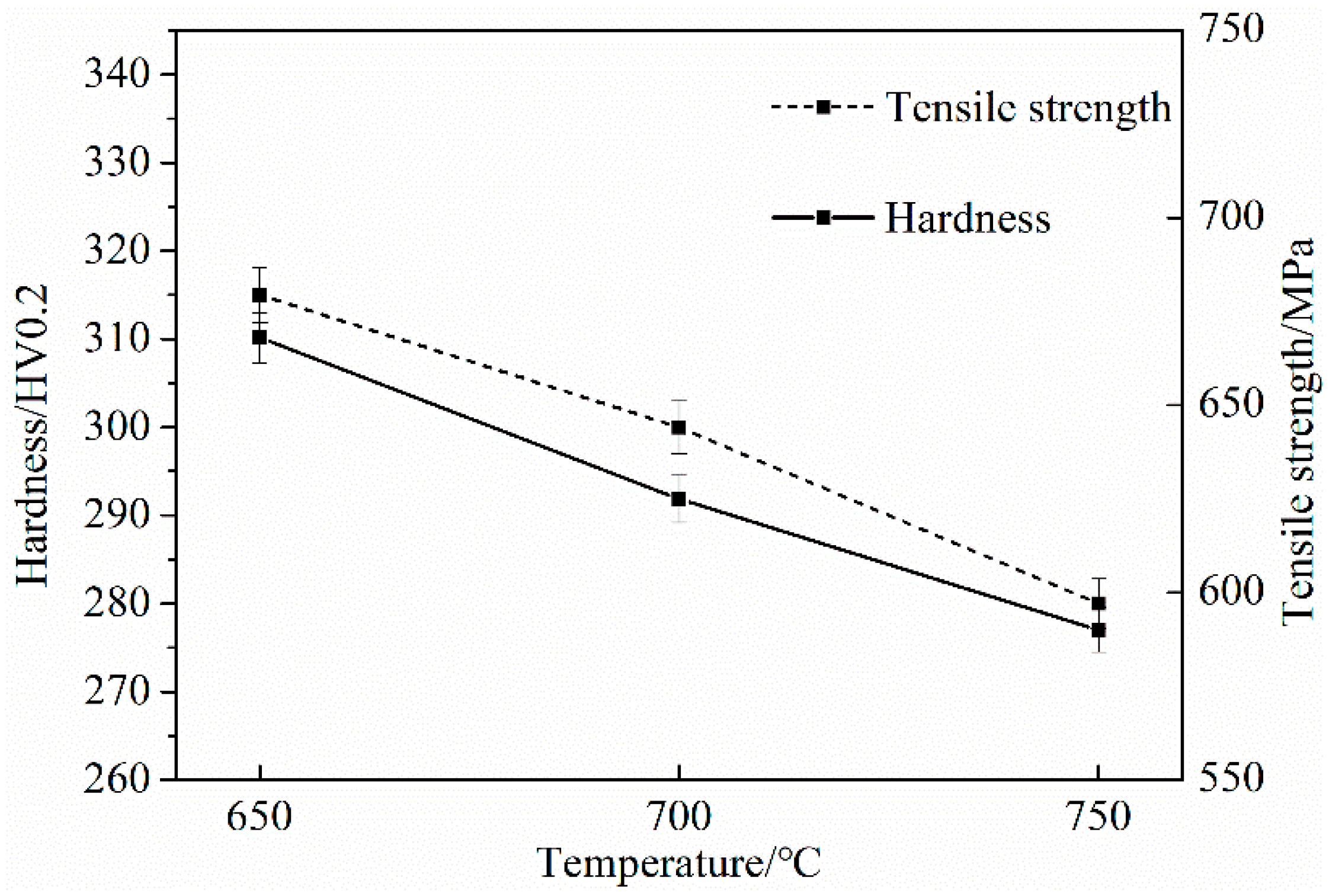

3.4. Mechanical Property

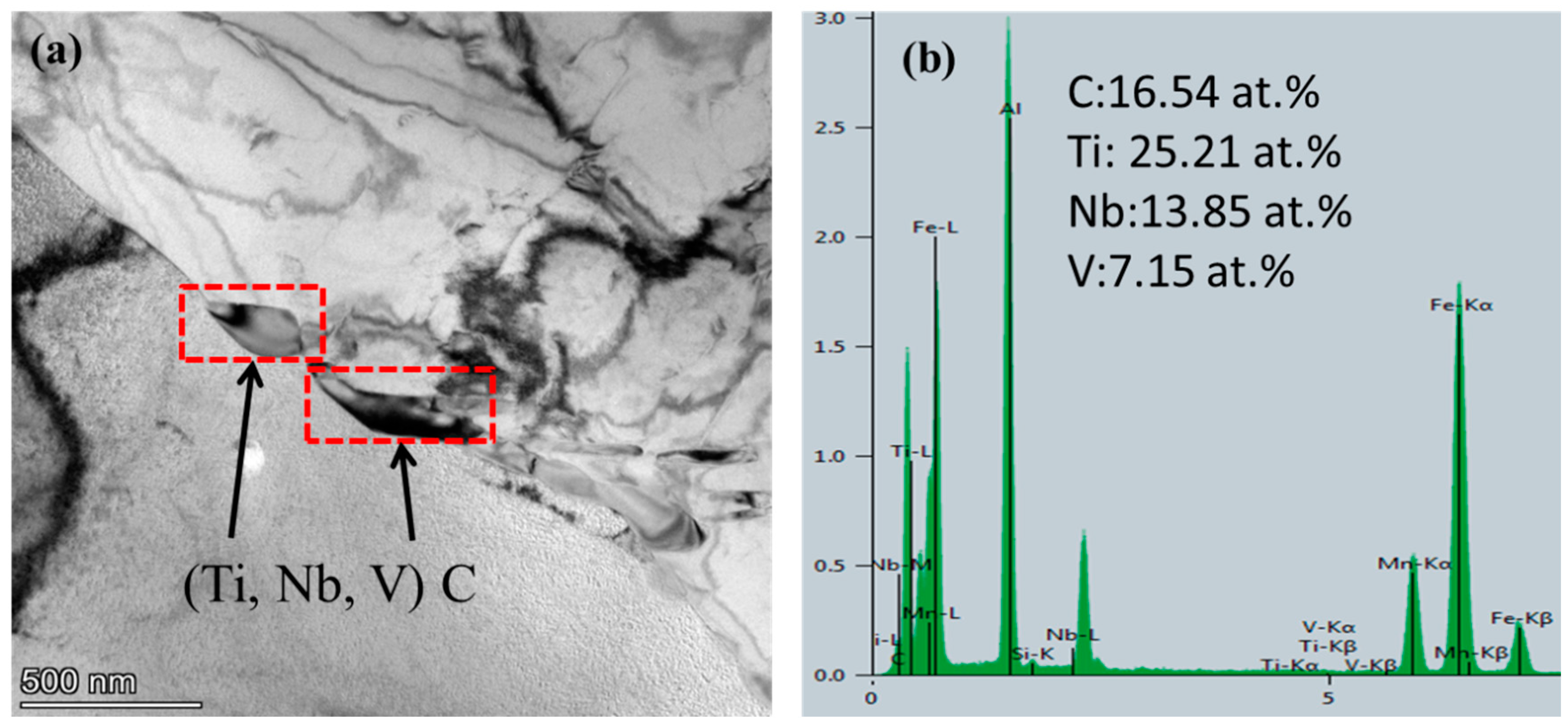

