Cohesive Strength and Structural Stability of the Ni-Based Superalloys

Abstract

:1. Introduction

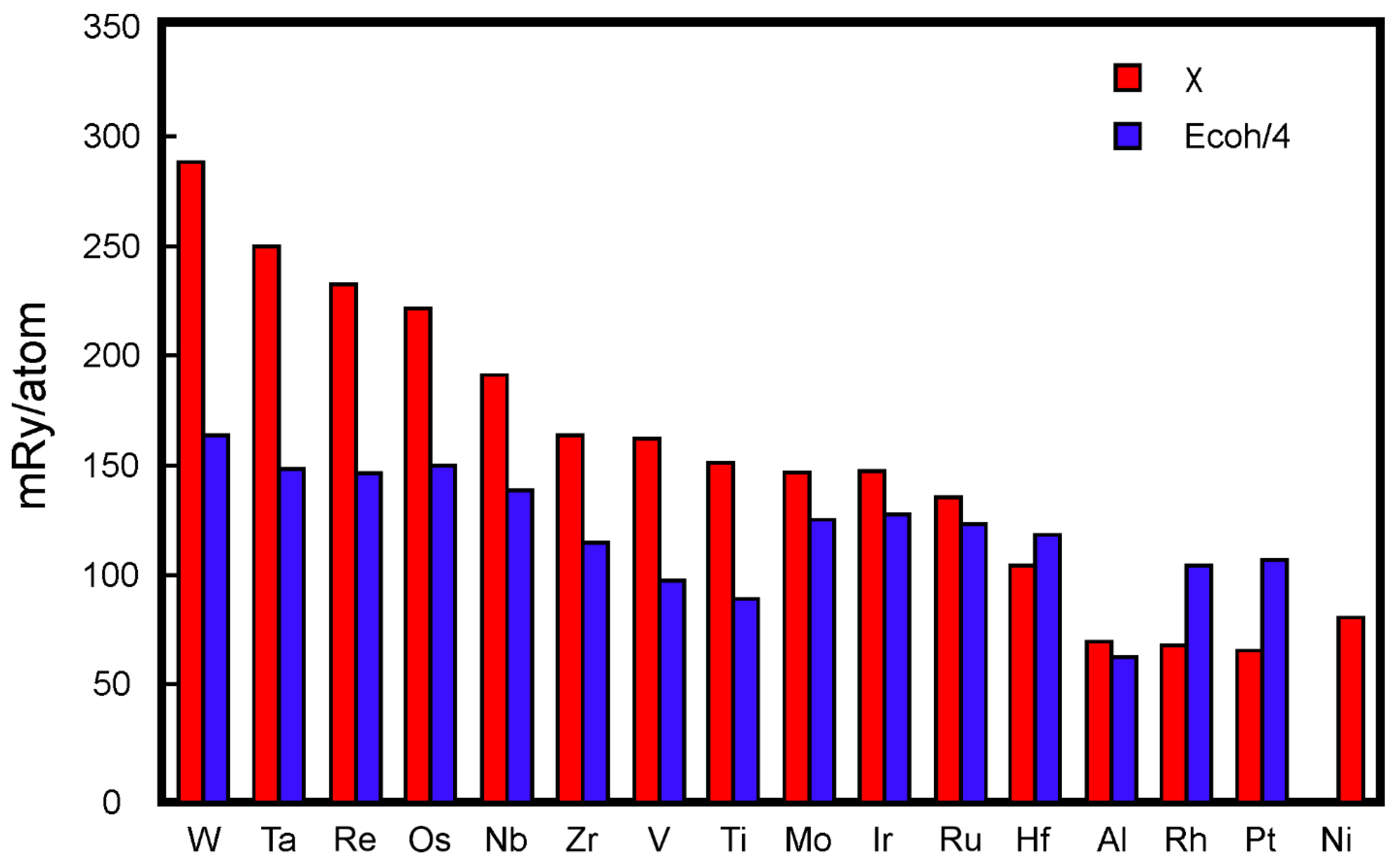

