Effect of Nano-SiO2 on the Microstructure and Mechanical Properties of Concrete under High Temperature Conditions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mixture Composition, Mixing Process and Forming Specimens

2.3. Structural Characterization

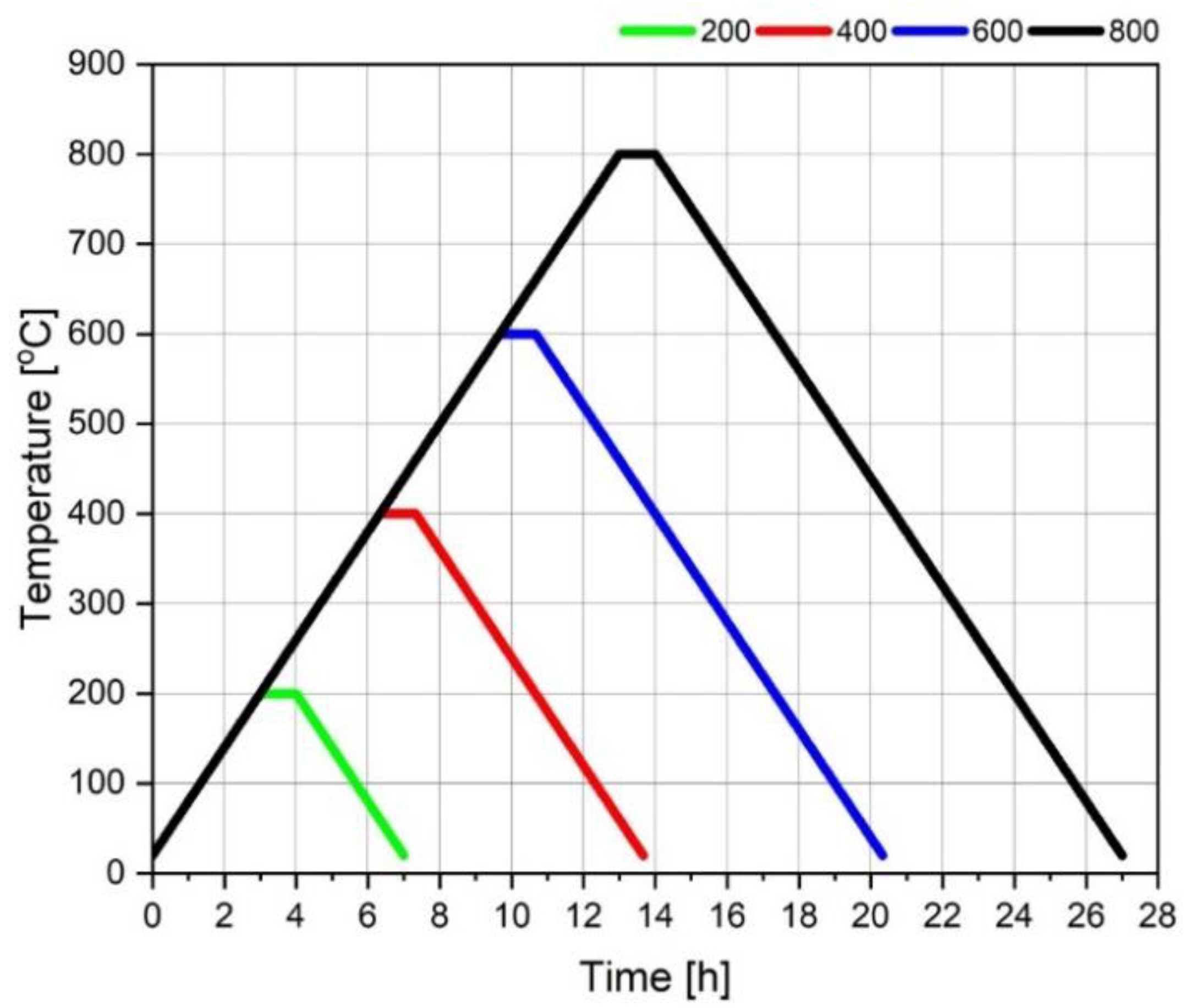

2.4. Mechanical Performance of Concrete

3. Results and Discussion

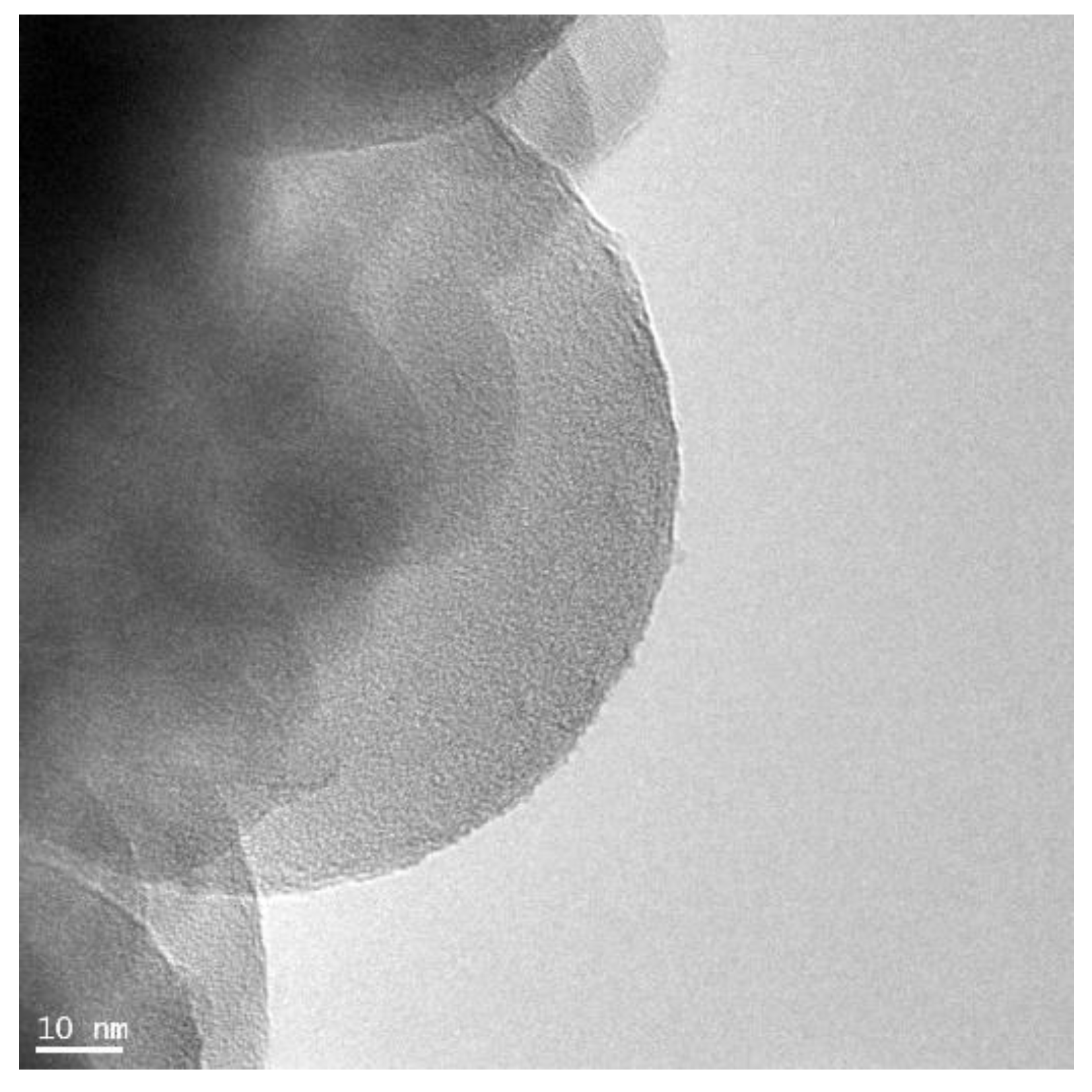

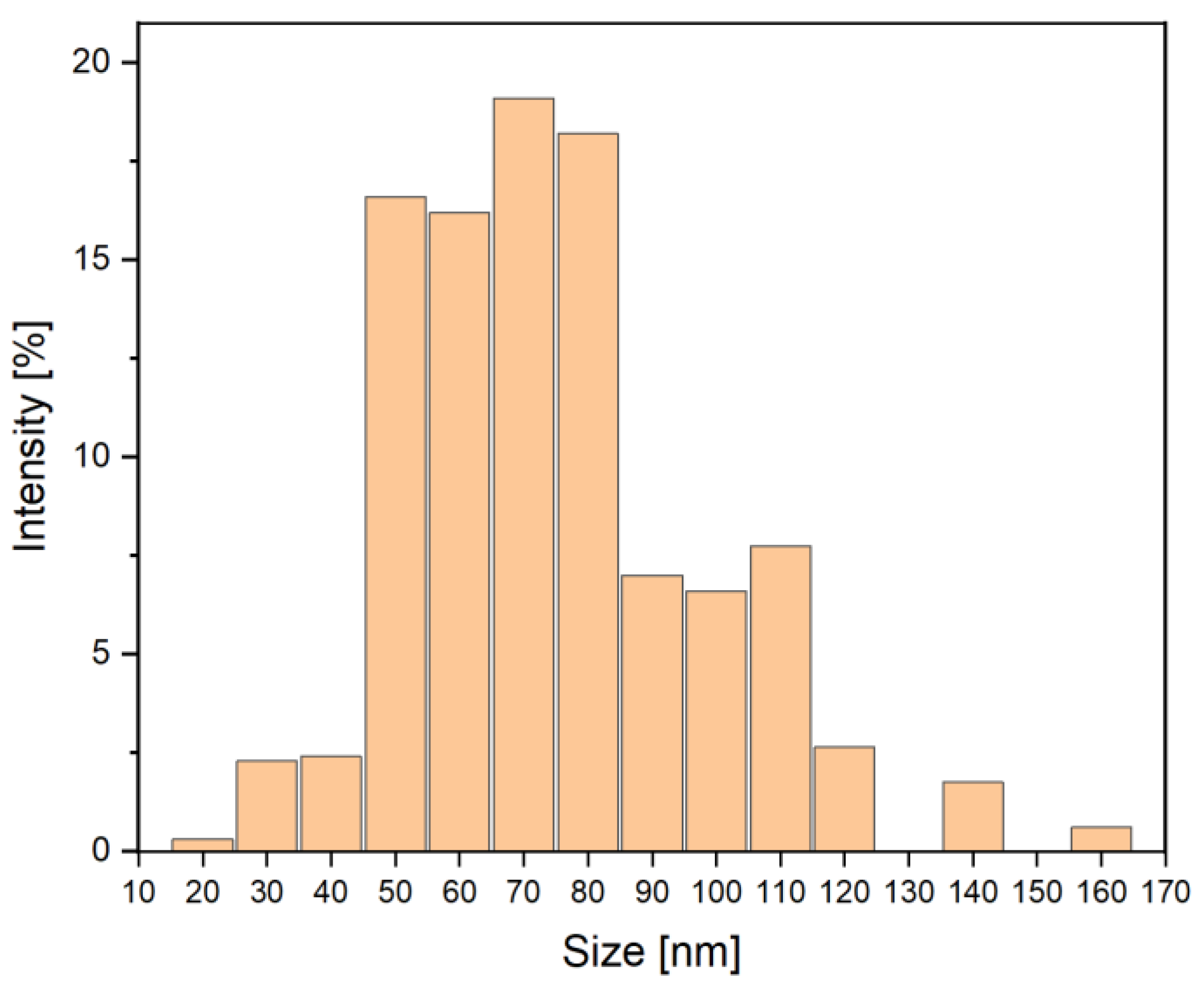

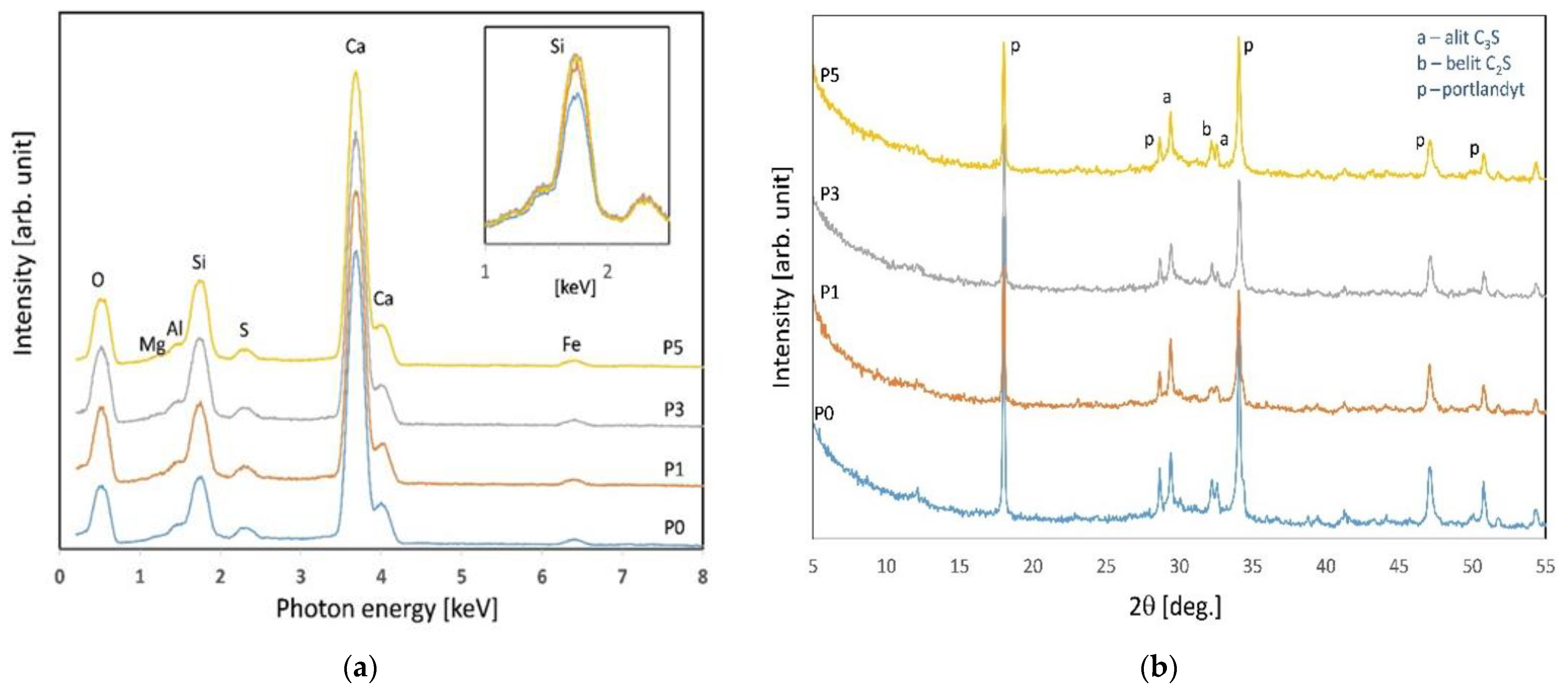

3.1. Characteristics of Nanosilica

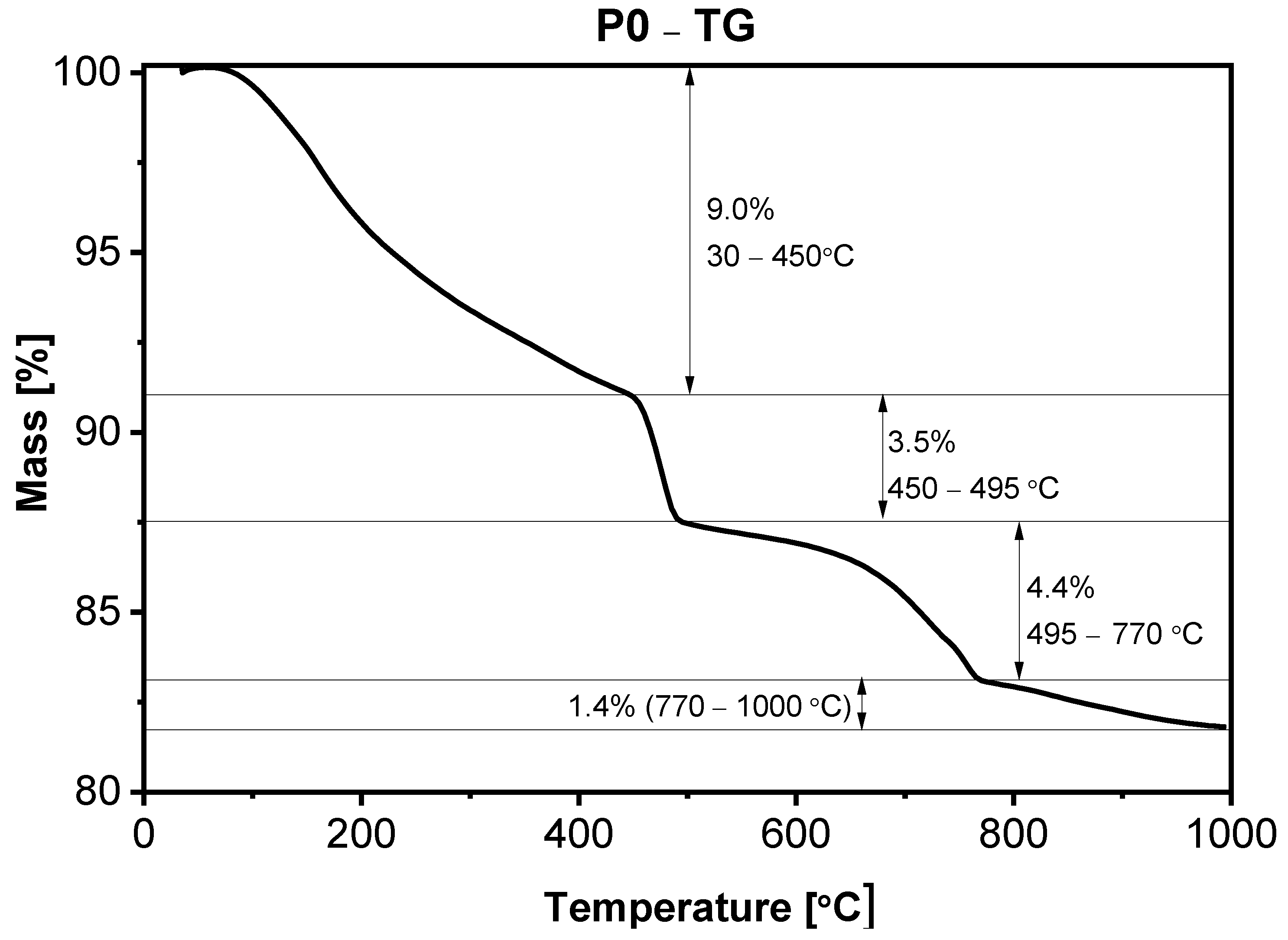

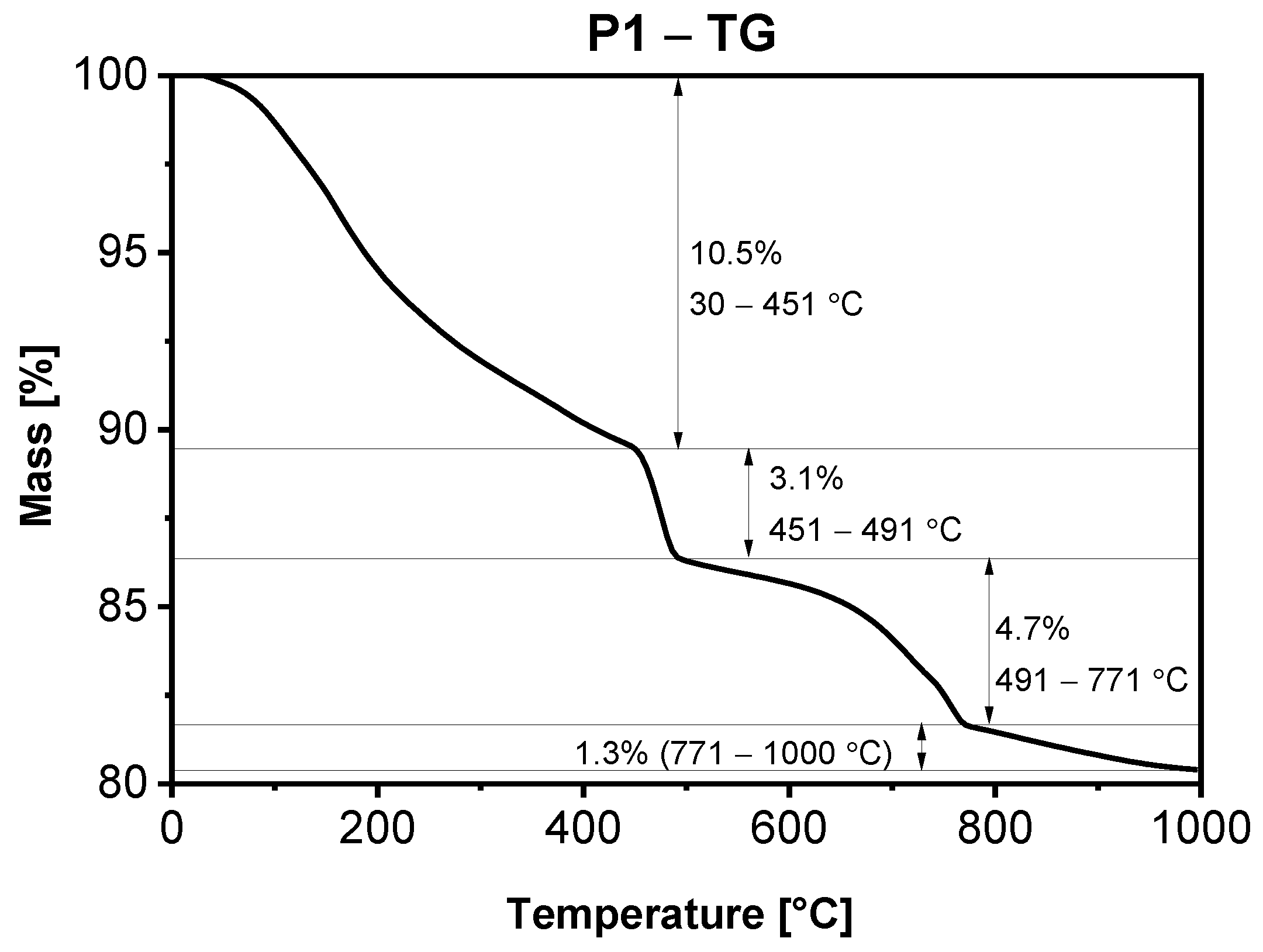

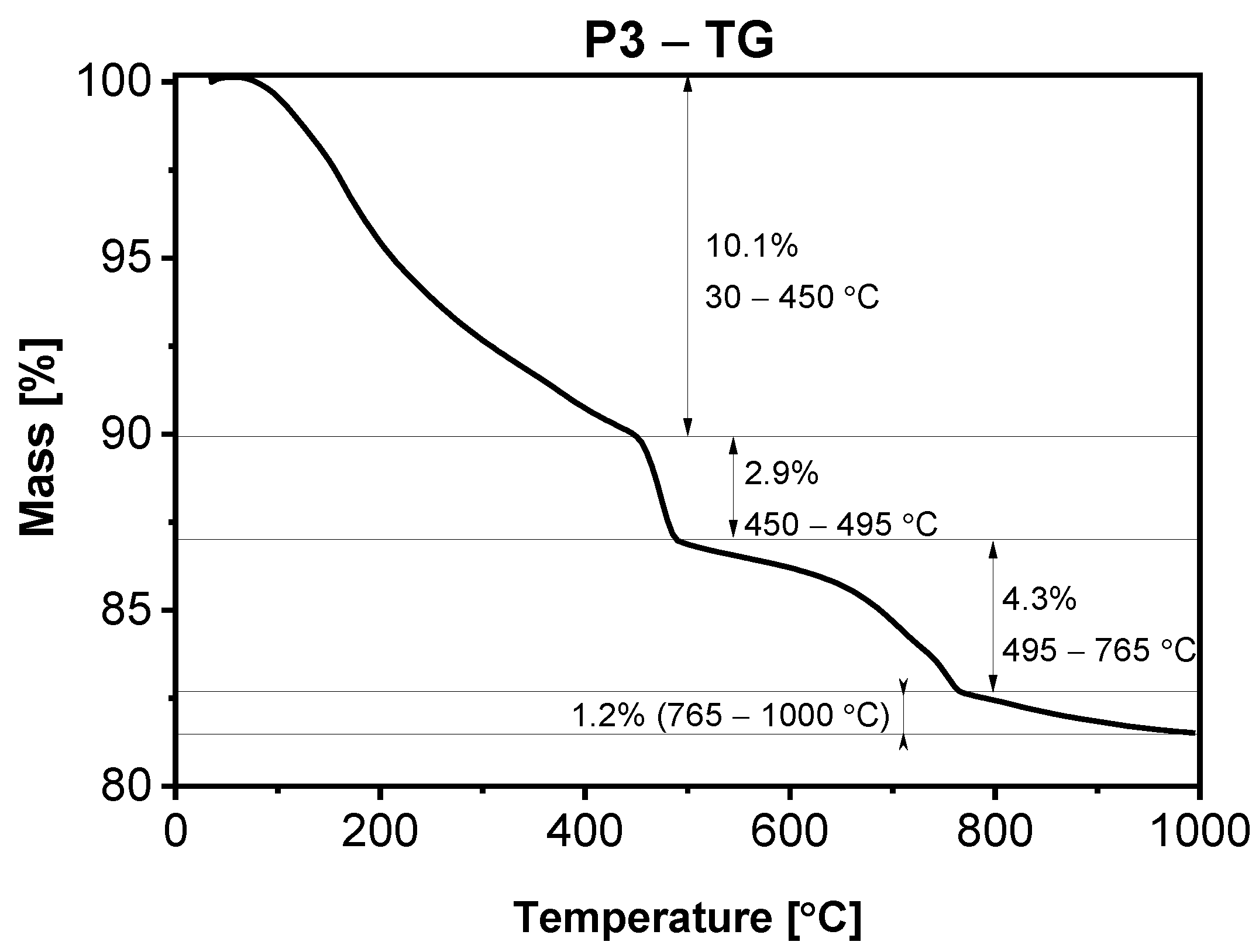

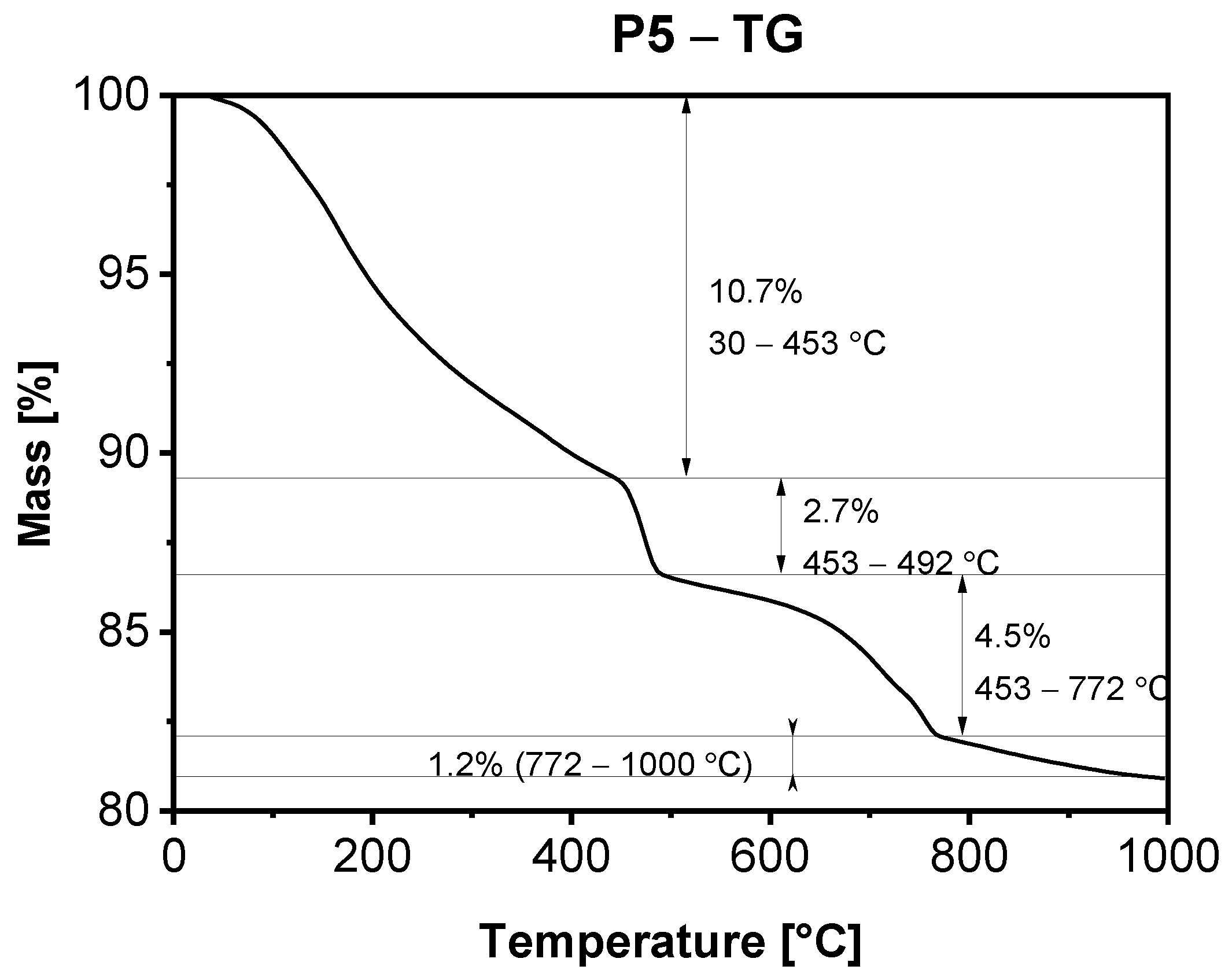

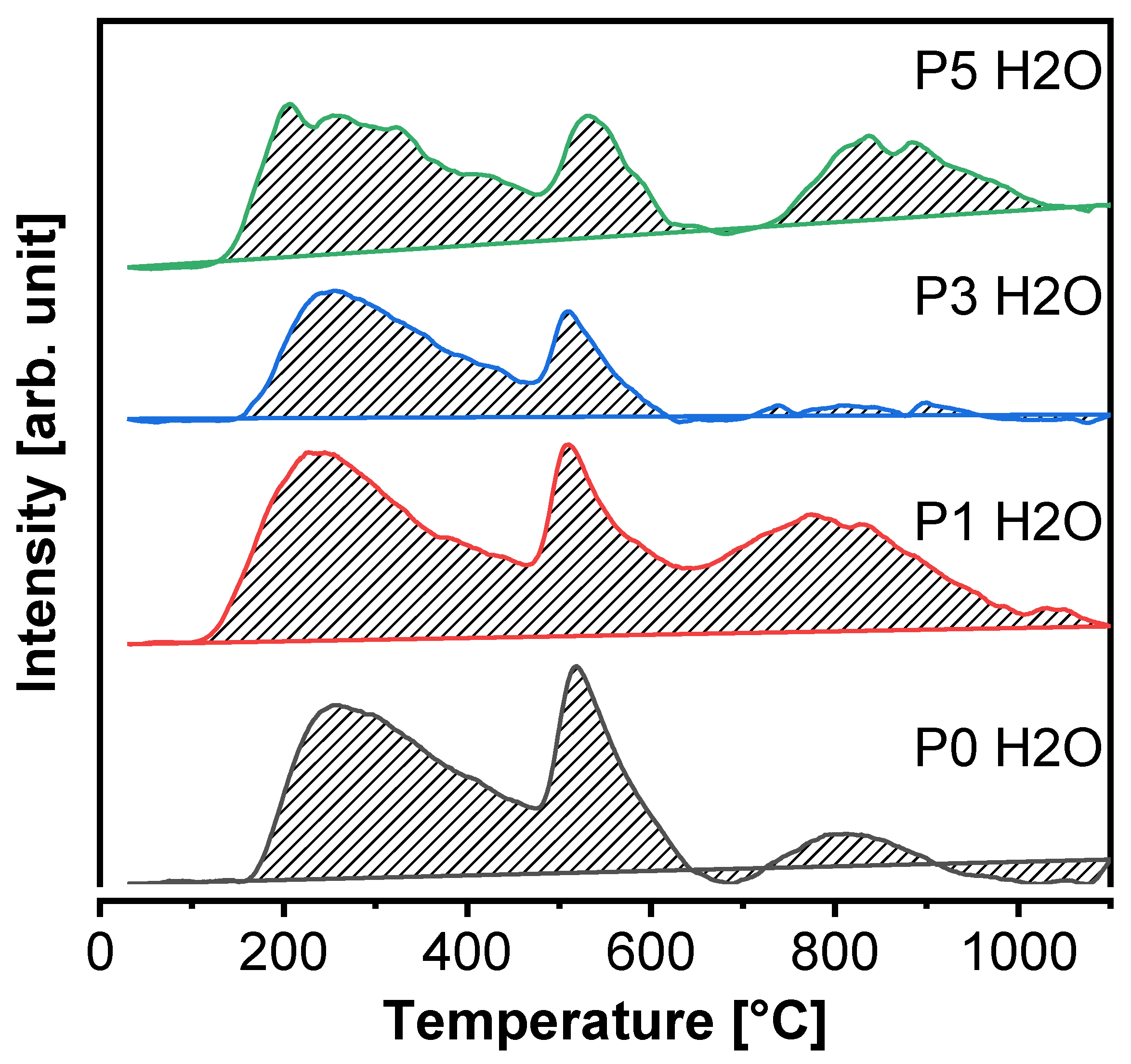

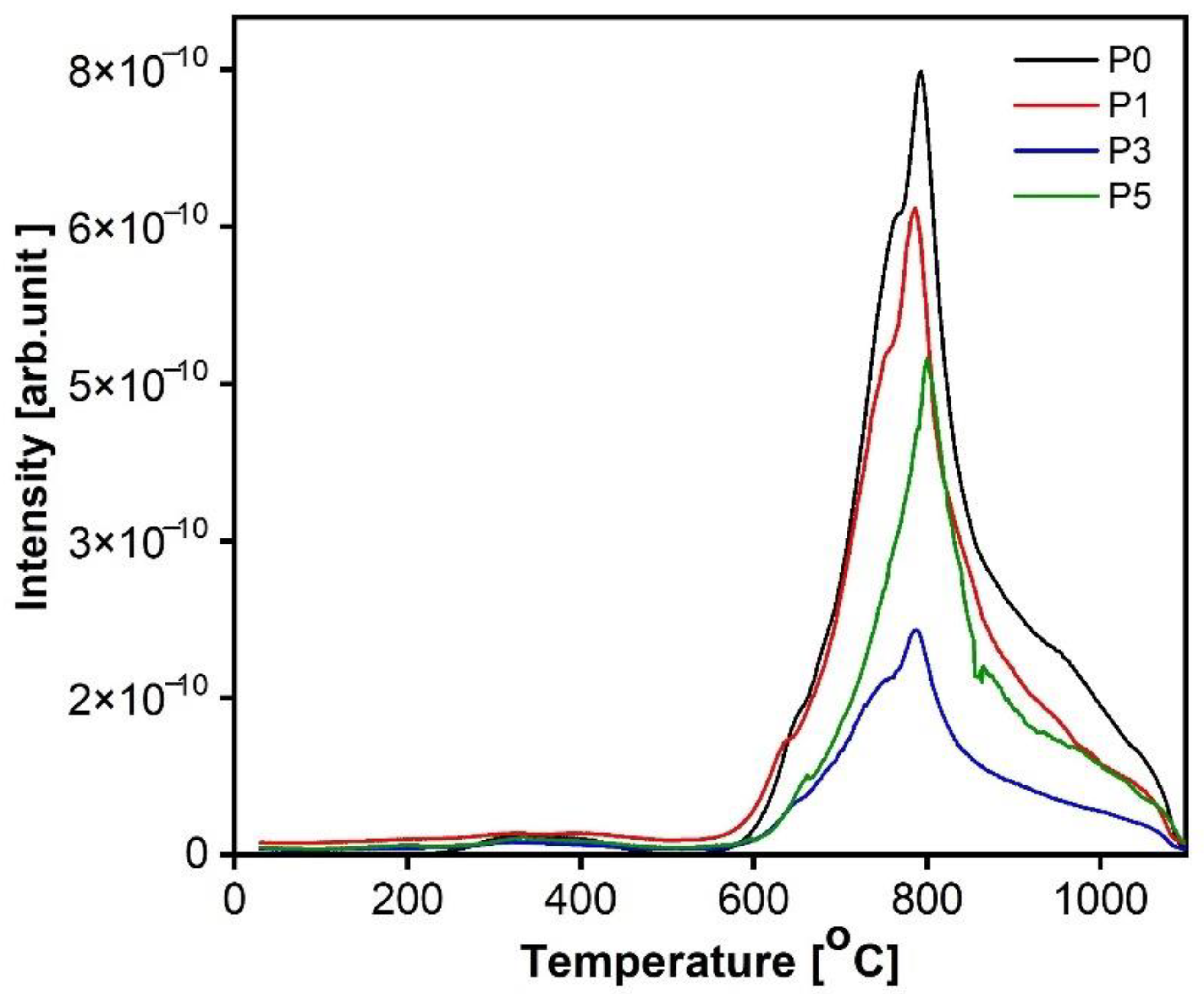

