Confinement Effect and Efficiency of Concentrically Loaded RACFCST Stub Columns

Abstract

:1. Introduction

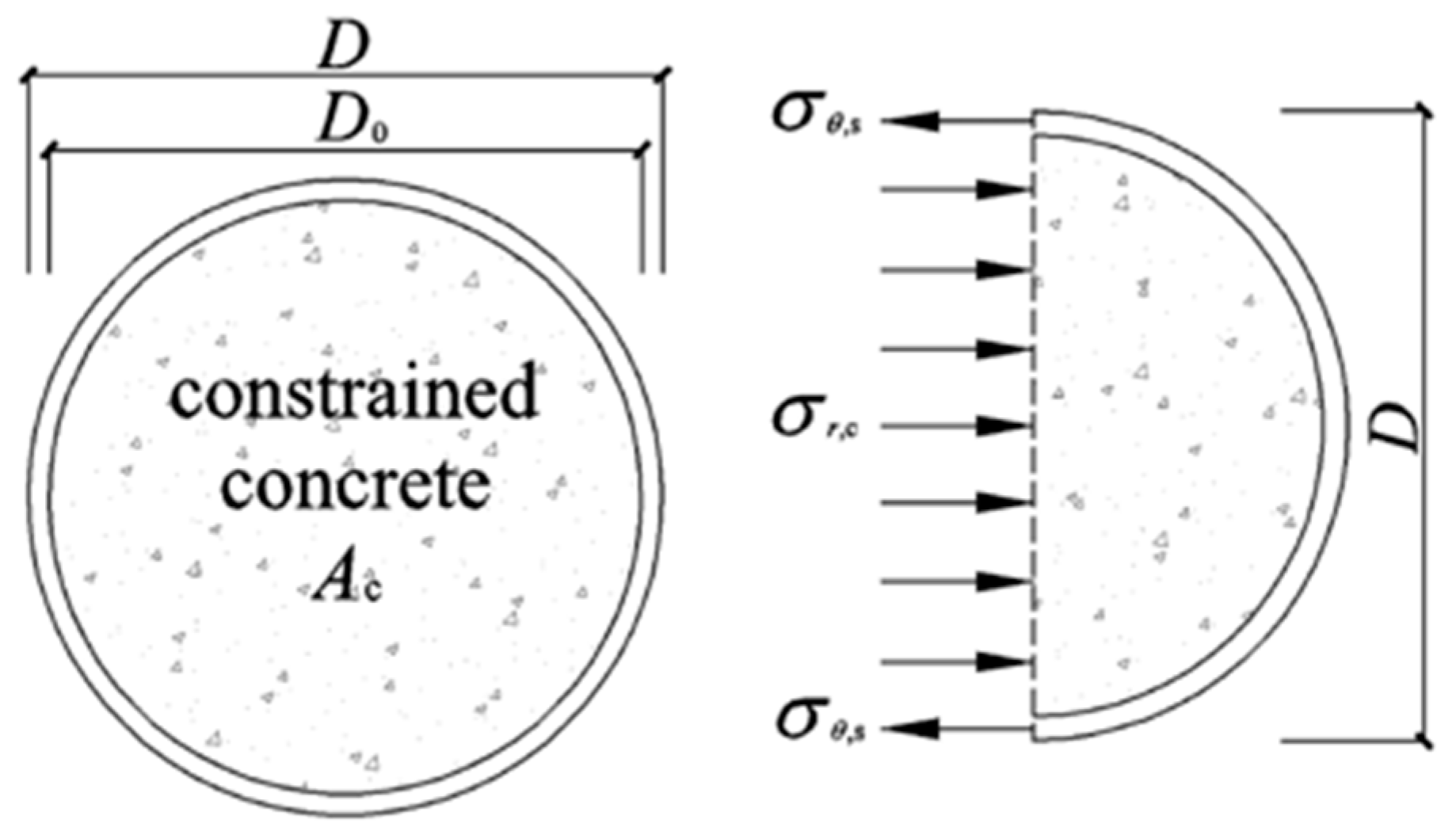

2. Finite Element Modeling of RACFCST Stub Columns

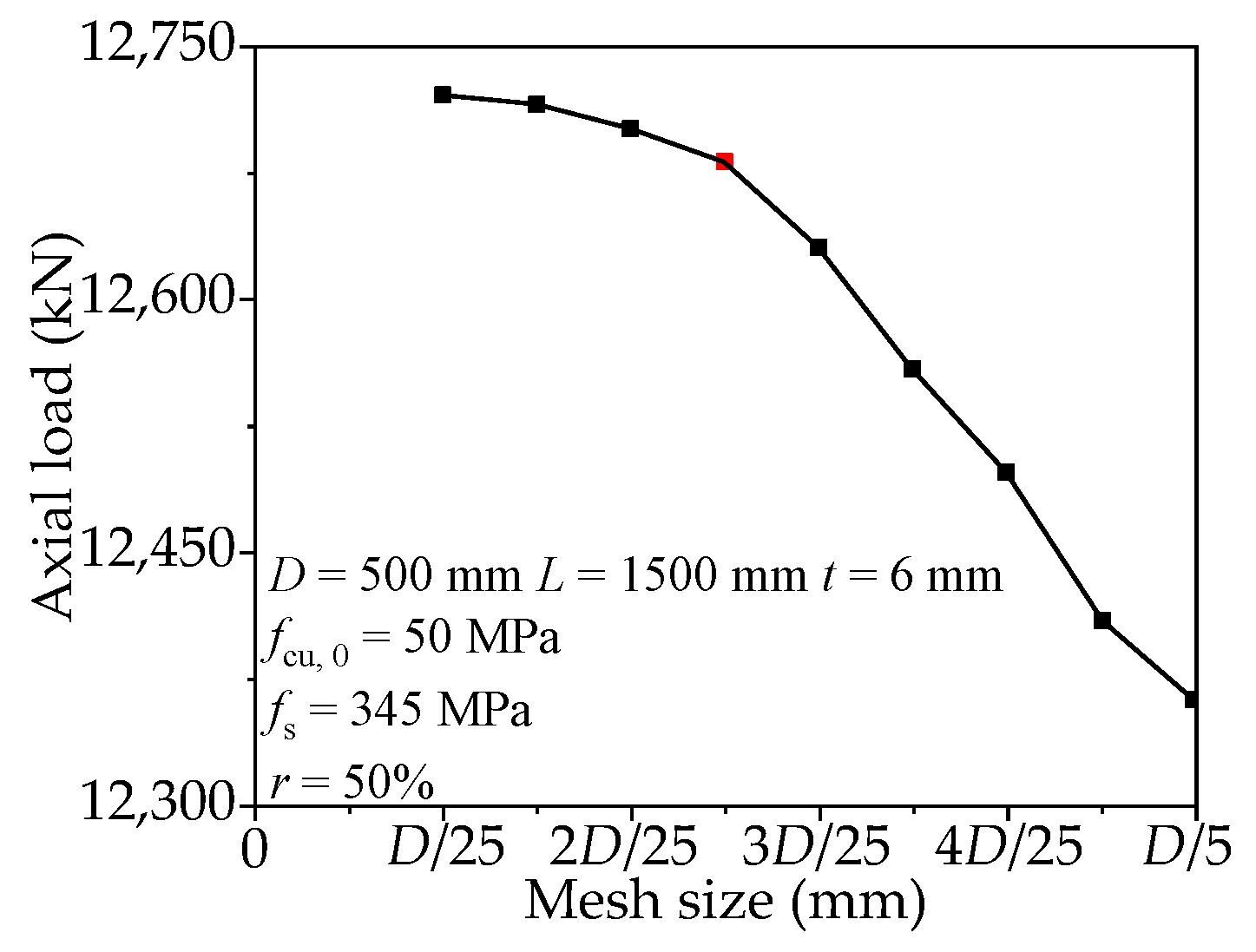

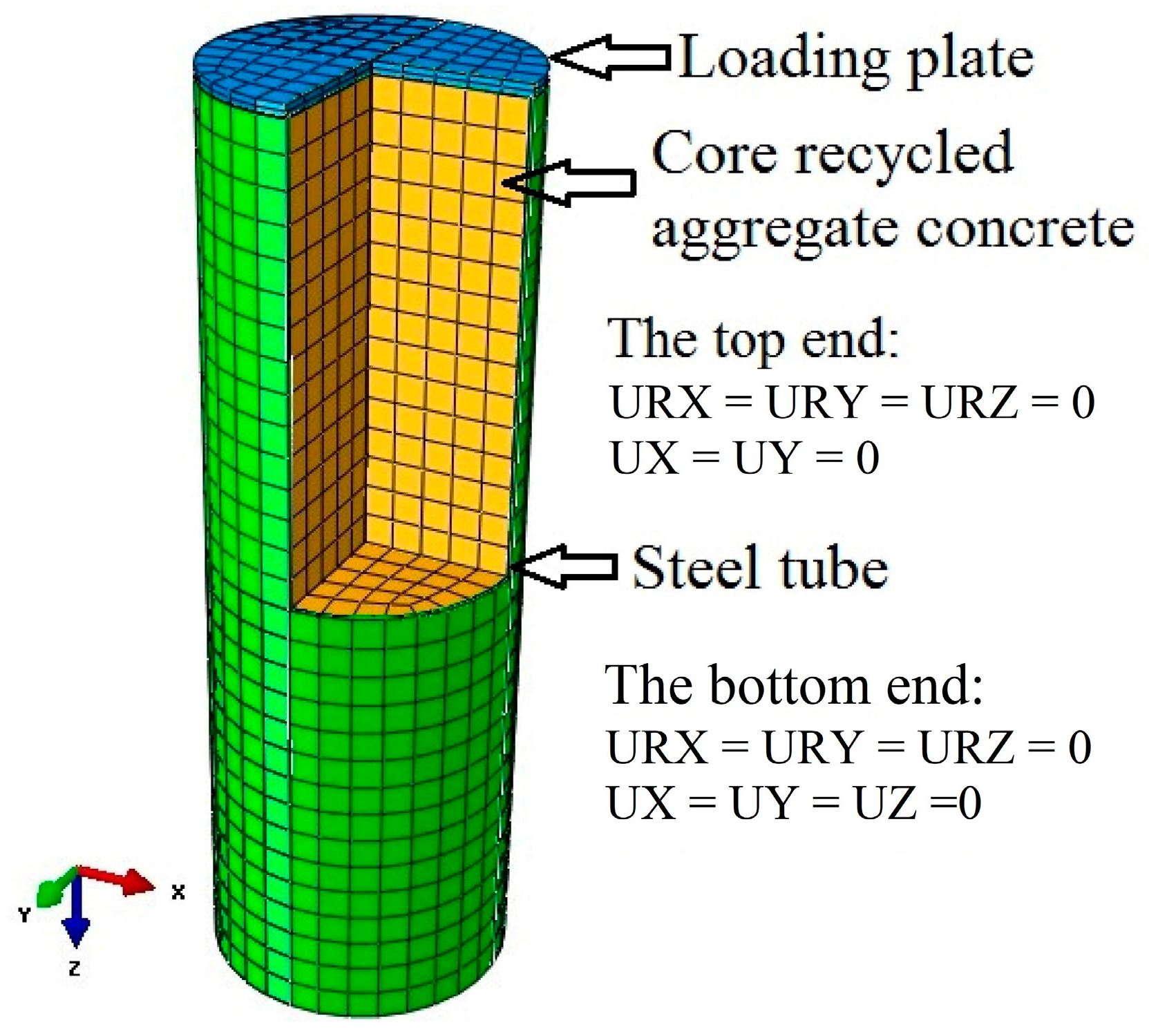

2.1. Modeling Method

2.2. Constitutive Relation of Infilled Recycled Aggregate Concrete

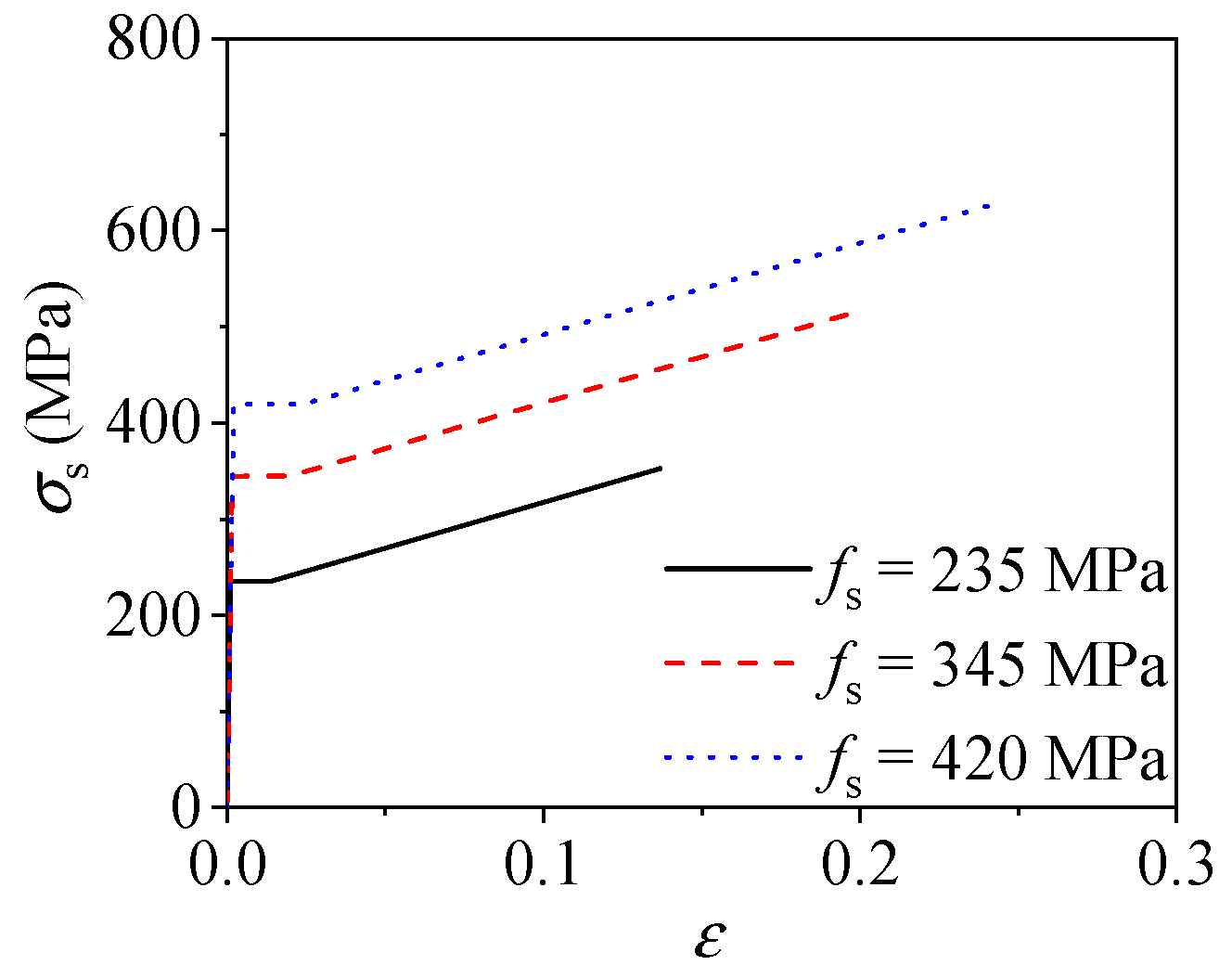