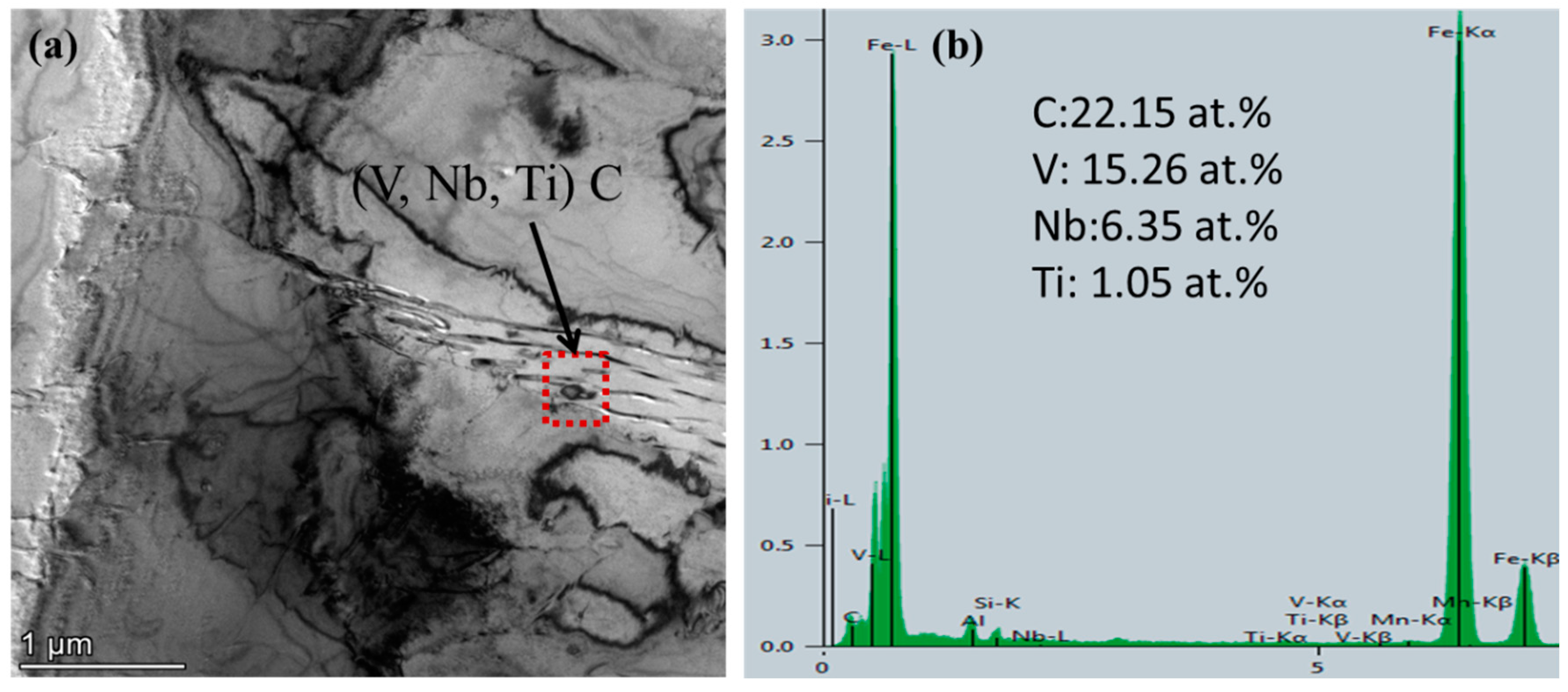

3.5. Characterization of Precipitates

4. Discussion

5. Conclusions

- (1)

