Corrosion Properties of S-Phase/Cr2N Composite Coatings Deposited on Austenitic Stainless Steel

Abstract

1. Introduction

2. Materials and Methods

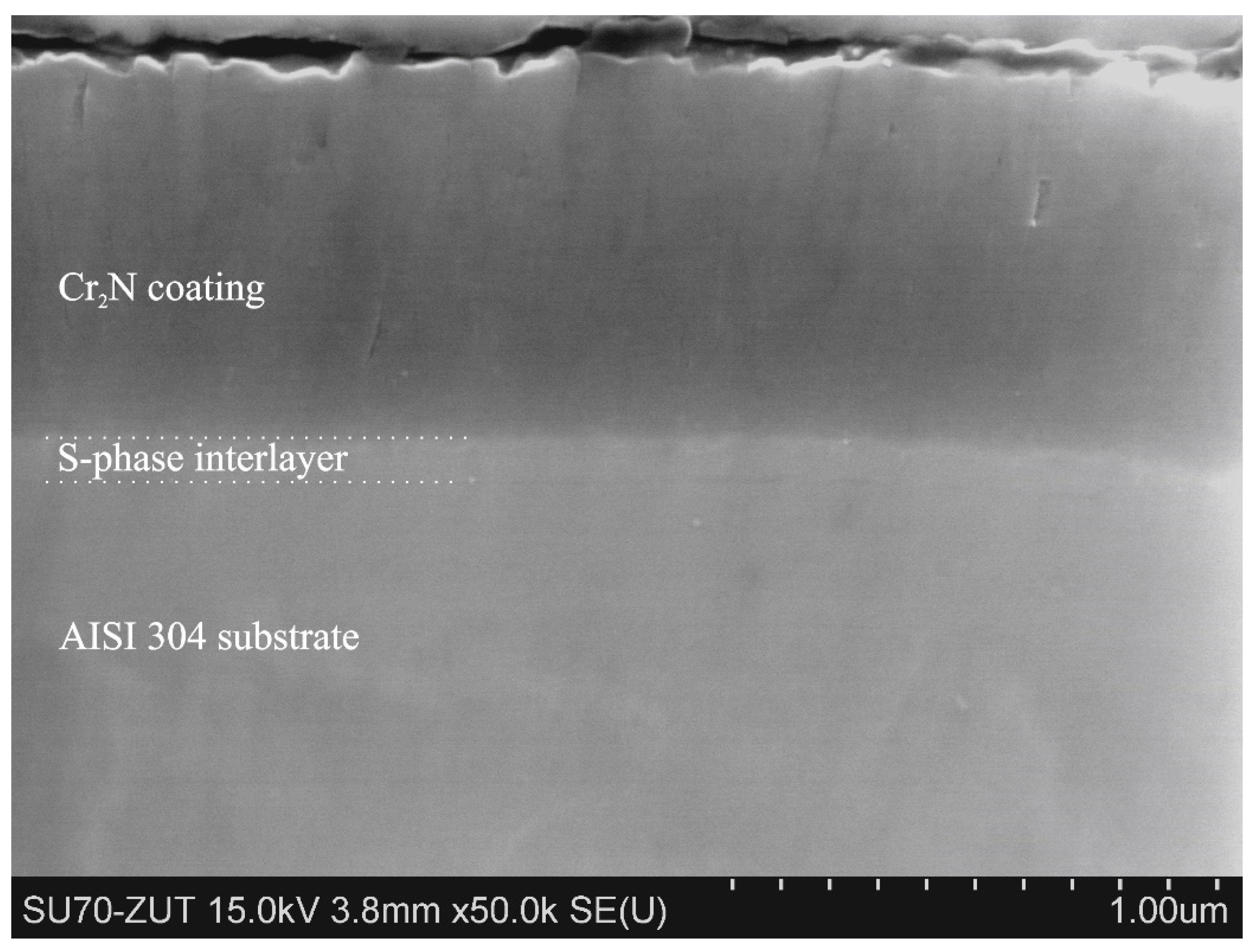

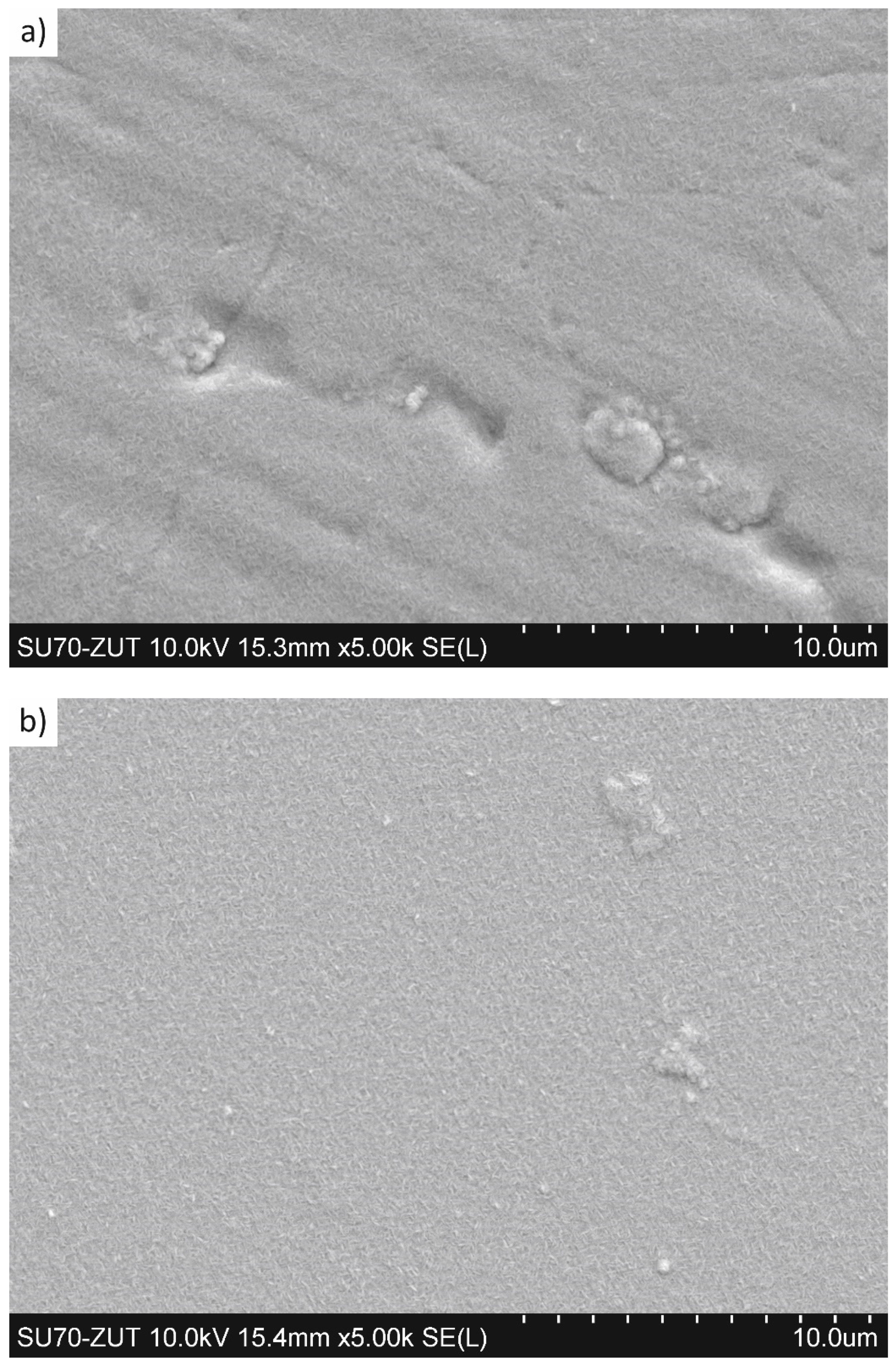

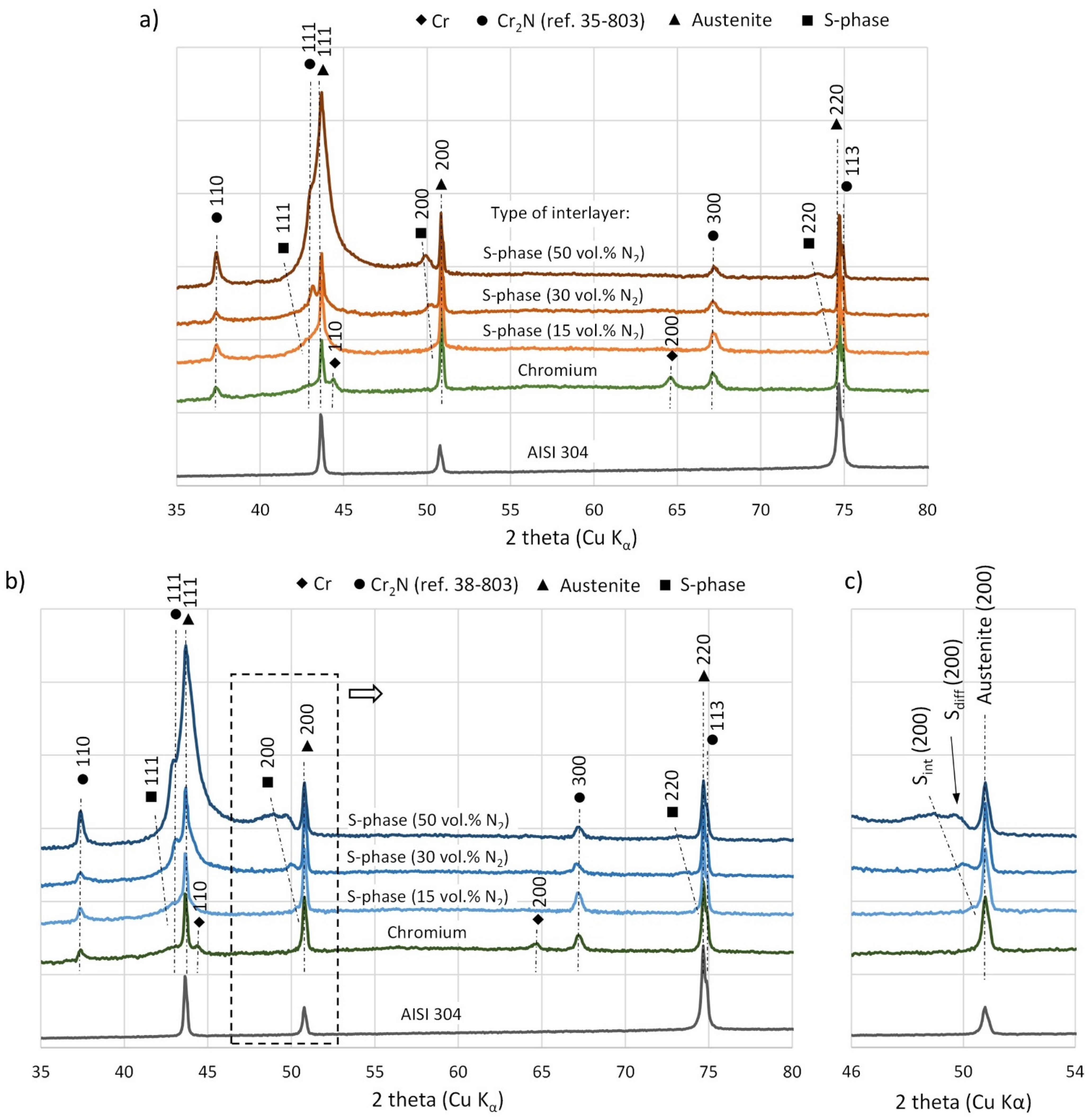