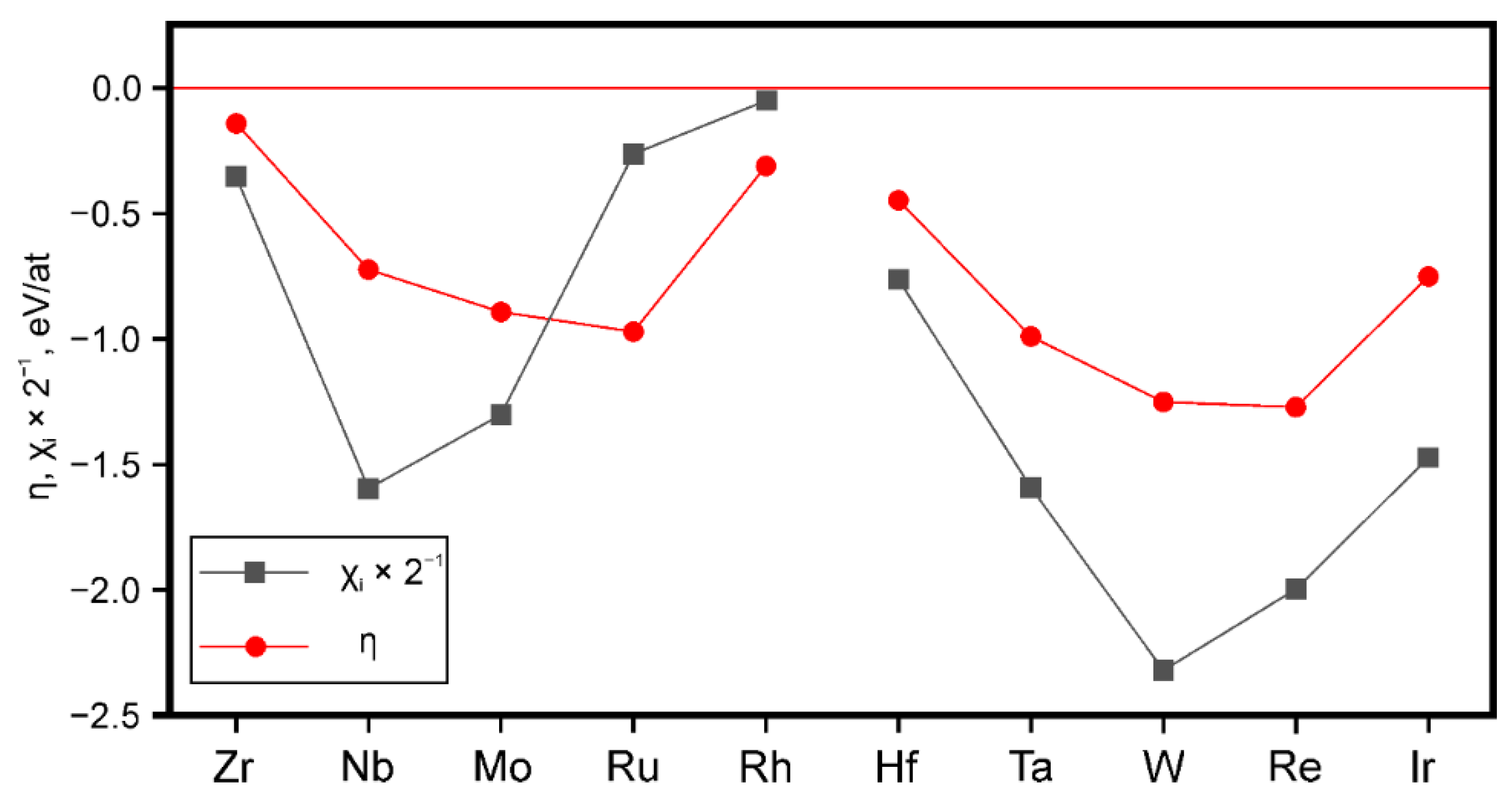

2. Theoretical Estimate of the Effect of Alloying on GB Cohesion and the Bulk

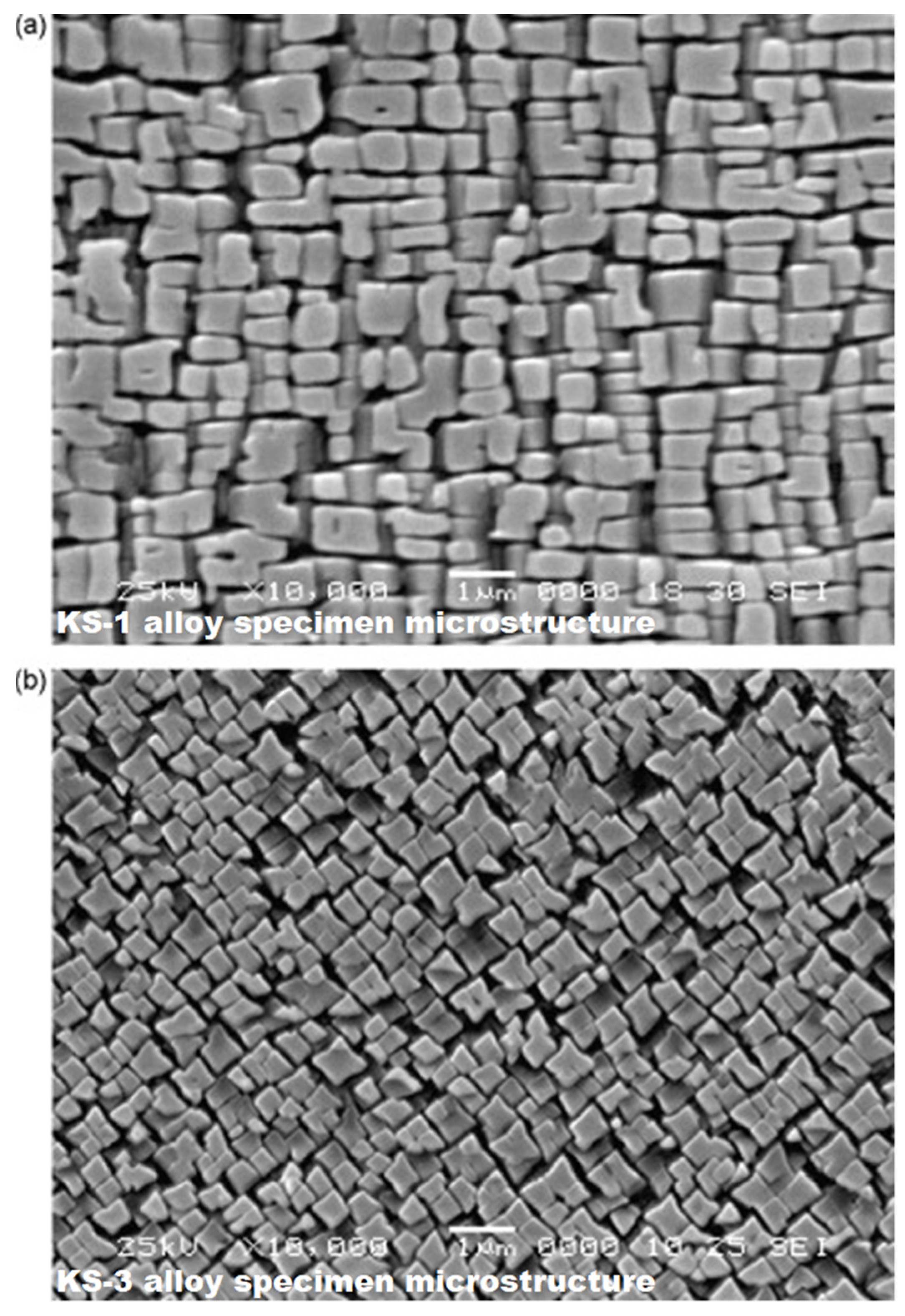