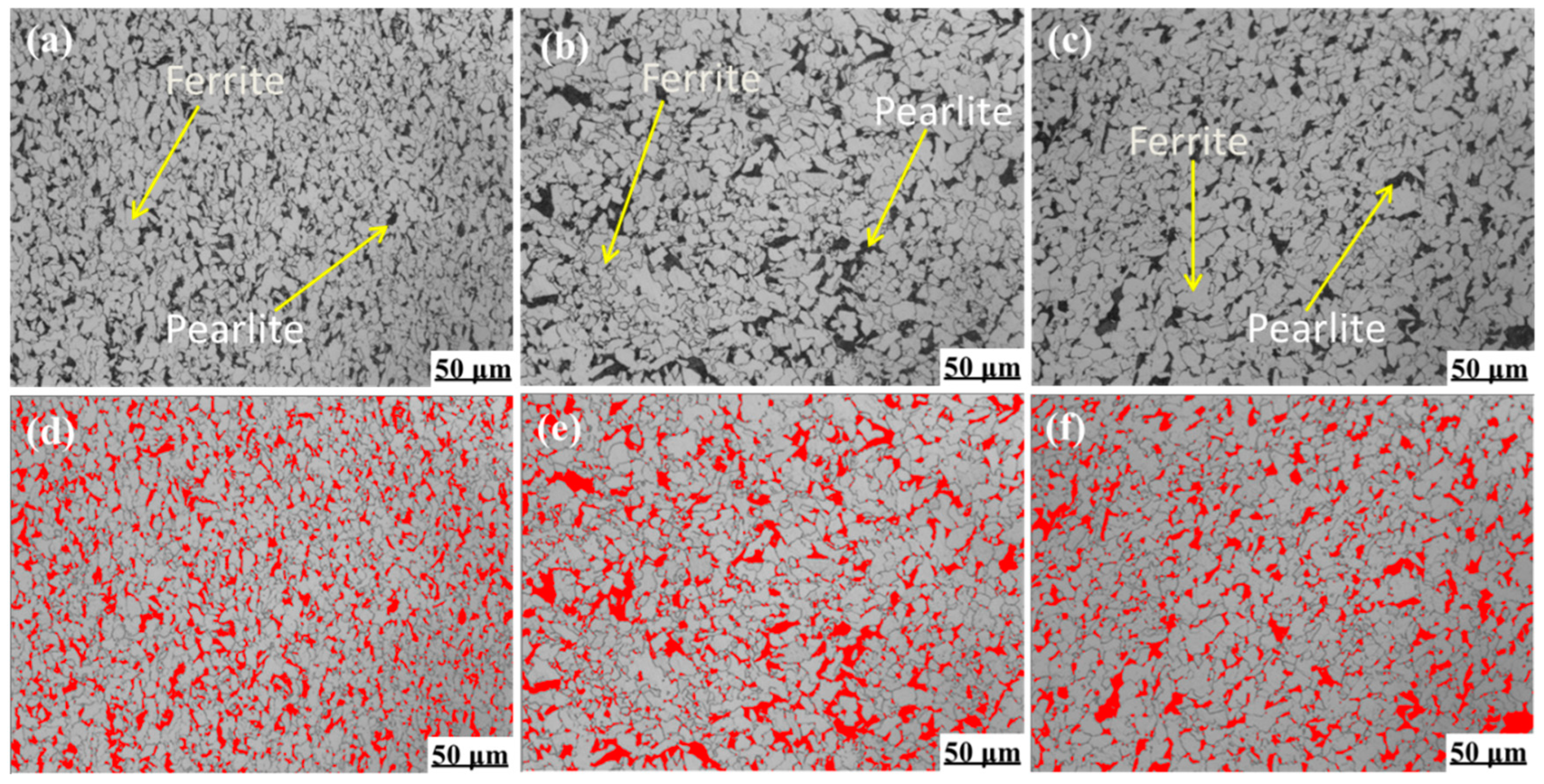

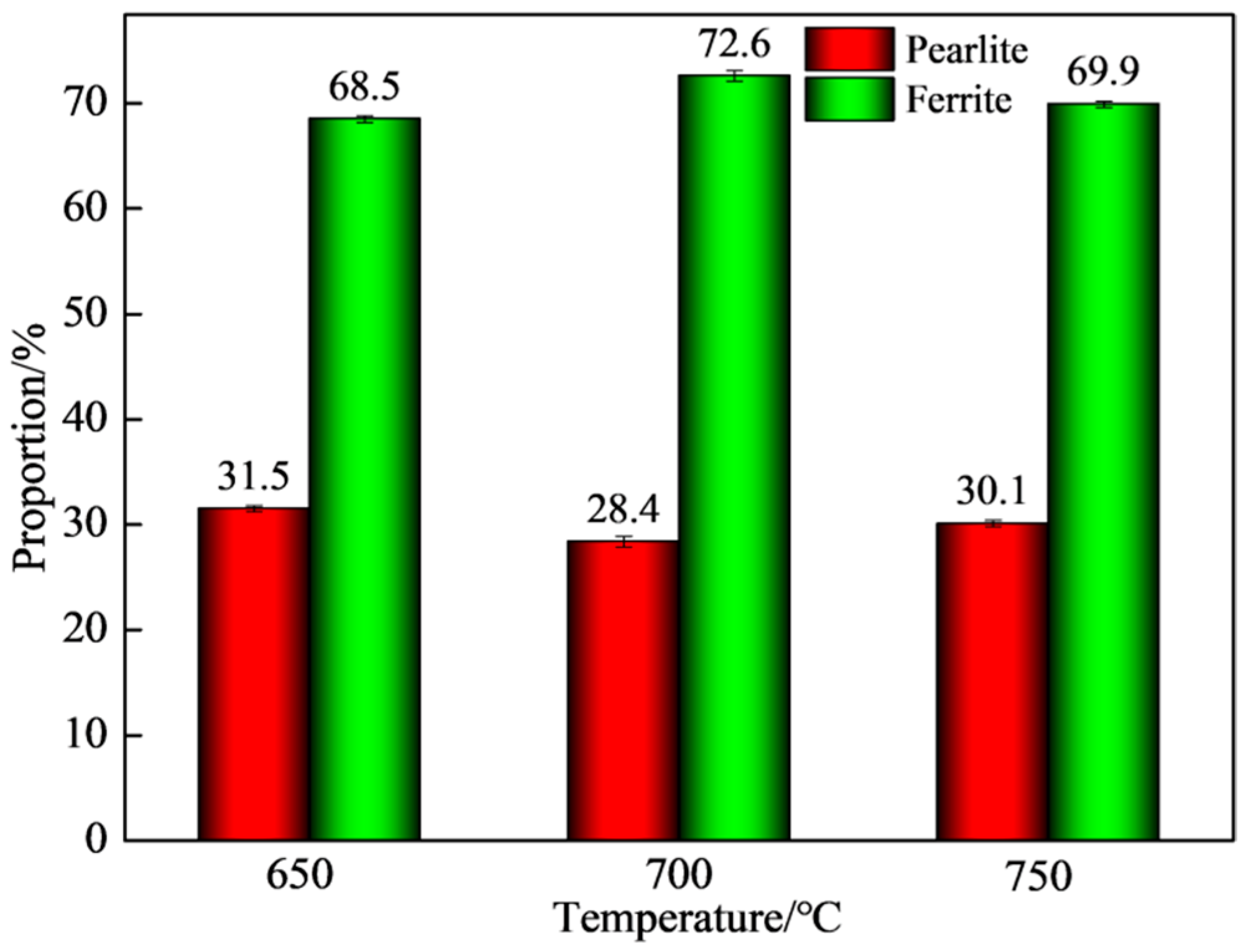

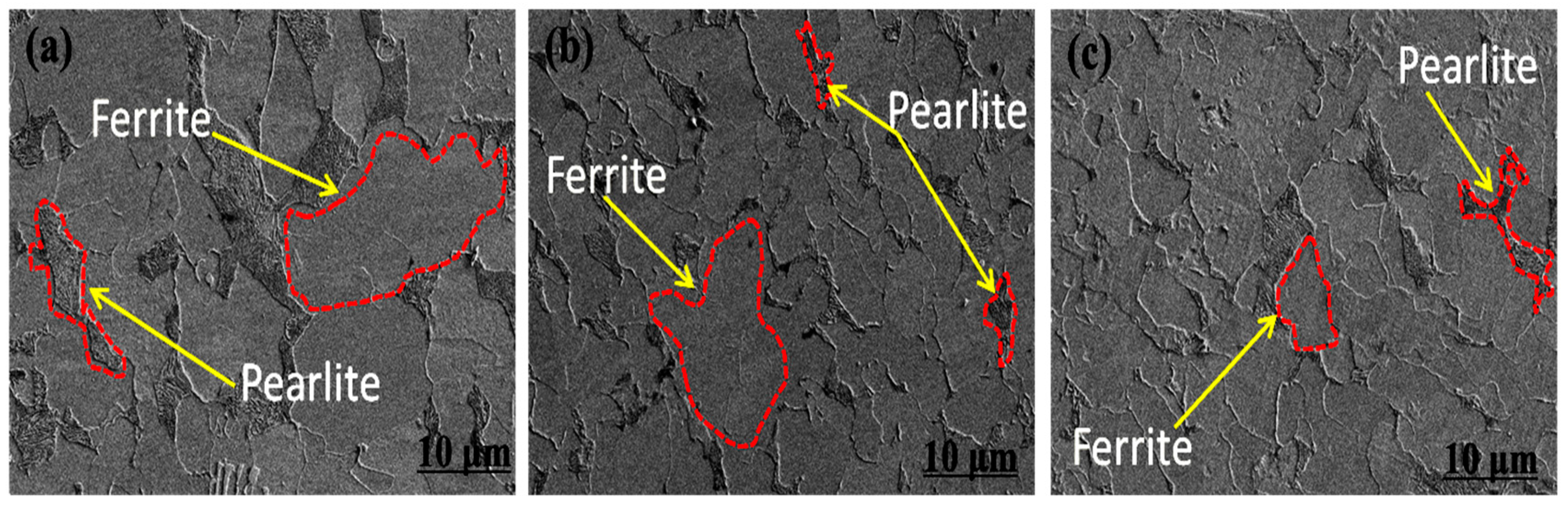

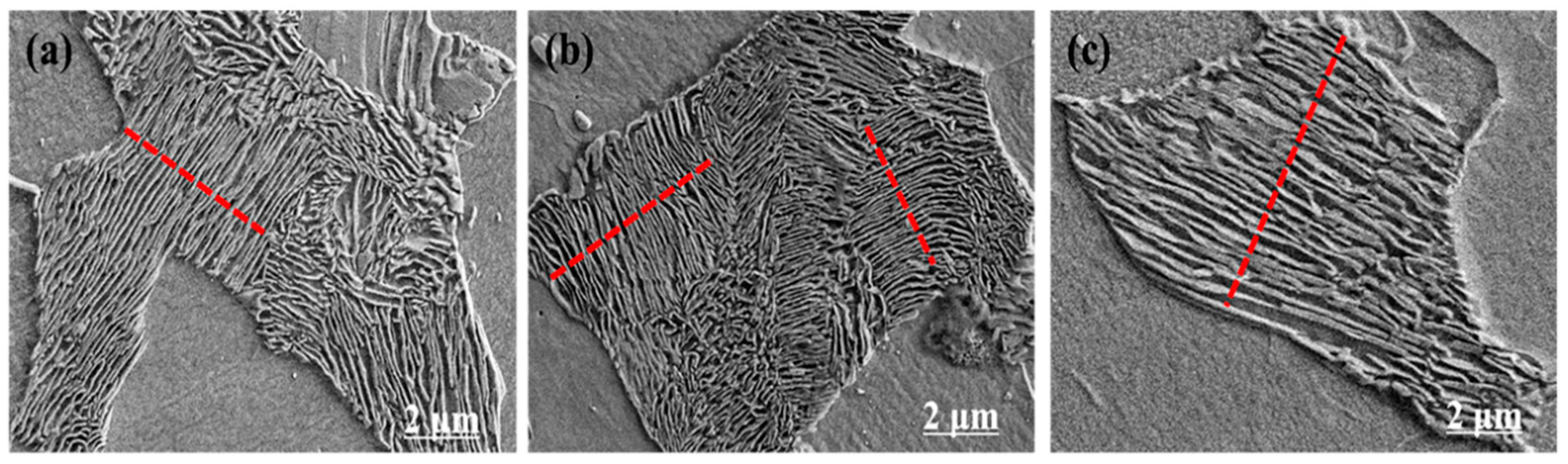

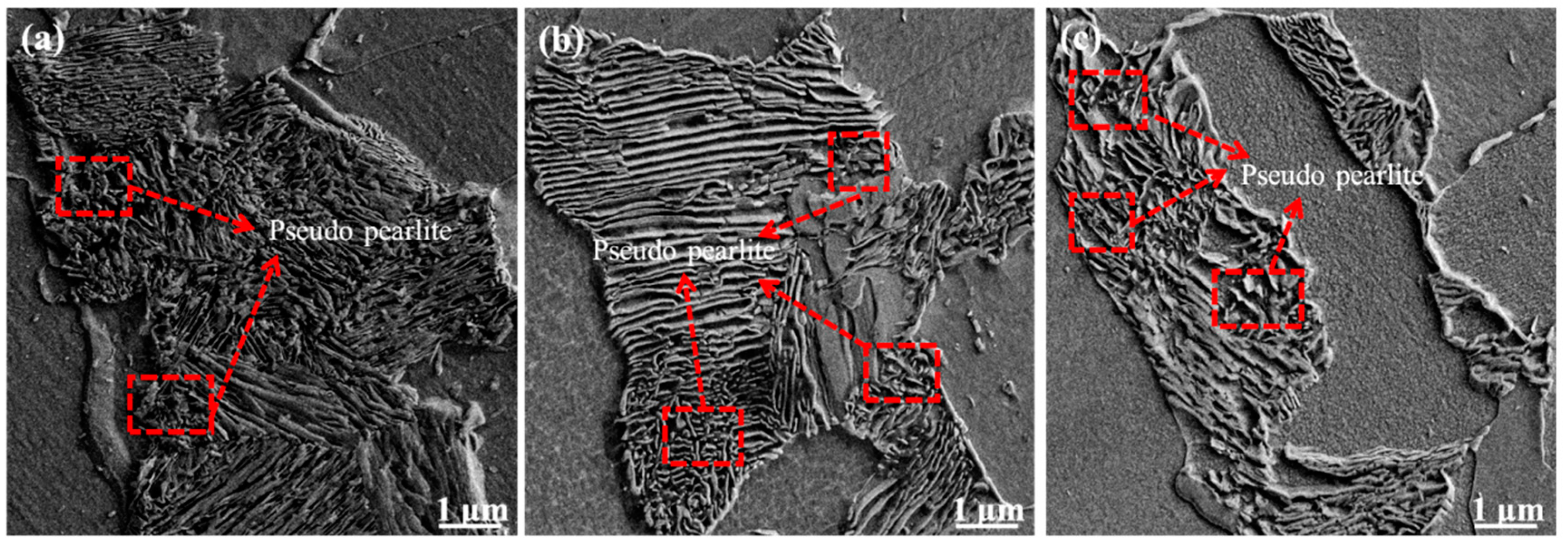

- The microstructure of the experimental steel was mainly composed of polygonal ferrite and pearlite. Pearlite was mainly composed of flakes, accompanied by a small amount of short rod-shaped or granular pseudo-pearlite, evenly distributed on the ferrite matrix. The grain size of ferrite and the interlayer spacing of pearlite decreased with the decreased of the final cooling temperature. When the final cooling temperature were 650 °C and 750 °C, the average ferrite grain size were 7.68 μm and 17.07 μm, respectively. The grain sizes were 11 and 9, respectively.

- (2)