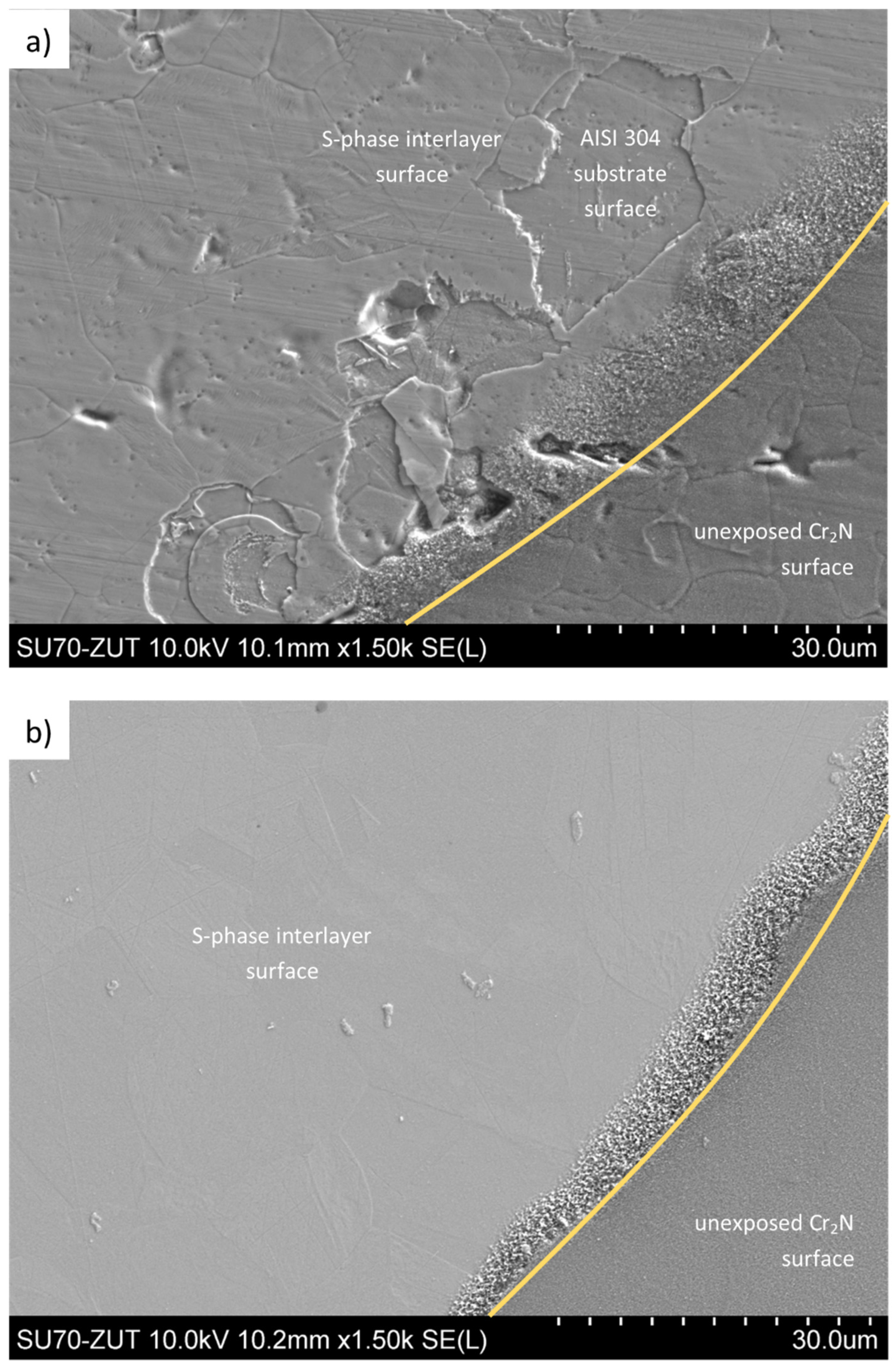

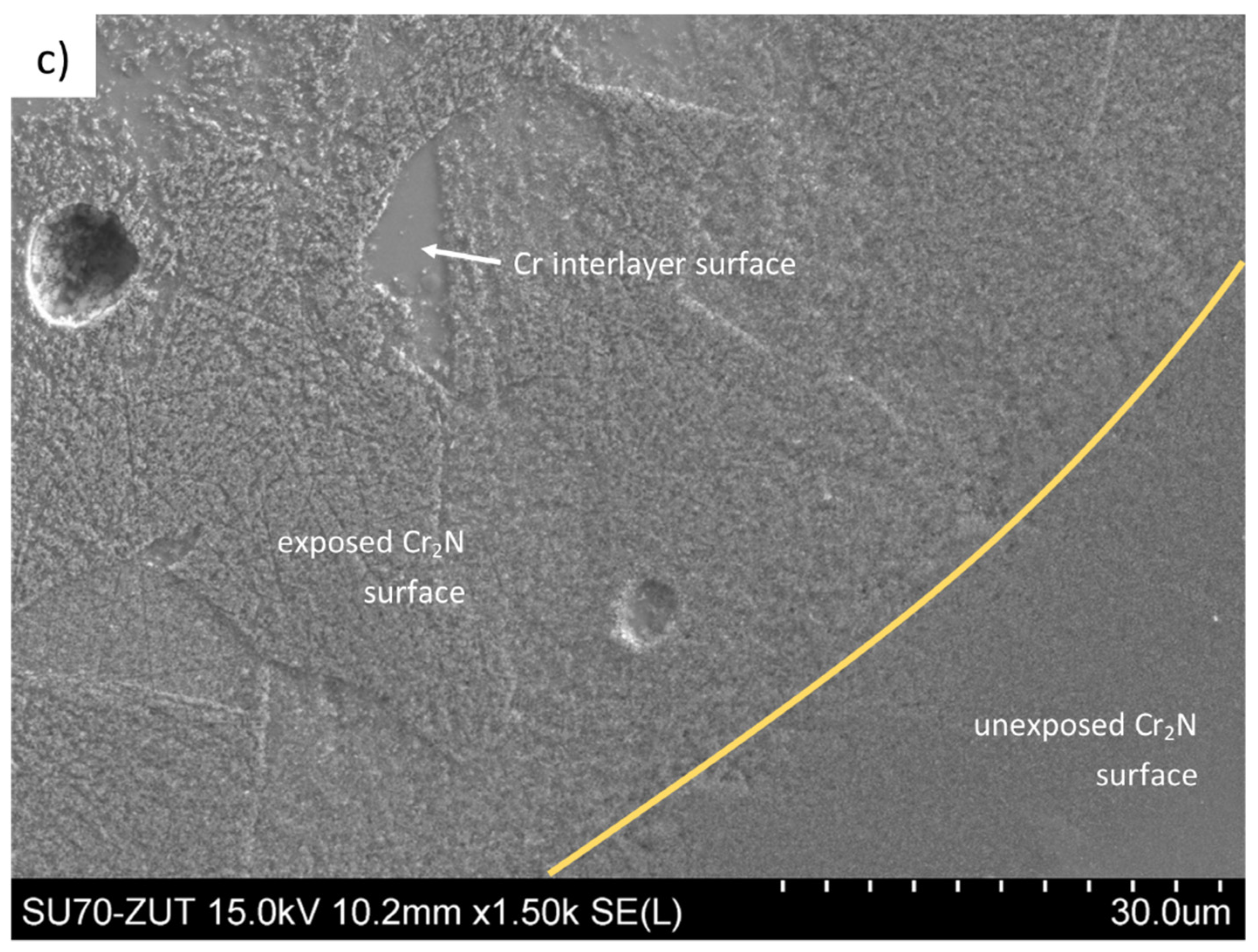

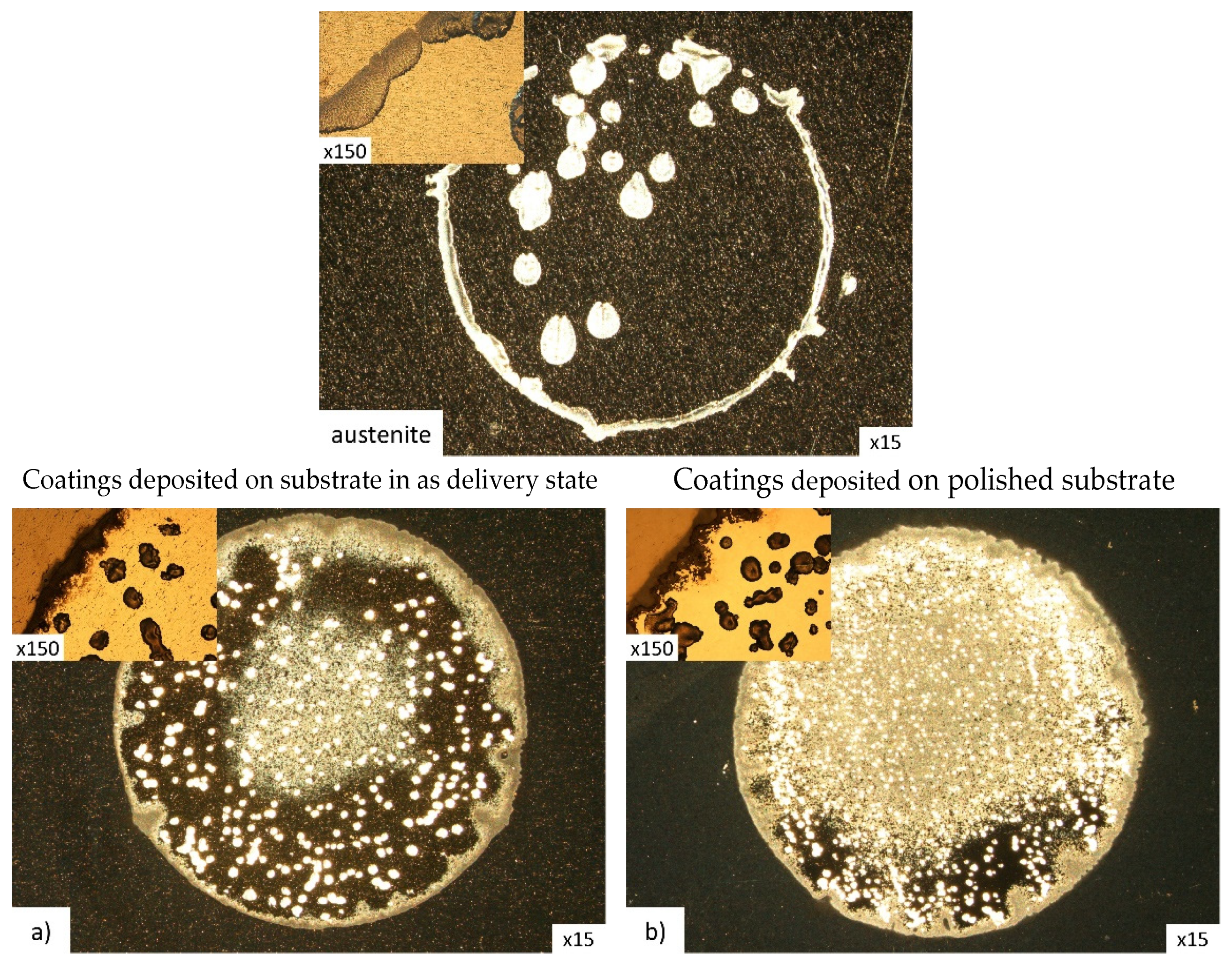

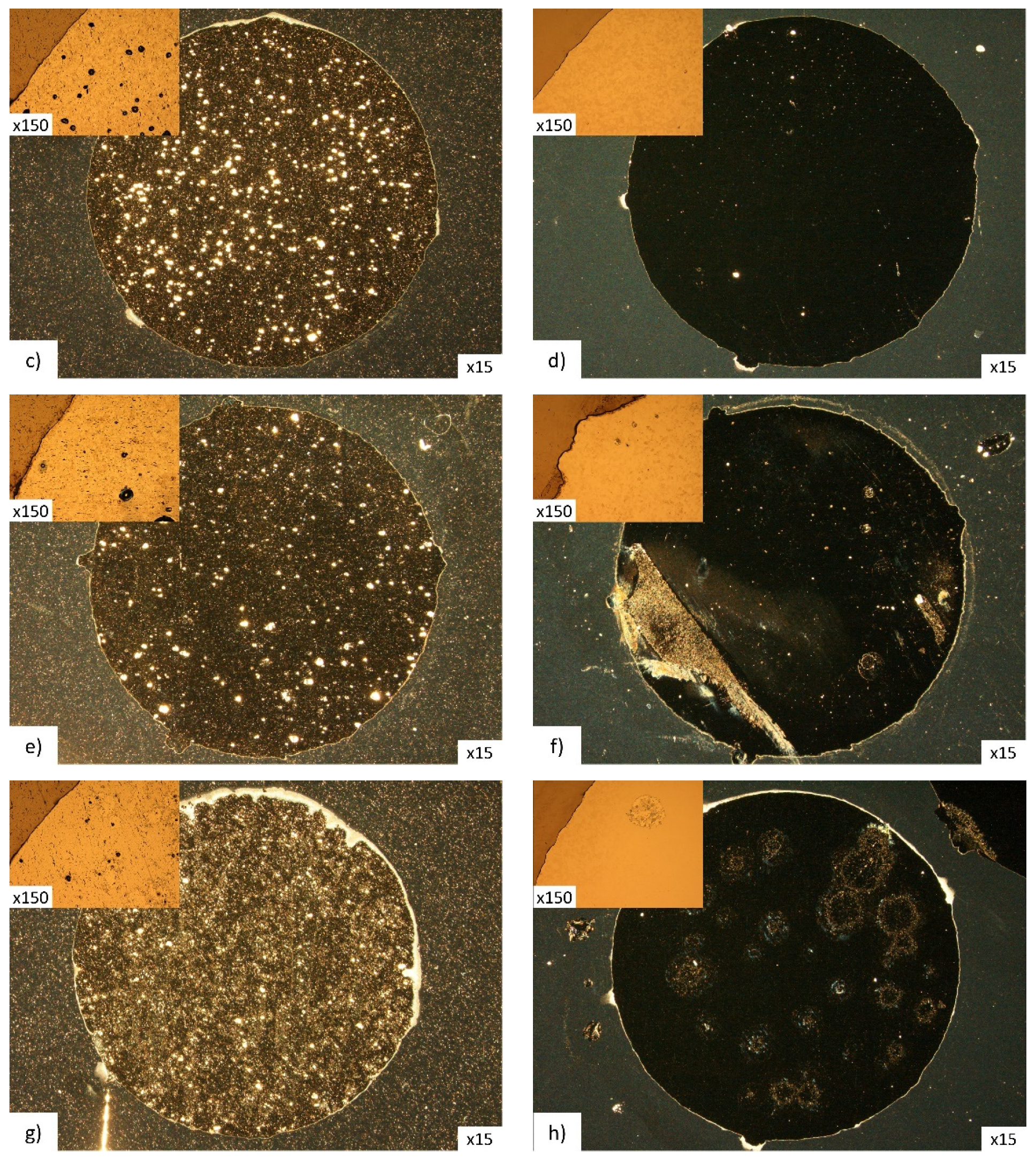