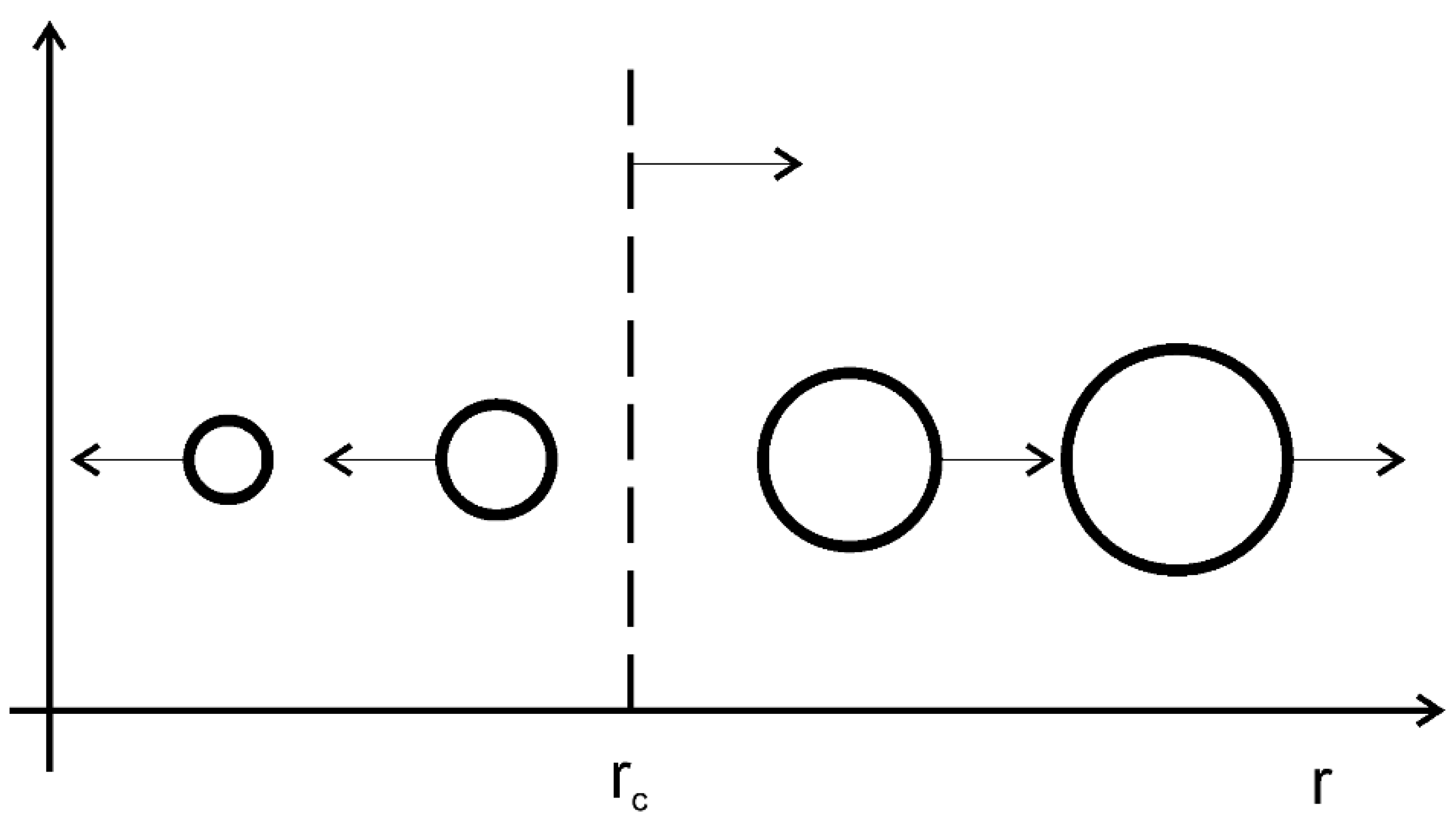

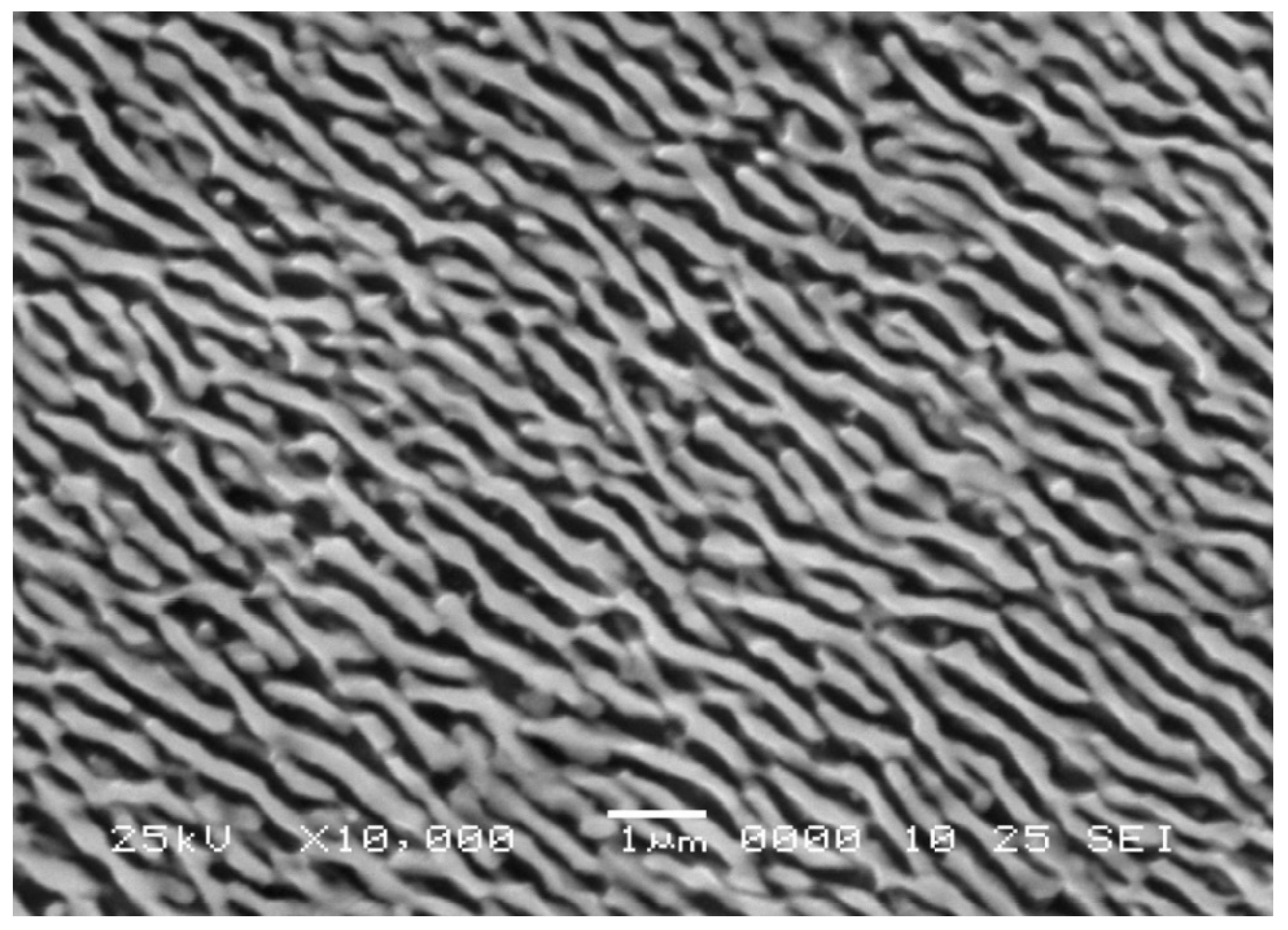

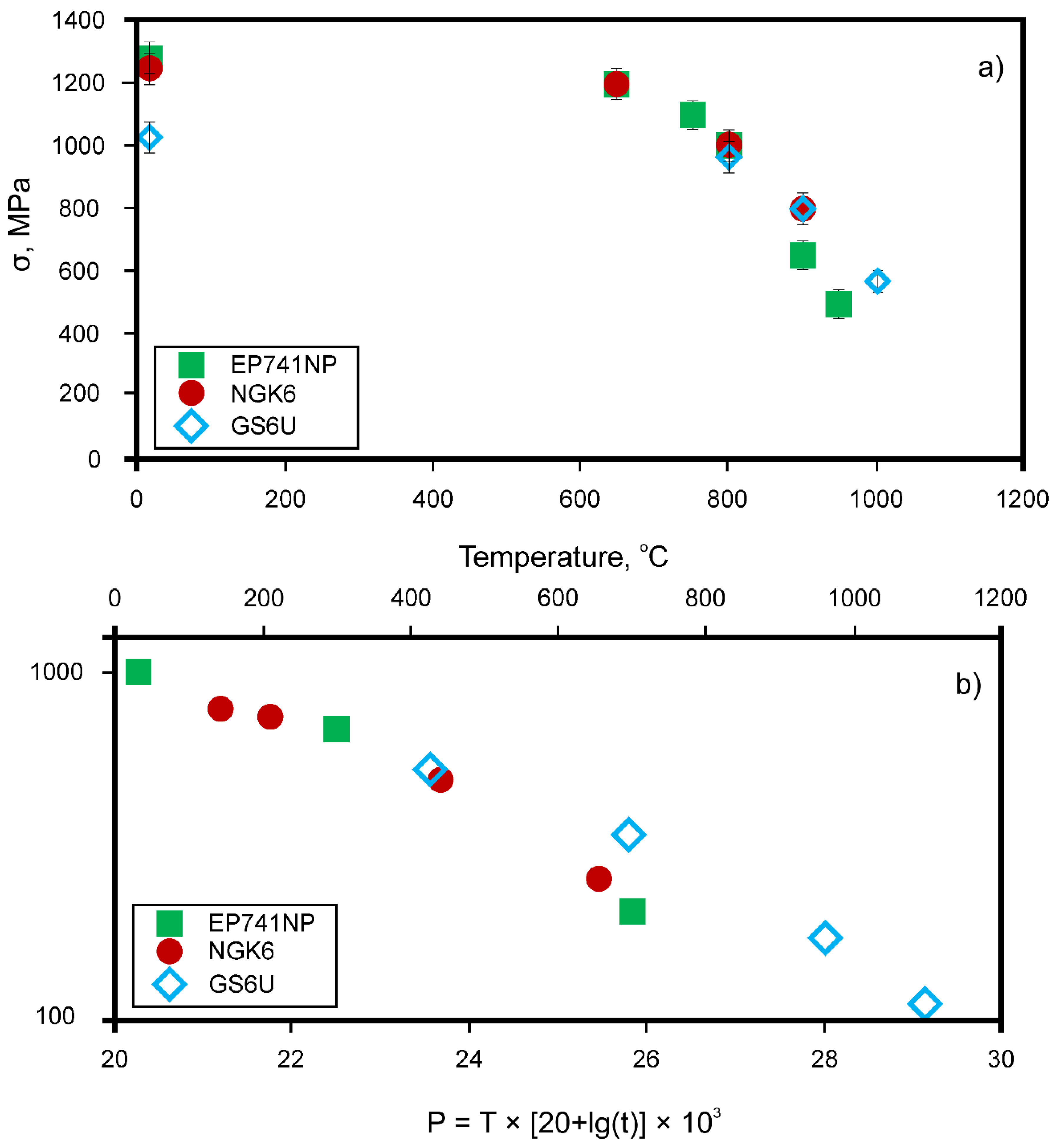

3. The Design of Ni-Based Single Crystal Superalloys

