Shear Strengthening of High Strength Concrete Beams That Contain Hooked-End Steel Fiber

Abstract

:1. Introduction

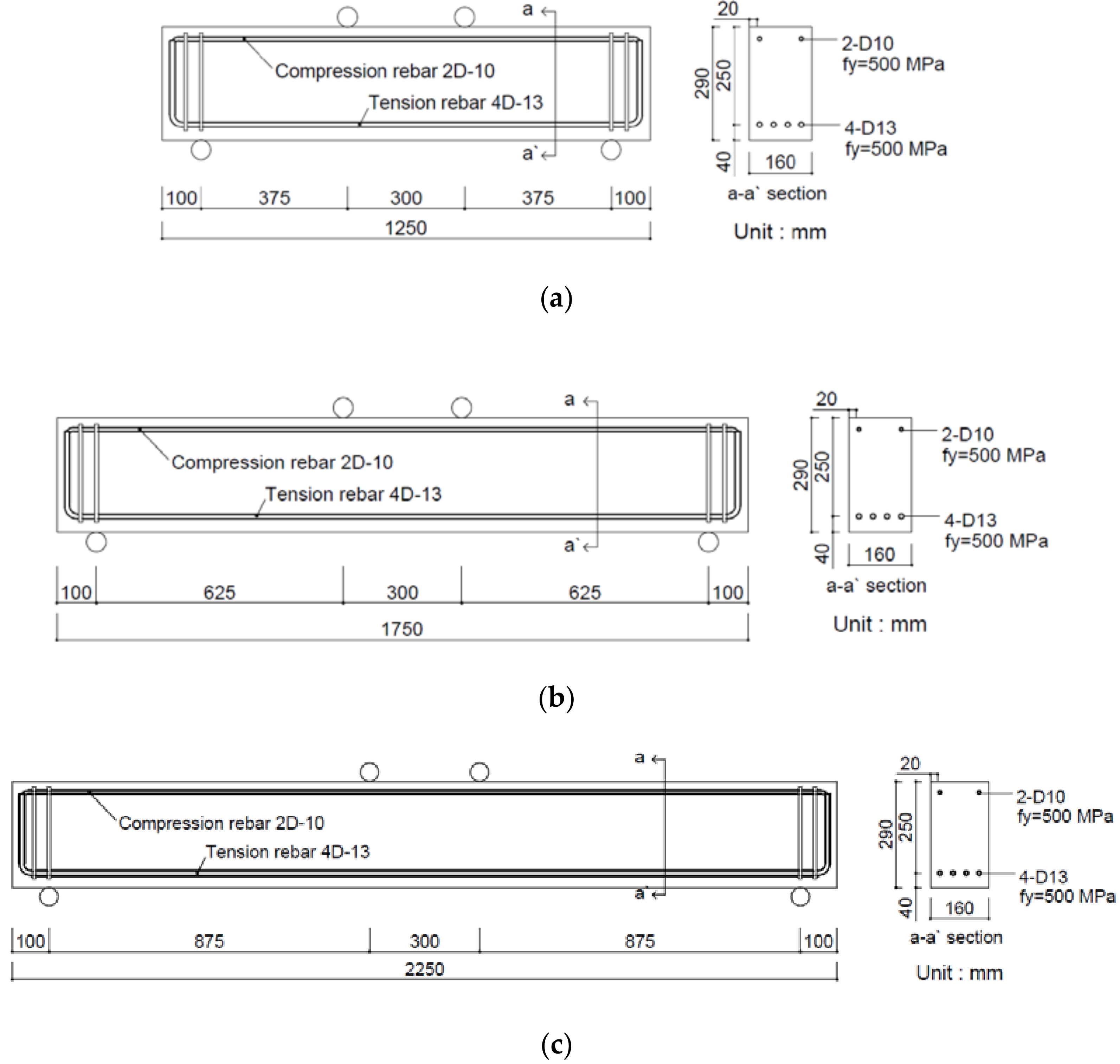

2. Experimental Program

2.1. Manufacturing of SFRC Beams

2.2. Manufacturing of SFRC Beams

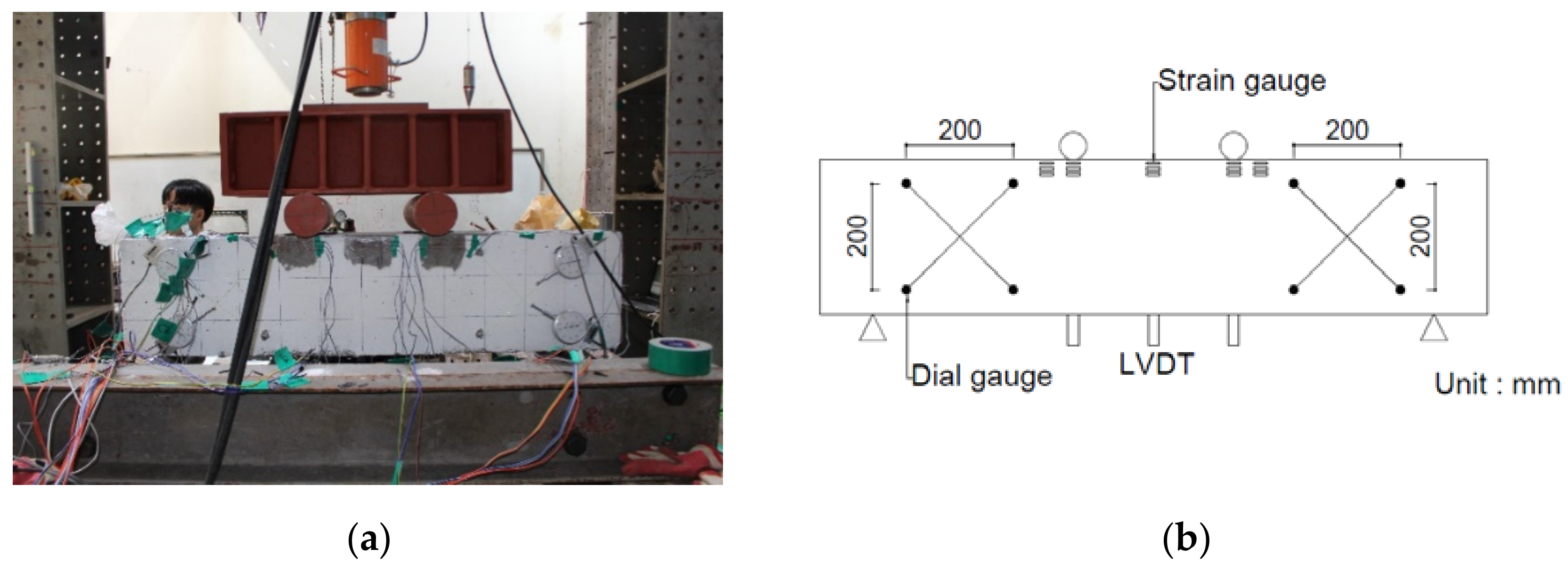

2.3. Test Set-Up and Instrumentation

3. Results and Discussion

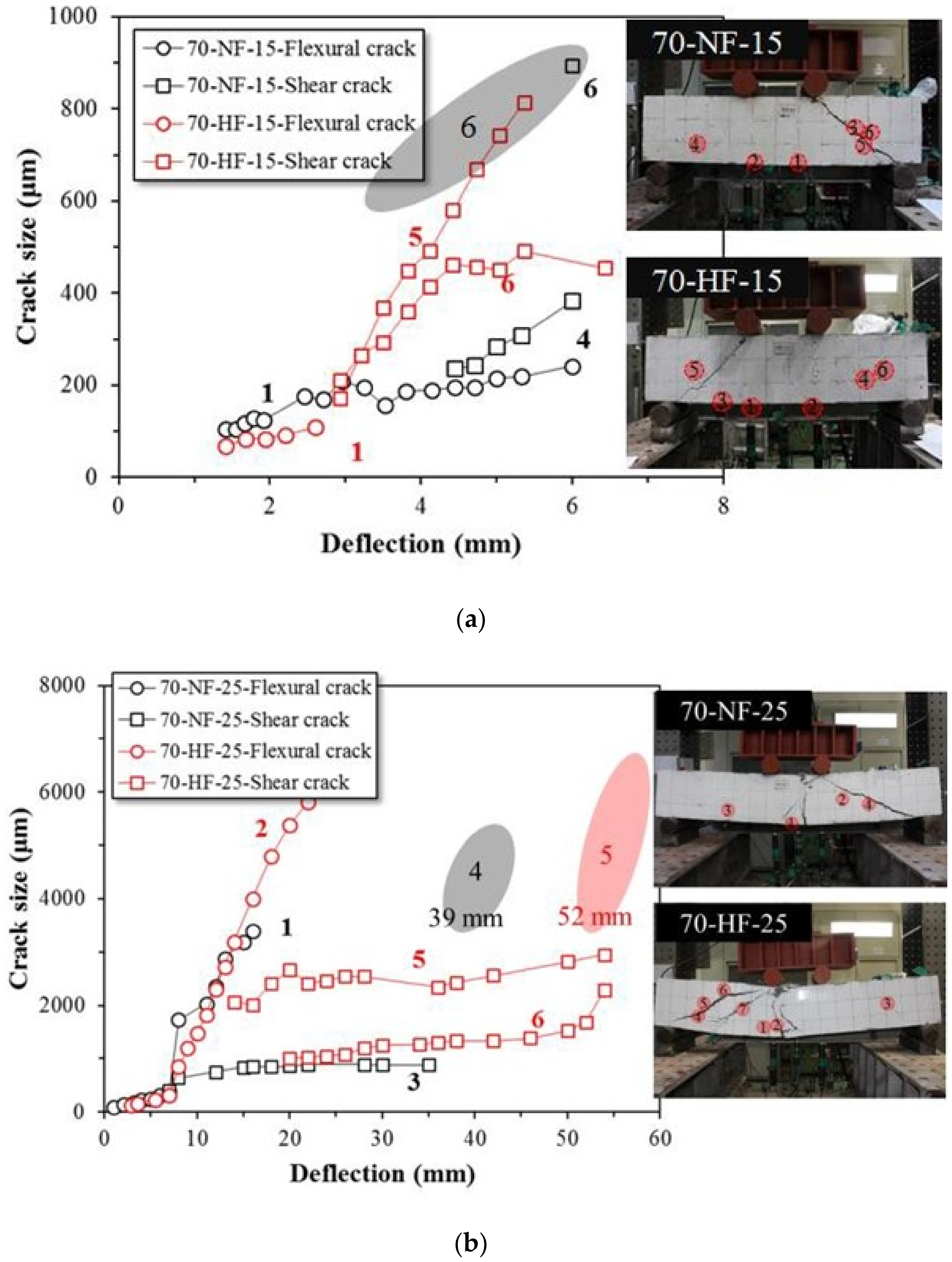

3.1. Crack Development and Failure Mode of SFRC Beam Specimens