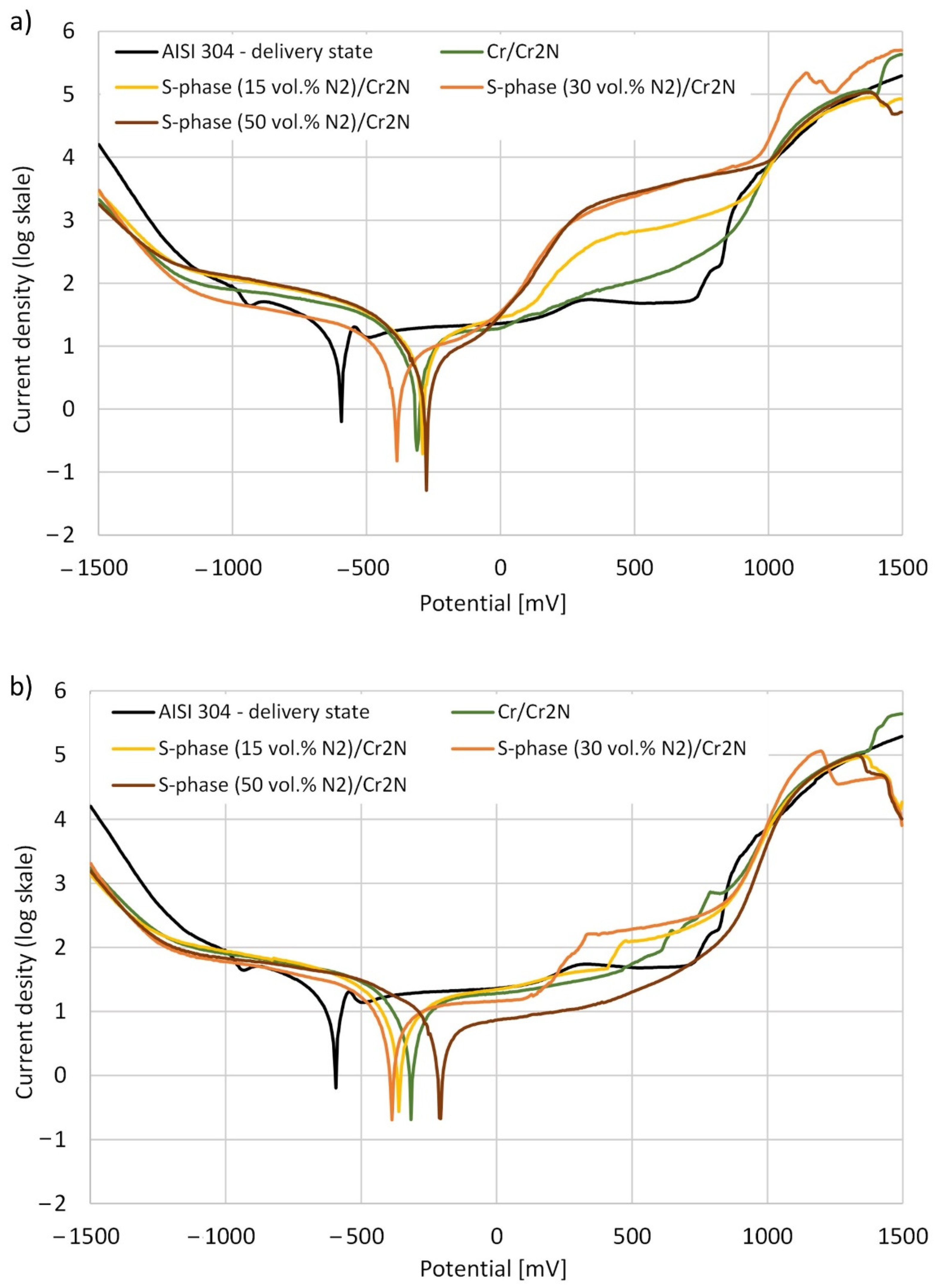

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Navinšek, B.; Panjan, P.; Milošev, I. Industrial applications of CrN (PVD) coatings, deposited at high and low temperatures. Surf. Coat. Technol. 1997, 97, 182–191. [Google Scholar] [CrossRef]