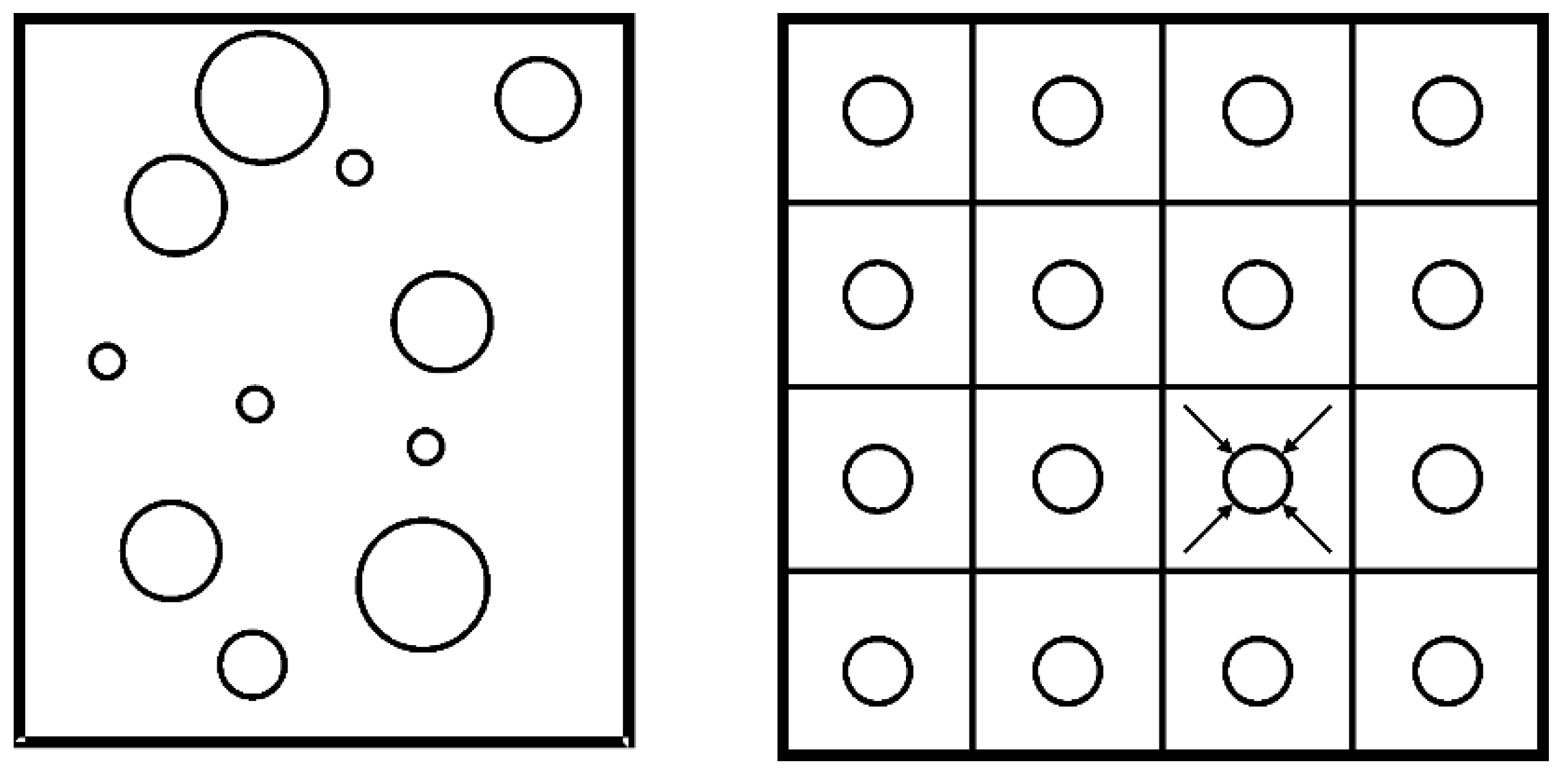

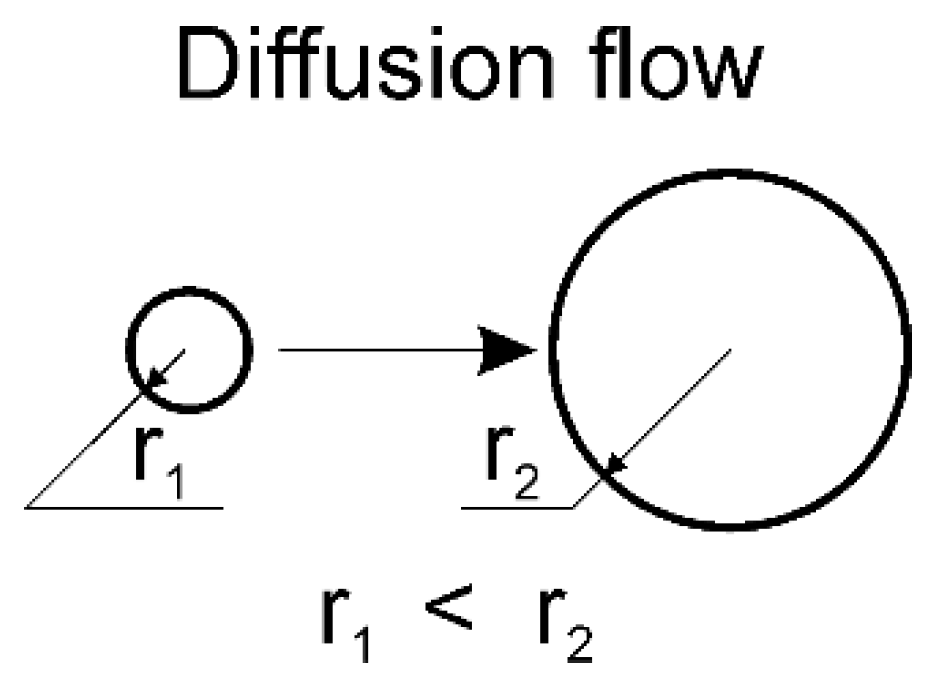

4. Features of the Microstructure of Ni-Based Superalloys and the Kinetics of Its Diffusion Coarsening Process

5. Theoretical Assessment of the Cohesive Strength of Grain Boundaries and Analysis of the Alloying System of Powder Disk HRAs