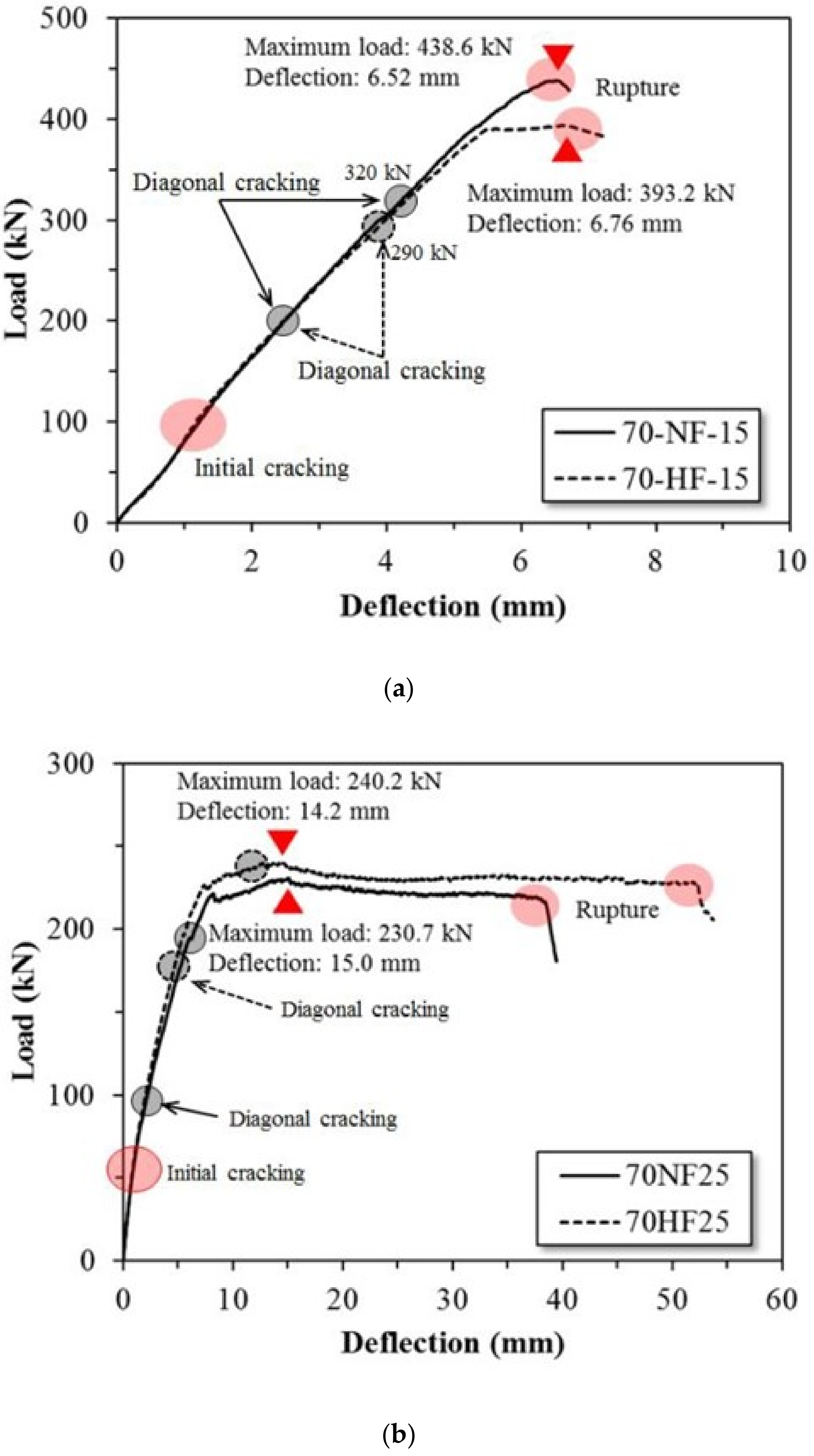

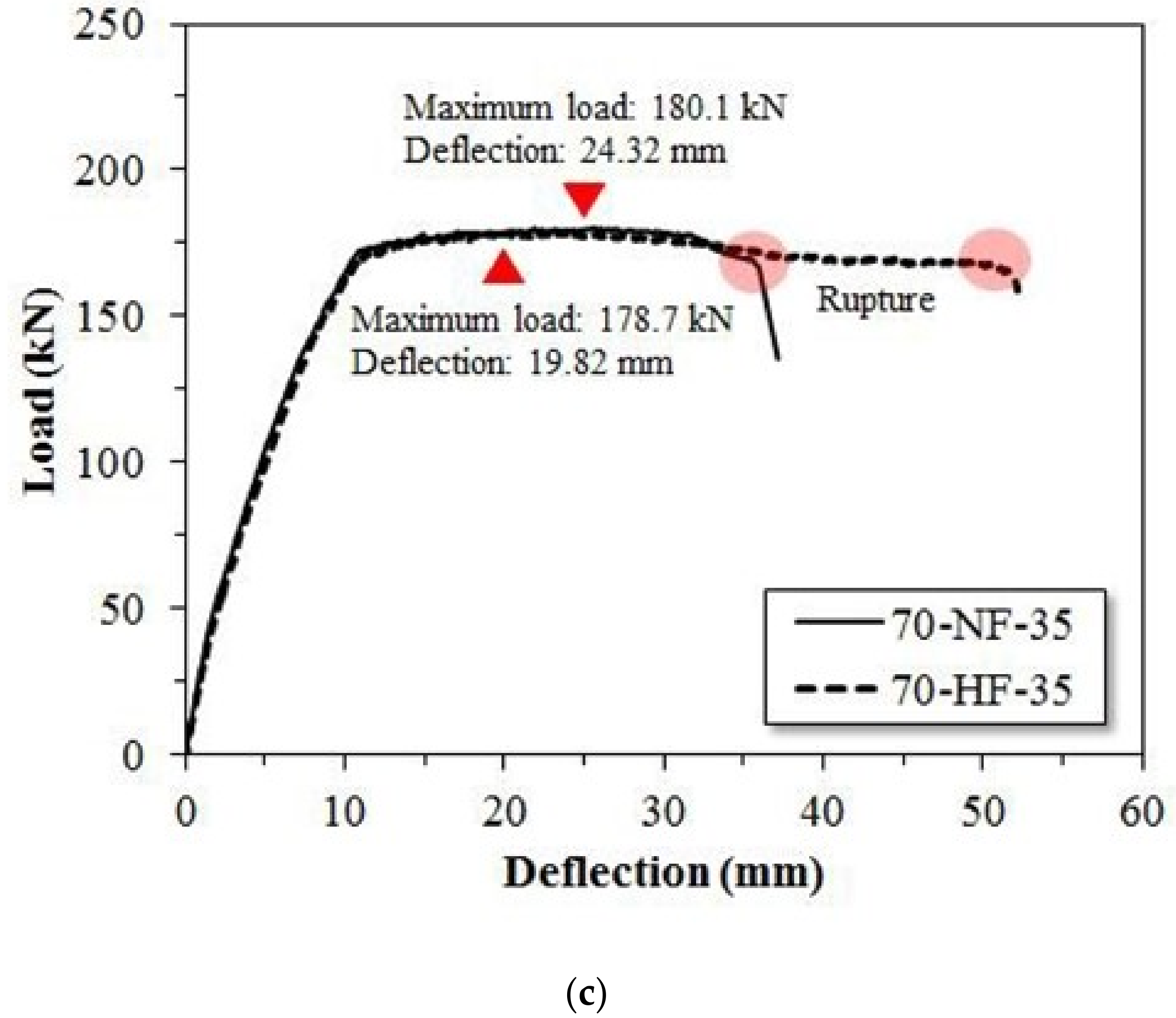

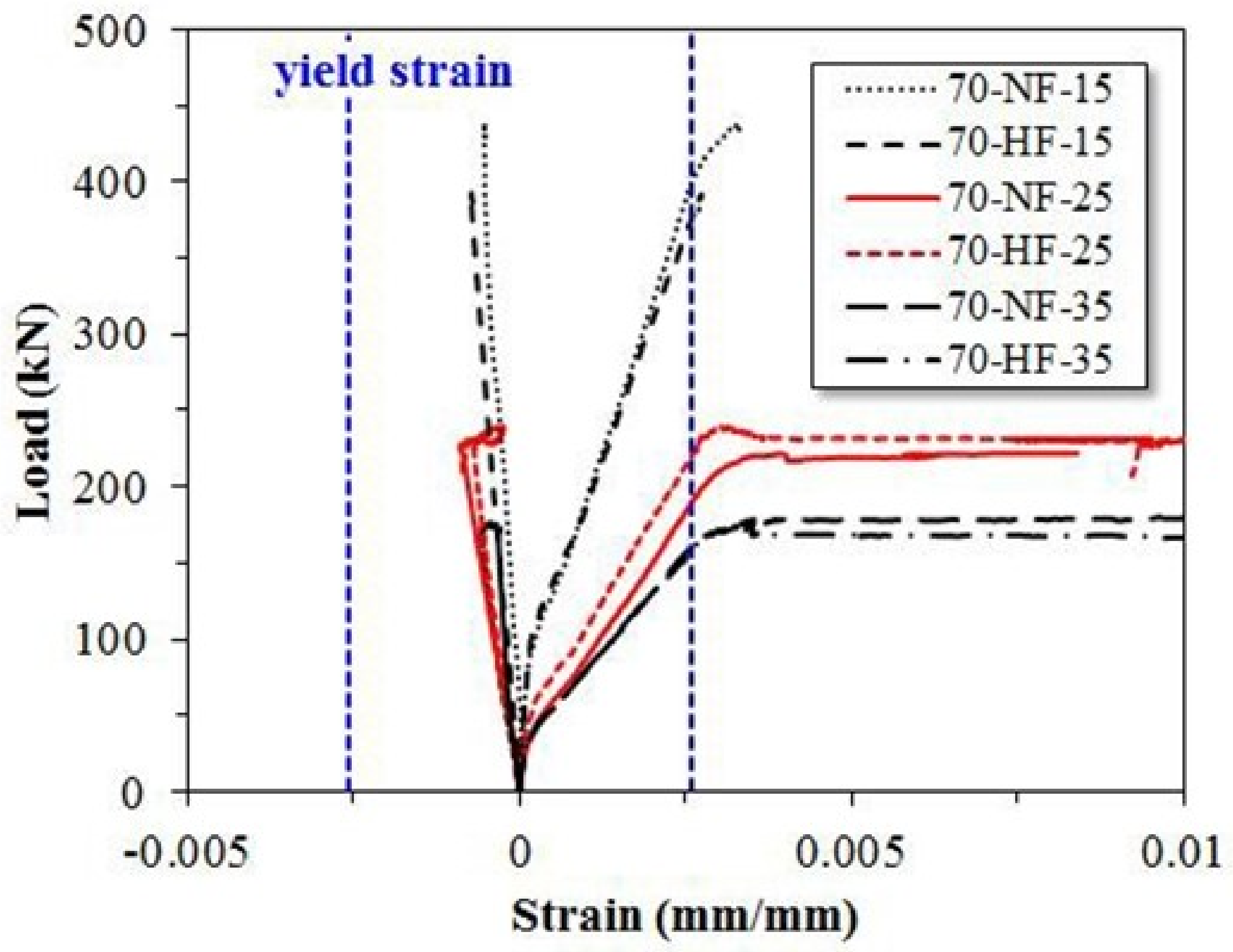

3.2. Load–Displacement Relationship

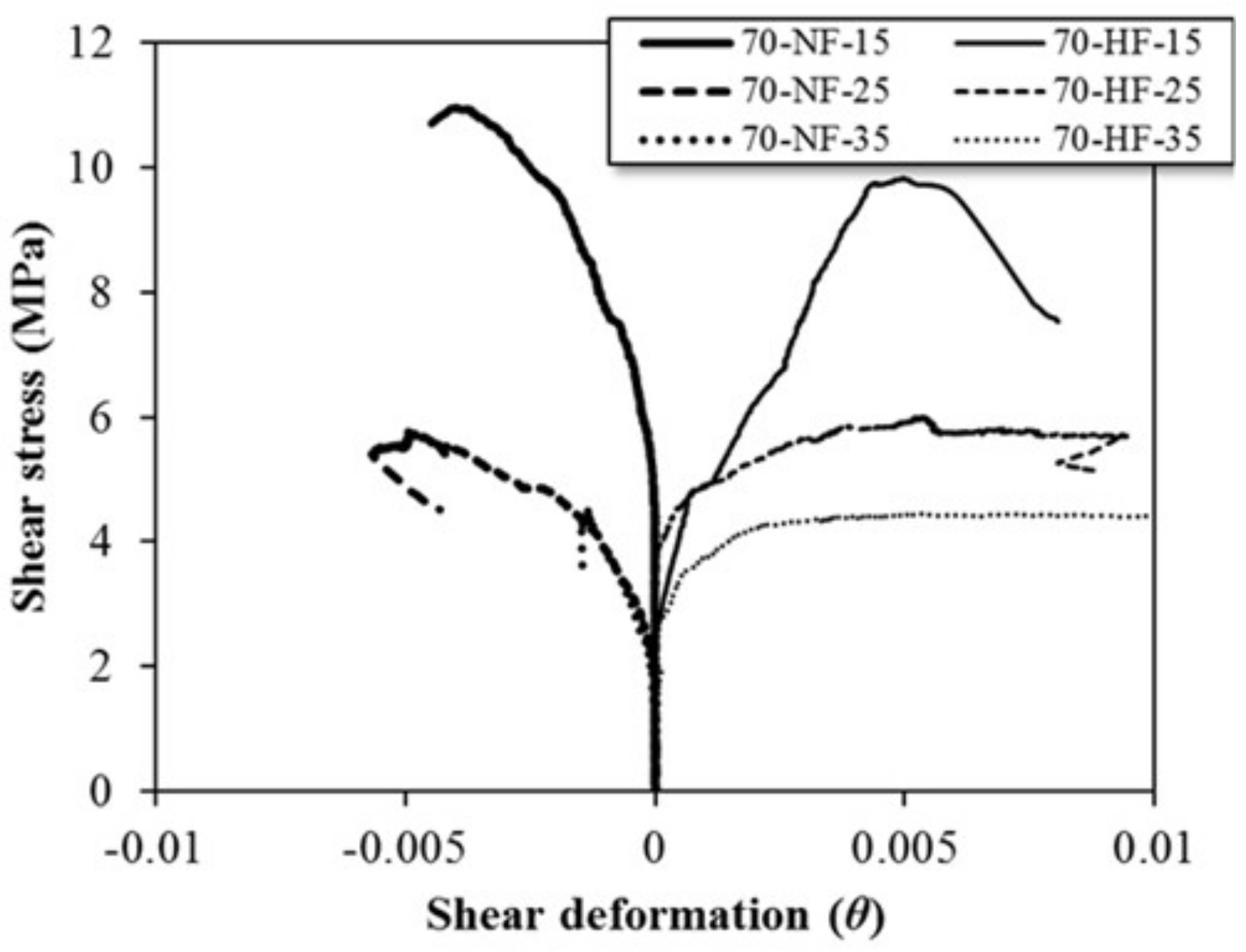

3.3. Shear Deformation

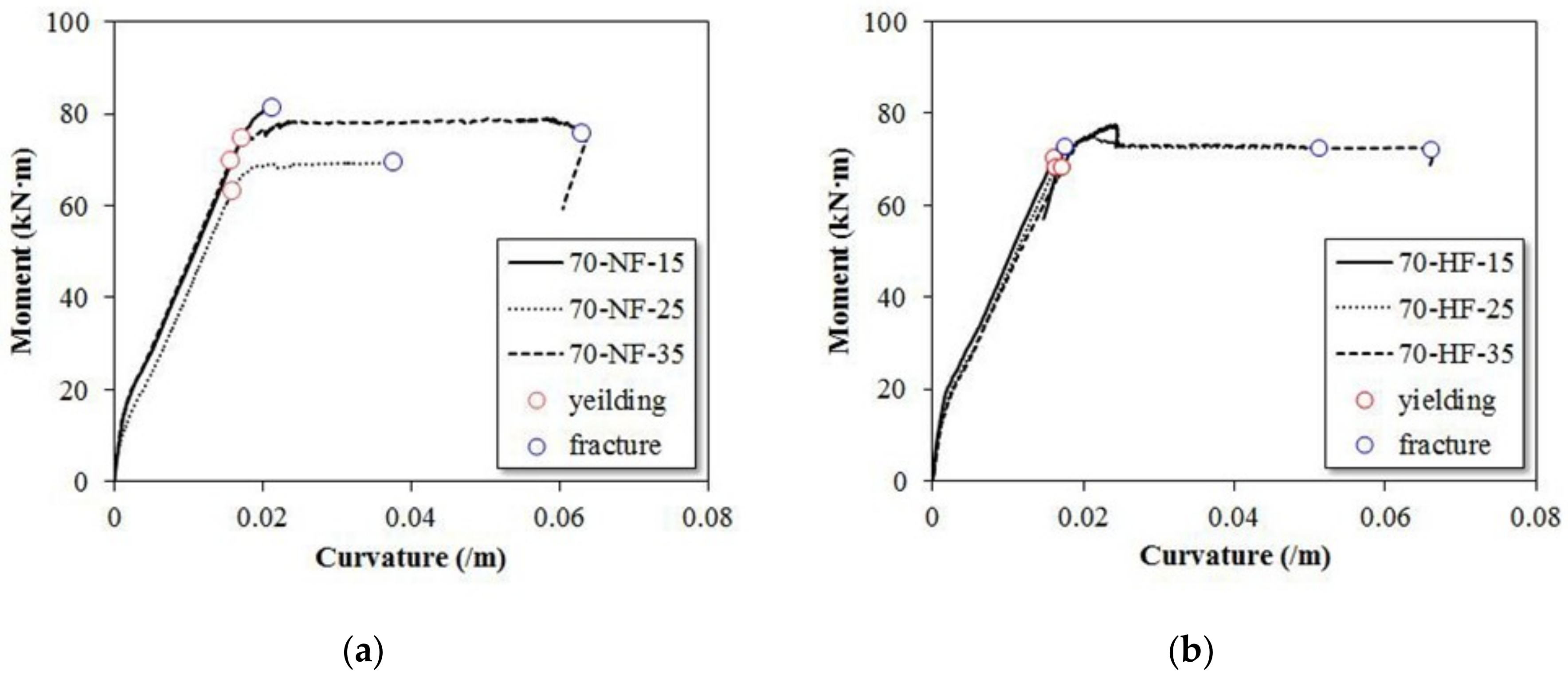

3.4. Moment–Curvature Relationship

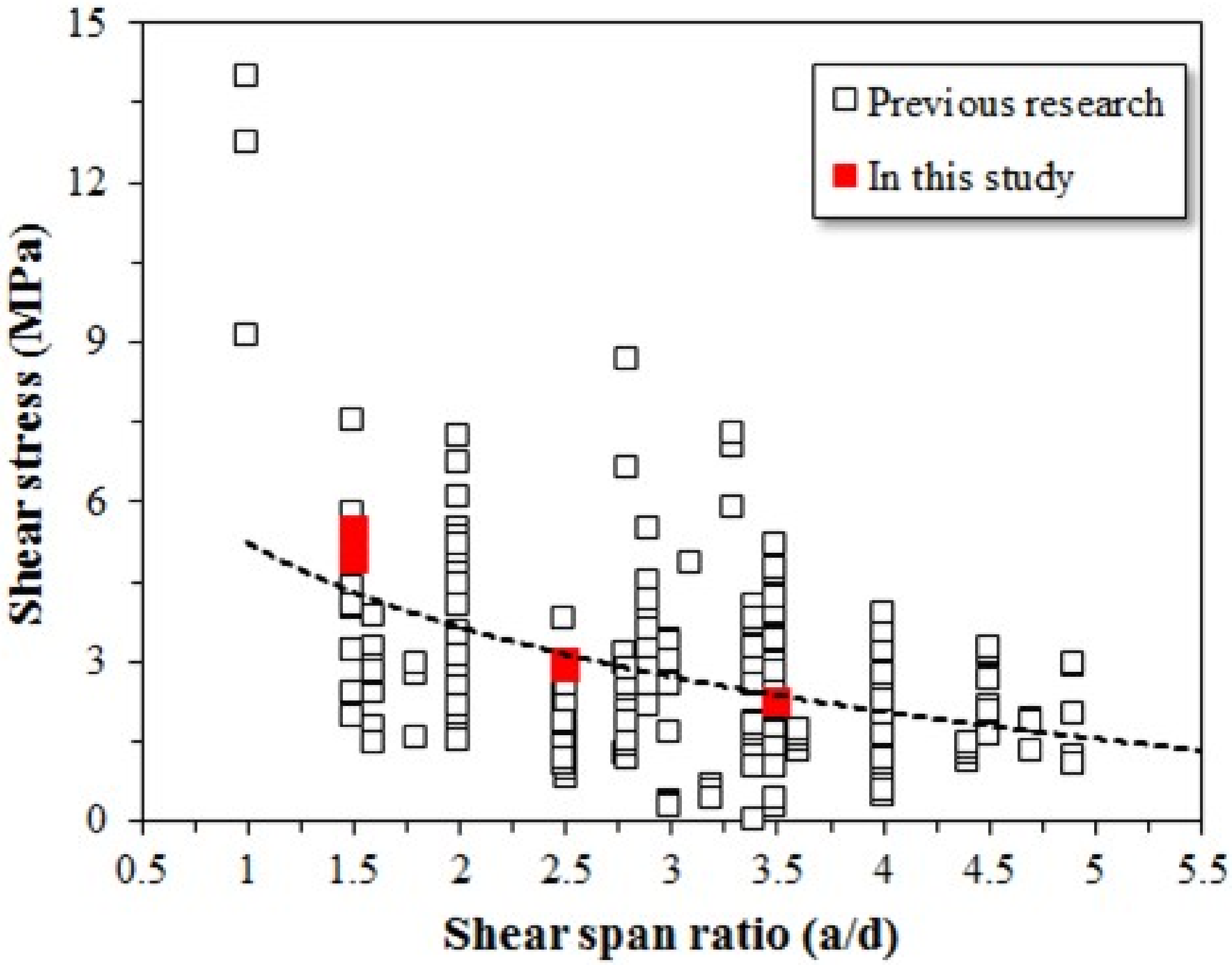

3.5. Shear Strength of SFRC Beam Specimens

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Casanova, P.; Rossi, P. Can steel fibers