2.3. Constitutive Relation of Steel Tube

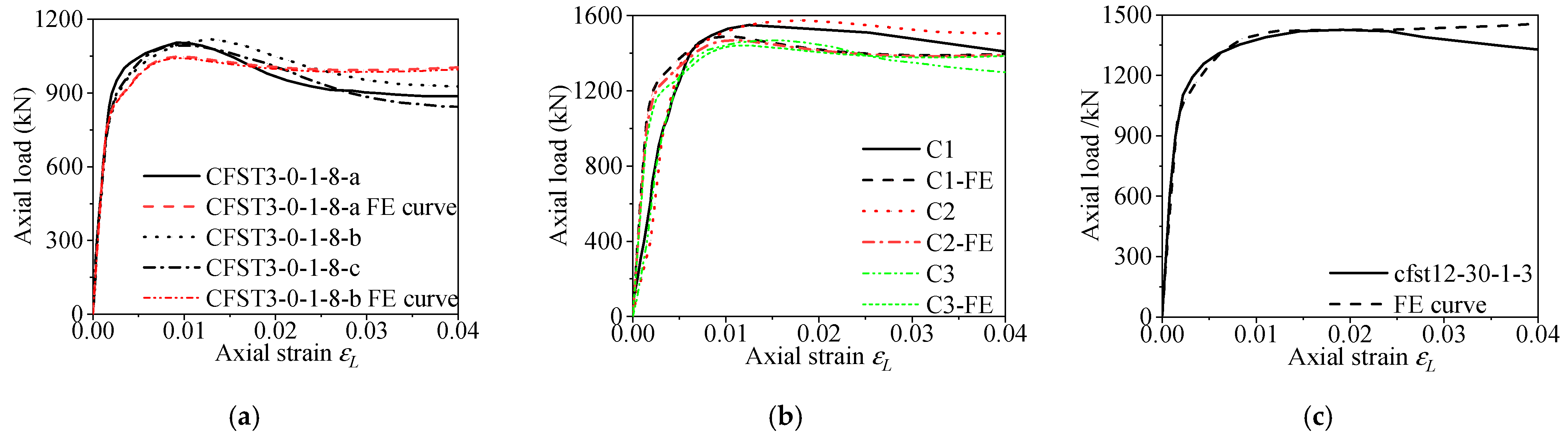

2.4. Model Validation

3. Investigation of Confinement Effect and Efficiency of RACFCST Stub Columns under Axial Loading

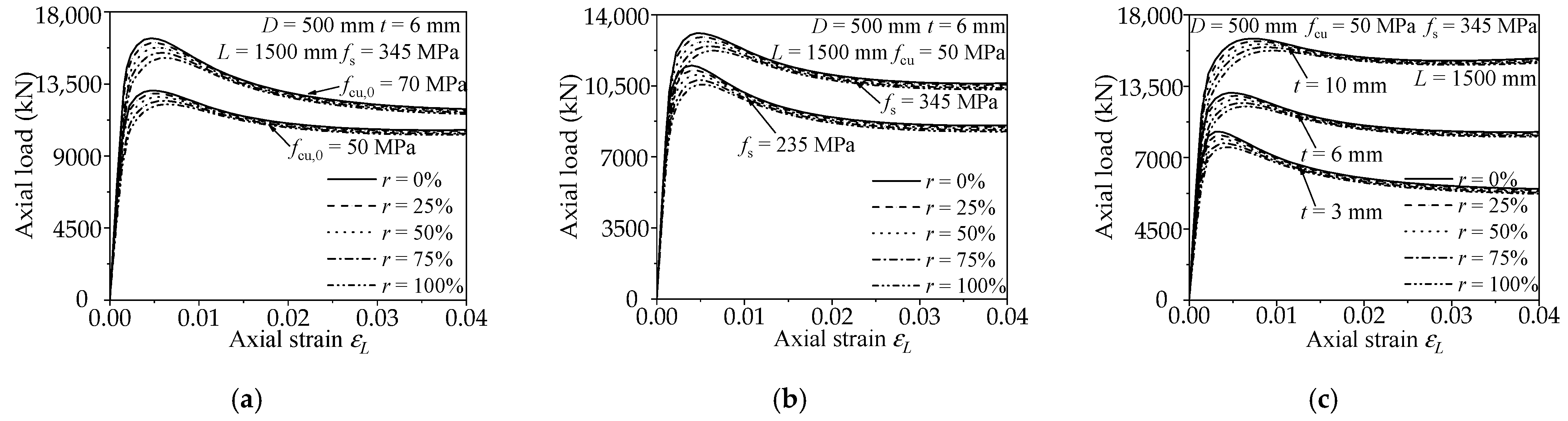

3.1. Parametric Analysis

3.2. Evaluation Criterion of the Confinement Effect and Efficiency

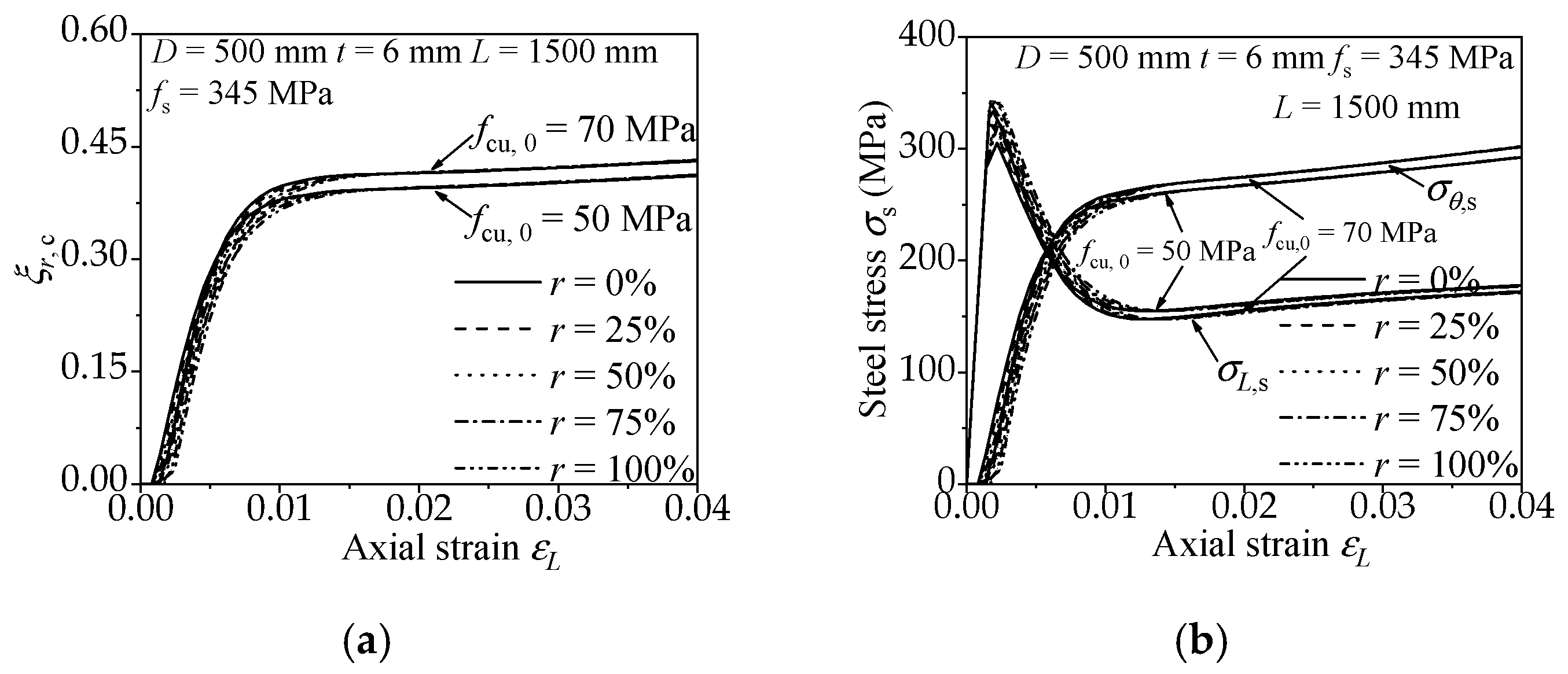

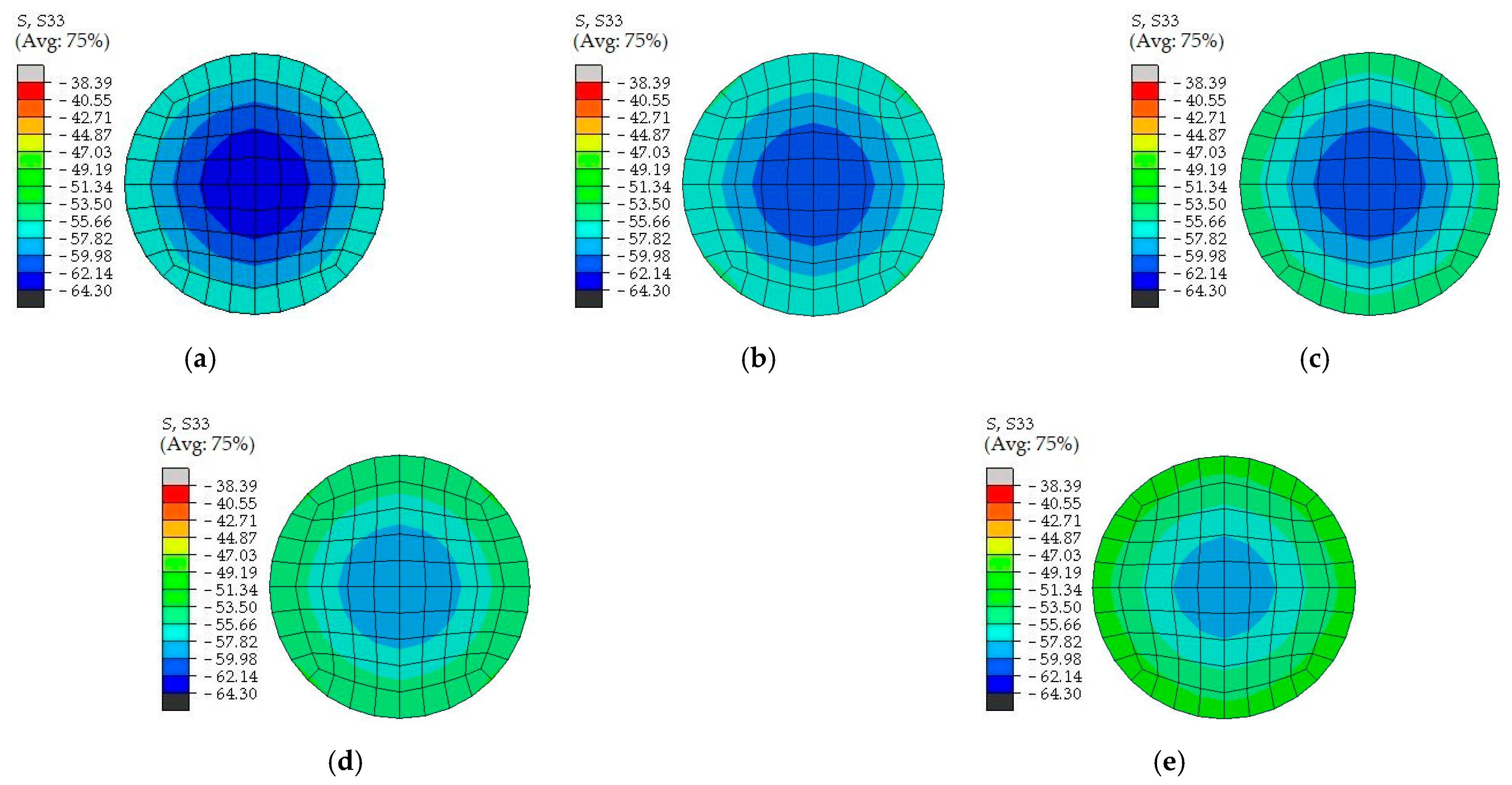

3.2.1. Concrete Strength