- Panjan, P.; Cvahte, P.; Čekada, M.; Navinšek, B.; Urankar, I. PVD CrN coating for protection of extrusion dies. Vacuum 2001, 61, 241–244. [Google Scholar] [CrossRef]

- Warcholinski, B.; Gilewicz, A. Multilayer coatings on tools for woodworking. Wear 2011, 271, 2812–2820. [Google Scholar] [CrossRef]

- Heinze, M. Wear resistance of hard coatings in plastics processing. Surf. Coat. Technol. 1998, 105, 38–44. [Google Scholar] [CrossRef]

- Gilewicz, A.; Murzynski, D.; Dobruchowska, E.; Kwiatkowski, J.; Olik, R.; Ratajski, J.; Warcholinski, B. Wear and corrosion behavior of CrCN/CrN coatings deposited by cathodic arc evaporation on nitrided 42CrMo4 steel substrates. Prot. Met. Phys. Chem. Surf. 2017, 53, 312–321. [Google Scholar] [CrossRef]

- Ando, E.; Suzuki, S. Optical and mechanical properties of Cr and CrNx films by dc magnetron sputtering. J. Non. Cryst. Solids 1997, 218, 68–73. [Google Scholar] [CrossRef]

- Roquiny, P.; Bodart, F.; Terwagne, G. Colour control of titanium nitride coatings produced by reactive magnetron sputtering at temperature less than 100 °C. Surf. Coat. Technol. 1999, 116–119, 278–283. [Google Scholar] [CrossRef]

- Tian, R. Chromium nitride/Cr coated 316L stainless steel as bipolar plate for proton exchange membrane fuel cell. J. Power Sources 2011, 196, 1258–1263. [Google Scholar] [CrossRef]

- Haghighat Ghahfarokhi, H.; Saatchi, A.; Monirvaghefi, S.M. Corrosion Investigation of Chromium Nitride and Chromium Carbide Coatings for PEM Fuel Cell Bipolar Plates in Simulated Cathode Condition. Fuel Cells 2016, 16, 356–364. [Google Scholar] [CrossRef]

- Lavigne, O.; Alemany-Dumont, C.; Normand, B.; Berthon-Fabry, S.; Metkemeijer, R. Thin chromium nitride PVD coatings on stainless steel for conductive component as bipolar plates of PEM fuel cells: Ex-situ and in-situ performances evaluation. Int. J. Hydrogen Energy 2012, 37, 10789–10797. [Google Scholar] [CrossRef]

- Lin, J.; Wu, Z.L.; Zhang, X.H.; Mishra, B.; Moore, J.J.; Sproul, W.D. A comparative study of CrNx coatings Synthesized by dc and pulsed dc magnetron sputtering. Thin Solid Film. 2009, 517, 1887–1894. [Google Scholar] [CrossRef]

- Han, S.; Lin, J.H.; Tsai, S.H.; Chung, S.C.; Wang, D.Y.; Lu, F.H.; Shih, H.C. Corrosion and tribological studies of chromium nitride coated on steel with an interlayer of electroplated chromium. Surf. Coat. Technol. 2000, 133–134, 460–465. [Google Scholar] [CrossRef]

- Liu, C.; Leyland, A.; Bi, Q.; Matthews, A. Corrosion resistance of multi-layered plasma-assisted physical vapour deposition TiN and CrN coatings. Surf. Coat. Technol. 2001, 141, 164–173. [Google Scholar] [CrossRef]

- Dong, H.; Sun, Y.; Bell, T. Enhanced corrosion resistance of duplex coatings. Surf. Coat. Technol. 1997, 90, 91–101. [Google Scholar] [CrossRef]

- Gredić, T.; Zlatanović, M.; Popović, N. Bogdanov Properties of TiN coatings deposited onto hot work steel substrates plasma nitrided at low pressure. Surf. Coat. Technol. 1992, 54–55, 502–507. [Google Scholar] [CrossRef]

- Aubert, A.; Gillet, R.; Gaucher, A.; Terrat, J.P. Hard chrome coatings deposited by physical vapour deposition. Thin Solid Film. 1983, 108, 165–172. [Google Scholar] [CrossRef]

- Hones, P.; Sanjines, R.; Levy, F. Characterization of sputter-deposited chromium nitride thin films for hard coatings. Surf. Coat. Technol. 1997, 94–95, 398–402. [Google Scholar] [CrossRef]

- Pakala, M.; Lin, R.Y. Reactive sputter deposition of chromium nitride coatings. Surf. Coat. Technol. 1996, 81, 233–239. [Google Scholar] [CrossRef]

- Shan, L.; Wang, Y.; Li, J.; Chen, J. Effect of N2 flow rate on microstructure and mechanical properties of PVD CrNx coatings for tribological application in seawater. Surf. Coat. Technol. 2014, 242, 74–82. [Google Scholar] [CrossRef]

- Shah, H.N.; Jayaganthan, R.; Kaur, D.; Chandra, R. Influence of sputtering parameters and nitrogen on the microstructure of chromium nitride thin films deposited on steel substrate by direct-current reactive magnetron sputtering. Thin Solid Film. 2010, 518, 5762–5768. [Google Scholar] [CrossRef]

- Jagielski, J.; Khanna, A.S.; Kucinski, J.; Mishra, D.S.; Racolta, P.; Sioshansi, P.; Tobin, E.; Thereska, J.; Uglov, V.; Vilaithong, T.; et al. Effect of chromium nitride coating on the corrosion and wear resistance of stainless steel. Appl. Surf. Sci. 2000, 156, 47–64. [Google Scholar] [CrossRef]