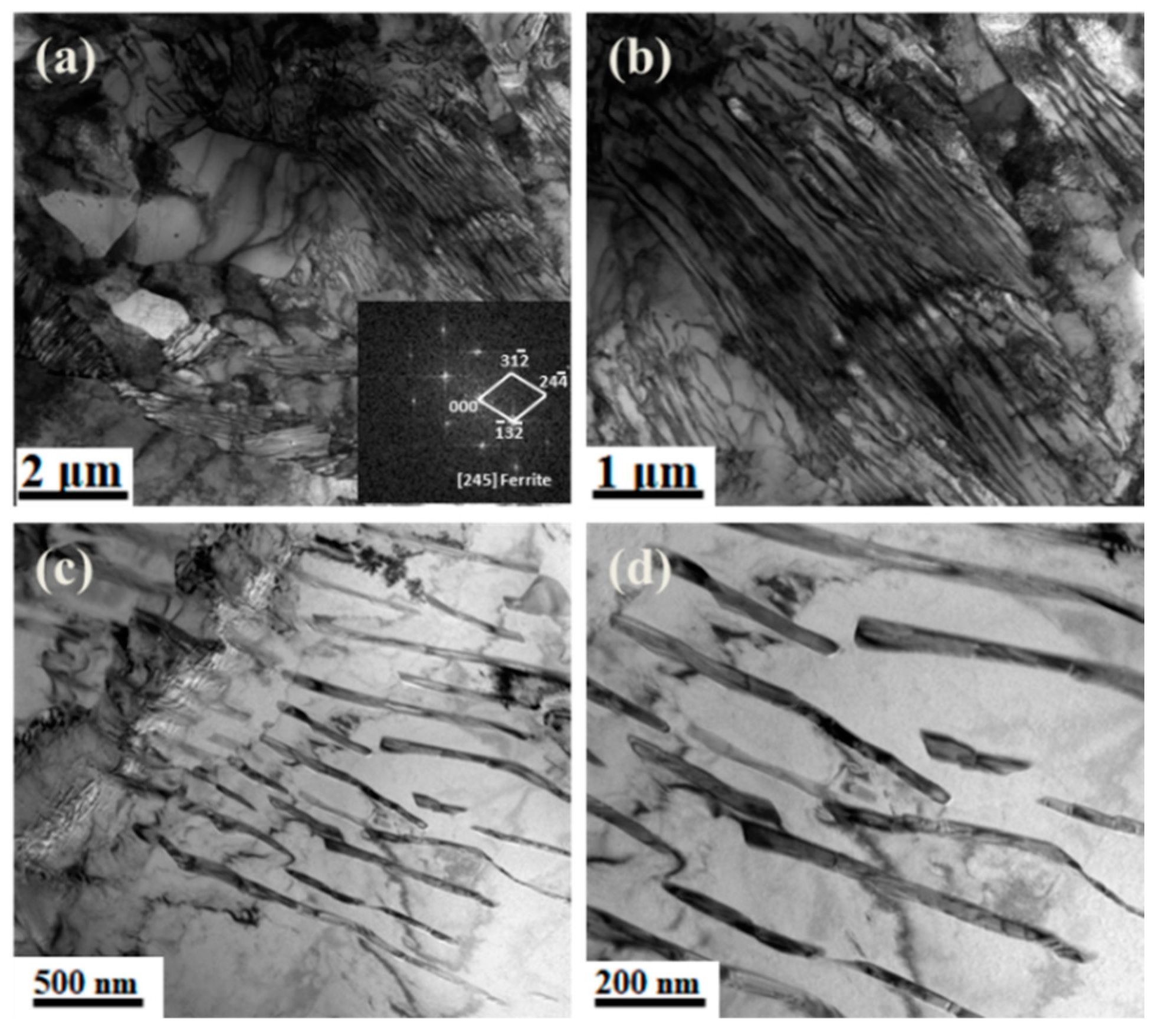

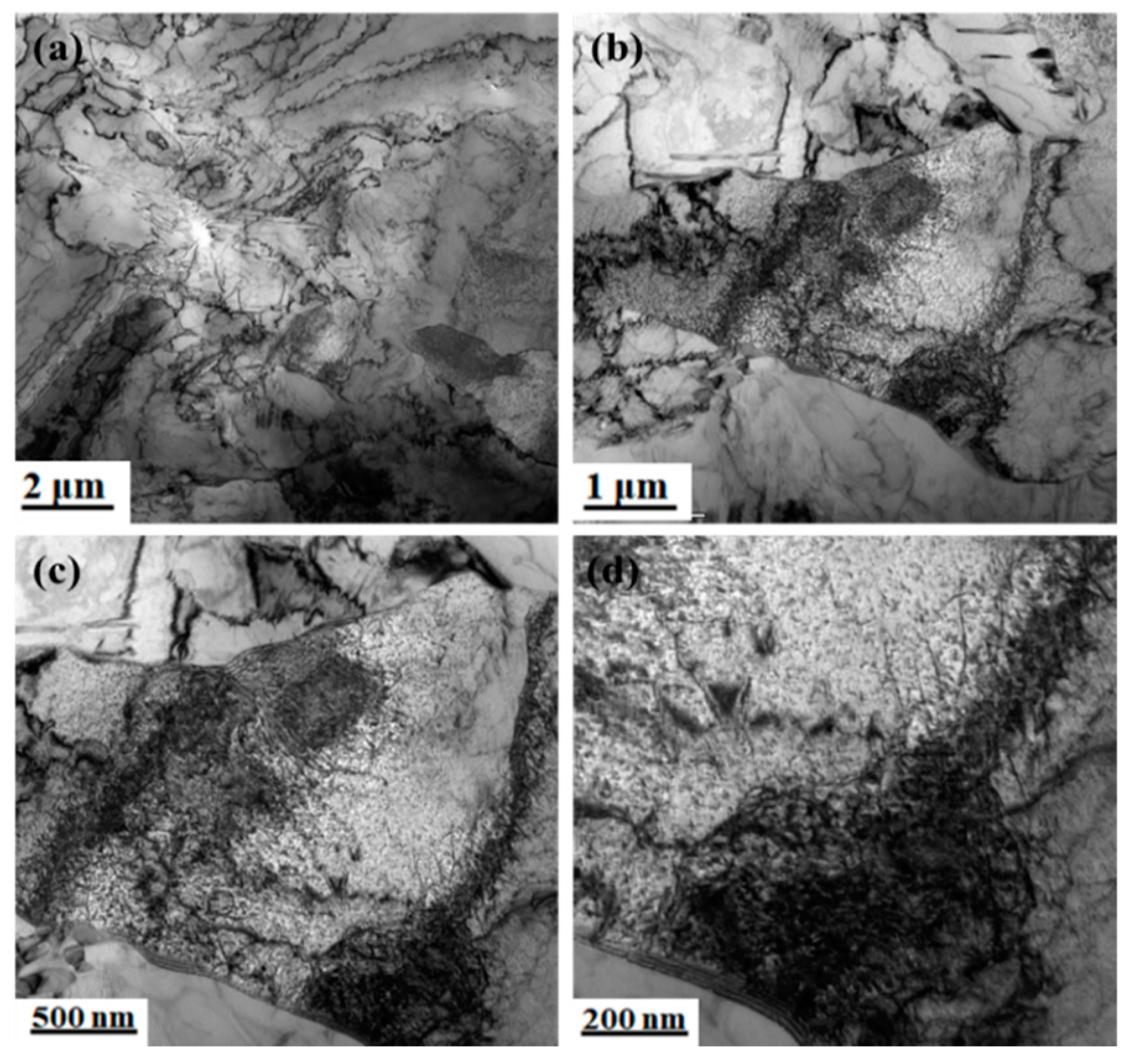

- In the experimental steel, the polygonal ferrite grain boundaries had high dislocation orientation, but there were some lower dislocation grain boundaries and subgrain boundaries in the ferrite grains. The high-density dislocations were distributed on the ferrite grain boundaries, which could