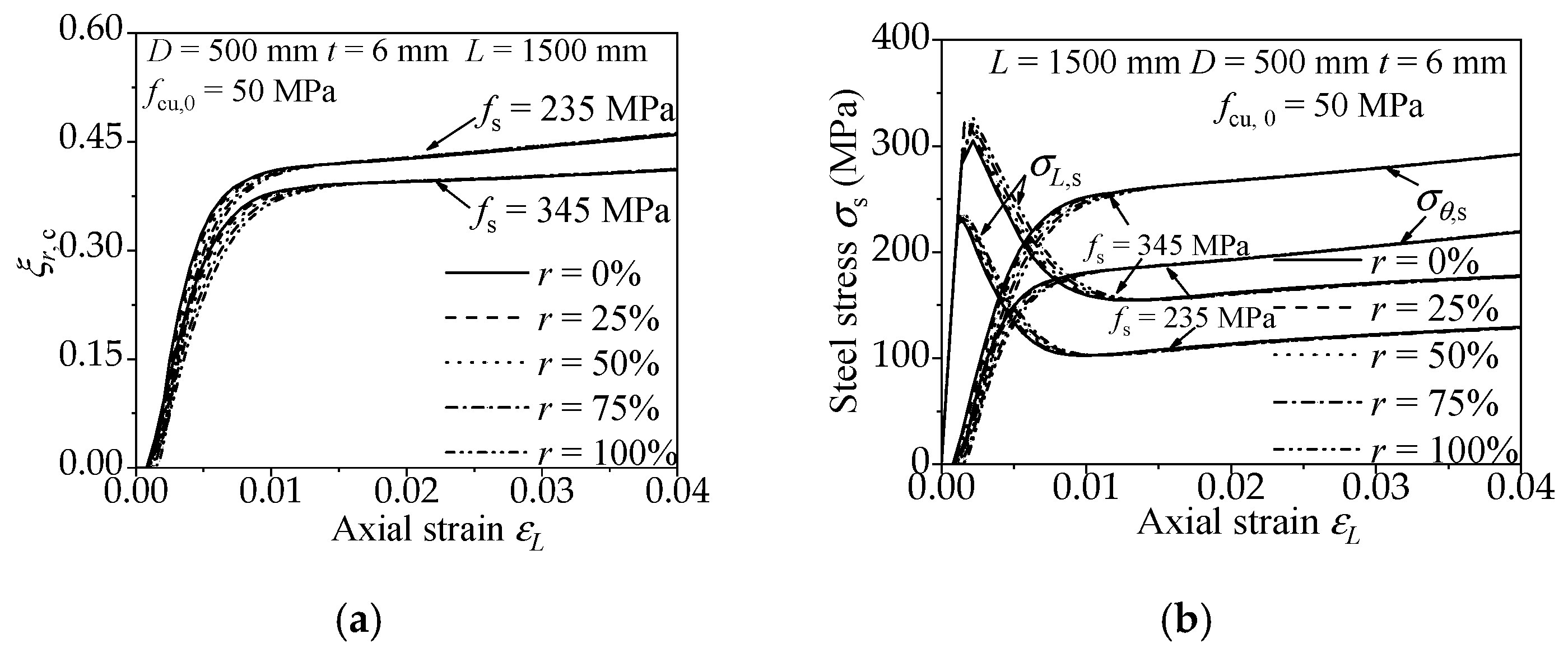

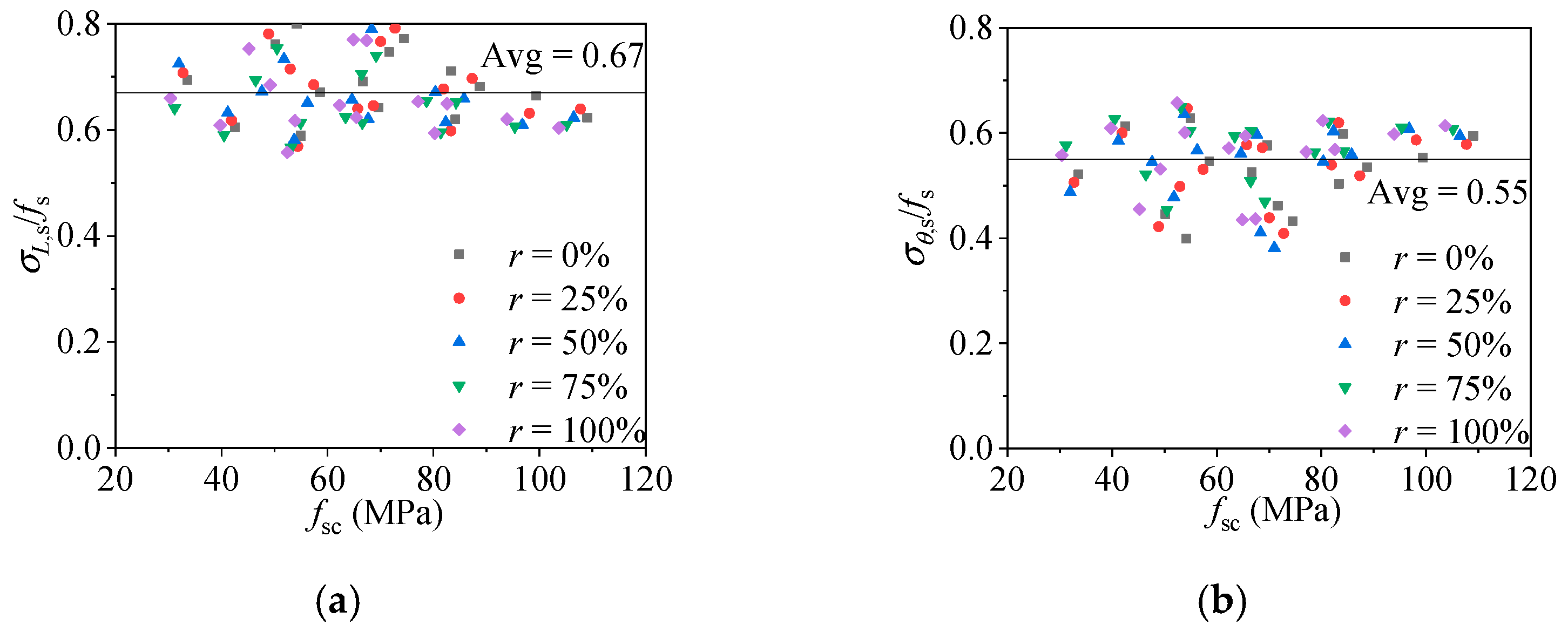

3.2.2. Steel Strength

3.2.3. Steel Ratio

3.2.4. The Replacement Ratio of Recycled Aggregate

- (1)

- The increase of replacement ratio of recycled aggregate r results in the radial concrete confinement coefficient ξr,c of RACFCST stub columns being smaller at the initial phase of the loading process. However, at the end of loading, ξr,c with different r tends to be the same.

- (2)

- The axial stress decreased after reaching the peak point, the transverse stress gradually increased under continuous axial loading, and the axial stress–strain curve intersects with the transverse stress curve in the end. However, the intersection point of the longitudinal and the lateral stress–strain curve is slightly postponed with the increase of the recycled aggregate replacement ratio.