replace transverse reinforcements in reinforced concrete beams? Mater. J. 1997, 94, 341–354. [Google Scholar]

- Mansur, M.A.; Ong, K.C.G.; Paramasivam, P. Shear strength of fibrous concrete beams without stirrups. J. Struct. Eng. 1986, 112, 2066–2079. [Google Scholar] [CrossRef]

- Li, V.C.; Ward, R.; Hamza, A.M. Steel and synthetic fibers as shear reinforcement. ACI Mater. J. 1992, 89, 499–508. [Google Scholar]

- Swamy, R.N.; Jones, R.; Chiam, A.T. Influence of steel fibers on the shear resistance of lightweight concrete I-beams. Struct. J. 1993, 90, 103–114. [Google Scholar]

- Oh, Y.H.; Kim, J.H. Estimation of Flexural and Shear Strength for Steel Fiber Reinforced Flexural Members without Shear Reinforcements. J. Korea Inst. Struct. Maint. Insp. 2008, 20, 257–267. [Google Scholar]

- Yakoub, H.E. Shear stress prediction: Steel fiber-reinforced concrete beams without stirrups. ACI Struct. J. 2011, 108, 304. [Google Scholar]

- Sahoo, D.R.; Sharma, A. Effect of steel fiber content on behavior of concrete beams with and without stirrups. ACI Struct. J. 2014, 111, 1157. [Google Scholar] [CrossRef]

- Lee, H.H. Capacity Evaluation of High Strength SFRC Beams according to Shear Span to Depth Ratio. J. Korea Inst. Struct. Maint. Insp. 2014, 18, 76–83. [Google Scholar]

- Soroushian, P.; Bayasi, Z. Fiber type effects on the performance of steel fiber reinforced concrete. ACI Mater. J. 1991, 88, 129–134. [Google Scholar]

- Kim, C.G.; Park, H.G.; Hong, G.H.; Kang, S.M. Evaluation on Shear Contribution of Steel Fiber Reinforced Concrete in Place of Minimum Shear Reinforcement. J. Korea Inst. Struct. Maint. Insp. 2008, 27, 603–613. [Google Scholar]

- Ashour, S.A.; Hasanain, G.S.; Wafa, F.F. Shear behavior of high-strength fiber reinforced concrete beams. ACI Struct. J. 1992, 89, 176–184. [Google Scholar]

- Kwak, Y.K.; Eberhard, M.O.; Kim, W.S.; Kim, J. Shear strength of steel fiber-reinforced concrete beams without stirrups. ACI Struct. J. 2002, 99, 530–538. [Google Scholar]

- Imam, M.; Vandewalle, L.; Mortelmans, F.; Van Gemert, D. Shear domain of fibre-reinforced high-strength concrete beams. Eng. Struct. 1997, 19, 738–747. [Google Scholar] [CrossRef]

- Shin, S.W.; Oh, J.G.; Ghosh, S.K. Shear behavior of laboratory-sized high-strength concrete beams reinforced with bars and steel fibers. Spec. Publ. 1994, 142, 181–200. [Google Scholar]