effectively block the initiation and propagation of cracks.

- (3)

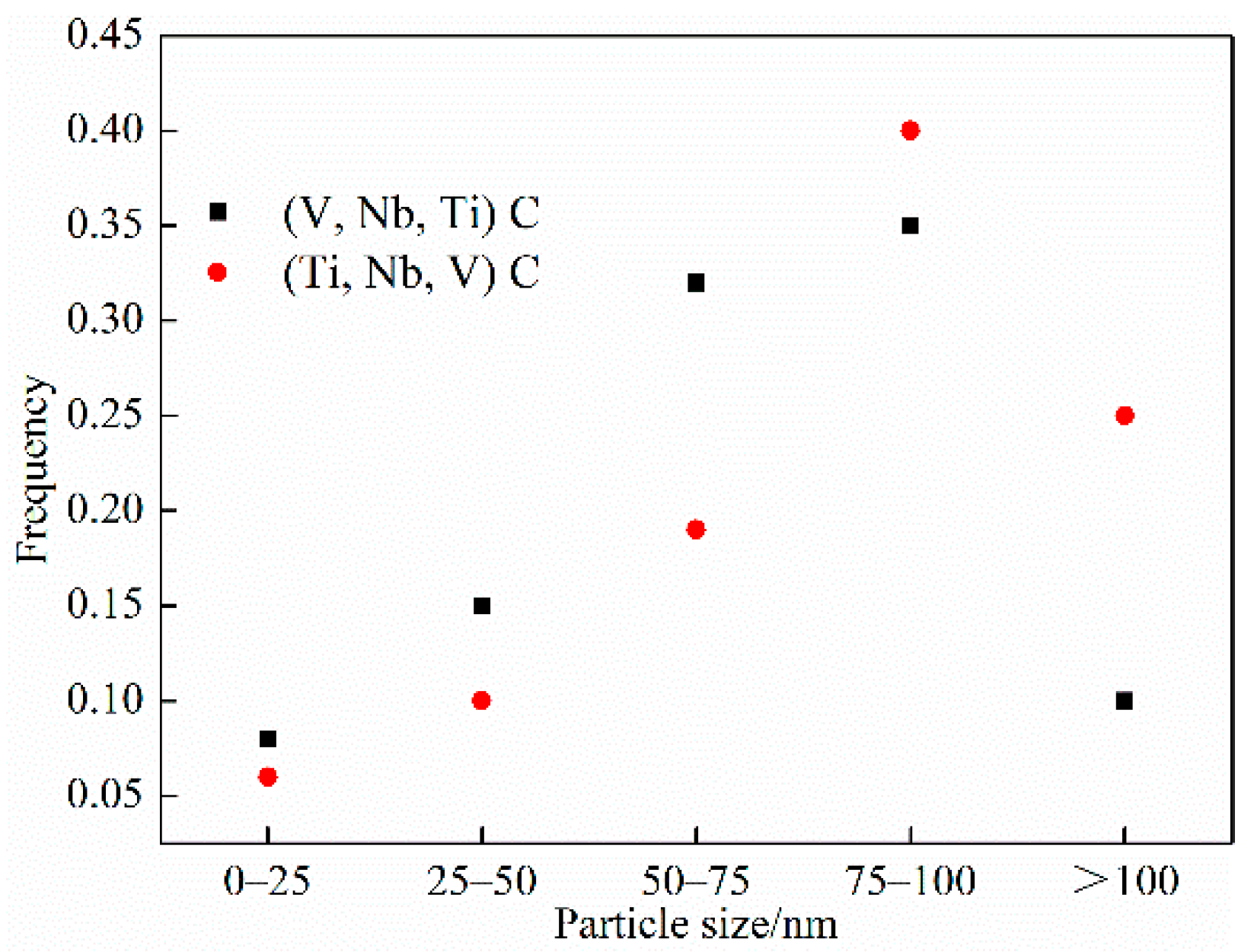

- The main precipitates in the test steel were (Ti, Nb, V) C and (V, Nb, Ti) C. The precipitates were round or narrow, about 70–100 nm in size, and distributed in ferrite grain boundaries and crystals. (V, Nb, Ti)C had obvious precipitation strengthening effect on steel.