6. Features of the Microstructure of Ni-Based Superalloys Obtained Using Additive Technologies

7. Other Examples Application of the Approach: Beyond Ni-Based Alloys

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sims, C.; Stoloff, N.; Hagel, W. (Eds.) Superalloys II: High-Temperature Materials for Aerospace and Industrial Power; John Wiley and Sons: New York, NY, USA, 1987. [Google Scholar]

- Reed, R. The Superalloys. Fundamentals and Applications; Cambridge University Press: New York, NY, USA, 2006. [Google Scholar] [CrossRef]

- Logunov, A. Nickel Superalloys for Gas Turbine Blades and Disks; Izdatel’skii dom «Gazoturbinnie tehnologii»: Rybinsk, Russia, 2017. (In Russian) [Google Scholar]

- Petrov, D.A.; Tumanov, A.T. Device for making single-crystal products. U.S. Patent No. 4,015,657, 5 April 1977. [Google Scholar]

- Bokshtein, S.; Ginsburg, S.; Razumovskii, I.; Kishkin, S.; Stroganov, G. Autoradiography of Interfaces and Structural Stability of Alloys; Metallurgiya: Moscow, Russia, 1987. (In Russian) [Google Scholar]

- Bokstein, B.; Mendelev, M.; Srolovitz, D. Thermodynamics and Kinetics in Materials Science; Oxford University Press: Oxford, UK, 2005. [Google Scholar]

- Koptev, Y.N. (Ed.) 50 Years Ahead of the Century; Rossiiskoe Kosmicheskoe Agentstvo: Moscow, Russia, 1998. [Google Scholar]

- Beresnev, A.; Logunov, A.; Logacheva, A.; Razumovskii, I. Powder and granular materials. Tekhnol. Metallov 2009, 12, 24–37. (In Russian) [Google Scholar]

- Kornilov, I. Physico-Chemical Bases of Heat Resistance of Alloys; Academy of Sciences of the USSR: Moscow, Russia, 1961. (In Russian) [Google Scholar]

- Kittel, C. Introduction to Solid State Physics, 7th ed.; Wiley: New York, NY, USA, 1996. [Google Scholar]

- Razumovskii, I.; Ruban, A.; Razumovskiy, V.; Logunov, A.; Larionov, V.; Ospennikova, O.; Poklad, V.; Johansson, B. New generation of Ni-based superalloys designed on the basis of first-principles calculations. Mater. Sci. Eng. A 2008, 497, 18–24. [Google Scholar] [CrossRef]

- Razumovskiy, V.; Lozovoi, A.; Razumovskii, I. First principles aided design of a new Ni-base superalloy: Influence of transition metal alloying elements on grain boundary and bulk cohesion. Acta Mat. 2015, 82, 369–377. [Google Scholar] [CrossRef]

- Rice, J.; Thomson, R. Ductile versus brittle behaviour of crystals. Philos. Mag. 1974, 29, 73–97. [Google Scholar] [CrossRef]

- Rice, J.; Wang, J.-S. Embrittlement of interfaces by solute segregation. Mater. Sci. Eng. A 1989, 107, 23–40. [Google Scholar] [CrossRef]

- Finnis, M. The theory of metal-ceramic interfaces. J. Phys. Condens. Matter 1996, 8, 5811. [Google Scholar] [CrossRef]

- Lejcek, P. Grain Boundary Segregation in Metals; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Harrison, L. Influence of dislocations on diffusion kinetics in solids with particular reference to the alkali halides. Trans. Faraday Soc. 1961, 57, 1191–1199. [Google Scholar] [CrossRef]

- Mishin, Y.; Asta, M.; Li, J. Atomistic modeling of interfaces and their impact on microstructure and properties. Acta Mater. 2010, 58, 1117–1151. [Google Scholar] [CrossRef] [Green Version]

- Blavette, D.; Duval, P.; Letellier, L.; Guttmann, M. Atomic-scale APFIM and TEM investigation of grain boundary microchemistry in Astroloy nickel base superalloys. Acta Mater. 1996, 44, 4995–5005. [Google Scholar] [CrossRef]

- Ebner, A.S.; Jakob, S.; Clemens, H.; Pippan, R.; Maier-Kiener, V.; He, S.; Ecker, W.; Scheiber, D.; Razumovskiy, V.I. Grain boundary segregation in Ni-base alloys: A combined atom probe tomography and first principles study. Acta Mat. 2021, 221, 117354. [Google Scholar] [CrossRef]

- Bokstein, B.; Razumovskii, I. Grain Boundary Diffusion and Segregation in Interstitial Solid Solutions Based on BCC Transition Metals: Carbon in Niobium. Interface Sci. 2003, 11, 41–49. [Google Scholar] [CrossRef]

- Razumovskiy, V.; Divinski, S.; Romaner, L. Solute segregation in Cu: DFT vs. Experiment. Acta Mater. 2018, 147, 122–132. [Google Scholar] [CrossRef]

- Logunov, A.; Razumovskii, I.; Stroganov, G.; Ruban, A.; Razumovskii, V.; Larionov, V.; Ospennikova, O.; Poklad, V. Theoretical Analysis of the Alloying System and Design of New Nickel-Base Superalloys. Dokl. Akad. Nauk. 2008, 421, 621–624. [Google Scholar] [CrossRef]

- Logunov, A.; Marinin, S.; Poklad, V.; Razumovskii, I. Hot Isostatic Pressing of single crystals of heat-resistant nickel alloys. Technol. Light Alloys 2005, 1, 71–77. [Google Scholar]

- Eliseev, Y.; Poklad, V.; Ospennikova, O.; Larionov, V.; Logunov, A.; Razumovskii, I. Composition of Heat-Resistant Nickel Alloy for Single-Crystal Casting (Options). Russian Patent No. 2,348,724, 3 October 2009. [Google Scholar]

- Avrami, M.J. Kinetics of phase change. I General theory. J. Chem. Phys. 1939, 7, 1103. [Google Scholar] [CrossRef]