3.3. Contrast of CFCST and RACFCST Stub Columns under Axial Compression

4. Practical Design Formula of Load-Bearing Capacity of RACFCST Stub Columns

4.1. Formulation

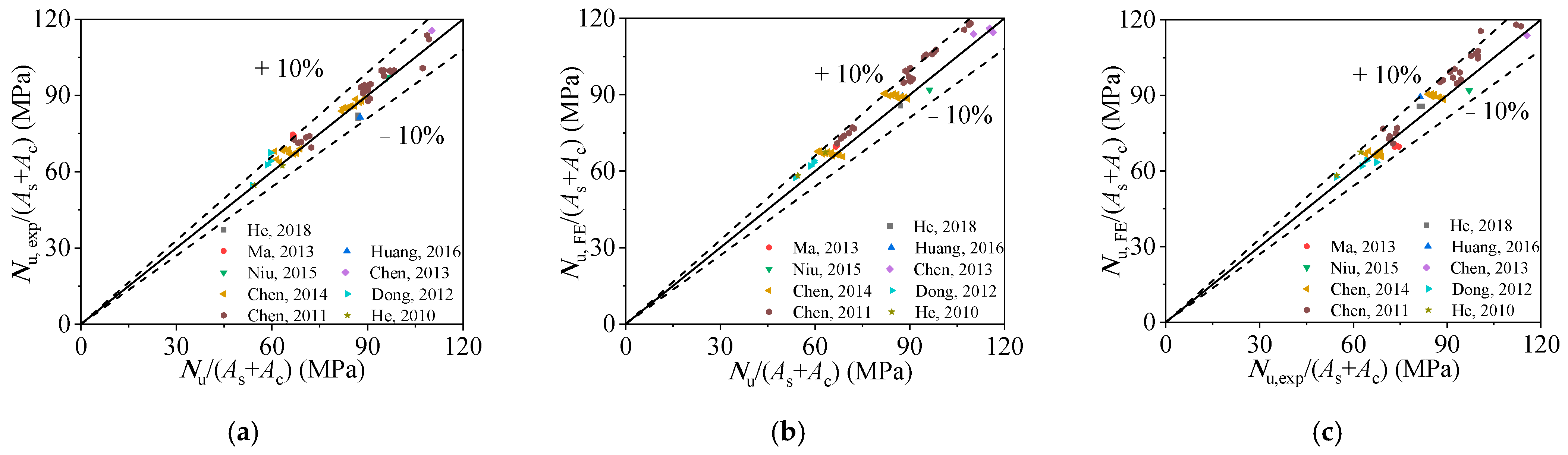

4.2. Formula Validation

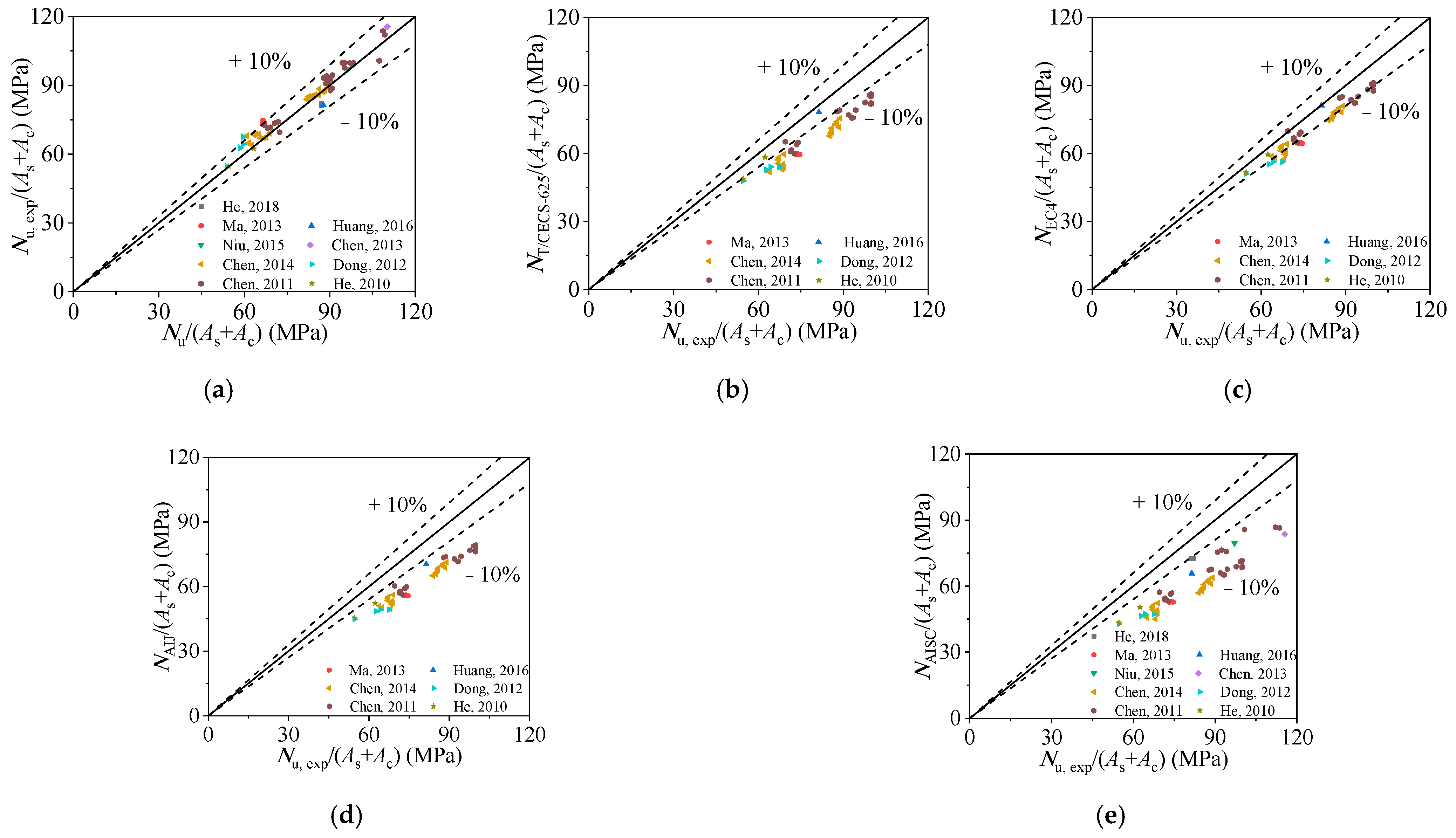

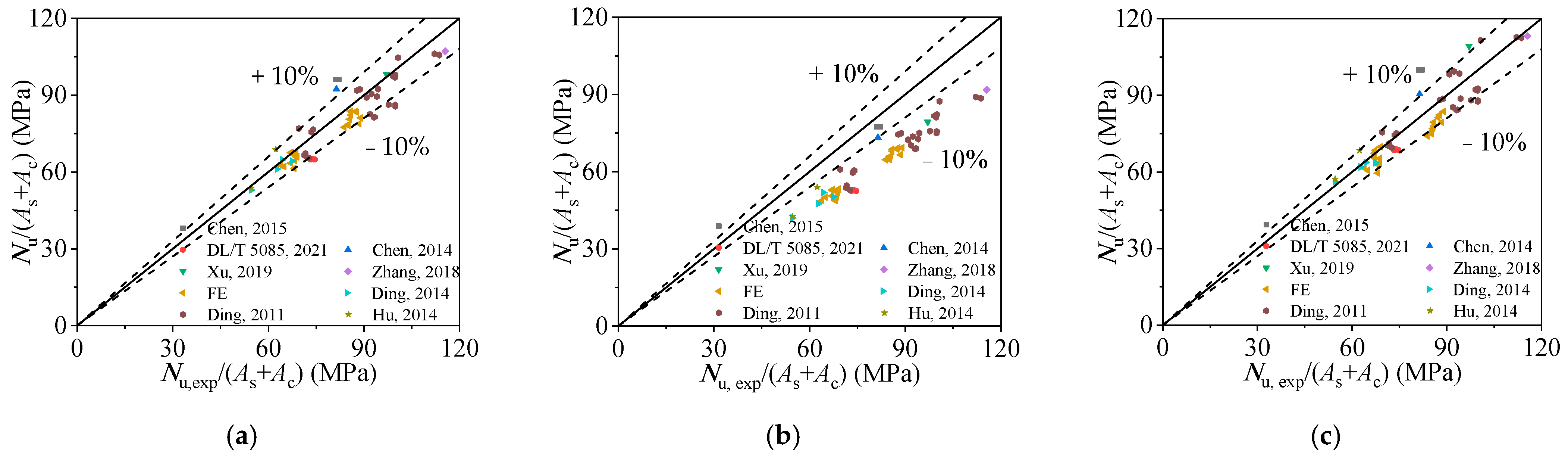

4.3. Comparison of Existing Formulae

5. Conclusions

- The FE models of RACFCST stub columns under axial compression can be modeled utilizing the triaxial RAC plastic-damage and steel constitutive relations. The good agreement between the experimental results and the FE calculation results indicates the validity of the FE model.

- On the basis of verifying the FE modeling method, parameter analysis was conducted on the full-scale RACFCST stub columns. The analytical results indicate that the recycled aggregate slightly weakened the confinement effect between the steel tube and infilled RAC.

- The conclusions can be drawn from parametric analysis, the ξr,c–axial strain curves and steel stress–axial strain curves indicate that the materials’ strength (fcu, fs) and specimen dimensions (ρ) impact on the confinement efficiency in the axial loading process. However, the effect of replacement rate of recycled aggregate (r) on the confinement effect and efficiency of RACFCST in the limit state can be ignored.

- An equation for calculating the ultimate bearing capacity of RACFCST stub columns was proposed by the superposition method. The confinement coefficient (K) of RACFCST axial compression stub columns is 1.7. The proposed equation is more precise and compendious than current international design codes and other scholars’ literature.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mehta, P.K.; Meryman, H. Tools for reducing carbon emissions due to cement consumption. Struct. Mag. 2009, 1, 11–15. [Google Scholar]

- Sonawane, T.R.; Pimplikar, S.S. Use of recycled aggregate in concrete. JMCE 2013, 2, 52–59. [Google Scholar]

- Oikonomou, N.D. Recycled concrete aggregates. Cem. Concr. Comp. 2005, 27, 315–318. [Google Scholar] [CrossRef]

- Xiao, J.Z.; Li, W.G.; Fan, Y.H.; Huang, X. An overview of study on recycled aggregate concrete in China (1996–2011). Constr. Build. Mater. 2012, 31, 364–383. [Google Scholar] [CrossRef]

- Manzi, S.; Mazzotti, C.; Bignozzi, M.C. Short and long-term behavior of structural concrete with recycled concrete aggregate. Cem. Concr. Compos. 2013, 37, 312–318. [Google Scholar] [CrossRef]

- Ajdukiewicz, A.; Kliszczewicz, A. Influence of recycled aggregates on mechanical properties of HS/HPC. Cem. Concr. Compos. 2002, 24, 269–279. [Google Scholar] [CrossRef]

- Liu, Y.C.; Lyu, F.; Ding, F.X.; Wang, E.; Xu, Y.L.; Yuan, T.; Deng, C.; Luo, C. Numerical study of confinement effect and efficiency of concentrically loaded RACFRST stub columns. Front. Mater. 2021, 8, 630774. [Google Scholar] [CrossRef]