- (4)

- With the decrease of the final cooling temperature, the tensile strength and hardness gradually increased. When the final cooling temperature is 750 °C, the fracture types were equiaxed dimples and a few shear planes.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, J.M.; Sun, W.H.; Hao, S. Mechanical properties and microstructure of X120 grade high strength pipeline steel. J. Iron Steel Res. 2010, 17, 63–67. [Google Scholar] [CrossRef]

- Thompson, S.W. Microstructural characterization of an as-quenched HSLA-100 plate steel via transmission electron microscopy. Mater. Charact. 2013, 77, 89–98. [Google Scholar] [CrossRef]

- Cui, K.; Yang, H.; Yao, S.; Li, Z.; Wang, G.; Zhao, H.; Nan, X. Effects of V–N Microalloying on Microstructure and Property in the Welding Heat Affected Zone of Constructional Steel. Metals 2022, 12, 480. [Google Scholar] [CrossRef]

- Yang, Y.; Zhao, X.M.; Dong, C.Y.; Zhao, X.Y. Influence of Hot Deformation and Precipitates on the Recrystallization of Nb-V-Ti Free-Cutting Steel. Metals 2020, 10, 1587. [Google Scholar] [CrossRef]

- Wang, B.; Wang, Z.D.; Wang, B.X.; Wang, G.D.; Misra, R.D.K. The relationship between microstructural evolution and mechanical properties of heavy plate of low-mn steel during ultra fast cooling. Metall. Mater. Trans. A 2015, 46, 2834–2843. [Google Scholar] [CrossRef][Green Version]

- Ghosh, S.; Mula, S. Thermomechanical processing of low carbon Nb–Ti stabilized microalloyed steel: Microstructure and mechanical properties. Mater. Sci. Eng. A 2015, 646, 218–233. [Google Scholar] [CrossRef]

- Gong, P.; Palmiere, E.J.; Rainforth, W.M. Thermomechanical processing route to achieve ultrafine grains in low carbon microalloyed steels. Acta Mater. 2016, 119, 43–54. [Google Scholar] [CrossRef]

- He, G.; Peng, T.; Jiang, B. Recrystallization Behavior and Texture Evolution in Low Carbon Steel during Hot Deformation in Austenite/Ferrite Region. Steel Res. Int. 2021, 92, 2100047. [Google Scholar] [CrossRef]

- Wu, G. Hot-Deformation Behavior and Processing Maps of a Low-Carbon Fe-2 wt% Nb Steel. Metals 2021, 11, 1939–1940. [Google Scholar]

- Sun, M.; Xu, Y.; Du, W. Influence of Coiling Temperature on Microstructure, Precipitation Behaviors and Mechanical Properties of a Low Carbon Ti Micro-Alloyed Steel. Metals 2020, 10, 1173–1182. [Google Scholar] [CrossRef]

- Guo, W.; Ding, N.; Liu, L.; Liu, C.; Li, N. Flow behavior and microstructure of a Mo–V–Ti micro-alloyed high-strength steel. Metallogr. Microstruct. Anal. 2020, 9, 252–260. [Google Scholar] [CrossRef]

- Thakur, S.K.; Harish, L.; Das, A.K.; Rath, S.; Jha, B.K. Hot deformation behavior and processing map of Nb-V-Ti micro-alloyed steel. Mater. Today Proc. 2020, 28, 1973–1979. [Google Scholar] [CrossRef]

- Xu, Q.; Wang, J.; Ding, Z.; Xia, J.; Rasa, A.R.; Shen, Q. Experimental investigation and analysis on anchorage performance of 635mpa hot-rolled ribbed high strength rebars. Structures 2021, 30, 574–584. [Google Scholar] [CrossRef]

- Bai, D.Q.; Yue, S.; Sun, W.P.; Jonas, J.J. Effect of rolling parameters on the no-recrystallization temperature (Tnr) in Nb-bearing steels Metall. Mater. Sci. Eng. A 1993, 24, 2151–2159. [Google Scholar]

- Pereda, B.; Rodríguez-Ibabe, J.M.; Lopez, B. Improved model of kinetics of strain induced precipitation and microstructure evolution of Nb microalloyed steels during multipass rolling. ISIJ Int. 2008, 48, 1457–1466. [Google Scholar] [CrossRef]

- Kostryzhev, A.G.; Shahrani, A.A.; Zhu, C.; Ringer, S.P.; Pereloma, V. Effect of Austenitising and Deformation Temperatures on Dynamic Recrystallisation in Nb-Ti Microalloyed Steel. Mater. Sci. Forum 2013, 753, 431–434. [Google Scholar] [CrossRef]

- Shanmugam, S.; Tanniru, M.; Misra, R. Precipitation in V bearing microalloyed steel containing low concentrations of Ti and Nb. Mater. Sci. Technol. 2013, 21, 883–892. [Google Scholar] [CrossRef]

- Akhlaghi, S.; Ivey, D.G. Precipitation Behaviour of a Grade 100 Structural Steel. Can. Metall. Q. 2014, 41, 111–119. [Google Scholar] [CrossRef]

- Zhang, X.Q.; Cai, Q.Z.; Zhou, G.F.; Chen, Q.F.; Xiong, Y.Z. Microstructure and mechanical properties of V-Ti-N microalloyed steel used for fracture splitting connecting rod. J. Mater. Sci. 2011, 46, 1789–1795. [Google Scholar] [CrossRef]

- Li, Y.; Wilson, J.A.; Crowther, D.N.; Mitchell, P.S.; Craven, A.J.; Baker, T.N. The effects of vanadium, niobium, titanium and zirconium on the microstructure and mechanical properties of thin slab cast steels. ISIJ Int. 2004, 44, 1093–1102. [Google Scholar] [CrossRef]