3.2. Thermogravimetric Analysis

3.3. Porosity Structure

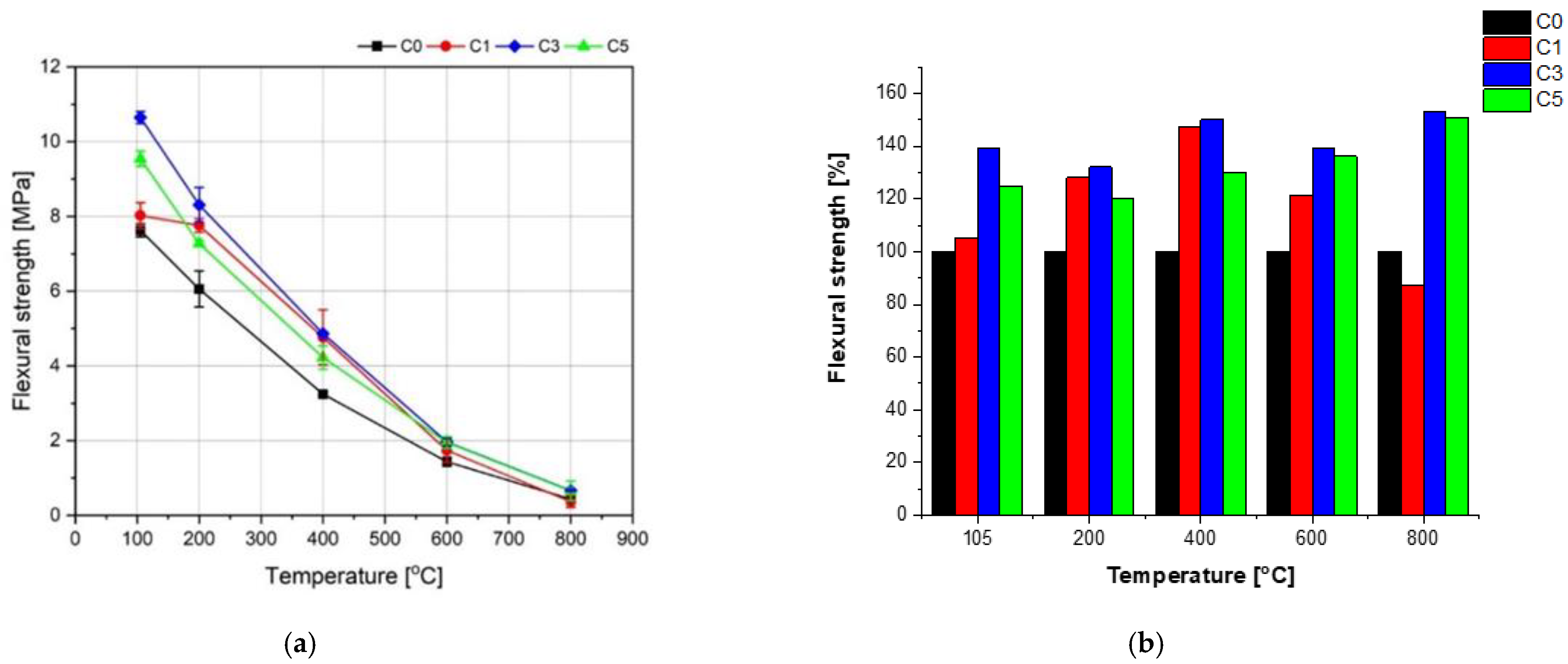

3.4. Flexural Strength of Concretes before and after Heating

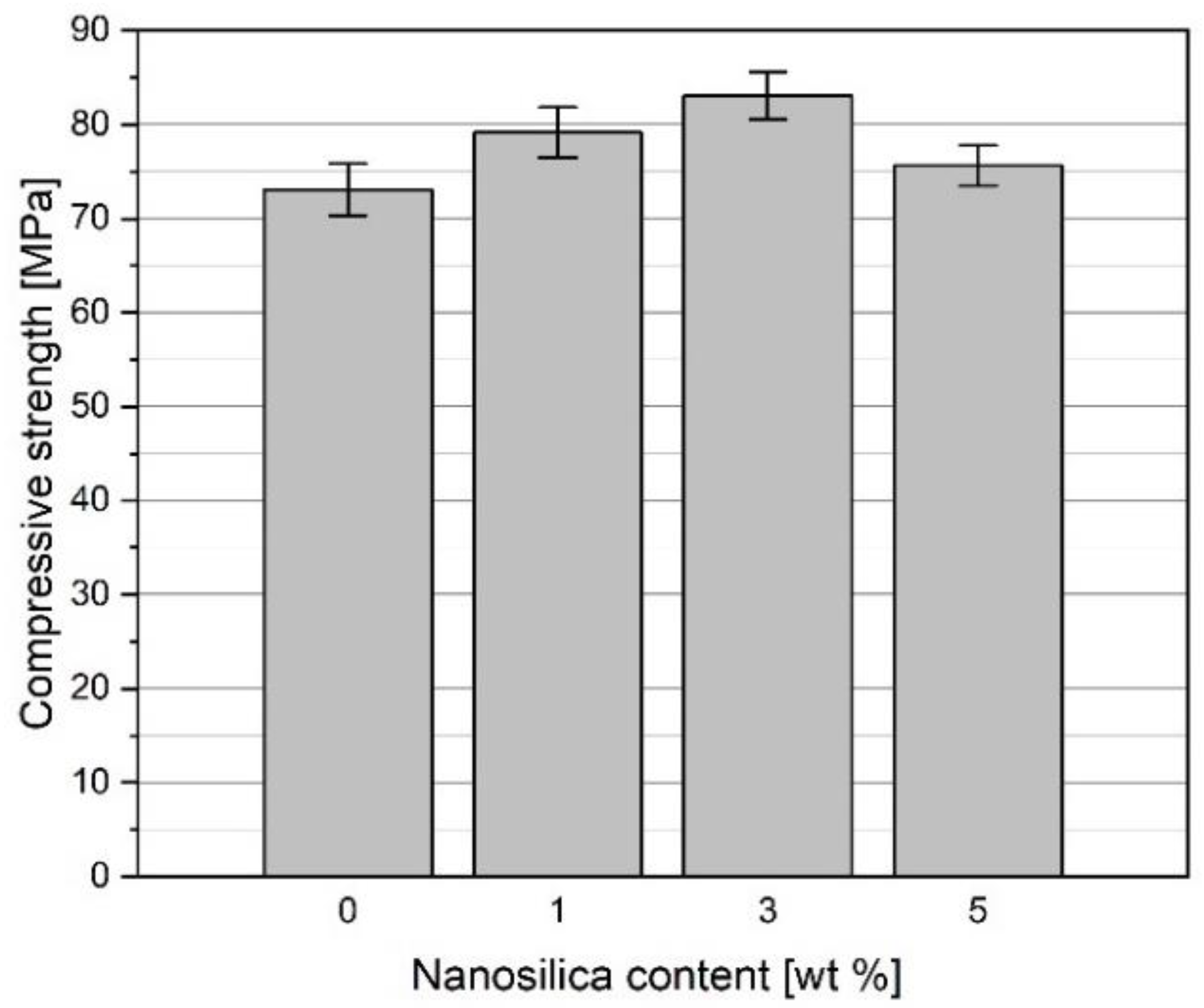

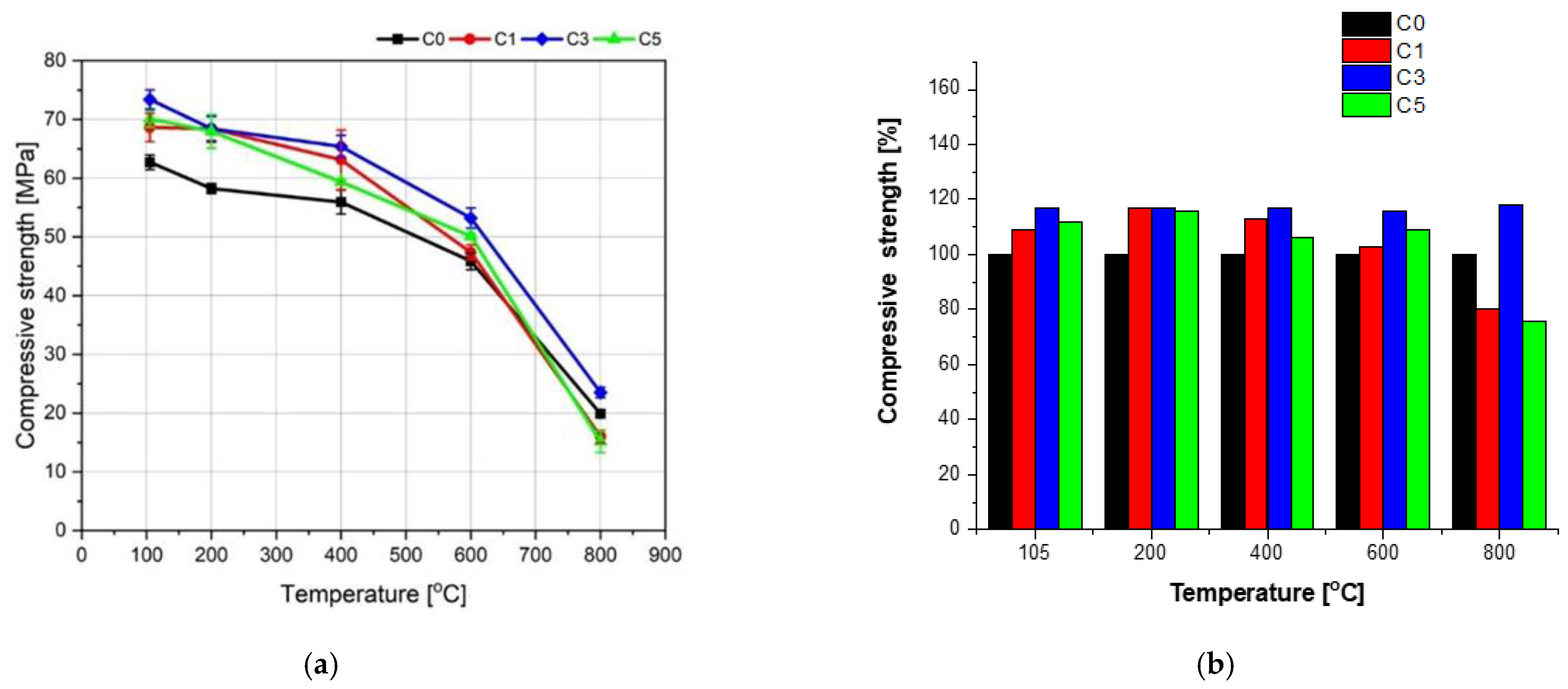

3.5. Compressive Strength of Concretes before and after Heating

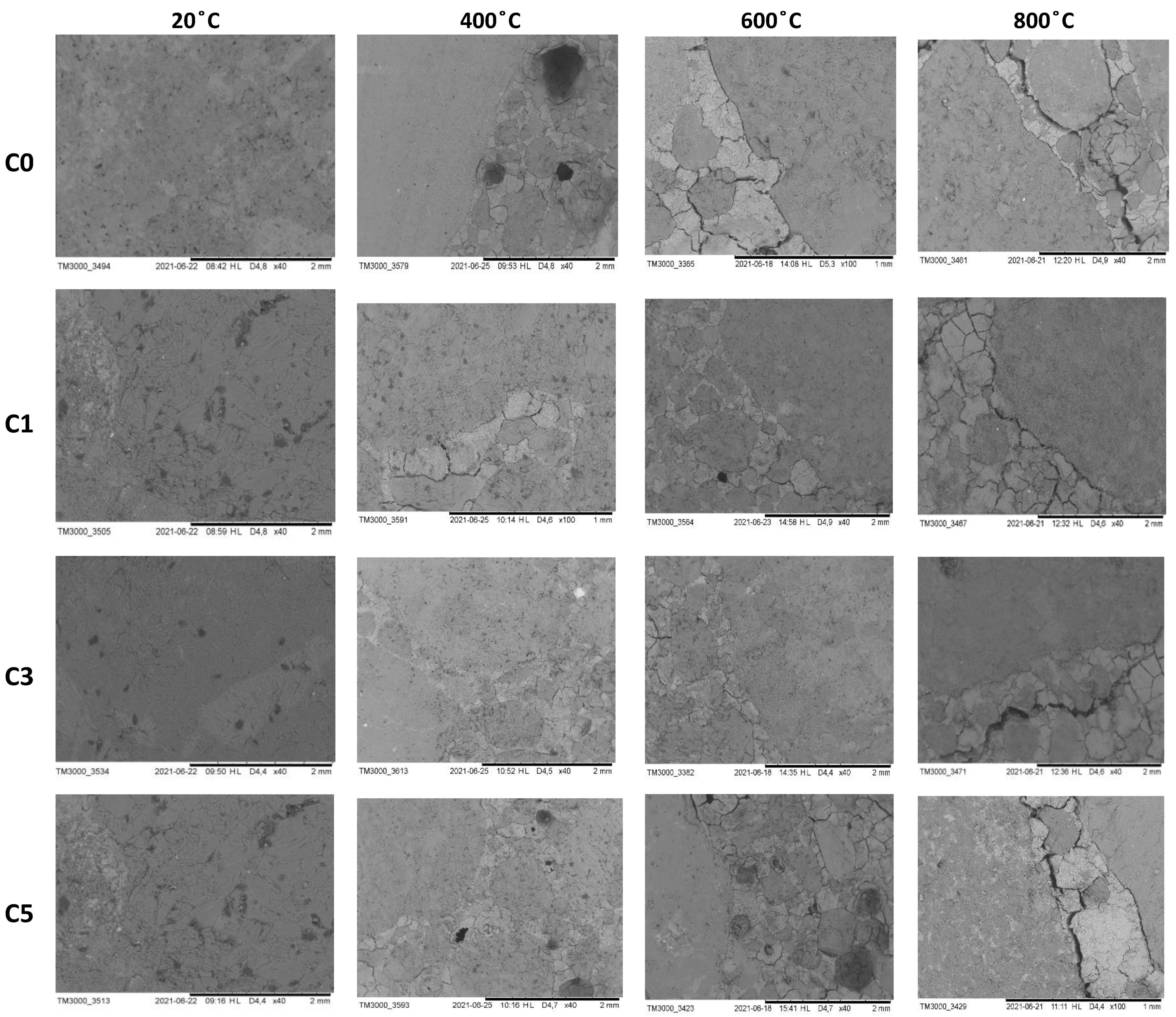

3.6. SEM Analysis of the Coarse Aggregate—Cement Matrix Contact Zone in the Concrete Specimens Containing NS after Heating

4. Conclusions

- The increase of the flexural strength of the concrete modified with NS compared to unmodified concrete at 20 °C is slight, and for the tested specimens was a maximum of 5.7%. The obtained results are hard to compare to those reported in the literature due to the various