- Xiao, J.Z.; Li, J.B.; Zhang, C. Mechanical properties of recycled aggregate concrete under uniaxial loading. Cem. Concr. Res. 2005, 35, 1187–1194. [Google Scholar] [CrossRef]

- Javier Zega, C.; Di Maio, A.A. Recycled concrete made with different natural coarse aggregates exposed to high temperature. Constr. Build. Mater. 2009, 23, 2047–2052. [Google Scholar] [CrossRef]

- Katz, A. Treatments for the improvement of recycled aggregate. J. Mater. Civ. Eng. 2004, 16, 597–603. [Google Scholar] [CrossRef]

- Li, Y.; Fu, T.H.; Wang, R.J.; Li, Y. An assessment of microcracks in the interfacial transition zone of recycled concrete aggregates cured by CO2. Constr. Build. Mater. 2020, 236, 11. [Google Scholar] [CrossRef]

- Hasan, D.; Özgür, Ç. Influence of basalt fiber on physical and mechanical properties of treated recycled aggregate concrete. Constr. Build. Mater. 2020, 254, 119216. [Google Scholar] [CrossRef]

- Wang, Y.G.; Li, S.P.; Hughes, P.; Fan, Y.H. Mechanical properties and microstructure of basalt fibre and nano-silica reinforced recycled concrete after exposure to ele-vated temperatures. Constr. Build. Mater. 2020, 247, 118561. [Google Scholar] [CrossRef]

- Gao, C.; Huang, L.; Yan, L.B.; Jin, R.Y.; Chen, H.Z. Mechanical properties of recycled aggregate concrete modified by nano-particles. Constr. Build. Mater. 2020, 241, 118030. [Google Scholar] [CrossRef]

- Wang, Y.Y.; Chen, J.; Geng, Y. Testing and analysis of axially loaded normal-strength recycled aggregate concrete filled steel tubular stub columns. Eng. Struct. 2015, 86, 192–212. [Google Scholar] [CrossRef]

- Chen, Z.P.; Ke, X.J.; Xue, J.Y.; Su, Y.S. Mechanical performance and ultimate bearing capacity calculation of steel tube confined recycled coarse aggregate concrete. Chin. Civ. Eng. J. 2013, 46, 70–77. [Google Scholar]

- Yang, Y.F.; Han, L.H. Experimental behaviour of recycled aggregate concrete filled steel tubular columns. J. Constr. Steel. Res. 2006, 62, 1310–1324. [Google Scholar] [CrossRef]

- Dong, J.F.; Wang, Q.Y.; Guan, Z.W. Material and structural response of steel tube confined recycled earthquake waste concrete subjected to axial compression. Mag. Concr. Res. 2016, 68, 271–282. [Google Scholar] [CrossRef]

- Zhang, X.G.; Chen, Z.P.; Xue, J.Y.; Su, Y.S.; Fan, J. Experimental study and mechanical behavior analysis of recycled aggregate concrete filled steel tubular long columns under axial compression. J. Build. Struc. 2012, 33, 12–20. [Google Scholar]

- Zhang, X.G.; Chen, Z.G.; Wang, J.M.; Xue, J.Y.; Zheng, S.F.; Li, Q.L.; Su, Y.S. Study on eccentric compression behaviors of recycled aggregate concrete filled steel tubular long columns. Eng. Mech. 2013, 30, 331–340. [Google Scholar]

- Chen, Z.P.; He, T.Y.; Xu, J.J.; Liu, X. Performance and bearing capacity of recycled aggregate concrete-filled circular steel tube-column under axial compression. J. Guangxi Univ. Nat. Sci. Ed. 2015, 40, 897–907. [Google Scholar] [CrossRef]

- DL/T 5085-2021. Code for Design of Steel-Concrete Composite Structure; National Energy Adiministration: Beijing, China, 2021.

- Chen, M.C.; Liu, J.J.; Huang, H. Study on circle recycled aggregate concrete-filled steel tube under axial compression. Concrete 2014, 12, 43–48. [Google Scholar]

- Xu, W.; Bai, Y.; Luo, D. Calculation methods for recycled aggregate concrete filled circular steel tubular short columns. J. Shenyang Univ. Tech. 2019, 41, 339–343. [Google Scholar]

- Lyu, W.Q.; Han, L.H.; Hou, C.J.E.S. Axial compressive behaviour and design calculations on recycled aggregate concrete-filled steel tubular (RAC-FST) stub columns. Eng. Struct. 2021, 241, 112452. [Google Scholar] [CrossRef]

- Zhang, T.; Ding, F.X.; Wang, L.P.; Liu, X.M.; Jiang, G.S. Behavior of polygonal concrete-filled steel tubular stub columns under axial loading. Steel Compos. Struct. 2018, 28, 573–588. [Google Scholar] [CrossRef]

- Hibbitt, B.K.D.; Sorensen, P. ABAQUS Standard User’s and Reference Manuals; Version 6.14; Dassault Systèmes: Johnston, RI, USA, 2014. [Google Scholar]

- Ding, F.X.; Fang, C.J.; Gong, Y.Z.; Yu, Z.W.; Hu, L.N. Unified Calculation Method of Uniaxial Mechanical Performance Index of Recycled Concrete. J. Arch. Civ. Eng. 2014, 31, 16–22. [Google Scholar]

- Ding, F.X.; Ying, X.Y.; Zhou, L.C.; Yu, Z.W. Unified calculation method and its application in determining the uniaxial mechanical properties of concrete. Front. Struct. Civ. Eng. 2011, 5, 381–393. [Google Scholar] [CrossRef]

- Hu, L.N. Mechanical Performance of Recycled Concrete-Filled Circular Steel Tubular Column; Central South University: Changsha, China, 2014. [Google Scholar]

- Ding, F.X.; Zhu, J.; Cheng, S.S.; Liu, X.M. Comparative study of stirrup-confined circular concrete-filled steel tubular stub columns under axial loading. Thin Walled Struct. 2018, 123, 294–304. [Google Scholar] [CrossRef] [Green Version]

- Lu, D.R.; Wang, W.J.; Ding, F.X.; Liu, X.M.; Fang, C.J. The impact of stirrups on the composite action of concrete-filled steel tubular stub columns under axial loading. Structures 2021, 30, 768–802. [Google Scholar] [CrossRef]

- Ding, F.X.; Wang, W.J.; Lu, D.R.; Liu, X.M. Study on the behavior of concrete-filled square double-skin steel tubular stub columns under axial loading. Structures 2020, 23, 665–676. [Google Scholar] [CrossRef]

- Ding, F.X.; Wang, W.J.; Liu, X.M.; Wang, L.P.; Sun, Y. Mechanical behavior of outer square inner circular concrete filled dual steel tubular stub columns. Steel Compos. Struct. 2021, 38, 305–317. [Google Scholar] [CrossRef]

- Ding, F.X.; Sheng, S.J.; Yu, Y.J.; Yu, Z.W. Mechanical behaviors of concrete-filled rectangular steel tubular under pure torsion. Steel Compos. Struct. 2019, 31, 291–301. [Google Scholar] [CrossRef]

- Ding, F.X.; Fu, Q.; Wen, B.; Zhou, Q.S.; Liu, X.M. Behavior of circular concrete-filled steel tubular columns under pure torsion. Steel Compos. Struct. 2018, 26, 501–511. [Google Scholar] [CrossRef]

- Ding, F.X.; Luo, L.; Wang, L.P.; Cheng, S.S.; Yu, Z.W. Pseudo-static tests of terminal stirrup-confined concrete-filled rectangular steel tubular columns. J. Constr. Steel. Res. 2018, 144, 135–152. [Google Scholar] [CrossRef] [Green Version]

- He, Z.J.; Tian, L.L.; Zhang, Z.J.; Zhang, X.S. Study of recycled aggregate concrete filled steel tubular column under axial load and its core recycled concrete under multi-axial mechanics. Build. Struct. 2018, 48, 560–566. [Google Scholar] [CrossRef]

- Ma, J. Static Behavior of Recycled Aggregate Concrete Filled Circular Steel Tubular Columns; Harbin Institute of Technology: Harbin, China, 2013. [Google Scholar]

- Huang, H.; Guo, X.Y.; Chen, M.Y. Comparative experimental research on recycled aggregate concrete filled steel tubular columns subjected to axial compression. Build. Struct. 2016, 46, 34–39 + 49. [Google Scholar]

- Niu, H.C.; Cao, W.L. Full-scale testing of high-strength RACFST columns subjected to axial compression. Mag. Concr. Res. 2015, 67, 257–270. [Google Scholar] [CrossRef]

- Chen, J.; Zeng, L. Experiment on mechanical performance of axial compression of recycled concrete-filled steel-tubular stub columns. J. Lanzhou Univ. Tech. 2013, 39, 112–116. [Google Scholar] [CrossRef]

- Chen, Z.P.; Xu, J.J.; Xue, J.Y.; Su, Y.S. Performance and calculations of recycled aggregate concrete-filled steel tubular (RACFST) short columns under axial compression. Int. J. Steel Struct. 2014, 14, 31–42. [Google Scholar] [CrossRef]