- Hu, J.; Du, L.X.; Wang, J.J.; Hui, X.; Gao, C.R.; Misra, R. Structure mechanical property relationship in low carbon microalloyed steel plate processed using controlled rolling and two-stage continuous cooling. Mater. Sci. Eng. A 2013, 585, 197–204. [Google Scholar] [CrossRef]

- Bikmukhametov, I.; Beladi, H.; Wang, J.; Hodgson, P.D.; Timokhina, I. The effect of strain on interphase precipitation characteristics in a Ti-Mo steel. Acta Mater. 2019, 170, 75–86. [Google Scholar] [CrossRef]

- Li, H.Y.; Wang, F.Y.; Zeng, C.T.; Li, Y.H.; Cao, J. Determination and analysis of CCT curve of 3crmo steel. Sci. Technol. 2011, 42, 1928–1933. [Google Scholar]

- Lu, C.B. Analysis of pseudo pearlite in low carbon steel. Steel 2015, 50, 68–72. [Google Scholar]

- Zhang, Y.J.; Miyamoto, G.; Shinbo, K.; Furuhara, T. Effects of α/γ orientation relationship on VC interphase precipitation in low-carbon steels. Scr. Mater. 2013, 69, 17–20. [Google Scholar] [CrossRef]

- Wang, Z.Q.; Wang, J.D.; Dong, H.K.; Yuan, Y.; Jiang, F.C. Hardening Through an Ultrafine Carbide Precipitation in Austenite of a Low-Carbon Steel Containing Titanium and Tungsten. Metall. Mater. Trans. A 2020, 51, 3778–3788. [Google Scholar] [CrossRef]

- Gong, P.; Liu, X.G.; Rijkenberg, A.; Rainforth, W.M. The effect of molybdenum on interphase precipitation and microstructures in microalloyed steels containing titanium and vanadium. Acta Mater. 2018, 161, 374–387. [Google Scholar] [CrossRef]

- Chen, M.Y.; Goune, M.; Verdier, M.; Brechet, Y.; Yang, J.R. Interphase precipitation in vanadium-alloyed steels: Strengthening contribution and morphological variability with austenite to ferrite transformation. Acta Mater. 2014, 64, 78–92. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Sun, X.J.; Wang, Z.Q.; Li, Z.D.; Yong, Q.L.; Wang, G.D. Carbide precipitation in austenite of Nb–Mo-bearing low-carbon steel during stress relaxation. Mater. Lett. 2015, 159, 249–252. [Google Scholar] [CrossRef]

- Yen, H.W.; Chen, P.Y.; Huang, C.Y.; Yang, J.R. Interphase precipitation of nanometer-sized carbides in a titanium–molybdenum-bearing low-carbon steel. Acta Mater. 2011, 59, 6264–6274. [Google Scholar] [CrossRef]

- Iza-Mendia, A.; Altuna, M.A.; Pereda, B.; Gutiérrez, I. Precipitation of Nb in Ferrite After Austenite Conditioning. Part I: Microstructural Characterization. Metall. Mater. Trans. A 2012, 43, 4553–4570. [Google Scholar] [CrossRef]

- Altuna, M.A.; Iza-Mendia, A.; Gutiérrez, I. Precipitation of Nb in ferrite after austenite conditioning. Part II: Strengthening contribution in high-strength low-alloy (HSLA) steels. Metall. Mater. Trans. A 2012, 43, 4571–4586. [Google Scholar] [CrossRef]

- Karmakar, A.; Biswas, S.; Mukherjee, S.; Chakrabarti, D.; Mukherjee, K.V. Effect of composition and thermo-mechanical processing schedule on the microstructure, precipitation and strengthening of Nb-microalloyed steel. Mater. Sci. Eng. A 2017, 690, 158–169. [Google Scholar] [CrossRef]

- Challa, V.S.A.; Zhou, W.H.; Misra, R.D.K.; Malley, R.O.; Jansto, S.G. The effect of coiling temperature on the microstructure and mechanical properties of a niobium–titanium microalloyed steel processed via thin slab casting. Mater. Sci. Eng. A 2014, 595, 143–153. [Google Scholar] [CrossRef]

- Davenport, A.T.; Berry, F.G.; Honeycombe, R.W.K. Interface precipitation in iron alloys. Met. Sci. J. 1968, 2, 104–106. [Google Scholar] [CrossRef]

- Dunlop, G.L.; Honeycombe, R.W.K. Ferrite morphologies and carbide precipitation in a Cr–Mo–V creep resisting steel. Met. Sci. J. 2013, 10, 124–132. [Google Scholar] [CrossRef]

- Chen, C.Y.; Chen, C.C.; Yang, J.R. Microstructure characterization of nanometer carbides heterogeneous precipitation in Ti–Nb and Ti–Nb–Mo steel. Mater. Charact. 2014, 88, 69–79. [Google Scholar] [CrossRef]

| No | C | Si | Mn | P | S | O | Nb | V | Ti | N |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.20 | 0.38 | 1.40 | 0.019 | 0.012 | 0.005 | 0.023 | 0.088 | 0.012 | 0.0083 |

| Temperature/°C | Ferrite Grain Size/μm | Grain Size Grade |

|---|---|---|

| 650 | 7.68 ± 1.3 | 11 ± 0.25 |

| 700 | 10.67 ± 1.5 | 10 ± 0.25 |

| 750 | 17.07 ± 1.6 | 9 ± 0.25 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, S.; Li, C.; Li, Z.; Zhuang, C.; Zeng, Z.; Wang, J. Effect of Thermal Simulation Process on Microstructure of Seismic Steel Bars. Materials 2022, 15, 3438. https://doi.org/10.3390/ma15103438

Huang S, Li C, Li Z, Zhuang C, Zeng Z, Wang J. Effect of Thermal Simulation Process on Microstructure of Seismic Steel Bars. Materials. 2022; 15(10):3438. https://doi.org/10.3390/ma15103438

Chicago/Turabian StyleHuang, Sheng, Changrong Li, Zhiying Li, Changling Zhuang, Zeyun Zeng, and Jie Wang. 2022. "Effect of Thermal Simulation Process on Microstructure of Seismic Steel Bars" Materials 15, no. 10: 3438. https://doi.org/10.3390/ma15103438

APA StyleHuang, S., Li, C., Li, Z., Zhuang, C., Zeng, Z., & Wang, J. (2022). Effect of Thermal Simulation Process on Microstructure of Seismic Steel Bars. Materials, 15(10), 3438. https://doi.org/10.3390/ma15103438