compositions of the concrete, including multiple sizes and contents of the applied NS. However, some influence of NS on the flexural strength of the cement concrete is demonstrated. For the concrete C5, a downfall of the flexural strength in reference to the concrete without NS was noted, mainly due to the increased total porosity of the concrete C5. A positive effect of NS admixture on the flexural strength of concrete has been observed within the considered temperature range.

- The favorable effect of NS on the compressive strength of concrete at 20 °C was observed. The highest increase of the strength, by 13.7%, was noted for the concrete C3. It is hard to compare the obtained results with the investigations reported by other authors. The literature data show that the growths of the concrete strength in the presence of NS are smaller than for the cement pastes or mortars. According to the authors’ opinion, the NS content in the concrete C3 was so close to the optimum that despite the increasing porosity, the amount of water was sufficient to wet the NS particles and react to cement’s components to create more C–S–H phase with the higher stiffness. The above explanation has been indirectly confirmed by TG and MS investigations on the cement pastes.

- The presence of NS in the concrete improved the compressive strength at a high temperature. The effect was less significant than the flexural strength; the increase averaged about 20% within the temperature range from 105 to 600 °C. What is essential, at 800 °C, a favorable effect of NS on maintaining the compressive strength was also observed (an increase by 18% in relation to the concrete C0 in the case of the concrete C3). It has been observed that in specimens C3 at 800 °C, the main crack occurred in the cement matrix and not on the coarse aggregate border. The above phenomenon could be the reason for the higher residual strength at this temperature, which, in turn, could be evidence of strengthening the coarse aggregate—cement matrix contact zone. ITZ is a crucial place in ordinary concrete from the point of view of durability at a high temperature. The described phenomenon seems to be very interesting and needs further investigation.

- The improvement of the mechanical performance of the concrete containing NS at a temperature up to 600 °C is caused by compaction of the structure and the creation of the C–S–H phase with high stiffness (resulting from the longer silicate chain C–S–H). This explanation was confirmed by TG and MS investigations. The above assumptions require further testing with the use, for instance, the nanoindentation technique or atomic force microscopy.

- In general, a positive influence of NS admixture on the concrete mechanical performance at a high temperature was demonstrated. It has been confirmed that there is an optimum content of NS enabling the creation of the best structure at the given concrete composition, which, in turn, allows the improved concrete resistance to high temperature. For the tested concrete compositions, the optimum content of NS was 3% of the cement mass.