- Dong, J.F.; Hou, M.; Wang, Q.Y.; Yuan, S.C. Experimental research on the mechanical behaviour of recycled aggregate concrete and its short columns. In Proceedings of the Third National Symposium on Recycled Concrete, Qingdao, China, 6–8 September 2012; pp. 193–199. [Google Scholar]

- Chen, J. Static Behavior of Recycled Aggregate Concrete Filled Steel Tubular Stub Columns Under Axial Compression Loading; Harbin Institute of Technology: Harbin, China, 2011. [Google Scholar]

- He, D.; Wang, Q.Y.; Qiu, C.Z.; Shi, X.S.; Dong, J.F. The theoretical and experimental analysis of load-deformation of recycled concrete filled steel tubes subjected axial compression. In Proceedings of the Sichuan Society in Mech.: J. Sichuan Univ. (Eng. Science Edition), Chengdu, China, 1 September 2010; pp. 55–59. [Google Scholar]

- Chen, Z.Y.; Zhu, J.Q.; Wu, P.G. High-Strength Concrete and Its Applications; Tsinghua University Press: Beijing, China, 1992. [Google Scholar]

- Ding, F.X.; Yu, Z.W.; Bai, Y.; Gong, Y.Z. Elasto-plastic analysis of circular concrete-filled steel tube stub columns. J. Constr. Steel. Res. 2011, 67, 1567–1577. [Google Scholar] [CrossRef]

- Ding, F.X.; Yin, Y.X.; Mao, J.F.; Wang, L.P.; Yu, Y.J.; Luo, L.; Yu, Z.W. Analytical behaviors of concrete-filled circular stainless steel tubular (CFCSST) stub columns under axial loading. Structures 2019, 19, 277–285. [Google Scholar] [CrossRef]

- ACI-318-Building Code Requirements for Structural Concrete and Commentary ACI Committee 318; American Concrete Institute: Detroit, MI, USA, 2011.

- T/CECS 625-Technical Specification for Recycled Aggregate Concrete-Filled Steel Tubular Structures; Architecture & Building Press: Beijing, China, 2019.

- Eurocode Design of Steel Composite Steel and Concrete Structures, Part 1-1, General Rules And Rules for Building, BS EN 1994-1-1; British Standards Institution: London, UK, 2004.

- AIJ. Recommendations for Design and Construction of Concrete Filled Steel Tubular Structures; Architectural Institute of Japan: Tokyo, Japan, 1997. [Google Scholar]

- AISC. Specification for Structural Steel Buildings. ANSI/AISC 360-16; American Institute of Steel Construction: Chicago, IL, USA, 2016. [Google Scholar]

| Dilation Angle | Eccentricity | fb0/fc0 | K | Viscosity Parameter |

|---|---|---|---|---|

| 40 | 0.1 | 1.225 | 0.6667 | 0.005 |

| Specimens | Ref. | D × t × L (mm) | r | fcur150 (MPa) | fs (MPa) | Nu,exp (kN) | Nu,FE (kN) | Nu,exp/Nu,FE | Nu,exp/Nu | Nu,FE/Nu |

| AC-6-1 | [38] | 219 × 3.50 × 600 | 0.5 | 69.21 | 313 | 3055.00 | 3224.51 | 0.947 | 0.938 | 0.990 |

| AC-6-2 | [38] | 219 × 3.50 × 600 | 0.5 | 69.21 | 313 | 3093.00 | 3224.51 | 0.959 | 0.950 | 0.990 |

| AC-6-3 | [38] | 219 × 3.50 × 600 | 0.5 | 69.21 | 313 | 3073.00 | 3224.51 | 0.953 | 0.944 | 0.990 |

| CFST3-0-1-8-a | [39] | 138 × 2.72 × 420 | 1 | 40.52 | 299.4 | 1104.00 | 1047.60 | 1.054 | 1.093 | 1.037 |

| CFST3-0-1-8-b | [39] | 138 × 2.69 × 420 | 1 | 40.52 | 299.4 | 1115.00 | 1040.98 | 1.071 | 1.111 | 1.037 |

| CFST3-0-1-8-c | [39] | 138 × 2.69 × 420 | 1 | 40.52 | 299.4 | 1095.00 | 1040.98 | 1.052 | 1.091 | 1.037 |

| C-S-R | [40] | 165 × 3.54 × 480 | 0.5 | 50.00 | 368 | 1739.94 | 1909.81 | 0.911 | 0.925 | 1.015 |

| C1 | [41] | 508 × 8.76 × 1500 | 1 | 72.36 | 355.8 | 19,662.20 | 18,617.9 | 1.056 | 0.998 | 0.945 |

| C1 | [42] | 127 × 4.20 × 390 | 0.3 | 72.06 | 298.3 | 1552.50 | 1448.78 | 1.072 | 1.051 | 0.981 |

| C2 | [42] | 127 × 4.20 × 390 | 0.6 | 70.38 | 298.3 | 1568.00 | 1468.97 | 1.067 | 1.070 | 1.002 |

| C3 | [42] | 127 × 4.20 × 390 | 1 | 63.89 | 298.3 | 1462.50 | 1441.01 | 1.015 | 1.040 | 1.025 |

| CA-1 | [43] | 88 × 2.50 × 285 | 0.1 | 29.14 | 342.7 | 517.53 | 547.57 | 0.945 | 1.031 | 1.091 |

| CA-2 | [43] | 88 × 2.50 × 285 | 0.2 | 28.20 | 342.7 | 509.70 | 545.92 | 0.934 | 1.024 | 1.097 |

| CA-3 | [43] | 88 × 2.50 × 285 | 0.3 | 32.36 | 342.7 | 522.24 | 544.09 | 0.960 | 1.011 | 1.053 |

| CA-4 | [43] | 88 × 2.50 × 285 | 0.4 | 33.82 | 342.7 | 521.73 | 542.07 | 0.962 | 0.997 | 1.036 |

| CA-5 | [43] | 88 × 2.50 × 285 | 0.5 | 31.51 | 342.7 | 519.93 | 539.67 | 0.963 | 1.013 | 1.052 |

| CA-6 | [43] | 88 × 2.50 × 285 | 0.6 | 30.33 | 342.7 | 517.23 | 537.34 | 0.963 | 1.018 | 1.058 |

| CA-7 | [43] | 88 × 2.50 × 285 | 0.7 | 35.86 | 342.7 | 530.88 | 534.81 | 0.993 | 0.995 | 1.002 |

| CA-8 | [43] | 88 × 2.50 × 285 | 0.8 | 36.96 | 342.7 | 533.13 | 531.96 | 1.002 | 0.989 | 0.987 |

| CA-9 | [43] | 88 × 2.50 × 285 | 0.9 | 34.30 | 342.7 | 538.08 | 529.05 | 1.017 | 1.021 | 1.004 |

| CA-10 | [43] | 88 × 2.50 × 285 | 1 | 38.43 | 342.7 | 540.96 | 525.88 | 1.029 | 0.990 | 0.962 |

| CB-1 | [43] | 112 × 2.00 × 360 | 0.1 | 29.14 | 357.2 | 639.63 | 669.04 | 0.956 | 1.054 | 1.102 |

| CB-2 | [43] | 112 × 2.00 × 360 | 0.2 | 28.2 | 357.2 | 670.41 | 667.08 | 1.005 | 1.117 | 1.111 |

| CB-3 | [43] | 112 × 2.00 × 360 | 0.3 | 32.36 | 357.2 | 677.64 | 664.94 | 1.019 | 1.072 | 1.052 |

| CB-4 | [43] | 112 × 2.00 × 360 | 0.4 | 33.82 | 357.2 | 676.59 | 662.59 | 1.021 | 1.051 | 1.029 |

| CB-5 | [43] | 112 × 2.00 × 360 | 0.5 | 31.51 | 357.2 | 673.65 | 659.92 | 1.021 | 1.076 | 1.054 |

| CB-6 | [43] | 112 × 2.00 × 360 | 0.6 | 30.33 | 357.2 | 629.16 | 657.43 | 0.957 | 1.019 | 1.064 |

| CB-7 | [43] | 112 × 2.00 × 360 | 0.7 | 35.86 | 357.2 | 660.00 | 655.00 | 1.008 | 0.999 | 0.991 |

| CB-8 | [43] | 112 × 2.00 × 360 | 0.8 | 36.96 | 357.2 | 662.73 | 652.16 | 1.016 | 0.989 | 0.973 |

| CB-9 | [43] | 112 × 2.00 × 360 | 0.9 | 34.30 | 357.2 | 660.09 | 649.79 | 1.016 | 1.016 | 1.000 |

| CB-10 | [43] | 112 × 2.00 × 360 | 1 | 38.43 | 357.2 | 679.68 | 646.94 | 1.051 | 0.996 | 0.948 |

| C1-1 | [44] | 114 × 1.80 × 400 | 0.25 | 40.08 | 300.0 | 656.00 | 655.18 | 1.001 | 1.078 | 1.077 |

| C2-1 | [44] | 114 × 1.80 × 400 | 0.5 | 40.11 | 300.0 | 688.00 | 647.42 | 1.063 | 1.128 | 1.062 |

| C3-1 | [44] | 114 × 1.80 × 400 | 0.75 | 38.86 | 300.0 | 640.00 | 632.67 | 1.012 | 1.065 | 1.053 |

| C4-1 | [44] | 114 × 1.70 × 400 | 1 | 35.02 | 300.0 | 557.00 | 587.28 | 0.948 | 1.007 | 1.061 |

| cfst8-30-0.5-1 | [45] | 140 × 2.71 × 420 | 0.5 | 44.4 | 309.0 | 1131.00 | 1153.39 | 0.981 | 1.035 | 1.056 |