- Kuruppu, M.L.; Negrea, G.; Ivanov, I.P.; Rohde, S.L. Monolithic and multilayer Cr/CrN, Cr/Cr2N, and Cr2N/CrN coatings on hard and soft substrates. J. Vac. Sci. Technol. A Vac. Surf. Film. 1998, 16, 1949–1955. [Google Scholar] [CrossRef]

- Li, G.; Deshpande, P.; Li, J.H.; Lin, R.Y. Nano Cr interlayered CrN coatings on steels. Tsinghua Sci. Technol. 2005, 10, 690–698. [Google Scholar] [CrossRef]

- Cunha, L.; Andritschky, M. Residual stress, surface defects and corrosion resistance of CrN hard coatings. Surf. Coat. Technol. 1999, 111, 158–162. [Google Scholar] [CrossRef]

- Park, M.J.; Leyland, A.; Matthews, A. Corrosion performance of layered coatings produced by physical vapour deposition. Surf. Coat. Technol. 1990, 43–44, 481–492. [Google Scholar] [CrossRef]

- Jehn, H.A. Improvement of the corrosion resistance of PVD hard coating-substrate systems. Surf. Coat. Technol. 2000, 125, 212–217. [Google Scholar] [CrossRef]

- Petrogalli, C.; Montesano, L.; Gelfi, M.; La Vecchia, G.M.; Solazzi, L. Tribological and corrosion behavior of CrN coatings: Roles of substrate and deposition defects. Surf. Coat. Technol. 2014, 258, 878–885. [Google Scholar] [CrossRef]

- Creus, J.; Idrissi, H.; Mazille, H.; Sanchette, F.; Jacquot, P. Improvement of the corrosion resistance of CrN coated steel by an interlayer. Surf. Coat. Technol. 1998, 107, 183–190. [Google Scholar] [CrossRef]

- Cunha, L.; Andritschky, M.; Rebouta, L.; Silva, R. Corrosion of TiN, (TiAl)N and CrN hard coatings produced by magnetron sputtering. Thin Solid Film. 1998, 317, 351–355. [Google Scholar] [CrossRef]

- Stockemer, J.; Winand, R.; Vanden Brande, P. Comparison of wear and corrosion behaviors of Cr and CrN sputtered coatings. Surf. Coat. Technol. 1999, 115, 230–233. [Google Scholar] [CrossRef]

- Chipatecua, Y.L.; Olaya, J.J.; Arias, D.F. Corrosion behaviour of CrN/Cr multilayers on stainless steel deposited by unbalanced magnetron sputtering. Vacuum 2012, 86, 1393–1401. [Google Scholar] [CrossRef]

- Liu, C.; Bi, Q.; Ziegele, H.; Leyland, A.; Matthews, A. Structure and corrosion properties of PVD Cr–N coatings. J. Vac. Sci. Technol. A Vac. Surf. Film. 2002, 20, 772–780. [Google Scholar] [CrossRef]

- Cunha, L.; Andritschky, M.; Rebouta, L.; Pischow, K. Corrosion of CrN and TiAlN coatings in chloride-containing atmospheres. Surf. Coat. Technol. 1999, 116–119, 1152–1160. [Google Scholar] [CrossRef]

- Dong, H. S-phase surface engineering of Fe-Cr, Co-Cr and Ni-Cr alloys. Int. Mater. Rev. 2010, 55, 65–98. [Google Scholar] [CrossRef]

- Fryska, S.; Baranowska, J. Microstructure of reactive magnetron sputtered S-phase coatings with a diffusion sub-layer. Vacuum 2017, 142, 72–80. [Google Scholar] [CrossRef]

- Billard, A.; Foos, M.; Frantz, C.; Gantois, M. Corrosion-resistant and hard 310 stainless steel-carbon coatings prepared by reactive d.c. magnetron sputtering. Surf. Coat. Technol. 1990, 43–44, 521–532. [Google Scholar] [CrossRef]

- Fryska, S.; Baranowska, J. Characterization of mechanical properties of S-phase coatings. Mater. Eng. 2017, 1, 29–34. [Google Scholar] [CrossRef][Green Version]

- Alresheedi, F.I.; Krzanowski, J.E. Structure and morphology of stainless steel coatings sputter-deposited in a nitrogen/argon atmosphere. Surf. Coat. Technol. 2017, 314, 105–112. [Google Scholar] [CrossRef]

- Dahm, K.L.; Betts, A.J.; Dearnley, P.A. Chemical structure and corrosion behaviour of S phase coatings. Surf. Eng. 2010, 26, 271–276. [Google Scholar] [CrossRef]

- Aldrich-Smith, G.; Teer, D.G.; Dearnley, P.A. Corrosion-wear response of sputtered CrN and S-phase coated austenitic stainless steel. Surf. Coat. Technol. 1999, 116–119, 1161–1165. [Google Scholar] [CrossRef]

- Fryska, S. Tribocorrosion resistance of nitrogen stabilized stainless steel coatings. Mater. Eng. 2015, 1, 75–79. [Google Scholar] [CrossRef]

- Fossati, A.; Borgioli, F.; Galvanetto, E.; Bacci, T. Corrosion resistance properties of glow-discharge nitrided AISI 316L austenitic stainless steel in NaCl solutions. Corros. Sci. 2006, 48, 1513–1527. [Google Scholar] [CrossRef]

- Li, C.X.; Bell, T. Corrosion properties of active screen plasma nitrided 316 austenitic stainless steel. Corros. Sci. 2004, 46, 1527–1547. [Google Scholar] [CrossRef]

- Fryska, S.; Słowik, J.; Baranowska, J. Structure and mechanical properties of chromium nitride/S-phase composite coatings deposited on 304 stainless steel. Thin Solid Film. 2019, 676, 144–150. [Google Scholar] [CrossRef]