- The method of dispersing NS in the mixing water appeared ineffective in the case of the concrete C5. The superplasticizer content was too low to evenly disperse the large amount of NS in the cement matrix, which led to the increased porosity and worse mechanical performance of the concrete.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kurdowski, W. Cement and Concrete Chemistry; Springer: London, UK, 2014. [Google Scholar]

- Phrompet, C.; Sriwong, C.; Ruttanapun, C. Mechanical, dielectric, thermal and antibacterial properties of reduced graphene oxide (rGO)-nanosized C3AH6 cement nanocomposites for smart cement-based materials. Compos. Part B Eng. 2019, 175, 107128. [Google Scholar] [CrossRef]

- Sikora, P.; Cendrowski, K.; Markowska-Szczupak, A.; Horszczaruk, E.; Mijowska, E. The effects of silica/titania nanocomposite on the mechanical and bactericidal properties of cement mortars. Constr. Build. Mater. 2017, 150, 738–746. [Google Scholar] [CrossRef]

- Faraldos, M.; Kropp, R.; Anderson, M.A.; Sobolev, K. Photocatalytic hydrophobic concrete coatings to combat air pollution. Catal. Today 2016, 259, 228–236. [Google Scholar] [CrossRef]

- Cardellicchio, L. On conservation issues of contemporary architecture: The technical design development and the ageing process of the Jubilee Church in Rome by Richard Meier. Front. Archit. Res. 2018, 7, 107–121. [Google Scholar] [CrossRef]

- Cardellicchio, L. Self-cleaning and colour-preserving efficiency of photocatalytic concrete: Case study of the Jubilee Church in Rome. Build. Res. Inf. 2019, 48, 1–20. [Google Scholar] [CrossRef]

- Li, Z.; Han, B.; Yu, X.; Zheng, Q.; Wang, Y. Comparison of the mechanical property and microstructures of cementitious composites with nano- and micro-rutile phase TiO2. Arch. Civ. Mech. Eng. 2019, 19, 615–662. [Google Scholar] [CrossRef]

- Zhao, L.; Guo, X.; Liu, Y.; Zhao, Y.; Chen, Z.; Zhang, Y.; Guo, L.; Shu, X.; Liu, J. Hydration kinetics, pore structure, 3D network calcium silicate hydrate, and mechanical behavior of graphene oxide reinforced cement composites. Constr. Build. Mater. 2018, 190, 150–163. [Google Scholar] [CrossRef]

- Pisello, A.L.; Alessandro, A.D.; Sambuco, S.; Rallini, M.; Ubertini, F.; Asdrubali, F.; Materazzi, A.L.; Cotana, F. Multipurpose experimental characterization of smart nanocomposite cement-based materials for thermal-energy efficiency and strain-sensing capability. Sol. Energy Mater. Sol. Cells 2017, 161, 77–88. [Google Scholar] [CrossRef]

- Abbas Mohajerani, A.; Burnett, L.; Smith, J.V.; Kurmus, H.; Milas, J.; Arulrajah, A.; Horpibulsuk, S.; Kadir, A.A. Nanoparticles in Construction Materials and Other Applications, and Implications of Nanoparticle Use. Materials 2019, 12, 3052. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Du, S.; Wu, J.; AlShareedah, O.; Shi, X. Nanotechnology in Cement-Based Materials: A Review of Durability, Modeling, and Advanced Characterization. Nanomaterials 2019, 9, 1213. [Google Scholar] [CrossRef] [Green Version]

- Bautista-Gutierrez, K.P.; Herrera-May, A.L.; Santamaría-López, J.M.; Honorato-Moreno, A.; Zamora-Castro, S.A. Recent Progress in Nanomaterials for Modern Concrete Infrastructure: Advantages and Challenges. Materials 2019, 12, 3548. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Flores-Vivian, I.; Pradoto, R.G.K.; Moini, M.; Kozhukhova, M.; Potapov, V.; Sobolev, K. The effect of SiO2 nanoparticles derived from hydrothermal solutions on the performance of portland cement based materials. Front. Struct. Civ. Eng. 2017, 11, 436–445. [Google Scholar] [CrossRef]

- Heidari, A.; Tavakoli, D. A study of the mechanical properties of ground ceramic powder concrete incorporating nano-SiO2 particles. Constr. Build. Mater. 2013, 38, 255–264. [Google Scholar] [CrossRef]

- Sivasankaran, U.; Raman, S.; Nallusamy, S. Experimental analysis of mechanical properties on concrete with nano silica additive. J. Nano Res. 2019, 57, 93–104. [Google Scholar] [CrossRef]

- de Abreu, G.B.; Marques-Costa, S.M.; Gumieri, A.G.; Fonseca-Calixto, J.M.; França, F.C.; Silva, C.; Delgado-Quinõnes, A. Mechanical properties and microstructure of high performance concrete containing stabilized nano-silica. Matéria 2017, 22, e11824. [Google Scholar]

- Nik, A.S.; Omran, O.L. Estimation of compressive strength of self-compacted concrete with fibers consisting nano-SiO2 using ultrasonic pulse velocity. Constr. Build. Mater. 2013, 44, 654–666. [Google Scholar]

- Zhang, P.; Li, Q.; Chen, Y.; Shi, Y.; Ling, Y.-F. Durability of steel fiber-reinforced concrete containing SiO2 Nano-Particles. Materials 2019, 12, 2184. [Google Scholar] [CrossRef] [Green Version]

- Mondal, P.; Shah, S.P.; Marks, L.D.; Gaitero, J.J. Comparative study of the effects of microsilica and nanosilica in concrete. Transp. Res. Record. 2010, 2141, 6–9. [Google Scholar] [CrossRef] [Green Version]

- Biricik, H.; Sarier, N. Comparative study of the characteristics of nano silica—Silica fume—and fly ash—incorporated cement mortars. Mater. Res. 2014, 17, 570–582. [Google Scholar] [CrossRef]

- Sikora, P. The microstructural and thermal characteristics of silica nanoparticle-modified cement mortars after exposure to high temperatures. Nanotechnol. Constr. 2020, 12, 108–115. [Google Scholar]

- Du, H.; Du, S.; Liu, X. Durability performances of concrete with nano-silica. Constr. Build. Mater. 2014, 73, 705–712. [Google Scholar] [CrossRef] [Green Version]

- Sun, J.; Shen, X.; Tan, G.; Tanner, J.E. Modification effects of nano-SiO2 on early compressive strength and hydration characteristics of high-volume fly ash concrete. J. Mater. Civ. Eng. 2019, 31, 04019057. [Google Scholar] [CrossRef]

- Said, A.; Zeidan, M.S.; Bassuoni, M.; Tian, Y. Properties of concrete incorporating nano-silica. Constr. Build. Mater. 2012, 36, 838–844. [Google Scholar] [CrossRef]

- Varghese, L.; Raa, V.V.L.K.; Parameswaran, L. Nanosilica-added concrete: Strength and its correlation with time-dependent properties. Proc. Inst. Civ. Eng. Constr. Mater. 2019, 172, 85–94. [Google Scholar] [CrossRef]

- Quercia, G.; Spiesz, P.; Hüsken, G.; Brouwers, H.; Jos, J. SCC modification by use of amorphous nano-silica. Cem. Concr. Compos. 2014, 45, 69–81. [Google Scholar] [CrossRef] [Green Version]

- De Schutter, G. Evaluation of water absorption of concrete as a measure for resistance against carbonation and chloride migration. Mater. Struct. 2004, 37, 591–596. [Google Scholar] [CrossRef]

- Horszczaruk, E.; Łukowski, P.; Seul, C. Influence of Dispersing Method on the Quality of Nano-Admixtures Homogenization in Cement Matrix. Materials 2020, 13, 4865. [Google Scholar] [CrossRef]

- Mahapatra, C.K.; Barai, S.V. Temperature impact on residual properties of self-compacting based hybrid fiber reinforced concrete with fly ash and colloidal nano silica. Constr. Build. Mater. 2019, 198, 120–132. [Google Scholar] [CrossRef]

- Shahrajabian, F.; Behfarnia, K. The effects of nano particles on freeze and thaw resistance of alkali-activated slag concrete. Constr. Build. Mater. 2018, 176, 172–178. [Google Scholar] [CrossRef]

- El-Gamal, S.M.A.; Abo-El-Enein, S.a.; El-Hosiny, F.I.; Amin, M.S.; Ramadan, M. Thermal resistance, microstructure and mechanical properties of type I Portland cement pastes containing low-cost nanoparticles. J. Therm. Anal. Calorim. 2018, 131, 949–968. [Google Scholar] [CrossRef]

- Heikal, M.; Ismail, M.N.; Ibrahim, N.S. Physico-mechanical, microstructure char-acteristics andfire resistance of cement pastes containing Al2O3 nano-particles. Constr. Build. Mater. 2015, 91, 232–242. [Google Scholar] [CrossRef]

- Irshidat, M.H.; Al-Saleh, M.H. Thermal performance andfire resistance of nanoclaymodified cementitious materials. Construct. Build. Mater. 2018, 159, 213–219. [Google Scholar] [CrossRef]

- Horszczaruk, E.; Sikora, P.; Cendrowski, K.; Mijowska, E. The effect of elevated temperature on the properties of cement mortars containing nanosilica and heavyweight aggregates. Constr. Build. Mater. 2017, 137, 420–431. [Google Scholar] [CrossRef]

- Sikora, P.; Elrahman, M.A.; Chung, S.-Y.; Cendrowski, K.; Mijowska, E.; Stephan, D. Mechanical and microstructural properties of cement pastes containing carbon nanotubes and carbon nanotube-silica core-shell structures, exposed to elevated temperature. Cem. Concr. Compos. 2019, 95, 193–204. [Google Scholar] [CrossRef]

- Shah, S.P.; Hou, P.; Konsta-Gdoutos, M.S. Nano-modification of cementitious material: Toward a stronger and durable concrete. J. Sustain. Cem.-Based Mater. 2015, 5, 1–22. [Google Scholar] [CrossRef]

- Silvestre, J.; Silvestre, N.; de Brito, J. Review on concrete nanotechnology. Eur. J. Environ. Civ. Eng. 2015, 20, 455–485. [Google Scholar] [CrossRef]

- Cendrowski, K.; Sikora, P.; Zielinska, B.; Horszczaruk, E.; Mijowska, E. Chemical and thermal stability of core-shelled magnetite nanoparticles and solid silica. Appl. Surf. Sci. 2017, 407, 391–397. [Google Scholar] [CrossRef]

- Horszczaruk, E.; Jedrzejewski, R.; Baranowska, J.; Mijowska, E. Application of the Nanoindentation Method in Assessing of Properties of Cement Composites Modified with Silica-Magnetite Nanostructures. In Proceedings of the MATBUD’2018—8th Scientific-Technical Conference on Material Problems in Civil Engineering, Cracow, Poland, 25–27 June 2018; Volume 163, p. 02002. Available online: https://doi.org/10.1051/matecconf/201816302002 (accessed on 15 June 2018).