| cfst8-30-0.5-2 | [45] | 140 × 2.79 × 420 | 0.5 | 44.4 | 309.0 | 1139.00 | 1186.13 | 0.960 | 1.027 | 1.069 |

| cfst8-30-0.5-3 | [45] | 140 × 2.83 × 420 | 0.5 | 44.4 | 309.0 | 1070.00 | 1180.90 | 0.906 | 0.957 | 1.057 |

| cfst8-30-1-1 | [45] | 140 × 2.80 × 420 | 1 | 41.1 | 309.0 | 1102.00 | 1136.38 | 0.970 | 1.026 | 1.058 |

| cfst8-30-1-2 | [45] | 140 × 2.73 × 420 | 1 | 41.1 | 309.0 | 1098.00 | 1121.57 | 0.979 | 1.036 | 1.059 |

| cfst8-30-1-3 | [45] | 140 × 2.64 × 420 | 1 | 41.1 | 309.0 | 1118.00 | 1091.54 | 1.024 | 1.074 | 1.049 |

| cfst8-50-1-1 | [45] | 140 × 2.72 × 420 | 1 | 65.0 | 309.0 | 1447.00 | 1524.47 | 0.949 | 1.056 | 1.113 |

| cfst8-50-1-2 | [45] | 140 × 2.69 × 420 | 1 | 65.0 | 309.0 | 1398.00 | 1528.15 | 0.915 | 1.025 | 1.120 |

| cfst8-50-1-3 | [45] | 140 × 2.81 × 420 | 1 | 65.0 | 309.0 | 1421.00 | 1546.02 | 0.919 | 1.024 | 1.114 |

| cfst12-30-0.5-1 | [45] | 140 × 3.85 × 420 | 0.5 | 44.4 | 335.3 | 1365.00 | 1477.94 | 0.924 | 0.974 | 1.055 |

| cfst12-30-0.5-2 | [45] | 140 × 3.86 × 420 | 0.5 | 44.4 | 335.3 | 1453.00 | 1481.02 | 0.981 | 1.035 | 1.055 |

| cfst12-30-0.5-3 | [45] | 140 × 3.81 × 420 | 0.5 | 44.4 | 335.3 | 1351.00 | 1465.91 | 0.922 | 0.970 | 1.053 |

| cfst12-30-1-1 | [45] | 140 × 3.96 × 420 | 1 | 41.1 | 335.3 | 1414.00 | 1493.01 | 0.947 | 1.018 | 1.074 |

| cfst12-30-1-2 | [45] | 140 × 3.85 × 420 | 1 | 41.1 | 335.3 | 1437.00 | 1459.93 | 0.984 | 1.053 | 1.070 |

| cfst12-30-1-3 | [45] | 140 × 3.84 × 420 | 1 | 41.1 | 335.3 | 1433.00 | 1456.81 | 0.984 | 1.052 | 1.069 |

| cfst12-50-1-1 | [45] | 140 × 3.78 × 420 | 1 | 65.0 | 335.3 | 1550.00 | 1777.14 | 0.872 | 0.938 | 1.076 |

| cfst12-50-1-2 | [45] | 140 × 3.92 × 420 | 1 | 65.0 | 335.3 | 1725.00 | 1816.21 | 0.950 | 1.026 | 1.080 |

| cfst12-50-1-3 | [45] | 140 × 3.88 × 420 | 1 | 65.0 | 335.3 | 1749.00 | 1806.76 | 0.968 | 1.045 | 1.080 |

| cfst15-30-0.5-1 | [45] | 133 × 4.57 × 400 | 0.5 | 44.4 | 302.0 | 1385.00 | 1471.08 | 0.941 | 1.024 | 1.088 |

| cfst15-30-0.5-2 | [45] | 133 × 4.61 × 400 | 0.5 | 44.4 | 302.0 | 1377.00 | 1481.14 | 0.930 | 1.013 | 1.090 |

| cfst15-30-0.5-3 | [45] | 133 × 4.66 × 400 | 0.5 | 44.4 | 302.0 | 1387.00 | 1493.71 | 0.929 | 1.013 | 1.091 |

| cfst15-30-1-1 | [45] | 133 × 4.56 × 400 | 1 | 41.1 | 302.0 | 1386.00 | 1453.04 | 0.954 | 1.051 | 1.102 |

| cfst15-30-1-2 | [45] | 133 × 4.61 × 400 | 1 | 41.1 | 302.0 | 1387.00 | 1466.15 | 0.946 | 1.045 | 1.104 |

| cfst15-30-1-3 | [45] | 133 × 4.62 × 400 | 1 | 41.1 | 302.0 | 1357.00 | 1467.43 | 0.925 | 1.021 | 1.104 |

| C2-1 | [46] | 114 × 1.84 × 396 | 0.5 | 43.9 | 300.0 | 636.50 | 688.42 | 0.925 | 0.982 | 1.062 |

| C4-2 | [46] | 114 × 1.70 × 401 | 1 | 35.9 | 300.0 | 557.50 | 594.73 | 0.937 | 0.994 | 1.061 |

| Mean | 0.978 | 1.024 | 1.049 | |||||||

| COV. | 0.048 | 0.042 | 0.041 |

| D (mm) | L (mm) | t (mm) | r | fcu,0 (MPa) | fs (MPa) |

|---|---|---|---|---|---|

| 500 | 1500 | 3 | 0.00, 0.25, 0.50, 0.75, 1.00 | 30, 50 | 235 |

| 500 | 1500 | 3 | 0.00, 0.25, 0.50, 0.75, 1.00 | 50, 70 | 345 |

| 500 | 1500 | 3 | 0.00, 0.25, 0.50, 0.75, 1.00 | 70 | 420 |

| 500 | 1500 | 6 | 0.00, 0.25, 0.50, 0.75, 1.00 | 30, 50 | 235 |

| 500 | 1500 | 6 | 0.00, 0.25, 0.50, 0.75, 1.00 | 50, 70 | 345 |

| 500 | 1500 | 6 | 0.00, 0.25, 0.50, 0.75, 1.00 | 70 | 420 |

| 500 | 1500 | 10 | 0.00, 0.25, 0.50, 0.75, 1.00 | 30, 50 | 235 |

| 500 | 1500 | 10 | 0.00, 0.25, 0.50, 0.75, 1.00 | 50, 70 | 345 |

| 500 | 1500 | 10 | 0.00, 0.25, 0.50, 0.75, 1.00 | 70 | 420 |

| Code | Yield Strength of Steel (MPa) | Compressive Strength of Concrete (MPa) | Diameter to Thickness Ratio |

|---|---|---|---|

| ACI-318-11 [50] | All | All | |

| T/CECS 625-2019 [51] | 235 ≤ fy ≤ 460 | 30 ≤ fcur,150 ≤ 50 | ≤135(235/fy) |

| EC4 (2004) [52] | 235 ≤ fy ≤ 460 | 20 ≤ fc,150 ≤ 50 or 25 ≤ fcu,150 ≤ 60 | ≤90(235/fy) |

| AIJ (1997) [53] | 235 ≤ fy ≤ 355 | fc,100 ≤ 58.8 | ≤1.5(23500/F) |

| AISC 360-16 (2016) [54] | fy ≤ 525 | 21 ≤ ≤ 69 | ≤0.31(Es/fy) |

| Reference | Formulae | Remarks | Total | Average Values (Nu,exp/Nu,ref) | Dispersion Coefficient |

|---|---|---|---|---|---|

| ACI-318-11 (2011) [50] | Circular | 61 | 1.429 | 0.060 | |

| T/CECS 625-2019 [51] | Circular | 44 | 1.188 | 0.046 | |

| EC4 (2004) [52] | Circular | 48 | 1.103 | 0.037 | |

| AIJ (1997) [53] | Circular | 48 | 1.267 | 0.037 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, E.; Liu, Y.; Lyu, F.; Ding, F.; Xu, Y. Confinement Effect and Efficiency of Concentrically Loaded RACFCST Stub Columns. Materials 2022, 15, 154. https://doi.org/10.3390/ma15010154

Wang E, Liu Y, Lyu F, Ding F, Xu Y. Confinement Effect and Efficiency of Concentrically Loaded RACFCST Stub Columns. Materials. 2022; 15(1):154. https://doi.org/10.3390/ma15010154

Chicago/Turabian StyleWang, En, Yicen Liu, Fei Lyu, Faxing Ding, and Yunlong Xu. 2022. "Confinement Effect and Efficiency of Concentrically Loaded RACFCST Stub Columns" Materials 15, no. 1: 154. https://doi.org/10.3390/ma15010154

APA StyleWang, E., Liu, Y., Lyu, F., Ding, F., & Xu, Y. (2022). Confinement Effect and Efficiency of Concentrically Loaded RACFCST Stub Columns. Materials, 15(1), 154. https://doi.org/10.3390/ma15010154