- Khuntia, M.; Stojadinovic, B.; Goel, S.C. Shear strength of normal and high-strength fiber reinforced concrete beams without stirrups. ACI Struct. J. 1999, 96, 282–289. [Google Scholar]

- Dinh, H.H. Shear Behavior of Steel Fiber Reinforced Concrete Beams without Stirrup Reinforcement. Ph.D. Thesis, University of Michigan, Ann Arbor, MI, USA, 2009. [Google Scholar]

- Jang, S.J.; Kang, D.H.; Ahn, K.L.; Park, W.S.; Kim, S.W.; Yun, H.D. Feasibility of using high-performance steel fibre reinforced concrete for simplifying reinforcement details of critical members. Int. J. Polym. Sci. 2015, 2015, 850562. [Google Scholar] [CrossRef] [Green Version]

- Yoo, D.Y.; Yuan, T.; Yang, J.M.; Yoon, Y.S. Feasibility of replacing minimum shear reinforcement with steel fibers for sustainable high-strength concrete beams. Eng. Struct. 2017, 147, 207–222. [Google Scholar] [CrossRef]

- Code, M. Fib Model Code for Concrete Structures 2010. Document Competence Center Siegmar Kästl eK: Ostfildern, Germany, 2010. [Google Scholar]

- EN 14651. ; Test Method for Metallic Fibered Concrete—Measuring the Flexural Tensile Strength (Limit of Proportionality (LOP), Residual). BSI: Hong Kong, China, 2005.

- ASTM C 1609. ; Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam with Third-Point Loading). American Society for Testing and Materials International: West Conshohocken, PA, USA, 2002.

| Mixture | Section (mm × mm) | d (mm) | Longitudinal Rebar | ρ (%) | Vf (%) | Fiber Tensile Strength (MPa) | a/d | |

|---|---|---|---|---|---|---|---|---|

| Bottom | Top | |||||||

| 70-NF-1.5 | (b × h) 160 × 290 | 250 | 4-D13 | 2-D10 | 1.27 | 0.75 | 1200 | 1.5 |

| 70-NF-2.5 | 2.5 | |||||||

| 70-NF-3.5 | 3.5 | |||||||

| 70-HF-1.5 | 160 × 290 | 250 | 4-D13 | 2-D10 | 1.27 | 0.75 | 1600 | 1.5 |

| 70-HF-2.5 | 2.5 | |||||||

| 70-HF-3.5 | 3.5 | |||||||

| W/B | Air (%) | Unit Weight (kg/m3) | |||||

|---|---|---|---|---|---|---|---|

| W | C | SF | S | G | Steel Fiber | ||

| 0.33 | 4 | 165 | 475 | 25 | 643 | 813 | 58.9 |

| Type | Length (mm) | Diameter (mm) | Aspect Ratio (l/d) | Tensile Strength (MPa) |

|---|---|---|---|---|

| Normal strength steel fiber | 35 | 0.55 | 64 | 1200 |

| High strength steel fiber | 35 | 0.55 | 64 | 1600 |

| Rebar Size | Yielding Strength (MPa) | Strain at Yielding | Tensile Strength (MPa) | Elastic Modulus (GPa) |

|---|---|---|---|---|

| D10 | 473.1 | 0.00233 | 637.2 | 208.7 |

| D13 | 515.8 | 0.00257 | 689.1 | 200.8 |

| Mixture | Py (kN) | Δy (mm) | Pmax (kN) | Δmax (mm) | Pu (kN) | Δu (mm) | Δu/Δy |

|---|---|---|---|---|---|---|---|

| 70-NF-15 | 398.79 | 5.47 | - | - | 438.60 | 6.52 | 1.19 |

| 70-NF-25 | 221.25 | 8.27 | 230.7 | 15.0 | 213.76 | 38.55 | 4.66 |

| 70-NF-35 | 169.70 | 9.22 | 180.1 | 24.32 | 166.43 | 35.95 | 3.90 |

| 70-HF-15 | 389.65 | 5.50 | - | - | 393.20 | 6.76 | 1.23 |

| 70-HF-25 | 225.83 | 7.29 | 240.2 | 14.2 | 225.83 | 52.32 | 7.18 |

| 70-HF-35 | 167.41 | 11.62 | 178.7 | 19.82 | 159.58 | 48.78 | 4.20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yun, H.-D.; Jeong, G.-Y.; Choi, W.-C. Shear Strengthening of High Strength Concrete Beams That Contain Hooked-End Steel Fiber. Materials 2022, 15, 17. https://doi.org/10.3390/ma15010017

Yun H-D, Jeong G-Y, Choi W-C. Shear Strengthening of High Strength Concrete Beams That Contain Hooked-End Steel Fiber. Materials. 2022; 15(1):17. https://doi.org/10.3390/ma15010017

Chicago/Turabian StyleYun, Hyun-Do, Gwon-Young Jeong, and Won-Chang Choi. 2022. "Shear Strengthening of High Strength Concrete Beams That Contain Hooked-End Steel Fiber" Materials 15, no. 1: 17. https://doi.org/10.3390/ma15010017

APA StyleYun, H.-D., Jeong, G.-Y., & Choi, W.-C. (2022). Shear Strengthening of High Strength Concrete Beams That Contain Hooked-End Steel Fiber. Materials, 15(1), 17. https://doi.org/10.3390/ma15010017