- Kim, Y.S.; Lee, I.S.; Choi, J.Y.; Jun, S.; Kim, D.; Cha, B.C.; Kim, D.W. Corrosion behavior of niobium-coated 316L stainless steels as metal bipolar plates for polymer electrolyte membrane fuel cells. Materials 2021, 14, 4972. [Google Scholar] [CrossRef]

| Outer Coating | Interlayer | Nitrogen Concentration during Interlayer Doposition | Substrate |

|---|---|---|---|

| Cr2N | chrome | 0 | 1× DS + 1× P |

| S-phase | 15 vol.% | 1× DS + 1× P | |

| 30 vol.% | 1× DS + 1× P | ||

| 50 vol.% | 1× DS + 1× P |

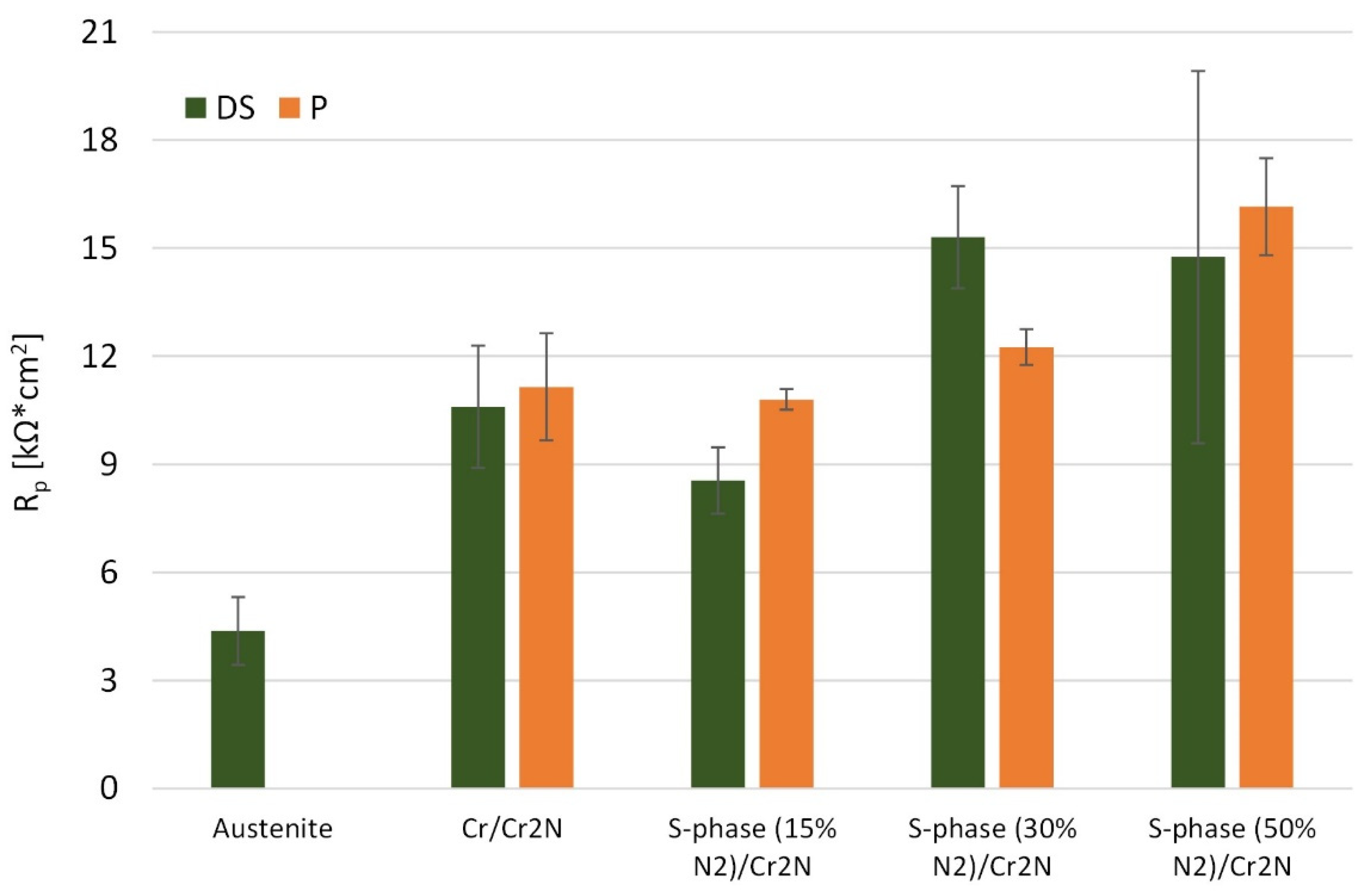

| Ecorr [mV] | icorr [μA/cm2] | Rp [kΩ*cm2] | ||||

|---|---|---|---|---|---|---|

| Substrate initial state | DS | P | DS | P | DS | P |

| Austenitic stainless steel | −576 | 10.4 | 4.4 | |||

| Cr/Cr2N | −307 | −317 | 1.5 | 2.1 | 10.6 | 11.2 |

| S-phase (15 vol.% of N2)/Cr2N | −288 | −355 | 4.5 | 5.1 | 8.6 | 10.8 |

| S-phase (30 vol.% of N2)/Cr2N | −385 | −378 | 6.1 | 5.1 | 15.3 | 12.3 |

| S-phase (50 vol.% of N2)/Cr2N | −270 | −202 | 3.1 | 4.2 | 14.8 | 16.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fryska, S.; Baranowska, J. Corrosion Properties of S-Phase/Cr2N Composite Coatings Deposited on Austenitic Stainless Steel. Materials 2022, 15, 266. https://doi.org/10.3390/ma15010266

Fryska S, Baranowska J. Corrosion Properties of S-Phase/Cr2N Composite Coatings Deposited on Austenitic Stainless Steel. Materials. 2022; 15(1):266. https://doi.org/10.3390/ma15010266

Chicago/Turabian StyleFryska, Sebastian, and Jolanta Baranowska. 2022. "Corrosion Properties of S-Phase/Cr2N Composite Coatings Deposited on Austenitic Stainless Steel" Materials 15, no. 1: 266. https://doi.org/10.3390/ma15010266

APA StyleFryska, S., & Baranowska, J. (2022). Corrosion Properties of S-Phase/Cr2N Composite Coatings Deposited on Austenitic Stainless Steel. Materials, 15(1), 266. https://doi.org/10.3390/ma15010266