- Wert, C.A. Precipitation from Solid Solutions of C and N in α-Iron. J. Appl. Phys. 1949, 20, 943–949. [Google Scholar] [CrossRef]

- Zener, C. Growth of spherical precipitates from solid solution. J. Appl. Phys. 1949, 20, 950–953. [Google Scholar] [CrossRef]

- Ham, F.S. Shape-preserving solutions of the time-dependent diffusion equation. Quart. Appl. Math. 1959, 17, 137–145. [Google Scholar] [CrossRef] [Green Version]

- Lifshitz, I.M.; Slyozov, V.V. The kinetics of precipitation from supersaturated solid solutions. J. Phys. Chem. Solids 1961, 19, 35–50. [Google Scholar] [CrossRef]

- Wagner, C. Theorie der Alterung von Niderschlagen durch Umlosen. Zs. Electrochem. 1961, 65, 581–591. [Google Scholar]

- Razumovskii, I.; Bykov, Y.; Beresnev, A.; Poklad, V.; Razumovskiy, V. Effect of the Particle Size of γ′ Phase on the Mechanical Properties of Ni base Superalloy. Adv. Mater. Res. 2011, 278, 96–101. [Google Scholar] [CrossRef] [Green Version]

- Bykov, Y.; Razumovskii, I. Investigation of the effect of microstructure dispersion on the mechanical properties of a heat-resistant nickel alloy. Perspect. Mater. 2010, 1, 10–15. [Google Scholar]

- Bokstein, B.S. Diffusion in Metals, 2th ed.; Lenand: Moscow, Russian, 2019. (In Russian) [Google Scholar]

- Mehrer, H. Diffusion in Solids; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Nathal, M.; Ebert, L. Gamma prime shape changes during creep of a Ni-base superalloy. Scripta Metal. 1983, 17, 1151–1154. [Google Scholar] [CrossRef]

- Gayda, J.; Srolovitz, D.A. Monte Carlo-finite element model for strain energy controlled microstructural evolution: “Rafting” in superalloys. Acta Metall. 1989, 37, 641–650. [Google Scholar] [CrossRef] [Green Version]

- Nabarro, F.; Cress, C.; Kotschy, P. The thermodynamic driving force for rafting in superalloys. Acta Mat. 1996, 44, 3189–3198. [Google Scholar] [CrossRef] [Green Version]

- Kardashova, S.; Lozovoi, A.; Razumovskii, I. Diffusion Coarsening of the Lamellar Structure in Two-Phase Ti-47.5 at. % Al Intermetallic Alloy. Acta Metall. 1994, 42, 3341–3348. [Google Scholar] [CrossRef]

- Mishin, Y.; Orekhov, N.; Alyoshin, G.; Noat, P.; Razumovskii, I. Model of diffusion coarsening of the raft structure in single crystals of Ni-based superalloys. Mater. Sci. Eng. A 1993, 171, 163–168. [Google Scholar] [CrossRef]

- Lozovoi, A.; Razumovskii, I. Diffusion coarsening of the lamellar structure in two-phase intermetallic alloys. Mater. Sci. Forum 1996, 207–209, 513–516. [Google Scholar] [CrossRef]

- Bokshtein, S.; Bolberova, E.; Ignatova, I.; Kishkin, S.; Razumovskii, I. The effect of the γ/γ′ misfit on the diffusion permeability of the interphase boundaries. Fiz. Metall. Metalloved. 1985, 59, 936–942. (In Russian) [Google Scholar]

- Razumovskii, I.; Razumovskiy, V.; Logachev, I.; Rodin, A.; Razumovsky, M. Segregation of Refractory Metals at Grain Boundaries in High-Temperature Alloys. Russ. Metall. 2020, 11, 1292–1299. [Google Scholar] [CrossRef]

- Beresnev, A.; Logacheva, A.; Logachev, A.; Logunov, A.; Razumovskii, I.; Taran, P. Heat-Resistant Granular Ni-Based Alloy Containing C, Cr, Co, W, Mo, Ti, Al, Nb, Ta, Hf, B, Zr, Ce, La, Yt and Ni in Specific Weight Percentage. Russian Patent No. 2,396,366, 10 August 2010. [Google Scholar]

- Gibson, I.; Rosen, D.W.; Stucker, B. Additive Manufacturing Technologies: Rapid Prototyping to Direct Digital Manufacturing; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2009; Volume 459. [Google Scholar]

- Moussaoui, K.; Rubio, W.; Mousseigne, M.; Sultan, T.; Rezai, F. Effects of Selective Laser Melting additive manufacturing parameters of Inconel 718 on porosity, microstructure and mechanical properties. Mater. Sci. Eng. A 2018, 735, 182–190. [Google Scholar] [CrossRef] [Green Version]

- Beresnev, A.; Razumovskii, I. Hot isostatic pressing for additive manufacturing. Addit. Technol. 2017, 4, 50–54. [Google Scholar]

- Ospennikova, O.; Min, L.; Rogalev, A.; Vadeev, B. Investigation of the chemical composition, structure, and mechanical properties of the EP648 alloy obtained by deformation, investment casting, and selective laser melting. Quest. Mater. Sci. 2020, 1, 44–54. [Google Scholar]

- Sentyurina, Z.A.; Logacheva, A.I.; Gusakov, M.S.; Logachev, I.A. Promising directions of research in the field of additive technologies implemented by JSC «Kompozit». In Proceedings of the 14th International Conference «Novie Materiali i Tehnologii: Poroshkovaya Metallurgiya, Kompozicionnie Materiali, Zashitnie Pokritiya, Svarka», Minsk, Belarus, 9–11 September 2020; pp. 604–608. (In Russian). [Google Scholar]

- Razumovskii, I.; Logacheva, A.; Razumovskiy, V.; Logachev, I.; Razumovsky, M. Modern Powder Metallurgy: Chemical Composition Design for Improved Heat Resistant Alloys. Metals 2021, 11, 1215. [Google Scholar] [CrossRef]