- Sikora, P.; Cendrowski, K.; Horszczaruk, E.; Mijowska, E. The effects of Fe3O4 and Fe3O4/SiO2 nanoparticles on the mechanical properties of cement mortars exposed to elevated temperatures. Constr. Build. Mater. 2018, 182, 441–450. [Google Scholar] [CrossRef]

- Arioz, O. Effects of elevated temperatures on properties of concrete. Fire Saf. J. 2007, 42, 516–522. [Google Scholar] [CrossRef]

- Lee, J.; Xi, Y.; Willam, K.; Jung, Y. A multiscale model for modulus of elasticity of concrete at high temperatures. Cem. Concr. Res. 2009, 39, 754–762. [Google Scholar] [CrossRef]

- Ozawa, M.; Morimoto, H. Effects of various fibres on high-temperature spalling in high-performance concrete. Constr. Build. Mater. 2014, 71, 83–92. [Google Scholar] [CrossRef]

- Yuan, G.; Li, Q. The use of surface coating in enhancing the mechanical properties and durability of concrete exposed to elevated temperature. Constr. Build. Mater. 2015, 95, 375–383. [Google Scholar] [CrossRef]

- Hager, I.; Mróz, K.; Tracz, T.; Hager, I.; Tracz, T. Concrete propensity to fire spalling: Testing and observations. MATEC Web Conf. 2018, 163, 02004. [Google Scholar] [CrossRef]

- Mixing Water for Concrete—Specification for Sampling, Testing and Assessing the Suitability of Water, Including Water Recovered from Processes in the Concrete Industry, As Mixing Water for Concrete; EN 1008; European Committee for Standarization: Brussels, Belgium, 2002.

- Testing Hardened Concrete—Part 5: Flexural Strength of Test Specimens; EN 12390-5; European Committee for Standarization: Brussels, Belgium, 2019.

- Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens; EN 12390-3; European Committee for Standarization: Brussels, Belgium, 2019.

- Oltulu, M.; Sahin, R. Pore structure analysis of hardened cement mortars containing silica fume and different nano-powders. Constr. Build. Mater. 2014, 53, 658–664. [Google Scholar] [CrossRef]

- Federowicz, K.; Figueiredo, V.A.; Al-kroom, H.; Abdel-Gawwad, H.A.; Elrahman, M.A.; Sikora, P. The Effects of Temperature Curing on the Strength Development, Transport Properties, and Freeze-Thaw Resistance of Blast Furnace Slag Cement Mortars Modified with Nanosilica. Materials 2020, 13, 5800. [Google Scholar] [CrossRef]

- Jalal, M.; Pouladkhan, A.; Harandi, O.F.; Jafari, D. Comparative study on effects of Class F fly ash, nano silica and silica fume on properties of high performance self compacting concrete. Constr. Build. Mater. 2015, 94, 90–104. [Google Scholar] [CrossRef]

- Hasan-Nattaj, F.; Nematzadeh, M. The effect of forta-ferro and steel fibers on mechanical properties of high-strength concrete with and without silica fume and nano-silica. Constr. Build. Mater. 2017, 137, 557–572. [Google Scholar] [CrossRef]

- Chithra, S.; Kumar, S.R.R.S.; Chinnaraju, K. The effect of Colloidal Nanosilica on workability, mechanical and durability properties of high Performance Concrete with Copper slag as partial fine aggregate. Constr. Build. Mater. 2016, 113, 794–804. [Google Scholar] [CrossRef]

- Behzadian, R.; Shahrajabian, H. Experimental Study of the Effect of Nano-silica on the Mechanical Properties of Concrete/PET Composites. KSCE J. Civ. Eng. 2019, 23, 3660–3668. [Google Scholar] [CrossRef]

- Mukharjee, S.; Barai, S.V. Influence of nano-silica on the properties of recycled aggregate concrete. Constr. Build. Mater. 2014, 55, 29–37. [Google Scholar] [CrossRef]

- Abhilash, P.P.; Nayak, K.; Sangoju, B.; Kumar, R.; Kumar, V. Effect of nano-silica in concrete; a review. Constr. Build. Mater. 2021, 278, 1–19. [Google Scholar]

- Sikora, P.; Elrahman, M.A.; Stephan, D. The Influence of Nanomaterials on the Thermal Resistance of Cement-Based Composites—A Review. Nanomaterials 2018, 8, 465. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| CaO | SiO2 | Fe2O3 | SO3 | Al2O3 | MgO | K2O | Cl− | Na2O |

|---|---|---|---|---|---|---|---|---|

| 63.77 | 21.07 | 4.12 | 3.2 | 3.11 | 0.58 | 0.37 | 0.071 | 0.05 |

| Aggregate | Sieve [mm]/Remains on the Sieve [%] | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 | 0.125 | 0.25 | 0.5 | 1 | 2 | 4 | 8 | 16 | |

| Sand | 5.7 | 0.3 | 37.7 | 46.5 | 6.7 | 2.6 | 0.5 | 0 | 0 |

| Gravel | 0.3 | 0.9 | 0.9 | 1.9 | 3.2 | 35.1 | 55.4 | 2.3 | 0 |

| Designation | Cement (C) | Water | Nanosilica (NS) | Superplasticizer (SP) |

|---|---|---|---|---|

| P0 | 1.0 | 0.5 | 0.0 | 0.006 |

| P1 | 1.0 | 0.5 | 0.01 | 0.010 |

| P3 | 1.0 | 0.5 | 0.03 | 0.018 |

| P5 | 1.0 | 0.5 | 0.05 | 0.026 |

| Designation | Sand 0–2 mm | Gravel 2–8 mm | Cement | Water | NS | NS/C | SP | SP/C |

|---|---|---|---|---|---|---|---|---|

| C0 | 950 | 950 | 340 | 150 | 0.00 | 0.0% | 2.04 | 0.6% |

| C1 | 950 | 950 | 340 | 147 | 6.8 | 1.0% | 3.40 | 1.0% |

| C3 | 950 | 950 | 340 | 140 | 20.4 | 3.0% | 6.12 | 1.8% |

| C5 | 950 | 950 | 340 | 133 | 34.0 | 5.0% | 8.84 | 2.6% |

| Specimen Type | C0 | C1 | C3 | C5 |

|---|---|---|---|---|

| Total surface area [m2/g] | 3.120 | 3.369 | 3.601 | 5.310 |

| Pore tortuosity [–] | 2.077 | 2.149 | 2.108 | 1.957 |

| Permeability [nm2] | 0.003 | 0.001 | 0.002 | 0.003 |

| Total porosity [%] | 14.152 | 11.112 | 13.819 | 17.241 |

| Average pore volume [cm3/g] | 0.054 | 0.040 | 0.050 | 0.068 |

| Average specific surface area of pores [m2/g] | 0.612 | 0.866 | 1.003 | 1.060 |

| Median pore volume [cm3/g] | 0.034 | 0.024 | 0.032 | 0.041 |

| Median specific surface area [m2/g] | 1.560 | 1.685 | 1.801 | 2.655 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brzozowski, P.; Strzałkowski, J.; Rychtowski, P.; Wróbel, R.; Tryba, B.; Horszczaruk, E. Effect of Nano-SiO2 on the Microstructure and Mechanical Properties of Concrete under High Temperature Conditions. Materials 2022, 15, 166. https://doi.org/10.3390/ma15010166

Brzozowski P, Strzałkowski J, Rychtowski P, Wróbel R, Tryba B, Horszczaruk E. Effect of Nano-SiO2 on the Microstructure and Mechanical Properties of Concrete under High Temperature Conditions. Materials. 2022; 15(1):166. https://doi.org/10.3390/ma15010166

Chicago/Turabian StyleBrzozowski, Piotr, Jarosław Strzałkowski, Piotr Rychtowski, Rafał Wróbel, Beata Tryba, and Elżbieta Horszczaruk. 2022. "Effect of Nano-SiO2 on the Microstructure and Mechanical Properties of Concrete under High Temperature Conditions" Materials 15, no. 1: 166. https://doi.org/10.3390/ma15010166

APA StyleBrzozowski, P., Strzałkowski, J., Rychtowski, P., Wróbel, R., Tryba, B., & Horszczaruk, E. (2022). Effect of Nano-SiO2 on the Microstructure and Mechanical Properties of Concrete under High Temperature Conditions. Materials, 15(1), 166. https://doi.org/10.3390/ma15010166