- Razumovskii, I.M.; Beresnev, A.G.; Logacheva, A.I.; Razumovskii, M.I.; Bokshtein, B.S.; Rodin, A.O. Alloys based on many refractory metals—next generation of high-temperature composite materials. Konstrukts. Kompozit. Mater. 2019, 1, 45–50. (In Russian) [Google Scholar]

- Razumovskiy, V.; Scheiber, D.; Butrim, V.; Trushnikova, A.; Varlamova, S.; Razumovskii, I.; Beresnev, A. New Cr-Ni-base alloy for high-temperature applications designed based on first principles calculations. Adv. Condens. Matter Phys. 2018, 2018, 9383981. [Google Scholar] [CrossRef] [Green Version]

- Logacheva, A.; Logachev, I.; Razumovskii, V.; Razumovskii, I.; Kosyrev, K. Development of a theoretical procedure for assessingthe balance of the chemical composition of a high-temperature titanium alloy of a next generation and the creation on this basis of a technique for optimizing the compositions of titanium alloys. Titanium 2012, 4, 27–31. (In Russian) [Google Scholar]

- Yeh, J.W. Alloy design strategies and future trends in high-entropy alloys. JOM 2013, 65, 1759–1771. [Google Scholar] [CrossRef]

- Razumovskii, I.M.; Logacheva, A.I.; Beresnev, A.G.; Logachev, I.A.; Razumovsky, M.I.; Mar’in, S.S. Current trends in the development of powder metallurgy: Design and production of heat-resistant alloys. Konstrukts. Kompozit. Mater. 2021, 2, 29–40. (In Russian) [Google Scholar] [CrossRef]

- Pickering, E.J.; Jones, N.G. High-entropy alloys: A critical assessment of their founding principles and future prospects. Int. Mater. Rev. 2016, 61, 183–202. [Google Scholar] [CrossRef] [Green Version]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef] [Green Version]

- Zou, Y.; Maiti, S.; Steurer, W.; Spolenak, R. Sizedependent plasticity in an Nb25Mo25Ta25W25 refractory high-entropy alloy. Acta Mater. 2014, 65, 85–97. [Google Scholar] [CrossRef]

- Scheiber, D.; Pippan, R.; Puschnig, P.; Romaner, L. Ab initio calculations of grain boundaries in bcc metals. Model. Simul. Mater. Sci. Eng. 2016, 24, 035013. [Google Scholar] [CrossRef]

- Scheiber, D.; Pippan, R.; Puschnig, P.; Ruban, A.V.; Romaner, L. Ab initio search for cohesion enhancing solute elements at grain boundaries in molybdenum and tungsten. Int. J. Refract. Met. Hard Mater. 2016, 60, 75–81. [Google Scholar] [CrossRef]

- Scheiber, D.; Razumovskiy, V.I.; Puschnig, P.; Pippan, R.; Romaner, L. Ab initio description of segregation and cohesion of grain boundaries in W–25 at % Re alloys. Acta Mater. 2015, 88, 180–189. [Google Scholar] [CrossRef]

| Ni-Based Alloy | W | Ta | Re | Cr + Co + Ti + Nb + Al | Others, Nominal |

|---|---|---|---|---|---|

| KS-1 | 16.0 | 6.3 | 0 | 12.3 | 0.02La + 02Y + 0.02Ce |

| KS-2 | 15.0 | 6.3 | 2.0 | 13.3 | 0.02La + 02Y + 0.02Ce |

| KS-3 | 9.9 | 7.6 | 5.5 | 9.7 | 0.02La + 02Y + 0.02Ce |

| Ni-Base Alloy | Chemical Alloy Composition (wt.%) | σ1001000 (MPa) | σ5001000 (MPa) |

|---|---|---|---|

| KS-1 | 16 W, 5Ta | 255 | 194 |

| KS-2 | (12–15) W, 8Ta, 2Re | 270 | - |

| KS-3 | 10 W, 8Ta, 6Re | 330 | 263 |

| CMSX-2 | 8 W, 6Ta | 226 | 180 |

| CMSX-4 | 6 W, 7Ta, 3Re | 270 | 190 |

| CMSX-10M | 5 W, 8Ta, 6Re | 300 | 215 |

| EPM-102 | 6 W, 8.25Ta, 6Re, 3Ru | 330 | 240 |

| Sample Status | Ultimate Tensile Strength UTS (σB) (MPa) | Yield Strength (σ0,2) (MPa) | Elongation δ (%) |

|---|---|---|---|

| As-built | 1083 ± 27 | 853 ± 16 | 10.5 ± 4.3 |

| After HIP | 1292 ± 25 | 811± 5 | 24.9 ± 1.3 |

| After HIP + complete heat treatment | 1455 ± 52 | 1023 ± 34 | 21.4 ± 6.7 |

| Standard P/M | 1275 | 834 | 13 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Razumovskii, I.; Bokstein, B.; Logacheva, A.; Logachev, I.; Razumovsky, M. Cohesive Strength and Structural Stability of the Ni-Based Superalloys. Materials 2022, 15, 200. https://doi.org/10.3390/ma15010200

Razumovskii I, Bokstein B, Logacheva A, Logachev I, Razumovsky M. Cohesive Strength and Structural Stability of the Ni-Based Superalloys. Materials. 2022; 15(1):200. https://doi.org/10.3390/ma15010200

Chicago/Turabian StyleRazumovskii, Igor, Boris Bokstein, Alla Logacheva, Ivan Logachev, and Mikhail Razumovsky. 2022. "Cohesive Strength and Structural Stability of the Ni-Based Superalloys" Materials 15, no. 1: 200. https://doi.org/10.3390/ma15010200

APA StyleRazumovskii, I., Bokstein, B., Logacheva, A., Logachev, I., & Razumovsky, M. (2022). Cohesive Strength and Structural Stability of the Ni-Based Superalloys. Materials, 15(1), 200. https://doi.org/10.3390/ma15010200